Page 1

Fitters’ Notes Heat Exchangers

Contents

MicroChannel Heat Exchanger – Construction ........................................................................................................ 2

MicroChannel Heat Exchanger – Cleaning Procedure .......................................................................................... 4

Micro Plate Heat Exchanger – MPHE Instructions ................................................................................................... 5

MicroChannel Heat Exchanger – MCHE Instructions ............................................................................................. 7

Troubleshooting Refrigerant Systems Using Plate Heat Exchangers ............................................................... 9

DKRCC.PF.000.G1.02 / 520H6410

Exchangers

Heat

1

Page 2

Fitters’ Notes Heat Exchangers

MicroChannel

Heat Exchanger –

Construction

The fi gure on the right represents the basic

structure of a MicroChannel heat exchanger.

The actual design depends on the specifi ed

application.

Flow arrangement

The MicroChannel condenser is often designed

with multiple passes (parallel fl ow) with fewer

tubes in each successive pass.

Accidentally connecting the outlet tube to

the outlet header of the MCHE will result in

excessively high refrigerant-side pressure loss

and poor heat exchanger performance.

End plate Side plate Fin Tube

B a ffl e

Manifold

Inlet

Many

tubes

The inlet and outlet tubes are designed only

for connection and to support their own weight.

Unfortunately they locate where handles would

be, and often look like handles. Never lift an

MCHE by the inlet and outlet tubes.

Mounting

The MicroChannel heat exchanger must

be mounted with at least some fl exible

brackets, so movement is possible without

applying unnecessary stress/tension to the

heat exchanger or its connections.

It is preferable for the mounting brackets

of the MCHE to touch only rubber or plastic

grommets, washers, bumpers, etc. Direct

contact with metal fasteners and/or frames

can result in galvanic corrosion unless

appropriate steps are taken to prevent it, e.g.

careful alloy selection, paints/coatings, etc.

To meet customer-specifi c requirements,

diff erent mounting types are available.

Outlet

Few

tubes

Mounting bracket

2

DKRCC.PF.000.G1.02 / 520H6410

Page 3

Fitters’ Notes Heat Exchangers

MicroChannel

Heat Exchanger –

Construction

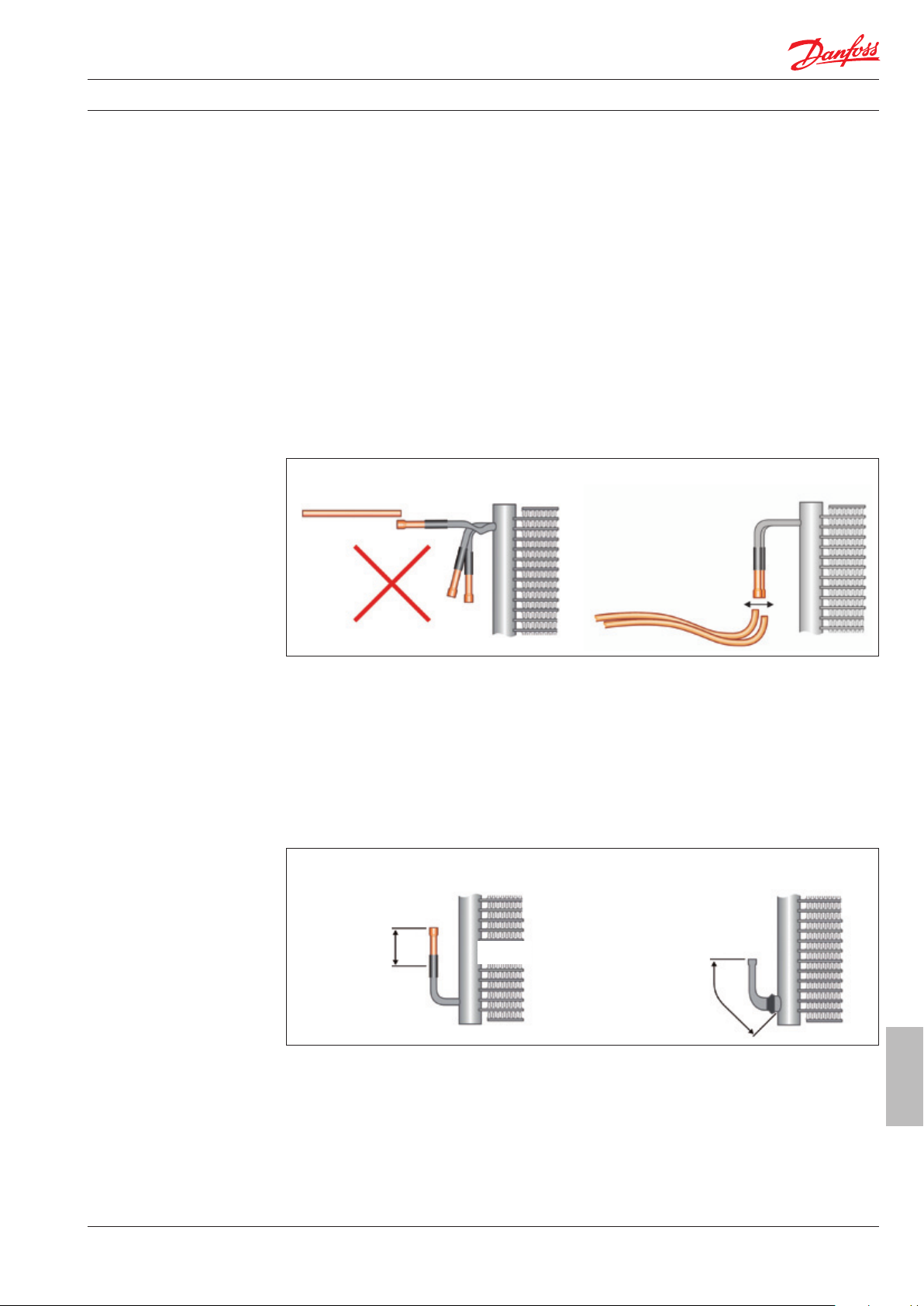

Inlet/outlet connections

Inlet/outlet connections should be designed

so the stress from thermal expansion will not

be transferred to the tubing.

Inlet/outlet connections should also be

supported/designed so brazed joints are

not exposed to stress/ tension.

To avoid damaging or collapsing the thin-

walled aluminium inlet/outlet tubes,

mating tubes should be pre-bent/prepared

so no bending/forcing is needed during

installation.

When copper and aluminium tubes are joined

together, galvanic corrosion of the aluminium

can result. To prevent this the joint is protected

with paint, resin or a plastic heat shrink tube.

Avoid stress/ collapse of tube

Allow some

movement due

to thermal

expansion

To protect the Cu-Al brazing and shrink tube,

the tube length after the joint on inlet/outlet

pipes should be longer than 70 mm. When

brazing the coil into your system, additional

protection can be obtained by dry nitrogen

purging and/or wrapping the copper stub tube

with a wet cloth. The aluminium inlet/outlet

tube on the MCHE must also be at least 70 mm

long to protect the tube-header braze joint.

The pipe length after the brazing joint should be longer than 70 mm.

≥70 mm

≥70 mm

Exchangers

Heat

DKRCC.PF.000.G1.02 / 520H6410

3

Page 4

Fitters’ Notes Heat Exchangers

MicroChannel Heat

Exchanger – Cleaning

Procedure

Compared with fin & tube heat exchangers, MicroChannel coils tend to accumulate more dirt

on the surface and less dirt inside, which can make them easier to clean.

Step 1. Remove surface debris

Remove surface dirt, leaves, fibres, etc., with a vacuum cleaner (preferably with a brush or other

soft attachment rather than a metal tube), compressed air blown from the inside out, and/ or a soft

bristle (not wire!) brush. Do not impact or scrape the coil with the vacuum tube, air nozzle, etc.

Step 2. Rinse

Do not use any chemicals (including those advertised as coil cleaners) to wash MicroChannel

heat exchangers. They can cause corrosion. Rinse only.

Hose the MCHE off gently, preferably from the inside out and top to bottom, running the water

through every fin passage until it comes out clean. MicroChannel fins are stronger than those of

traditional fin & tube coils, but must still be handled with care. Do not bang the hose into the coil.

We recommend putting your thumb over the end of the hose rather than using a nozzle end

because the resulting spray is gentler and impact damage is less likely.

Step 3: Optional blow dry

MicroChannel heat exchangers, because of their fin geometry, tend to retain water more than

traditional fin & tube coils. Depending on the specific design and installation of your coil,

it may be beneficial to blow or vacuum out the rinse water from your unit to speed drying and

prevent pooling.

Warning!

While it is possible to carefully clean with a pressure washer, it is also possible to totally destroy

a coil with a pressure washer. We therefore do not recommend their use.

4

DKRCC.PF.000.G1.02 / 520H6410

Page 5

Fitters’ Notes Heat Exchangers

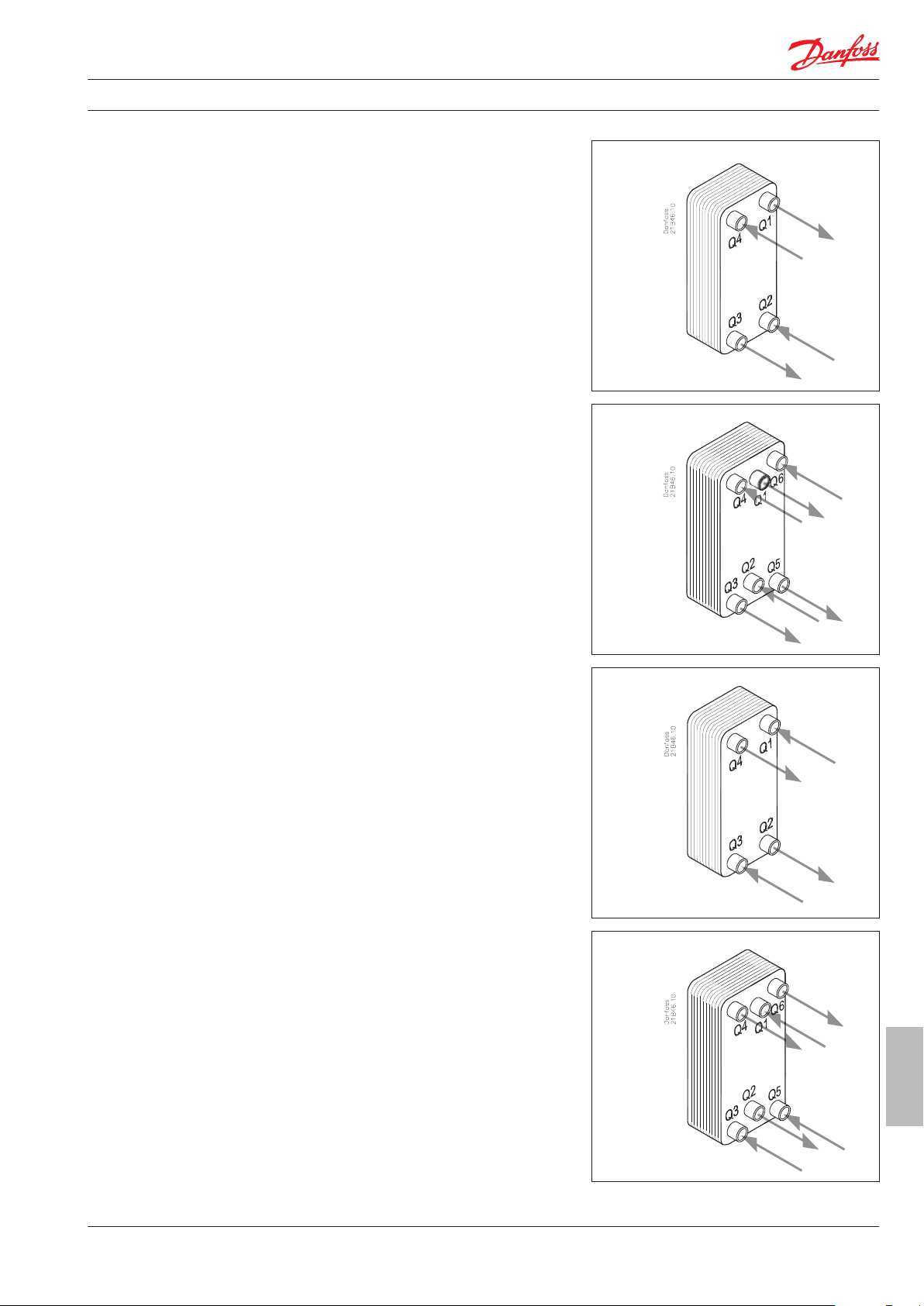

Condensers

Q1

Q2Q3

Q4

Condensers

Evaporators

Q1

Q2

Q3

Q4

Q5

Q6

Q1

Q2Q3

Q4

Q1

Q2

Q3

Q4

Q5

Q6

Q1

Q2Q3

Q4

Q1

Q2Q3

Q4

Micro Plate Heat

Exchanger – MPHE

Instructions

General information

Store dry at 17 °C (62 °F) to 50 °C (122 °F).

The performance of Danfoss MPHEs is based on

their installation, maintenance and operating

conditions being in accordance with the manual.

Danfoss cannot assume any liability for MPHEs

that do not meet these criteria. Mount MPHEs

vertically (see figs. right).

Condensers

Connect the refrigerant (gas) to the upper left

connection, Q4 (Dual circuit: upper left, Q4,

and right, Q6), and the condensate to the lower

left connection, Q3 (Dual circuit: lower left, Q3,

and lower right, Q5). Connect the water/ brine

circuit inlet to the lower right connection, Q2,

and the outlet to the upper right connection,

Q1 (Dual circuit: inlet lower middle, Q2, and

outlet upper middle, Q1).

Evaporators

Connect the refrigerant (liquid) to the lower left

connection Q3 (Dual circuit: lower left Q3 and

lower right Q5) and the refrigerant (gas) outlet to

the upper left connection Q4 (Dual circuit:

upper left Q4 and upper right Q6). Connect

the water/brine circuit inlet to the upper right

connection, Q1, and the outlet to the lower right

connection, Q2 (Dual circuit: inlet upper middle,

Q1, and outlet lower middle, Q2).

Strainer

If any of the media contain particles of 1 mm

or larger, we recommend that a strainer

(16–20 mesh) be installed before the MPHE.

IMPORTANT:

MPHEs have sharp edges. Their surfaces can be

very hot or cold. Media they contain may be at

high pressure. For product information, refer to

the product label.

Condensers

Dual Circuit

Condensers

Evaporators

DKRCC.PF.000.G1.02 / 520H6410

Dual Circuit

Evaporators

Exchangers

5

Heat

Page 6

Fitters’ Notes Heat Exchangers

Micro Plate Heat

Exchanger – MPHE

Instructions

Insulation

It is recommended that the product be insulated

during operation. Use expanded cellular rubber

insulation to create a vapour barrier and prevent

heat losses.

Mechanical mounting

A Bracket mounting

(for versions without mounting

bolts or screws)

B Mounting with bolts

(for versions with bolts)

C Rubber pads.

Stud Bolt M6 1/4” M8 M10 M12

Max. Torque 10 12 15 18 22

Connecting pipes

Model 22 30 55/62 118 117 212

Torque 350 350 400 1000 1000 1000

Max. Temp. <<<<<<<<<<< 800 °C / 1472 °F >>>>>>>>>

Soldering procedure

Degrease and polish the connection surface.

Use nitrogen gas inside the MPHE to avoid

oxidation during soldering. Apply flux with

a brush. Insert the copper pipe into the

connection, and braze with min. 45% silver

solder.

Maintenance – Back flow cleaning

Use a strainer or filter. Use a 5% solution of

a weak acid such as phosphoric or citric acid.

Reverse the normal flow direction, and

increase the flow rate to 1.5 times normal.

6

DKRCC.PF.000.G1.02 / 520H6410

Page 7

Fitters’ Notes Heat Exchangers

MicroChannel Heat

Exchanger – MCHE

Instructions

Storage/ handling

Store in a dry, clean environment, 0 °C (32 °F)

to

50 °C (122 °F). Keep in packaging until

installation.

Keep vertical during storage and

transportation. Do not stack fl at on top of

each other. The fi ns are easily bent, leading

to irreparable damage. The tube walls are

vulnerable, and can be punctured by sharp

objects. Never lift or carry MCHEs by their

inlet/outlet tubes. Never hit or drop MCHEs

on their edges.

Preparation and Installation

The Danfoss MCHE condenser is designed to

have the airfl ow and refrigerant in crossfl ow

confi guration. Arrange the two fl ows correctly.

Ensure that the air fl ow is distributed evenly

across the entire face area in accordance with

the technical specifi cation to attain the specifi ed

capacity. This can be achieved by housing the

air fl ow and making sure there are no short-cuts

between the fan intake and outlet. Seal the wide

gaps on both sides of the face area with sealing

tape (see fi g. 2).

Fig. 1

When brazing the lines to the copper

connections, use a wet rag at the base

of the copper connection to minimise heating

of the copper/aluminium transition

(see fi g. 3).

Never bend or stress the aluminium tube

or the brazed joints. Aluminium MCHEs expand

and contract more than other heat exchangers.

Fig. 2

Fig. 3

Exchangers

Heat

DKRCC.PF.000.G1.02 / 520H6410

7

Page 8

Fitters’ Notes Heat Exchangers

MicroChannel Heat

Exchanger – MCHE

Instructions

Thermal expansion causes MCHEs to

expand/contract in two dimensions (see fi g. 4).

Installation support brackets must be designed

to allow this movement.

Remember to insert plastic/rubber/foam

between

the aluminium coil and dissimilar metals

(see fi g. 5).

Refrigerant charge

Danfoss MCHE condensers require a signifi cantly

smaller refrigerant charge than round tube

condensers. Over-charging will result in higher

head pressure and loss of system capacity.

Charge in accordance with the OEM’s instructions.

If these are not available, follow the instructions

below.

Fig. 4

Sealing

Steel frame

Sealing

MCHE

Sealing

Charge as follows:

1. Under full- or near full-load operating

conditions, put approximately 1/3rd the

nominal charge (by mass of refrigerant) in

the system. Allow the system to stabilise,

and check for gas bubbles in the liquid line

sight glass.

2. Add small amounts of refrigerant successively,

allowing the system to stabilise each time and

checking for bubbles as before.

3. Once there are few or no gas bubbles entering

the expansion valve, the charge is most likely

correct.

4. If the system is operating with a head pressure

higher than that specifi ed, remove refrigerant

from the system.

Corrosion

To prevent galvanic corrosion, avoid contact

between the aluminium MCHE and dissimilar

metals by separating them with plastic, rubber

or foam tape (see fi g. 5).

Also take care never to expose the MCHE to

dissimilar metal chips, dust or fi lings from

adjacent handling or manufacturing.

Fig. 5

8

DKRCC.PF.000.G1.02 / 520H6410

Page 9

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

Symptoms

High condensing pressure

Low condensing pressure

Low evaporating pressure

Possible causes of high condensing pressure

Condenser water flow too low

Condenser water inlet temperature too high

Refrigerant overcharge

Condenser internal volume is small compared

with evaporator volume

Oil in condenser

Non-condensable gases in refrigerant circuit

Air in condenser water side

Dirt in water side – surface fouling or blocked

water channels

Overload from evaporator side

Temperature differences in condenser side

too big

How to detect: Water (or brine) flow too low

Measure the flow using manual regulating

valve (A)

Measure the pressure difference across the

pump (B) and check the flow from the pump

manual or selection program

Measure the condenser pressure loss from

the drain (D) and venting (C) connections and

check the flow from the selection program

Measure the compressor operating conditions

and calculate the condenser capacity Qc.

Measure the water inlet and outlet temperature difference ΔT. Calculate the water mass

flow m.

Danfoss

R64-2071.10

C

Qc [kJ/s]

m = ----------------------- = [kg/s]

ΔT [K] × 4.2 kJ/kg K

How to detect: Refrigerant overcharge

Overcharge will reduce the internal surface

area used for condensing. The smaller area

increases not only the temperature difference

between the condensing temperature and

the refrigerant media but also the condensing

pressure.

Measure the condensing pressure (A) and

establish the corresponding saturated liquid

temperature

Measure the liquid temperature at the con-

denser outlet (B)

Calculate the subcooling (B-A)

Excessive subcooling will indicate overcharge.

A

Danfoss

R64-2065.10

B

D

A

Danfoss

R64-2068.10

B

Exchangers

Heat

DKRCC.PF.000.G1.02 / 520H6410

9

Page 10

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to detect: Condenser volume is too small

Specific to chillers and heat pumps

without a liquid receiver having relatively

high internal evaporator volume

In nominal operating conditions the

condensing pressure and subcooling may

be normal

In low-load conditions and low evaporating

temperatures more refrigerant will accumulate

in the condenser, increasing the condensing

temperature and subcooling as in the case of

overcharge

Check the evaporator and condenser internal

volumes

Consider installing a liquid receiver

How to detect: Oil in the condenser

Specific to chillers and heat pumps without

a liquid receiver

Low suction gas superheat and short running

times increase the amount of oil leaving the

compressor

The compressor oil charge may be bigger

than the condenser internal volume

Oil collecting in the condenser reduces the

surface area available for condensing. This will

increase the condensing temperature

Check the oil level of the compressor if possi-

ble. Check the compressor running times and

suction gas superheat

Danfoss

R64-2066.10

Danfoss

R64-2069.10

How to detect: Non-condensable gases

Non-condensable gases have the same

effect as overcharge. The condensing

pressure will rise and there will be excessive

subcooling.

The high-pressure manometer may

sometimes vibrate due to non-condensable

gases

Non-condensable gases will collect in the

top part of the condenser, making it the best

place to purge the system

How to detect: Dirt in the water side of the

condenser

Impurities in the water or brine side may cause

fouling and even block some water channels.

This will increase the condensing pressure

The condenser may be cleaned by pumping

water in the reverse direction compared with

normal operation. Cleaning agents may also

be used

It is recommended that filters be used in front

of plate heat exchangers

Danfoss

R64-2067.10

Danfoss

R64-2080.10

10

DKRCC.PF.000.G1.02 / 520H6410

Page 11

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to detect: Air in the water side of the condenser

Air in the water side of the condenser impairs

heat transfer

Air in the circulation pump will reduce the

water or brine flow

Besides increasing the condensing tempera-

ture, the air can cause a distinctive noise

that will help to identify the cause of the

problem

Check that the expansion tank (A) is

connected to the suction side of the

circulation pump and the pressure inside

the tank is correct

How to detect: High load from suction side

On a hot day with high humidity, the

refrigerant load from the air conditioning

system may exceed the refrigerant

capacity of the water chiller

If the expansion valve (A) does not have

a MOP function, the suction pressure (B)

will be high. The refrigerant capacity

will increase causing a high load on the

condenser and thus a high condensing

temperature (C)

Danfoss

R64-2086.10

A

C B

Danfoss

R64-2076.10

A

Possible causes of low condensing pressure

Condenser water flow too high

Water inlet temperature too low

Defective compressor valves

How to detect: Water (or brine) flow too high

Measure the flow using manual regulating

valve (A)

Measure the pressure difference across the

pump (B) and check the flow from the pump

manual or selection program

Measure the condenser pressure loss from

the drain (D) and venting (C) connections

and check the flow from the selection

program

Measure the compressor operating

conditions and calculate the condenser

capacity Qc. Measure the water inlet and

outlet temperature difference ΔT. Calculate

the water mass flow m.

C

A

Danfoss

R64-2074.10

B

D

Exchangers

Heat

Qc [kJ/s]

m = ----------------------- = [kg/s]

ΔT [K] × 4.2 kJ/kg K

DKRCC.PF.000.G1.02 / 520H6410

11

Page 12

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to correct: Condensing pressure too low

One way to solve the problem is to install

a pressure-actuated water valve (A) to the

water or brine inlet pipe

The valve will also protect the heat

exchanger from the pressure shocks that

may occur in industrial water systems when

valves are closed and opened rapidly

Possible causes of low evaporating pressure

Expansion valve is wrongly installed

Expansion valve is wrongly adjusted

Expansion valve is wrongly sized

Insufficient subcooling

Water or brine flow too low

Partial freezing

Air in water side

Dirt in water side – surface fouling or blocked

water channels

Uneven refrigerant distribution

Danfoss

R64-2077.10

A

Danfoss

R64-2070.10

How to detect: Expansion valve is wrongly installed

The pipe between the expansion valve and

heat exchanger should be straight.

A bend will act as a centrifugal separator.

On the outer side of the bend there will be

more liquid than vapour compared with the

inside of the bend, causing bad refrigerant

distribution inside the evaporator

This will result in lower evaporating pressure

and capacity

Thermostatic expansion valves in particular

are sensitive to the correct bulb mounting

12

DKRCC.PF.000.G1.02 / 520H6410

Page 13

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to detect: TEV installed upside down

If an expansion valve with internal pressure

equalizing is installed upside down, dirt

and oil may collect above the diaphragm.

This can increase the superheat and make

the operation of the valve slower

In expansion valves with external pressure

equalizing there is a risk that oil will collect

in the equalizing pipe, impairing valve

operation

In valves with MOP there is a risk of

refrigerant evaporating from the diaphragm,

which can cause charge migration

How to detect: Expansion valve is wrongly adjusted

Quite often the expansion valve is simply

installed without adjustment. This may

impair system efficiency and compressor

service life

High superheat will result in lower evaporat-

ing pressure (A) and thus lower capacity and

system COP

Low superheat will result in higher evaporat-

ing pressure (B). There is a risk of wet suction

gas reducing compressor service life. The

system refrigerant capacity and COP may

also be lower when part of the refrigerant

evaporates in the compressor and not in the

evaporator

B

Danfoss

A

R64-2072.10

How to detect: Expansion valve is wrongly sized

If the orifice in the expansion valve is too

small,

the evaporating temperature will be

low, reducing the refrigerant capacity and

system COP

If the orifice is too big it is impossible to

achieve stable superheat. Hunting will

shorten the expansion valve service life, and

wet suction gas may result in compressor

failure

DKRCC.PF.000.G1.02 / 520H6410

13

Exchangers

Heat

Page 14

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to detect: Insufficient subcooling

Insufficient subcooling, blocked filter drier,

tight bend in liquid line, small solenoid

valve, etc., may cause flash gas in the liquid

line that reduces expansion valve capacity

Flash gas often causes audible hunting

that is also visible in the suction pressure

manometer

The bubbles can be observed from the sight

glass if it is installed just before the expansion

valve

It is also possible to use an electronic sight

glass such as TIFF-4000A to determine the

state of the refrigerant

How to detect: Water (or brine) flow too low

Measure the evaporator water flow using

manual regulating valve (A)

Measure the pressure difference across the

pump (B) and check the flow from the pump

manual or selection program

Measure the evaporator pressure loss from

drain (D) and venting (C) connections and

check the flow from the selection program

Measure the compressor operating conditions

and calculate the refrigerant capacity Qo.

Measure the water inlet and outlet temperature difference ΔT. Calculate the water mass

flow m.

Danfoss

R64-2085.10

B

C

Danfoss

R64-2078.10

A

D

Qo [kJ/s]

m = ------------------------- = [kg/s]

ΔT [K] × 4.2 kJ/kg K

How to detect: Dirt in the evaporator

Impurities on the water side may cause foul-

ing and even block some water channels.

Fouling will reduce the evaporating pressure

and thus system capacity

Blocked water channels are very harmful to

TEV operation, because refrigerant droplets

may flow through the evaporator

The evaporator may be cleaned by pumping

water in the reverse direction compared with

normal operation. Cleaning agents may also

be used.

It is recommended that filters be used in front

of the plate heat exchangers

Danfoss

R64-2079.10

14

DKRCC.PF.000.G1.02 / 520H6410

Page 15

Fitters’ Notes Heat Exchangers

Troubleshooting

Refrigerant Systems Using

Plate Heat Exchangers

How to detect: Partial freezing

There is a risk of freezing when R407C and

other refrigerants with a high temperature

glide are used

Although the evaporating temperature is

above 0 °C the temperature in the evaporator

inlet may be below 0 °C

Even partial freezing will reduce the

refrigerant capacity and increase the risk

of evaporator breakdown

The risk can be evaluated by drawing the

cycle as a log p, h-diagram

In brine systems measure the freezing

point using good quality instruments or

simply put a sample in the freezer and note

its melting/freezing points

How to detect: Uneven liquid distribution

Although the evaporator water flow and

temperatures are according to the selection

program the evaporating temperature is

lower and superheat higher than it should be

The reason may be uneven liquid distribution

inside the evaporator

Carefully remove the insulation from

the evaporator’s side. Measure the surface

temperature at many points with a fastreacting thermometer

Temperature variations across the horizontal

plane will indicate uneven liquid (or water)

distribution inside the evaporator

Danfoss

R64-2081.10

DKRCC.PF.000.G1.02 / 520H6410

15

Exchangers

Heat

Loading...

Loading...