Page 1

Operating Guide

Electronic Heat Cost Allocator

Table of Contents 1. General ..................................................................................................................................... 3

1.1 Application.......................................................................................................................................................... 3

1.2 General Guidelines........................................................................................................................................... 3

1.2.1 Hazards and Disposal .............................................................................................................................. 3

1.2.2 Changing the Battery .............................................................................................................................. 3

1.2.3 Installation with Glue .............................................................................................................................. 3

1.2.4 Warranty ....................................................................................................................................................... 3

1.2.5 Compliant Use ............................................................................................................................................ 3

1.2.6 Non-compliant Use .................................................................................................................................. 3

1.2.7 Notes regarding Installation ................................................................................................................. 3

1.2.8 Protection against Outside Influences.............................................................................................. 3

1.2.9 Data Collection while the Device is open ........................................................................................ 4

1.2.10 Transport in Original Packaging .......................................................................................................... 4

1.2.11 New Programming ................................................................................................................................... 4

1.3 Restrictions ......................................................................................................................................................... 4

1.3.1 Applications ................................................................................................................................................ 4

1.3.2 Measurement using Single or Dual Sensors ................................................................................... 4

1.3.3 Exclusion of Liability ................................................................................................................................ 4

1.3.4 Modifications .............................................................................................................................................. 4

2. Product Description ................................................................................................................ 4

2.1 Packaging ........................................................................................................................................................... 4

2.2 General Description ........................................................................................................................................ 4

2.2.1 Type ................................................................................................................................................................ 4

2.2.2 Design ........................................................................................................................................................... 4

2.2.3 Characteristics ............................................................................................................................................ 5

2.2.4 Display ...........................................................................................................................................................5

2.2.5 Electronics ................................................................................................................................................... 5

2.2.6 Versions......................................................................................................................................................... 5

2.2.7 Optical Interface ........................................................................................................................................ 6

2.2.8 Radio Wireless M-Bus .............................................................................................................................. 6

2.3 Technical data .................................................................................................................................................... 6

3. Settings .................................................................................................................................... 7

3.1 Settings ................................................................................................................................................................ 7

3.2 Operating mode ............................................................................................................................................... 9

3.2.1 Cycle ............................................................................................................................................................... 9

© Danfoss | 2019.03 VU.SH.H1.02 | 1

Page 2

Operating Guide SonoHCA

Table of Contents

(continuous)

3.2.2 Single Sensor Version with Start Sensor ........................................................................................... 10

3.2.3 Dual Sensor Version ................................................................................................................................. 10

3.2.4 Comparison of the Measuring Principles ......................................................................................... 10

3.2.5 Temperature Measurement and Calculation .................................................................................. 10

3.2.6 Calculation of the Displayed Consumption Value ........................................................................ 11

3.2.7 Start of Counting ....................................................................................................................................... 11

3.3 Display and Additional Functions .............................................................................................................. 12

3.3.1 The Menu Sequences of the Digital Display................................................................................... 12

3.3.2 The Digital Display ................................................................................................................................... 12

3.3.3 Rolling Display ........................................................................................................................................... 15

3.3.4 Communication Indicator and Measuring Indicator • .......................................................... 16

3.3.5 Real Time Clock and Calendar ............................................................................................................. 16

3.3.6 Check code.................................................................................................................................................. 16

3.4 Special Functions ............................................................................................................................................. 17

3.4.1 Suppression of Summer Counting ..................................................................................................... 17

3.4.2 Annual Reset of the Consumption Value ......................................................................................... 17

3.4.3 Unit Scale and Product Scale ................................................................................................................ 17

3.5 Parameterization .............................................................................................................................................. 17

3.6 Error ....................................................................................................................................................................... 17

3.6.1 List of Errors ................................................................................................................................................. 17

4. Installation ............................................................................................................................... 18

4.1 Introduction ....................................................................................................................................................... 18

4.2 DIN Standard Requirements for the Installation .................................................................................. 18

4.3 General Restrictions ........................................................................................................................................ 18

4.4 Operating Range .............................................................................................................................................. 18

4.5 Allocator Installation Position – Standard Installation ....................................................................... 19

4.6 Mounting the Remote Sensor ..................................................................................................................... 20

4.7 Wall Mounting ................................................................................................................................................... 21

4.8 Installation of Fastening Parts Kits ............................................................................................................ 22

4.8.1 Installation to Sectional Radiator, direct mounting ..................................................................... 22

4.8.2 Sectional Radiator, wall mounting ..................................................................................................... 22

4.8.3 Installation on Folded Radiator ........................................................................................................... 23

4.8.4 Folded Radiator, wall mounting .......................................................................................................... 23

4.8.5 Installation to Panel Type Radiator ..................................................................................................... 24

4.8.6 Mounting of heat cost allocators with glue .................................................................................... 24

4.8.7 Panel Type Radiator, wall mounting .................................................................................................. 25

4.8.8 Installation to Panel-Type Radiator with Front Convection Plate ........................................... 25

4.8.9 Bathroom radiator – Towel rails ........................................................................................................... 26

4.8.10 Sectional Radiator wide .......................................................................................................................... 27

4.9 Overview mounting accessories ................................................................................................................ 27

4.10 Mounting and Sealing .................................................................................................................................... 28

5. Commissioning ........................................................................................................................28

5.1 Automatic commissioning during the installation.............................................................................. 28

5.2 Commissioning by pressing push button .............................................................................................. 29

5.3 Radio Standby ................................................................................................................................................... 29

5.3.1 Sleeping Mode ........................................................................................................................................... 30

5.3.2 Installation Mode ...................................................................................................................................... 30

5.3.3 Operation Mode ........................................................................................................................................ 30

6. Readout .................................................................................................................................... 30

6.1 Remote Radio Reading .................................................................................................................................. 31

6.1.1 General Information about the Remote Radio Readout............................................................. 31

6.1.2 WireIess M-Bus Remote Radio Readout ............................................................................................ 31

6.1.3 Readout using the Radio Central SonoCollect ............................................................................... 31

7. Rating factors ..........................................................................................................................32

7.1 Taking Measurements ..................................................................................................................................... 32

7.1.1 Rating of Radiators with Over Length or High Nominal Power ............................................... 32

7.1.2 Rating of Radiator ..................................................................................................................................... 32

7.2 Table of Rating Factors ................................................................................................................................... 33

7.3 Rating Factor according EN 834:2013 ........................................................................................................ 33

2 | VU.SH.H1.02 © Danfoss | 2019.03

Page 3

Operating Guide SonoHCA

1. General

This manual serves as a reference for users

and service personnel of the Danfoss heat cost

1.1 Application

allocators. It describes the use of the SonoHCA

heat cost allocators.

The heat cost allocator is a measuring device

to record the heat output of radiators in units.

Units are apartments, offices, and business,

commercial or industrial premises whose heat is

supplied through a central heating system or via

a conjoint district heating station.

The group of units constitutes one billing unit.

If one billing unit includes units with differences,

for example, from a technical standpoint (in

the form of different heating systems) or in

terms of consumption behaviour (i.e. in the

case of industrial premises and apartments), a

subdivision of the billing units into unit groups

may be necessary.

Each radiator is fitted with a heat cost allocator

which records and assesses the heat output of

the radiator and displays the consumption value.

1.2 General Guidelines 1.2.1 Hazards and Disposal

The heat cost allocators a re equipped with

respect the transpor t directives applicable in yo ur

coun try.

lithium batteries . This type of batte ry falls into

the category of ha zardous goods. Please

Handling of Lithium Batteries:

• Store in a dry place.

• Do not heat to more than 100°C and do not

throw into a fire.

• Do not store near a heat source.

• Do not store in direct sunlight.

• Do not short-circuit.

• Do not open or damage.

• Do not recharge.

• Keep out of reach of children.

1.2.2 Changing the Battery

The heat cost allocator’s battery is soldered.

Changing the battery is neither provided for nor

permitted.

Disposal

In order to protect the e nvironment, to

reduce waste of natural resources and

prevent pollution, the European Uni on

has adopted a directive stipulating

that electric al and electronic devices must be

recovered by their manufac turers in order to

ensure proper destruction or recycling.

Should you dispose of the device yourself, please

get information from your local authority on

recycling options.

The consumption value is the basis for allocating

the heating costs to each unit, which is necessary

for the annual billing of the heating costs.

The heat cost allocators are principally used in

the following units:

• Collective housing buildings.

• Offices or administrative buildings.

The typical users are:

• Measuring and billing services.

• Cooperatives or property managers.

• Building service companies, letting agencies.

The heat cost allocators can be installed on:

• Sectional radiators.

• Column/tube radiators.

• Panel radiators with horizontal or vertical

water flow.

• Flat register radiators.

• Convector heaters.

1.2.4 Warranty

The warranty rights are only valid if the devices

have been installed and used in compliance with

regulations and if the technical guidelines in

force have been followed.

1.2.5 Compliant Use

Installation of this product must comply with the

installation directives described in this manual

and carried out by personnel trained for this

purpose.

1.2.6 Non-compliant Use

Any application other than that described above

is not permitted.

1.2.7 Notes regarding Installation

Any inappropriate handling or faulty installation

may result in radiator leakage. Please respect the

recommendations of the installation notice for

the radiator.

1.2.8 Protection against Outside Influences

1.2.8.1 Lead seal

The heat cost allocator is closed with a safety

seal which cannot be removed without causing

damage. It is therefore impossible to open

the device without this being detected. After

installation, the electronic part of the device is

no longer accessible. The LCD display, the push

button and the optical itnterface are protected. It

is impossible to access the interior of the device

without damaging it.

1.2.3 Installation with Glue

Due to their chemical composition, the use of

glues emits vapours and can damage the plastic

casing of the heat cost allocator.

1.2.8.2 Electronic Detection of Opening

The electronic detector detects unauthorised

opening and closing of the heat cost allocator.

As soon as the housing of the heat cost allocator

VU.SH.H1.02 | 3© Danfoss | 2019.03

Page 4

Operating Guide SonoHCA

1.2 General Guidelines

(continuous)

1.3 Restrictions

is opened and / or removed, the electronic

detector triggers an error message. During

this time, the date of opening of the case, the

number of openings and the cumu-lative length

of time for which the case was open are saved

and may be read using the optical interface or

the radio.

1.2.9 Data Collection while the Device is

open

The heat cost allocators continue to collect data,

even if the electronic detector is activated.

1.3.1 Applications

The heat cost allocators may not be used in the

following cases:

• Steam heating.

• Air radiators.

• Floor heating.

• Ceiling radiant heating.

• Flap-controlled radiators.

• Radiators with a removable front plate

(attached with clips).

Heat cost allocators may only be attached to

radiators controlled by a combination of flaps

and valves if the control is disassembled or

locked in the ‘open’ position.

1.2.10 Transport in Original Packaging

The heat cost allocators must be transported in

their original packaging.

1.2.11 New Programming

Before each new instance of programming, save

the history of previous value readings.

1.3.2 Measurement using Single or Dual

Sensors

Combining the two systems in the same building

or in a single calculation unit is not permitted.

1.3.3 Exclusion of Liability

Danfoss rejects all liability when the conditions

of assembly and use described in this manual

as well as those described by the standard EN

834: 2013 are not observed.

1.3.4 Modifications

Danfoss reserves the right, without prior notice,

to make any modifications with a view to

improving the product.

2. Product Description

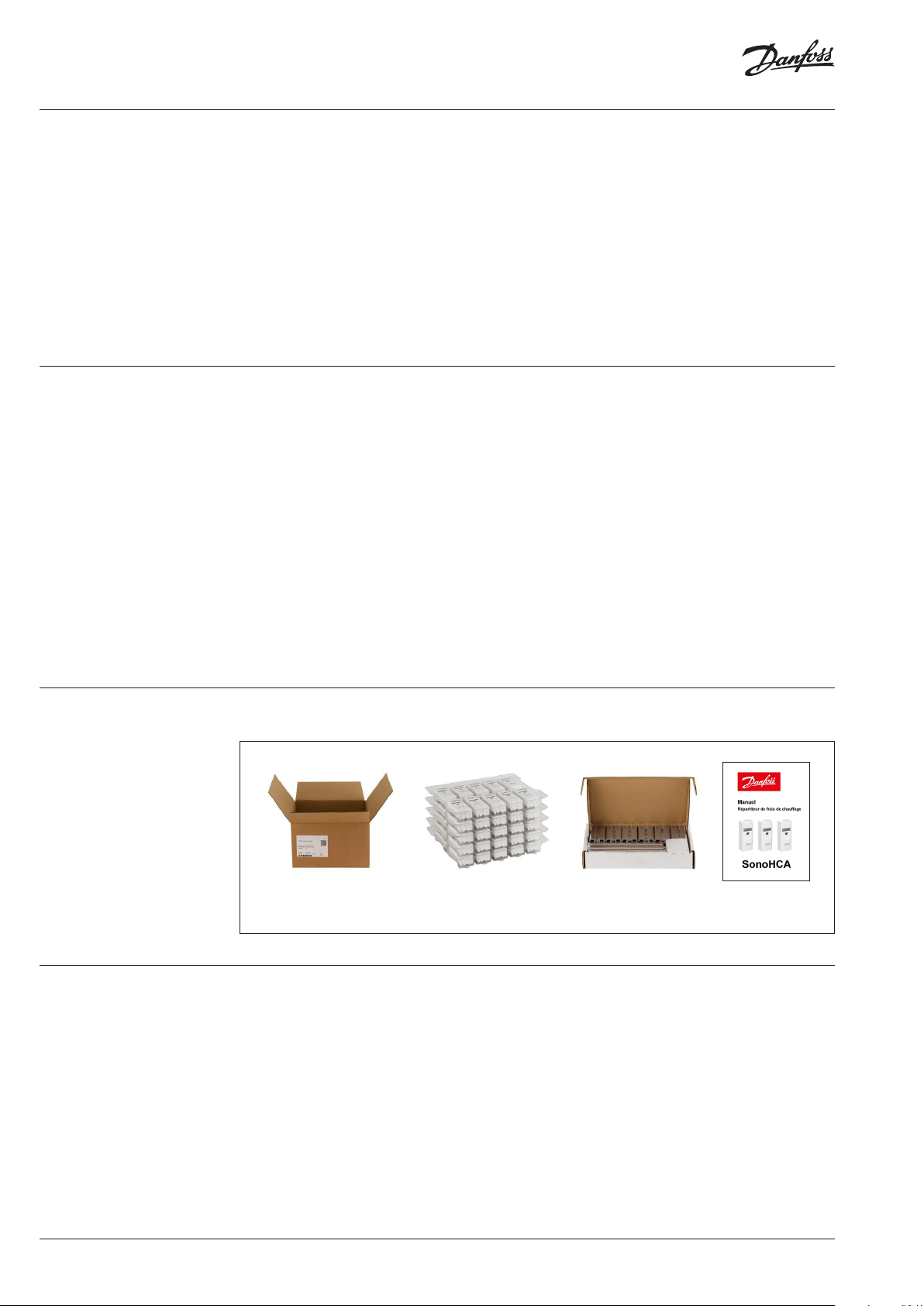

2.1 Packaging

2.2 General Description

Contents of the SonoHCA allocator box:

Box with label describing

the product

5 10-piece trays with

premounted lead seal

2.2.1 Type

The electronic heat cost allocators SonoHCA

operate either according to the single sensor

principle with start sensor or the double sensor

principle. The device has been developed and

approved in accordance with the European

Standard EN 83 4:2013.

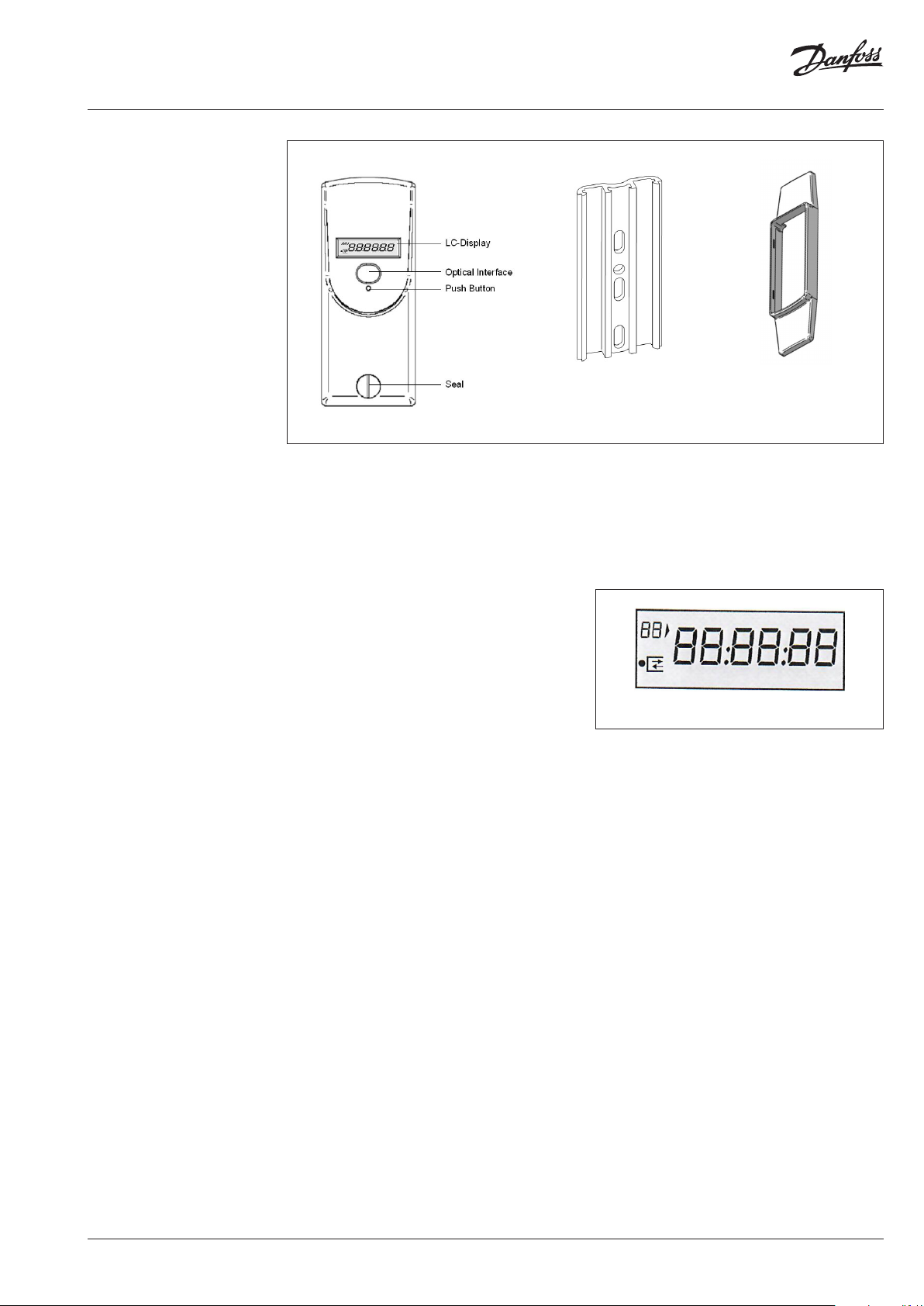

2.2.2 Design

The heat cost allocator consists of a

microprocessor, a lithium battery, two

temperature sensors, a heat conducting

aluminium back plate, a multi-functional display

and a plastic housing.

1 box of 50 back plates Installation guide

The measuring circuit consists of the

temperature sensors, the analogue-digital

conversion, the reference resistance for

standardising the measuring transformation and

the microprocessor for accessing the radia-tor

heat output. During each measuring the circuit

tolerances are eliminated with a reference

resistance and the heat cost allocator carries out

an automatic self-test.

4 | VU.SH.H1.02 © Danfoss | 2019.03

Page 5

Operating Guide SonoHCA

2.2 General Description

(continuous)

Standard aluminium back plate for

nearly all existing bolts with common

dimensions and mounting possibilities

– thus easy installation

2.2.3 Characteristics

• Measuring by two temperature sensors,

radiator and ambient temperature sensor

(NTC-resistor).

• Optional measuring principle: 1 sensor mode

with start sensor or two sensor mode.

• Unit scale or product scale.

• Recording of cumulated heat consumption on

the annual set day.

• Recording of 144 monthly values and 18

half monthly values for cumulated heat

consumption.

• Recording of 18 monthly values for the

maximum radiator temperature.

• Optical interface for the readout of the data

and programming

• For heat cost allocator SonoHCA, the radio

module comprises a unidirectional radio

transmitter.

Two telegrams: short telegram, OMS

compliant and long telegram for Walk-by

reading.User-friendly operation by push

button.

• 6-digit and high-contrast LCD display.

• Automatic commissioning during the

mounting on the aluminium back plate

(available when ordering).

• Check code for postcard mail-in method

• Possibility to connect a remote sensor on each

version of heat cost allocator. The remote

sensor will be automatically detected by the

heat cost allocator.

• Remote sensor version with 2 m cable.

• Standard aluminium back plate for nearly

all existing bolts with common dimensions

and installation possibilities – thus easy

installation (no cutting and welding of bolts

necessary).

• Snap-on blind to cover colour shadows for

increased aesthetics.

• Safe operation and fraud/manipulation

detection.

• Lithium battery with a capacity of up to 10+1

year.

• Meets EN 834:2013.

Snap-on blind to cover

colour shadows for

increased aesthetics

2.2.4 Display

The heat cost allocator has a LCD-display with 6

large main digits on the right and 2 smaller digits

on the left as well as two special symbols and

one communication indicator. The main digits

are separated by four decimal points. Below,

please find the display segments:

Display with all active segments

Normally, the heat cost allocators are supplied

with switched-off LCD-display. On request, the

heat cost allocators can also be supplied with

permanent LCD- display.

2.2.5 Electronics

The device has an electrical circuitry with

an 8-Bit-CMOS-micro controller of the latest

generation STM8L with extremely low current

consumption operating at a voltage as from

1.8 V.

The temperature measuring circuit with

automatic self-calibration measures the

discharging time of a capacitor. The accuracy

of the measuring circuit is independent of the

supply voltage.

2.2.6 Versions

For each version of heat cost allocator, it is

possible to plug the connector of the remote

sensor to an interface inside the heat cost

allocator.

Once equipped with a remote sensor, the heat

cost allocator will only work for an application

with remote sensor. Remote sensor version with

2 m cable.

VU.SH.H1.02 | 5© Danfoss | 2019.03

Page 6

Operating Guide SonoHCA

2.2 General Description

(continuous)

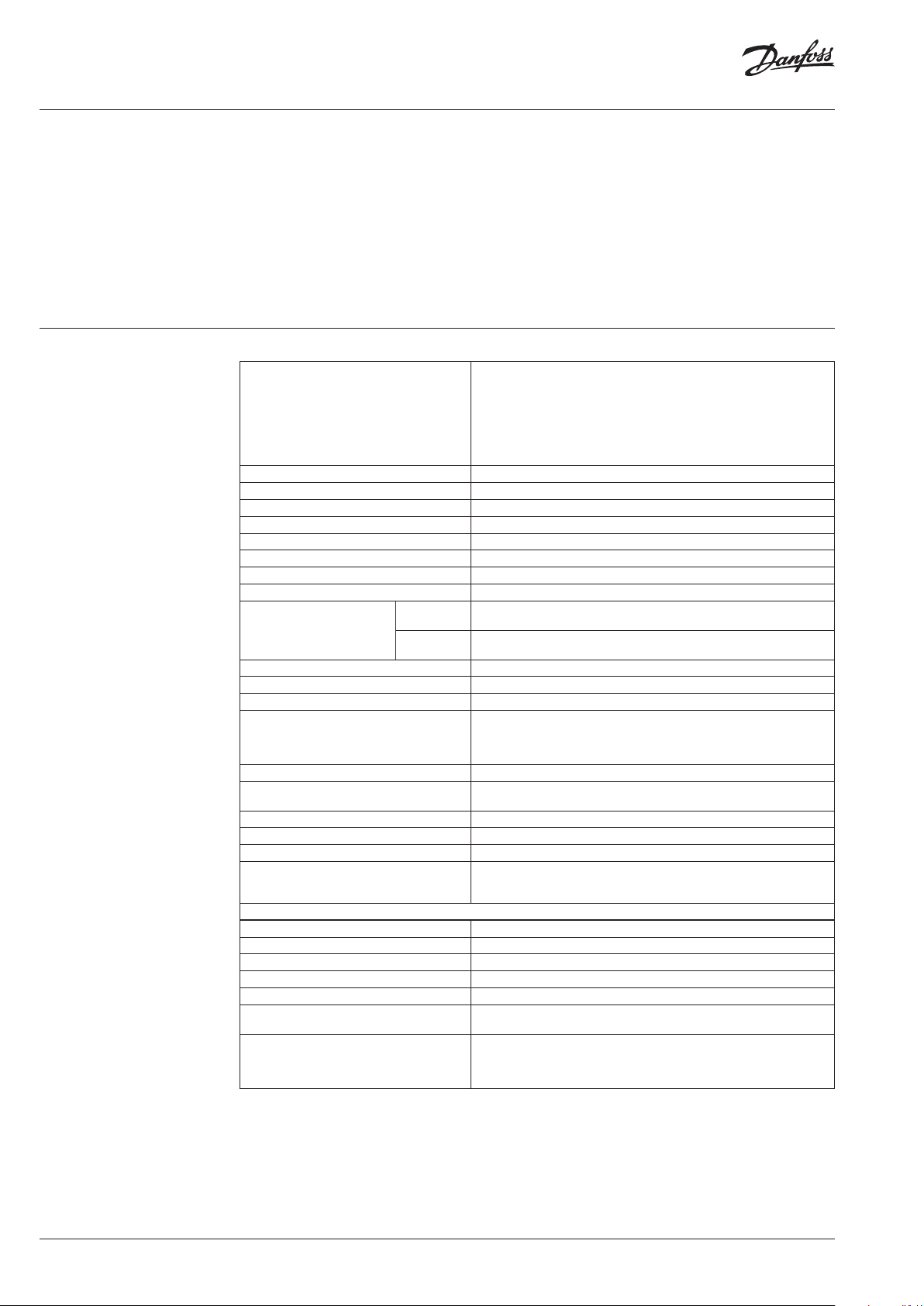

2.3 Technical data

2.2.7 Optical Interface

With a standardised optical probe the

consumption and configuration values can be

transferred directly to a computer. With the radio

heat cost allocator all consumption values can

be readout over the optical interface and over

radio. The data are transmitted in M-bus-format

acc. to EN13757-3. Authorised personnel can alter

the configuration of the device over the optical

interface with an optical probe.

Single sensor device with start sensor

for heating systems with tmmin ≥ 55 °C

Calculation with set reference temperature 20 °C

Optional measuring systems:

Optional scales: Unit scale or product scale

Current supply: 3 V-Lithium-battery

Life-span with 1 battery: > 10 years

Display: Liquid crystal display (LCD-display)

No. of displayed digits: 6 digits (000000 ... 999999)

Sensor temperature range: 0 °C ... 120 °C

Exponent: n = 1.33

Radiator – performance range: 4 Watt ... 16.000 Watt

(tm

... tm

Design temperature range:

Values: Rating fac tors see digital KC-data base

Models: Compact device or remote sensor device

Set day: Freely programmable

Data storage:

Self-test: Before every measuring

Start of counting:

Satndard version: EN 834:2013

Homologation according to: HK VO : A1.0 2. 2015

Conformity: CE

Standard mounting height:

Wireless M-Bus radio communication

Frequency: 868.95 MHz

Communication: Unidirectional

Protocol: Wireless M-Bus

Encryption: AE S-128

Transmission standard: EN 13757-4, mode T1

Broadcasting interval:

Data transmission periods:

(tm

min

min

... tm

Necessar y rating factors: KQ, KC, (KA, KT)

Double sensor device

for heating systems with tmmin ≥ 35 °C

Calculation with variable ref. temperature T-air sensor

Necessar y rating factors: KQ, KC, (KA, KT)

Single sensor device with start sensor

)

max

55 °C ... 105°C / 120 °C (compact- / remote sensor)

Double sensor system

)

max

35 °C ... 105°C / 120 °C (compact- / remote sensor)

144 monthly values and 18 half monthly values for cumulated heat

consumption, 18 monthly values for the maximum radiator temperature.

Maximum temperature of the current and previous year, all relevant

consumption values

Heating period 25°C – 40°C (programmable)

Off-heating period 25°C – 40°C (programmable)

At 75% of the overall height of the radiator.

If the height of the radiator is less than (<) 470 mm, the heat cost allocator

must be installed at 50% BH.

Short telegram (OMS): > 120 s

Long telegram (walk-by): > 120 s

Short telegram (OMS): 24 h/d,

7 days a week

Long telegram (walk-by): < 12 h/d,

7 days a week

2.2.8 Radio Wireless M-Bus

The radio heat cost allocator features a

transmitter circuit in the 868 MHz band with

integrated antenna.

This radio module comprises a unidirectional

radio transmitter which is used to transfer data

according to the wM-Bus (EN 13757-4) radio

communication protocol and in compliance with

the OMS (Open Metering System) Release V3.0.1.

6 | VU.SH.H1.02 © Danfoss | 2019.03

Page 7

Operating Guide SonoHCA

2.3 Technical data

(continuous)

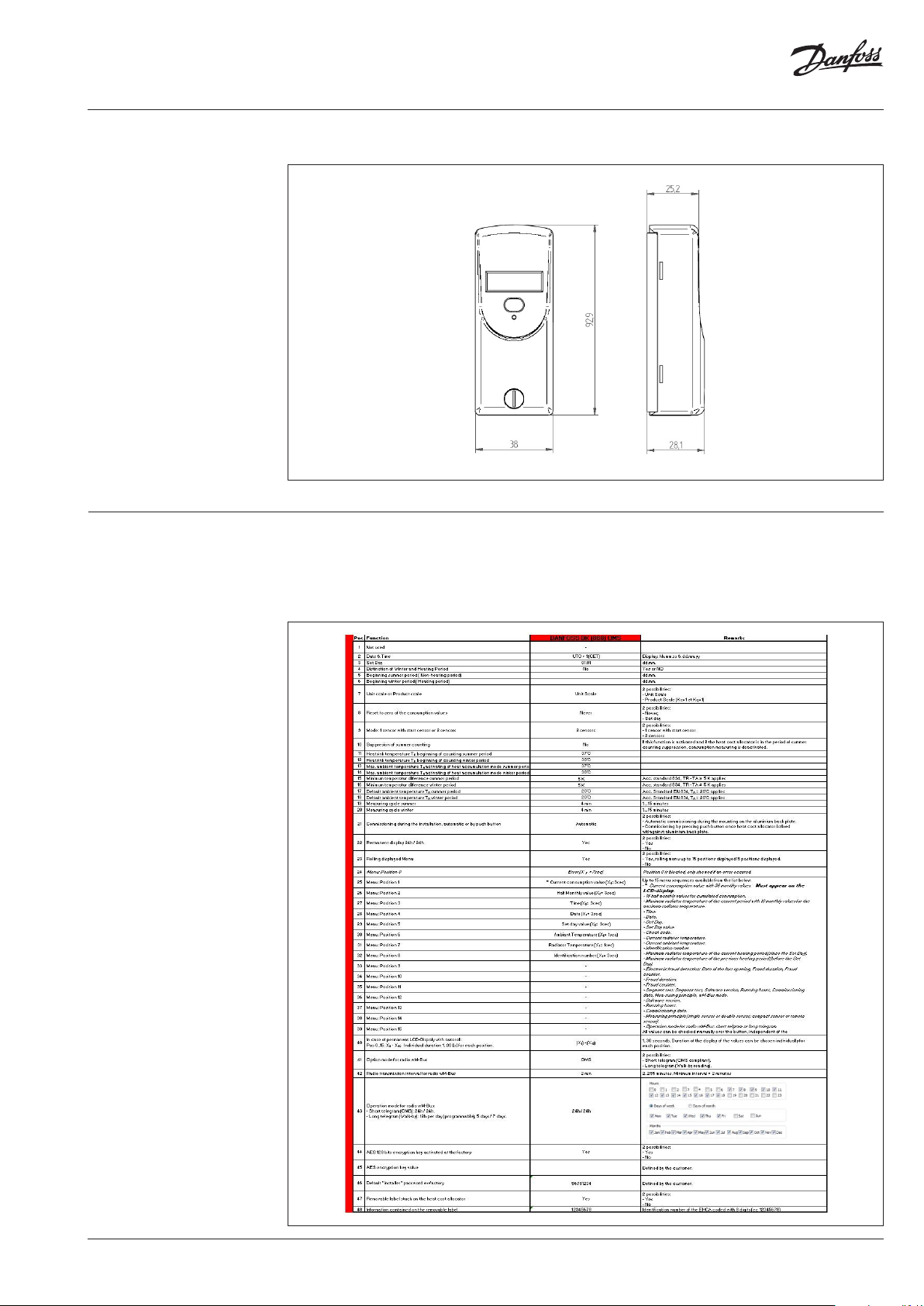

3. Settings

3.1 Settings

Dimension

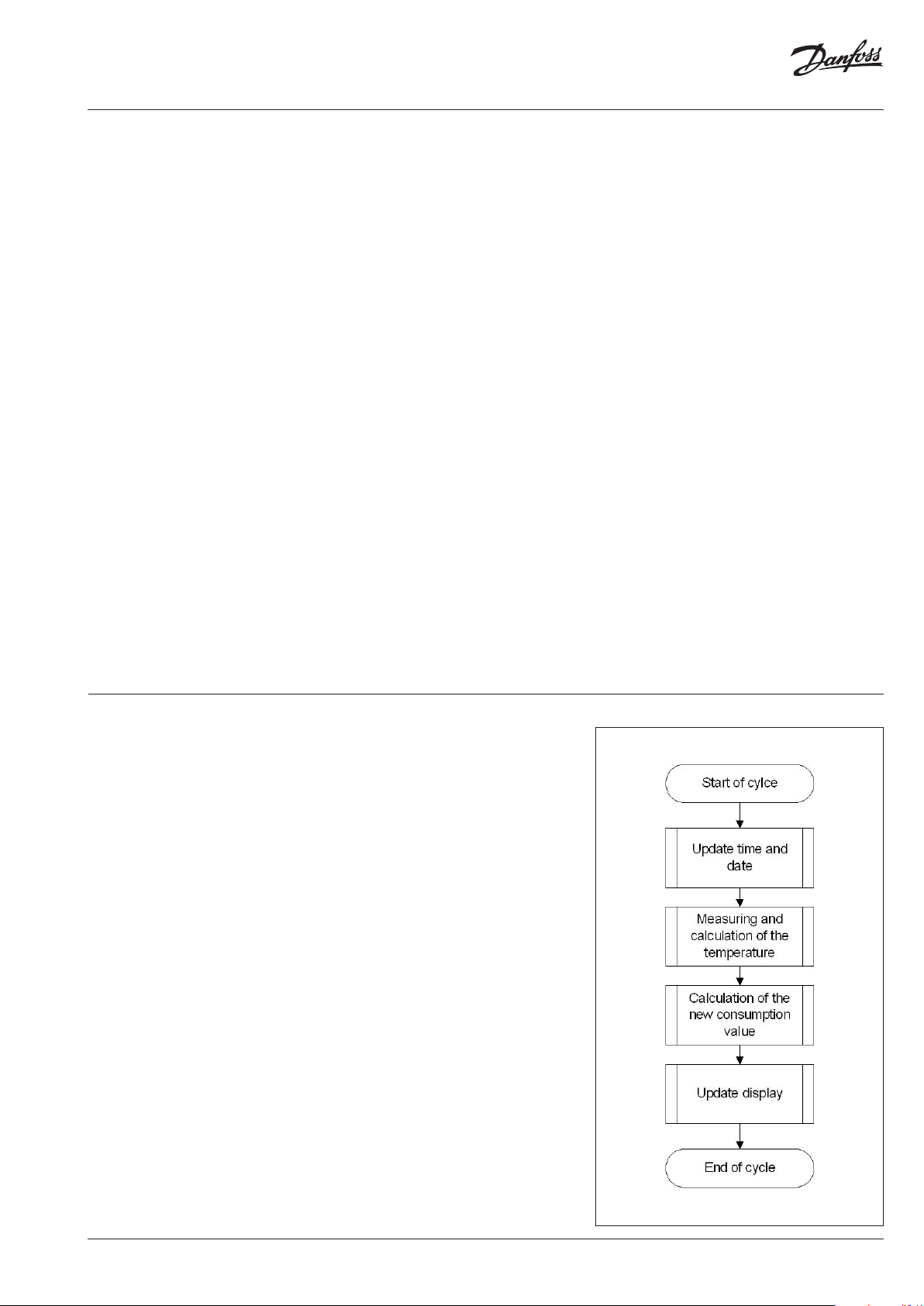

The following table can be used to determine

the configuration of the heat cost allocator by

combining the different settings options that

follow.

Due to distinctive technical features, not

all possible combinations are necessarily

achievable.

Configuration sheet for SonoHCA:

VU.SH.H1.02 | 7© Danfoss | 2019.03

Page 8

Operating Guide SonoHCA

3.1 Settings (continuous)

• Position 1: Not used.

• Position 2: Allocator Date and Standard

Time:

The UTC time zone will be programmed

in accordance with the country where the

allocator is in-stalled.

• Position 3: Set Day (yearly date):

It is possible to program an annual set day on

which the cumulative consumption value to

date is recorded.

• Position 4: Setting Winter / Summer

Periods:

2 options: yes / no.

If the ‘yes’ option is chosen, two different

specific heating periods (winter and summer)

with different start temperatures settings

depending on the current period can be

distinguished.

• Position 5: Set the Start of the Summer

Period:

Choose the date on which the summer period

will begin.

• Position 6: Set the Start of the Winter

Period:

Choose the date on which the winter period

or the heating period will begin.

• Position 7: Unit Scale and Product Scale:

2 options: unit scale / product scale.

Set the type of scale used when calculating

the display values.

By default, the KC and KQ evaluation factors

will be set to 1 for the product scale.

• Position 8: Set Cumulative Values to Zero:

2 options: set day / never.

Determine whether the units’ consumption

totalizer will be reset to zero on the set day or

never.

• Position 9: Single Sensor or Dual Sensor

Mode:

Set the measuring method used by the

allocator.

2 options: single sensor / two sensors.

Single sensor: determines the amount of

heat emitted by a radiator by measuring and

assessing the radiator’s temperature with

respect to that of the room temperature

measured at the start and fixed at 20°C.

Two sensors: determines the amount of heat

emitted by a radiator based on the measured

temperature of the radiator via the radiator

temperature sensor and the ambient air

sensor.

• Position 10: Elimination of Summer

Counting:

2 options: yes / no.

If the ‘yes’ option is chosen, consumption will

not be measured during the summer period.

• Position 11: Radiator Temperature TR ,

Start Counting Summer Period:

Set the threshold temperature for the start

(counting) of the allocator. When this start

temperature is reached, the allocator will

begin to count the consumption units.

• Position 12: Radiator Temperature TR ,

Start Counting Winter Period:

Set the threshold temperature for the start

(counting) of the allocator. When this start

temperature is reached, the allocator will

begin to count the consumption units.

• Position 13: Max. room temperature TA ,

Activation of Heat Accumulation Mode,

Sum-mer Period:

Set a reference temperature in order to

avoid an incorrect measurement due to heat

accumulation (e.g. if the radiator is hidden by

panels, thermal accumulation). The allocator

will automatically switch into single-sensor

mode when the ambient temperature

measurement surpasses the defined reference

temperature. Following this, the calculation

will use an ambient temperature set to

20°C rather than the temperature actually

measured.

• Position 14: Max. room temperature TA ,

Activation of Heat Accumulation Mode,

Winter Period:

Set a reference temperature in order to

avoid an incorrect measurement due to heat

accumula-tion (e.g. if the radiator is hidden by

panels, thermal accumulation). The allocator

will automatically switch into single-sensor

mode when the ambient temperature

measurement surpasses the defined reference

temperature. Following this, the calculation

will use an ambient temperature set to

20°C rather than the temperature actually

measured.

• Position 15: Minimum Temperature

Difference, Summer Period:

Set a reference value calculated using the

temperature difference between the radiator

and the ambient air. According to the

standard EN 834: TR - TA ≤ 5 K.

• Position 16: Minimum Temperature

Difference, Summer Period:

Set a reference value calculated using the

temperature difference between the radiator

and the ambient air. According to the

standard EN 834: TR - TA ≤ 5 K.

• Position 17: Standard Ambient

Temperature TA, Summer Period:

Ambient temperature value used to calculate

the unit’s consumption. Set by the standard

EN 834: TA = 20°C.

• Position 18: Standard Ambient

Temperature TA, Winter Period:

Ambient temperature value used to calculate

the unit’s consumption. Set by the standard

EN 834: TA = 20°C.

• Position 19: Measuring Cycle, Summer

Period:

Set a time interval to be used as an operations

measuring cycle. The allocator will therefore

usually be in sleep mode.

• Position 20: Measuring Cycle, Winter

Period:

Set a time interval to be used as an operations

measuring cycle. The allocator will therefore

usually be in sleep mode.

• Position 21: Commissioning of the

Allocator:

2 options: Automatic commissioning upon

installation on the back plate / By pressing

the push button after installation on the back

plate.

The allocator leaves the factory in sleep mode,

meaning that it does not measure or calculate

consumption. The transition from sleep to

installation mode can be carried out in 2

8 | VU.SH.H1.02 © Danfoss | 2019.03

Page 9

Operating Guide SonoHCA

different ways: automatically upon installation

on the aluminium back plate or by pressing

the push button after having installed it on

the aluminium back plate.

• Position 22: 24-hour Active Display:

2 options: yes / no.

If the ‘no’ option is chosen, the display will

always be switched off. By pressing the push

button, the LCD screen will become active.

After 3 minutes of inactivity, the screen will

automatically re-turn to deactivated mode.

If the ‘yes’ option is chosen, the display will be

active 24 hours a day.

• Position 23: Scrolling Display Menu:

2 options: yes / no.

If the ‘no’ option is chosen (static display), the

menu can be changed by pressing the push

button.

If the ‘yes’ option is chosen, the display will

automatically move from one menu to the

next. The display duration can be configured

individually for each duration.

• Position 24: Error Information Display:

If an error occurs, the Err message will appear

on the LCD screen. This information will

appear at the top of the menu sequence.

• Positions 25 to 39: 15 values which can be

displayed.

• Position 40: Programmable Display Time

for Each Value Shown.

• Position 41: Operation Mode for the

Wireless M-Bus Radio:

2 options: short telegram (OMS) / long

telegram (Walk-by).

• Position 42: Transmission Interval for

Wireless M-Bus Radio Telegram:

Set a transmission interval for sending

Wireless M-Bus radio telegrams.

• Position 43: Wireless M-Bus Radio

Telegram Transmission Period.

Short telegram (OMS): 24 hours a day, 7 days a

week.

Long telegram (walk-by): 12 hours chosen per

day (programmable), 7 days a week.

• Position 44: AES-128 Encryption Activated

at Factory:

2 options: yes / no.

If the ‘yes’ option is chosen, the encryption

key can be programmed according at the

customer’s request.

• Position 45: Decryption Key:

Contact the local Danfoss for Decryption Key.

• Position 46: Installer Password:

Default password: 56781234

This may be chosen by the customer.

• Position 47: Detachable Label Attached to

the Heat Cost Allocator:

2 options: yes / no.

If the ‘yes’ option is chosen, a detachable

label will be attached to the front face of the

allocator.

• Position 48: Information Contained on the

Detachable Label:

The information contained on the detachable

label may be chosen by the client.

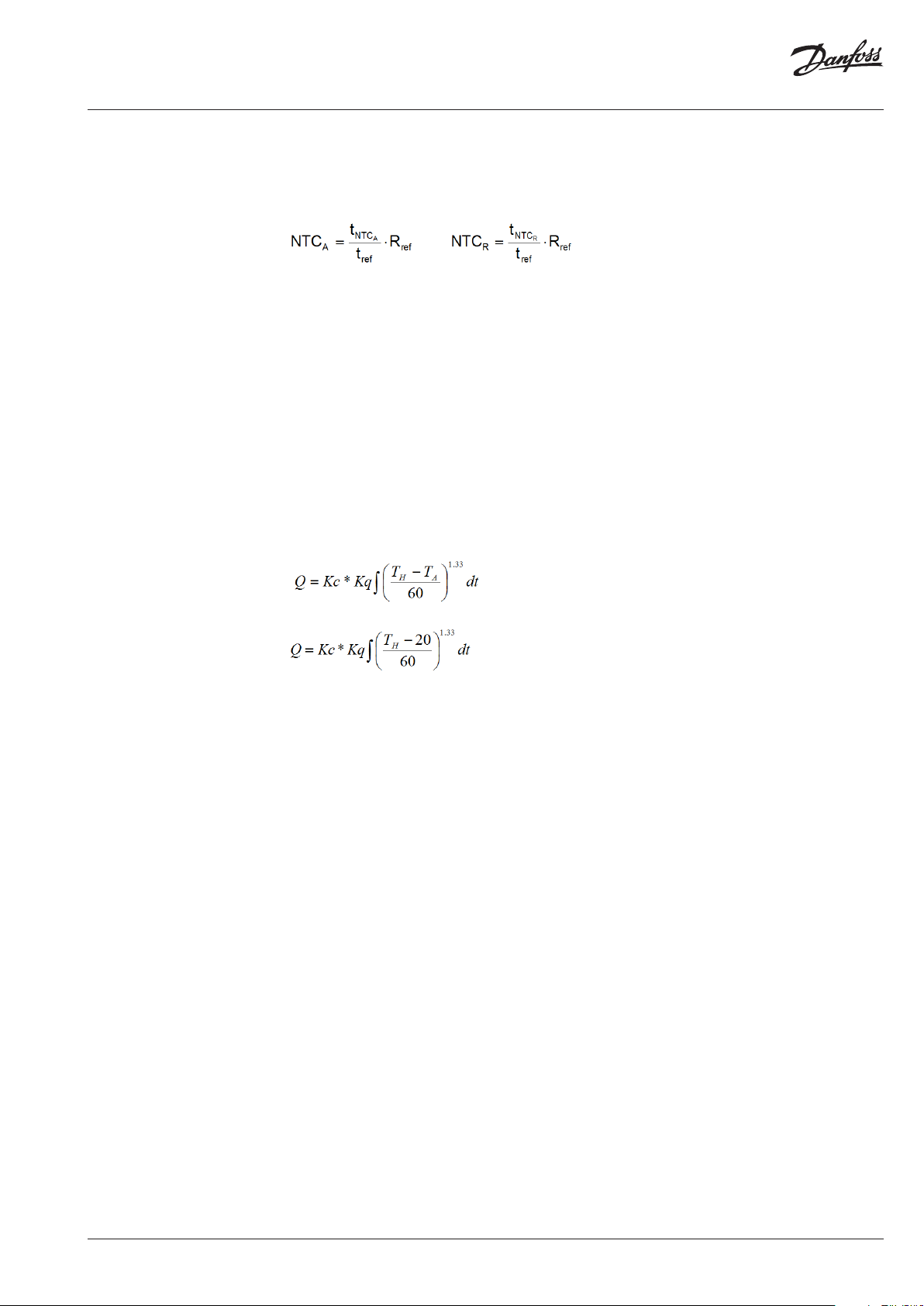

3.2 Operating mode 3.2.1 Cycle

The heat cost allocators SonoHCA operate in a

cycle of 4 minutes. Most of the time, the device is

in sleeping mode. Every 4 minutes the device is

set into operation and operates according to the

adjoining diagram.

The clock-pulse generator is a counter which is

completely independent from the rest of the

program. This counter is designed in a way so

that it is impossible to stall the cycle or to skip

one or more cycles.

Each cycle follows the adjoining diagram.

The measuring and calculating processes are

explained in detail later.

The tasks carried out during one cycle are taking

approx. 100 ms. This means that the device is in

sleeping mode more than 99.8 % of the time. It

can be set into operation between two cycles

over the optical probe or by pushing the button.

In this case it carries out the requested task and

then returns to sleeping mode.

In case an optical probe is connected or the

button is pushed during the course of the cycle,

the respective value is readout at the end of the

cycle.

The button can be pushed for an indefinite

period of time and the optical probe can be

left in its position since the normal function of

the device is not impaired by an influence from

outside.

VU.SH.H1.02 | 9© Danfoss | 2019.03

Page 10

Operating Guide SonoHCA

3.2 Operating mode

(continuous)

3.2.2 Single Sensor Version with Start Sensor

The start sensor of the single sensor version

serves as an ambient temperature sensor which

mainly functions during the heating up period.

The start temperature is the threshold

temperature of the radiator at which the device

always starts to carry out energy ratings. For

these ratings, the measured radiator temperature

and an assumed ambient temperature of 20° C

are used as calculation basis.

3.2.3 Dual Sensor Version

For the dual sensor version basically the

same specifications apply as for the single

sensor version with start sensor. However,

for calculating the room temperature the

real temperature, measured by the ambient

temperature sensor (corrected via the

corresponding radiator-dependent „Kairvalue“),

is used as the basis.

3.2.3.1 Heat Accumulation Mode

In order to avoid faulty measuring due to heat

accumulation (e.g. in case the radiator is hidden

by panels), the device switches from a defined

ambient temperature (e.g. 28°C) to the one

sensor mode and calculates with an ambient

temperature of 20° C.

3.2.4 Comparison of the Measuring

Principles

Single sensor device with start sensor

measuring principle

For heating systems with tm

≥ 55 °C

min

The heat cost allocator calculates with a set

reference temperature of 20 °C

Application:

Single sensor devices with start sensor are used

in areas where normal ambient temperatures are

given. For low temperature heating systems the

double sensor device is recommended.

For radiators which are covered or blocked by

fix-tures, normally the single sensor devices are

used because the double sensor device is not

in a posi-tion to capture the current ambient

temperature due to the heat accumulation.

double sensor system which then switches over

internally to the single sensor mode.

Within one billing unit, only one measuring principle

(either single sensor measuring principle with start sensor

or double sensor measuring principle) can be used. Mixed

fitments or the use of different types of devices in the

same billing unit is therefore also not allowed.

The processes for determining the K-value for

the single sensor device with start sensor and the

double sensor device are identical. It is only the

measuring principle that is different.

3.2.5 Temperature Measurement and

Calculation

The temperature is measured with an NTC –

resistor. For the resistance measurement the

discharging time of the capacitor is measured.

The measurement is carried out as follows:

3.2.5.1 Measuring of a Resistor, Principle

1. Charging of the capacitor

2. Discharging of the capacitor through the

resistance which is to be measured. At the

same time a 16+1 bit-timer starts with the

discharge to measure the discharging time

3. As soon as the voltage on the capacitor

terminals reaches a certain value, an interrupt

is induced and the timer stops. At the same

time the discharging of the capacitor is

stopped as well.

After the three mentioned stages, the timer

provides a 16-bit-value which corresponds to the

discharging time of the capacitor through the

resistance which is to be measured. In case the

resistance is known (reference resistance), the

constant ratio between discharging time and

resistance can be assessed.

3.2.5.2 Calculation of the Value of an

Unknown Resistance (e.g. sensor

resistance)

The capacitor C is loaded at constant current. The

interrupt at the end of the discharge is triggered

by the same threshold voltage (a fraction of the

discharge voltage). If these two conditions are

met, the discharge time is directly proportional

to the resistance. With a reference resistance R

whose exact value is known, it is now possible to

ref

calculate the unknown resistance value Rx with

the following equation:

Double sensor measuring principle

For heating systems with tm

≥ 35 °C

min

The heat cost allocator calculates with a variable

reference temperature T

air temperature

Application:

Double sensor devices are used in areas where

precise measuring of the ambient temperature

is necessary and/or in low temperature heating

systems.

Radiators which are covered or blocked by

fix-tures are detected automatically by the

From this equation the self-calibration of the

converter can be derived, which is given by

measuring the discharging time through the

reference resistance.

3.2.5.3 Measuring of the Radiator and

Ambient Temperature

The following measurements are carried out

during one cycle:

1. Measuring of the reference resistance Rref

2. Measuring of the ambient temperature sensor

NTC

A

10 | VU.SH.H1.02 © Danfoss | 2019.03

Page 11

Operating Guide SonoHCA

3.2 Operating mode

(continuous)

3. Measuring of the radiator temperature sensor

NTC

R

The measuring values are calculated with the

following formula:

The reference resistance value is defined ex

works with a tolerance of 0.5% with 50 ppm.

The reference resistance features an excellent

temperature and long-term stability.

The capacitor value and the threshold voltage

have to remain stable over the whole cycle.

However, they can vary at the medium- or long

term without causing any failures because the

self-calibration of the converter is repeated

in every cycle while measuring the reference

resistance.

3.2.6 Calculation of the Displayed

Consumption Value

The value displayed on the heat cost allocator is

calculated as follows:

Single sensor device

Double sensor device

3.2.7 Start of Counting

The updating (increment) of the consumption

value is carried out under the following

conditions:

During winter period (heating period):

(TR ≥ 25 °C)

or

(TR ≥ 20 °C) AND (TR - TA ≥ ΔT

MIN

)

During summer period (off heating period):

(TR ≥ 35 °C)

or

(TR ≥ 20 °C) AND (TR - TA ≥ ΔT

MIN

)

Explanation:

TR Radiator temperature

TA Ambient temperature

ΔT

Minimum temperature difference between

MIN

radiator and room

3K for standard device (winter heating

period standard setting)

4K for remote sensor device (summer

heating period standard setting)

Note:

The thresholds of starting (25°C et 35°C) are indicative

values. These temperatures of starting are adjusted

according to the needs and specif icities of the customer.

Explanation:

TH Temperature of the radiator surface in [°C]

TA Ambient temperature in [°C]

Q Displayed consumption value, without

unit

Kc Factor that carries back the ΔT measured at

a normalized value

Kq Factor Kq is a numerical value of the

nominal power of the radiator stated in

[KW]

Unit scale:

Kc = 1 and Kq = 1

Product scale:

Kc <> 1 and Kq <> 1

VU.SH.H1.02 | 11© Danfoss | 2019.03

Page 12

Operating Guide SonoHCA

3.3 Display and

Additional Functions

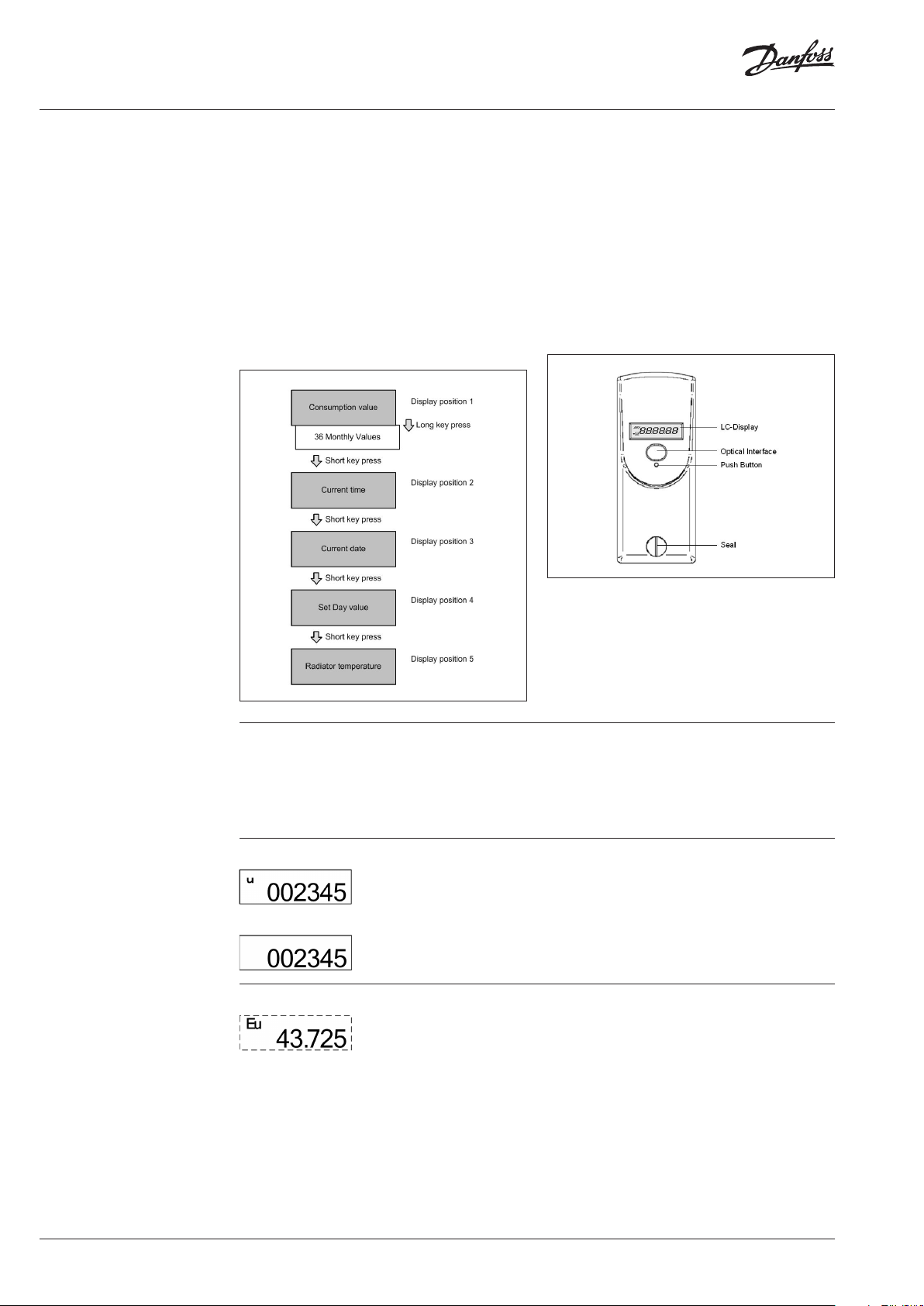

3.3.1 The Menu Sequences of the Digital

Display

The menu sequences

Ex-factory all menu sequences are activated.

With a software the order of the menu sequences

1 - 15 can be changed in any order. However the

order within the individual menu sequences 1 –

15 cannot be changed. It is also possible to hide

individual menu sequences so that they are not

visible to the end-user.

When reading out over the optical interface

or via radio the complete set of data is always

readout and transferred.

Operation of the Push Button

When pushing the button briefly the digital

display always goes to the next menu sequence.

When pushing the button in one menu sequence

for 2 seconds the individual values within the

selected menu sequence can be accessed. When

the last value within one menu sequence has

been displayed, the 1st position will be displayed

by pushing the button again.

If the button is not pushed for 2 minutes,

the digital display returns to the cumulated

consumption value.

3.3.2 The Digital Display

During normal operation the display is

deactivated and can be activated by pushing the

button.

Consumption Value Unit Scale

Consumption Value Product Scale

Indicazione in EURO

If the button is not pushed, the display will be

active for 2 minutes only.

On request, the heat cost allocator is also

available with permanent display 24h/24h or

with a rolling menu displayed.

On the display of the heat cost allocator with

unit scale an index u for unit is shown on the left

side. If the index u is not displayed, the heat cost

allocator is equipped with the product scale.

When commissioning the device this value is

000000. When reaching the value 999999, the

counting restarts automatically at 000000.

The heat cost allocators have the option to

display the heating cost in Euro.

The cost in Euro indicated on the display is only

approximate and is based on historical values

from the previous year.

The displayed cost does not necessarily

represent the charges to be paid.

Manufacturer and supplier decline any claims

concerning the use and interpretation of the

indicated values.

This option can be activated via a software.

12 | VU.SH.H1.02 © Danfoss | 2019.03

Page 13

Operating Guide SonoHCA

3.3 Display and

Additional Functions

3.3.2 The Digital Display

(continuous)

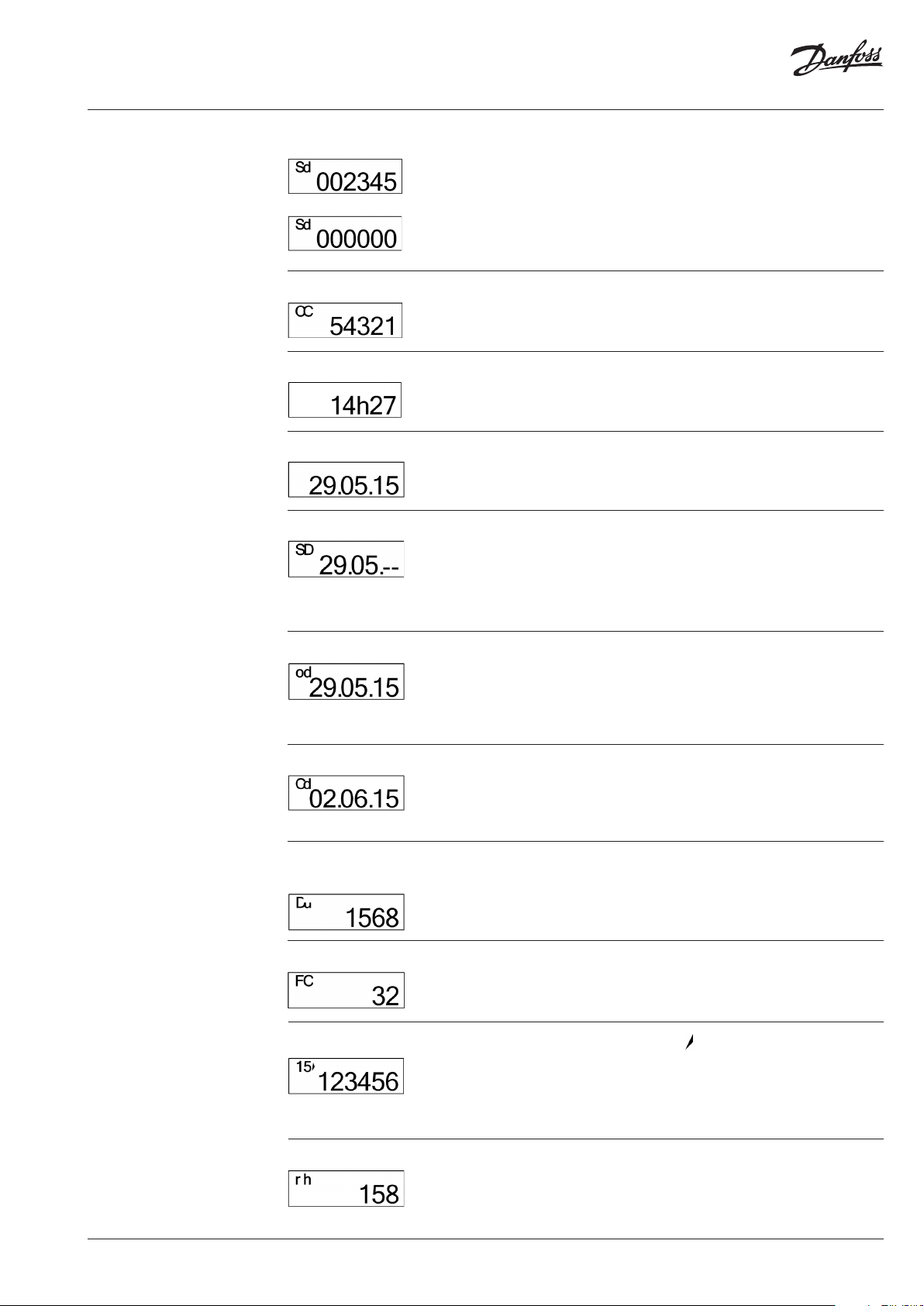

Set day Value

Check code

Time

Date

Set Day

With the index Sd the consumption value

recorded at midnight of the set day is displayed.

The consumption value recorded can be in unit

scale or in product scale. It’s depending of the

unit setting.

If a new device has not yet reached the

programmed set day, 000000 is displayed.

With the index CC the check code for the

plausibility check of the manual readout is

displayed.

The current time (always winter time).

The current date of the heat cost allocator.

It is possible to program an annual set day on

which the cumulated consumption value as

well as the maximal radiator temperature are

recorded.

With the index Sd the programmed annual set

day is displayed.

Date of Opening of the Device

Commissioning Date

Cumulated Duration of the Opening of the

Device

Fraud Counter This value indicates how many times the fraud /

Identification Number

Each heat cost allocator is equipped with a

manipulation protection which detects an

unauthorised opening of the device after

installation to the radiator. The date of the last

opening of the device is recorded and displayed

with the index od.

With the index Cd the commissioning date is

displayed, i.e. the date on which the device has

been activated by pushing the button or during

the mounting of the aluminium back plate if the

function automatic commissioning is set.

With the index du, the cumulated duration in

minutes during which the device was opened

is detected. This display turns up only after

commissioning in case the heat cost allocator

was opened or removed.

manipulation was activated.

With the index an 8 digit identification number

is displayed. Ex-factory the serial number is

identical with the identification number. The

first two digits of the identification number are

the two small digits on the left upper side of the

digital display.

Running Hours With the index rh, the running hours is displayed.

This value can be compared to the battery use

duration.

VU.SH.H1.02 | 13© Danfoss | 2019.03

Page 14

Operating Guide SonoHCA

3.3 Display and

Additional Functions

3.3.2 The Digital Display

(continuous)

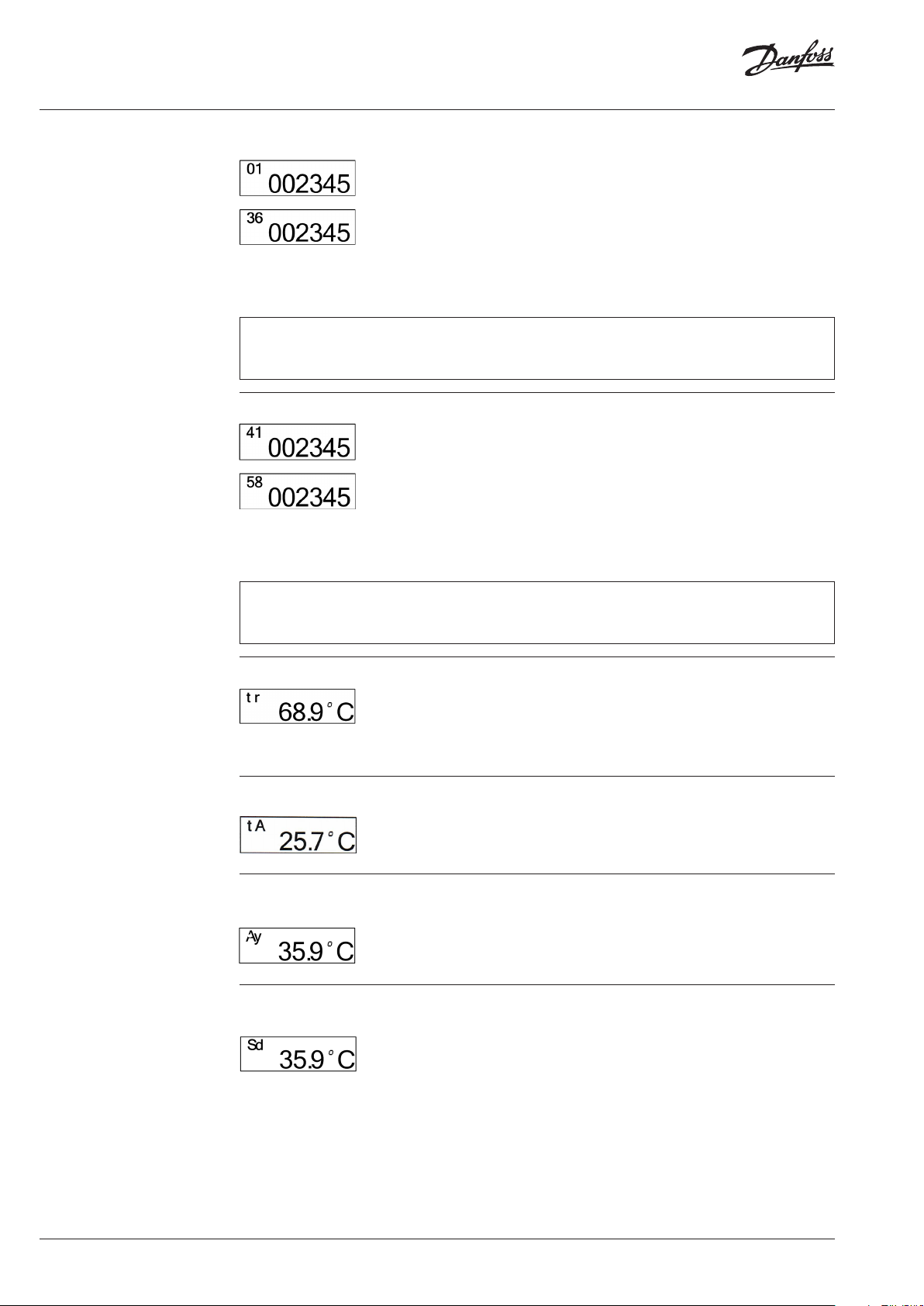

Monthly Values The cumulated consumption values are recorded

automatically at midnight on the last day of each

month.

Number of monthly values: 36

The small digits on the upper left side show

the number of previous monthly values. Digit

01 stands for the recent full month and digit 36

stands for the least recent month. All monthly

values are set to 000000 when the device is

commissioned.

Note :

Short telegram, OMS compliant: no monthly values transmitted via radio telegram.

Long telegram for Walk-by reading, the first 18 monthly values transmitted via radio telegram.

Half Monthly Values The cumulated consumption values are recorded

automatically at midnight on the 16th of each

month.

Number of monthly values: 18

The small digits on the upper left side indicate

the number of half monthly values. Digit 41

stands for the recent half monthly value and digit

58 for the least recent half monthly value. All

half monthly values are set to 000000 when the

device is commissioned.

Note :

Short telegram, OMS compliant and long telegram for Walk-by reading: no half monthly values transmitted

via radio telegram.

Radiator Temperature

Ambiant Temperature

Maximum Radiator Temperature of the

Current Heating Period

Maximum Radiator Temperature of the

Previous Heating Period

With the index tr the current radiator

temperature is displayed.

With the index tA the current ambient

temperature is displayed.

With the index ΠΨ the maximum radiator

temperature of the current heating period (since

the Set Day) is displayed.

With the index Sd the maximum radiator

temperature of the previous heating period

(before the Set Day) is displayed.

14 | VU.SH.H1.02 © Danfoss | 2019.03

Page 15

Operating Guide SonoHCA

3.3 Display and

Additional Functions

3.3.2 The Digital Display

(continuous)

Monthly Value for Maximum Radia-tor

Temperature

Software Version

Measuring Principle

Segment Test

With the index ΠΠ the maximum radiator

temperature of the currently month is displayed.

Number of monthly values: 18

Recording of 18 monthly values for the maximum

radiator temperature.

The small digits on the upper left side show

the number of previous monthly values. Digit

01 stands for the recent full month and digit 18

stands for the least recent month.

All monthly values are set to 000000 when the

device is commissioned.

On the right side the software version x.x.x of the

heat cost allocator is displayed.

The index -- or FF indicates the type of the

radiator sensor:

-- = Standard device, compact sensor.

FF = Remote sensor device, remote sensor.

1 SENS = single sensor device with start sensor.

2 SENS = double sensor device.

Segment test of the display.

Error Message

wM-Bus mode

3.3.3 Rolling Display

The SonoHCA also feature the possibility of a

rolling display 24h/24h.

With a software it is possible to individualize the

rolling display.

Up to 15 parameters can be chosen optionally

from the list below. These parameters can be

combined in any order and are then shown on

the rolling display.

• Consumption value.

• Time.

• Date.

• Set Day.

• Set Day value.

• Monthly values.

• Half monthly values.

• Radiator temperature.

• Ambient temperature.

• Identification number.

If an error is detected, Err is displayed in the first

display sequence with the corresponding error

message.

Telegram defined into heat cost allocator.

Type of telegram must be defined when

ordering.

Short telegram (Short ) used.

Long telegram (LonG) used.

• Maximum radiator temperature of the

previous heating period.

• Maximum radiator temperature of the current

heating period.

• 18 monthly values for the maximum radiator

temperature.

• Error code.

• Manipulation protection: storing of the

duration of the last manipulation with

date and the accumulated duration of all

manipulations in minutes.

• Fraud Counter.

• Segment test.

• Software version.

• Running hours.

• Commissioning date.

• Measuring principle, single sensor device with

start sensor or double sensor device.

• Short or long telegram for radio wM-Bus.

The duration of the display of the values can be

chosen individually between 1 - 30 seconds.

VU.SH.H1.02 | 15© Danfoss | 2019.03

Page 16

Operating Guide SonoHCA

3.3 Display and

Additional Functions

3.3.3 Rolling Display

(continuous)

Example:

Order and duration of display

• Pos 0: Error [5 s]

(parameter ex factory, cannot be changed)

(only displayed in case of an error message)

• Pos 1: Time [1 s]

• Pos 2: Segment test [5 s]

• Pos 3: Consumption value [10 s]

• Pos 4: Set Day [1 s]

• Pos 5: Set Day value [8 s]

• Pos 6: Monthly value [5 s]

• Pos 7: Blank (therefore no display).

• Pos 8 – Pos 15: Blank (therefore no display. It

is not necessary to occupy all positions).

3.3.4 Communication Indicator and

Measuring Indicator •

The communication indicator displays if the heat

cost allocator is currently making a calculation

and/or if it communicates internally or externally

over the optical or wireless interface.

The rolling display can also be deactivated by a

software, i.e. the device operates as in standard

menu mode except that only these values and

the values of the corresponding sub-menus that

have been de-fined in the rolling menu can be

displayed by pushing the button. After 2 minutes

during which the button has not been pushed,

the display goes out.

If the arrow of the communication indicator

points inwardly internal communication takes

place over the optical or wireless interface.

If the arrow of the communication indicator

points outwards external communication takes

place over the optical or wireless interface.

If the frame of the communication indicator

appears the heat cost allocator has detected a

wake-up signal.

If the point indicator appears the heat cost

allocator is carrying out a measuring or a

calculation.

3.3.5 Real Time Clock and Calendar

The device has a 24 h real time clock and a

calendar. However, the change from summer

to winter time is not taken into account. The

calendar is programmed until December 31

If the current date and time have to be updated over the optical interface or via radio, it is necessary to check the

date of the computer first. Date and time of the device aim at those of the computer. If the reading/programming

device (computer/PDA/ Smart Phone) has a wrong time, this time will be programmed into the heat cost allocator

and suddenly no longer be reached at the usual time, because the time of the heat cost allocator possibly is shifted

by several hours.

Important: The time on your readout / programming interface must always be set to winter time

3.3.6 Check code

A special additional feature of the electronic heat

cost allocator is the check code function for the

post-card mail-in method.

With especially developed algorithms a 5 digit

check code is generated out of several device

data. With this check code the values stated on

the postcards mailed-in by tenants can be cross

checked.

2099, including all leap years. The real time clock

as well as the date of the heat cost allocator can

be readout over the optical interface or via radio

and if necessary be updated.

For this check, the following parameters are

required:

• Identification number.

• The date.

• The current consumption value.

• The check code.

For the verification of the check code Danfoss

places all necessary tools (programs, formulas) at

the disposal of the authorized personnel.

16 | VU.SH.H1.02 © Danfoss | 2019.03

Page 17

Operating Guide SonoHCA

3.4 Special Functions

3.4.1 Suppression of Summer Counting

The period during which summer counting is

suppressed can be programmed by the software.

If the heat cost allocator is in the period of

summer counting suppression, consumption

measuring is de-activated. If an automatic

readout is carried out during this period the

temperatures can be read anyway since the

temperature measuring is still active.

3.4.2 Annual Reset of the Consumption Value

The function of the annual reset of the

cumulated consumption value can be

programmed by the soft-ware over the optical

interface. One of the following options can be

chosen for the reset:

• Set Day

• Never

Please note that only the cumulated

consumption value is reset. All other values are

not reset.

3.4.3 Unit Scale and Product Scale

For the heat cost allocators, distinction is made

between the unit scale and the product scale.

See chapter 7.2 Table of Rating Factors.

3.4.3.1 Advantages of the Unit Scale

If heat cost allocators are used with the same

scale on all radiators, this scale is called unit

scale. The display values are the same on the

different radiators if the heat cost allocators are

exposed to the same temperature for the same

period of time.

The evaluation of the display values is carried

out arithmetically with the rating factors of

the calculation software to receive the final

consumption values.

• Easy and quick installation of the heat cost

allocator, no programming necessary.

• Possible errors by doing the scaling on site are

avoided due to allocation by experts.

3.4.3.2 Advantages of the Product Scale

With the product scale, the radiator rating data

are programmed in the heat cost allocator on

site. The overall rating factor K is calculated

directly in the heat cost allocator and thus the

consumption value is displayed immediately.

• The actual consumption of each consuming

point within one billing unit can be compared

easily and quickly on site.

3.5 Parameterization

3.6 Error

A software allows the parameterization over the

optical interface.

To protect heat cost allocator against fraud, a

password has been integrated into the products,

therefore also in the software. The default

‘’installer’’ password ex-factory of the heat cost

allocator is ‘’56781234’’, and may be changed by

the user.

The heat cost allocator displays an error message

with the 3 letters “ Err. ” and a code. If several

errors occur at the same time, the different codes

are added together.

The error is displayed in the first position of the

display menu. It will still be possible to select

all the other display menus by pressing the

navigation button. If the navigation button is

no longer pressed for a period of 2 minutes, the

error code will automatically appear again in the

first position of a display menu.

Display of an error automatically disappears

when the error is no longer present.

3.6.1 List of Errors

• Err. 1 Manipulation (fraud).

• Err. 2 Measuring error.

• Err. 32 Push button constantly pushed.

• Err. 64 Measured temperature not within

temperature range (0...105°C ;

0...120°C remote sensor).

VU.SH.H1.02 | 17© Danfoss | 2019.03

Page 18

Operating Guide SonoHCA

4. Installation

4.1 Introduction

4.2 DIN Standard

Requirements for the

Installation

To guarantee the proper functioning of the heat

cost allocator SonoHCA, it is of great importance

that it is installed by an expert. On one hand, a

constant heat transfer between radiator and heat

cost allocator has to be guaranteed. On the other

hand, the installation of the heat cost allocators

on a large variety of radiator types should be as

easy as possible.

The installation can be carried out in two

different ways.

• The standard device is installed directly on

the radiator.

• For the wall-mounted version the remote

sensor is installed on the radiator and the heat

cost al-locator is wall-mounted.

• Heat cost allocators can be installed in

heating systems where the mean temperature

is between the upper operating temperature

limit t

limit t

technical data, see chapter 2.3 Technical data).

and the lower operating temperature

max

(t

min

max

and t

are stated in the

min

• The installation of the devices has to be

durable and avoid manipulations.

• The devices have to be installed in a place

where sufficient correlation between the

displayed value and the heat output of the

radiator is given over a maximum operating

range.

• Within a billing unit (in case of predistribution of the energy consumption:

within a users’ group) only heat cost allocators

of the same manufacturer and the same type

with identical rating systems may be used.

Each device type has to be identifiable as

such.

For the installation of the heat cost allocators,

special fastening-parts kits are available. To

avoid faulty installation, we also recommend

reading the Kc-data in the data base prior to the

installation.

(See chapter 7.2 Table of Rating Factors).

The heat cost allocator is an electronic device

which – like all other similar devices – has to

be handled with care. It is sensible to electric

discharge and contacting certain areas of the

PCB. Electric discharge can destroy the device

or – even worse - damage it in a way that it fails

after an indefinite period of time.

For this reason it is essential in any case to

avoid contact with the PCB.

• Combinations of radiators and heat cost

allocators with a measured value of c >

0.3 in basic condi-tion are not permitted.

In exceptional cases c-values of up to 0.4

are permitted within a billing unit if the

concerned heating surface does not exceed

25 % of the overall heated surface or if the

mean ambient temperature is above 80°C.

Heat cost allocators may only be installed to

radiators where the c-value is known at the

time of billing.

4.3 General Restrictions

Electronic heat cost allocators cannot be used

with steam heating, floor heating, ceiling radiant

heaters, flap-controlled radiators and electrical

radiator.

In case of combined valve- and flap-controlled

radiators, the installation of an electronic heat

Convector heaters where the performance can

be altered by an electric blower as well as heat

towel racks with an electric heating cartridge

may only be equipped with an electronic

heat cost allocator if the additional electric

attachments are dismounted or shut down.

cost allocator is only permitted if the flap control

is dismounted or maintained in position „open“.

4.4 Operating Range

SonoHCA can be used in heating systems

with the following mean heating medium

temperatures:

For single sensor devices with start sensor

A heat cost allocator can be used in heating

systems where the suitability of the system is in

line with the operating conditions for which the

heat cost allocator has been approved.

• 55°C…105° C for standard heat cost allocator.

• 55°C…120°C for wall-mounted heat cost

allocator (remote sensor).

For double sensor devices

• 35°C…105° C for standard heat cost allocators.

• 55°C…120°C for wall-mounted heat cost

allocators (remote sensor).

18 | VU.SH.H1.02 © Danfoss | 2019.03

Page 19

Operating Guide SonoHCA

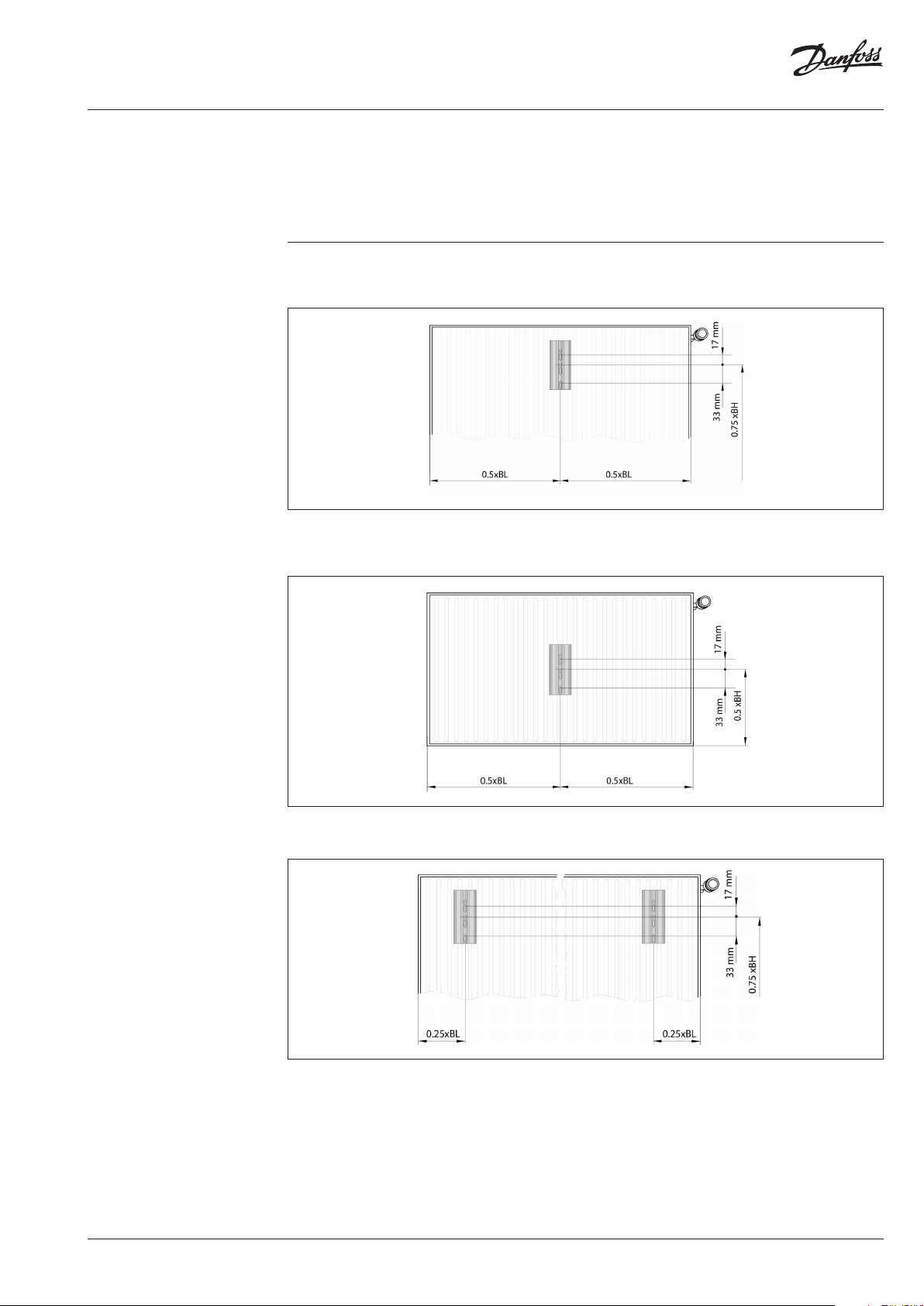

4.5 Allocator Installation

Position – Standard

Installation

The installation position on the radiator is

directly related to the type of radiator, its heating

power and the heat cost allocator. To guarantee

the correct data collection, the heat cost

allocators must be installed and used in a certain

position in accordance with requirements

• The SonoHCA heat cost allocator is always

installed in the centre of the overall length

(0.5 x BL) of the radiator, at a height of ¾ of

• If the height of the radiator is less than (<) 470

mm, the heat cost allocator must be installed

at 50% BH.

The radiator’s heat is transmitted directly

via the installation back plate to the device’s

temperature sensor or to its remote sensor

the overall height (0.75 x BH) measured from

the bottom.

• If the radiator has a length of more than 3 m,

two heat cost allocators must be installed.

General notes:

• The spacing for welding the M3 threaded

bolts must be 5 cm. Before welding, the

lacquer has to be removed from the welding

points. It must be ensured that the bolts are

welded onto a water-bearing area or a flute.

• Only use M3 bolts with a maximum length

of 8 mm or there is a risk that the device will

be damaged.

These radiators are considered to be 2

radiators arranged next to each other.

• Welding to aluminium radiators is not

permitted.

• If the radiator has an even number of sections

the heat cost allocator should be installed

between the middle sections.

• If the radiator has an uneven number of

sections the device should be installed next

to the valve-sided middle section.

• Mount the back plate through the 2 oval

holes, adjusted to the top edge of the holes.

VU.SH.H1.02 | 19© Danfoss | 2019.03

Page 20

Operating Guide SonoHCA

4.6 Mounting the Remote

Sensor

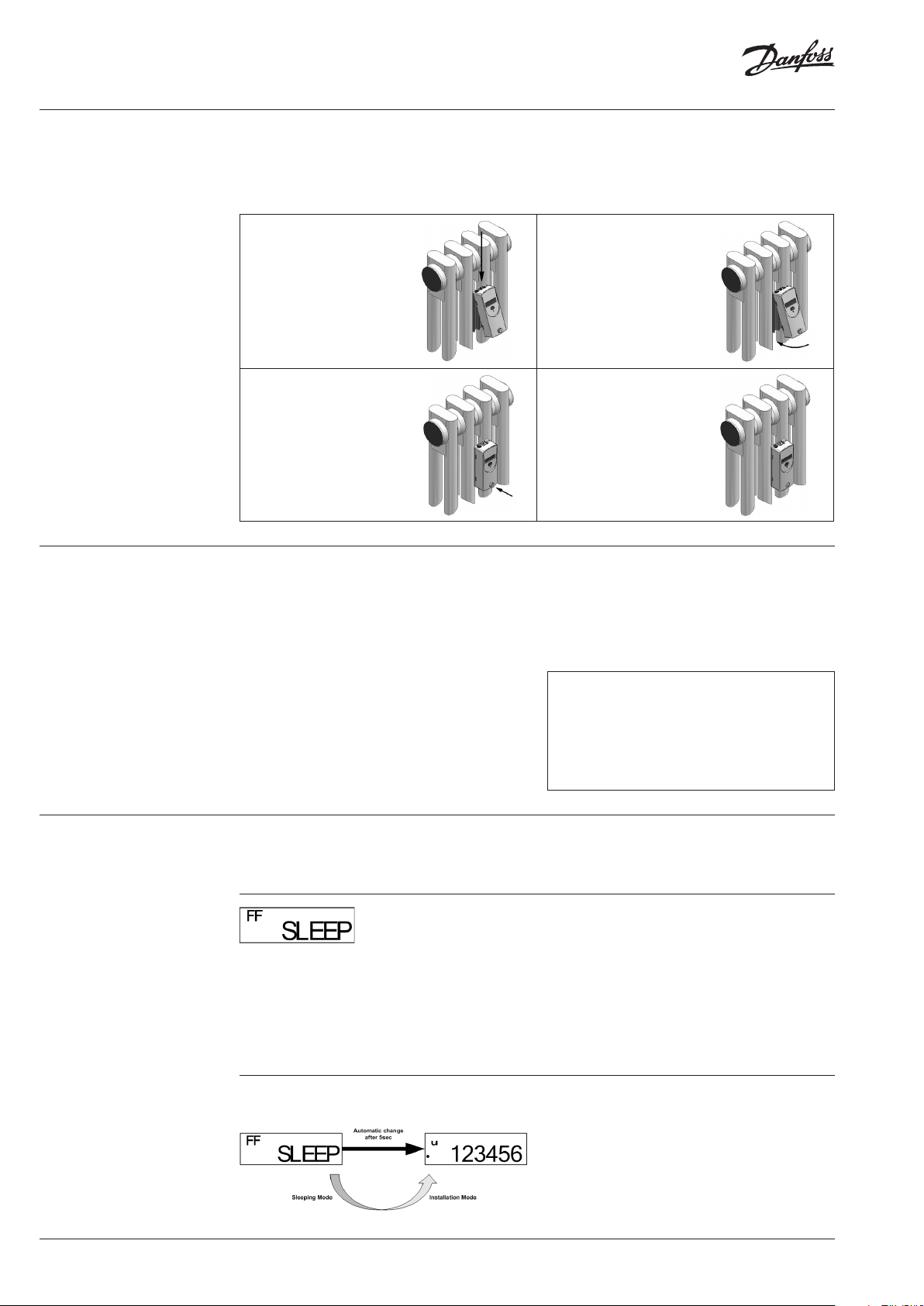

For each version of heat cost allocator, it is

possible to plug the connector of the remote

sensor into an interface inside the heat cost

allocator.

The remote sensor will be automatically

detected by the heat cost allocator.

Return the heat cost allocator and plug the connector of the

remote sensor into the interface inside the heat cost allocator.

Proceed to the commissioning of the heat cost

allocator on the aluminium back plate. Take care

not to stick the cable.

Remark concerning the recognition of the

remote sensor:

Once heat cost allocator is fixed with/against the

aluminium back plate, the LCD-display will show

the following message during few seconds:

Once equipped with a remote sensor, the

heat cost allocator will only work for an

application with re-mote sensor.

Remote sensor version with 2 m cable. The cable

includes a stopper-knot.

Stopper-knot

Insert the remote sensor cable into the

groove provided up to the slot of housing.

Place the stopper-knot inside the housing.

The knot will avoid any traction on the

con nect or.

Once heat cost allocator has recognized the

remote sensor, push the seal pre-installed by

Danfoss in the slot of the housing. Then press

until the seal clicks into the aluminium back

plate.

Respect the color code of the radiator sensor

and the remote sensor. For Heat cost allocator

SonoHCA the radiator sensor and the remote

sensor are manufactured in two colors white and

yellow.

Once equipped with a remote sensor, the heat

cost allocator will only work for an application

with remote sensor.

• The index FF indicates that the heat cost

allocator has recognized the remote sensor.

• If the remote sensor is not detected by the

device, the index -- will be displayed. The

index -- indicates also a standard device with

a compact sensor. If the remote sensor is not

recognized, check the plug connector in the

heat cost allocator.

If the remote sensor is disconnected from the

heat cost allocator, an error message will be

displayed.

During the commissioning of the heat cost

allocator on the aluminium back plate, there are

2 possibilities to turn on the heat cost allocator:

1. By an automatic commissioning during the

mounting on the aluminium back plate.

See chapter 5.1 Automatic commissioning

during the installation

By pushing the push button. See chapter

Commisoning by pressing push button.

20 | VU.SH.H1.02 © Danfoss | 2019.03

Page 21

Operating Guide SonoHCA

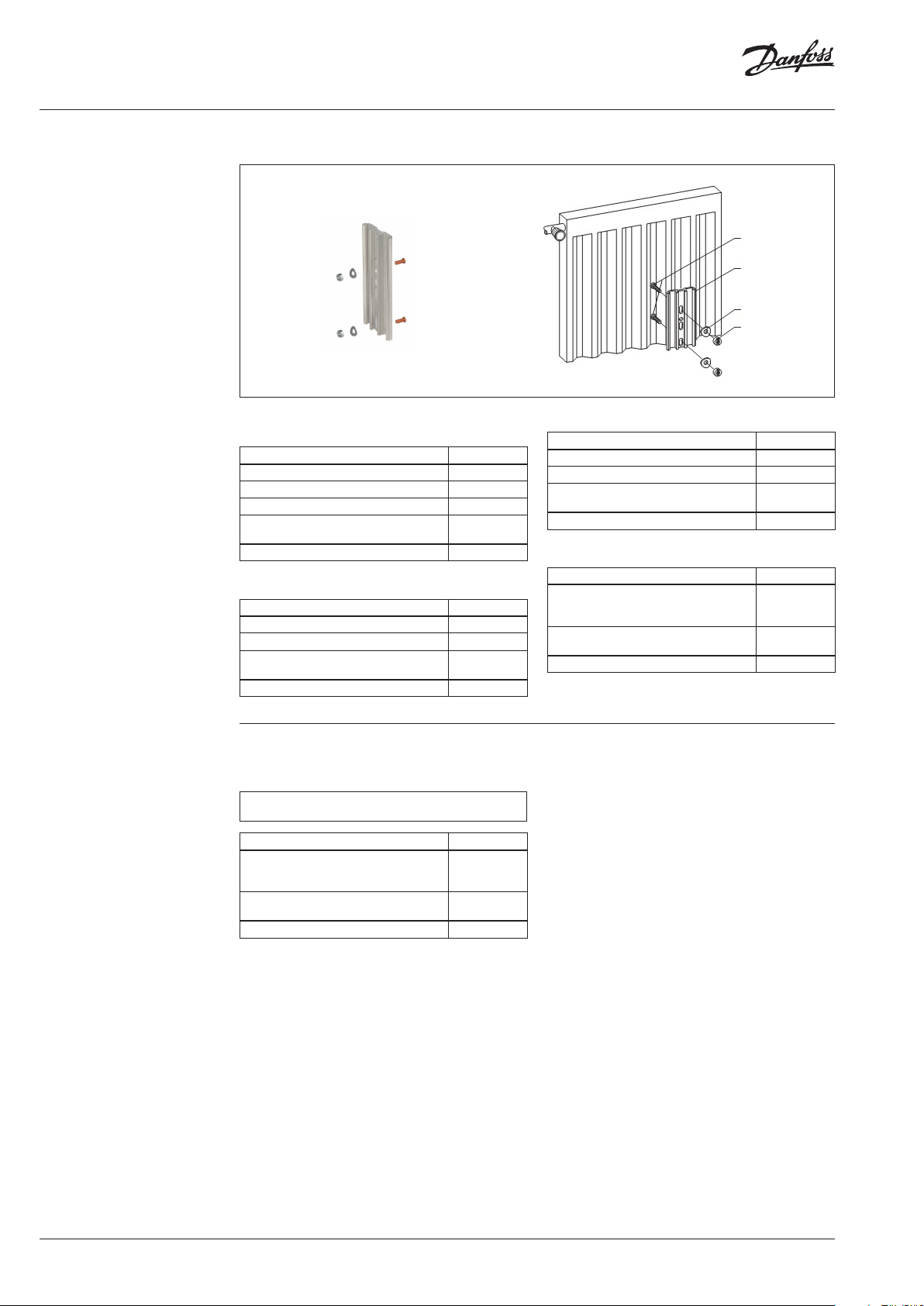

4.7 Wall Mounting

The heat cost allocator has to be wall-mounted if

the overall height of the radiator is less than 250

mm or if, for aesthetical reasons, the heat cost

allocator cannot be mounted directly onto the

radiator.

In this case, the heat cost allocator is wallmounted on the side opposite to the valve and at

a minimum distance from the radiator of 10 cm.

088H2424

088H2425

088H2420

• After marking and drilling the holes, the

aluminium profile is fastened with 2 metal

screws and 2 spring washer.

• The parts necessary for the wall-mounting are

included in the corresponding fastening-parts

kits for the installation of the remote sensor.

• After installation of the device to the wall and

the sensor to the radiator, the sensor cable is

laid in a cable duct.

088H2423

• Mount the back plate through the 2 oval holes

adjusted to the top edge of the 2 oval holes.

Mounting Accessories Part . No.

2 plastic dowels Ø5 mm 3.25 088H2424

1 aluminium back plate (supplied with

SonoHCA)

2 spring washers 088H2420

2 oval head wood screws 3 x 35 088H2423

088H2425

VU.SH.H1.02 | 21© Danfoss | 2019.03

Page 22

Operating Guide SonoHCA

4.8 Installation of

Fastening Parts Kits

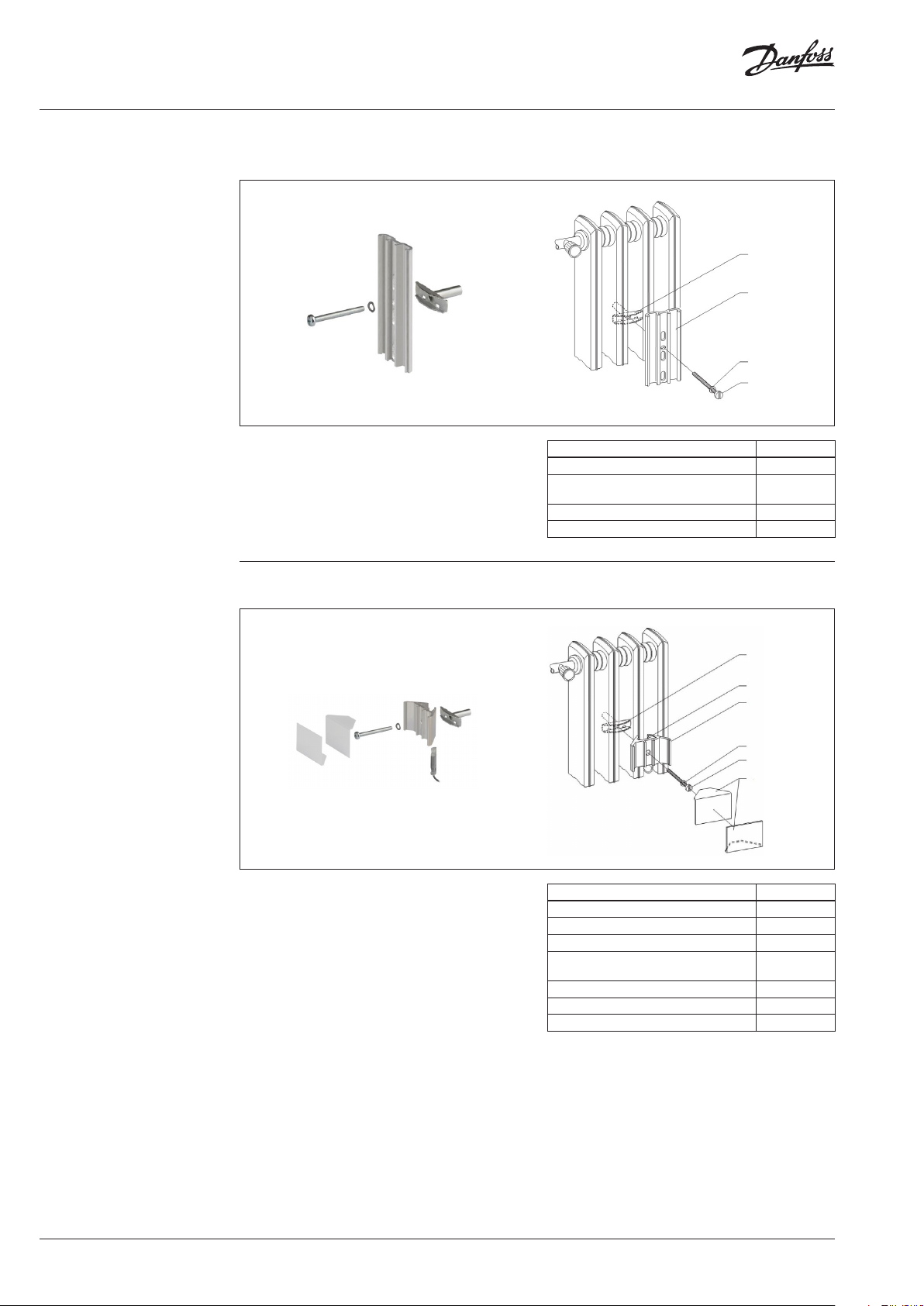

4.8.1 Installation to Sectional Radiator,

direct mounting

• For radiators made from cast iron it is

necessary to apply heat transfer compound

(Electrolube HTS) onto the contact surfaces

of the aluminium profile before installation.

Mount the back plate through the little hole

in the middle.

4.8.2 Sectional Radiator, wall mounting

088H2408

088H2425

088H2420

08 8H 2412

Mounting Accessories Code No.

1 tensioning bracket 088H2408

1 aluminium back plate (supplied with

SonoHCA)

1 cylinder head screw M4 x 40 088H2412

1 spring washer B 4 088H2420

088H2425

• The remote sensor has to be fixed in the

receiver housing with adhesive to avoid

loosening.

• The contact surfaces of the cover angles have

to be coated with adhesive before bringing

them together.

088H2408

Remote sensor

08 8H2410

088H2420

08 8H 2412

088H2406

Mounting Accessories Code No.

1 tensioning bracket 088H2408

1 aluminium profile „receiver housing“ 088H2410

1 spring washer B 4, DIN 128 088H2420

1 cylinder head screw M4 x 40 (with

crosshead)

2 cover angles, white 088H2406

2 plastic dowels Ø5 mm 3.25 (wall) 088H2424

2 oval head wood screws 3 x 35 (wall) 088H2423

088H2412

22 | VU.SH.H1.02 © Danfoss | 2019.03

Page 23

Operating Guide SonoHCA

4.8 Installation of

Fastening Parts Kits

(continuous)

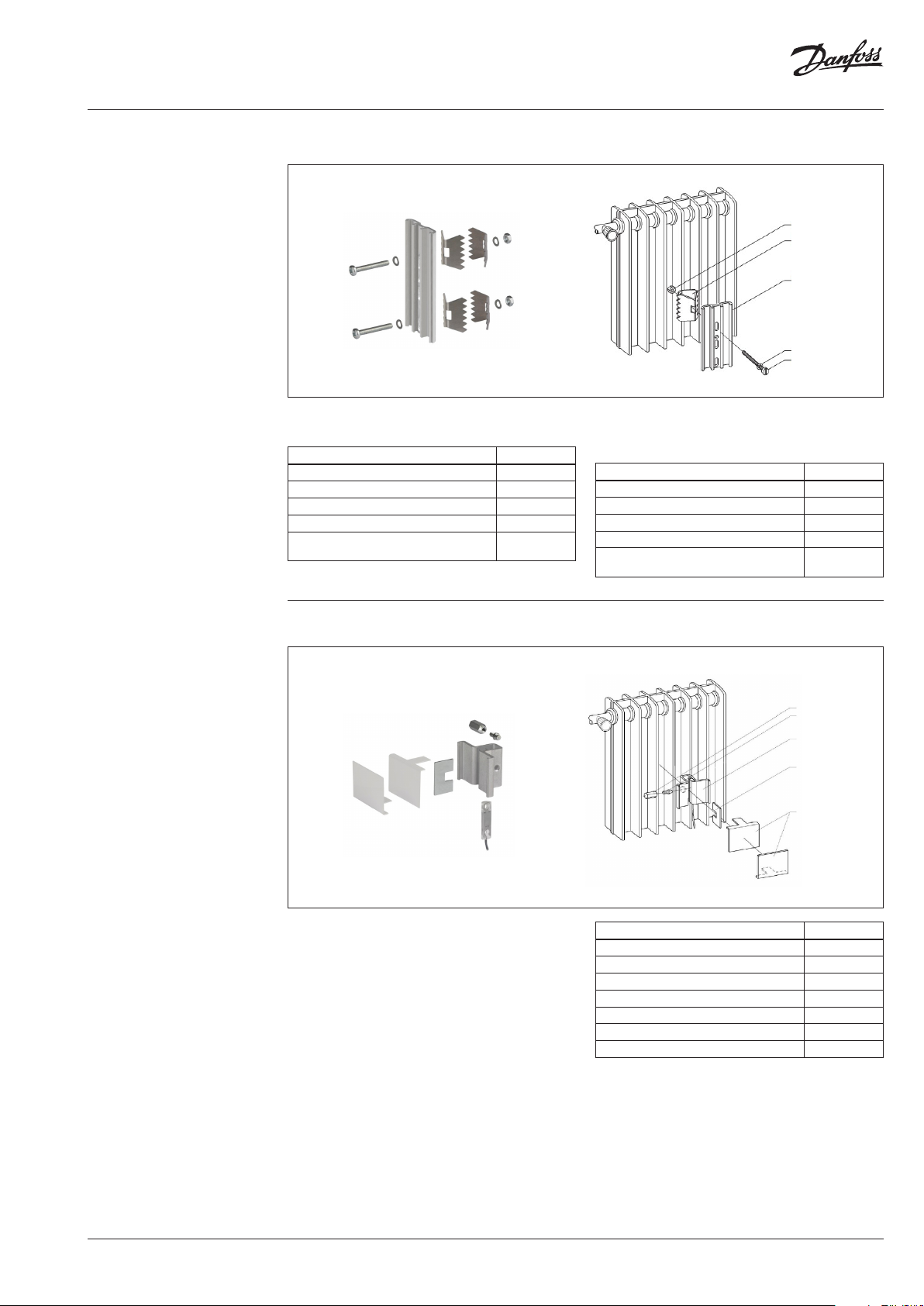

4.8.3 Installation on Folded Radiator

• Mount the aluminium back plate through the

small round hole.

Mounting Accessories Code No.

1 hexagon nut B M4, DIN 934 088H2413

2 bracing angles 088H2421

2 spring washers B4, DIN 128 088H2420

1 oval head screw M4 x 30 088H2411

1 aluminium back plate (supplied with

SonoHCA)

088H2425

08 8H 2413

08 8H2321

088H2425

088H242 0

0 88 H2411

• If necessary use 2 x 2 bracing angles to

improve more stability (photo) and, if needed,

short the screw.

Mounting Accessories Code No.

2 hexagon nut B M4, DIN 934 088H2413

2 x 2 bracing angles 088H2421

4 spring washers B4, DIN 128 088H2420

2 oval head screw M4 x 30 088H2411

1 aluminium back plate (supplied with

SonoHCA)

088H2425

4.8.4 Folded Radiator, wall mounting