Page 1

Data Sheet

Tube-in-tube heat exchanger

Type HE

Increases the system eciency and protects the system against liquid entering the compressor

Tube-in-tube heat exchanger type HE is used

primarily for heat transfer between the liquid

and suction lines of the refrigeration plant.

The purpose is to utilise the cooling eect,

utilise which without a heat exchanger is

otherwise lost to the ambient air via

uninsulated suction lines.

In the heat exchanger, this eect is used to

subcool the refrigerant liquid.

Features:

• High refrigeration capacity in evaporator

• Helps ensure vapour-free liquid ahead of the

expansion valve

• HE 0.5-1.5: May be used in the following EX

range: Category 3 (Zone 2)

• Maximum utilisation of the evaporator upon

setting the thermostatic expansion valve for

minimum superheat

• Helps prevent sweating and frosted-up

suction lines

AI124486417614en-001201

Page 2

Refrigerants

R22, R1270

(1)

, R134a, R290

(1)

, R404A, R407A, R407C, R407F, R448A, R449A, R450A, R452A, R507A, R513A, R600

(1)

, R600a

(1)

Operating temperature

-60 – 120 °C

Max. working pressure

PS / MWP = 28 bar

Max. test pressure

Pe = 40 bar

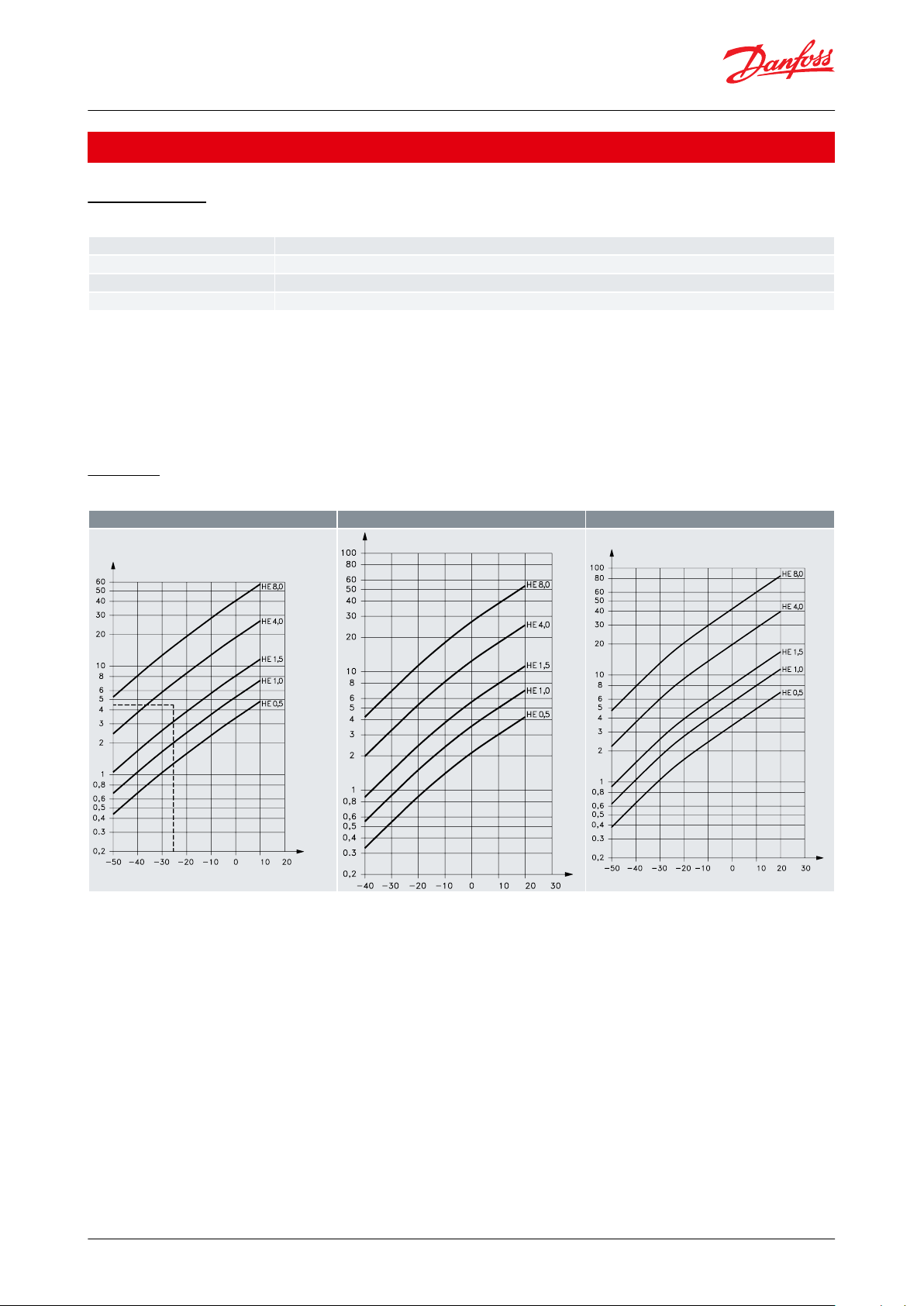

R22

R134a

R404A

Danfoss

15D51.11

[°C]

[te]

[kW]

[Qe]

Danfoss

15D50.11

[°C]

[te]

[Qe]

[kW]

Danfoss

15D52.11

[°C]

[te]

[Qe]

[kW]

Tube-in-tube heat exchanger, Type HE

Product specication

Technical data

Table 1: Technical data

(1)

(1)

HE 0.5 - 1.5 only

HE 0.5 - 1.5 only

This product (HE 0.5 - 1.5) is evaluated for R290, R600, R600a and R1270 by ignition source assessment in accordance

with standard EN ISO80079-36.

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Capacity

Table 2: Capacity

Precise heat exchanger sizing can be obtained from the curves which show plant capacity Qe for R22, R134a and

R404A depending on evaporating temperature te.

Example

Plant capacity Qe = 4.5 kW

Refrigerant = R22

Evaporating temperature te = -25 °C

The curve for R22 shows that an HE 4.0 is suitable. The curve for HE 4.0 lies immediately above the intersection of

the lines

through Qee= 4.5 kW and tee= -25 °C.

Heat ow Q during heat exchange is calculated from the formula: Q=k×A×∆tm

Q-heat ow in [W]

k-heat transfer coecient in [W/m2] [°C]

A transfer area of the heat exchanger in [m2]

∆tm average temperature dierence in [°C], calculated from the formula:

© Danfoss | Climate Solutions | 2021.03 AI124486417614en-001201 | 2

Page 3

Danfoss

16D36.14

1.2.3.4.Suction line connection

Liquid line connection

Inner chamber

Outer chamber

Type

K × A

Dry suction gas / refrigerant liquid

(1)

(normal use in refrigeration plants with uorinated refrigerants) [W] / [°C]

HE 0.5

2.3

HE 1.0

3.1

HE 1.5

4.9

HE 4.0

11.0

HE 8.0

23.0

Tube-in-tube heat exchanger, Type HE

Δtm=

max .

In

Δt

Δt

min .

max .

min .

Δt

− t

k × A values Determined by experiment (see table).

(1)

(1)

These gures apply to dry gas only.

These gures apply to dry gas only.

Even if a thermostatic expansion valve is used, the suction gas will carry very small liquid drops into the suction line.

Even if a thermostatic expansion valve is used, the suction gas will carry very small liquid drops into the suction line.

The ns of the HE catch these drops which then evaporate.

The ns of the HE catch these drops which then evaporate.

This may result in a smaller superheat than the theoretically calculated value.

This may result in a smaller superheat than the theoretically calculated value.

Design

Oset n sections are built into the inner chamber (3) and result in a turbulent gas ow with minimum ow

resistance. The gas ows straight through without changing direction and without oil pockets.

Refrigerant liquid ows in the opposite direction to the gas, through the small outer chamber (4). The ow is guided

by a built-in wire coil so that maximum heat transfer is achieved. The hot liquid owing through the outer chamber

normally protects the outer tube from “sweating”.

Dimensions [mm] and weights [kg]

Figure 1: Dimensions [mm] and weights [kg]

© Danfoss | Climate Solutions | 2021.03 AI124486417614en-001201 | 3

Page 4

Type

H

1

L

L1L

2

øD

Net weight

Volume

Outer cham‐

ber[cm3]

Inner cham‐

ber[cm3]

HE 0.520178107

27.5

0.3

8.5

23

HE 1.025268129

30.2

0.52545

HE 1.5303231410

36.2140

100

HE 4.0383732010

48.3

1.580260

HE 8.0484072910

60.3

2.3

175

475

Type

Solder connection ODF

Code no.

Liquid line

Suction line

[in.]

[mm]

[in.]

[mm]

HE 0.5

–6–12015D0001

1/4–1/2–015D0002

HE 1.0

–10–16015D0003

3/8–5/8–015D0004

HE 1.5

–12–18015D0005

1/2–3/4–015D0006

HE 4.0

–12–28015D0007

1/2–1 1/8

–

015D0008

HE 8.0

–16–42015D0009

5/8–1 5/8

–

015D0010

File name

Document type

Document topic

Approvals Authority

Danfoss 034L9625.AB

Manufacturers Declaration

PED/RoHS

Danfoss

Danfoss 034R9541.AA

Manufacturers Declaration

China RoHS

Danfoss

Document - EAC RU ДDK.БЛ08.В.00327_18

EAC Declaration

EAC

EAC

Document - LLC CDC EURO-TYSK

UA.089.D.00001-19

UA Declaration

TYSK

TYSK

Tube-in-tube heat exchanger, Type HE

Table 3: Dimensions [mm] and weights [kg]

Ordering

Generally, the size of an HE heat exchanger can be determined from the connections corresponding to the pipe

dimensions of the refrigeration plant.

The design is such that normal suction gas velocities are achieved, with a subsequent small pressure drop. Thus the

heat exchanger capacity will match plant capacity.

At the same time, oil return to the compressor is ensured.

If the main object is to avoid sweating and frosting-up of the suction line, the HE can be chosen one size larger than

the size determined by the capacity. An HE used as an auxiliary condenser must always be selected according to the

connection dimensions.

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 4: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI124486417614en-001201 | 4

Page 5

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI124486417614en-001201 | 5

Loading...

Loading...