Fact Sheet

VLT® Refrigeration Drive FC 103

Regardless if you want to operate

compressors, pumps or fans, the

VLT® Refrigeration Drive FC 103

provides you the possibility to save

energy and extend the lifetime of

the components.

Speed control provides many benefits

in all motor driven parts of refrigeration applications. The VLT® Refrige ration

Drive moves the user in the position to

profit from this in a very simple way.

One drive for all

The VLT® Refrigeration Drive FC 103

covers a power range between 1.1315 kW. Available in a variety of protection classes the drive suits the needs

of pump, fan and compressor applica-

Dedicated to

refrigeration

application

Designed to suit

fans, pumps and

compressors in any

kind of refrigeration

application.

tions. Every application and power size

can be operated and programmed with

the same common user interface.

The wizard menu also supports the

commissioning engineers if they

encounter any problems. The menu

will help the engineer troubleshoot

and offer solutions to get the drive

Easy commissioning

The VLT® Refrigeration Drive FC 103

up and running again if there is a

problem.

offers a setup Wizard, using common

refrigeration terms rather than

computer language, making installation

quick and easy for service technicians

and installers.

Product range

3 x 200 – 240 V ...............................1.1 – 45 kW

3 x 380 – 480 V ............................1.1 – 450 kW

3 x 525 – 600 V ............................1.1 – 630 kW

With 110% overload torque

Feature Benefit

General features

Robust single enclosure Maintenance free

Protection classes IP 20/21/55/66 Fits every application

Coated electronics (class 3C2 or 3C3) Withstands challenging environments

Max. ambient temp. 50° C without derating

(D-frame 45° C)

Software features

Sleep mode Optimum system effi ciency

Thermostat/Pressostat function System protection

Fieldbus (AKD LON, Modbus RTU…) Open for all kind of controllers

Velocity-to-fl ow conversion Saves costs

Day/Night Control Reduces wear and energy consumption

Advanced energy monitoring Overview of energy consumption

Pressure to temperature conversion Saves costs

Compressors features

High starting torque Operates all types of compressor

PO optimization Optimum system effi ciency

Injection on/off Improves refrigeration processes

Discharge temperature monitor Protects the compressor

Pack controller Saves energy and reduce maintenance

Neutral zone controller Handling of unsymmetrical zones

Pump features

Pump cascade controller Saves energy and reduce maintenance

Dry pump protection and end of curve Protects the pump

Flow compensation Saves energy

Fan features

Broken belt detection Protects the system

Operate induction motors in parallel Reduces investment cost

Automatic Energy Optimizer AEO function Saves energy

No EMC concerns

Integrated DC link harmonic fi lters Low harmonic load on mains

Integrated EMC fi lters No external fi lters required

No external cooling or oversize necessary

www.vlt-drives.danfoss.com

Available enclosure ratings

IP 20 (NEMA 1) .............................1.1 – 400 kW

IP 21 (NEMA 1) .............................1.1 – 630 kW

IP 54 (NEMA 12) ........................ 110 – 630 kW

IP 55 (NEMA 12) .............................1.1 – 90 kW

IP 66 (NEMA 4X).............................1.1 – 90 kW

Standard coating providing extra protection for aggressive environments.

Options

A wide range of VLT® Refrigeration

FC 103 options are available mounted

and tested from the factory or as plugand-play options for update.

VLT® General Purpose I/O MCB 101

3 digital inputs, 2 digital outputs,

1 analogue current output,

2 analogue voltage inputs

VLT® Relay Card MCB 105

3 relay outputs

VLT® Analog I/O MCB109

3 Pt1000/Ni1000 inputs,

3 analogue voltage outputs

Buffer for Real Time Clock

Specifications

Mains supply (L1, L2, L3)

Supply voltage

Supply frequency 50/60 Hz

Displacement power factor (cos φ) near unity (> 0.98)

Switching on input supply L1, L2, L3 1–2 times/min.

Output data (U, V, W)

Output voltage 0 –100% of supply voltage

Switching on output Unlimited

Ramp times 1–3600 sec.

Output frequency 0–590 Hz

Digital inputs

Programmable digital inputs 6*

Logic PNP or NPN

Voltage level 0–24 VDC

* 2 can be used as digital outputs

Relay outputs

Programmable relay outputs 2 (240 VAC, 2 A and 400 VAC, 2 A)

Analogue input

Analogue inputs 2

Modes Voltage or current

Voltage level 0 V to +10 V (scaleable)

Current level 0/4 to 20 mA (scaleable)

Fieldbus communication

Standard built-in:

FC Protocol

Modbus RTU

N2 Metasys

200 – 240 V ±10%

380 – 480 V ±10%

525 – 600 V ±10%

Optional:

LonWorks for AKD (MCA 107)

Profi bus DP V1 (MCA 101)

Profi net SRT (MCA 120)

VLT® 24 V External Supply MCB 107

24 V DC external supply can be connected to supply control- and option

cards.

Power options

VLT® Advanced Harmonic Filter

For critical demands on harmonic

distortion

VLT® dU/dt Filter

For special demands on motor

isolation protection

VLT® Sine Wave Filter

For noiseless motor or special

demands on motor isolation

protection

PC software tools

VLT® Motion Control Tool MCT 10

Ideal for commissioning

and servicing the drive

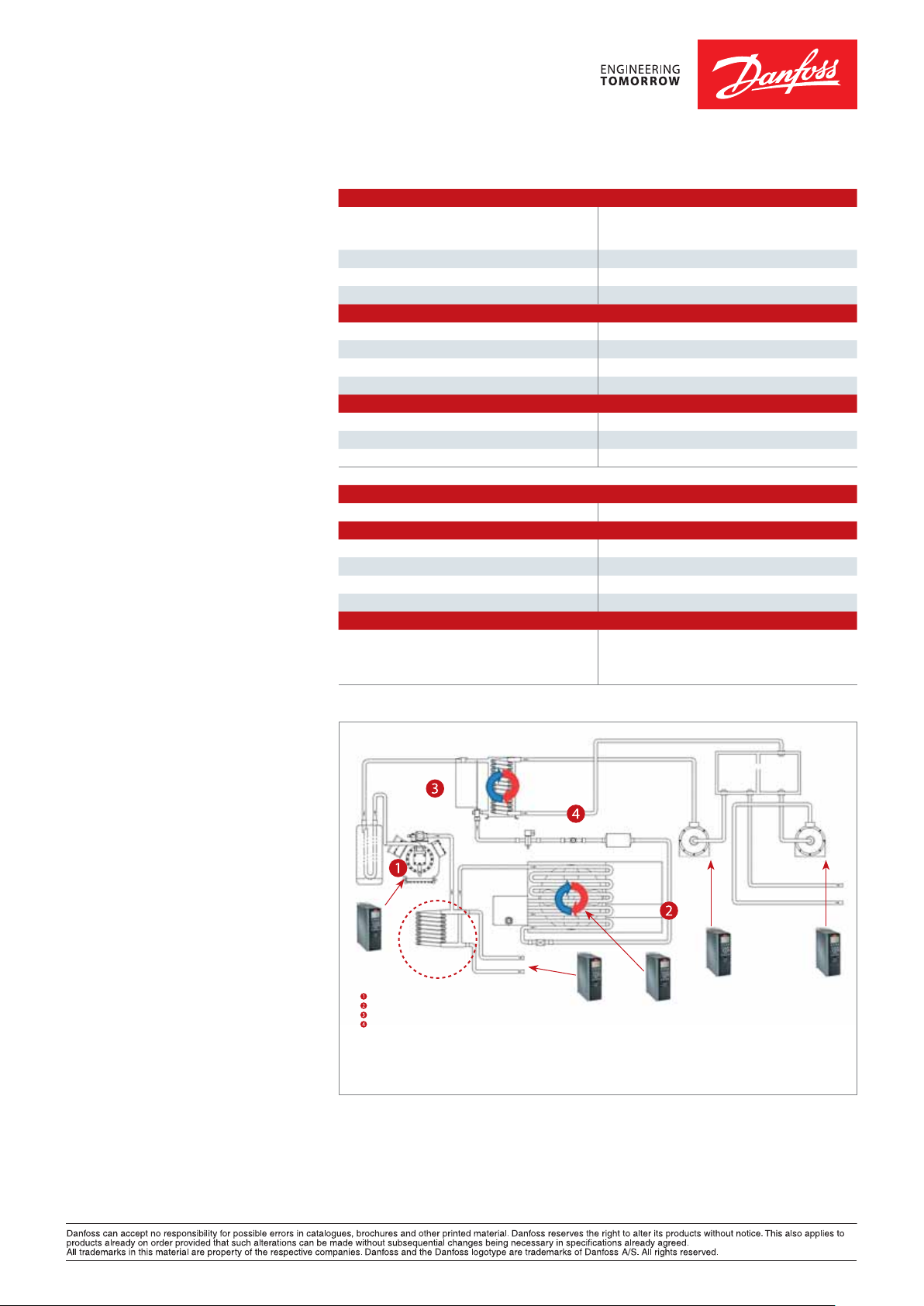

Spiral drum

Heat exchanger

Expansion va lve

Accumulator

Compressor

Heat reclaim coil

Compressor

Condenser

Metering device/expansion valve

Evaporator

Solenoid valve

Sightglass

Heated water out

Well water in

Filter drier

Horizon circuite d air cooled condense r

Ball valve

Condenser

circuit

Finned receiver

circuiet

Subcooling

circuiet

VLT® Refrigeration Drive FC 103 provides speed control of all

motor driven components and interacts with the major components

Circulation

pump

Glycol tank

Process

pump

Glycol supply

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFP.103.A4.02 © Copyright Danfoss Power Electronics | Danfoss VLT Drives PE-MSMBM | October 2014

Loading...

Loading...