Page 1

MAKING MODERN LIVING POSSIBLE

Design Guide

VLT® Refrigeration Drive FC 103

1.1–90 kW

vlt-drives.danfoss.com

Page 2

Page 3

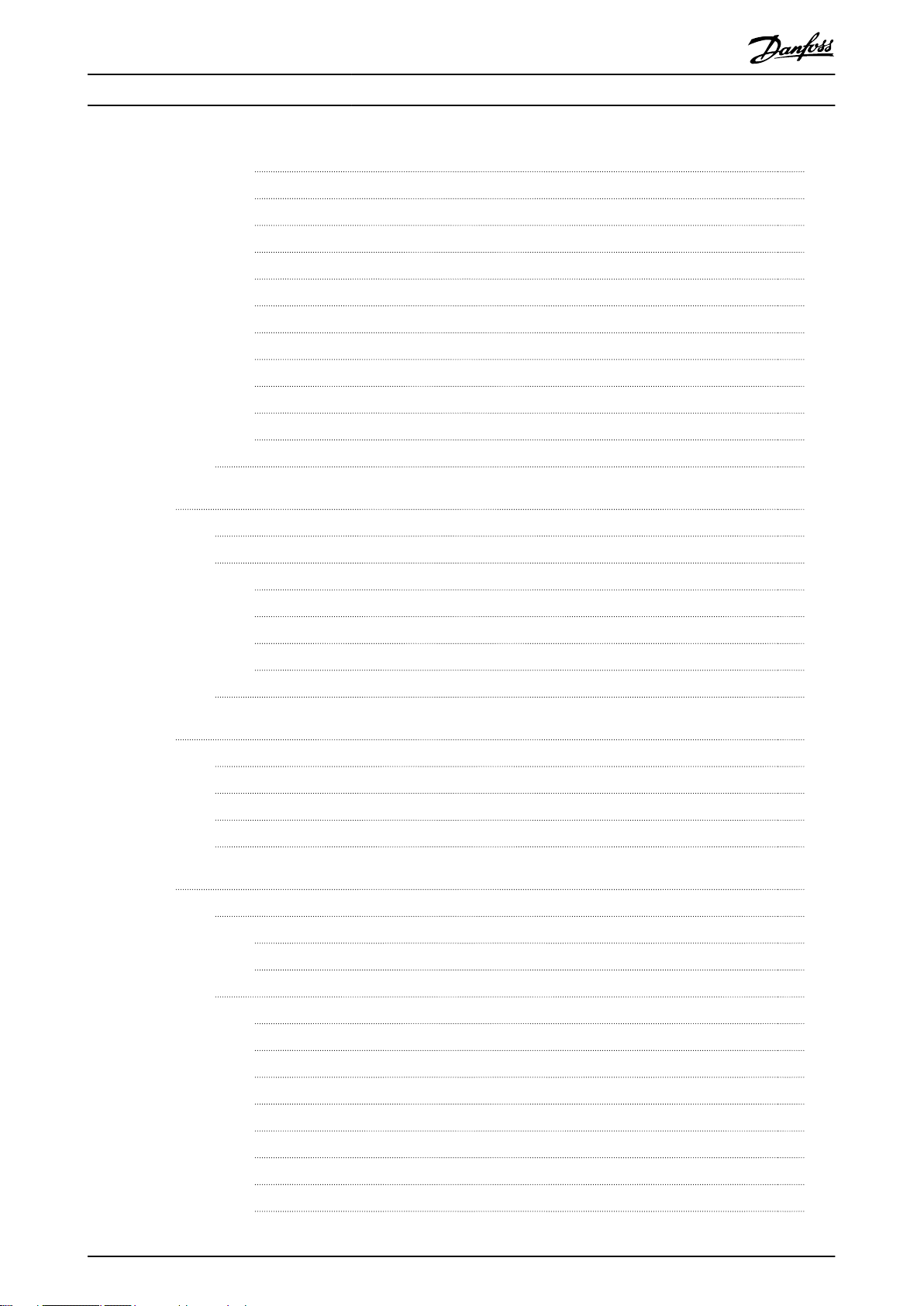

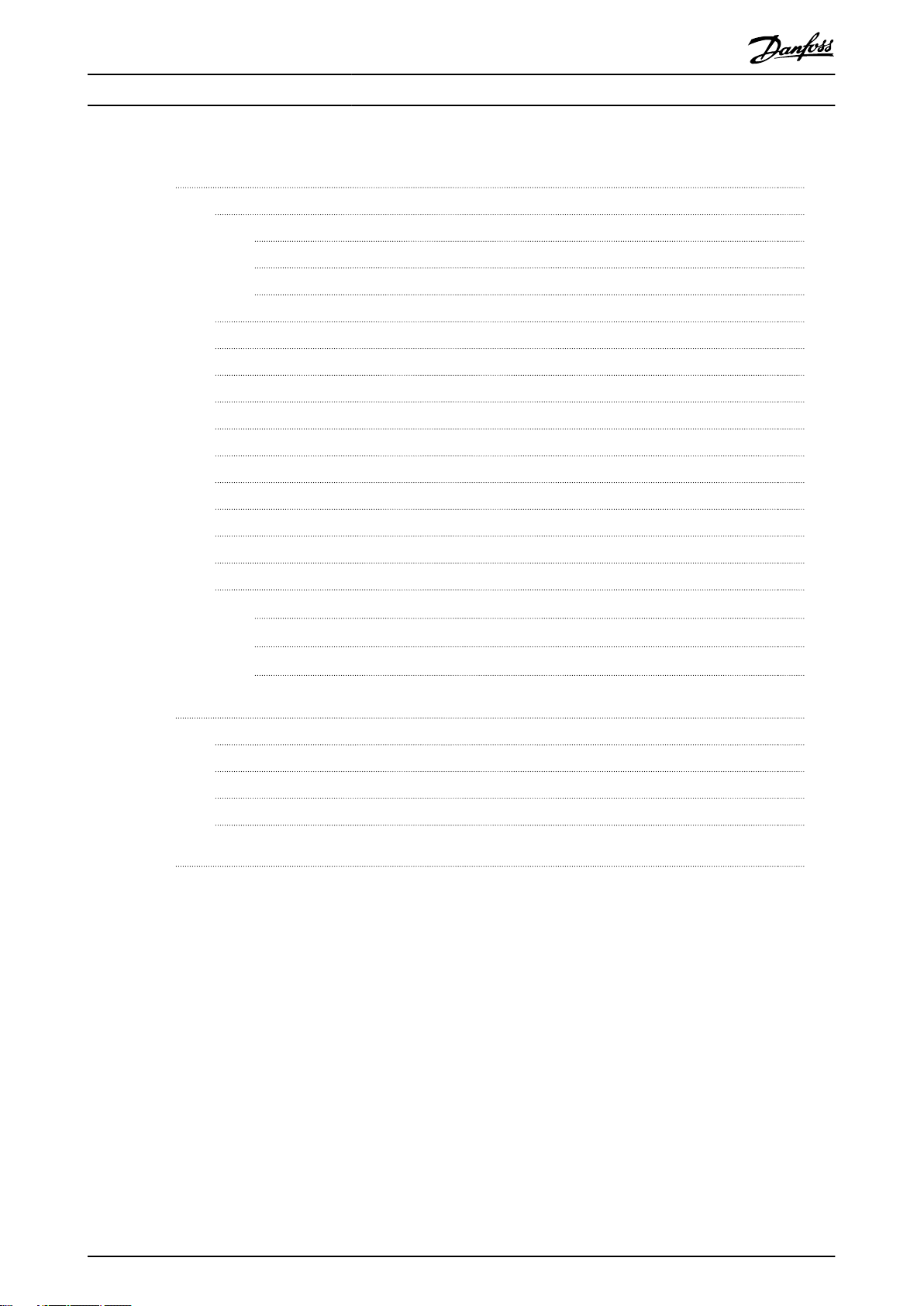

Contents Design Guide

Contents

1 Introduction

1.1 Purpose of the Design Guide

1.2 Organisation

1.3 Additional Resources

1.4 Abbreviations, Symbols and Conventions

1.5 Safety Symbols

1.6 Denitions

1.7 Document and Software Version

1.8 Approvals and Certications

1.8.1 CE Mark 10

1.8.1.1 Low Voltage Directive 10

1.8.1.2 EMC Directive 10

1.8.1.3 Machinery Directive 11

1.8.1.4 ErP Directive 11

1.8.2 C-tick Compliance 11

1.8.3 UL Compliance 11

1.8.4 Marine Compliance (ADN) 11

7

7

7

7

8

9

9

10

10

1.8.5 Export Control Regulations 12

1.9 Safety

1.9.1 General Safety Principles 12

2 Product Overview

2.1 Introduction

2.2 Description of Operation

2.3 Sequence of Operation

2.3.1 Rectier Section 18

2.3.2 Intermediate Section 18

2.3.3 Inverter Section 18

2.4 Control Structures

2.4.1 Control Structure Open Loop 19

2.4.2 Control Structure Closed Loop 19

2.4.3 Local (Hand On) and Remote (Auto On) Control 20

2.4.4 Reference Handling 21

2.4.5 Feedback Handling 23

2.5 Automated Operational Functions

12

14

14

17

18

19

24

2.5.1 Short-circuit Protection 24

2.5.2 Overvoltage Protection 24

2.5.3 Missing Motor Phase Detection 24

2.5.4 Mains Phase Imbalance Detection 25

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 1

Page 4

Contents

VLT® Refrigeration Drive FC 103

2.5.5 Switching on the Output 25

2.5.6 Overload Protection 25

2.5.7 Automatic Derating 25

2.5.8 Automatic Energy Optimisation 25

2.5.9 Automatic Switching Frequency Modulation 25

2.5.10 Automatic Derating for High Switching Frequency 26

2.5.11 Automatic Derating for Overtemperature 26

2.5.12 Auto Ramping 26

2.5.13 Current Limit Circuit 26

2.5.14 Power Fluctuation Performance 26

2.5.15 Motor Soft Start 26

2.5.16 Resonance Damping 26

2.5.17 Temperature-controlled Fans 26

2.5.18 EMC Compliance 26

2.5.19 Current Measurement on All Three Motor Phases 27

2.5.20 Galvanic Isolation of Control Terminals 27

2.6 Custom Application Functions

2.6.1 Automatic Motor Adaptation 27

2.6.2 Motor Thermal Protection 27

2.6.3 Mains Drop-out 27

2.6.4 Built-in PID Controllers 28

2.6.5 Automatic Restart 28

2.6.6 Flying Start 28

2.6.7 Full Torque at Reduced Speed 28

2.6.8 Frequency Bypass 28

2.6.9 Motor Preheat 28

2.6.10 Four Programmable Set-ups 29

2.6.11 DC Braking 29

2.6.12 Sleep Mode 29

2.6.13 Run Permissive 29

2.6.14 Smart Logic Control (SLC) 29

2.6.15 Safe Torque O Function 30

27

2.7 Fault, Warning and Alarm Functions

31

2.7.1 Operation at Overtemperature 31

2.7.2 High and Low Reference Warning 31

2.7.3 High and Low Feedback Warning 31

2.7.4 Phase Imbalance or Phase Loss 31

2.7.5 High Frequency Warning 31

2.7.6 Low Frequency Warning 31

2.7.7 High Current Warning 31

2 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 5

Contents Design Guide

2.7.8 Low Current Warning 31

2.7.9 No Load/Broken Belt Warning 31

2.7.10 Lost Serial Interface 32

2.8 User Interfaces and Programming

2.8.1 Local Control Panel 32

2.8.2 PC Software 33

2.8.2.1 MCT 10 Set-up Software 33

2.8.2.2 VLT® Harmonics Calculation Software MCT 31 33

2.8.2.3 Harmonic Calculation Software (HCS) 33

2.9 Maintenance

2.9.1 Storage 34

3 System Integration

3.1 Ambient Operating Conditions

3.1.1 Humidity 35

3.1.2 Temperature 36

3.1.3 Cooling 36

3.1.4 Motor-generated Overvoltage 37

3.1.5 Acoustic Noise 37

3.1.6 Vibration and Shock 37

3.1.7 Aggressive Atmospheres 37

32

34

35

35

3.1.8 IP Rating Denitions 38

3.1.9 Radio Frequency Interference 39

3.1.10 PELV and Galvanic Isolation Compliance 39

3.2 EMC, Harmonics, and Ground Leakage Protection

3.2.1 General Aspects of EMC Emissions 40

3.2.2 EMC Test Results (Emission) 42

3.2.3 Emission Requirements 43

3.2.4 Immunity Requirements 43

3.2.5 Motor Insulation 44

3.2.6 Motor Bearing Currents 44

3.2.7 Harmonics 45

3.2.8 Ground Leakage Current 47

3.3 Energy Eciency

3.3.1 IE and IES Classes 50

3.3.2 Power Loss Data and Eciency Data 50

3.3.3 Losses and Eciency of a Motor 51

3.3.4 Losses and Eciency of a Power Drive System 51

40

49

3.4 Mains Integration

3.4.1 Mains Congurations and EMC Eects 51

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 3

51

Page 6

Contents

VLT® Refrigeration Drive FC 103

3.4.2 Low-frequency Mains Interference 52

3.4.3 Analysing Mains Interference 53

3.4.4 Options for Reducing Mains Interference 53

3.4.5 Radio Frequency Interference 53

3.4.6 Classication of the Operating Site 53

3.4.7 Use with Isolated Input Source 54

3.4.8 Power Factor Correction 54

3.4.9 Input Power Delay 54

3.4.10 Mains Transients 54

3.4.11 Operation with a Standby Generator 54

3.5 Motor Integration

3.5.1 Motor Selection Considerations 55

3.5.2 Sine-wave and dU/dt Filters 55

3.5.3 Proper Motor Grounding 55

3.5.4 Motor Cables 55

3.5.5 Motor Cable Shielding 56

3.5.6 Connection of Multiple Motors 56

3.5.7 Motor Thermal Protection 57

3.5.8 Output Contactor 58

3.5.9 Energy Eciency 58

3.6 Additional Inputs and Outputs

3.6.1 Wiring Schematic 59

3.6.2 Relay Connections 60

3.6.3 EMC-compliant Electrical Connection 61

3.7 Mechanical Planning

3.7.1 Clearance 62

3.7.2 Wall Mounting 63

55

59

62

3.7.3 Access 63

3.8 Options and Accessories

3.8.1 Communication Options 66

3.8.2 Input/Output, Feedback, and Safety Options 66

3.8.3 Sine-wave Filters 66

3.8.4 dU/dt Filters 66

3.8.5 Harmonic Filters 66

3.8.6 IP21/NEMA Type 1 Enclosure Kit 67

3.8.7 Common-mode Filters 69

3.8.8 Remote Mounting Kit for LCP 69

3.8.9 Mounting Bracket for Enclosure Sizes A5, B1, B2, C1, and C2 70

3.9 Serial Interface RS485

3.9.1 Overview 71

4 Danfoss A/S © 08/2015 All rights reserved. MG16G202

63

71

Page 7

Contents Design Guide

3.9.2 Network Connection 72

3.9.3 RS485 Bus Termination 72

3.9.4 EMC Precautions 73

3.9.5 FC Protocol Overview 73

3.9.6 Network Conguration 73

3.9.7 FC Protocol Message Framing Structure 73

3.9.8 FC Protocol Examples 77

3.9.9 Modbus RTU Protocol 78

3.9.10 Modbus RTU Message Framing Structure 79

3.9.11 Access to Parameters 82

3.9.12 FC Drive Control Prole 83

3.10 System Design Checklist

4 Application Examples

4.1 Application Examples

4.2 Selected Application Features

4.2.1 SmartStart 91

4.2.2 Start/Stop 92

4.2.3 Pulse Start/Stop 92

4.2.4 Potentiometer Reference 93

4.3 Application Set-up Examples

5 Special Conditions

5.1 Derating

5.2 Manual Derating

5.3 Derating for Long Motor Cables or Cables with Larger Cross-section

5.4 Derating for Ambient Temperature

6 Type Code and Selection

89

91

91

91

93

99

99

99

99

100

104

6.1 Ordering

6.1.1 Introduction 104

6.1.2 Type Code 104

6.2 Options, Accessories, and Spare Parts

6.2.1 Ordering Numbers: Options and Accessories 105

6.2.2 Ordering Numbers: Harmonic Filters 107

6.2.3 Ordering Numbers: Sine-wave Filter Modules, 200–480 V AC 107

6.2.4 Ordering Numbers: Sine-wave Filter Modules, 525-600/690 V AC 108

6.2.5 Harmonic Filters 109

6.2.6 Sine-wave Filters 111

6.2.7 dU/dt Filters 113

6.2.8 Common Mode Filters 114

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 5

104

105

Page 8

Contents

VLT® Refrigeration Drive FC 103

7 Specications

7.1 Electrical Data

7.1.1 Mains Supply 3x200–240 V AC 115

7.1.2 Mains Supply 3x380–480 V AC 117

7.1.3 Mains Supply 3x525–600 V AC 119

7.2 Mains Supply

7.3 Motor Output and Motor Data

7.4 Ambient Conditions

7.5 Cable Specications

7.6 Control Input/Output and Control Data

7.7 Connection Tightening Torque

7.8 Fuses and Circuit Breakers

7.9 Power Ratings, Weight, and Dimensions

7.10 dU/dt Testing

7.11 Acoustic Noise Ratings

7.12 Selected Options

7.12.1 VLT® General Purpose I/O Module MCB 101 135

115

115

121

121

122

122

123

126

127

132

133

135

135

7.12.2 VLT® Relay Card MCB 105 136

7.12.3 VLT® Extended Relay Card MCB 113 138

8 Appendix - Selected Drawings

8.1 Mains Connection Drawings

8.2 Motor Connection Drawings

8.3 Relay Terminal Drawings

8.4 Cable Entry Holes

Index

140

140

143

145

146

151

6 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 9

Introduction Design Guide

1 Introduction

1.1 Purpose of the Design Guide

This design guide for VLT® Refrigeration Drive FC 103

frequency converters is intended for:

Project and systems engineers.

•

Design consultants.

•

Application and product specialists.

•

The design guide provides technical information to

understand the capabilities of the frequency converter for

integration into motor control and monitoring systems.

The purpose of the design guide is to provide design

considerations and planning data for integration of the

frequency converter into a system. The design guide caters

for selection of frequency converters and options for a

diversity of applications and installations.

Reviewing the detailed product information in the design

stage enables developing a well-conceived system with

optimal functionality and

VLT® is a registered trademark.

Organisation

1.2

Chapter 1 Introduction: The general purpose of the design

guide and compliance with international directives.

Chapter 2 Product Overview: The internal structure and

functionality of the frequency converter and operational

features.

Chapter 3 System Integration: Environmental conditions;

EMC, harmonics, and ground leakage; mains input; motors

and motor connections; other connections; mechanical

planning; and descriptions of options and accessories

available.

Chapter 4 Application Examples: Samples of product

applications and guidelines for use.

eciency.

Chapter 8 Appendix - Selected Drawings: A compilation of

graphics illustrating:

Mains and motor connections

•

Relay terminals

•

Cable entries

•

1.3 Additional Resources

Resources available to understand advanced operation of

the frequency converter, programming, and directives

compliance:

The VLT® Refrigeration Drive FC 103 Operating

•

Instructions (referenced as operating instructions in

this manual) provide detailed information for the

installation and start-up of the frequency

converter.

The VLT® Refrigeration Drive FC 103 Design Guide

•

provides information required for design and

planning for integration of the frequency

converter into a system.

®

The VLT

•

Guide (referenced as programming guide in this

manual) provides greater detail about how to

work with parameters and many application

examples.

The VLT® Safe Torque O Operating Instructions

•

describe how to use Danfoss frequency

converters in functional safety applications. This

manual is supplied with the frequency converter

when the STO option is present.

Supplemental publications and manuals are available for

download from vlt-drives.danfoss.com/Products/Detail/

Technical-Documents.

Refrigeration Drive FC 103 Programming

NOTICE

Optional equipment is available that may change some

of the information described in these publications. Be

sure to see the instructions supplied with the options for

specic requirements.

1 1

Chapter 5 Special Conditions: Details on unusual operational

environments.

Chapter 6 Type Code and Selection: Procedures for ordering

equipment and options to meet the intended use of the

system.

Chapter 7

table and graphics format.

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 7

Specications: A compilation of technical data in

Contact a Danfoss supplier or visit www.danfoss.com for

more information.

Page 10

Introduction

VLT® Refrigeration Drive FC 103

11

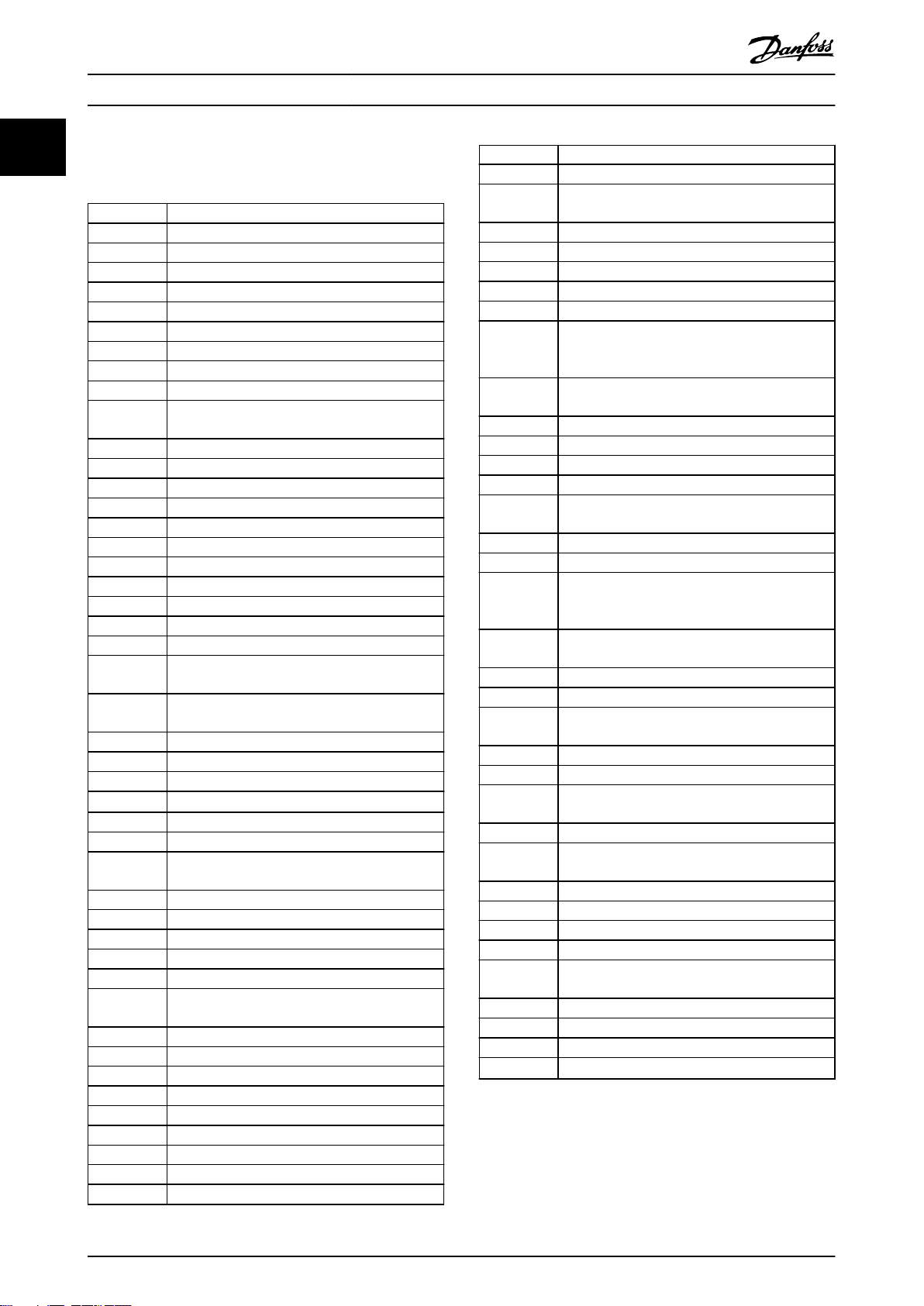

1.4 Abbreviations, Symbols and

Conventions

60° AVM 60° asynchronous vector modulation

A Ampere/AMP

AC Alternating current

AD Air discharge

AEO Automatic energy optimisation

AI Analog input

AMA Automatic motor adaptation

AWG American wire gauge

°C

CD Constant discharge

CDM Complete drive module: the frequency converter,

CM Common mode

CT Constant torque

DC Direct current

DI Digital input

DM Dierential mode

D-TYPE Drive dependent

EMC Electromagnetic compatibility

EMF Electromotive force

ETR Electronic thermal relay

f

JOG

f

M

f

MAX

f

MIN

f

M,N

FC Frequency converter

g Gramme

Hiperface®Hiperface® is a registered trademark by Stegmann

HO High overload

hp Horse power

HTL HTL encoder (10–30 V) pulses - High-voltage

Hz Hertz

I

INV

I

LIM

I

M,N

I

VLT,MAX

I

VLT,N

kHz Kilohertz

LCP Local control panel

lsb Least signicant bit

m Meter

Degrees celsius

feeding section and auxiliaries

Motor frequency when jog function is activated.

Motor frequency

Maximum output frequency, the frequency

converter applies on its output.

Minimum motor frequency from the frequency

converter

Nominal motor frequency

transistor logic

Rated inverter output current

Current limit

Nominal motor current

Maximum output current

Rated output current supplied by the frequency

converter

ms Millisecond

msb Most signicant bit

η

VLT

Eciency of the frequency converter dened as

ratio between power output and power input.

nF Capacitance in nano Farad

NLCP Numerical local control panel

Nm Newton meter

NO Normal overload

n

s

Online/

Oine

Synchronous motor speed

Changes to online parameters are activated

immediately after the data value is changed.

Parameters

P

br,cont.

Rated power of the brake resistor (average power

during continuous braking).

PCB Printed circuit board

PCD Process data

PDS Power drive system: a CDM and a motor

PELV Protective extra low voltage

P

m

Frequency converter nominal output power as

high overload (HO).

P

M,N

Nominal motor power

PM motor Permanent magnet motor

Process PID PID (Proportional Integrated Dierential) regulator

that maintains the speed, pressure, temperature,

and so on.

R

br,nom

Nominal resistor value that ensures a brake power

on the motor shaft of 150/160% for 1 minute

RCD Residual current device

Regen Regenerative terminals

R

min

Minimum permissible brake resistor value by

frequency converter

RMS Root mean square

RPM Revolutions per minute

R

rec

Recommended brake resistor resistance of

Danfoss brake resistors

s Second

SFAVM Stator ux-oriented asynchronous vector

modulation

STW Status word

SMPS Switch mode power supply

THD Total harmonic distortion

T

LIM

Torque limit

TTL TTL encoder (5 V) pulses - transistor transistor

logic

U

M,N

Nominal motor voltage

V Volts

VT Variable torque

VVC+

Voltage vector control plus

Table 1.1 Abbreviations

mA Milliampere

MCM Mille circular mil

MCT Motion control tool

mH Inductance in milli Henry

mm Millimeter

8 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 11

Introduction Design Guide

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicised text indicates:

Cross reference.

•

Link.

•

Footnote.

•

Parameter name, parameter group name,

•

parameter option.

All dimensions are in mm (inch).

* indicates a default setting of a parameter.

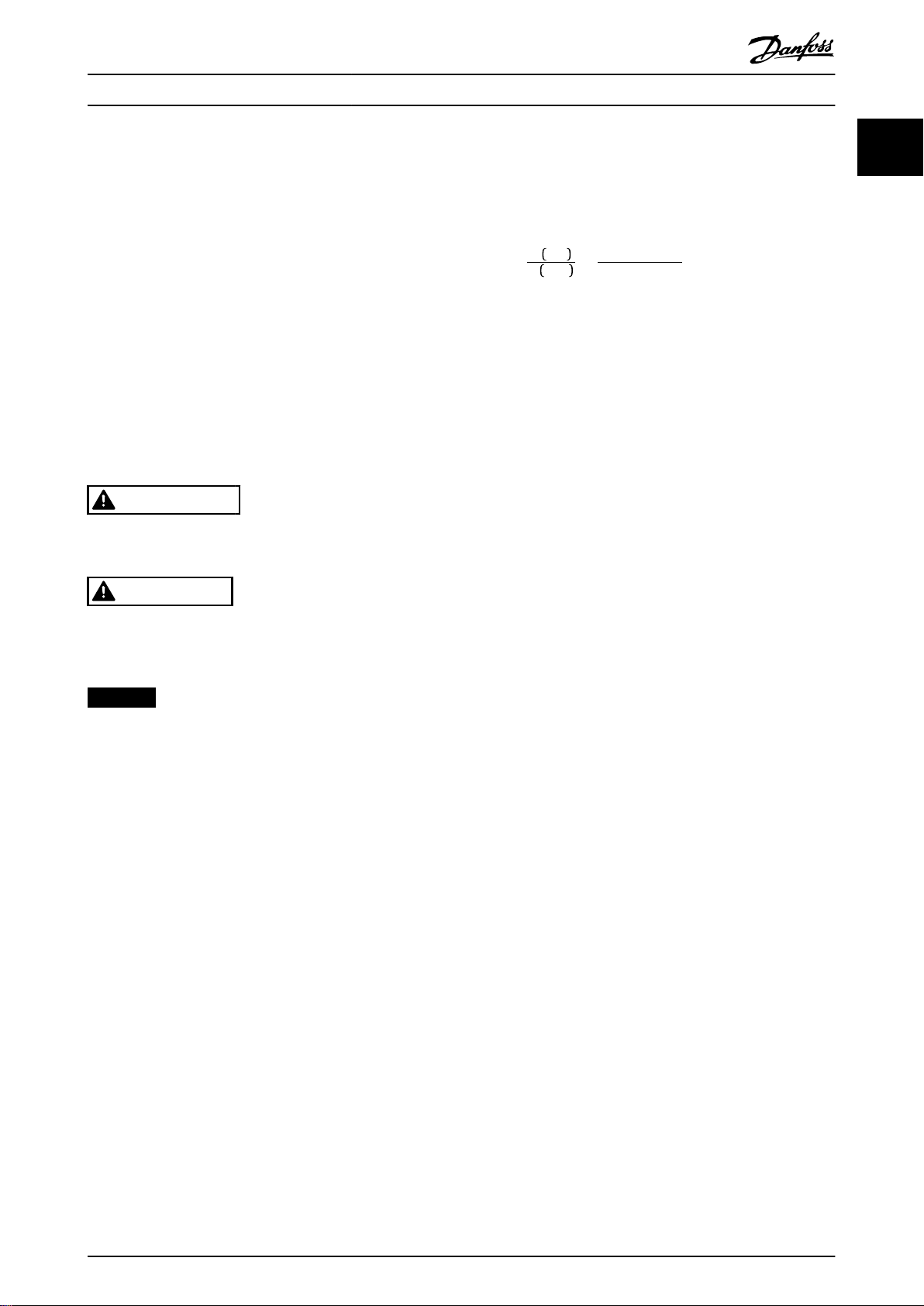

1.5 Safety Symbols

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

1.6 Denitions

Coast

The motor shaft is in free mode. No torque on the motor.

CT characteristics

Constant torque characteristics used for all applications

such as:

Conveyor belts.

•

Displacement pumps.

•

Cranes.

•

Initialising

If initialising is carried out (parameter 14-22 Operation

Mode), the frequency converter returns to the default

setting.

Intermittent duty cycle

An intermittent duty rating refers to a sequence of duty

cycles. Each cycle consists of an on-load and an

period. The operation can be either periodic duty or nonperiodic duty.

o-load

Power factor

The true power factor (lambda) considers all the

harmonics. The true power factor is always smaller than

the power factor (cosphi) that only considers the 1st

harmonics of current and voltage.

cosϕ =

Cosphi is also known as displacement power factor.

Both lambda and cosphi are stated for Danfoss VLT

frequency converters in chapter 7.2 Mains Supply.

The power factor indicates to which extent the frequency

converter imposes a load on the mains supply.

The lower the power factor, the higher the I

same kW performance.

In addition, a high power factor indicates that the

harmonic currents are low.

All Danfoss frequency converters have built-in DC coils in

the DC link. The coils ensure a high power factor and

reduce the THDi on the main supply.

Set-up

Save parameter settings in 4 set-ups. Change between the

4 parameter set-ups and edit 1 set-up while another set-up

is active.

Slip compensation

The frequency converter compensates for the motor slip by

giving the frequency a supplement that follows the

measured motor load, keeping the motor speed almost

constant.

Smart logic control (SLC)

The SLC is a sequence of

when the associated user-dened events are evaluated as

true by the SLC. (Parameter group 13-** Smart Logic).

FC standard bus

Includes RS485 bus with FC protocol or MC protocol. See

parameter 8-30 Protocol.

Thermistor

A temperature-dependent resistor placed where the

temperature is to be monitored (frequency converter or

motor).

Trip

A state entered in fault situations, such as when the

frequency converter is subject to an overtemperature or

when it protects the motor, process, or mechanism. Restart

is prevented until the cause of the fault has disappeared

and the trip state is cancelled. Cancel the trip state by:

Do not use trip for personal safety.

P kW

P kVA

Activating reset, or

•

Programming the frequency converter to reset

•

automatically

UλxIλxcosϕ

=

UλxIλ

®

for the

RMS

user-dened actions executed

1 1

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 9

Page 12

Introduction

VLT® Refrigeration Drive FC 103

11

Trip lock

A state entered in fault situations when the frequency

converter is protecting itself and requires physical

intervention, for example if the frequency converter is

subject to a short circuit on the output. A locked trip can

only be cancelled by cutting o mains, removing the cause

of the fault, and reconnecting the frequency converter.

Restart is prevented until the trip state is cancelled by

activating reset or, in some cases, by being programmed to

reset automatically. Do not use trip for personal safety.

VT characteristics

Variable torque characteristics for pumps and fans.

1.7 Document and Software Version

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome.

Table 1.2 shows the document version and the

corresponding software version.

Edition Remarks Software version

MG16G2xx Replaces MG16G1xx 1.4x

Table 1.2 Document and Software Version

Approvals and Certications

1.8

Frequency converters are designed in compliance with the

directives described in this section.

NOTICE

Frequency converters with an integrated safety function

must comply with the machinery directive.

EU Directive Version

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

Machinery Directive

ErP Directive 2009/125/EC

ATEX Directive 2014/34/EU

RoHS Directive 2002/95/EC

Table 1.3 EU Directives Applicable to Frequency Converters

1) Machinery Directive conformance is only required for frequency

converters with an integrated safety function.

Declarations of conformity are available on request.

1)

1.8.1.1 Low Voltage Directive

The Low Voltage Directive applies to all electrical

equipment in the 50–1000 V AC and the 75–1600 V DC

voltage ranges.

The aim of the directive is to ensure personal safety and

avoid property damage, when operating electrical

equipment that is installed, maintained, and used as

intended.

2014/32/EU

1.8.1.2 EMC Directive

For more information on approvals and certicates, go to

the download area at vlt-marine.danfoss.com/support/type-

approval-certicates/.

1.8.1 CE Mark

Illustration 1.1 CE

The CE mark (Communauté Européenne) indicates that the

product manufacturer conforms to all applicable EU

directives. The EU directives applicable to the design and

manufacture of frequency converters are listed in Table 1.3.

The purpose of the EMC (electromagnetic compatibility)

Directive is to reduce electromagnetic interference and

enhance immunity of electrical equipment and installations. The basic protection requirement of the EMC

Directive is that devices that generate electromagnetic

interference (EMI), or whose operation could be aected

by EMI, must be designed to limit the generation of

electromagnetic interference. The devices must have a

suitable degree of immunity to EMI when properly

installed, maintained, and used as intended.

Electrical equipment devices used alone or as part of a

system must bear the CE mark. Systems do not require the

CE mark, but must comply with the basic protection

requirements of the EMC Directive.

NOTICE

The CE mark does not regulate the quality of the

product. Technical specications cannot be deduced from

the CE mark.

10 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 13

Introduction Design Guide

1.8.1.3 Machinery Directive

The aim of the Machinery Directive is to ensure personal

safety and avoid property damage for mechanical

equipment used in its intended application. The Machinery

Directive applies to a machine consisting of an aggregate

of interconnected components or devices of which at least

1 is capable of mechanical movement.

Frequency converters with an integrated safety function

must comply with the Machinery Directive. Frequency

converters without a safety function do not fall under the

Machinery Directive. If a frequency converter is integrated

into a machinery system, Danfoss can provide information

on safety aspects relating to the frequency converter.

When frequency converters are used in machines with at

least 1 moving part, the machine manufacturer must

provide a declaration stating compliance with all relevant

statutes and safety measures.

1.8.1.4 ErP Directive

The ErP Directive is the European Ecodesign Directive for

energy-related products. The directive sets ecodesign

requirements for energy-related products, including

frequency converters. The aim of the directive is to

increase energy eciency and the level of protection of

the environment, while increasing the security of the

energy supply. Environmental impact of energy-related

products includes energy consumption throughout the

entire product life cycle.

1.8.2 C-tick Compliance

Illustration 1.2 C-tick

1.8.3 UL Compliance

UL Listed

Illustration 1.3 UL

NOTICE

525–690 V frequency converters are not certied for UL.

The frequency converter complies with UL 508C thermal

memory retention requirements. For more information,

refer to chapter 2.6.2 Motor Thermal Protection.

1.8.4 Marine Compliance (ADN)

Units with ingress protection rating IP55 (NEMA 12) or

higher prevent spark formation, and are classied as

limited explosion risk electrical apparatus in accordance

with the European Agreement concerning International

Carriage of Dangerous Goods by Inland Waterways (ADN).

For units with ingress protection rating IP20/Chassis, IP21/

NEMA 1, or IP54, prevent risk of spark formation as follows:

Do not install a mains switch.

•

Ensure that parameter 14-50 RFI Filter is set to [1]

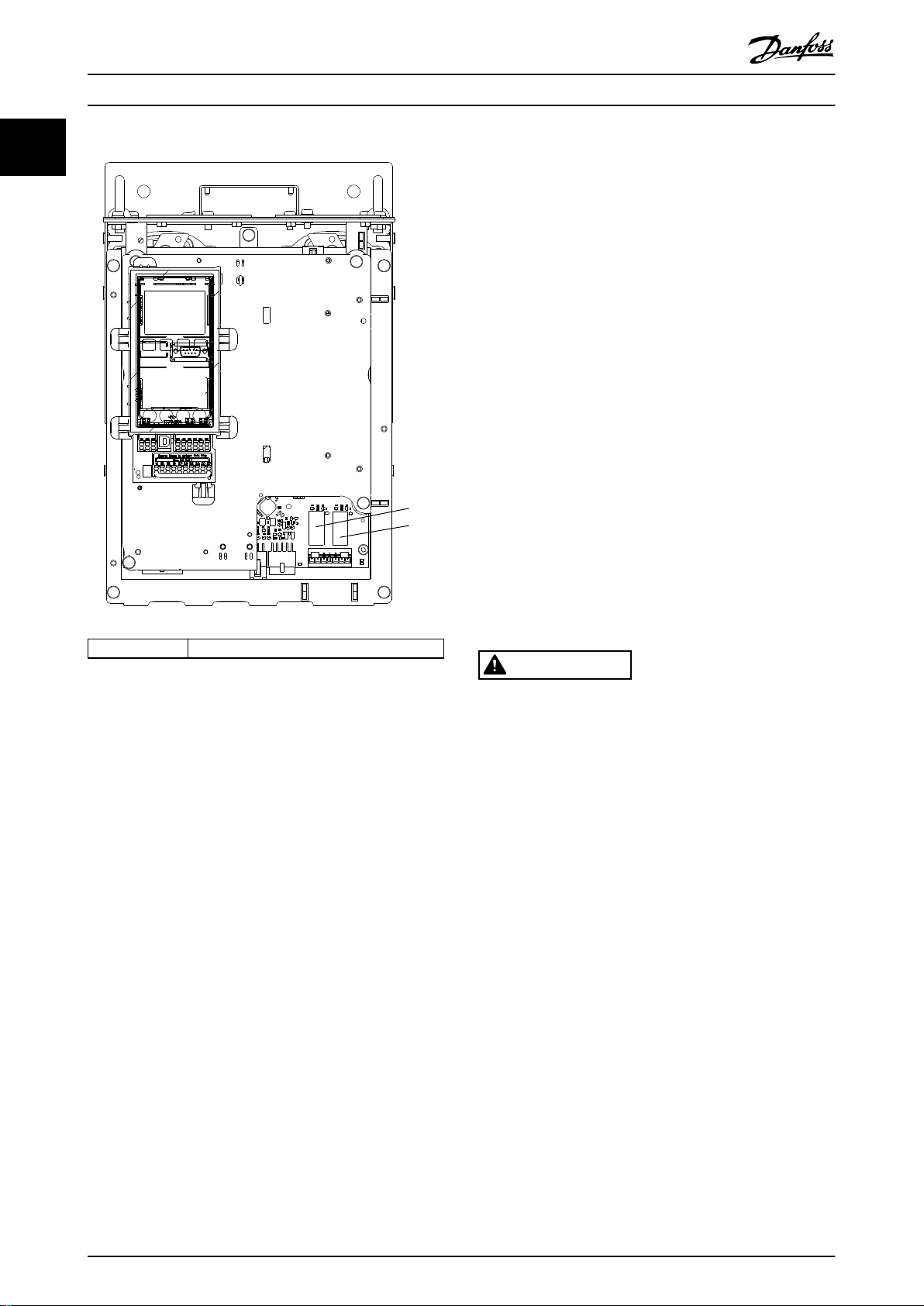

•

On.

Remove all relay plugs marked RELAY. See

•

Illustration 1.4.

Check which relay options are installed, if any.

•

The only permitted relay option is VLT® Extended

Relay Card MCB 113.

Go to vlt-marine.danfoss.com/support/type-approval-certif-

icates/ for additional marine approvals information.

1 1

The C-tick label indicates compliance with the applicable

technical standards for Electromagnetic Compatibility

(EMC). C-tick compliance is required for placing electrical

and electronic devices on the market in Australia and New

Zealand.

The C-tick regulatory is about conducted and radiated

emission. For frequency converters, apply the emission

limits specied in EN/IEC 61800-3.

A declaration of conformity can be provided on request.

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 11

Page 14

1

2

130BD832.10

Introduction

VLT® Refrigeration Drive FC 103

11

1.9

Safety

1.9.1 General Safety Principles

If handled improperly, frequency converters have the

potential for fatal injury as they contain high-voltage

components. Only

operate the equipment. Do not attempt repair work

without rst removing power from the frequency converter

and waiting the designated amount of time for stored

electrical energy to dissipate.

Strict adherence to safety precautions and notices is

mandatory for safe operation of the frequency converter.

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install and operate this

equipment.

Qualied personnel are dened as trained sta, who are

authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the qualied personnel must be

familiar with the instructions and safety measures

described in these operating instructions.

1, 2 Relay plugs

qualied personnel should install and

WARNING

Illustration 1.4 Location of Relay Plugs

Manufacturer declaration is available on request.

1.8.5 Export Control Regulations

Frequency converters can be subject to regional and/or

national export control regulations.

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC supply, or load sharing.

Failure to perform installation, start-up, and maintenance

by qualied personnel can result in death or serious

injury.

Only qualied personnel must perform instal-

•

lation, start-up, and maintenance.

The frequency converters that are subject to export control

regulations are classied by an ECCN number.

The ECCN number is provided in the documents

accompanying the frequency converter.

In case of re-export, it is the responsibility of the exporter

to ensure compliance with the relevant export control

regulations.

12 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 15

Introduction Design Guide

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor may start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start via an external

switch, a eldbus command, an input reference signal

from the LCP, or after a cleared fault condition.

To prevent unintended motor start:

Disconnect the frequency converter from the

•

mains.

Press [O/Reset] on the LCP before

•

programming parameters.

Completely wire and assemble the frequency

•

converter, motor, and any driven equipment

before connecting the frequency converter to

AC mains, DC supply, or load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors,

which can remain charged even when the frequency

converter is not powered. High voltage may be present

even when the warning LED indicator lights are o.

Failure to wait the specied time after power has been

removed before performing service or repair work, could

result in death or serious injury.

1. Stop the motor.

2. Disconnect AC mains, permanent magnet type

motors, and remote DC-link supplies, including

battery back-ups, UPS, and DC-link connections

to other frequency converters.

3. Wait for the capacitors to discharge fully, before

performing any service or repair work. The

duration of waiting time is specied in Table 1.4.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground

frequency converter properly can result in death or

serious injury.

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform installation, start-up, and maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this manual.

•

WARNING

UNINTENDED MOTOR ROTATION

WINDMILLING

Unintended rotation of permanent magnet motors

creates voltage and can charge the unit, resulting in

death, serious injury, or equipment damage.

Ensure that permanent magnet motors are

•

blocked to prevent unintended rotation.

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury, when the frequency converter is not

properly closed.

Ensure that all safety covers are in place and

•

securely fastened before applying power.

1 1

Voltage [V] Minimum waiting time (minutes)

4 15

200–240 1.1–3.7 kW 5.5–45 kW

380–480 1.1–7.5 kW 11–90 kW

525–600 1.1–7.5 kW 11–90 kW

Table 1.4 Discharge Time

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 13

Page 16

130BD889.10

60

50

40

30

20

10

H

s

0 100 200 300 400

(mwg)

1350rpm

1650rpm

0

10

20

30

(kW)

40

50

60

200100 300

(

m3 /h

)

(

m3 /h

)

400

1350rpm

1650rpm

P

shaft

1

Product Overview

VLT® Refrigeration Drive FC 103

2 Product Overview

22

2.1 Introduction

2.1.2 Energy Savings

This chapter provides an overview of the frequency

converter’s primary assemblies and circuitry. It describes

the internal electrical and signal processing functions. A

description of the internal control structure is also

included.

Also described are automated and optional frequency

converter functions available for designing robust

operating systems with sophisticated control and status

reporting performance.

2.1.1 Product Dedication to Refrigeration

Applications

The VLT® Refrigeration Drive FC 103 is designed for refrigeration applications. The integrated application wizard

guides the user through the commissioning process. The

range of standard and optional features includes:

Multi-zone cascade control

•

Neutral zone control.

•

Floating condensing temperature control.

•

Oil return management.

•

Multi-feedback evaporator control.

•

Cascade control.

•

Dry-run detection.

•

End of curve detection.

•

Motor alternation.

•

STO.

•

Sleep mode.

•

Password protection.

•

Overload protection.

•

Smart logic control.

•

Minimum speed monitor.

•

Free programmable texts for information,

•

warnings, and alerts.

When comparing with alternative control systems and

technologies, a frequency converter is the optimum energy

control system for controlling fan and pump systems.

By using a frequency converter to control the ow, a pump

speed reduction of 20% leads to energy savings of about

50% in typical applications.

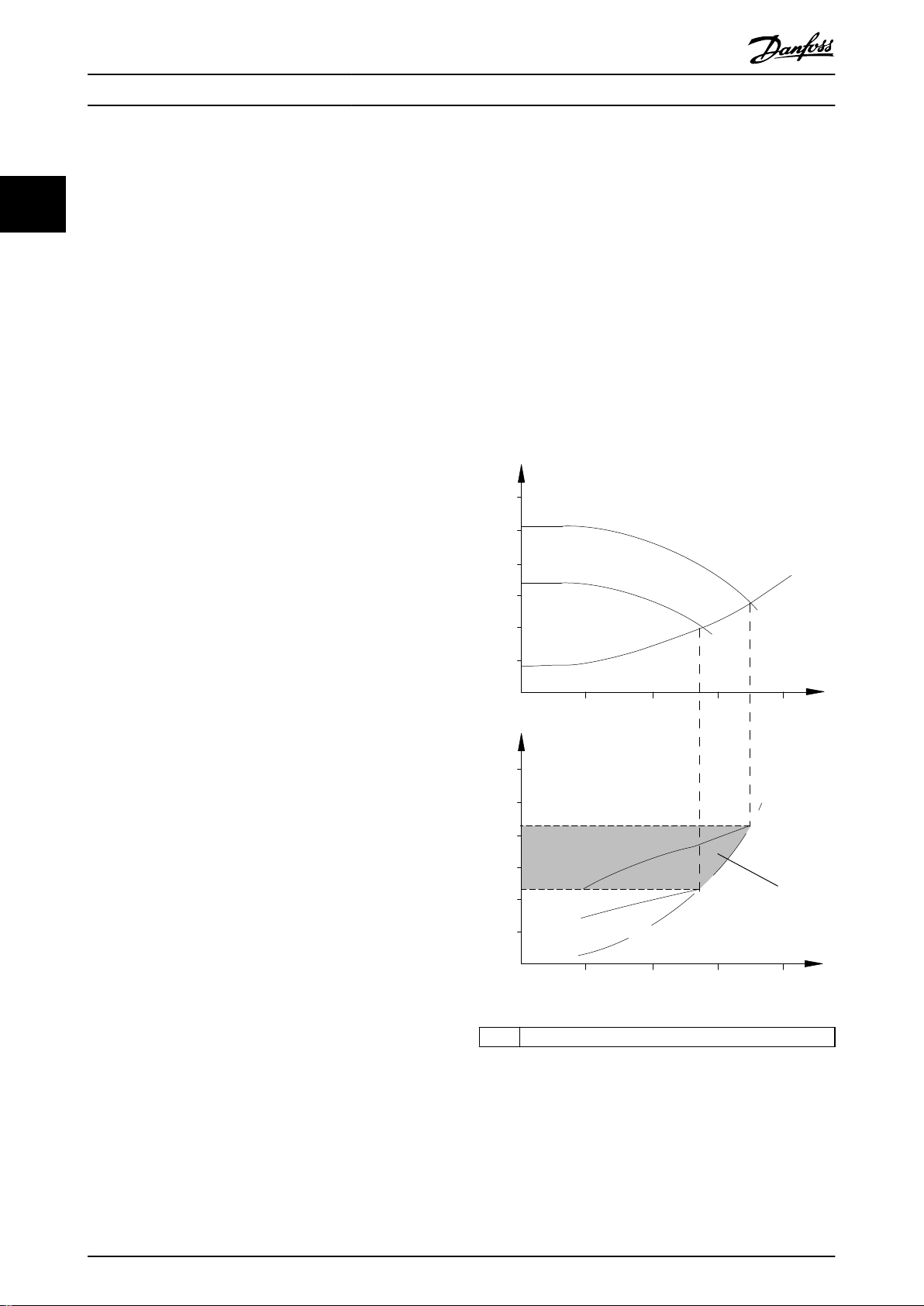

Illustration 2.1 shows an example of the achievable energy

reduction.

1 Energy saving

Illustration 2.1 Example: Energy Saving

14 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 17

n

100%

50%

25%

12,5%

50% 100%

80%

80%

175HA208.10

Power ~n

3

Pressure ~n

2

Flow ~n

500

[h]

t

1000

1500

2000

200100 300

[m

3

/h]

400

Q

175HA210.11

Product Overview Design Guide

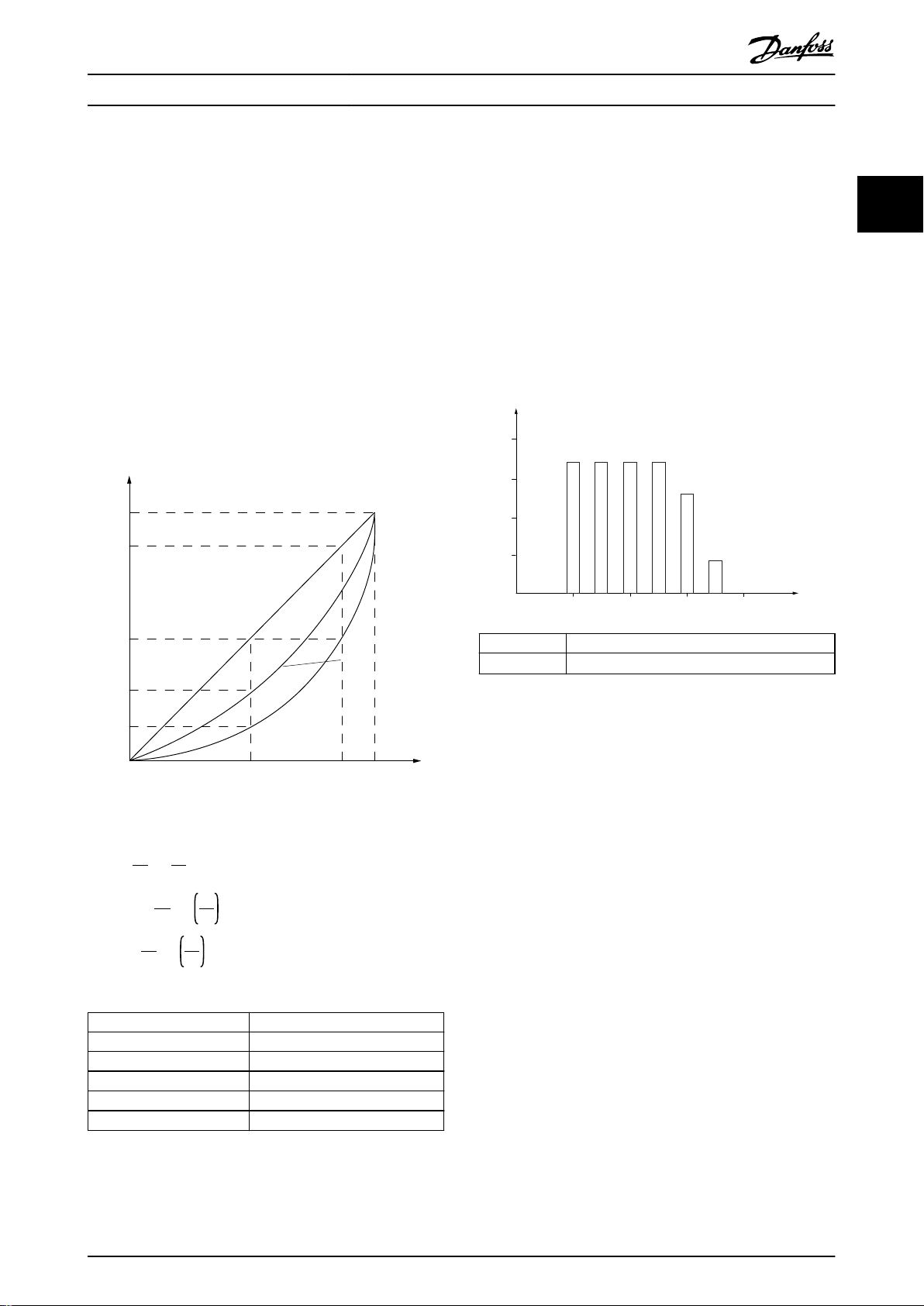

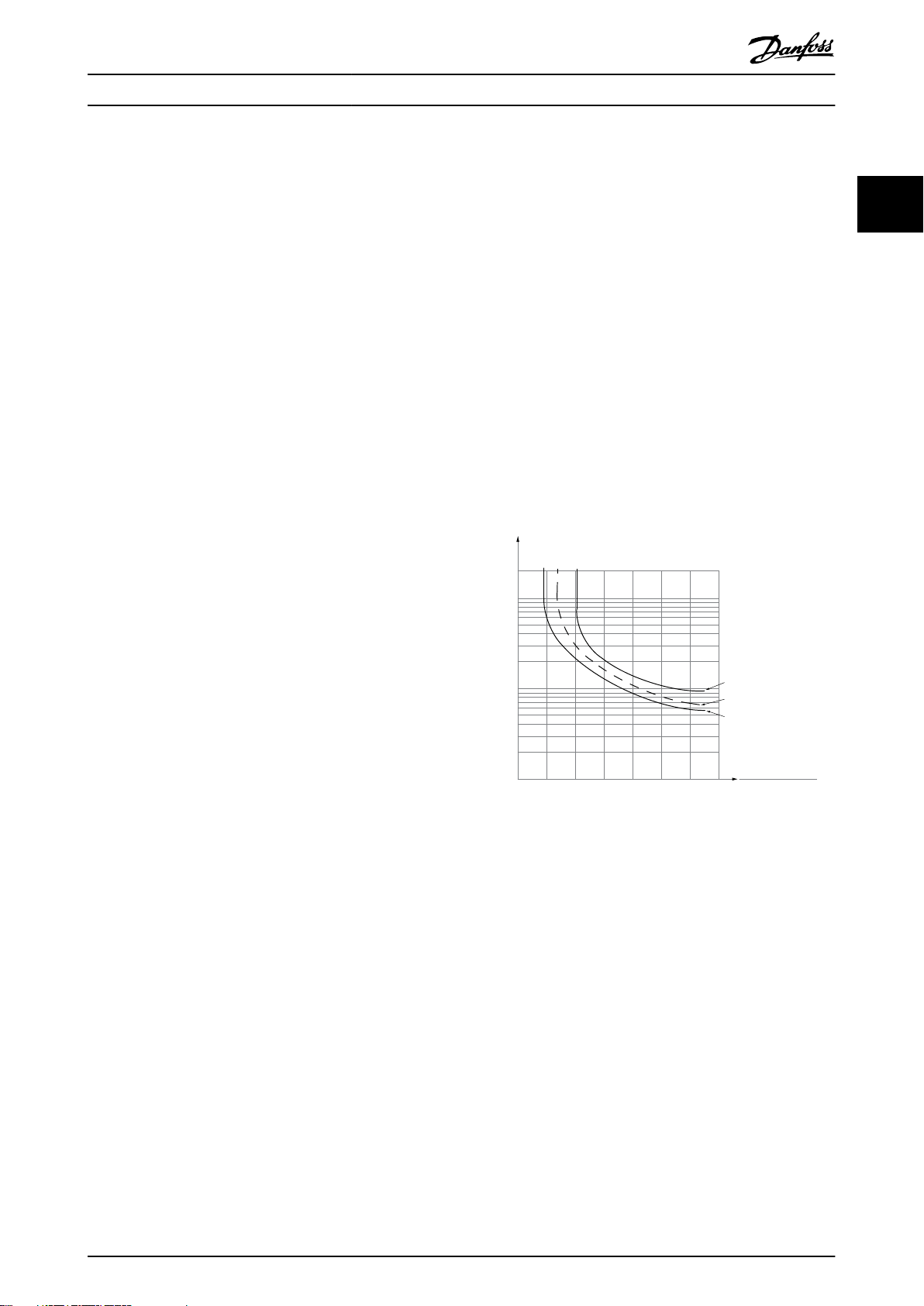

2.1.3 Example of Energy Savings

As shown in Illustration 2.2, the ow is controlled by

changing the pump speed, measured in RPM. By reducing

the speed only 20% from the rated speed, the ow is also

reduced by 20%. The ow is directly proportional to the

speed. The consumption of electricity is reduced by up to

50%.

If the system only has to supply a ow that corresponds to

100% a few days in a year, while the average is below 80%

of the rated ow for the remainder of the year, the energy

savings are even greater than 50%.

Illustration 2.2 describes the dependence of

and power consumption on pump speed in RPM for

centrifugal pumps.

ow, pressure,

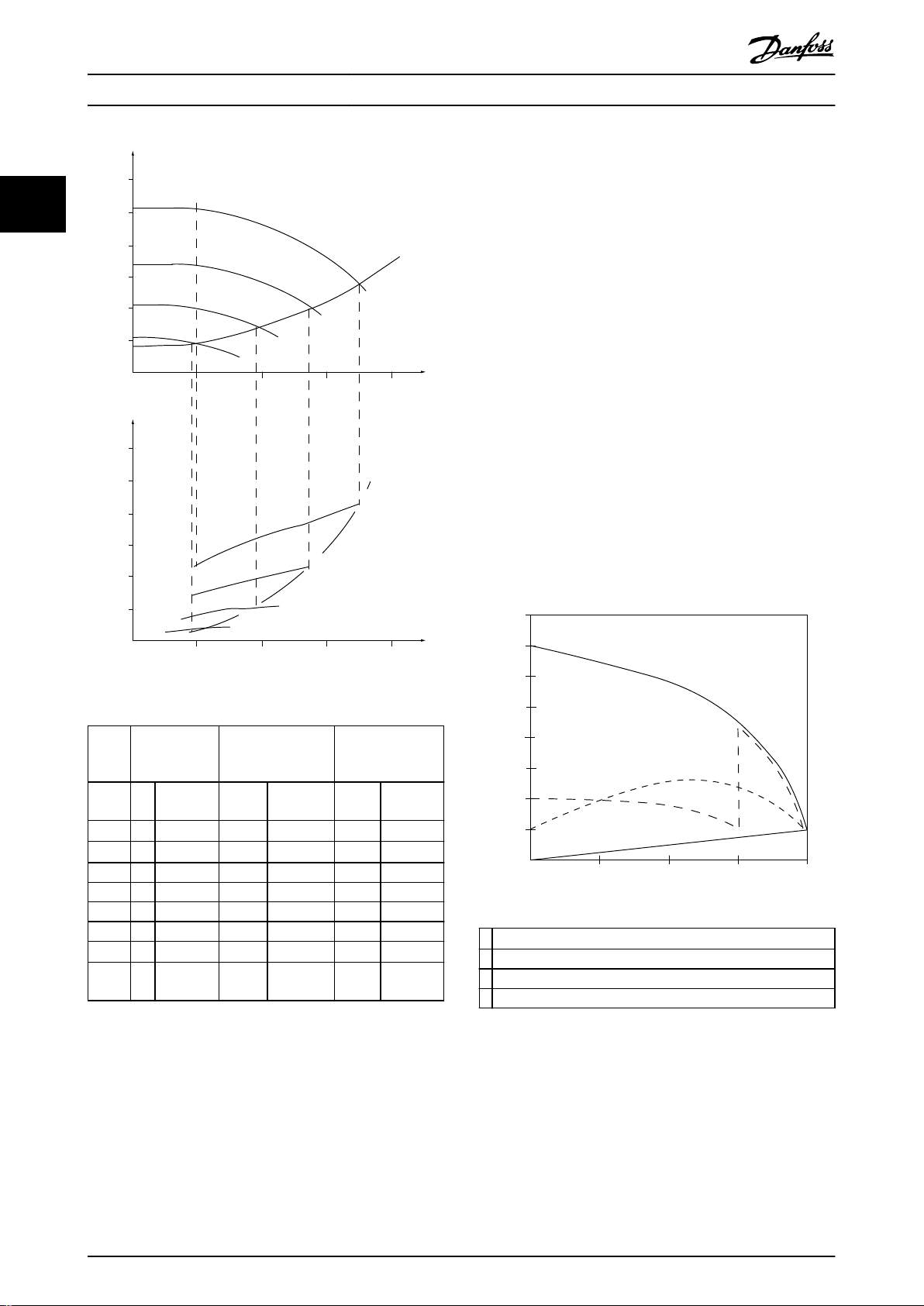

2.1.4 Example with Varying Flow over 1

Year

This example is calculated based on pump characteristics

obtained from a pump datasheet, shown in Illustration 2.4.

The result obtained shows energy savings in excess of 50%

at the given ow distribution over a year,

see Illustration 2.3. The payback period depends on the

price of electricity and the price of the frequency

converter. In this example, payback is less than a year,

when compared with valves and constant speed.

2 2

t [h] Duration of ow. See also Table 2.2.

Flowrate

Illustration 2.2 Anity Laws for Centrifugal Pumps

Q

n

1

Flow:

Pressure:

Power:

1

=

Q

n

2

2

H

1

=

H

2

P

1

=

P

2

2

n

1

n

2

3

n

1

n

2

Q [m3/h]

Illustration 2.3 Flow Distribution over 1 Year (Duration versus

Flowrate)

Assuming an equal eciency in the speed range.

Q=Flow P=Power

Q1=Flow 1 P1=Power 1

Q2=Reduced ow P2=Reduced power

H=Pressure n=Speed regulation

H1=Pressure 1 n1=Speed 1

H2=Reduced pressure n2=Reduced speed

Table 2.1 Anity Laws

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 15

Page 18

175HA209.11

60

50

40

30

20

10

H

s

0 100 200 300 400

(mwg)

B

C

A

750rpm

1050rpm

1350rpm

1650rpm

0

10

20

30

(kW)

40

50

60

200100 300

(

m3 /h

)

(

m3 /h

)

400

750rpm

1050rpm

1350rpm

1650rpm

P

shaft

C

1

B

1

A

1

Full load

% Full-load current

& speed

500

100

0

0 12,5 25 37,5 50Hz

200

300

400

600

700

800

4

3

2

1

175HA227.10

Product Overview

VLT® Refrigeration Drive FC 103

2.1.5 Improved Control

22

or pressure of a system.

Use a frequency converter to vary the speed of the

compressor, fan, or pump, obtaining variable control of

ow and pressure.

Furthermore, a frequency converter can quickly adapt the

speed of the compressor, fan, or pump to new ow or

pressure conditions in the system.

Obtain simple control of process (ow, level, or pressure)

utilising the built-in PI control.

2.1.6 Star/Delta Starter or Soft Starter

When large motors are started, it is necessary in many

countries to use equipment that limits the start-up current.

In more traditional systems, a star/delta starter or soft

starter is widely used. If a frequency converter is used,

such motor starters are not required.

As illustrated in Illustration 2.5, a frequency converter does

not consume more than rated current.

Use a frequency converter to improve control of the ow

Illustration 2.4 Energy Consumption at Dierent Speeds

Flow

Distribution Valve regulation Frequency

rate

% Duration Power Consump-

[m3/h]

[h] [kW] [kWh] [kW] [kWh]

350 5 438

42.5

300 15 1314 38.5 50.589 29.0 38.106

250 20 1752 35.0 61.320 18.5 32.412

200 20 1752 31.5 55.188 11.5 20.148

150 20 1752 28.0 49.056 6.5 11.388

100 20 1752

1008760 – 275.064 – 26.801

Σ

23.0

Table 2.2 Result

1) Power reading at point A1.

2) Power reading at point B1.

3) Power reading at point C1.

16 Danfoss A/S © 08/2015 All rights reserved. MG16G202

1)

2)

tion

18.615

40.296

Power Consump-

42.5

3.5

converter

control

1)

18.615

3)

tion

6.132

1

VLT® Refrigeration Drive FC 103

2 Star/delta starter

3 Soft starter

4 Start directly on mains

Illustration 2.5 Start-up Current

Page 19

Product Overview Design Guide

2.2 Description of Operation

The frequency converter supplies a regulated amount of

mains AC power to the motor to control its speed. The

frequency converter supplies variable frequency and

voltage to the motor.

The frequency converter is divided into 4 main modules:

Rectier

•

Intermediate DC bus circuit

•

Inverter

•

Control and regulation

•

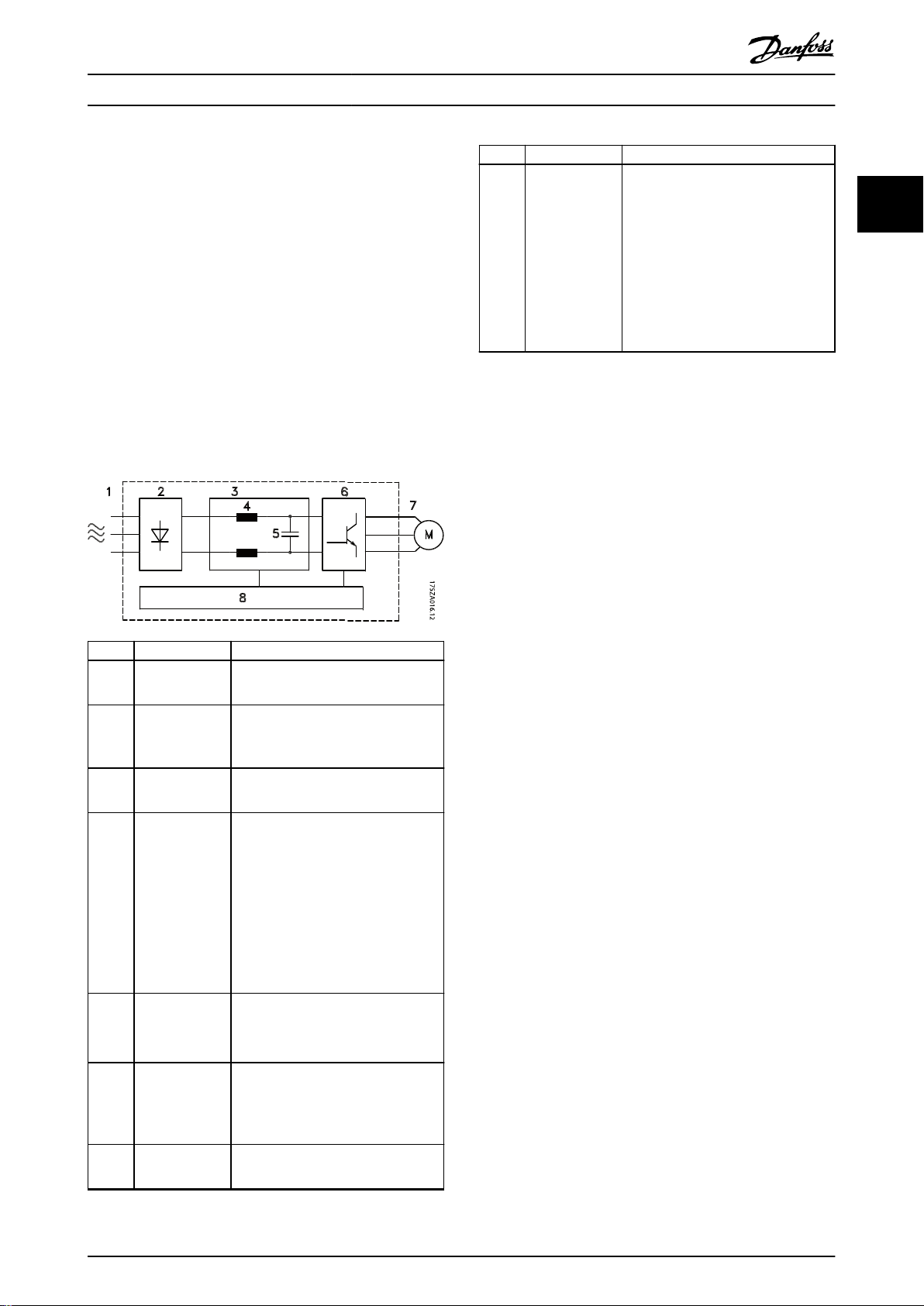

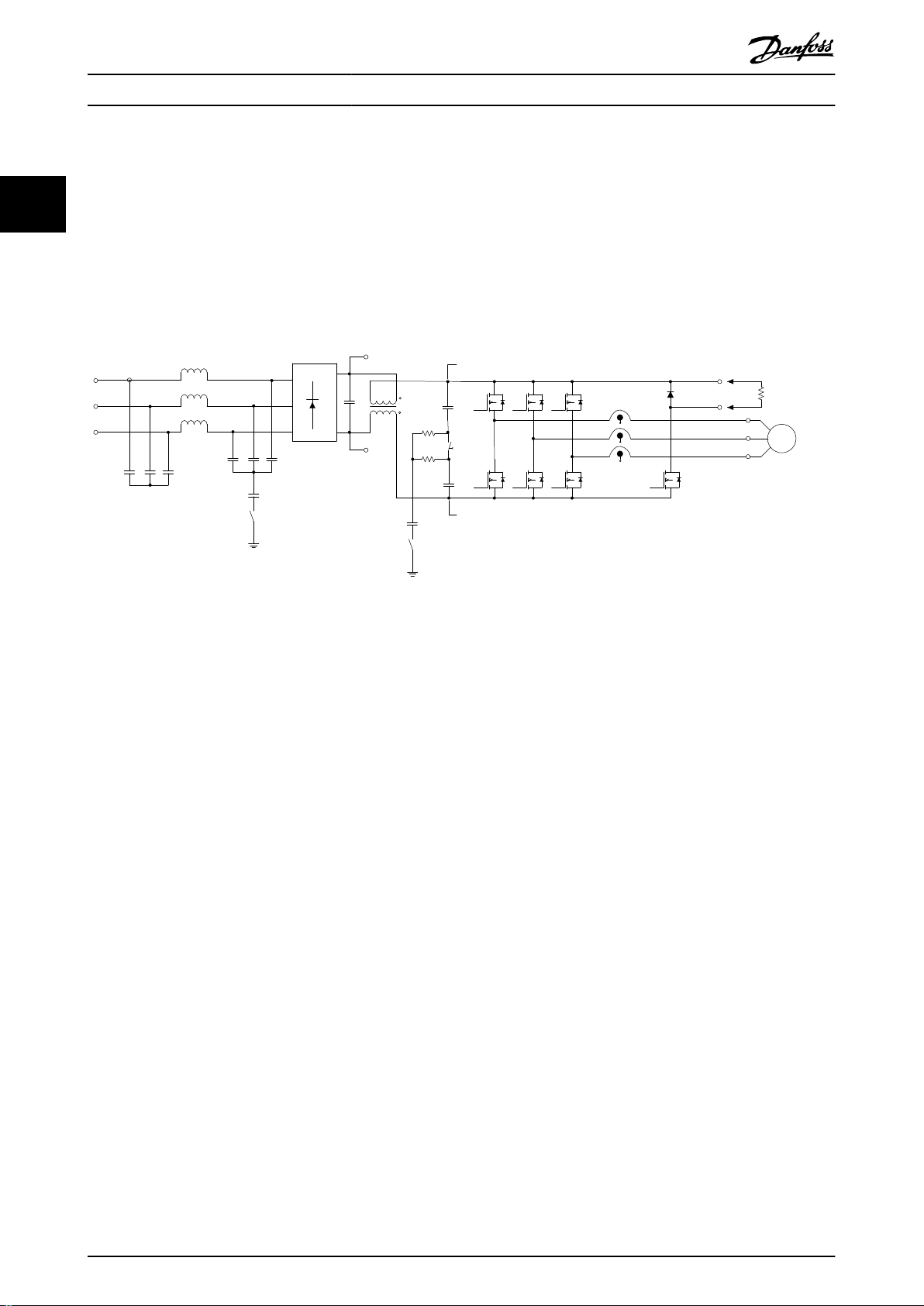

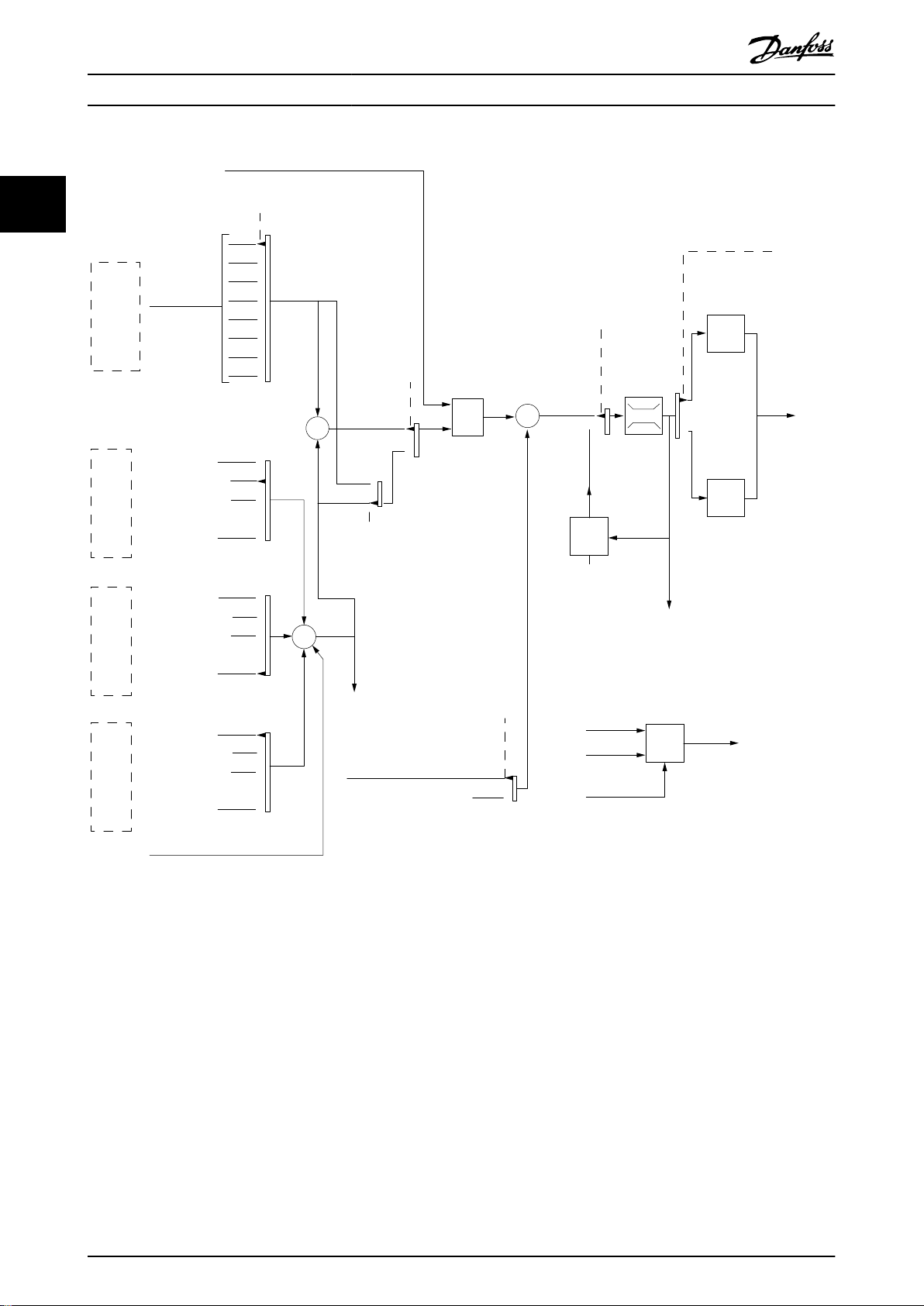

Illustration 2.6 is a block diagram of the internal

components of the frequency converter.

Area Title Functions

Input power, internal processing,

•

output, and motor current are

monitored to provide ecient

operation and control.

User interface and external

8 Control circuitry

Illustration 2.6 Frequency Converter Block Diagram

•

commands are monitored and

performed.

Status output and control can be

•

provided.

2 2

Area Title Functions

3-phase AC mains supply to the

1 Mains input

2 Rectier

3 DC bus

4 DC reactors

5 Capacitor bank

6 Inverter

7 Output to motor

•

frequency converter.

The rectier bridge converts the

•

AC input to DC current to supply

inverter power.

Intermediate DC bus circuit

•

handles the DC current.

Filter the intermediate DC circuit

•

voltage.

Prove mains transient protection.

•

Reduce RMS current.

•

Raise the power factor reected

•

back to the line.

Reduce harmonics on the AC

•

input.

Stores the DC power.

•

Provides ride-through protection

•

for short power losses.

Converts the DC into a controlled

•

PWM AC waveform for a

controlled variable output to the

motor.

Regulated 3-phase output power

•

to the motor.

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 17

Page 20

Inrush

R inr

Load sharing -

Load sharing +

LC Filter (5A)

LC Filter +

(5A)

Brake

Resistor

130BA193.14

M

L2 92

L1 91

L3 93

89(+)

88(-)

R+

82

R81

U 96

V 97

W 98

P 14-50 R Filter

Product Overview

VLT® Refrigeration Drive FC 103

2.2.1 Control Structure Principle

speed control of 3-phased, standard asynchronous motors

and non-salient PM motors.

The frequency converter recties AC voltage from

22

•

mains into DC voltage.

The DC voltage is converted into an AC current

•

with a variable amplitude and frequency.

The frequency converter manages various motor control

principles such as U/f special motor mode and VVC+. Shortcircuit behaviour of the frequency converter depends on

the 3 current transducers in the motor phases.

The frequency converter supplies the motor with variable

voltage/current and frequency, which enables variable

Illustration 2.7 Frequency Converter Structure

2.3 Sequence of Operation

2.3.1 Rectier Section

When power is applied to the frequency converter, it

enters through the mains terminals (L1, L2, and L3).

Depending on the unit

conguration, the power moves on

to the disconnect and/or RFI lter option.

2.3.2 Intermediate Section

Following the rectier section, voltage passes to the

intermediate section. A lter circuit consisting of the DC

bus inductor and the DC bus capacitor bank smoothes the

rectied voltage.

The DC bus inductor provides series impedance to

changing current. This aids the ltering process while

reducing harmonic distortion to the input AC current

waveform normally inherent in rectier circuits.

2.3.3 Inverter Section

In the inverter section, once a run command and speed

reference are present, the IGBTs begin switching to create

the output waveform. This waveform, as generated by the

Danfoss VVC+ PWM principle at the control card, provides

optimal performance and minimal losses in the motor.

18 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 21

130BB153.10

100%

0%

-100%

100%

P 3-13

Reference

site

Local

reference

scaled to

RPM or Hz

Auto mode

Hand mode

LCP Hand on,

o and auto

on keys

Linked to hand/auto

Local

Remote

Reference

Ramp

P 4-10

Motor speed

direction

To motor

control

Reference

handling

Remote

reference

P 4-13

Motor speed

high limit [RPM]

P 4-14

Motor speed

high limit [Hz]

P 4-11

Motor speed

low limit [RPM]

P 4-12

Motor speed

low limit [Hz]

P 3-4* Ramp 1

P 3-5* Ramp 2

P 20-81

PID Normal/Inverse

Control

PID

Ref.

Handling

Feedback

Handling

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

(Illustration)

(Illustration)

130BA359.12

100%

0%

-100%

100%

*[-1]

_

+

Product Overview Design Guide

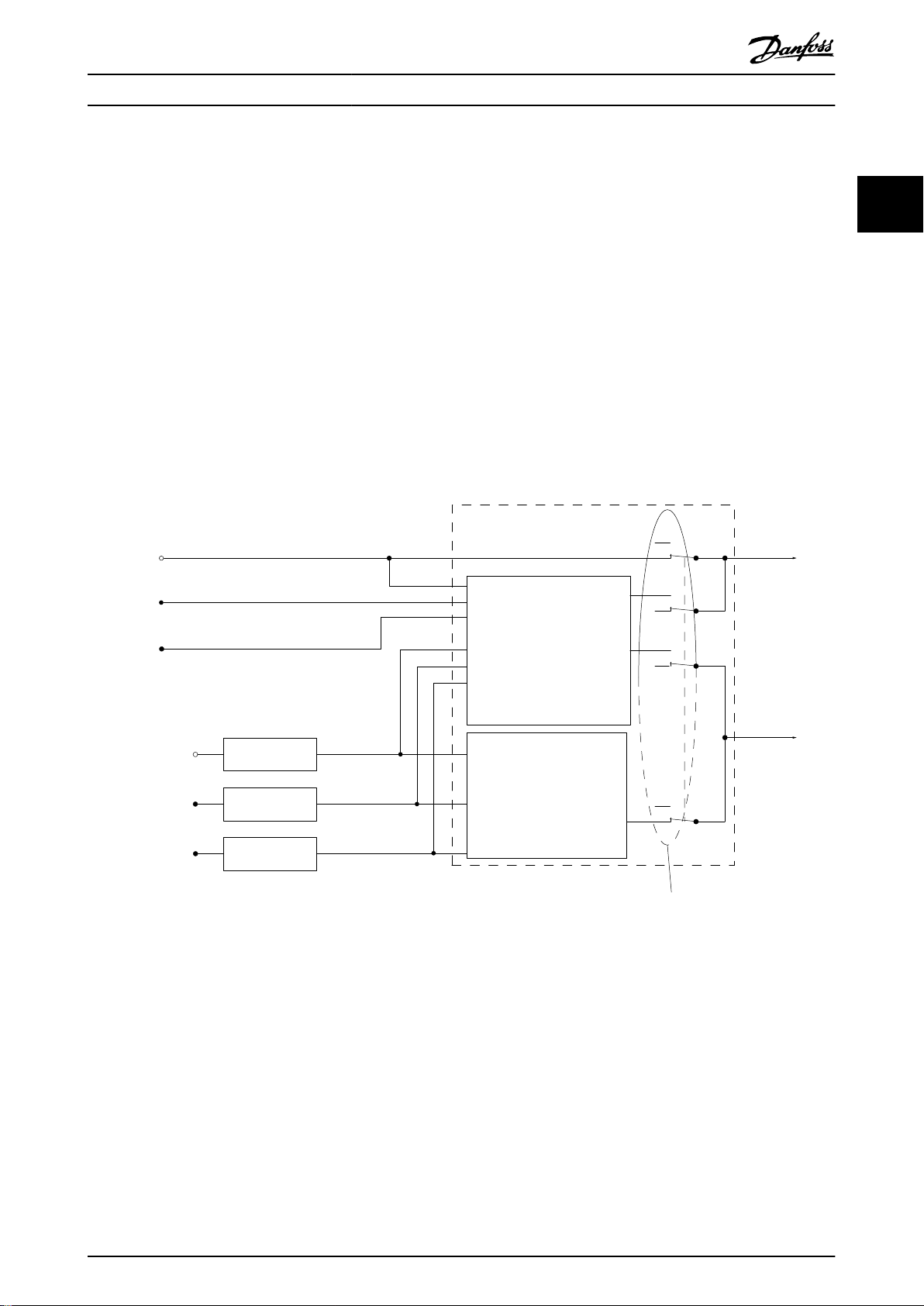

2.4 Control Structures

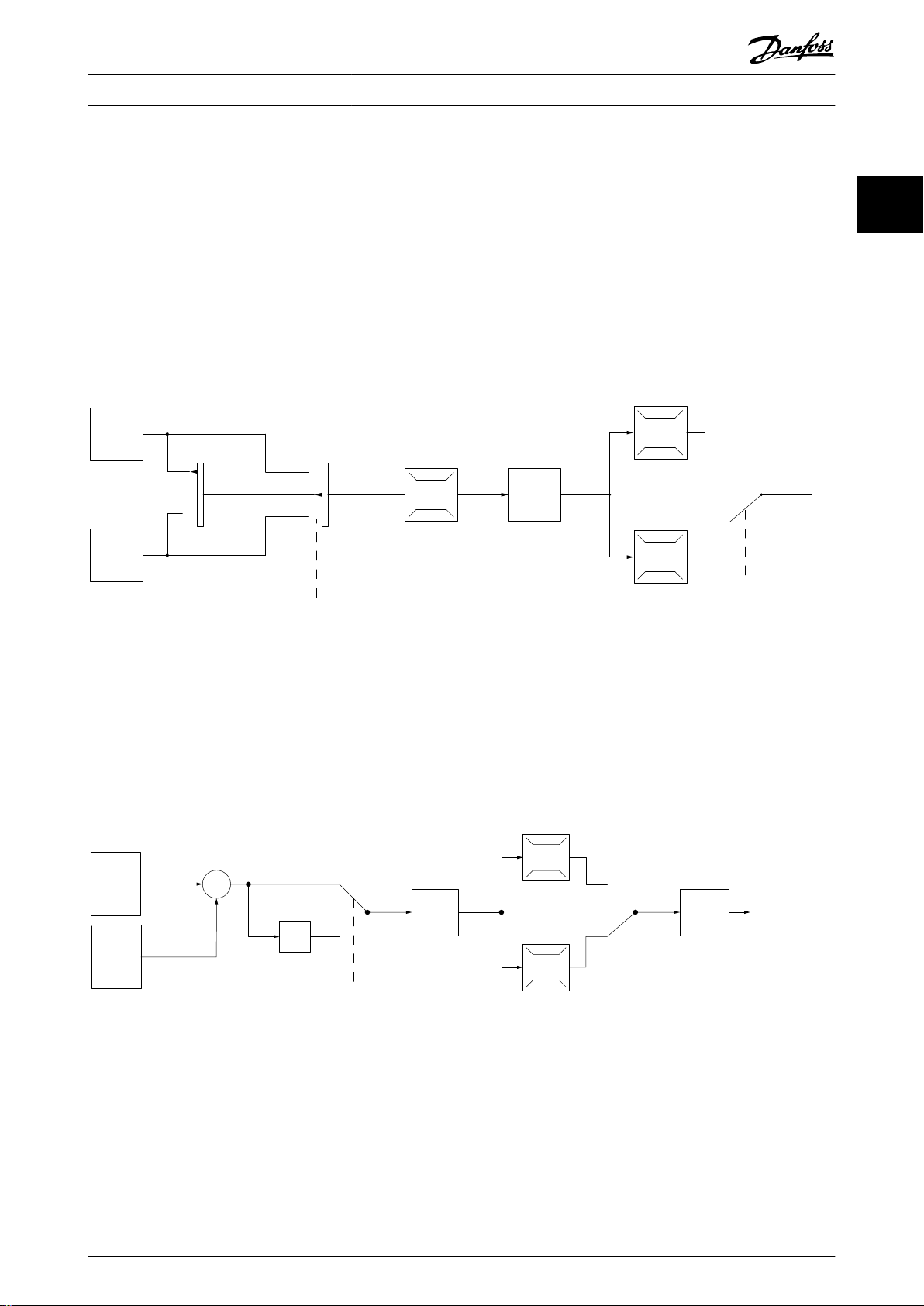

2.4.1 Control Structure Open Loop

When operating in open-loop mode, the frequency

converter responds to input commands manually via the

LCP keys or remotely via the analog/digital inputs or serial

bus.

In the conguration shown in Illustration 2.8, the frequency

converter operates in open-loop mode. It receives input

from either the LCP (Hand mode) or via a remote signal

(Auto mode). The signal (speed reference) is received and

conditioned with the following:

Programmed minimum and maximum motor

•

speed limits (in RPM and Hz).

Ramp-up and ramp-down times.

•

Motor rotation direction.

•

The reference is then passed on to control the motor.

2 2

Illustration 2.8 Block Diagram of Open-loop Mode

2.4.2 Control Structure Closed Loop

frequency converter can provide status and alarm

messages, along with many other programmable options,

In closed-loop mode, an internal PID controller allows the

frequency converter to process system reference and

for external system monitoring while operating

independently in closed loop.

feedback signals to act as an independent control unit. The

Illustration 2.9 Block Diagram of Closed-loop Controller

For example, consider a pump application in which the

speed of a pump is controlled so that the static pressure in

a pipe is constant (see Illustration 2.9). The frequency

converter receives a feedback signal from a sensor in the

system. It compares this feedback to a setpoint reference

value and determines the error, if any, between these 2

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 19

signals. It then adjusts the speed of the motor to correct

this error.

The static pressure setpoint is the reference signal to the

frequency converter. A static pressure sensor measures the

actual static pressure in the pipe and provides this

Page 22

Remote

reference

Local

reference

Auto mode

Hand mode

Linked to hand/auto

Local

Remote

Reference

130BA245.11

LCP Hand on,

o and auto

on keys

P 3-13

Reference site

130BD893.10

open loop

Scale to

RPM or

Hz

Scale to

closed loop

unit

closed loop

Local

ref.

Local

reference

Conguration

mode

P 1-00

Product Overview

VLT® Refrigeration Drive FC 103

information to the frequency converter as a feedback

signal. If the feedback signal exceeds the setpoint

reference, the frequency converter ramps down to reduce

22

the pressure. Similarly, if the pipe pressure is lower than

the setpoint reference, the frequency converter ramps up

to increase the pump pressure.

While the default values for the frequency converter in

closed loop often provide satisfactory performance, system

control can often be optimised by tuning the PID

parameters. Auto tuning is provided for this optimisation.

Other programmable features include:

Inverse regulation - motor speed increases when

•

a feedback signal is high. This is useful in

compressor applications, where speed needs to

be increased if the pressure/temperarure is too

high.

Start-up frequency - lets the system quickly reach

•

an operating status before the PID controller

takes over.

Built-in lowpass lter - reduces feedback signal

•

noise.

2.4.3 Local (Hand On) and Remote (Auto

On) Control

Operate the frequency converter manually via the LCP, or

remotely via analog and digital inputs, and serial bus.

Active reference and conguration mode

The active reference is either a local reference or a remote

reference. Remote reference is the default setting.

To use the local reference, congure in Hand

•

mode. To enable Hand mode, adapt parameter

settings in parameter group 0–4* LCP Keypad. For

more information, refer to the programming

guide.

To use the remote reference, congure in Auto

•

mode, which is the default mode. In Auto mode,

it is possible to control the frequency converter

via the digital inputs and various serial interfaces

(RS485, USB, or an optional eldbus).

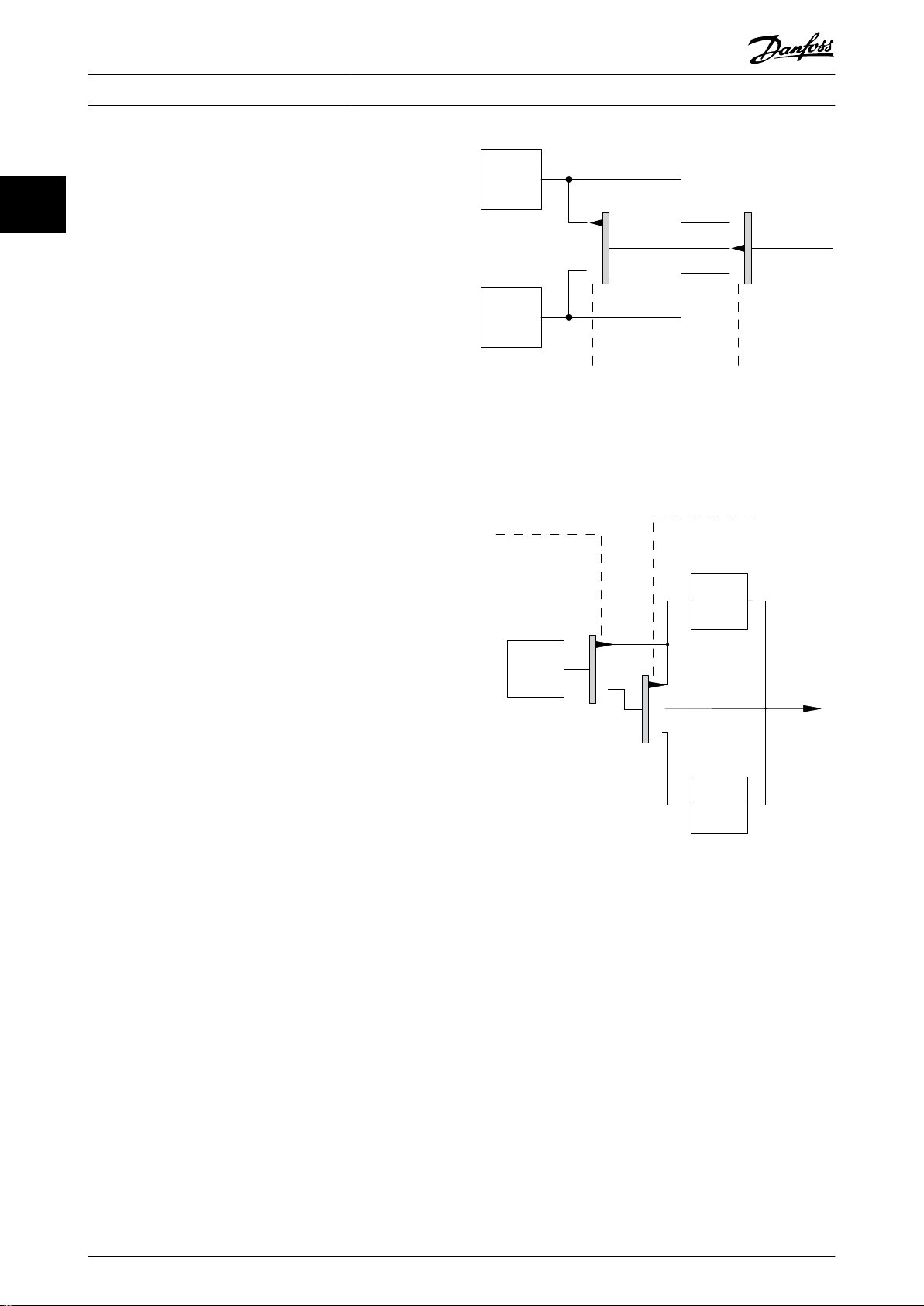

Illustration 2.10 shows the conguration mode

•

resulting from active reference selection, either

local or remote.

Illustration 2.11 shows manual conguration mode

•

for local reference.

Illustration 2.10 Active Reference

Illustration 2.11 Manual Conguration Mode

Application control principle

Either the remote reference or the local reference is active

at any time. Both cannot be active simultaneously. Set the

application control principle (that is, open loop or closed

loop) in parameter 1-00 Conguration Mode, as shown in

Table 2.3.

When the local reference is active, set the application

control principle in parameter 1-05 Local Mode Congu-

ration.

Set the reference site in parameter 3-13 Reference Site, as

shown in Table 2.3.

For more information, refer to the programming guide.

20 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 23

Product Overview Design Guide

[Hand On]

[Auto On]

LCP Keys

Hand Linked to Hand/Auto Local

Hand⇒O

Auto Linked to Hand/Auto Remote

Auto⇒O

All keys Local Local

All keys Remote Remote

Table 2.3 Local and Remote Reference Congurations

Parameter 3-13 Reference

Site

Linked to Hand/Auto Local

Linked to Hand/Auto Remote

Active Reference

2.4.4 Reference Handling

Reference handling is applicable in both open- and closedloop operation.

Internal and external references

Up to 8 internal preset references can be programmed into

the frequency converter. The active internal preset

reference can be selected externally through digital control

inputs or the serial communications bus.

External references can also be supplied to the frequency

converter, most commonly through an analog control

input. All reference sources and the bus reference are

added to produce the total external reference. As active

reference select one of the following:

The external reference

•

The preset reference

•

The setpoint

•

The sum of all the above 3

•

The active reference can be scaled.

The scaled reference is calculated as follows:

Reference = X + X ×

Where X is the external reference, the preset reference, or

the sum of these references, and Y is parameter 3-14 Preset

Relative Reference in [%].

If Y, parameter 3-14 Preset Relative Reference, is set to 0%,

the scaling does not aect the reference.

Remote reference

A remote reference is comprised of the following (see

Illustration 2.12):

Preset references

•

External references:

•

- Analog inputs

- Pulse frequency inputs

- Digital potentiometer inputs

- Serial communication bus references

A preset relative reference

•

A feedback controlled setpoint

•

Y

100

2 2

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 21

Page 24

Preset relative ref.

Preset ref.Ref. 1 source

Ext. closed loop outputs

No function

Analog inputs

Frequency inputs

No function

No function

Freeze ref.

Speed up/ speed down

ref.

Remote

Ref. in %

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Open loop

Freeze ref.

&

increase/

decrease

ref.

Scale to

RPM,Hz

or %

Scale to

Closed

loop

unit

Relative

X+X*Y

/100

DigiPot

DigiPot

DigiPot

max ref.

min ref.

[0]

on

o

Conguration mode

Closed loop

Input command:

Ref. function

Ref. Preset

Input command:

Preset ref. bit0, bit1, bit2

External

reference

in %

Bus

reference

Open loop

From Feedback Handling

Setpoint

Conguration mode

Input command:

Input command:

Digipot ref.

Increase

Decrease

Clear

DigiPot

Closed loop

Ref. 2 sourceRef. 3 source

Analog inputs

Frequency inputs

Analog inputs

Frequency inputs

Ext. closed loop outputs

Ext. closed loop outputs

P 3-10P 3-15P 3-16P 3-17

Y

X

%

%

P 1-00

P 3-14

±100%

130BA357.12

P 3-04

±200%

±200%

±200%

0%

±200%

P 1-00

±200%

0/1

0/1

0/1

Product Overview

VLT® Refrigeration Drive FC 103

22

Illustration 2.12 Remote Reference Handling

22 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 25

Setpoint 1

P 20-21

Setpoint 2

P 20-22

Setpoint 3

P 20-23

Feedback 1 Source

P 20-00

Feedback 2 Source

P 20-03

Feedback 3 Source

P 20-06

Feedback conv.

P 20-01

Feedback conv.

P 20-04

Feedback conv.

P 20-07

Feedback 1

Feedback 2

Feedback 3

Feedback

Feedback Function

P 20-20

Multi setpoint min.

Multi setpoint max.

Feedback 1 only

Feedback 2 only

Feedback 3 only

Sum (1+2+3)

Dierence (1-2)

Average (1+2+3)

Minimum (1|2|3)

Maximum (1|2|3)

Setpoint to

Reference

Handling

0%

0%

0%

0%

130BA354.12

Product Overview Design Guide

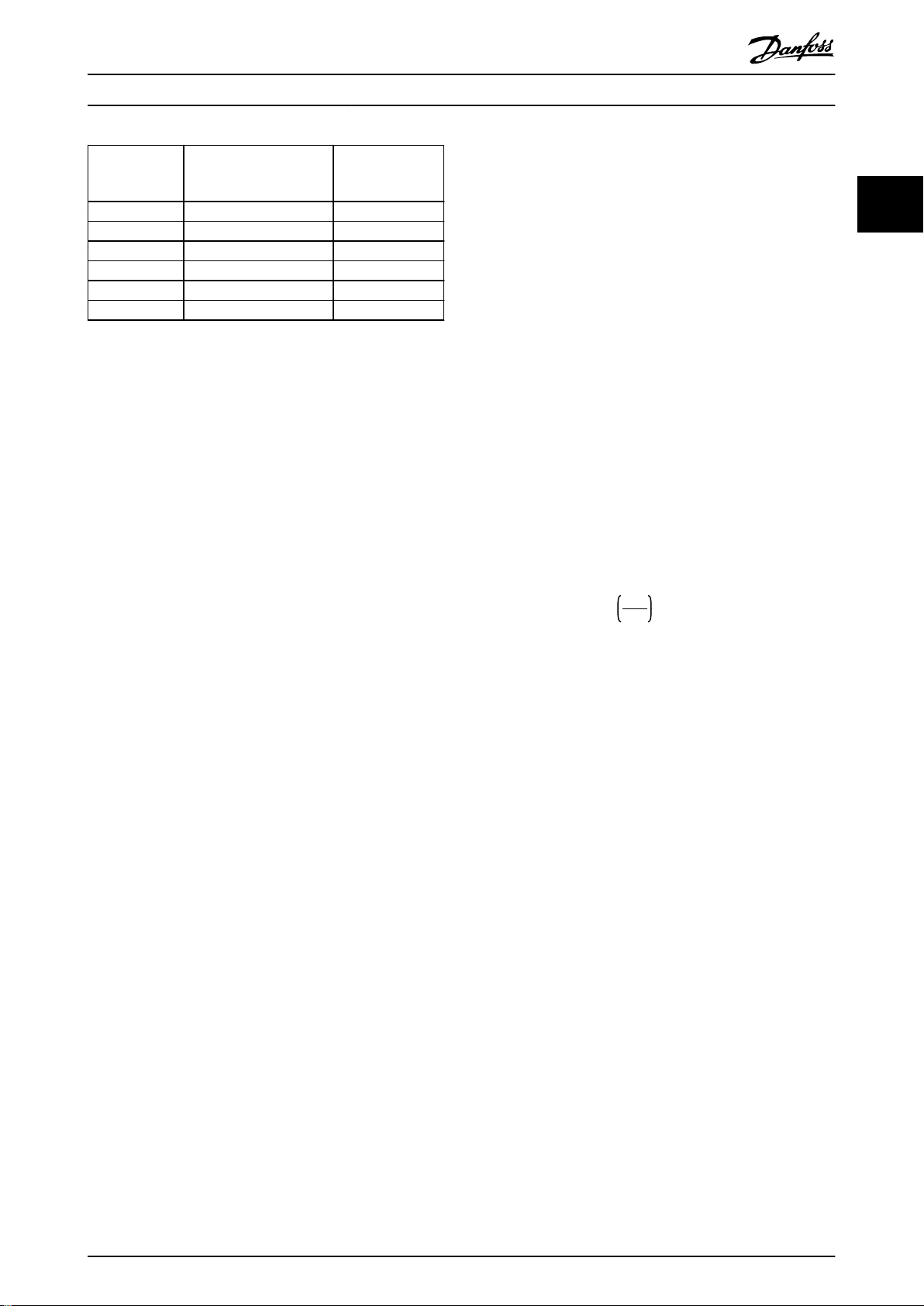

2.4.5 Feedback Handling

Feedback handling can be congured to work with

applications requiring advanced control, such as multiple

setpoints and multiple types of feedback (see

Illustration 2.13.

3 types of control are common:

Single zone, single setpoint

This control type is a basic feedback

Setpoint 1 is added to any other reference (if any) and the

feedback signal is selected.

Multi-zone, single setpoint

This control type uses 2 or 3 feedback sensors but only 1

setpoint. The feedback can be added, subtracted, or

averaged. In addition, the maximum or minimum value can

be used. Setpoint 1 is used exclusively in this congu-

ration.

conguration.

Multi-zone, setpoint/feedback

The setpoint/feedback pair with the largest dierence

controls the speed of the frequency converter. The

maximum attempts to keep all zones at or below their

respective setpoints, while minimum attempts to keep all

zones at or above their respective setpoints.

Example

A 2-zone, 2-setpoint application. Zone 1 setpoint is 15 bar,

and the feedback is 5.5 bar. Zone 2 setpoint is 4.4 bar, and

the feedback is 4.6 bar. If maximum is selected, the zone 2

setpoint and feedback are sent to the PID controller, since

it has the smaller dierence (feedback is higher than

setpoint, resulting in a negative dierence). If minimum is

selected, the zone 1 setpoint and feedback is sent to the

PID controller, since it has the larger dierence (feedback is

lower than setpoint, resulting in a positive dierence).

2 2

Illustration 2.13 Block Diagram of Feedback Signal Processing

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 23

Page 26

+

-

PID

P

P

P

130BA358.11

Ref.

signal

Desired

ow

P 20-07

FB conversion

Ref.

FB

Flow

FB

signal

Flow

P 20-04

P 20-01

Product Overview

VLT® Refrigeration Drive FC 103

Feedback conversion

In some applications, it is useful to convert the feedback

signal. One example is using a pressure signal to provide

22

ow feedback. Since the square root of pressure is proportional to ow, the square root of the pressure signal yields

a value proportional to the ow, see Illustration 2.14.

Illustration 2.14 Feedback Conversion

2.5 Automated Operational Functions

Automated operational features are active as soon as the

frequency converter is operating. Most of them require no

programming or set-up. Understanding that these features

are present can optimise a system design and possibly

avoid introducing redundant components or functionality.

For details of any set-up required, in particular motor

parameters, refer to the programming guide.

The frequency converter has a range of built-in protection

functions to protect itself and the motor when it runs.

2.5.1 Short-circuit Protection

2.5.2 Overvoltage Protection

Motor-generated overvoltage

When the motor acts as a generator, the voltage in the DC

link increases. This behaviour occurs in the following cases:

The load drives the motor (at constant output

•

frequency from the frequency converter), for

example, the load generates energy.

During deceleration (ramp down) with high

•

inertia moment, low friction, and a too short

ramp-down time for the energy to be dissipated

as a loss in the frequency converter, the motor,

and the installation.

Incorrect slip compensation setting may cause

•

higher DC-link voltage.

Back EMF from PM motor operation. If coasted at

•

high RPM, the PM motor back EMF may

potentially exceed the maximum voltage

tolerance of the frequency converter and cause

damage. To prevent this situation, the value of

parameter 4-19 Max Output Frequency is automatically limited via an internal calculation based on

the value of parameter 1-40 Back EMF at 1000

RPM, parameter 1-25 Motor Nominal Speed, and

parameter 1-39 Motor Poles.

NOTICE

To avoid motor overspeeding (for example due to

excessive windmilling eects or uncontrolled water ow),

equip the frequency converter with a brake resistor.

Handle the overvoltage by either using a brake function

(parameter 2-10 Brake Function) or using overvoltage

control (parameter 2-17 Over-voltage Control).

Motor (phase-phase)

The frequency converter is protected against short circuits

on the motor side by current measurement in each of the

motor phases or in the DC link. A short circuit between 2

output phases causes an overcurrent in the inverter. The

inverter is turned o when the short-circuit current

exceeds the permitted value (Alarm 16, Trip Lock).

Mains side

A frequency converter that works correctly limits the

current it can draw from the supply. Use fuses and/or

circuit breakers on the supply side as protection in case of

component break-down inside the frequency converter

(rst fault). See chapter 7.8 Fuses and Circuit Breakers for

more information.

NOTICE

To ensure compliance with IEC 60364 for CE or NEC 2009

for UL, it is mandatory to use fuses and/or circuit

breakers.

24 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Overvoltage control (OVC)

OVC reduces the risk of the frequency converter tripping

due to an overvoltage on the DC-link. This is managed by

automatically extending the ramp-down time.

NOTICE

OVC can be activated for PM motors (PM VVC+).

2.5.3 Missing Motor Phase Detection

The missing motor phase function (parameter 4-58 Missing

Motor Phase Function) is enabled by default to avoid motor

damage in the case that a motor phase is missing. The

default setting is 1000 ms, but it can be adjusted for a

faster detection.

Page 27

Product Overview Design Guide

2.5.4 Mains Phase Imbalance Detection

Operation under severe mains imbalance conditions

reduces the lifetime of the motor. If the motor is operated

continuously near nominal load, conditions are considered

severe. The default setting trips the frequency converter in

case of mains imbalance (parameter 14-12 Function at

Mains Imbalance).

2.5.5 Switching on the Output

Adding a switch to the output between the motor and the

frequency converter is permitted. Fault messages may

appear. To catch a spinning motor, enable ying start.

2.5.6 Overload Protection

Torque limit

The torque limit feature protects the motor against

overload, independent of the speed. Torque limit is

controlled in parameter 4-16 Torque Limit Motor Mode or

parameter 4-17 Torque Limit Generator Mode, and the time

before the torque limit warning trips is controlled in

parameter 14-25 Trip Delay at Torque Limit.

Current limit

The current limit is controlled in parameter 4-18 Current

Limit.

Speed limit

Dene lower and upper limits for the operating speed

range using 1 or more of the following parameters:

Parameter 4-11 Motor Speed Low Limit [RPM].

•

Parameter 4-12 Motor Speed Low Limit [Hz] and

•

parameter 4-13 Motor Speed High Limit [RPM].

Parameter 4-14 Motor Speed High Limit [Hz].

•

For example, the operating speed range can be dened as

between 30 and 50/60 Hz.

Parameter 4-19 Max Output Frequency limits the maximum

output speed the frequency converter can provide.

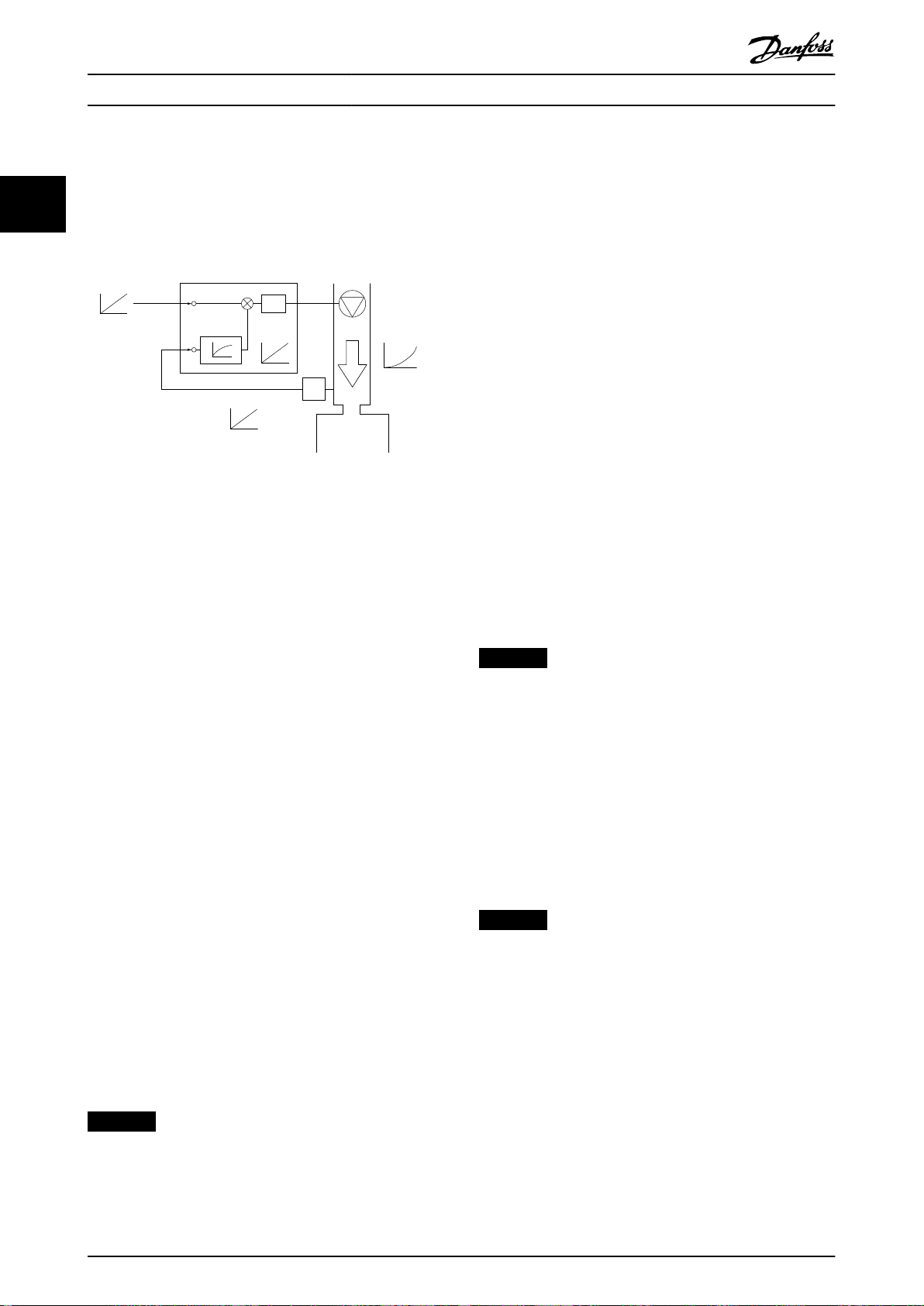

ETR

ETR is an electronic feature that simulates a bimetal relay

based on internal measurements. The characteristic is

shown in Illustration 2.15.

Voltage limit

When a certain hard-coded voltage level is reached, the

frequency converter turns o to protect the transistors and

the DC link capacitors.

Overtemperature

The frequency converter has built-in temperature sensors

and reacts immediately to critical values via hard-coded

limits.

2.5.7 Automatic Derating

The frequency converter constantly checks for critical

levels:

High temperature on the control card or heat sink

•

High motor load

•

High DC-link voltage

•

Low motor speed

•

As a response to a critical level, the frequency converter

adjusts the switching frequency. For high internal temperatures and low motor speed, the frequency converters can

also force the PWM pattern to SFAVM.

NOTICE

The automatic derating is dierent when

parameter 14-55 Output Filter is set to [2] Sine-Wave Filter

Fixed.

2.5.8 Automatic Energy Optimisation

Automatic energy optimisation (AEO) directs the frequency

converter to monitor the load on the motor continuously

and adjust the output voltage to maximise eciency.

Under light load, the voltage is reduced and the motor

current is minimised. The motor benets from:

Increased eciency.

•

Reduced heating.

•

Quieter operation.

•

There is no need to select a V/Hz curve because the

frequency converter automatically adjusts motor voltage.

2.5.9 Automatic Switching Frequency

Modulation

The frequency converter generates short electrical pulses

to form an AC wave pattern. The switching frequency is

the rate of these pulses. A low switching frequency (slow

pulsing rate) causes audible noise in the motor, making a

higher switching frequency preferable. A high switching

frequency, however, generates heat in the frequency

converter which can limit the amount of current available

to the motor.

Automatic switching frequency modulation regulates these

conditions automatically to provide the highest switching

frequency without overheating the frequency converter. By

providing a regulated high switching frequency, it quiets

motor operating noise at slow speeds, when audible noise

control is critical, and produces full output power to the

motor when required.

2 2

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 25

Page 28

Product Overview

VLT® Refrigeration Drive FC 103

2.5.10 Automatic Derating for High

2.5.14 Power Fluctuation Performance

Switching Frequency

22

The frequency converter is designed for continuous, fullload operation at switching frequencies between 3.0 and

4.5 kHz (this frequency range depends on power size). A

switching frequency exceeding the maximum permissible

range generates increased heat in the frequency converter

and requires the output current to be derated.

An automatic feature of the frequency converter is loaddependent switching frequency control. This feature allows

the motor to

the load allow.

benet from as high a switching frequency as

2.5.11 Automatic Derating for

The frequency converter withstands mains uctuations

such as:

Transients.

•

Momentary drop-outs.

•

Short voltage drops.

•

Surges.

•

The frequency converter automatically compensates for

input voltages ±10% from the nominal to provide full rated

motor voltage and torque. With auto restart selected, the

frequency converter automatically powers up after a

voltage trip. With

synchronises to motor rotation before start.

ying start, the frequency converter

Overtemperature

Automatic overtemperature derating works to prevent

tripping the frequency converter at high temperature.

Internal temperature sensors measure conditions to protect

the power components from overheating. The frequency

converter can automatically reduce the switching

frequency to maintain the operating temperature within

safe limits. After reducing the switching frequency, the

frequency converter can also reduce the output frequency

and current by as much as 30% to avoid an overtemperature trip.

2.5.15 Motor Soft Start

The frequency converter supplies the right amount of

current to the motor to overcome load inertia and bring

the motor up to speed. This avoids full mains voltage

being applied to a stationary or slow-turning motor, which

generates high current and heat. This inherent soft start

feature reduces thermal load and mechanical stress,

extends motor life, and provides quieter system operation.

2.5.16 Resonance Damping

2.5.12 Auto Ramping

A motor trying to accelerate a load too quickly for the

current available can cause the frequency converter to trip.

The same is true for too quick a deceleration. Auto

ramping protects against these situations by extending the

motor ramping rate (acceleration or deceleration) to match

the available current.

2.5.13 Current Limit Circuit

When a load exceeds the current capability of the

frequency converter normal operation (from an undersized

frequency converter or motor), current limit reduces the

output frequency to ramp down the motor and reduce the

load. An adjustable timer is available to limit operation in

this condition for 60 s or less. The factory default limit is

110% of the rated motor current to minimise overcurrent

stress.

Eliminate high frequency motor resonance noise through

resonance damping. Automatic or manually selected

frequency damping is available.

2.5.17 Temperature-controlled Fans

Sensors in the frequency converter control the temperature

of the internal cooling fans. Often, the cooling fans do not

run during low load operation, or when in sleep mode or

standby. This reduces noise, increases eciency, and

extends the operating life of the fan.

2.5.18 EMC Compliance

Electromagnetic interference (EMI) or radio frequency

interference (RFI, in case of radio frequency) is disturbance

that can aect an electrical circuit due to electromagnetic

induction or radiation from an external source. The

frequency converter is designed to comply with the EMC

product standard for frequency converters IEC 61800-3 as

well as the European standard EN 55011. To comply with

the emission levels in EN 55011, screen and terminate the

motor cable properly terminated. For more information

regarding EMC performance, see chapter 3.2.2 EMC Test

Results (Emission).

26 Danfoss A/S © 08/2015 All rights reserved. MG16G202

Page 29

1.21.0 1.4

30

10

20

100

60

40

50

1.81.6 2.0

2000

500

200

400

300

1000

600

t [s]

175ZA052.12

f

OUT

= 2 x f

M,N

f

OUT

= 0.2 x f

M,N

f

OUT

= 1 x f

M,N

(par. 1-23)

IMN(par. 1-24)

I

M

Product Overview Design Guide

2.5.19 Current Measurement on All Three

Motor Phases

Output current to the motor is continuously measured on

all 3 phases to protect the frequency converter and motor

against short circuits, ground faults, and phase loss. Output

ground faults are instantly detected. If a motor phase is

lost, the frequency converter stops immediately and

reports which phase is missing.

2.5.20 Galvanic Isolation of Control

Terminals

All control terminals and output relay terminals are galvanically isolated from mains power. This means the controller

circuitry is completely protected from the input current.

The output relay terminals require their own grounding.

This isolation meets the stringent protective extra-low

voltage (PELV) requirements for isolation.

The components that make up the galvanic isolation are:

Power supply, including signal isolation.

•

Gate drive for the IGBTs, trigger transformers, and

•

optocouplers.

The output current Hall eect transducers.

•

2.6.2 Motor Thermal Protection

Motor thermal protection can be provided in 3 ways:

Via direct temperature sensing via the PTC sensor

•

in the motor windings and connected on a

standard AI or DI.

Mechanical thermal switch (Klixon type) on a DI.

•

Via the built-in electronic thermal relay (ETR) for

•

asynchronous motors.

ETR calculates motor temperature by measuring current,

frequency, and operating time. The frequency converter

shows the thermal load on the motor in percentage and

can issue a warning at a programmable overload setpoint.

Programmable options at the overload allow the frequency

converter to stop the motor, reduce output, or ignore the

condition. Even at low speeds, the frequency converter

meets I2t Class 20 electronic motor overload standards.

2 2

Custom Application Functions

2.6

Custom application functions are the most common

features programmed in the frequency converter for

enhanced system performance. They require minimum

programming or set-up. Understanding that these

functions are available can optimise the system design and

possibly avoid introducing redundant components or

functionality. See the programming guide for instructions

on activating these functions.

2.6.1 Automatic Motor Adaptation

Automatic motor adaptation (AMA) is an automated test

procedure used to measure the electrical characteristics of

the motor. AMA provides an accurate electronic model of

the motor. It allows the frequency converter to calculate

optimal performance and eciency with the motor.

Running the AMA procedure also maximises the automatic

energy optimisation feature of the frequency converter.

AMA is performed without the motor rotating and without

uncoupling the load from the motor.

MG16G202 Danfoss A/S © 08/2015 All rights reserved. 27

Illustration 2.15 ETR Characteristics

The X-axis in Illustration 2.15 shows the ratio between I

and I

before the ETR cuts o and trips the frequency converter.

The curves show the characteristic nominal speed, at twice

the nominal speed and at 0.2 x the nominal speed.

At lower speed, the ETR cuts o at lower heat due to less

cooling of the motor. In that way, the motor is protected

from being overheated even at low speed. The ETR feature

calculates the motor temperature based on actual current

and speed. The calculated temperature is visible as a

readout parameter in parameter 16-18 Motor Thermal.

nominal. The Y-axis shows the time in seconds

motor

2.6.3 Mains Drop-out

During a mains drop-out, the frequency converter keeps

running until the DC-link voltage drops below the

minimum stop level. The minimum stop level is typically

15% below the lowest rated supply voltage. The mains

motor

Page 30

Product Overview

VLT® Refrigeration Drive FC 103

voltage before the drop-out and the motor load

determines how long it takes for the frequency converter

to coast.

22

Congure the frequency converter(parameter 14-10 Mains

Failure) to dierent types of behaviour during mains drop-

out,

Trip lock once the DC link is exhausted.

•

Coast with ying start whenever mains return

•

(parameter 1-73 Flying Start).

Kinetic back-up.

•

Controlled ramp down.

•

Flying start

This selection makes it possible to catch a motor that spins

freely due to a mains drop-out. This option is relevant for

centrifuges and fans.

Kinetic back-up

This selection ensures that the frequency converter runs as

long as there is energy in the system. For short mains

drop-out, the operation is restored after mains return,

without bringing the application to a stop or losing control

at any time. Several variants of kinetic back-up can be

selected.

Congure the behaviour of the frequency converter at

mains drop-out, in parameter 14-10 Mains Failure and

parameter 1-73 Flying Start.

NOTICE

Coast is recommended for compressors as the inertia is