12

1

2

4

3

5

6

7

1

12

8

8

8 8

2

9

10

10

11

FBH

TWA-K

Data Sheet

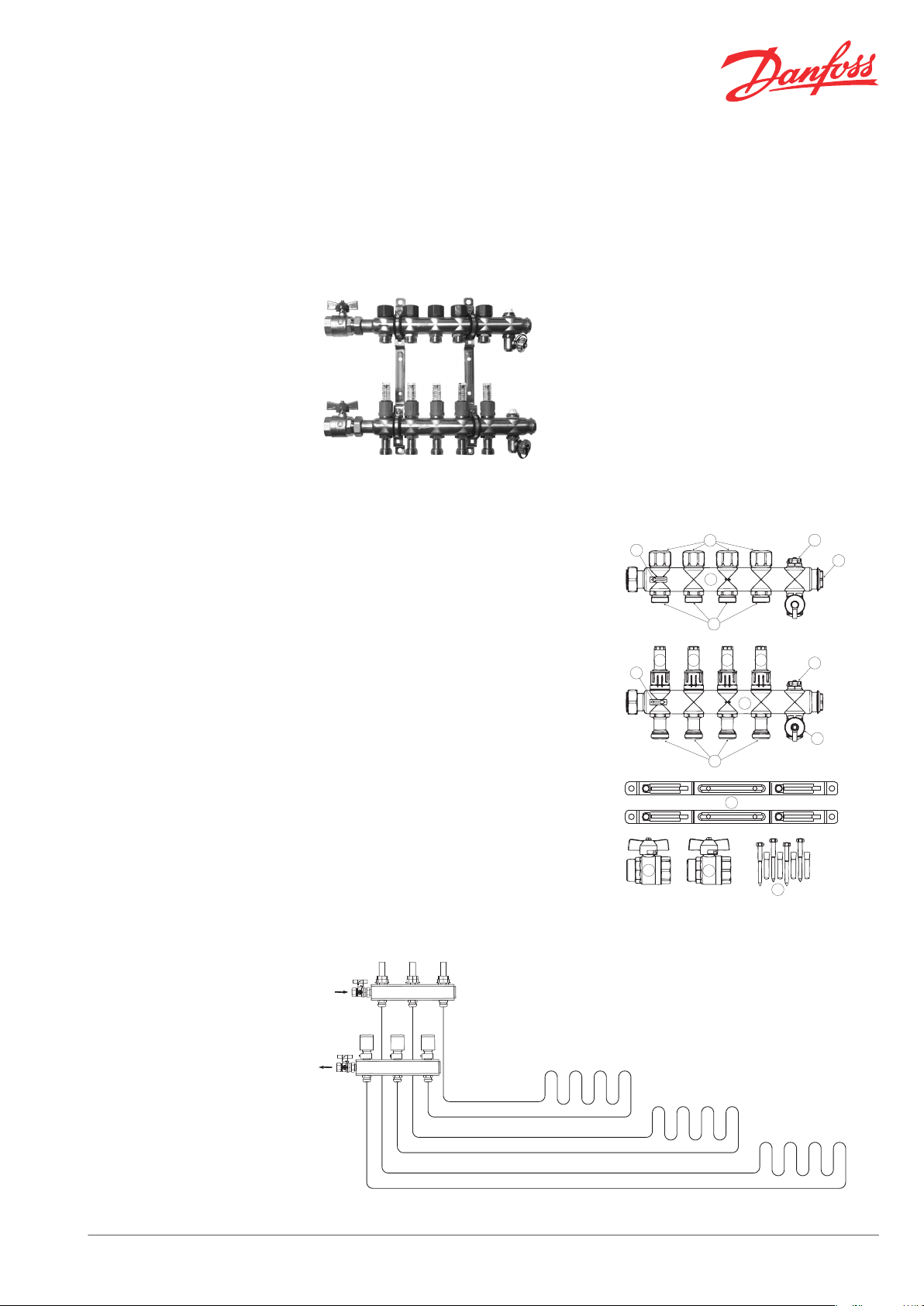

FBH Floor Heating Manifold

Application

The FBH floor heating manifold is used for controlling the water flow in floor heating systems.

Each string of the floor heating system is connected to the manifold, thus making it possible to

control water flow or heat supply for each room

individually.

The FBH range includes manifolds from 2 to 12

outlets.

FBH floor heating manifolds are supplied with all

necessary parts included:

1 supply manifold with flowmeter and possi-

▪

bility for individual shut-off of each circuit

1 return manifold

▪

2 ball valves

▪

2 brackets with screws and plugs

▪

The manifold valves can be controlled electronically by TWA-K thermal actuators or act as selfacting units by means of remote temperature adjusters, either by using CF2 or wired system.

Scope of Delivery

1.

Manifold body, stainless steel

2. Air-vent valve

3.

Cap on regulation valve M30x1.5 mm

4. 1” plug

5. Euro cone

6. Drain valve

7. Brackets

8. Flowmeter

9. Euro cone

10. Flow mark

11. Fastener set

12. 1” ball valves, 2 pcs., incl. flat packing

System Layout

Danfoss Heating Solutions VDUDR302 © Danfoss 08/2012 1

Data Sheet FBH Floor Heating Manifold

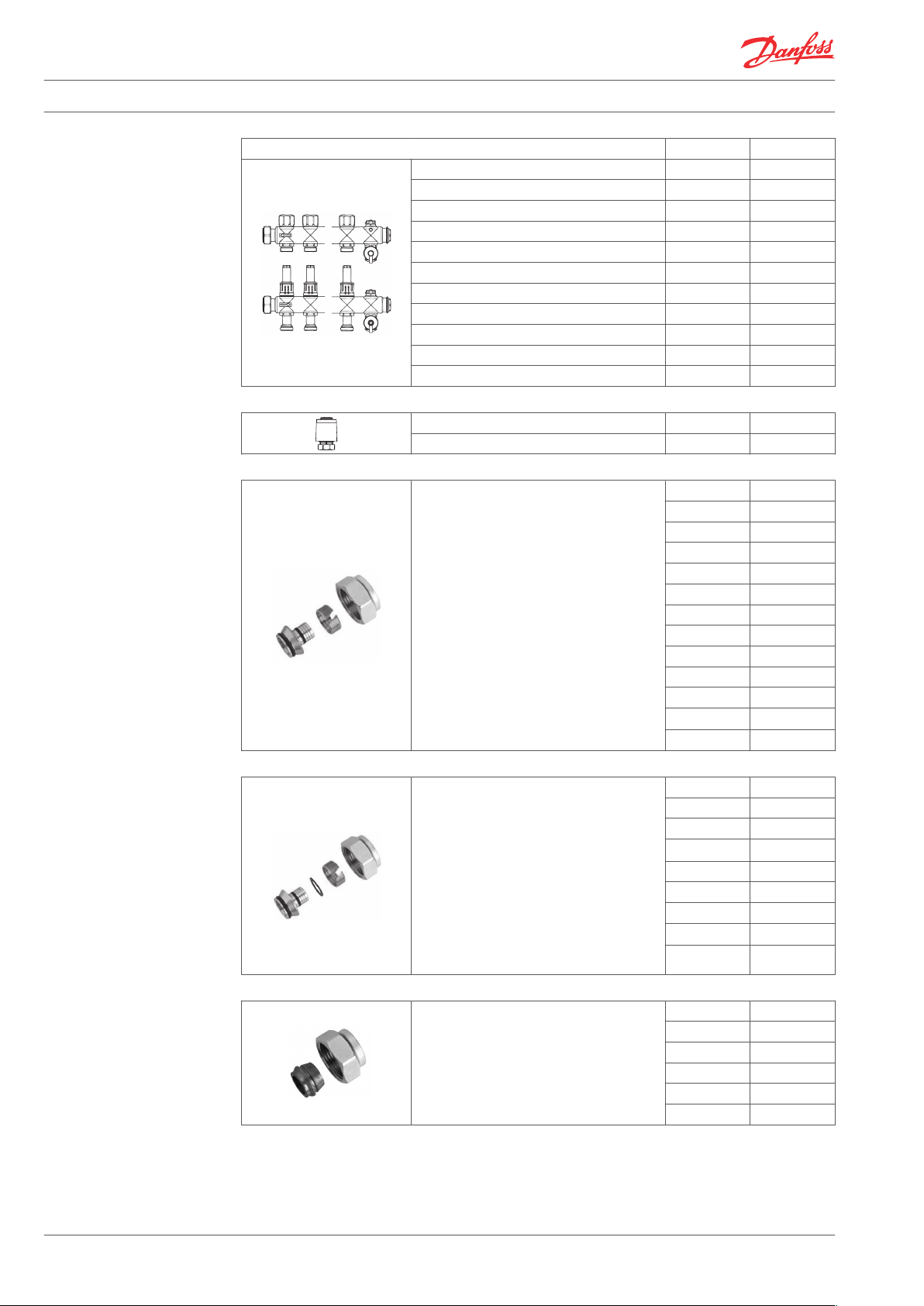

Ordering

Product Description Type/Size Code no.

FBH Manifold 2+2, stainless steel FBH-2F 088X0302

FBH Manifold 3+3, stainless steel FBH-3F 088X0303

FBH Manifold 4+4, stainless steel FBH-4F 088X0304

FBH Manifold 5+5, stainless steel FBH-5F 088X0305

FBH Manifold 6+6, stainless steel FBH-6F 088X0306

FBH Manifold 7+7, stainless steel FBH-7F 088X0307

FBH Manifold 8+8, stainless steel FBH-8F 088X0308

FBH Manifold 9+9, stainless steel FBH-9F 088X0309

FBH Manifold 10+10, stainless steel FBH-10F 088X0310

FBH Manifold 11+11, stainless steel FBH-11F 088X0311

FBH Manifold 12+12, stainless steel FBH-12F 088X0312

Thermal actuator - 24 V - NC TWA-K 088H3140

Thermal actuator - 230 V - NC TWA-K 088H3142

12x2 mm 013G4152

Compression fittings for PEX tubing in accordance with ISO 15875.

Max working pressure: 6 bar

▪

Test pressure: 10 bar

▪

Max flow temperature: 95 °C

▪

G ¾” internal thread

▪

Max flow temperature given by the tube

manufacturer must not be exceeded.

Compression fittings also suitable for

PERT tubing in accordance with ISO

15875.

13x2 mm 013G4153

14x2 mm 013G4154

15x2.5 mm 013G4155

16x 1.5 mm 013G4157

16x2 mm 013G4156

16x2.2 mm 013G4163

17x2 mm 013G4162

18x2 mm 013G4158

18x2.5 mm 013G4159

20x2 mm 013G4160

20x2.25 mm

20x2.5 mm 013G4161

013G4093

Compression fittings for ALUPEX tubing.

Max working pressure: 6 bar

▪

Test pressure: 10 bar

▪

Max flow temperature: 95 °C

▪

G ¾” internal thread

▪

Max flow temperature given by the tube

manufacturer must not be exceeded.

Compression fittings also suitable for

PERT/ALU/PERT tubing.

Compression fittings for STEEL and COPPER tubing.

Max working pressure: 6 bar

▪

Test pressure: 10 bar

▪

Max flow temperature: 120 °C

▪

G ¾” internal thread

▪

12x2 mm 013G4182

14x2 mm 013G4184

15x2.5 mm 013G4185

16x2 mm

16x2.25 mm 013G4187

18x2 mm 013G4188

20x2 mm 013G4190

20x2.25 mm

20x2.5 mm 013G4191

10 mm 013G4120

12 mm 013G4122

14 mm 013G4124

15 mm 013G4125

16 mm 013G4126

18 mm 013G4128

013G4186

013G4093

2 VDUDR302 © Danfoss 08/2012 Danfoss Heating Solutions

Q (l/h) =

50 W/m2 x 25 m

2

5°C x 1.16

= 216 l/h

Q (l/h) =

50 W/m2 x 15 m

2

5°C x 1.16

= 129 l/h

10 20 30 40 50 70 100 200 300 400 500 700 1000

1

2

3

4

5

6

8

20

30

40

50

600,6

0,5

0,4

0,3

0,2

0,1

0,08

0,06

0,05

0,04

0,03

0,02

0,01

10

p

p

Q [l/h]

[kPa]

[bar]

0,1

0,2

0,3

0,4

0,5

0,6

0,8

1

2

3

4

5

6

p

[mWg]

75

80

100

8

10

0,8

1

2

2

½ ½

3

3

4

Max

½

4

Data Sheet FBH Floor Heating Manifold

Capacity/Commissioning

The pre-setting of the manifold valves determines the flow in the floor heating tubes and

is therefore an important factor for obtaining

optimal hydraulic balance in the system.

A correct hydraulic balance is important if opti-

mal comfort shall be achieved with a minimum of

energy consumption and is easily carried out following the example shown below.

Example

Room 1 1 Determine longest tube/largest room 25 m²

2 Desired cooling (ΔT) 5°C (typical)

3 Determine heat requirement for the room 50 W/m²

4 Conversion factor 1.16

5 Calculation of flow for the room

Room 2 6 Determine area for the next room 15 m²

Calculation of flow for the room (ΔT and

7

heat requirement is assumed identical for

the rooms in this case)

FBH manifold with TWA-K

Presetting with TWA-K actuators on the supply

manifold can be carried out by opening the regulation valve by turning fully to open. Then adjust

each flow meter to obtain flow as calculated (see

example).

If the right flow cannot be obtained, the

▪

pump must be replaced with a larger one.

Start balancing with fully open the flow me-

▪

ter for circuit with the longest pipe length.

Next open flow meter for the circuit with

second longest pipe length, until wanted

flow is indicated in flow meter and so on.

When all circuits are done, go back to the

Close all flow meters.

▪

Fully open all circuits, starting with the lon-

▪

gest pipe length, then the second longest

etc.

▪

first and adjust for wear to wanted flow.

The pressure drop is calculated as sum of: ΔPpipe (longest circuit) + ΔP flow manifold.

Pressure loss / flow manifold set

(Turns - opening flow meter)

Danfoss Heating Solutions VDUDR302 © Danfoss 08/2012 3

50

L1

6732

200

52

Data Sheet FBH Floor Heating Manifold

Design

Operation Conditions

Dimensions

Supply manifold with flowmeter

Description Material

1. Sightglass Heat resistant plastic

2. Flowmeter nut Plastic

3. Adjusting cap Plastic

4. Supply manifold body St

5. O-rings EPDM

6. Connection nipple Brass

Max differential pressure: 0.6 bar

Max working pressure: Manifold with flowmeter 6 bar

Max test pressure: Manifold with flowmeter 10 bar

Max flow temperature: 90 °C

ainless st

eel

Type 2+2 3+3 4+4 5+5 6+6 7+7 8+8 9+9 10+10 11+11 12+12

L1 (mm) 192 242 292 342 392 442 492 542 592 642 692

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss Heating Solutions and the Danfoss Heating Solutions logotype are trademarks of Danfoss A/S. All rights reserved.

4 VDUDR302 © Danfoss 08/2012 Danfoss Heating Solutions

Loading...

Loading...