REFRIGERATION AND AIR CONDITIONING

Technical information

Fault Location on

PL, TL, NL, FR Compressors

COMPRESSORS

This Hermetic Note is directed especially to the service network, for household appliances and similar. For detailed information on compressors see the

data sheets.

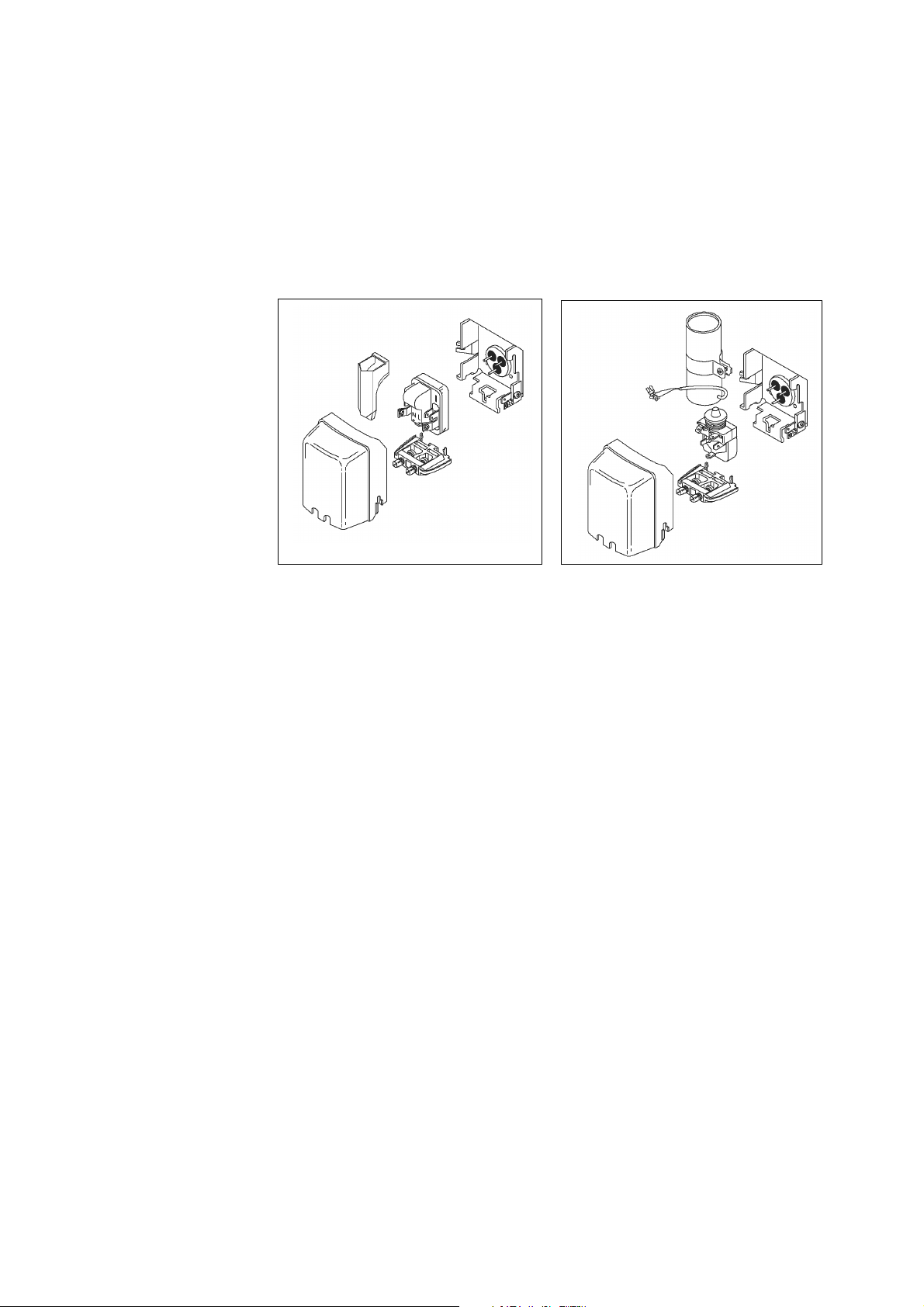

Compressors type PL, TL, NL, FR and partly SC are equipped with a PTC

starting device (fig. 1) or a relay and start capacitor (fig. 2). The motor protector

is built into the windings.

In the event of a start failure, with a cold compressor, up to 15 minutes can

elapse before the protector cuts out the compressor.

When the protector cuts out and the compressor is warm, it can take up to 1

hour before the protector cuts in the compressor again.

The compressor must not be started without the electrical equipment.

Before beginning systematic fault location, a good rule is to cut the supply

voltage for at least 5 minutes. This ensures that the PTC starting device has

cooled off and is ready for start.

A voltage drop or blackout within the first minutes of a pull down of the

appliance with cold compressor, can lead to an interlocking situation. A

compressor with PTC can not start at non equalized pressure and the PTC

does not cool down so fast. It can take more than 1 hour until the appliance

then operates normally again.

To avoid unneccessary protector operation and consequent waiting time, it is

important to carry out fault location in the sequence given below. Tests are

made according to desriptions on following page.

• Remove electrical equipment

• Check electrical connection between main and start pins of compressor

terminal

• Check electrical connection between main and common pins of

compressor terminal

• Replace compressor, if above connection checks failed

• Else, replace electrical equipment

If the compressor still does not operate, most probably it is no electrical

compressor failure. For more detailed fault location, see the tables.

General

Fault location

Electrical compressor

quick check

Fig. 1: PTC starting device Fig. 2: Starting relay

Fault location table :

Most common fault reasons, detectable before dis-mounting compressor.

Customer

claim

No/reduced

cooling

First analysis

Compressor

does not run

Compressor

runs 100%

Compressor

runs on/off

Possible cause

Compressor gets no

or bad power supply

Defective starting

equipment

Compressor with PTC

can not start at

pressure difference

PTC defective

Relay defective

Compressor

overloaded

Defective motor

windings

Defective protector

Mechanically blocked

compressor

No or low refrigerant

charge

Too high ambient

temperature

Too high condensing

temperature

Capillary partly

blocked

Valves coked or

damaged

Thermostat not OK

Wrong refrigerant

charge

Ice block built up on

evaporator

Compressors trips on

motor protector

Check

Voltage at plug and fuse

Aplicance energized

Thermostat function

Cables and connections in appliance

Voltage at compressor terminals

Relay function by shaking to hear if

armature is working

Start capacitor function

PTC by shaking

PTC resistance 10 to 100 Ohm

between M and S pin

Stop time long enough for pressure

equalization

PTC resistance 10 to 100 Ohm

between M and S pin

Relay function by shaking, to hear

moving of armature

Condenser pressure and ventilation

Ambient temperature too high

according to type label of appliance

Check winding resistances

Check protector with ohmmeter

Start with proper starting equipment, voltage and conditions,

windings and protector OK

Recharge and search for leaks

Ambient temperature according to

type label of appliance

Condenser and compressor

ventilation

Recharge and search for leaks,

measure suction pressure. Capillary

blocked, if pressure very low

Recharge and search for leaks

Thermostat type and function

Recharge and search for leaks

Check for ice on evaporator

Thermostat function and settings

Internal no-frost fan function

Compressor load, compressor and

condenser ventilation

Compressor voltage supply for

minimum 187 V

Compressor voltage supply for drop

outs. Check thermostat and appliance cables for loose connections

Motor windings resistance for partly

short circuit or earth connection

Activity

(depends on result)

Replace relay

Replace start capacitor

Replace if noise appears

Replace PTC

Adjust thermostat

difference

Replace PTC

Replace relay and

capacitor

Ensure proper ventilation

Replace compressor

Replace compressor

Replace compressor

Ensure leakfree system

and proper charge,

replace drieer

Ensure proper ventilation

and wall distance

Replace compressor, if

still not cooling properly

Replace thermostat

Ensure leakfree system

and proper charge,

replace drier

Defrost properly

Replace thermostat

Ensure proper ventilation

and wall distance

Ensure proper power

supply

Fix all connections

Replace compressor

Customer

claim

Noise

Fuses are

blown by

appliance

First analysis

Rattle or

humming

Banging at

start or stop of

compressor

Relay clicking

frequently after

start

Short circuit in

appliance

Short circuit in

compressor

Fuse blows at

compressor

start

Starting capacitor exploded

Starting relay

cap blown off

Possible cause

Tube touching cabinet

Compressor touching

cabinet

Broken internal

suspension spring or

discharge tube

Resonance

Fan noise

Compressor block hitting housing internally

Compressor overloaded

Relay defective

Defective cabling in

appliance

Defective thermostat

Ground connection

Defective terminals

Short circuit between

cables at terminals

Short circuit in

compressor motor

Supply voltage too

low

Fuse loaded by too

many appliances

Resettable fuse too

quick acting

Partly short circuit to

earth

Defective relay

Wrong relay type

Extremely many starts

and stops of compressor

Short circuit in compressor motor

Check

Tube placing

Compressor mounting and rubber

feet

Listen to compressor with screwdriver against compressor with edge

and to your ear with grip

Find vibrating mounting parts

Vibration of fan or fan mounting

Compressor overload by pressure

Fan function

Refrigerant charge

Pressure equalization before start

and number of on/off cycles

Ambient temperature according to

type label

Ventilation to compressor and condenser. Check fan function

Right relay type for compressor

All connecting cables and power

supply cord for loose connections,

short circuits

Thermostat connections

Resistance from line/neutral to earth

For burns on the terminal pins

Connectors and cables at compressor

Resistance values in windings

Resistance between terminals and

earth

Supply voltage at compresor start

>187 V

Total fuse load

Fuse load and type

Resistance between terminals and

earth

Relay function by shaking, to hear

moving of armature

Relay type

Relay type

Thermostat defect or differences too

small

Compressor motor resistances

Activity

(depends on result)

Bend tube to their right

place, carefully

Place rubber feet and

mounting accessories

correctly

Replace compressor, if

abnormal sounds

Place or fix correctly

Fix fan and blade, replace,

if defective

Clean condenser if dusty.

Make sure, that ventilation

gaps for air circulation are

satisfactory

Recharge, if too high

Adjust thermostat, if stop

time less than 5 min

Take appliance out of

function, if ambient too

hot

Clean condenser if dusty.

Make sure, that ventilation

gaps for air circulation are

satisfactory

Replace relay, if wrong

Fix connections properly

Fix connections properly

Replace electrical

accessories

Insulate cables and

connectors

Replace compressor, if

short circuited

Connect applaince to

different fuse

If possible replace by

slightly slower type

Replace compressor, if

short circuited

Replace relay and

capacitor

Replace relay and cap

Replace relay and cap

Adjust or replace

thermostat

Replace compressor

Resistance between pins M (main) and S (start) on compressor terminals is

measured with an ohm-meter, see figure 3.

• Connection: Main and start

windings normally OK

• No connection: Main or start winding

defective: Replace compressor

At cold compressor (ca. 25°C) the values are ca. 10 to 100 Ohm for 220-240 V

compressors. For partial short circuit detection, exact values are needed from

data sheets of the specific compressor, which can be found on the Danfoss

Compressors homepage.

Resistance between pins M (main) and C (common) on compressor terminals

is measured with an ohm-meter, see figure 3 and 4.

• Connection: Protector OK

• No connection: Compressor cold: Protector defective: Replace

compressor

Compressor hot: Protector could be

OK, but cut out: Wait for reset

Remove relay from compressor.

Measure connection between connectors 10 and 12 (see figure 5):

• No connection: Relay defective: Replace relay

Measure connection between connectors 10 and 11:

In normal vertical position (like mounted, solenoid upward):

• Connection: Relay defective: Replace relay

• No connection: OK

In top-down position (solenoid downward):

• Connection: OK

• No connection: Relay defective: Replace relay

Remove PTC from compressor.

Shake by hand. Pin C can slightly rattle.

• Internal rattle

noise

(except pin C): PTC defect: Replace PTC

Measure resistance between pins M and S, see figure 6.

Resistance value between 10 and 100 Ohm at room temperature for 220 V

PTC.

• Connection: PTC working: OK

• No connection: PTC defect: Replace PTC

Check main and

start winding

Check protector

Check relay

Check PTC

Fig. 4: Windings and protectorFig. 3: Compressor terminals

Fig. 5: Relay connections Fig. 6: PTC connections (backside)

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss Compressors GmbH

Mads-Clausen-Strasse 7

Postfach 1443, D-24939 Flensburg

Telefon: (0461) 4941-0

International +49 461 4941-0

Telefax: +49 461 44715

Telex: 227 43 dancom d

CN.71.B5.02

Produced by Danfoss G1 Advertising Agency 01.07.UF.JN.AO

www.danfoss.com/compressors

Loading...

Loading...