Page 1

Fact Sheet

ExtensionBoxTM for VLT® OneGearDrive®

Increase the available torque in conveyor applications up to 1000 Nm with

easy to install extension for the VLT® OneGearDrive®.

Long and broad conveyors, such as

those used for buff ering and accumulation tables, or unpressurized

reunifi cation in fi lling lines, often

require a high torque. Although the

VLT® OneGearDrive® already delivers

high torque over a wide speed range,

certain applications may demand more.

Easy to install

The ExtensionBox™ is an accessory

that is designed to be easy to attach

to any OneGearDrive, which then can

be fitted to the conveyor frame with a

torque arm. Power is transmitted to the

conveyor via a special belt. As a result

known disadvantages of a gear stage

are avoided. Instead, owners now have

an oil and maintenance free solution

that extends the available torque of

the permanent magnet motor driven

OneGearDrive significantly.

Easy spare parts handling

The ExtensionBox™ offers an additional

advantage in that the number of

OneGearDrive variants in stock in the

plant is not increased. This supports

owners in keeping storage and

maintenance costs low.

Broader application area

The VLT OneGearDrive is already

an industry favorite as part of

Danfoss VLT® FlexConcept®, which is

widely used in the food and beverage

industry to increase energy effi ciency

and reliability.

With the new extension box, the

OneGearDrive extends the scope of

FlexConcept to other high torque

applications that now also can utilize

energy-effi cient and matched

components.

Feature Benefit

– High system effi ciency incl.

VLT® OneGearDrive® and VLT® frequency

converter

– Completely smooth enclosure leaves no

crevics or dirt traps

– Only one ratio extends the torque range of

the OneGearDrive up to 1000 Nm

– Gearbox without breather vents and

oil free operation

– Service port

– 40 mm hollow shaft optional with 1.5” or

high quality stainless steel (AISI 316 Ti)

– Save money and energy – up to 40% energy

compared to conventional systems

– Easy to clean

– Save production

– Up to 70% reduction in variants reduces spare

part stock

– Reduces maintenance costs lower-

contamination risks

– Flexible adaption to customer standards

– Enhanced corrosion resistance

www.vlt-drives.danfoss.com

Page 2

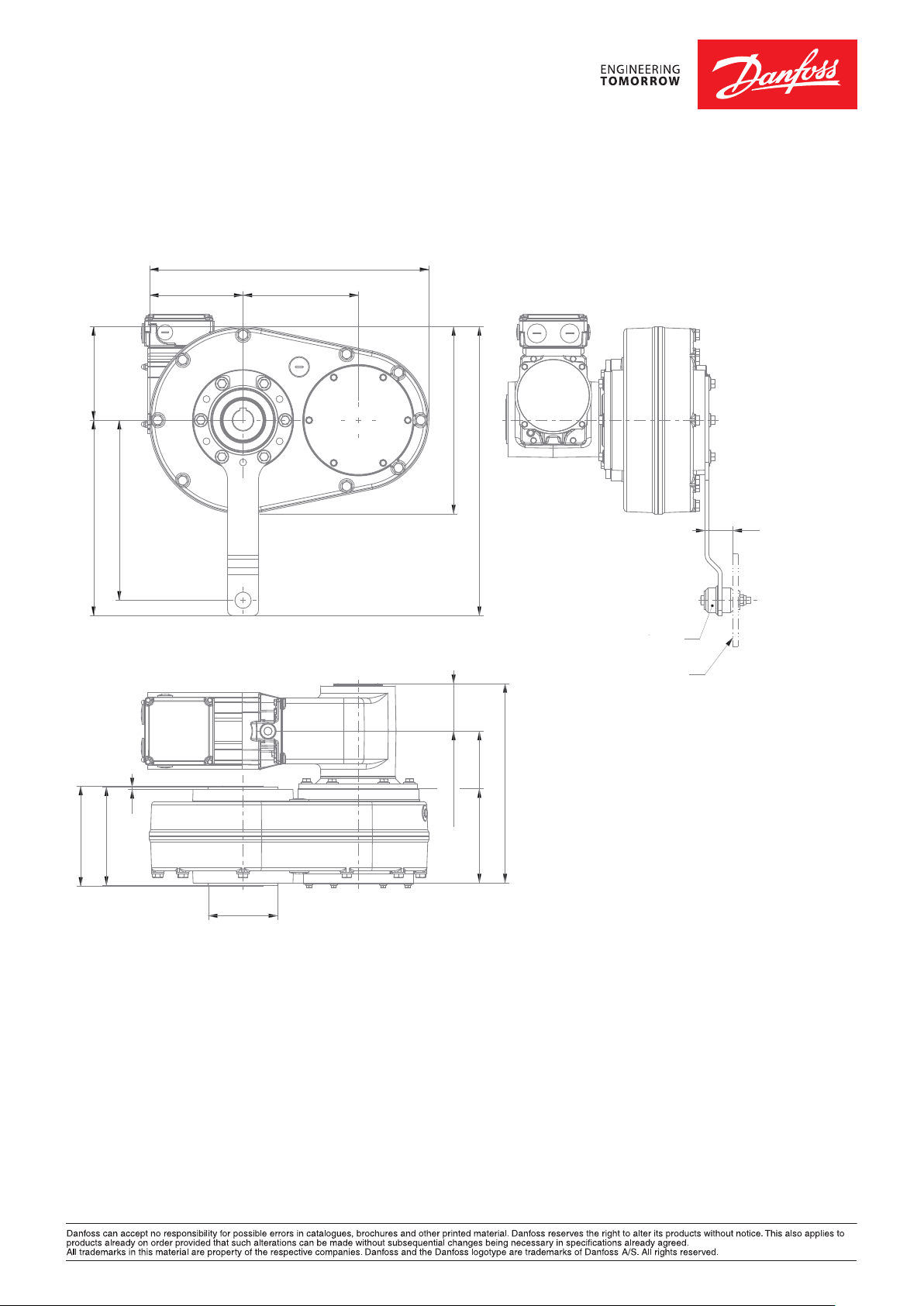

Dimensions

543.4

182380

350

182

224.4

364

562

54

Torque arm fastening set

Customer support frame

387.5

183 112

194.5

191.5

5

0

135 - 0.2

92.5 ( = 185/2 )

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.vlt-drives.danfoss.com, E-mail: info@danfoss.com

DKDD.PFM.700.A2.02 © Copyright Danfoss Power Electronics | Danfoss VLT Drives PE-MSMBM | 2015.03

Loading...

Loading...