Page 1

Installation Guide

Expansion Module

for Danfoss Icon™ Master

© Danfoss | FEC | 2018.12 | 1AN28953970588601-000201 | VIMDE20F | 088N2100

Page 2

Installation Guide Expansion Module for Danfoss Icon™ Master

2 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 3

Installation Guide Expansion Module for Danfoss Icon™ Master

Content

Expansion Module for Danfoss Icon™ Master .................................................... 4

Expansion Module for Danfoss Icon™ Master ...................................................24

Expansion Module for Danfoss Icon™ Master ...................................................44

Expansion Module for Danfoss Icon™ Master ...................................................64

Expansion Module for Danfoss Icon™ Master ...................................................84

Expansion Module for Danfoss Icon™ Master ..................................................104

Expansion Module for Danfoss Icon™ Master ..................................................124

Expansion Module for Danfoss Icon™ Master ..................................................144

Expansion Module for Danfoss Icon™ Master ..................................................164

Expansion Module for Danfoss Icon™ Master ..................................................184

Expansion Module for Danfoss Icon™ Master ..................................................204

Expansion Module for Danfoss Icon™ Master ..................................................224

Expansion Module for Danfoss Icon™ Master ..................................................244

Expansion Module for Danfoss Icon™ Master ..................................................264

Expansion Module for Danfoss Icon™ Master ..................................................284

GB

DE

FR

IT

NL

DK

SE

NO

IS

FI

CN

LT

PL

TR

UA

Expansion Module for Danfoss Icon™ Master ..................................................304

© Danfoss | FEC | 2018.12 | 3VIMDE20F / 088N2100

RU

Page 4

Installation Guide Expansion Module for Danfoss Icon™ Master

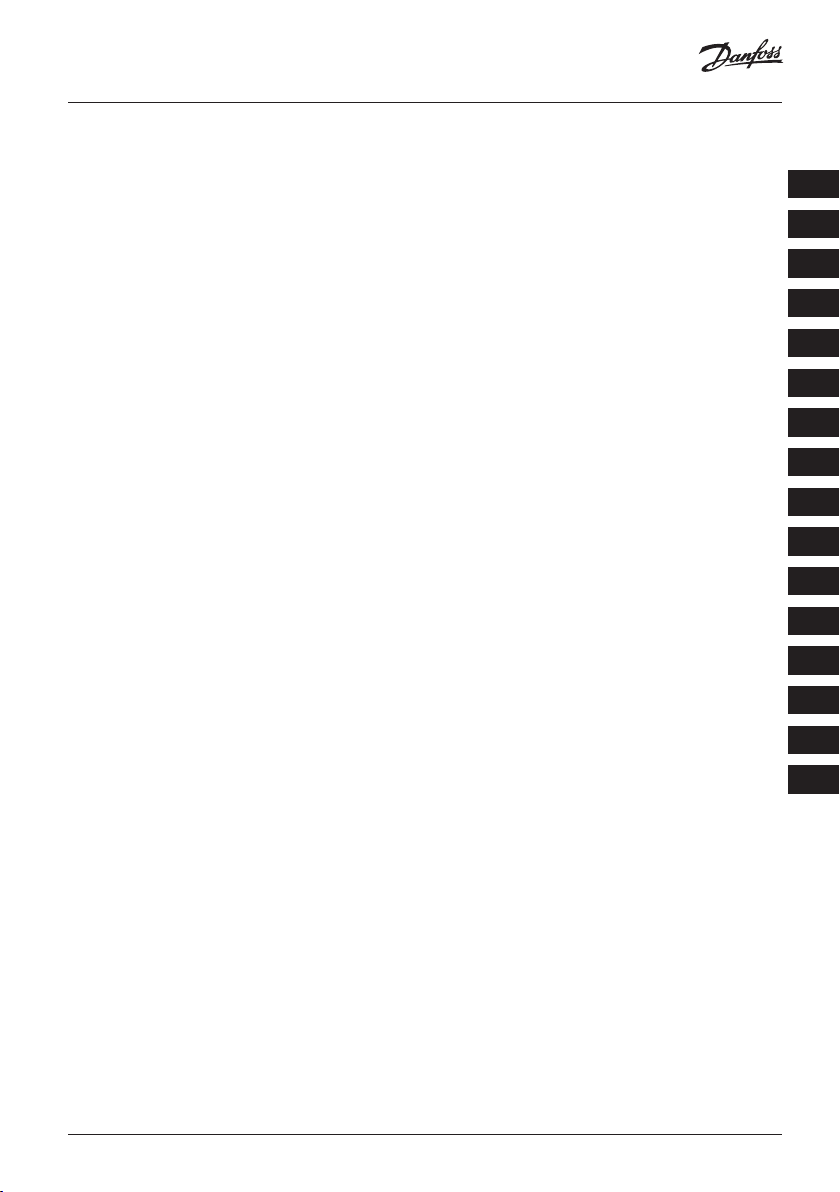

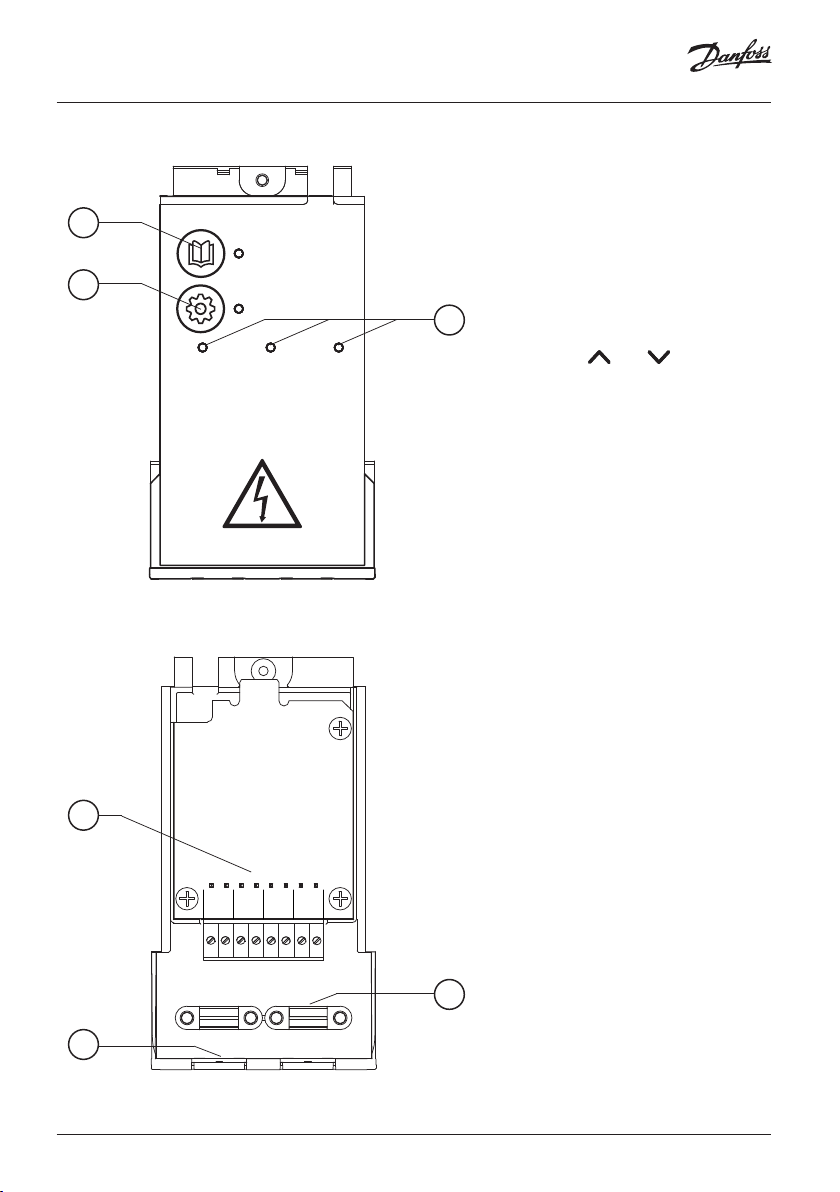

Perform wirring according to electrical

diagram, then insert the Expansion

1

APPLICATION

2

IN 1

SETTINGS

IN 2 IN 3

3

Module into the Danfoss Icon™ Master

Controller for extra features.

1. Use this key to choose application.

2. Use the key to set application

3. LED’s indicate the state of the inputs

4. Terminals for connection of various

5. Cable strain relief.

6. Break away for wiring /cables.

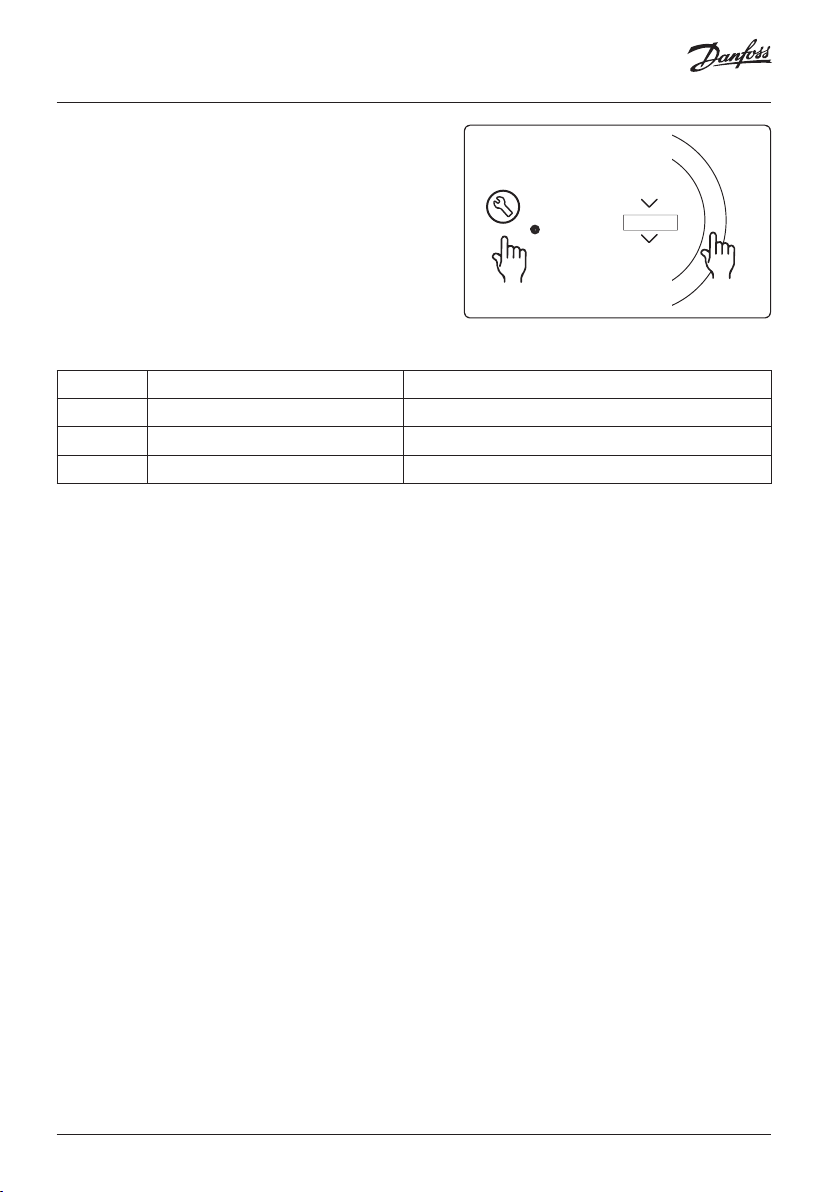

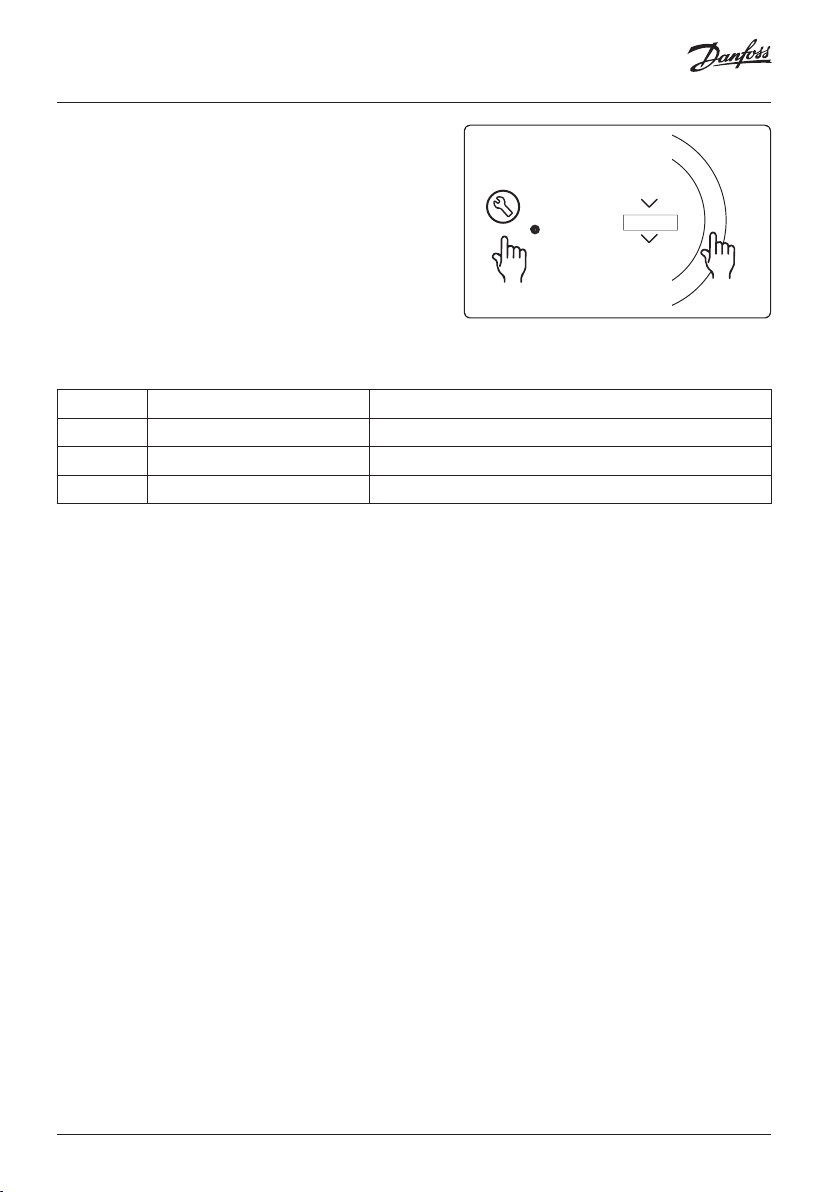

Press application key and then use

and to choose application

1-11 and confirm with “OK”. See

applications drawings to help you

choose the correct application.

specific settings. See in application

description which settings are

available for the chosen application.

1 to 3. See application description

for the specific application.

wiring /external devices.

4

IN 3 IN 2 IN 1

PWR3

PT

24

1000

VDC

5

6

4 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 5

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0001: 2-pipe system, fixed supply temperature, electronically

controlled.

Optional: Global standby.

Application description

Floor heating system with electronic supply temperature control. The supply temperature is set to a fixed

value.

The system uses a PT1000 sensor to detect and control the supply temperature and is also used to ensure

that the temperature does not exceed the max. allowed temperature. If connected, the system will control

the circulation pump and the heat demand signal for e.g. a boiler or heat pump. The pump and heat

demand signal will be on when minimum 1 circuit has a heat demand. Output 1 must be used for TWA on

mixing shunt.

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

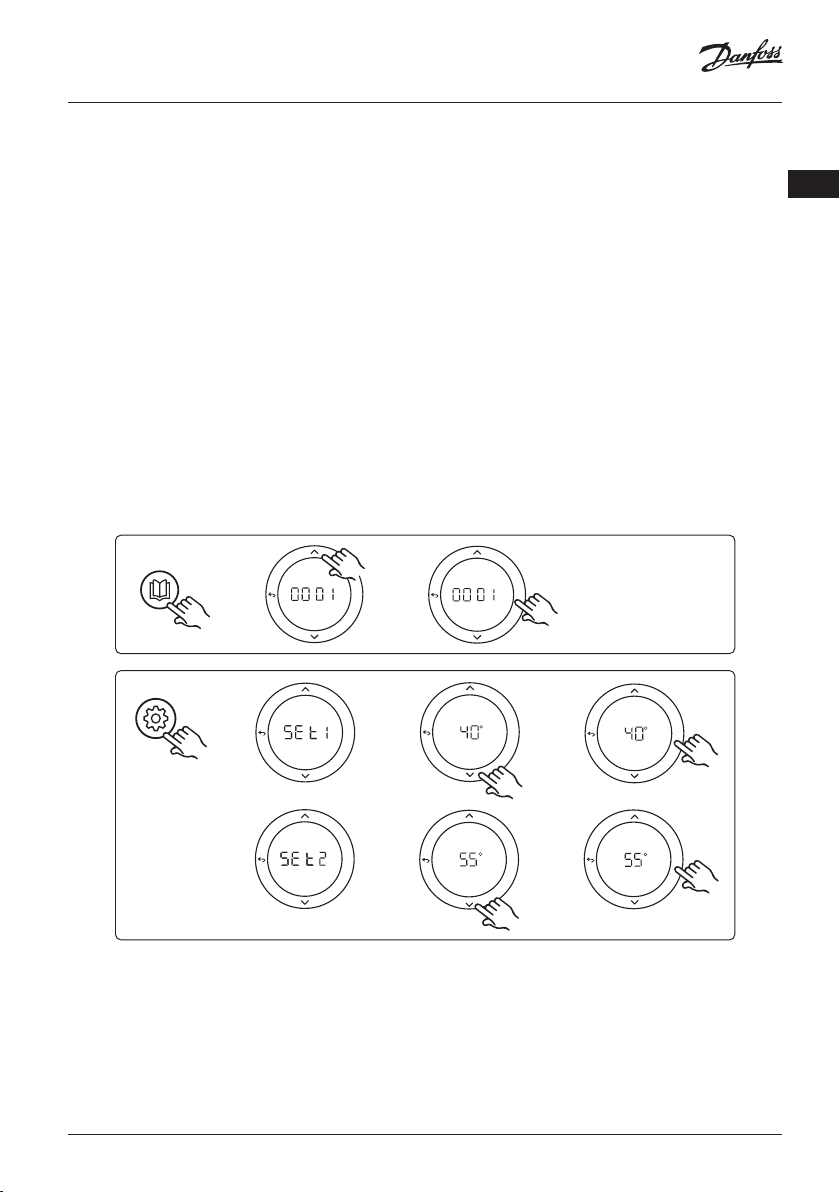

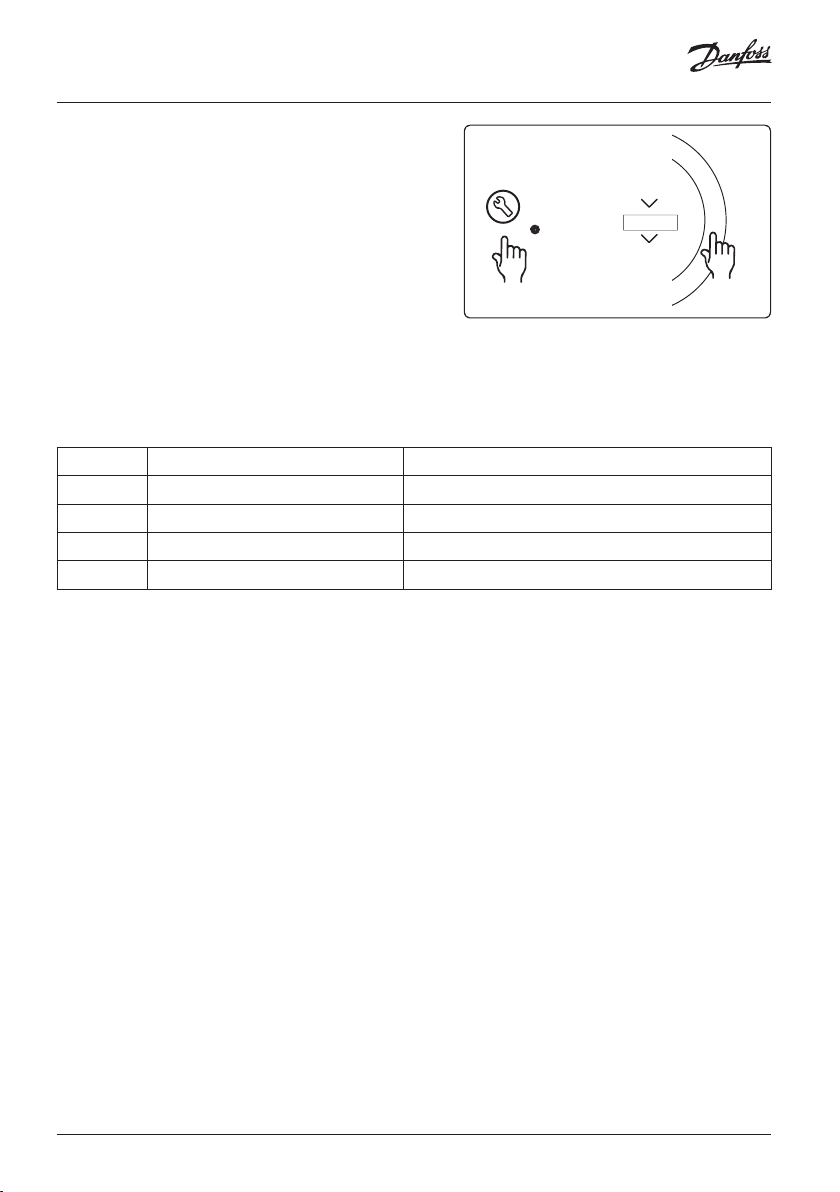

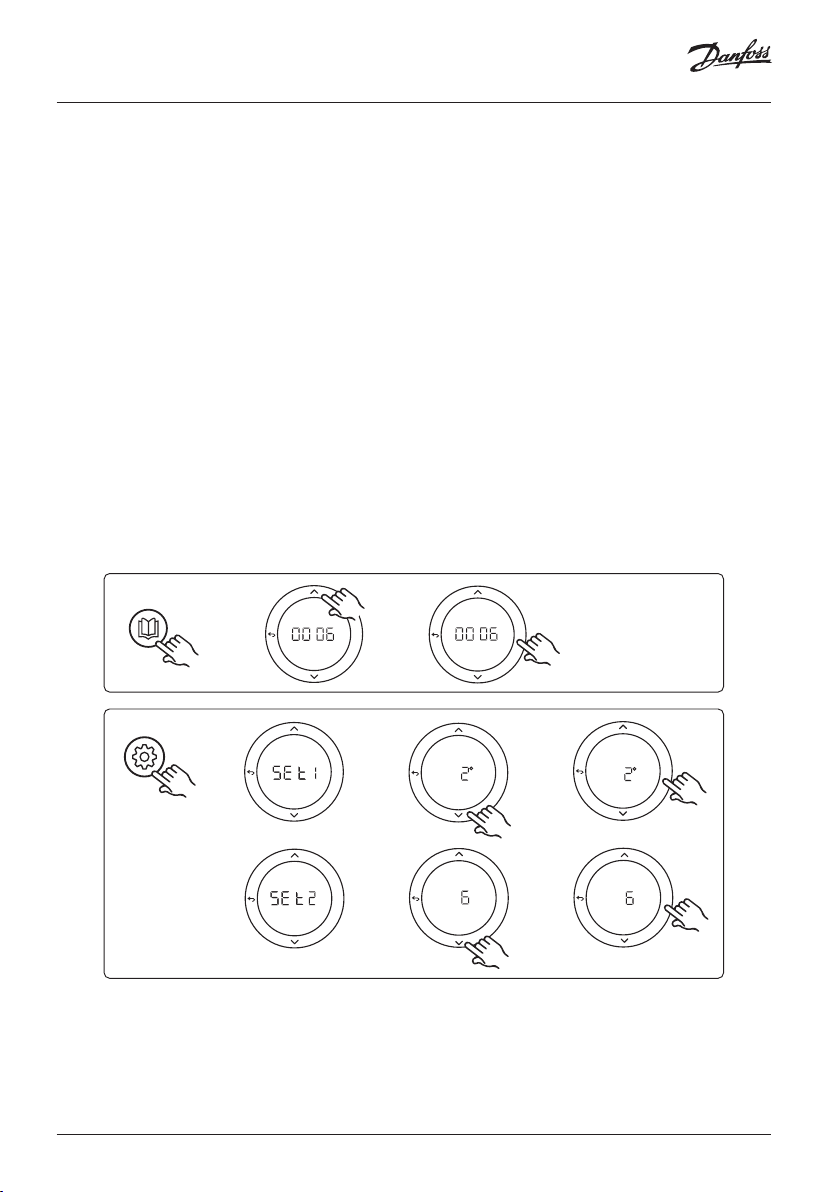

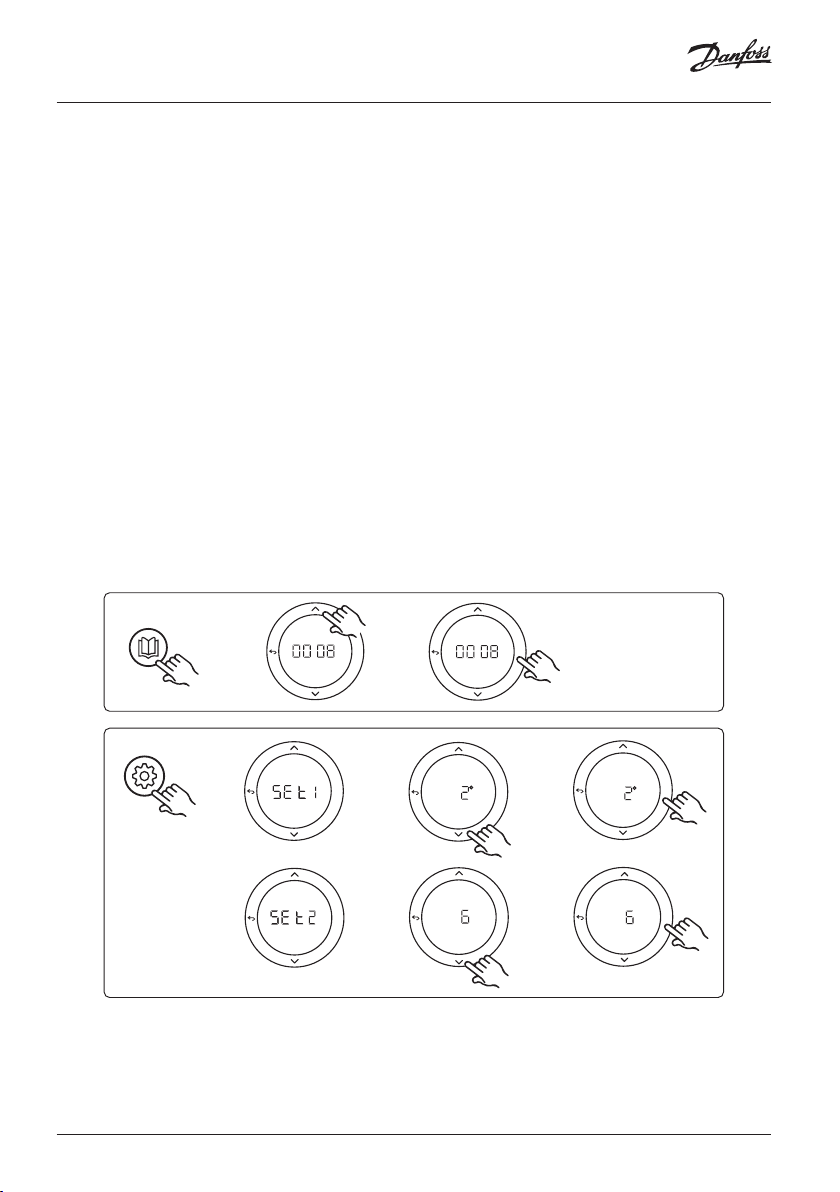

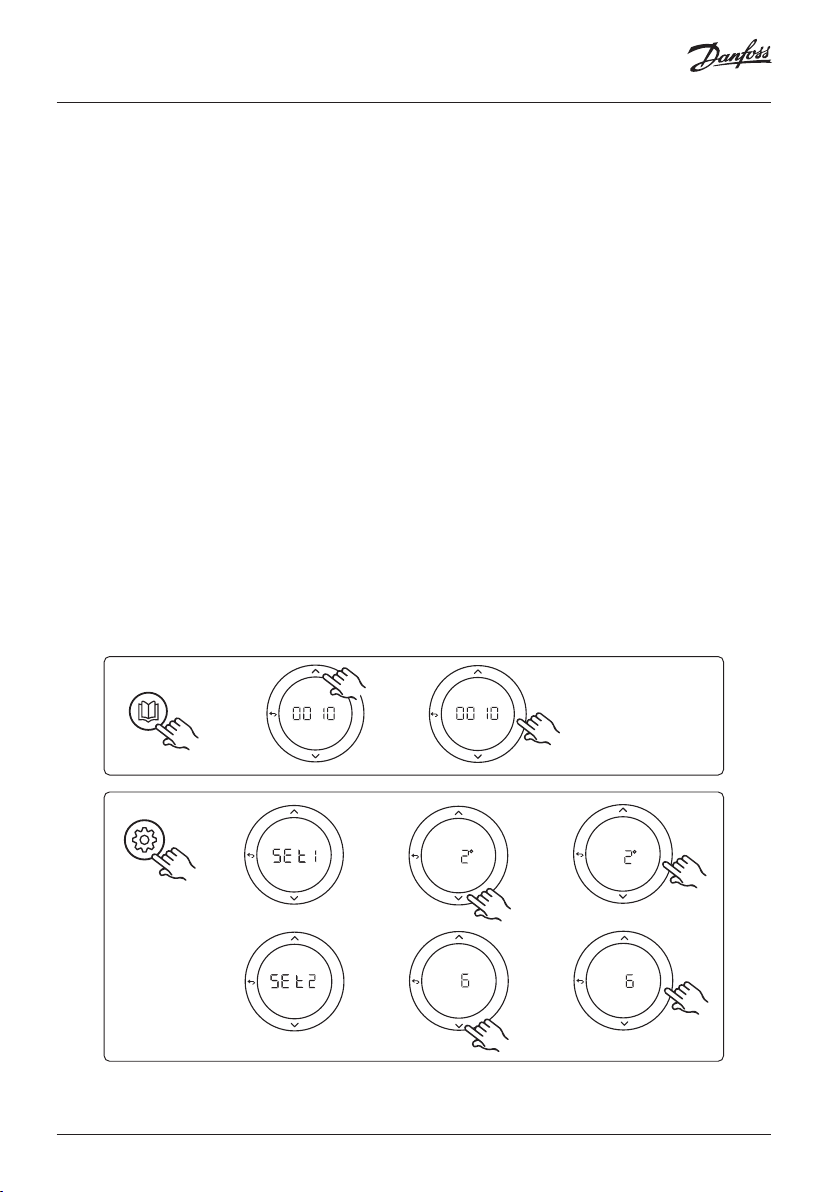

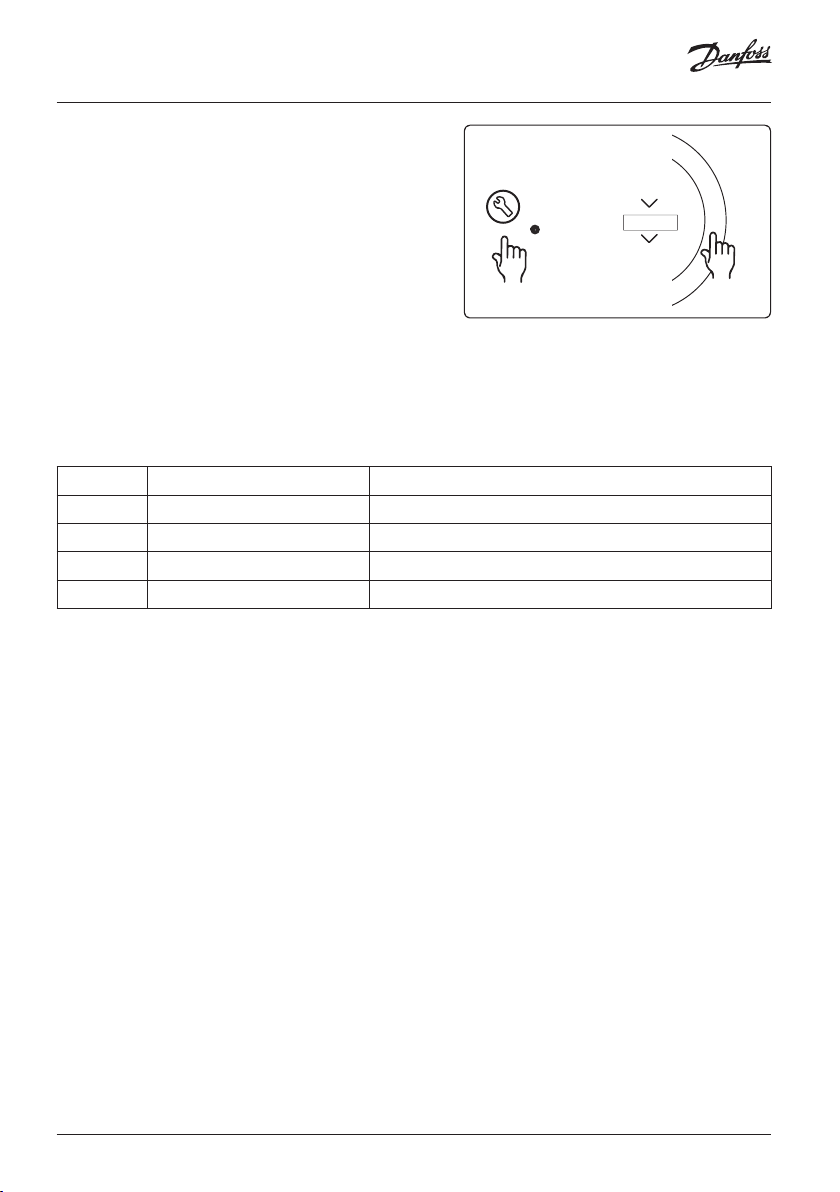

Settings

“SET 1” = Set desired supply flow temperature [25-70°C]

“SET 2” = Set desired safety cut-off temperature [30-75°C]

Note: temperature must be higher than flow temperature.

GB

APPLICATION

SETTINGS

OK

OK

OK

OK

OK

OK

OK

OK

© Danfoss | FEC | 2018.12 | 5VIMDE20F / 088N2100

Page 6

Installation Guide Expansion Module for Danfoss Icon™ Master

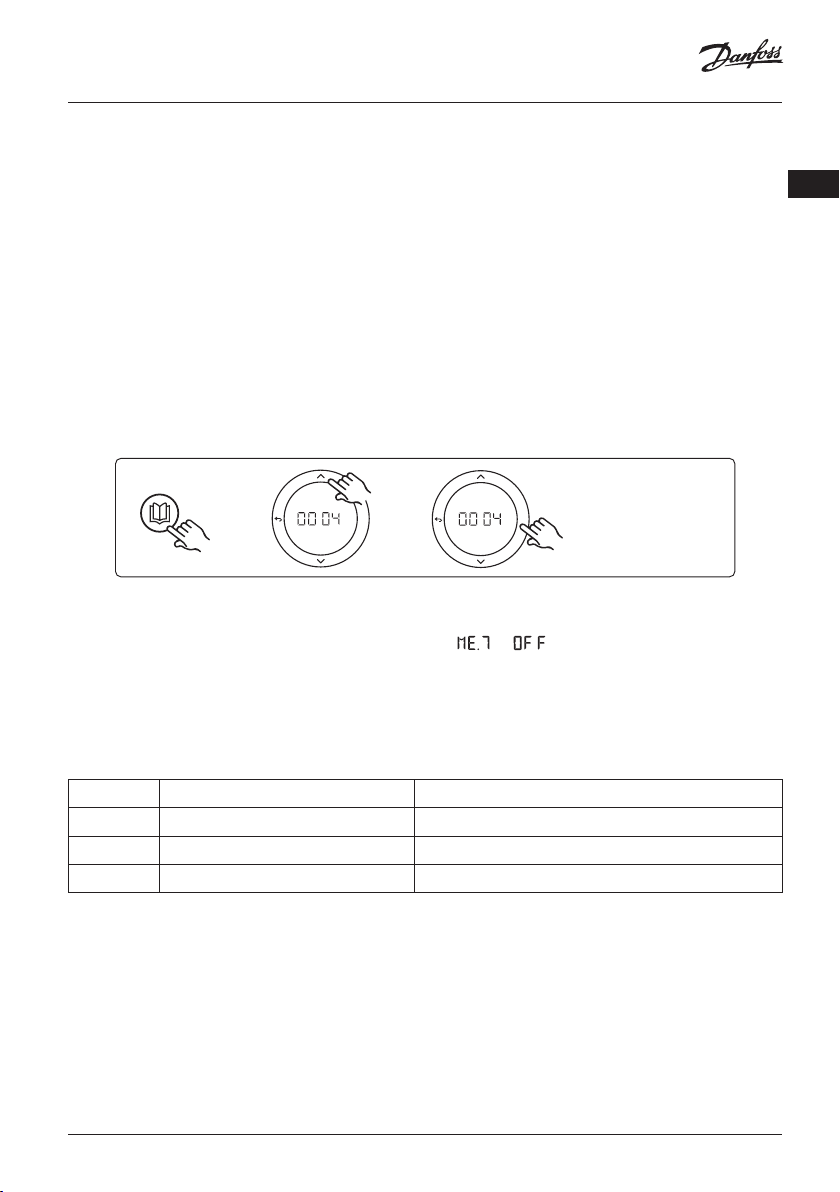

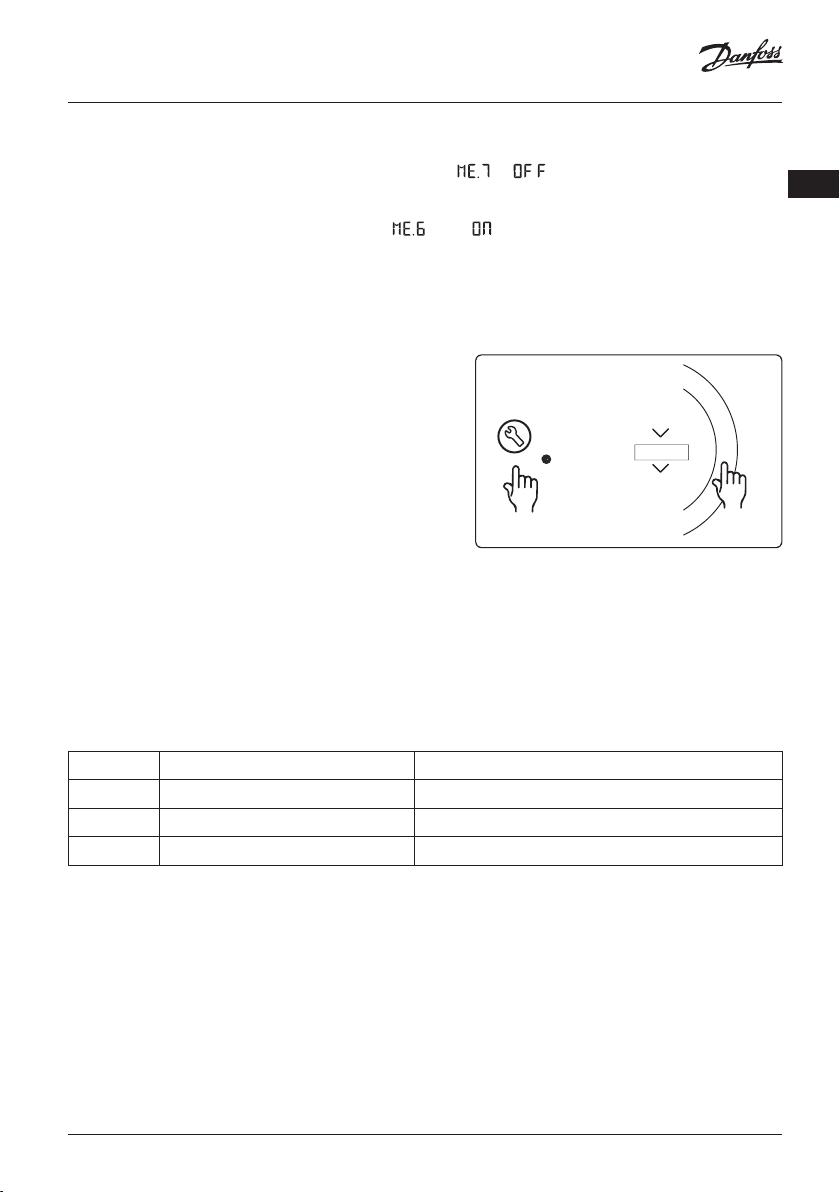

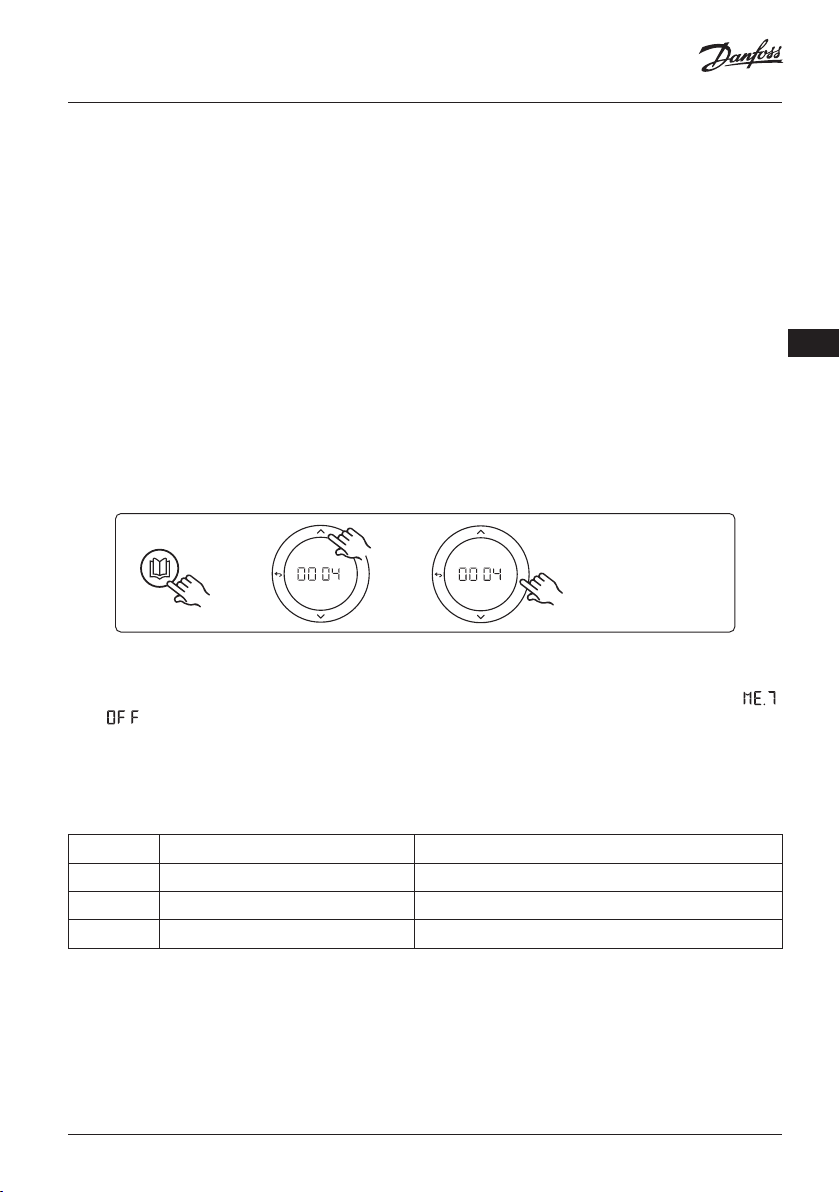

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

O

Step 1:1 Go to mixing shunt control valve actuator, and

verify that the valve opens fully (up to 3 minutes opening

time can be expected). After 5 minutes, the mixing shunt

valve actuator will close again.

During the 5 minute test period, the display on the Master

Controller will also show the measured supply flow temperature in the display.

Parts list

Pos. 1 088U0093-96 1 pc. Danfoss FHM-Cx Mixing shunt

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 087B1165 1 pc. ESM-11 PT-1000 sensor

Pos. 5. NC: 088H3110 / NC: 193B2148 1 pc. thermal actuator, 24 V (types TWA-A or ABN-FBH)

OK

6 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 7

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0002: 2-pipe system with demand based supply temperature

control.

Optional: Global standby.

Application description

Floor heating system with electronic supply temperature control.

The demand based supply temperature is controlled depending on the heat demand from the rooms.

The system uses a PT1000 sensor to detect the supply temperature and is also used to ensure that the

temperature does not exceed the max. allowed temperature via a safety Tmax. If connected, the system

will control the circulation pump and the heat demand signal for e.g. a boiler or heat pump. The pump and

heat demand signal will be on when minimum 1 circuit has a heat demand. Output 1 must be used for

TWA on mixing shunt.

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

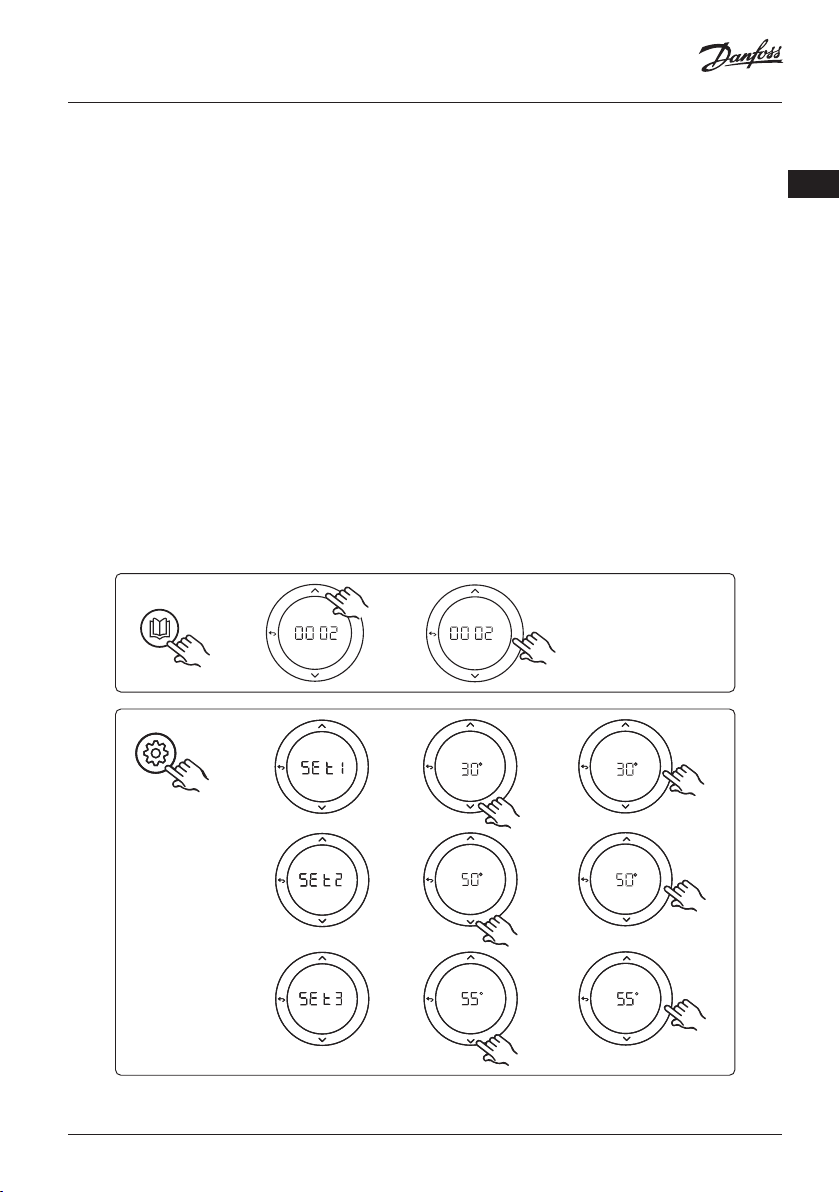

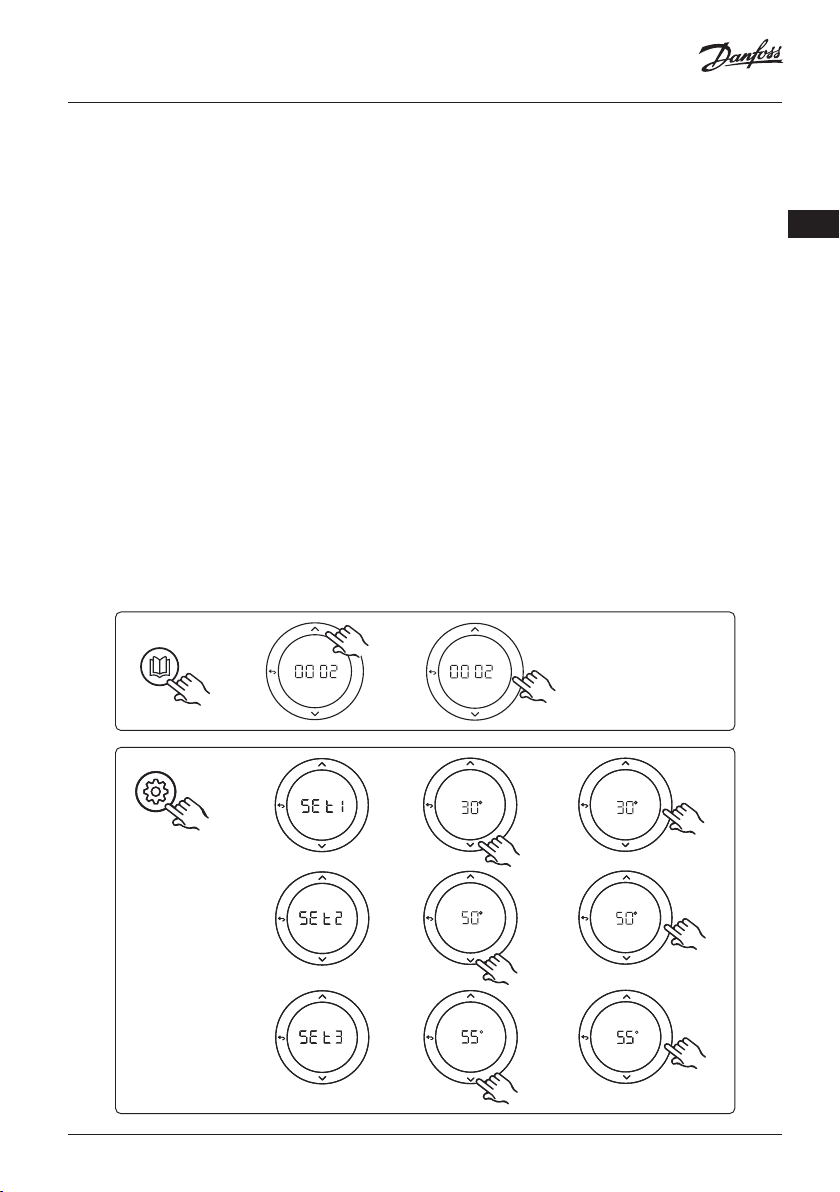

Settings

“SET 1” = Set desired min. supply flow temperature [25-65°C]

“SET 2” = Set desired max. supply flow [30-70°C]

Note: temperature cannot be set less than 5°C higher than min. supply flow temperature.

“SET 3” = Set desired safety cut-off temperature [30-75°C]

Note: temperature must be higher than flow temperature.

GB

APPLICATION

SETTINGSSETTINGS

OK

OKOK

OKOK

OKOK

OK

OKOK

OKOK

OKOK

OKOK

OKOK

OKOK

© Danfoss | FEC | 2018.12 | 7VIMDE20F / 088N2100

Page 8

Installation Guide Expansion Module for Danfoss Icon™ Master

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

O

Step 1:1 Go to mixing shunt control valve actuator, and

verify that the valve opens fully (up to 3 minutes opening

time can be expected). After 5 minutes, the mixing shunt

valve actuator will close again.

During the 5 minute test period, the display on the master

controller will also show the measured supply flow temperature in the display.

Parts list

Pos. 1 088U0093-96 1 pc. Danfoss FHM-Cx Mixing shunt

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 087B1165 1 pc. ESM-11 PT-1000 sensor

Pos. 5. NC: 088H3110 / NC: 193B2148 1 pc. thermal actuator, 24 V (types TWA-A or ABN-FBH)

OK

8 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 9

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0003: 2-pipe system with automatic changeover for cooling based

on supply temperature.

Optional: Dewpoint sensor (recommended), Global standby, Circulation pump and heat demand

signal.

Application description

Floor heating system with automatic changeover for cooling based on supply temperature input.

The supply temperature is monitered using a PT1000 sensor. Based on the measurement, the system

switches to heating or cooling. If connected, the system will control the circulation pump which will be

turned on when minimum 1 room has a heat or cooling demand.

The heat signal for e.g. a boiler or heat pump is only activated when the system is in heating mode and

minimum 1 room has a heat demand. For cooling applications it is always recommended to have a dew

point sensor installed in the system to prevent moisture damage to floor and installations in cases where

the relative humidty exceeds dew point.

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

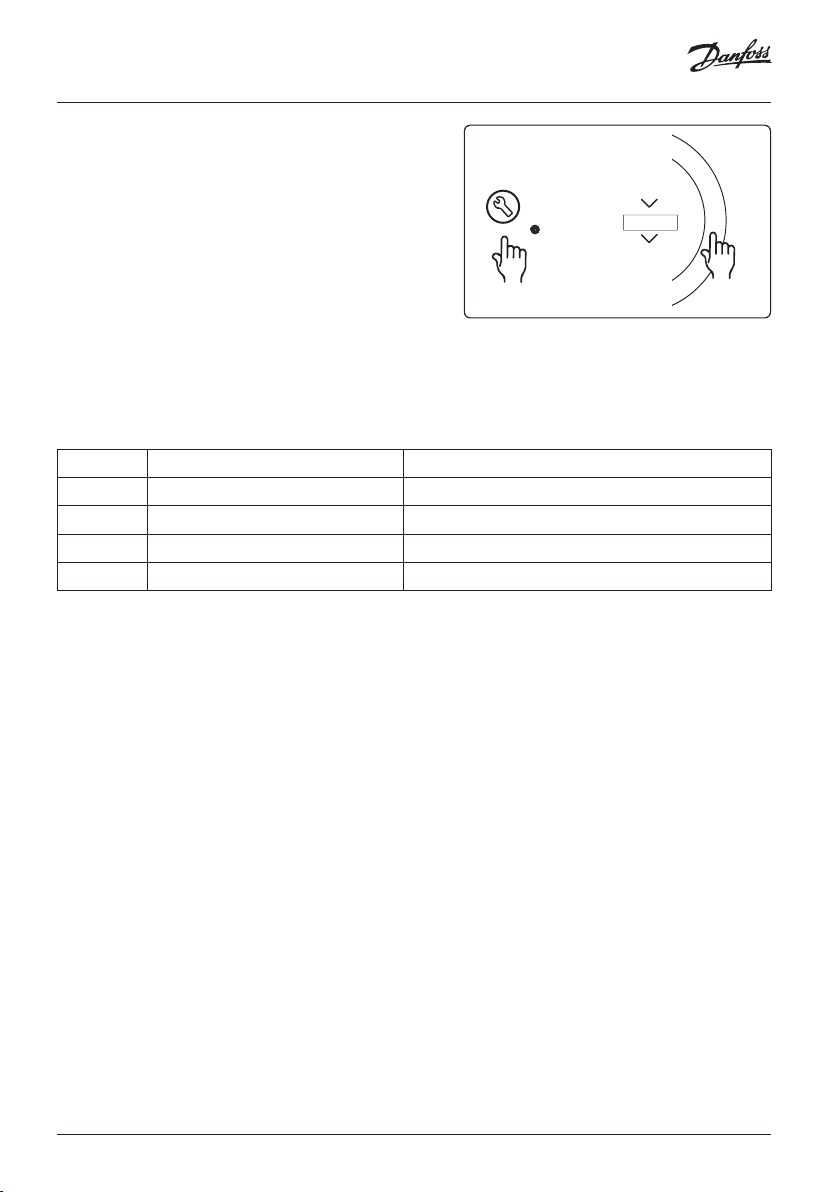

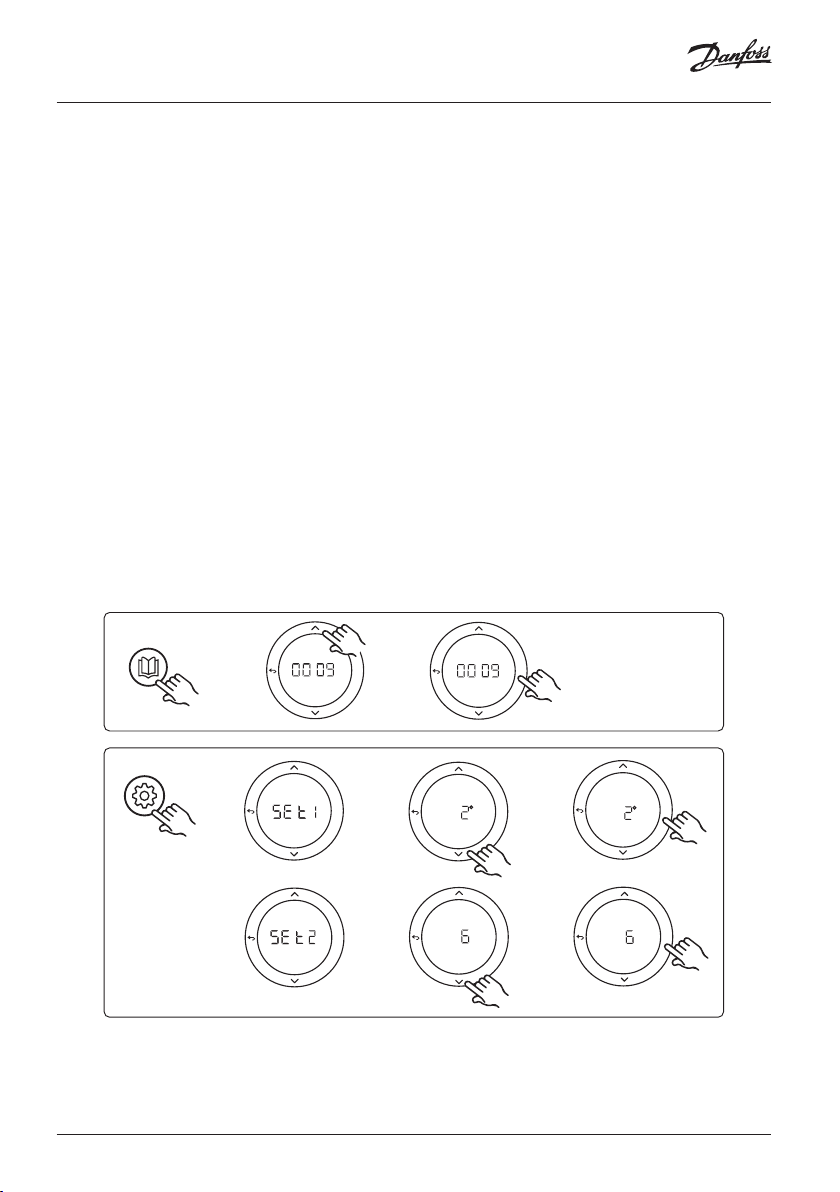

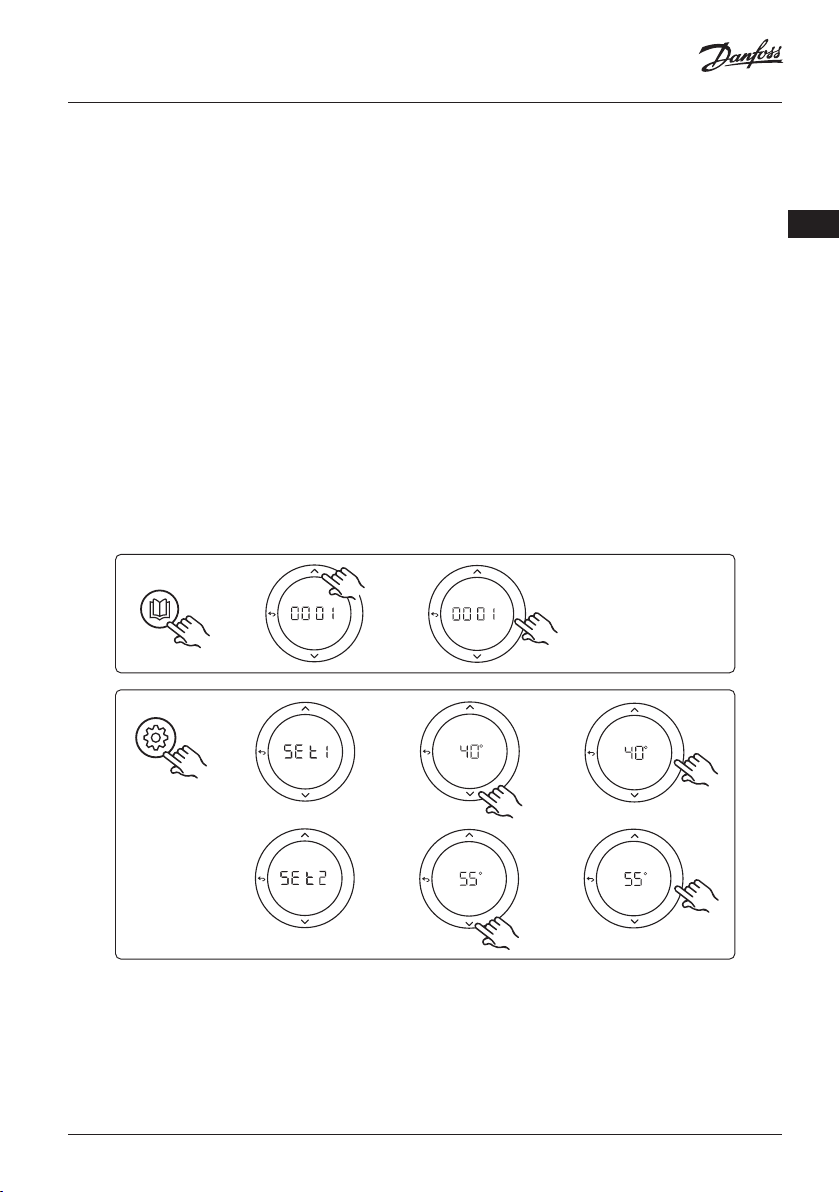

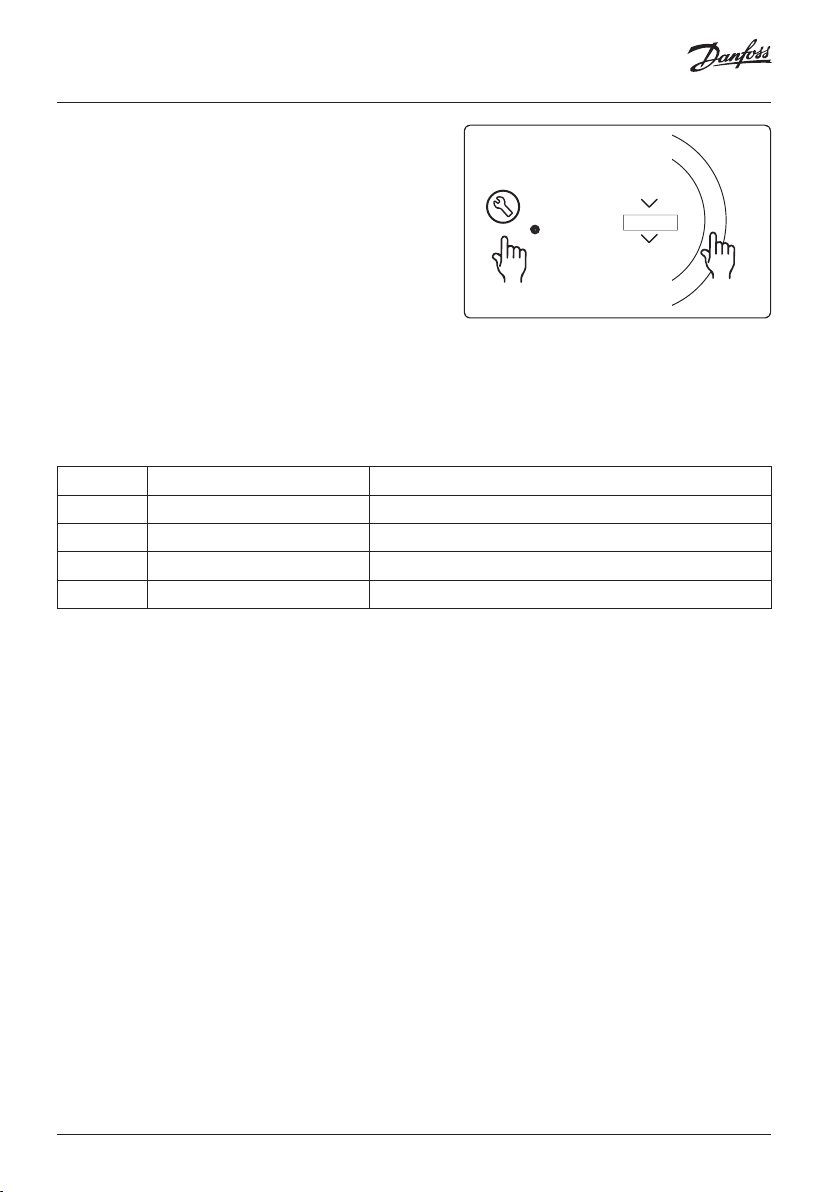

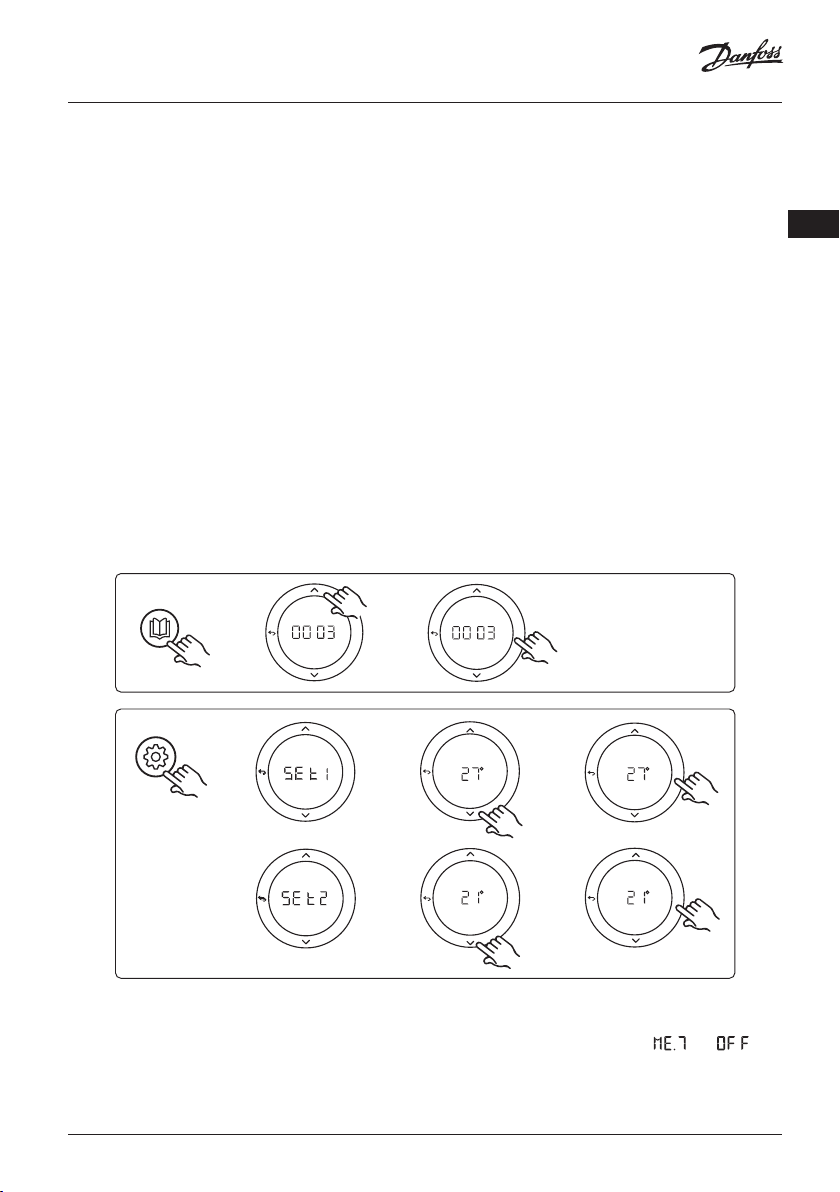

Settings

“SET 1” = Set supply flow temperature for change-over to heating [25-55°C]

“SET 2” = Set supply flow temperature for change-over to cooling [15-25°C]

Note: temperature cannot be set higher than 2°C lower than heating change-over temperature.

GB

APPLICATION

SETTINGS

OK

OK

OK

OK

OK

OK

OK

OK

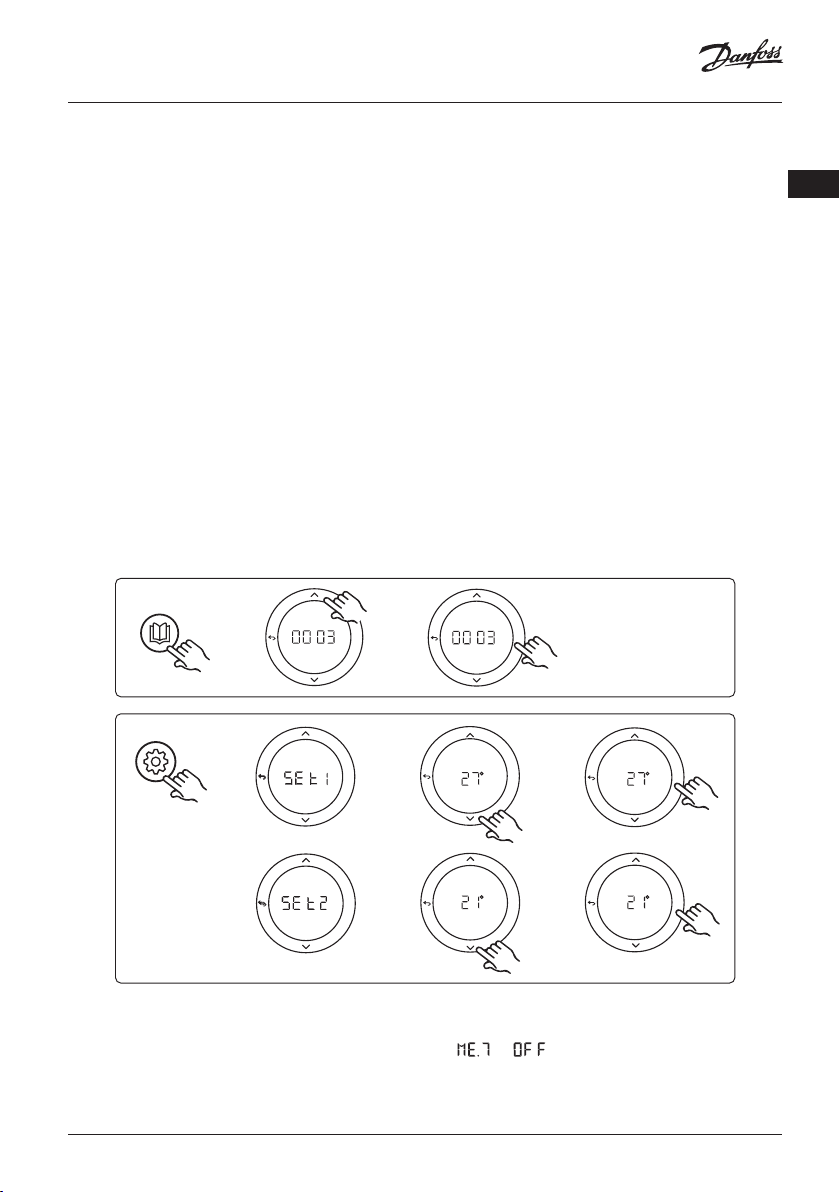

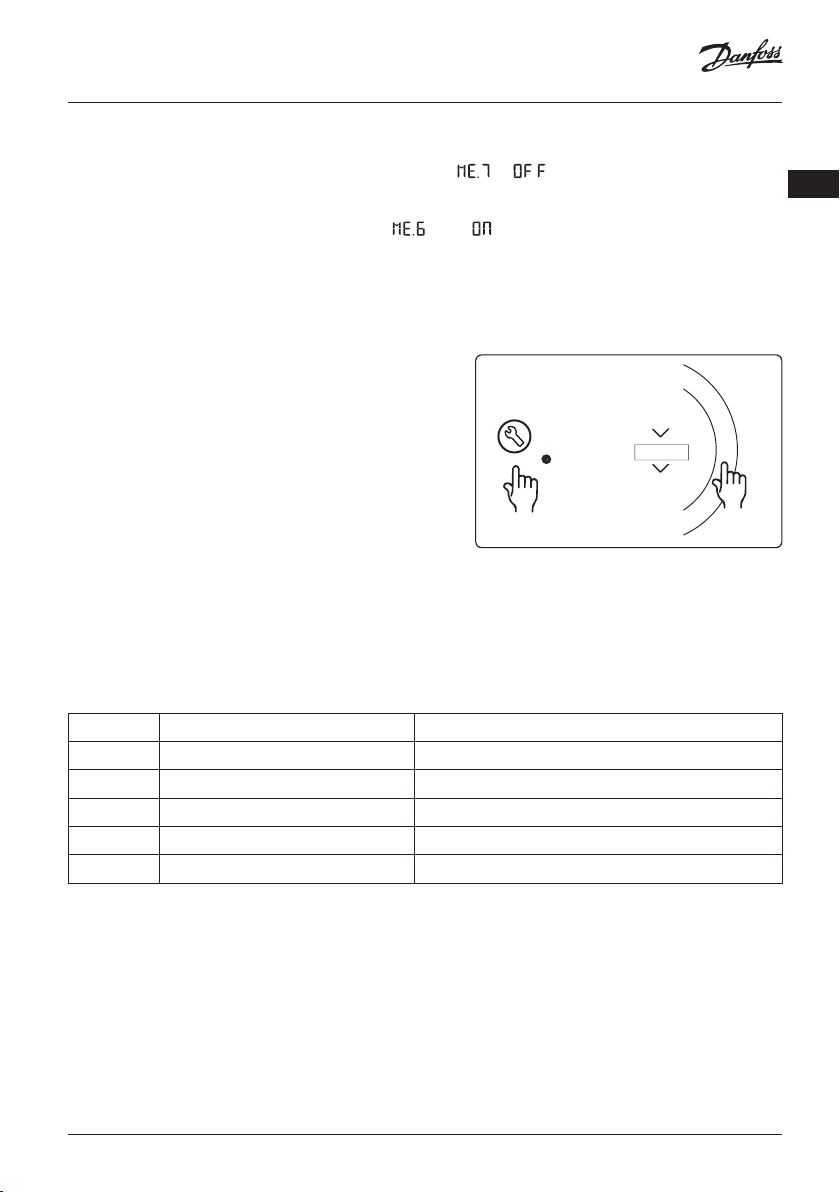

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

© Danfoss | FEC | 2018.12 | 9VIMDE20F / 088N2100

Page 10

Installation Guide Expansion Module for Danfoss Icon™ Master

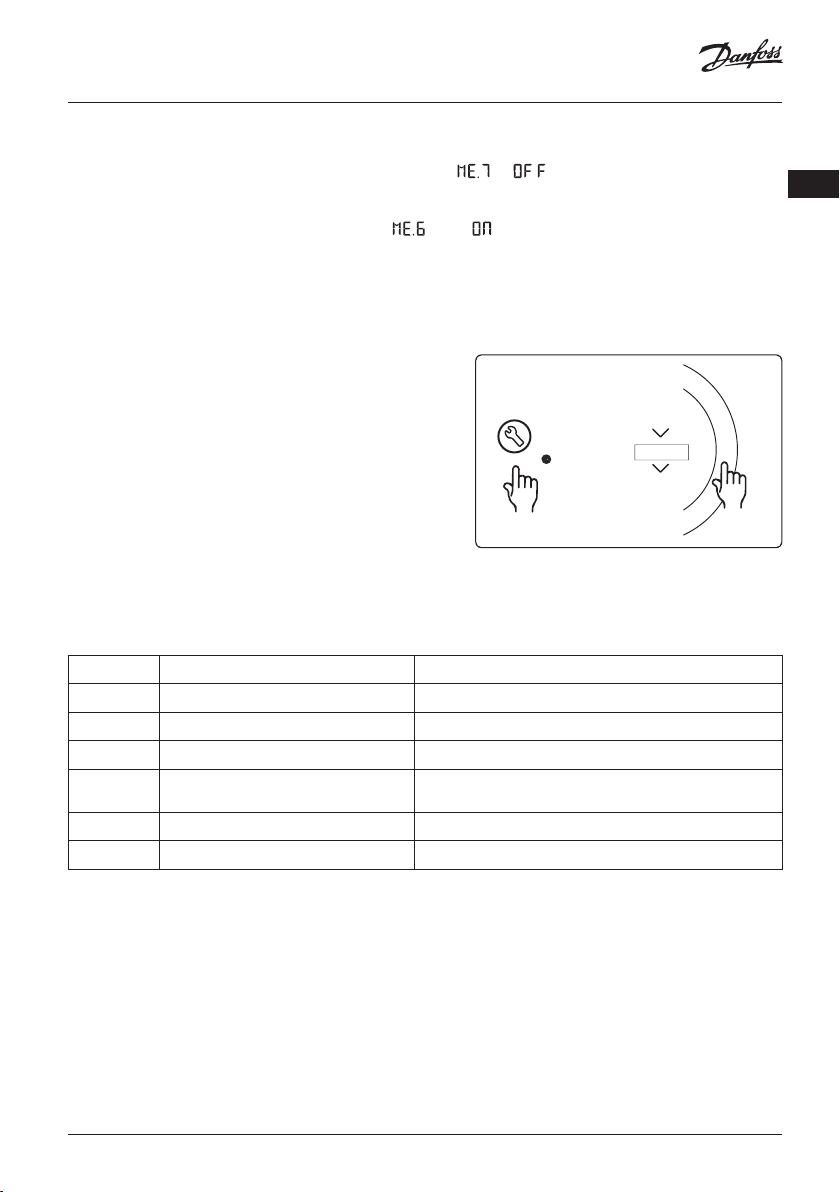

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

O

Step 1:1 During the 1 minute test period, the display on

the master controller will show the measured supply flow

temperature in the display.

Parts list

Pos. 1 087B1165 1 pc. ESM-11 PT1000 sensor

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, type CF-DS

OK

10 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 11

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0004: 2 pipe system with heat pump controlled changeover to

cooling.

Optional: Dewpoint sensor (recommended), Circulation pump and heat demand signal.

Application description

Floor heating system with automatic changeover for cooling controlled by heat source e.g. heat pump.

The heat pump provides the cooling signal to the Danfoss Icon™ Master, when the heat pump goes into

cooling mode thus activating cooling mode. If connected, the system will control the circulation pump and

it will be turned on when minimum 1 room has a heat or cooling demand.

The heat signal for e.g. a boiler or heat pump is only activated when the system is in heating mode and

minimum 1 room has a heat demand. For cooling applications it is always recommended to have a dew

point sensor installed in the system to prevent moisture damage to floor and installations in cases where

the relative humidty exceeds dew point.

Settings

No settings necessary.

GB

APPLICATION

OK

OK

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Application test function

Not relevant.

Parts list

Pos. 1 NA 1 pc. heat pump

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, type CF-DS

© Danfoss | FEC | 2018.12 | 11VIMDE20F / 088N2100

Page 12

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0005: 2 pipe system with hybrid Air/water heat pump with integrated condensing boiler (example: Itho Cool Cube). Change over ordered from

reference room thermostat.

Optional: Dewpoint sensor (recommended) and Global standby.

Application description

Floor heating system with cooling done via e.g. Coolcube used as heating and cooling source.

The Icon™ system controls the heat and cooling demand by activating the corrosponding relay (PWR1

and potential free relay). For cooling applications it is always recommended to have a dew point sensor

installed in the system to prevent moisture damage to floor and installations in cases where the relative

humidty exceeds dew point. Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled).

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

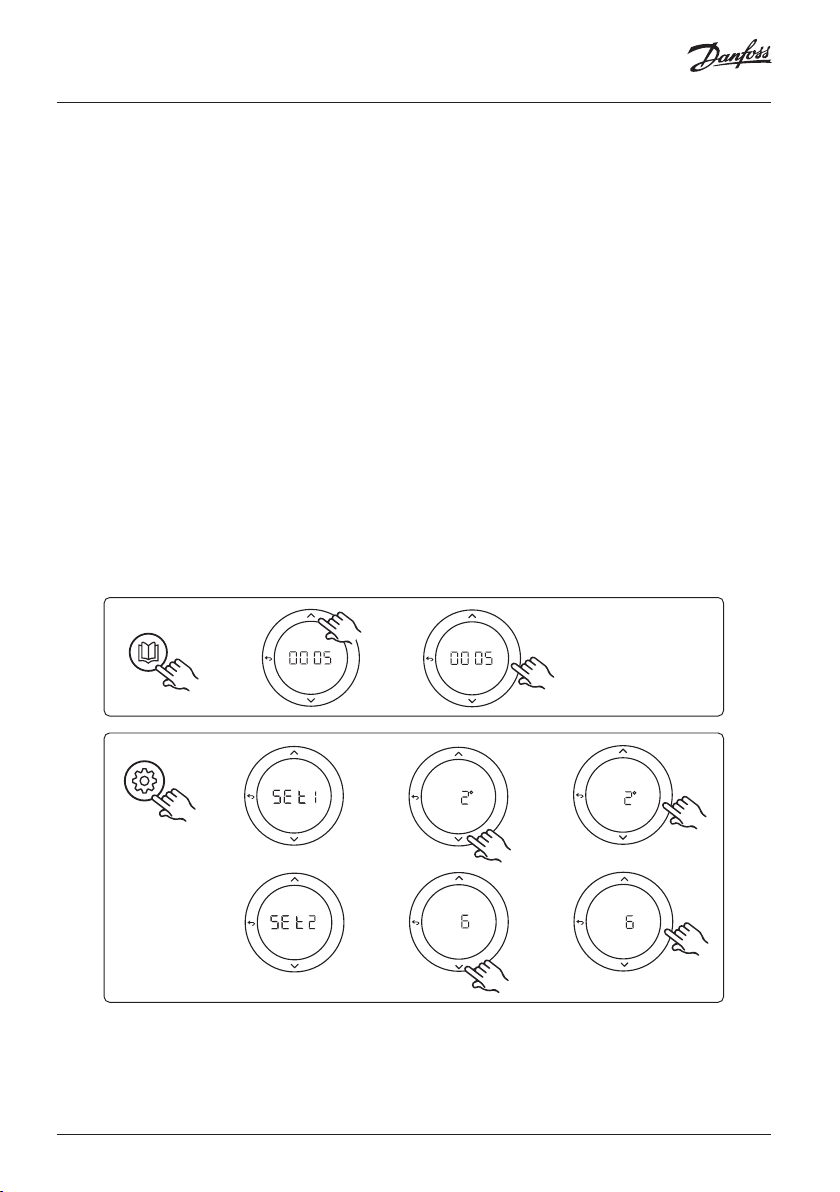

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

12 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 13

Installation Guide Expansion Module for Danfoss Icon™ Master

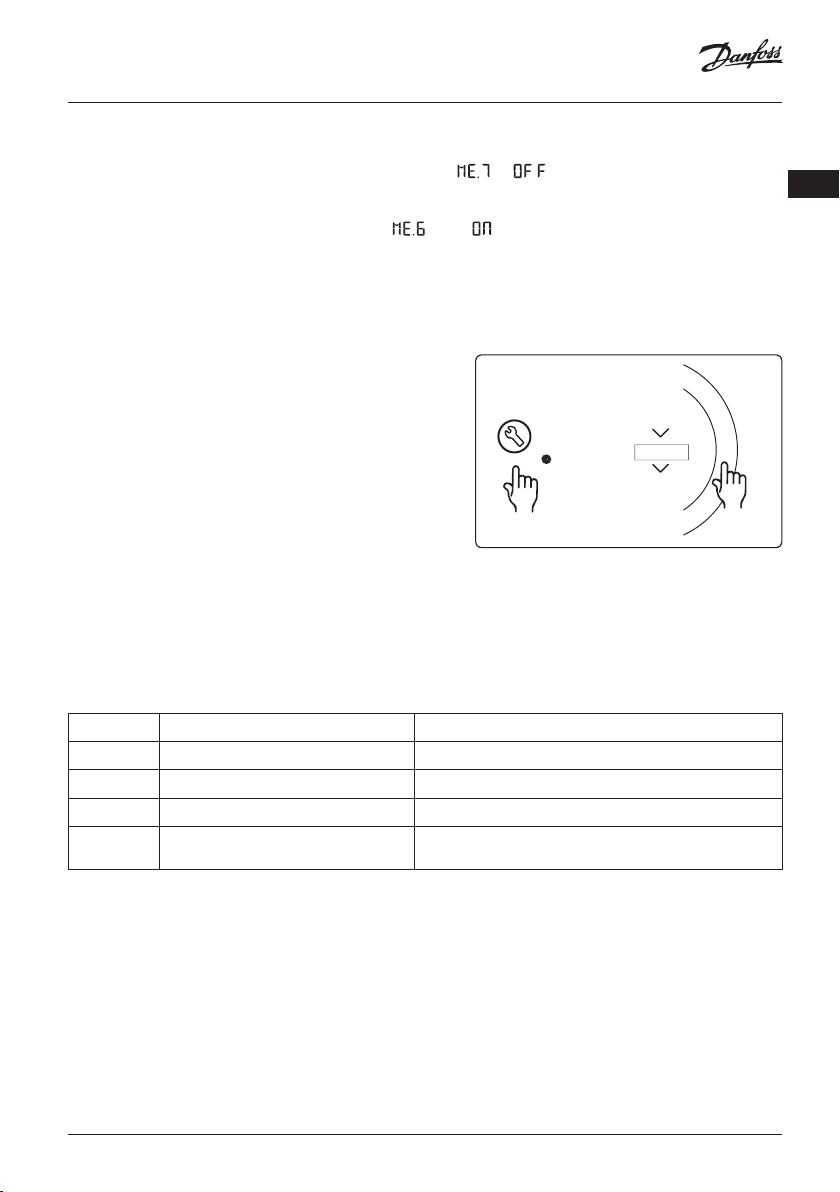

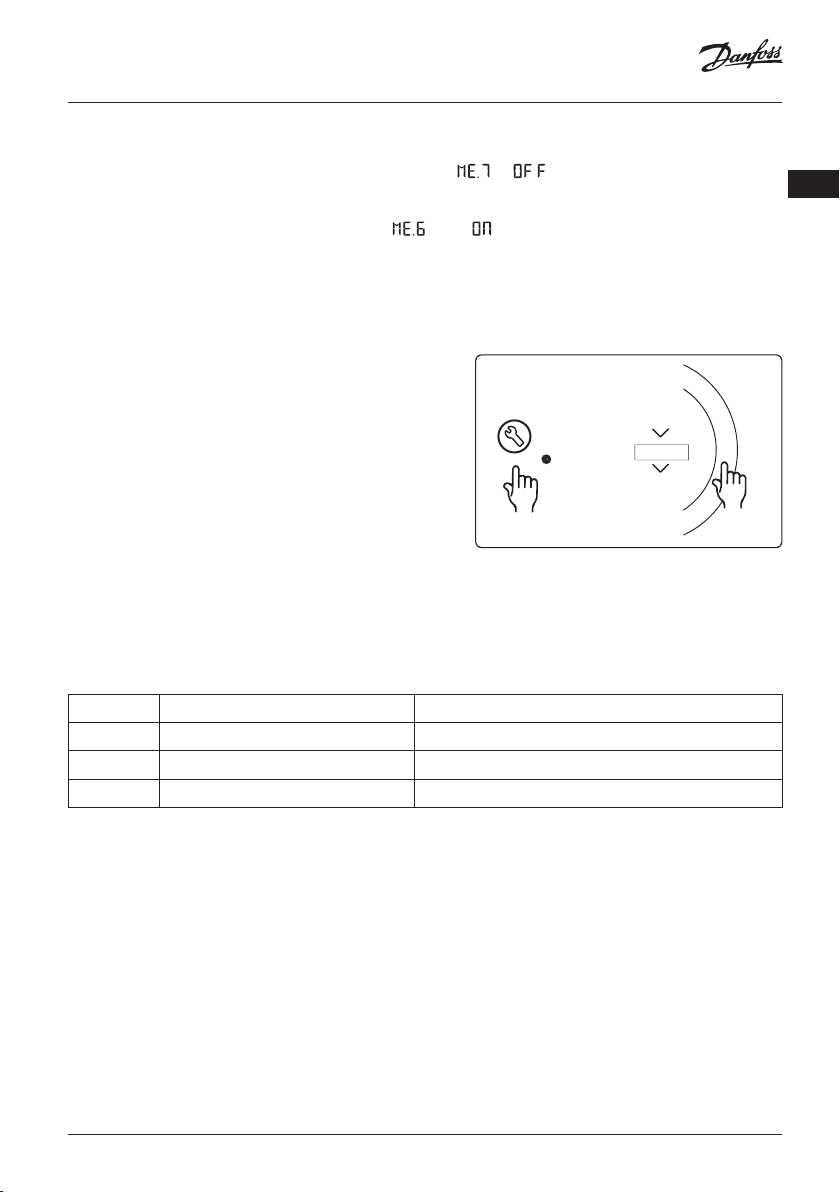

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

Step 1:3 During the first minute of the test, the heat

source is set to "heating mode" via "PWR1 output". Check

on heat source user interface that heating is active.

Step 2:3 During the second minute of the test, the heat

source is set to "cooling mode" via "Relay output". Check

on heat source user interface that cooling is active

Step 3:3 During the third minute of the test, the heat

source is set to "neutral mode", neither heating nor cooling

is active.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

GB

Parts list

Pos. 1 NA 1 pc. e.g. Coolcube

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, type CF-DS

Pos. 5. NA

External relay (convert 230 V to potential free relay), not

supplied by Danfoss

© Danfoss | FEC | 2018.12 | 13VIMDE20F / 088N2100

Page 14

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0006: 3-pipe system with cooling control via motorized valve and

common return, change over signal ordered by reference room thermostat.

Optional: Dewpoint sensor (recommended), Global standby and heat demand signal relay.

Application description

3 -pipe Floor heating system with cooling controlled via motorized valve and common return.

The Icon™ system controls the heat and cooling demand by activating the corresponding relay (PWR1

and PWR2). For cooling applications it is always recommended to have a dew point sensor installed in the

system to prevent moisture damage to floor and installations in cases where the relative humidty exceeds

dew point. Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled).

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

14 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 15

Installation Guide Expansion Module for Danfoss Icon™ Master

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

Step 1:2 During the first minute of the test, the AMZ 113

valve is set to "heating mode" via "PWR1 output going

ON". Check on valve/actuator that position is correct for

"heating".

Step 2:2 During the second minute of the test, the AMZ

113 valve is set to "cooling mode" via "PWR1 output going

OFF". Check on valve/actuator that position is correct for

"Cooling".

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

GB

Parts list

Pos. 1 DN15: 082G5511 DN20: 088G5512 1 pc. AMZ 113 (3 -way valve)

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, type CF-DS

© Danfoss | FEC | 2018.12 | 15VIMDE20F / 088N2100

Page 16

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0007: 3-pipe system with cooling control via thermal actuators and

common return controlled by reference room thermostat.

Optional: Dewpoint sensor (recommended), Global standby, pump relay and heat demand signal.

Application description

3 -pipe Floor heating system with cooling controlled via thermal actuators and common return.

The Icon™ system controls the heat and cooling demand by activating the corresponding outputs (M1 and

M2). For cooling applications it is always recommended to have a dew point sensor installed in the system

to prevent moisture damage to floor and installations in cases where the relative humidty exceeds dew

point. Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled).

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

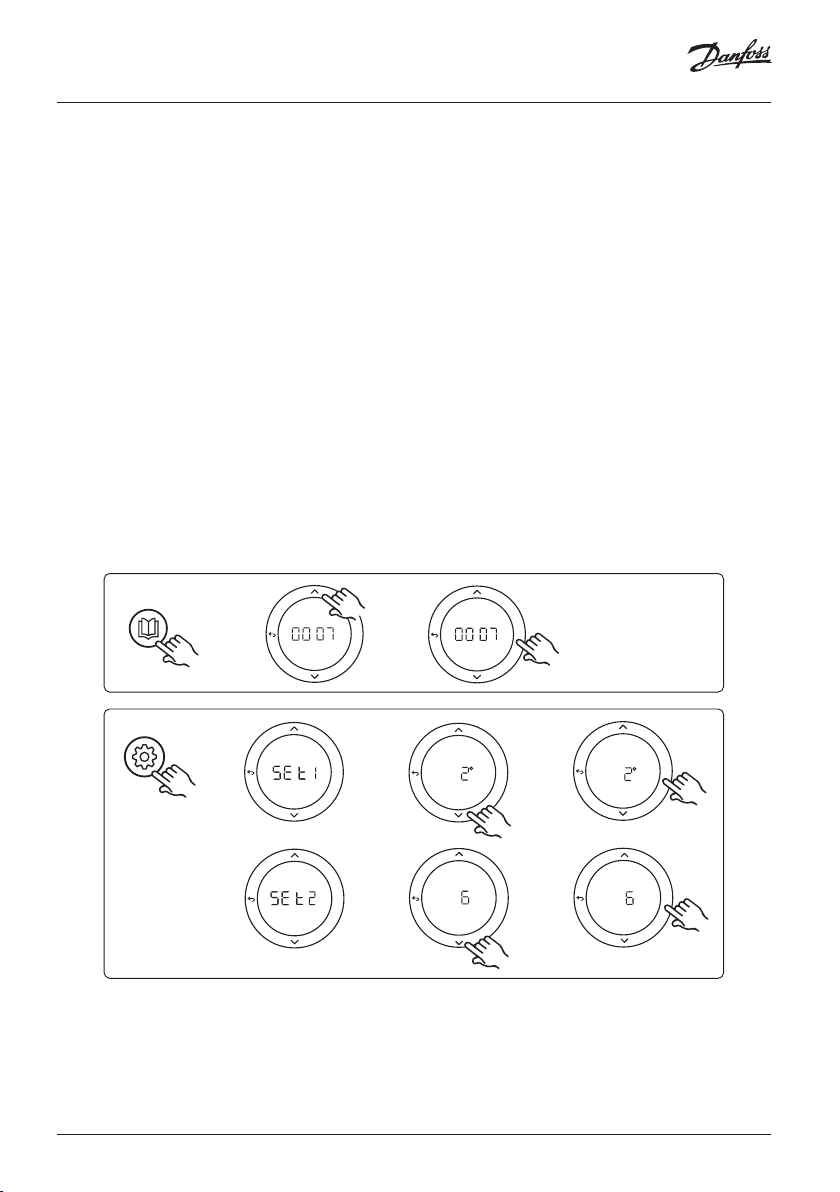

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

16 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 17

Installation Guide Expansion Module for Danfoss Icon™ Master

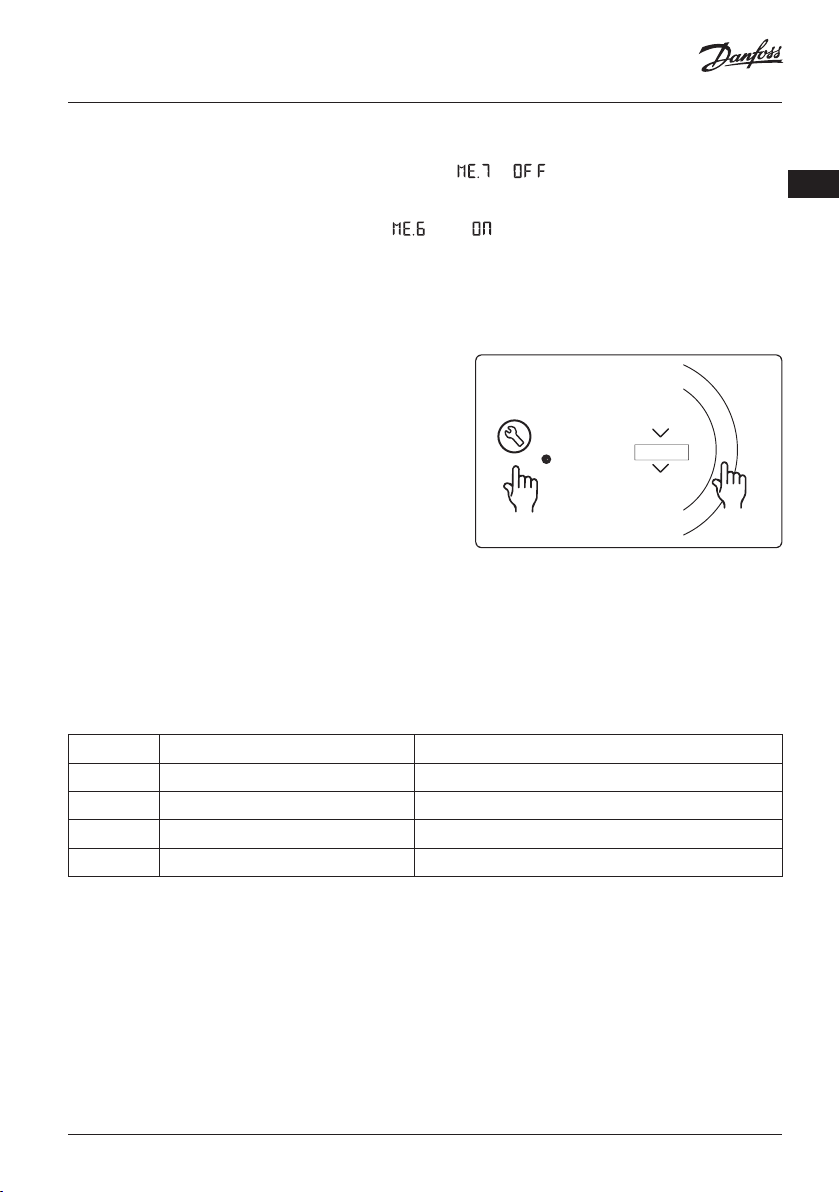

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

Step 1:3 During the first five minutes, the output 1

is set to "ON" = heating mode/hot flow side (up to 3

minutes opening time can be expected).

Step 2:3 During next five minutes, the output 1 is

set to "OFF", and the outputs 3 & 4 are set to "ON"

= cooling mode/cold flow side (up to 3 minutes

opening time can be expected).

Step 3:3 During last 5 minutes, all outputs 1 and 2

should close.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

GB

Parts list

Pos. 1 DN15: 013G3094 DN20: 013G3016 2 pcs. RA-C valve

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1pc. dew point sensor, type CF-DS

Pos. 5a & 5b 088H3110 2 pcs. thermal actuator, 24 V TWA-A

© Danfoss | FEC | 2018.12 | 17VIMDE20F / 088N2100

Page 18

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0008: 3-pipe system with cooling control via motorized actuators

and common return controlled by reference room thermostat.

Optional: Dewpoint sensor (recommended), Global standby, pump relay and heat demand signal.

Application description

3 -pipe Floor heating system with cooling controlled via motorized actuators and common return.

The Icon™ system controls the heat and cooling demand by activating the corrosponding outputs (PWR1

and potential free relay). For cooling applications it is always recommended to have a dew point sensor

installed in the system to prevent moisture damage to floor and installations in cases where the relative

humidty exceeds dew point. Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled)

If no heating or cooling demand is present, the two shut-off valves will close (AMZ 112).

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

18 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 19

Installation Guide Expansion Module for Danfoss Icon™ Master

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

Step 1:3 During the first minute of the test, the AMZ 112

valve of the hot flow side is set to "heating mode" via

"PWR1 output going ON". Check on valve/actuator that

position is correct for "heating".

Step 2:3 During the second minute of the test, the AMZ

112 valve on the cold flow side is set to "cooling mode"

via "PWR1 output going OFF" and "Relay output" going

ON. Check on valve/actuator that position is correct for

"cooling".

Step 3:3 During last minute of the test, botm AMZ 112

valves are closed.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

GB

Parts list

Pos. 1a & 1b DN15: 082G5511 DN20: 082G5512 2 pcs. AMZ112

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 set Danfoss Manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, Type CF-DS

© Danfoss | FEC | 2018.12 | 19VIMDE20F / 088N2100

Page 20

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0009: 4-pipe system with 6-port valve, automatic change over for

cooling controlled by a reference room thermostat. (Require external 24 VAC PSU).

Optional: Dewpoint sensor (recommended), shut-off function and Global standy.

Application description

Floor heating system with automatic changeover for cooling via 6-way changeover valve controlled by a

reference room thermostat.

The system can be configured with optional shut off function via a Danfoss AMZ-112 2-way ball valve and

Global standby. For cooling applications it is always recommended to have a dew point sensor installed

in the system to prevent moisture damage to floor and installations in cases where the relative humidty

exceeds dew point. Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled).

If no heating or cooling demand is present, the shut-off valve will close.

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a 15

degree celcius setpoint.

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

20 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 21

Installation Guide Expansion Module for Danfoss Icon™ Master

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

RUN

INSTALL

UNINSTALL

TEST

Test steps

Step 1:3 During the first two minutes, the AMZ 112 valve

goes to position "Flow" and the ChangeOver6 valve goes

to position "Cooling" for 1 minute.

Step 2:3 The ChangeOver6 valve now goes to position

"Heating" for 1 minute.

Step 3:3 The AMZ 112 valve goes to position "No Flow".

Parts list

Pos. 1 DN 15: 003Z3150 / DN 20: 003Z31511 1 pc. Danfoss ChangeOver6 6-port valve

Pos. 2 003Z3155 1 pc. Danfoss ChangeOver6 actuator

Pos. 3 DN15: 082G5501 / DN20: 082G55021 1 pc. AMZ 112

Pos. 4 088U05XX / 088U06XX / 088U07XX 1 pc. Danfoss manifold (types FHF or BasicPlus or SSM)

Pos. 5 N/A

Pos. 6 088U0251 1 pc. dew point sensor, type CF-DS

Pos. 7 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

1 pc. external power supply 230 V->24 VAC, not supplied by

Danfoss. Minimum 5 VA output on 24 V side.

TEST NET

TEST APP

TEST FL

OK

O

GB

© Danfoss | FEC | 2018.12 | 21VIMDE20F / 088N2100

Page 22

Installation Guide Expansion Module for Danfoss Icon™ Master

Application 0010: 4-pipe system with 2-way valves on supply pipes and automatic

change over for cooling controlled by a reference room thermostat.

Optional: Dewpoint sensor (recommended), circulation pump, heat demand signal and Global

standby.

Application description

4-pipe system with 2-way valves on supply pipes and automatic change over for cooling controlled by

reference room thermostat.

The system activates cooling mode via 2-way valves with thermal actuators on supply and return side by

activating the corresponding outputs (M1 - M4). Note: In this application outputs 1, 2, 3 & 4 on Danfoss Icon™

Master is used for the application and cannot be assigned to thermostats.

For cooling applications it is always recommended to have a dew point sensor installed in the system to

prevent moisture damage to floor and installations in cases where the relative humidty exceeds dew point.

Four conditions must be true before cooling in a room is allowed:

• Reference room temperature must exceed the room setpoint + cooling hysterhesis.

• No room has called for heating within neutral time.

• The dew point sensor must not be active / no condensation risk present.

• The room thermostat must be enabled for cooling (default = enabled).

The Global standby is a potential free input that can be used to remotely put the system in Global away

mode e.g. via an external 3rd party GSM module. When global standby input is active, all rooms receive a

15 degree celcius setpoint.

Settings

“SET 1” = Set desired cooling hysterhesis for change-over [+2 to +4K]

“SET 2” = Set neutral time that must pass without active heating or cooling, before change-over can be

activated [3-6 Hrs.]

APPLICATION

SETTINGS

22 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 23

Installation Guide Expansion Module for Danfoss Icon™ Master

Settings on thermostat

Excluding rooms from cooling: To exclude a room from cooling - typically in bathrooms where cooling

would be uncomfortable - go to thermostat and set menu to . See Thermostat Installation Guide

for further information.

Choose reference room thermostat: To assign a thermostat as reference room thermostat, go to the

desired reference room thermostat and in menu set to .

When selected the thermostat will control when the system goes from heating mode to cooling mode

based on the actual temperature in the room.

It is only possible to have one reference thermostat per system and if more than one thermostats are

assigned as reference, the last assigned will overwrite the previous reference room thermostats and cause

these to revert to normal function.

Application test function

Enter the “Test” menu via the installer key.

The Application test (APP test) is specific for each application. The test is split into steps to ensure that all components are installed correctly. Please follow the process.

Test steps

Step 1:3 During the first five minutes, the outputs 1&2 are

set to "ON" = heating mode/hot flow side (up to 3 minutes

opening time can be expected).

Step 2:3 During next five minutes, the outputs 1&2 are set

to "OFF", and the outputs 3 & 4 are set to "ON" = cooling

mode/cold flow side (up to 3 minutes opening time can be

expected).

Step 3:3 During last 5 minutes, all outputs 1, 2, 3 and 4

should close.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

GB

Parts list

Pos. 1 DN15: 013G3094 DN20: 013G3016 4 pcs. RA-C valve

Pos. 2 088U05XX / 088U06XX / 088U07XX 1 pc. Danfoss manifold (types FHF or BasicPlus or SSM)

Pos. 3 NC: 088H3110 / NO: 088H3111 xx pcs. thermal actuator, 24 V TWA-A

Pos. 4 088U0251 1 pc. dew point sensor, type CF-DS

Pos. 5 NC: 088H3110 2 pcs. thermal actuator, 24 V TWA-A

Pos. 6 NC: 088H3110 2 pcs. thermal actuator, 24 V TWA-A

© Danfoss | FEC | 2018.12 | 23VIMDE20F / 088N2100

Page 24

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Die Verdrahtung gemäß dem

Schaltdiagramm durchführen und

1

APPLICATION

anschließend das Erweiterungsmodul

für zusätzliche Funktionen in den

Danfoss Icon™ Hauptregler einführen.

2

IN 1

SETTINGS

IN 2 IN 3

3

1. Mit dieser Taste können Sie die

Anwendung auswählen. Drücken

Sie die Anwendungstaste, wählen

Sie mit und Anwendung

1-11 aus und bestätigen Sie mit

„OK“. Wählen Sie die geeignete

Anwendung mithilfe der Anwendungszeichnungen aus.

2. Mit dieser Taste können Sie

anwendungsspezifische Einstellungen einstellen. Die für die gewählte Anwendung verfügbaren

Einstellungen sind in der Anwendungsbeschreibung aufgeführt.

3. LED-Leuchten zeigen den Status

der Eingänge 1 bis 3 an. Vgl. die

Anwendungsbeschreibung für die

jeweilige Anwendung.

4. Anschlussklemmen für den Anschluss verschiedener Verdrahtungen/externer Geräte.

5. Kabel-Zugentlastung.

6. Lösevorrichtung für Verdrahtung/

Kabel.

4

IN 3 IN 2 IN 1

PWR3

PT

24

1000

VDC

5

6

24 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 25

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0001: Zweirohrsystem, vorgegebene Zulufttemperatur, elektronisch kontrolliert.

Optional: Global Standby.

Anwendungsbeschreibung

Fußbodenheizungssystem mit elektronischer Regelung der Zulufttemperatur. Die Zulufttemperatur ist auf

einen vorgegebenen Wert eingestellt.

Das System nutzt einen PT1000-Fühler, um die Zulufttemperatur zu erkennen und zu regeln, und wird auch

eingesetzt, um sicherzustellen, dass die Temperatur nicht die zulässige Höchsttemperatur übersteigt. Wenn

verbunden, steuert das System die Umwälzpumpe und das Heizbedarfssignal, beispielsweise für einen

Kessel oder eine Wärmepumpe. Die Pumpe und das Heizbedarfssignal sind eingeschaltet, wenn bei mindestens einem Kreislauf Heizbedarf besteht. Ausgang 1 muss für TWA an der Mischergruppe verwendet

werden.

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Vorlauftemperatur [25-70 °C] einstellen

„SET 2“ = Gewünschte Sicherheits-Abschalttemperatur [30-75 °C] einstellen

Hinweis: Die Temperatur muss über der Vorlauftemperatur liegen.

APPLICATION

SETTINGS

OK

OK

OK

OK

OK

DE

OK

OK

OK

© Danfoss | FEC | 2018.12 | 25VIMDE20F / 088N2100

Page 26

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:1 Gehen Sie zum Regelventilantrieb der Mischer-

gruppe und überprüfen Sie, ob sich das Ventil vollständig

öffnet (es sind bis zu drei Minuten Öffnungszeit zu erwarten). Nach fünf Minuten schließt sich der Ventilantrieb der

Mischergruppe wieder.

Während der fünfminütigen Testphase zeigt das Display am

Hauptregler auch die gemessene Vorlauftemperatur an.

Teileliste

Pos. 1 088U0093-96 1 Stk. Danfoss FHM-Cx Mischergruppe

Pos. 2 088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

Pos. 3 NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

Pos. 4 087B1165 1 Stk. ESM-11 PT-1000 Fühler

Pos. 5. NC: 088H3110/NC: 193B2148 1 Stk. Thermischer Stellantrieb, 24 V (Typen TWA-A oder ABN-FBH)

26 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 27

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0002: Zweirohrsystem mit bedarfsbasierter Regelung der

Zulufttemperatur.

Optional: Globales Standby.

Anwendungsbeschreibung

Fußbodenheizungssystem mit elektronischer Regelung der Zulufttemperatur.

Die bedarfsbasierte Zulufttemperatur wird je nach dem Heizbedarf aus den Räumen geregelt. Das System

nutzt einen PT1000-Fühler, um die Zulufttemperatur zu erkennen, und wird auch eingesetzt, um mithilfe

eines Sicherheits-Tmax sicherzustellen, dass die Temperatur nicht die zulässige Höchsttemperatur übersteigt. Wenn verbunden, steuert das System die Umwälzpumpe und das Heizbedarfssignal, beispielsweise

für einen Kessel oder eine Wärmepumpe. Die Pumpe und das Heizbedarfssignal sind eingeschaltet, wenn

bei mindestens einem Kreislauf Heizbedarf besteht. Ausgang 1 muss für TWA an der Mischergruppe

verwendet werden.

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

“SET 1” = Set desired min. supply flow temperature [25-65°C]

„SET 1“ = Gewünschte minimale Vorlauftemperatur [25-65 °C] einstellen

„SET 2“ = Gewünschte maximale Vorlauftemperatur [30-70 °C] einstellen

Hinweis: Die Temperatur muss mindestens 5 °C höher als die minimale Vorlauftemperatur eingestellt werden.

„SET 3“ = Gewünschte Sicherheits-Abschalttemperatur [30-75 °C] einstellen

Hinweis: Die Temperatur muss über der Vorlauftemperatur liegen.

APPLICATION

SETTINGSSETTINGS

OK

OKOK

OK

OKOK

OKOK

DE

OKOK

OKOK

OKOK

OKOK

OKOK

OKOK

© Danfoss | FEC | 2018.12 | 27VIMDE20F / 088N2100

Page 28

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

Testschritte

Schritt 1:1 Gehen Sie zum Regelventilantrieb der Mischer-

gruppe und überprüfen Sie, ob sich das Ventil vollständig

öffnet (es sind bis zu drei Minuten Öffnungszeit zu erwarten). Nach fünf Minuten schließt sich der Ventilantrieb der

Mischergruppe wieder.

Während der fünfminütigen Testphase zeigt das Display am

Hauptregler auch die gemessene Vorlauftemperatur an.

Teileliste

Pos. 1

Pos. 2

Pos. 3

Pos. 4

Pos. 5.

088U0093-96 1 Stk. Danfoss FHM-Cx Mischergruppe

088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

087B1165 1 Stk. ESM-11 PT-1000 Fühler

NC: 088H3110/NC: 193B2148 1 Stk. Thermischer Stellantrieb, 24 V (Typen TWA-A oder ABN-FBH)

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

28 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 29

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0003: Zweirohrsystem mit automatischer Umschaltung zur Kühlung

auf der Grundlage der Zulufttemperatur.

Optional: Taupunktfühler (empfohlen), Globales Standby, Umwälzpumpe und Heizbedarfssignal.

Anwendungsbeschreibung

Fußbodenheizungssystem mit automatischer Umschaltung zur Kühlung auf der Grundlage des Zulufttemperatureingangs.

Die Zulufttemperatur wird mittels eines PT1000-Fühlers überwacht. Je nach Messung schaltet das System

von Heizung auf Kühlung um. Wenn verbunden, steuert das System die Umwälzpumpe, die eingeschaltet

wird, wenn mindestens ein Raum Heiz- oder Kühlbedarf hat.

Das Heizsignal für beispielsweise einen Kessel oder eine Wärmepumpe wird nur aktiviert, wenn sich das

System im Heizmodus befindet und mindestens ein Raum Heizbedarf hat. Für Kühlanwendungen empfiehlt

es sich immer, im System einen Taupunktfühler installiert zu haben, um Feuchtigkeitsschäden an Boden

und Installationen zu vermeiden, wenn die relative Luftfeuchte den Taupunkt übersteigt.

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Vorlauftemperatur für die Umschaltung zum Heizen [25-55 °C] einstellen

„SET 2“ = Vorlauftemperatur für die Umschaltung zum Kühlen [15-25 °C] einstellen

Hinweis: Die Temperatur kann nicht höher als 2 °C unter der Umschalttemperatur zum Heizen eingestellt werden.

APPLICATION

SETTINGS

OK

OK

OK

OK

OK

DE

OK

OK

OK

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

© Danfoss | FEC | 2018.12 | 29VIMDE20F / 088N2100

Page 30

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

Testschritte

Schritt 1:1 Während der einminütigen Testphase zeigt das

Display am Hauptregler die gemessene Vorlauftemperatur

an.

Teileliste

Pos. 1

Pos. 2

Pos. 3

Pos. 4

087B1165 1 Stk. ESM-11 PT1000 Fühler

088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

088U0251 1 Stk. Taupunktfühler, Typ CF-DS

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

30 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

Page 31

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0004: Zweirohrsystem mit wärmepumpengeregelter Umschaltung

zur Kühlung.

Optional: Taupunktfühler (empfohlen), Umwälzpumpe und Heizbedarfssignal.

Anwendungsbeschreibung

Fußbodenheizungssystem mit automatischer Umschaltung zur Kühlung, die durch eine Wärmequelle wie z.

B. eine Wärmepumpe gesteuert wird.

Wenn die Wärmepumpe in den Kühlmodus umschaltet, gibt sie ein Kühlsignal an den Danfoss Icon™

Master ab und aktiviert so den Kühlmodus. Wenn verbunden, steuert das System die Umwälzpumpe, die

eingeschaltet wird, wenn mindestens ein Raum Heiz- oder Kühlbedarf hat.

Das Heizsignal für beispielsweise einen Kessel oder eine Wärmepumpe wird nur aktiviert, wenn sich das

System im Heizmodus befindet und mindestens ein Raum Heizbedarf hat. Für Kühlanwendungen empfiehlt

es sich immer, im System einen Taupunktfühler installiert zu haben, um Feuchtigkeitsschäden an Boden

und Installationen zu vermeiden, wenn die relative Luftfeuchte den Taupunkt übersteigt.

Einstellungen

Keine Einstellungen erforderlich.

APPLICATION

OK

OK

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Ba-

dezimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Anwendungstestfunktion

Nicht relevant.

Teileliste

Pos. 1

Pos. 2

Pos. 3

Pos. 4

NA 1 Stk. Wärmepumpe

088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

088U0251 1 Stk. Taupunktfühler, Typ CF-DS

DE

© Danfoss | FEC | 2018.12 | 31VIMDE20F / 088N2100

Page 32

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0005: Zweirohrsystem mit hybrider Luft-Wasser-Wärmepumpe mit

integriertem Brennwertkessel (Beispiel: Itho Cool Cube). Umschaltung vom

Referenzraumthermostat angefordert.

Optional: Taupunktfühler (empfohlen) und Globales Standby.

Anwendungsbeschreibung

Fußbodenheizungssystem mit Kühlung über z. B. Coolcube als Wärme- und Kühlquelle.

Das Icon™ -System steuert den Heiz- und Kühlbedarf durch Aktivierung des entsprechenden Relais (PWR1

und potentialfreies Relais). Für Kühlanwendungen empfiehlt es sich immer, im System einen Taupunktfühler installiert zu haben, um Feuchtigkeitsschäden an Boden und Installationen zu vermeiden, wenn die

relative Luftfeuchte den Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig ist, müssen vier

Bedingungen erfüllt sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert).

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

32 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 33

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im Raum,

wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:3 In der ersten Minute des Tests wird die Wär-

mequelle über den „Ausgang PWR1“ in den „Heizmodus“

versetzt. Überprüfen Sie an der Benutzeroberfläche der

Wärmequelle, ob die Heizung aktiv ist.

Schritt 2:3 In der zweiten Minute des Tests wird die Wärmequelle über einen „Relaisausgang“ in den „Kühlmodus“

versetzt. Überprüfen Sie an der Benutzeroberfläche der

Wärmequelle, ob die Kühlung aktiv ist.

Schritt 3:3 In der dritten Minute des Tests wird die Wärmequelle in den „neutralen Modus“ versetzt und weder

Heizung noch Kühlung sind aktiv.

DE

Teileliste

Pos. 1 NA 1 Stk., z. B. Coolcube

Pos. 2 088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

Pos. 3 NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

Pos. 4 088U0251 1 Stk. Taupunktfühler, Typ CF-DS

Pos. 5 NA

Externes Relais (Umwandlung von 230 V in potentialfreies Relais)

Wird von Danfoss nicht zur Verfügung gestellt

© Danfoss | FEC | 2018.12 | 33VIMDE20F / 088N2100

Page 34

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0006: Dreirohrsystem mit Kühlungssteuerung über motorisiertes

Ventil und gemeinsame Rückführung, Umschaltsignal von Referenzraumthermostat abgegeben.

Optional: Taupunktfühler (empfohlen), Globales Standby, und Heizbedarfssignalrelais.

Anwendungsbeschreibung

Dreirohr-Fußbodenheizungssystem mit Kühlungssteuerung über motorisiertes Ventil und gemeinsame

Rückführung.

Das Icon™ -System steuert den Heiz- und Kühlbedarf durch Aktivierung des entsprechenden Relais (PWR1

und PWR2). Für Kühlanwendungen empfiehlt es sich immer, im System einen Taupunktfühler installiert zu

haben, um Feuchtigkeitsschäden an Boden und Installationen zu vermeiden, wenn die relative Luftfeuchte

den Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig ist, müssen vier Bedingungen erfüllt

sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert).

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

34 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 35

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im

Raum, wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:2 In der ersten Minute des Tests wird das Ventil

AMZ 113 über die „Aktivierung des Ausgangs PWR1“ in

den „Heizmodus“ versetzt. Überprüfen Sie am Ventil/Stellantrieb, dass die Position für die „Heizung“ korrekt ist.

Schritt 2:2 In der zweiten Minute des Tests wird das Ventil

AMZ 113 über die „Deaktivierung des Ausgangs PWR1“ in

den „Kühlmodus“ versetzt. Überprüfen Sie am Ventil/Stellantrieb, dass die Position für die „Kühlung“ korrekt ist.

DE

Teileliste

Pos. 1

Pos. 2

Pos. 3

Pos. 4

DN 15: 082G5511 DN20: 088G5512 1 Stk. AMZ 113 (3-Wege-Ventil)

088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

088U0251 1 Stk. Taupunktfühler, Typ CF-DS

© Danfoss | FEC | 2018.12 | 35VIMDE20F / 088N2100

Page 36

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0007: Dreirohrsystem mit Kühlungssteuerung über thermische

Stellantriebe und gemeinsame Rückführung, gesteuert durch das Referenzraumthermostat.

Optional: Taupunktfühler (empfohlen), Globales Standby, Pumpenrelais und Heizbedarfssignal.

Anwendungsbeschreibung

Dreirohr-Fußbodenheizungssystem mit Kühlungssteuerung über thermische Stellantriebe und gemeinsame Rückführung.

Das Icon™ -System steuert den Heiz- und Kühlbedarf durch Aktivierung des entsprechenden Relais (M1 und

M2). Für Kühlanwendungen empfiehlt es sich immer, im System einen Taupunktfühler installiert zu haben,

um Feuchtigkeitsschäden an Boden und Installationen zu vermeiden, wenn die relative Luftfeuchte den

Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig ist, müssen vier Bedingungen erfüllt sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert).

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

36 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 37

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im Raum,

wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:3 In den ersten fünf Minuten stehen

die Aus gänge 1 auf „ON“ = Heizmodus/Seite mit

heißem Durchfluss (es sind bis zu drei Minuten

Öffnungszeit zu erwarten).

Schritt 2:3 In den nächsten fünf Minuten stehen die

Ausgänge 1 auf „OFF“ und die Ausgänge 2 auf „ON“

= Kühlmodus/Seite mit kaltem Durchfluss (es sind

bis zu drei Minuten Öffnungszeit zu erwarten).

Schritt 3:3 In den letzten fünf Minuten sollten sich

alle Ausgänge 1 und 2 schließen.

DE

Teileliste

Pos. 1 DN 15: 013G3094 DN20: 013G3016 2 Stk. RA-C-Ventil

Pos. 2 088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

Pos. 3 NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

Pos. 4 088U0251 1 Stk. Taupunktfühler, Typ CF-DS

Pos. 5a & 5b 088H3110 2 Stk. Thermischer Stellantrieb, 24 V TWA-A

© Danfoss | FEC | 2018.12 | 37VIMDE20F / 088N2100

Page 38

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0008: Dreirohrsystem mit Kühlungssteuerung über motorisierte

Stellantriebe und gemeinsame Rückführung, gesteuert durch das Referenzraumthermostat.

Optional: Taupunktfühler (empfohlen), Globales Standby, Pumpenrelais und Heizbedarfssignal.

Anwendungsbeschreibung

Dreirohr-Fußbodenheizungssystem mit Kühlungssteuerung über motorisierte Stellantriebe und gemeinsame Rückführung.

Das Icon™ -System steuert den Heiz- und Kühlbedarf durch Aktivierung der entsprechenden Ausgänge (PWR1 und potentialfreies Relais). Für Kühlanwendungen empfiehlt es sich immer, im System einen

Taupunktfühler installiert zu haben, um Feuchtigkeitsschäden an Boden und Installationen zu vermeiden,

wenn die relative Luftfeuchte den Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig ist,

müssen vier Bedingungen erfüllt sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert)

Wenn kein Heiz- oder Kühlbedarf vorliegt, schließen sich die beiden Absperrventile (AMZ 112).

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

38 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 39

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im Raum,

wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:3 In der ersten Minute des Tests wird das Ventil

AMZ 112 der Seite mit dem heißen Durchfluss über die

„Aktivierung des Ausgangs PWR1“ in den „Heizmodus“

versetzt. Überprüfen Sie am Ventil/Stellantrieb, dass die

Position für die „Heizung“ korrekt ist.

Schritt 2:3 In der zweiten Minute des Tests wird das Ventil

AMZ 112 der Seite mit dem kalten Durchfluss über die

„Deaktivierung des Ausgangs PWR1“ und die Aktivierung

des „Relaisausgangs“ in den „Kühlmodus“ versetzt. Überprüfen Sie am Ventil/Stellantrieb, dass die Position für die

„Kühlung“ korrekt ist.

Schritt 3:3 In der letzten Minute des Tests sind beide AMZ

112-Ventile geschlossen.

DE

Teileliste

Pos. 1a & 1b DN 15: 082G5511 DN20: 082G5512 2 Stk. AMZ112

Pos. 2 088U05XX/088U06XX/088U07XX 1 Satz Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

Pos. 3 NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

Pos. 4 088U0251 1 Stk. Taupunktfühler, Typ CF-DS

© Danfoss | FEC | 2018.12 | 39VIMDE20F / 088N2100

Page 40

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0009: Vierrohrsystem mit 6-Wege-Ventil, automatischer Umschaltung zur Kühlung, gesteuert durch einen Referenzraumthermostat.

(Externe 24 VAC PSU erforderlich).

Optional: Taupunktfühler (empfohlen), Abschaltfunktion und Globales Standby.

Anwendungsbeschreibung

Fußbodenheizungssystem mit automatischer Umschaltung zur Kühlung über ein 6-Wege-Umschaltventil,

das durch einen Referenzraumthermostat gesteuert wird.

Das System kann mit einer optionalen Abschaltfunktion über einen Danfoss AMZ-112-2-Wege-Kugelhahn

und Globales Standby konfiguriert werden. Für Kühlanwendungen empfiehlt es sich immer, im System

einen Taupunktfühler installiert zu haben, um Feuchtigkeitsschäden an Boden und Installationen zu vermeiden, wenn die relative Luftfeuchte den Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig

ist, müssen vier Bedingungen erfüllt sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert).

Wenn kein Heiz- oder Kühlbedarf vorliegt, schließt sich das Absperrventil.

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

40 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 41

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im Raum,

wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:3 In den ersten beiden Minuten stellt sich das

AMZ 112-Ventil in die Position „Durchfluss“ und das ChangeOver6 Ventil eine Minute lang in die Position „Kühlung“.

Schritt 2:3 Das ChangeOver6 Ventil stellt sich nun eine

Minute lang in die Position „Heizung“.

Schritt 3:3 Das AMZ 112-Ventil stellt sich in die Position

„Kein Durchfluss“.

DE

Teileliste

Pos. 1

Pos. 2 003Z3155 1 Stk. Danfoss ChangeOver6 Stellantrieb

Pos. 3

Pos. 4 088U05XX/088U06XX/088U07XX 1 Stk. Danfoss Verteiler (Typen FHF oder BasicPlus oder SSM)

Pos. 5 N/A

Pos. 6 088U0251 1 Stk. Taupunktfühler, Typ CF-DS

Pos. 7 NC: 088H3110/NO: 088H3111 xx Stk. Thermischer Stellantrieb, 24 V TWA-A

DN 15: 003Z3150/DN 20:

003Z31511

DN 15: 082G5501/DN20:

082G55021

1 Stk. Danfoss ChangeOver6 6-Wege-Ventil

1 Stk. AMZ 112

1 Stk. Externe Spannungsversorgung 230V->24VAC Wird von

Danfoss nicht zur Verfügung gestellt. Mindestens 5VA-Ausgang

auf der 24V-Seite.

© Danfoss | FEC | 2018.12 | 41VIMDE20F / 088N2100

Page 42

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Anwendung 0010: Vierrohrsystem mit 2-Wege-Ventilen an den Vorläufen und

automatischer Umschaltung zur Kühlung, gesteuert durch einen Referenzraumthermostat.

Optional: Taupunktfühler (empfohlen), Umwälzpumpe, Heizbedarfssignal und Globales Standby.

Anwendungsbeschreibung

Vierrohrsystem mit 2-Wege-Ventilen an den Vorläufen und automatischer Umschaltung zur Kühlung,

gesteuert durch Referenzraumthermostat.

Das System aktiviert den Kühlmodus über 2-Wege-Ventile mit thermischen Stellantrieben an den Vor- und

Rückläufen durch Aktivierung der entsprechenden Ausgänge (M1 – M4). Hinweis: Bei dieser Anwendung

werden die Ausgänge 1, 2 3 und 4 am Danfoss Icon™ Master für die Anwendung verwendet und können keinen

Thermostaten zugewiesen werden.

Für Kühlanwendungen empfiehlt es sich immer, im System einen Taupunktfühler installiert zu haben, um

Feuchtigkeitsschäden an Boden und Installationen zu vermeiden, wenn die relative Luftfeuchte den Taupunkt übersteigt. Bevor die Kühlung in einem Raum zulässig ist, müssen vier Bedingungen erfüllt sein:

• Die Referenzraumtemperatur muss den Raumsollwert und die Kühlhysterese überschreiten.

• Kein Raum hat innerhalb der neutralen Zeit Heizung angefordert.

• Der Taupunktfühler darf nicht aktiv sein/es darf kein Kondensationsrisiko vorliegen.

• Die Kühlung muss am Raumthermostat aktiviert sein (voreingestellt = aktiviert).

Das Globale Standby ist ein potentialfreier Eingang, mit dem das System per Fernzugriff in den Globalen

Abwesenheitsmodus versetzt werden kann, z. B. über ein externes GSM-Modul eines Drittanbieters. Wenn

der globale Standby-Eingang aktiv ist, erhalten alle Räume einen Sollwert von 15 Grad Celsius.

Einstellungen

„SET 1“ = Gewünschte Kühlhysterese für die Umschaltung [+2 bis +4 K] einstellen

„SET 2“ = Neutrale Zeit einstellen, die ohne aktive Heizung bzw. Kühlung vergehen muss, bevor die Um-

schaltung aktiviert werden kann [3-6 Std.]

APPLICATION

SETTINGS

42 | © Danfoss | FEC | 2018.12 VIMDE20F / 088N2100

OK

OK

OK

OK

OK

OK

OK

OK

Page 43

Installationsanleitung Erweiterungsmodus für Danfoss Icon™ Master

Einstellungen des Thermostats

Räume von der Kühlung ausschließen: Um einen Raum von der Kühlung auszuschließen, etwa ein Bade-

zimmer, in dem eine Kühlung unangenehm wäre, den Thermostat aufsuchen und Menü auf

einstellen. Weitere Informationen sind in der Installationsanleitung des Thermostats enthalten.

Referenzraumthermostat wählen: Um einen Thermostat als Referenzraumthermostat zu bestimmen, den

gewünschten Referenzraumthermostat aufsuchen und Menü auf einstellen.

Nachdem der Thermostat ausgewählt wurde, steuert dieser anhand der tatsächlichen Temperatur im Raum,

wann das System vom Heizmodus in den Kühlmodus umschaltet.

Es kann nur einen Referenzraumthermostat je System geben. Werden mehr als ein Thermostat als Referenz

bestimmt, überschreibt der zuletzt bestimmte Thermostat alle vorher bestimmten Referenzraumthermostate,

sodass diese zur Normalfunktion zurückkehren.

Anwendungstestfunktion

Rufen Sie über die Installateurstaste das Menü „Test“ auf.

Der Anwendungstest (APP-Test) ist anwendungsspezifisch.

Der Test ist in mehrere Schritte unterteilt, um sicherzustellen, dass alle Komponenten ordnungsgemäß installiert

werden. Befolgen Sie bitte das Verfahren.

RUN

INSTALL

UNINSTALL

TEST

TEST NET

TEST APP

TEST FL

OK

O

Testschritte

Schritt 1:3 In den ersten fünf Minuten stehen die Aus-

gänge 1 und 2 auf „ON“ = Heizmodus/Seite mit heißem

Durchfluss (es sind bis zu drei Minuten Öffnungszeit zu

erwarten).

Schritt 2:3 In den nächsten fünf Minuten stehen die

Ausgänge 1 und 2 auf „OFF“ und die Ausgänge 3 und 4 auf

„ON“ = Kühlmodus/Seite mit kaltem Durchfluss (es sind bis

zu drei Minuten Öffnungszeit zu erwarten).

Schritt 3:3 In den letzten fünf Minuten sollten sich alle

Ausgänge 1, 2, 3 und 4 schließen.

DE

Teileliste

Pos. 1 DN 15: 013G3094 DN20: 013G3016 4 Stk. RA-C-Ventil