Data sheet

Solenoid valves

Type EVU for fluorinated refrigerants

EVU solenoid valves are designed to fit into

compact refrigeration systems. Available in direct

and pilot operated versions, they can be applied in

liquid, suction, and hot gas lines with fluorinated

refrigerants.

EVU solenoid valves can be used in many different

refrigeration systems and are specially designed

for:

y commercial refrigeration systems

y refrigeration appliances

y liquid coolers

y ice cube machines

y mobile refrigeration systems

y heat pump systems

y air conditioning units

EVU valves are available in straightway

or angleway design. All valves are semi hermetically

sealed and are not serviceable. The standard coil is

available with 3-core cable connection, DIN plug

and 0.25 US spade.

EVU valve bodies and coils are ordered separately

in industrial pack.

Features y Compact construction small dimensions,

low weight for both valve and coil.

y Semi-hermetic construction. Metallic sealing

between armature tube and valve body. Bimetal

connections to the brass

housing Benefits:

– high strength of joints and high

vibration resistance

− maximum external tightness within

the whole temperature and pressure

operation range

y Bimetal connections simple, fast soldering

without the need of wet cloth or

refrigration pliers.

© Danfoss | DCS (rja) | 2016.02

y Direct and servo operated mini piston compact

solenoid valve.

y Universal application for

− liquid, suction, and hot gas applications

− reduced power consumption

y Simple and fast mounting of coil

− clip-on/off

y Small encapsulated coils with long life time

under extreme conditions.

y Refrigerants:

R744, R22/R407C, R404A/R507, R410A,

R134a, R407A, R23.

For other refrigerants, please contact Danfoss.

y Large MOPD range − up to 36 bar.

DKRCC.PD.BD0.1A.22 | 1

Data sheet | Product name, Solenoid valve, type EVU for fluorinated refrigerants

Approvals

Technical data

• UL Recognized Component (Canadian and US)

• PED (97/23/EC A3.P3)

• Low Voltage Directive (LVD) 2006/95/EC

Refrigerants

R744, R22/R407C, R404A/R507, R410A, R134a,

Ambient temperature

-40 – 140 °F

R407A, R23.

For other refrigerants, please contact Danfoss.

MOPD operating range

EVU 1: 0 psi up to 275 psi

Temperature of medium

EVU 2 – 8: 0.029 psi up to 522 psi

-40 – 221 °F

Humidity

0 − 100% R.H. (0-97% R.H. non-condensation

condition if IP level is below IPX5).

Opening differential pressure

with standard coil

Typ e

Min.

EVU 1 0.000 348

EVU 2 0.029 522 -40 – 221 1015 0.23

EVU 3 0.029 522 -40 – 221 1015 0.35

EVU 4 0.029 522 -40 – 221 1015 0.58

EVU 5

EVU 6 0.029 522 -40 – 221 1015 0.93

EVU 8 0.029 522 -40 – 221 1015 1.15

1)

Cv value is the water flow in [gal/min] at a pressure drop across

valve ∆p = 1 psi, ρ = 10 lbs/gal

2)

MOPD for media in gas form is approximately 14 psi greater

3)

For coil 208 – 240V, 60 Hz, MOPD is 250 psi

0.029 522 -40 – 221 1015 0.76

∆p [psi]

Max. (=MOPD) liquid

8 W AC [°F] [psi] [gal/min]

3)

Temperature

of medium

2)

-40 – 221 1015 0. 11

MOPD (Max. Opening Pressure Differential) is

measured with highest media and ambient

temperature and 15% below nominal voltage

Max. working

pressure

Ps

Cv – value

1)

1)

Rated liquid and suction vapor

capacity are based on:

y Evaporating temperature te

= 40 °F

y Liquid temperature ahead

of valve tl = 100 °F

y Pressure drop ∆p across

valve

– with liquid ∆p = 2 psi for

R134a,

∆p = 3 psi for R22/R407C,

R404A and R507,

–

with suction vapor ∆p = 1 psi

Rated hot gas capacity is based

on:

y Condensing temperature tc

= 100 °F

y Hot gas temperature th =

140 °F

y Pressure drop across valve

∆p = 2 psi

© Danfoss | DCS (rja) | 2016.02

Rated capacity 1) / [TR]

Typ e

R22/

R407C

EVU 1 0.64 0.48 0.44 0.64 0.55 0.04 0.05 0.06 0.12 0.10 0.10 0.18

EVU 2 1.27 0.96 0.87 1.27 0.11 0.08 0.09 0.13 0. 24 0.19 0 .19 0.36

EVU 3 1.9 0 1.45 1.31 1.90 0.16 0.12 0.14 0.19 0.35 0.29 0.28 0.53

EVU 4 3 .19 2 .41 2.18 3.17 0.26 0.20 0.23 0.32 0.59 0.48 0.47 0.89

EVU 5 4 .12 3.13 2.83 4.12 0.34 0.26 0.30 0.42 0.76 0.62 0.61 1.16

EVU 6 5.07 3.86 3.49 5.07 0.42 0.32 0.37 0.51 0.94 0.77 0.76 1.42

EVU 8 6.34 4.83 4.36 6.34 0.53 0.40 0.46 0.64 1.18 0.96 0.95 1.78

Metric conversions

y 1 psi = 0.07 bar

y5/9 (t1 °F -32) = 12 °C

Liquid Suction vapour Hot gas

R134a

R404A/

R507

R410A

R22/

R407C

R134a

R404A/

R507

R410A

R22/

R407C

R134a

y 1 lb = 0.454 kg

y 1 oz = 28.35 gram

y US gal/min = 0.86 m3/h

R404A/

R507

R410A

y 1 TR = 3.5 Kw

y 1 in = 25.4 mm

y 1 ft = 0.3 m

DKRCC.PD.BD0.1A.22 | 2

Data sheet | Product name, Solenoid valve, type EVU for fluorinated refrigerants

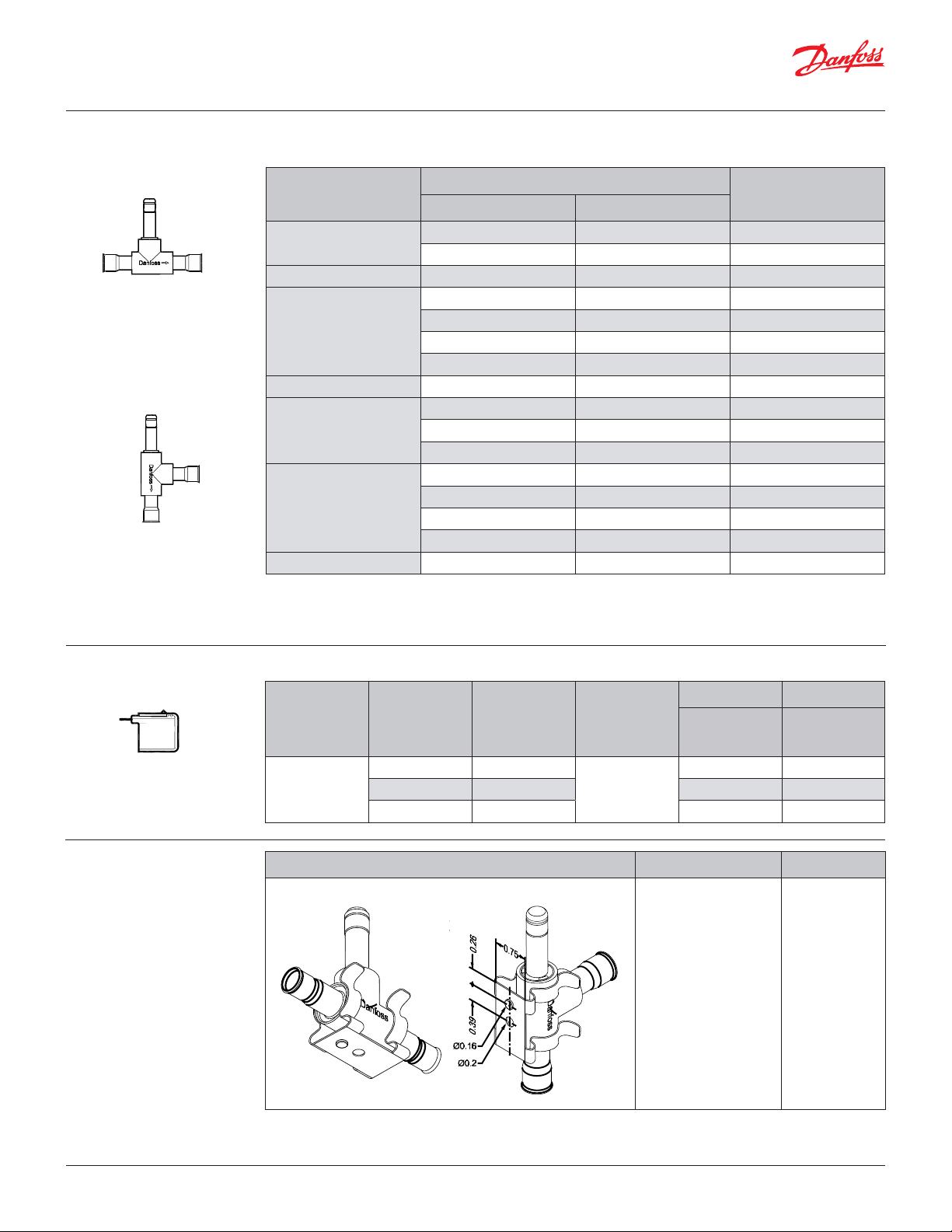

Ordering valve

EVU 1– 6

EVU 8

Normally closed NC

4

4

8

8

8

2

Connection

Code no.

— 032F7005

— 032F5024

— 032F5026

— 032F7000

— 032F5046

— 032F50 49

Typ e

[in.] [mm]

1

EVU 1

/

— 6 032F7004

EVU 2 — 6 032F5053

1

/

EVU 3

— 6 032F5025

3

/

— 10 032F5027

EVU 4 — 10 032F5037

3

/

EVU 5

— 10 032F7001

— 12 032F7003

3

/

EVU 6

— 10 032F5047

1

/

— 12 032F5048

EVU 8 — 12 032F8009

The valve code numbers on above are with coil

sealing O-ring. This should be removed for

US-coils with the external frame.

Ordering Coils Alternating current AC

Typ e

0,25 in.

US spade

EVU 1, EVU 2,

EVU 3, EVU 4,

EVU 5, EVU 6,

EVU 8

Accessories

Voltage

[V]

208 – 240 50 / 60

110 – 120 50 / 60 042N8233 042N4233

24 50 / 60 042N8236 042N4236

Frequency

[Hz]

Power

consumption

Holding: 8 W

16 VA

Inrush: 32 VA

Code no. Code no.

Industrial pack

40-off with

US spade IP00

Single pack with

US spade IP00

042N8230 042N4230

Part Description Code no.

Bracket for fixing of valve.

Industrial pack

032F8036

© Danfoss | DCS (rja) | 2016.02

DKRCC.PD.BD0.1A.22 | 3

Data sheet | Product name, Solenoid valve, type EVU for fluorinated refrigerants

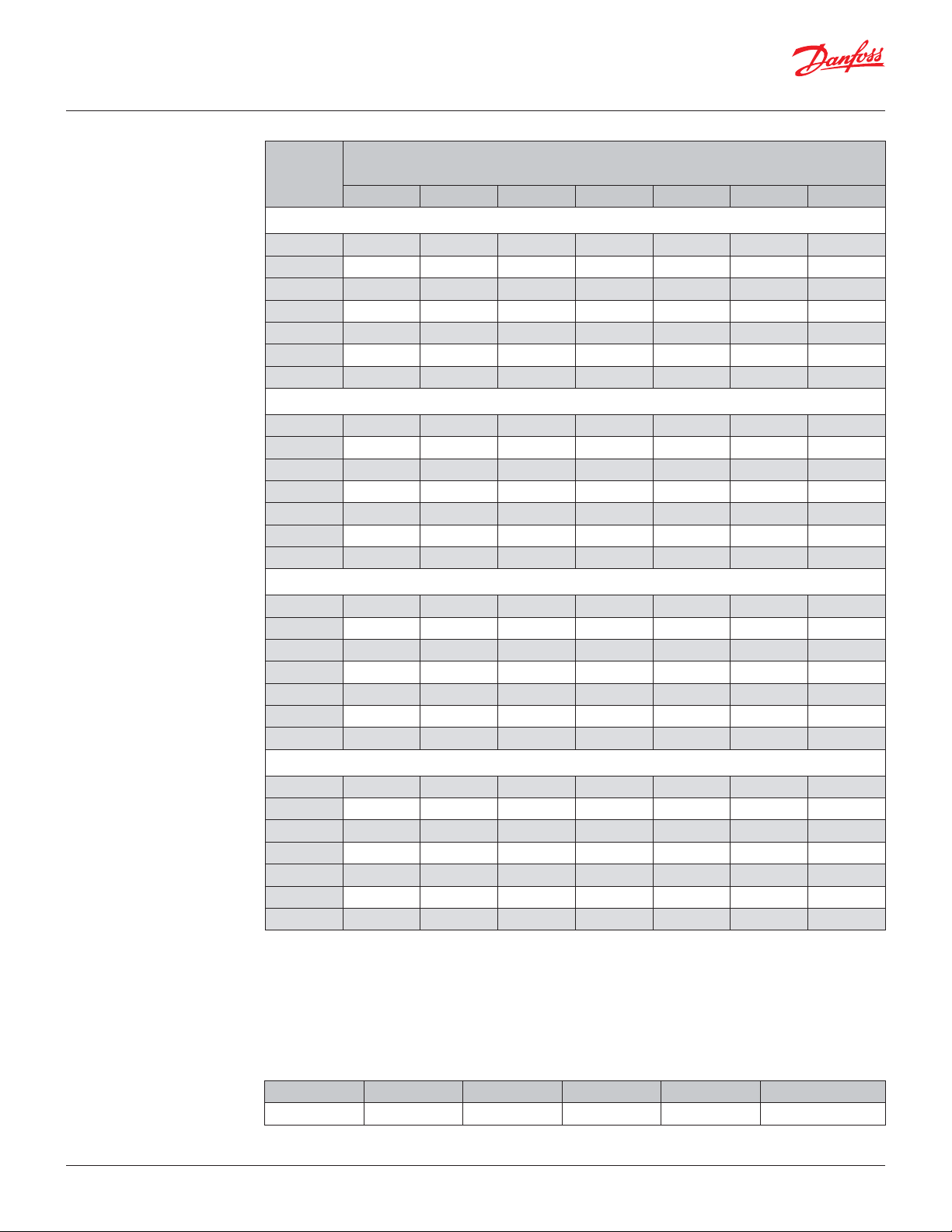

Capacity

Liquid capacity

Capacities are based on:

– liquid temperature

tl = 100 °F

– evaporating temperature

te = 40 °F

– superheat temperature

(te + 10 °F) = 50 °F

Metric conversions

1 psi = 0.07 bar

5

/9 (t1 °F - 32) = t2 °C

1 TR = 3.5 kW

Liquid capacity Qo [TR]

Typ e

1 2 3 4 5 6 7

at pressure drop across valve ∆p [bar]

R22/R407C

EVU 1

EVU 2 0.68 1.03 1.27 1.46 1. 63 1.79 1.93

EVU 3 1.02 1.55 1.90 2.19 2.45 2.69 2.90

EVU 4 1.69 2.59 3.17 3.66 4.09 4.48 4.84

EVU 5 2.20 3.36 4.12 4.75 5.31 5.83 6.29

EVU 6 2.71 4.14 5.07 5.85 6.54 7.17 7.74

EVU 8

0.34 0.52 0.64 0.73 0.82 0.85 0.97

3.39 5.18 6.34 7.31 8.18 8.96 9.68

R134A

EVU 1

EVU 2 0.68 0.96 1.18 1. 36 1. 52 1.67 1.80

EVU 3 1.02 1.45 1.77 2.05 2.29 2.51 2.71

EVU 4 1.71 2.41 2.59 3 .41 3.81 4.18 4.84

EVU 5

EVU 6 2.73 3.86 4.73 5.45 6.10 6.68 7. 22

EVU 8 3.41 4.83 5.91 6.81 7. 63 8.35 9.03

0.34 0.48 0.59 0.68 0.76 0.84 0.90

2.22 3 .13 3.84 4.43 4.96 5.43 5.86

R404A/507

EVU 1 0.25 0.36 0.44 0.51 0.57 0.62 0.67

EVU 2 0.50 0.71 0.87 1.01 1.13 1.23 1.33

EVU 3 0.76 1.07 1.31 1.51 1.69 1.85 2.00

EVU 4 1.26 1.78 2.18 2.52 2.81 3.09 3.33

EVU 5 1.64 2.31 2.83 3.27 3.66 4.01 4.33

EVU 6 2.02 2.85 3.49 4.03 4.50 4.94 5.33

EVU 8 2.53 3.56 4.36 5.04 5.63 6.18 6.66

R410a

EVU 1 0.34 0.52 0.64 0.73 0.82 0.90 0.97

EVU 2 0.68 1. 03 1.27 1. 46 1.63 1.79 1.93

EVU 3

EVU 4 1.69 2.59 3.17 3.66 4.07 4.48 4.84

EVU 5 2.20 3.36 4.12 4.75 5.29 5.83 6.29

EVU 6 2.71 4 .14 5.07 5.85 6. 51 7.17 7.74

EVU 8

1.02 1.55 1.90 2.19 2.44 2.69 2.90

3.39 5.18 6.34 7.31 8.14 8.96 9.68

© Danfoss | DCS (rja) | 2016.02

Correction factors

When liquid temperature tl ahead of the expansion

valve is other than 100°F, adjust the table capacities

by multiplying them by the appropriate correction

factor found in the following table.

Correction factors for liquid temperature t

tl [°F] 80 90 100 110 120

Factor 1.10 1.05 1.0 0 0.95 0.90

l

DKRCC.PD.BD0.1A.22 | 4

Loading...

Loading...