Page 1

Data Sheet

Solenoid valves

Type EVU

Normally Closed (NC)

EVU solenoid valves are designed to t into

compact refrigeration systems. Available in

direct and servo operated versions, they can be

applied in liquid, suction, and hot gas lines with

uorinated refrigerants.

EVU solenoid valves can be used in many

dierent refrigeration systems and are specially

designed for:

• Commercial refrigeration systems

• Refrigeration appliances

• Liquid coolers

• Ice cube machines

• Mobile refrigeration systems

• Heat pump systems

• Air conditioning units

EVU valves are available in straightway or

angleway design. All valves are semi

hermetically sealed and are not serviceable.

The standard coil is available with 3-core cable

connection and DIN plug.

EVU valve bodies and coils are ordered

separately.

AI263435875820en-000501

Page 2

Solenoid valves, Type EVU

Features

• Compact construction with small dimensions, low weight for both valve and coil.

• Semi-hermetic construction. Metallic sealing between armature tube and valve body. Bimetal connections to the

brass housing benets:

◦ High strength of joints and high vibration resistance

◦ Maximum external tightness within the whole temperature and pressure operation range

• Bimetal connections simple, fast soldering without the need of wet cloth or refrigration pliers.

• Direct and servo operated mini piston compact solenoid valve.

• Universal application for

◦ Liquid, Suction, and Hot gas applications

◦ Reduced power consumption

• Simple and fast mounting of coil, Clip clip - ON / OFF.

• Small encapsulated coils with long life time under extreme conditions.

• Large MOPD range - up to 36 bar.

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 2

Page 3

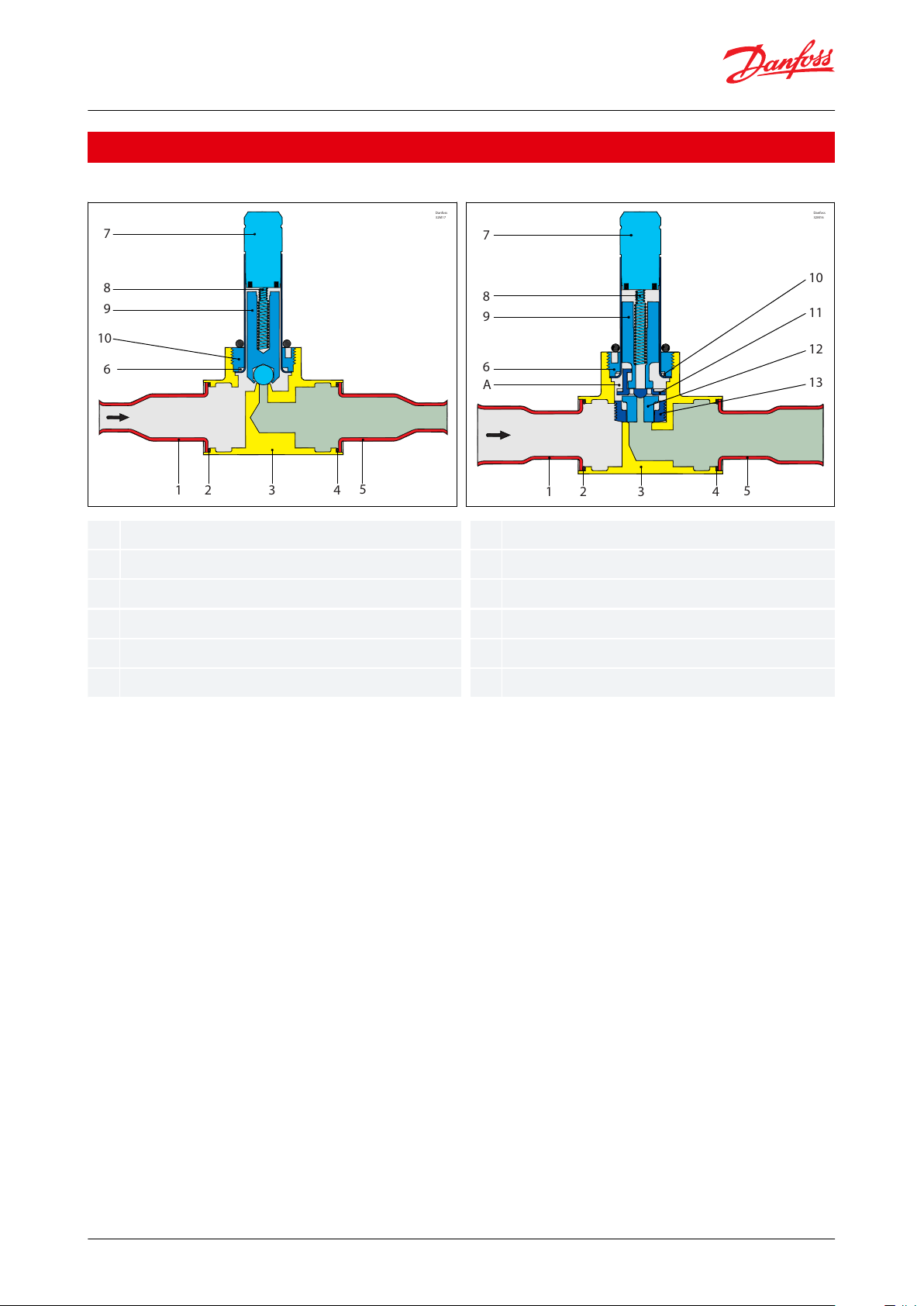

7

8

9

6

1 2 3 4

5

10

Danfoss

32M17

1 2 3 4

5

13

12

11

10

7

8

9

6

A

Danfoss

32M16

1, 5

2, 43678910111213A

Solder connection

Solder ring

Valve housing

Union nut

Armature tube

Return spring

Armature

Support ring

Pilot plate (servo)

Seat plate (servo)

Piston (servo)

Servo chamber

Solenoid valves, Type EVU

Functions

Figure 1: Direct operated

Figure 2: Servo operated

Direct operated

EVU 1 is direct operated. The valve opens directly for full ow when the armature (9) moves up into the magnetic

eld of the coil.

This means that the valve can operate at 0 bar dierential pressure. Thus, inlet pressure and spring force act to close

the valve when the coil is currentless.

Servo operated

EVU 2 to 8 are servo operated piston solenoid valves. The servo piston principle results in a fast operating and

compact valve that is able to open against a high dierential pressure. The valve closes rather soft, because the pilot

system does not fully close before the main orice has closed. This minimizes liquid hammer.

When the coil is currentless, the main orice, seat plate (12) and pilot orice (on the pilot plate (11)) are closed. The

pilot orice and main orice are held closed by the armature spring force and the dierential pressure between inlet

and outlet sides.

When current is applied to the coil, the armature (9) is drawn up into the magnetic eld and thus lifts the pilot plate

(11) and opens for the pilot orice so that the de-energising of the servo chamber (A) starts and the pressure is

relieved to the level of the outlet side. As the inlet pressure that acts on the bottom of the piston (13) now is higher

than the pressure in the servo chamber (A), the piston is moved upwards and lifts both the pilot plate (11) and the

seat plate (12). When the seat plate is lifted, the main orice opens for full ow.

Therefore a minimum dierential pressure of 0.02 bar is necessary to open the valve and keep it open.

When the current to the coil is switched o, the spring (8) forces the armature (9) down towards the pilot plate (11).

The pressure in the servo chamber (A) increases and the piston will no longer be able to hold the seat plate (12) in

lifted position, by which the main orice closes. The armature (9) continues its downwards movement until the pilot

orice on the pilot plate (11) is fully closed.

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 3

Page 4

Solenoid valves, Type EVU

Media

Refrigerants

R1233zd(E), R1234yf, R1234ze(E), R1270, R134a, R22/R407C, R23, R290, R32, R404A/R507A, R407A, R407F, R407H,

R410A, R422B, R422D, R438A, R444B, R448A, R449A, R449B, R450A, R452A, R452B, R454A, R454B, R454C, R455A,

R463A, R513A, R513B, R515A, R515B, R516A, R600, R600a, R744

For a complete list of approved refrigerants, visit store.danfoss.com and search for individual code numbers, where

refrigerants are listed as part of technical data.

NOTE:

Special note for R1233zd(E), R1234yf, R1234ze(E), R1270, R152A, R290, R32, R444B, R452B, R454A, R454B, R454C,

R455A, R516A, R600 and R600a: This product is validated in accordance to ATEX, ISO 5149, IEC 60335-2-24, IEC

60335-2-40 and UL. Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335.

The EVU can be applied on systems with the above specied refrigerants as working uid.

For countries where safety standards are not an indispensable part of the safety system Danfoss recommends the

installer gets a third party approval of any system containing ammable refrigerant.

NOTE:

Please follow specic selection criteria stated in the datasheet for these particular refrigerants.

Temperature of medium

-40 – 105 °C max. 130 °C during defrosting

Ambient temperature

-40 – 50 °C

MOPD operating range

0.02 bar up to 36 bar

Humidity

0 − 100% R.H. (0-97% R.H. non-condensation condition if IP level is below IPX5).

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 4

Page 5

No.

Description

Material

Alloys

Mat. no.

Standard

W.no.

DIN

EN

1, 5

Solder connection (Bi-metallic tube)

Stainless steel/Cu

–

––––2, 4

Solder ring

Silver

L-Ag 15P

CP102–1044

1044

3

Valve body

Brass

CuZn40Pb2

CW617N

2.0402

17672-1

12165

6

Union nut

Brass

CuZn39Pb2

CW612N

2.0380

17672-1

12164

7

Armature tube

Stainless steel

X6CrMoS17

–

1.4105–10088

8

Return spring

Spring wire stainless

X10CrNi18-8

–

1.4310–10088

9

Armature

Stainless steel

X4CrMoS18

–

1.410SIL

–

10088

10

Support ring

Teon

PTFE

––––11

Pilot plate

Thermoplast

PEEK

––––12

Seat plate

Teon

PTFE

––––13

Piston

Brass

CuZn39Pb2

CW612N

2.0380

17672-1

12164

Type

Opening dierential pressure with standard coil ∆p [bar]

Temperature of me‐

dium

Max. working pres‐

sure

Kv-value

(1)

Min.

Max. (=MOPD) liquid

(2)

6 W AC

14 W DC

[°C]

[bar]

[m3/h]

EVU 1

0.00

24

(3)

19

-40 – 105

70

0.10

EVU 2

0.023628

-40 – 105

70

0.20

EVU 3

0.023628

-40 – 105

70

0.30

EVU 4

0.023628

-40 – 105

70

0.50

EVU 5

0.023628

-40 – 105

70

0.65

EVU 6

0.023628

-40 – 105

70

0.80

EVU 8

0.023625

-40 – 105

70

1.00

Type

Liquid

Suction vapour

Hot gas

R22/

R407C

R134a

R404A/

R507

R410A

R22/

R407C

R134a

R404A/

R507

R410A

R22/

R407C

R134a

R404A/

R507

R410A

EVU 1

2.01

1.85

1.40

2.01

0.23

0.16

0.20

0.29

0.93

0.73

0.75

1.40

EVU 2

4.02

2.96

2.24

3.22

0.45

0.33

0.40

0.58

1.85

1.47

1.51

2.79

EVU 3

6.03

5.55

4.20

6.03

0.68

0.49

0.60

0.87

2.78

2.20

2.26

4.19

EVU 4

10.05

9.25

7.00

10.05

1.30

0.82

1.00

1.45

4.63

3.67

3.77

6.99

EVU 5

13.07

12.03

9.10

13.07

1.46

1.06

1.30

1.89

6.01

4.77

4.90

9.81

EVU 6

16.08

14.80

11.20

16.08

1.80

1.30

1.60

2.32

7.40

5.86

6.02

11.18

EVU 8

20.10

18.50

14.00

20.10

2.25

1.63

2.00

2.90

9.25

7.33

7.53

13.97

Solenoid valves, Type EVU

Product specication

Design and materials

Table 1: Design and material specications

Technical data

Table 2: Technical data

(1)

(1)

The Kv value is the water ow in m3/h at a pressure drop across the valve of 1 bar, ρ = 1000 kg/m3.

The Kv value is the water ow in m3/h at a pressure drop across the valve of 1 bar, ρ = 1000 kg/m3.

(2)

(2)

MOPD for media in gas form is approx. 8 bar higher. MOPD is measured with highest media and ambient temperature and 15% below nominal

MOPD for media in gas form is approx. 8 bar higher. MOPD is measured with highest media and ambient temperature and 15% below nominal

voltage.

voltage.

(3)

(3)

For coil 208-240 V, 60 Hz, MOPD is 17 bar.

For coil 208-240 V, 60 Hz, MOPD is 17 bar.

Rated capacity [kW]

Table 3: Rated capacity [kW]

Rated liquid and suction capacity is based on:

• evaporating temperature te = -10 °C,

• liquid temperature ahead of the valve tl = 25 °C,

• pressure drop in valve ∆p = 0.15 bar

Rated hot gas capacity is based on:

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 5

Page 6

Danfoss

32M18

33

10

10

15 20

86

10

54

9.5

19

30

45 min.

Danfoss

32M19

45 min.

10

54

9.5

10

15 20

86

10

19

30

Danfoss

32M21

45 min.

10

54

40

19

20.5

86

45

20.5

10

10

Product description

Net weight (approx.)

Coil 6 W

0.1

Coil with cable

0.15

Valve

0.1

Solenoid valves, Type EVU

• Condensing temperature tc = 40 °C,

• Pressure drop across valve ∆p = 0.8 bar,

• Hot gas temperature th = 65 °C

• Subcooling of refrigerant ∆t

sub

= 4 K

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with the Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Dimensions [mm] and weight [kg]

Figure 3: EVU 1 – EVU 6, mounted with DIN coil connection

Figure 5: EVU 8

Figure 4: EVU 1 – EVU 6

Table 4: Net weight [kg]

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 6

Page 7

Danfoss

32M8215

Danfoss

32M8216

Type

Connection

Industrial pack

Multi pack

[in.]

[mm]

Code no.

Pcs

Code no.

EVU 1

1

⁄4

–

032F7005

40

032F9524–6

032F700440–

EVU 2–6

032F5053

40

032F9529

EVU 3

1

⁄4

–

032F5024

40

032F9525–6

032F5025

40

032F9530

3

⁄8

–

032F5026

40

032F5111–10

032F502740–

EVU 4–10

032F5037

40

032F9531

EVU 5

3

⁄8

–

032F7000

40

032F9526–10

032F7001

40

032F9532–12

032F700340–

EVU 6

3

⁄8

–

032F5046

40

032F9527–10

032F504740–

1

⁄2

–

032F5049

40

032F9528–12

032F5048

40

032F9533

EVU 8–12

032F800940–

Solenoid valves, Type EVU

Ordering

Packaging information

• Single pack 1 product in a box with installation guide.

• Multi pack box with x pieces single pack (can be split).

• Industrial pack x pieces in one box (cannot be split)

Ordering valve

Figure 6: EVU 1 – EVU 6

Figure 7: EVU 8

Table 5: Normally closed (NC)

Ordering Coils

NOTE:

Special note for R1233zd(E), R1234yf, R1234ze(E), R1270, R152A, R290, R32, R444B, R452B, R454A, R454B, R454C,

R455A, R516A, R600 and R600a: The EVU coil (IP65/67) is validated in accordance to ISO 5149, IEC 60335 (ref. IEC/EN

60079-15). Ignition risk is evaluated in accordance to ISO 5149 and IEC 60335 (ref. IEC/EN 60079-15).

Please make sure that there is no spark, arc on the spade connection during the application. If coils are below IPx5,

they must be protected against ultraviolet, moisture and major impact, especially the connection of coils.

Always Install a fuse ahead of the coil: rated current: two times of rated current, time lag: medium, to avoid short

circuit.

The coil used in an area of not more than pollution degree 2.

Follow the installation guide to mount the coil correctly, and apply o-ring for sealing to prevent moisture

penetrating inside the coil.

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 7

Page 8

Danfoss

42N9042

Type

Ambient

Temp.

Supply volt‐

age

Voltage varia‐

tion

Frequency

Power consumption

Industrial pack

Multi pack

[°C]

[V]

[Hz]

[W]

[VA]

Code no.

Pcs.

Code no.

AS024CS

-40 – 50

24

-15% – 10%

50

9.5

18

–-042N7608

24

-15% – 10%

60

7.0

14

AS230CS

-40 – 50

230

-15% – 10%

50

8.0

16

–-042N7601

208 – 240

-15% – 10%

60

7.0

14

AS240CS

-40 – 50

240

-15% – 10%

50

6.5

13

–-042N7602

240

-15% – 10%

60

5.0

10

Danfoss

42N9041

Type

Ambient

Temp.

Supply volt‐

age

Voltage varia‐

tion

Frequency

Power consumption

Industrial pack

Multi pack

[°C]

[V]

[Hz]

[W]

[VA]

Code no.

Pcs.

Code no.

AU115CS

-40 – 50

115

-15% – 10%

50

7.0

14

–-042N7662

115

-15% – 10%

60

5.0

10

AU230CS

-40 – 50

230

-15% – 10%

50

7.0

14

042N8651

20

042N7651

230

-15% – 10%

60

5.0

10

AU240CS

-40 – 50

240

-15% – 10%

50

6.5

13

042N865220–

240

-15% – 10%

60

5.0

10

Solenoid valves, Type EVU

IMPORTANT:

The EVU coil (IP65/67) can be applied on systems with the above specied refrigerants as the working uid. For

countries where safety standards are not an indispensable part of the safety system, Danfoss recommends the

installer to get a third party approval of the system containing ammable refrigerant.

NOTE:

please follow specic selection criteria stated in the datasheet for these particular refrigerants.

NOTE:

The EVU coil (IP65/67) has NOT been veried ATEX or IECEx or IEC 60079 series zone 2 compliant. This product is only

validated for systems in compliance with ISO5149, IEC 60335 (ref. IEC/EN 60079-15). It is the responsibility of the user

to verify such compliance. Improper use can cause explosion, re, leakage potentially causing death, personal injury,

or damage to property.

Figure 8: DIN spade connection

Table 6: Alternating current [AC] - with DIN plug - IP65

NOTE:

The three pins on the coil can be tted with spade tabs, 6.3 mm wide (to DIN 46247). The two current carrying pins

can also be tted with spade tabs, 4.8. mm wide. Max. lead cross section: 1.5 mm2. If DIN plug is used (DIN 43650)

the leads must be connected in the socket. The socket is tted with a Pg 11 screwed entry for 6 – 12 mm.

Figure 9: Cable connection

Table 7: Alternating current [AC] - with 1 m cable - IP67

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 8

Page 9

Danfoss

42N9042

Type

Ambient

Temp.

Supply volt‐

age

Voltage varia‐

tion

Frequency

Power consumption

Industrial pack

Multi pack

[°C]

[V]

[Hz]

[W]

[VA]

Code no.

Pcs.

Code no.

AZ240CS

-40 – 50

230

-15% – 10%

50

8.0

16

042N8201

40

042N4201

208 – 240

-15% – 10%

60

7.0

14

AZ120CS

-40 – 50

115

-15% – 10%

50

8.5

16

042N8202

40

042N4202

110 – 120

-15% – 10%

60

7.0

14

AZ024CS

-40 – 50

24

-15% – 10%

50

9.5

18

042N8203

40

042N4203

24

-15% – 10%

60

7.0

14

Danfoss

42N9041

Type

Ambient

Temp.

Supply volt‐

age

Voltage varia‐

tion

Frequency

Power consumption

Industrial pack

Multi pack

[°C]

[V]

[Hz]

[W]

[VA]

Code no.

Pcs.

Code no.

AU012DS

-40 – 50

12

±10%DC12–042N8696

20

042N7696

AU024DS

-40 – 50

24

±10%DC14–042N8697

20

042N7697

Danfoss

42N9042

Type

Ambient

Temp.

Supply volt‐

age

Voltage varia‐

tion

Frequency

Power consumption

Industrial pack

Multi pack

[°C]

[V]

[Hz]

[W]

[VA]

Code no.

Pcs.

Code no.

AS012DS

-40 – 60

12

±10%DC14–042N868640–

AS024D

-40 – 50

24

±10%DC14–042N8687

40

042N7687

Solenoid valves, Type EVU

Figure 10: DIN spade connection (UL recognized)

Table 8: Alternating current [AC] - DIN spade connection (UL recognized) IP00

Figure 11: Cable connection

Table 9: Direct current [DC] - with 1 m cable IP67

Figure 12: DIN spade connection

Table 10: Direct current [DC] - with DIN spade IP00

NOTE:

DC coils with 0.25 in. US spade can be supplied on request

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 9

Page 10

Part

Description

Code no.

Multi pack

Pcs.

Industrial pack

Pcs.

Danfoss

42N9043

DIN plug (EN175301-803 type A)

042N0156––

–

Danfoss

32M15

O-ring for sealing the coil. Industrial pack (50 pcs.) NB: Valve body

suppplied with O-ring

032F6115––

–

Danfoss

32M20

10

Ø5.2

Ø4.9

Bracket for xing of valve.

––032F8036

40

Solenoid valves, Type EVU

Accessories

Table 11: Accessories

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 10

Page 11

Document name

Document type

Document topic

Approval authority

MH7648

Electrical - Safety Certicate

UL

Solenoid valves, Type EVU

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 12: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 11

Page 12

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI263435875820en-000501 | 12

Loading...

Loading...