Page 1

Data Sheet

Solenoid Valve

Type EVT

EVT high pressure range is a direct or servo

operated solenoid valve specially designed to

t into CO2 transcritical refrigeration systems.

They can be applied in following applications:

• EVT 1.2 direct operated for oil return, pressure

equalization/relief control, high pressure hot

gas bypass/dump and hot gas defrost.

• EVT 2.0 and 3.0 servo operated for high

pressure hot gas bypass/dump and hot gas

defrost application.

EVT valves and coils are sold separately.

Features

• Direct and servo operated mini piston

solenoid valve with compact construction

• Simple and fast mounting of Danfoss Clip-on

coil

• Designed for media temperature up to 150°C

• Working pressure up to 140 bar with standard

coils

• Copper solder connections for brazing

• Stainless steel connections for Swagelok

ttings

• Body material in ECO brass (lead free < 0.1%)

• Robust design ensures long lifetime

• Supplied in version normally closed (NC)

• In accordance with

◦ RoHS II

◦ REACH

◦ LVD and PED

AI383432144920en-000101

Page 2

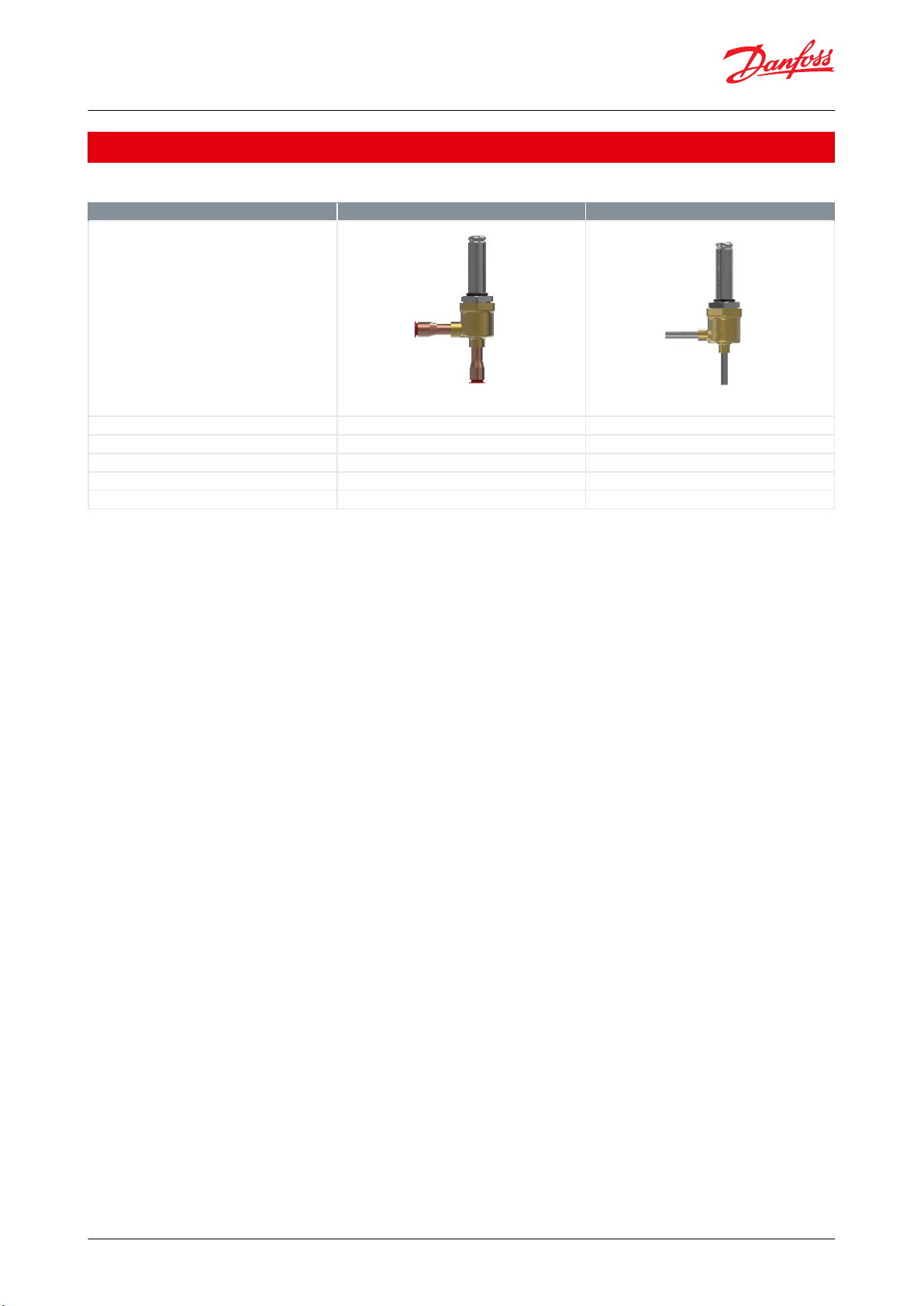

Features

EVT

EVT

Connection

Copper

Stainless steel

DN [mm]

1.2 – 3.0

1.2 – 3.0

Connection

ODF 3/8”

ODM 6mm

Max. working pressure [bar]

140

140

Function

NC

NC

Solenoid Valve, Type EVT

Portfolio overview

Table 1: Portfolio overview

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 2

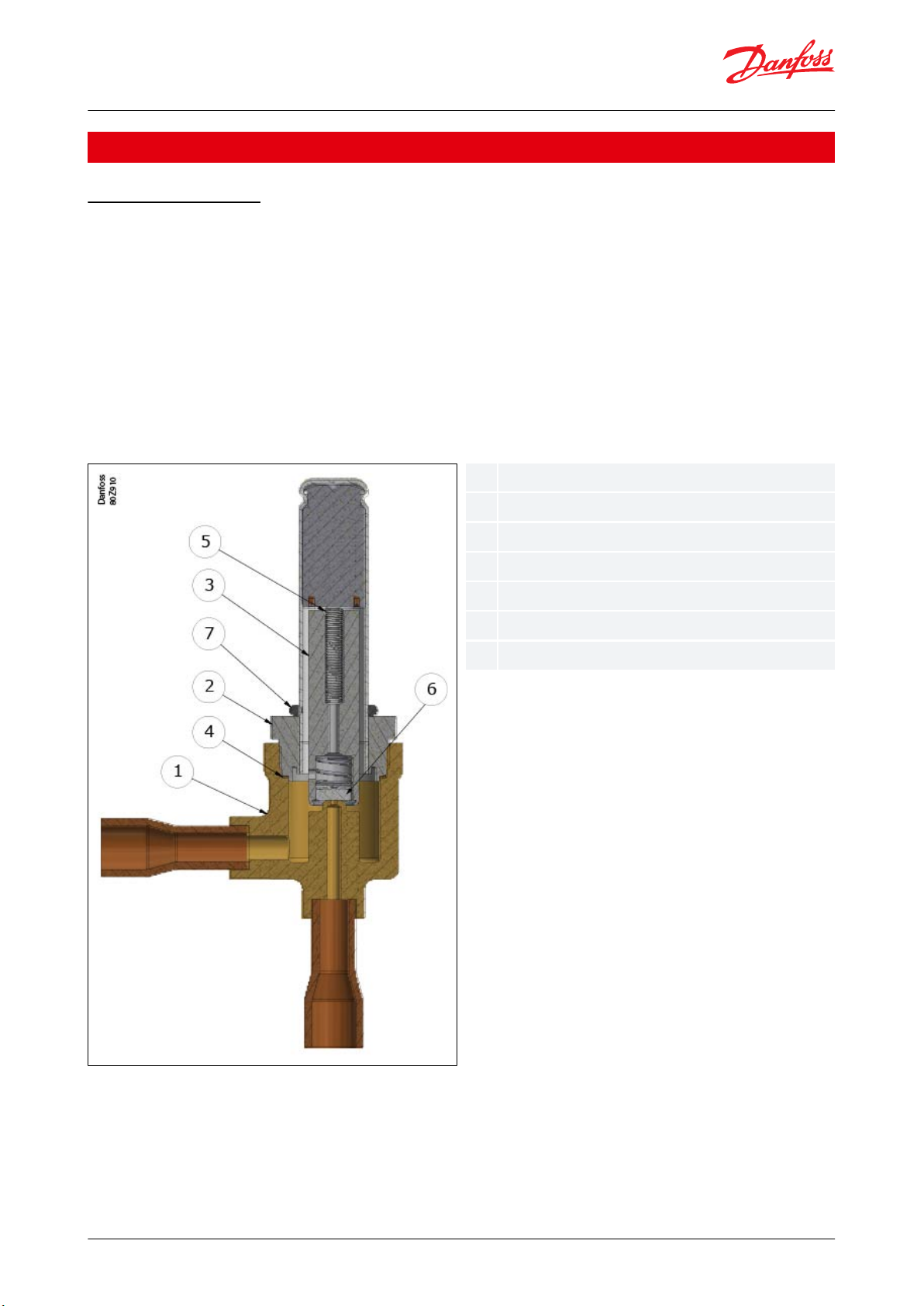

Page 3

1234567

Valve housing

Cover

Armature assembly

Gasket

Armature spring

Seat plate

Coil O-ring

Solenoid Valve, Type EVT

Functions

Normally closed (NC)

Direct operated

EVT 1.2 is direct operated. This means that the valve can operate at 0bar dierential pressure.

Coil voltage disconnected (closed):

When the voltage to the coil is disconnected, the armature (3) with the seat plate (6) is pressed down against the

valve orice by the closing spring (5) and inlet pressure. The valve will be closed for as long as the coil is

disconnected.

Coil voltage connected (open):

The valve opens directly for full ow when the voltage is applied to coil, the armature (3) with seat plate is lifted

clear of the valve orice. The valve will be open for as long as there is voltage to the coil.

Figure 1: Direct operated

Servo operated

EVT 2.0 and 3.0 is servo operated piston solenoid valves. The servo piston principle results in a fast operating and

compact valve that can open against a high dierential pressure.

Coil voltage disconnected (closed):

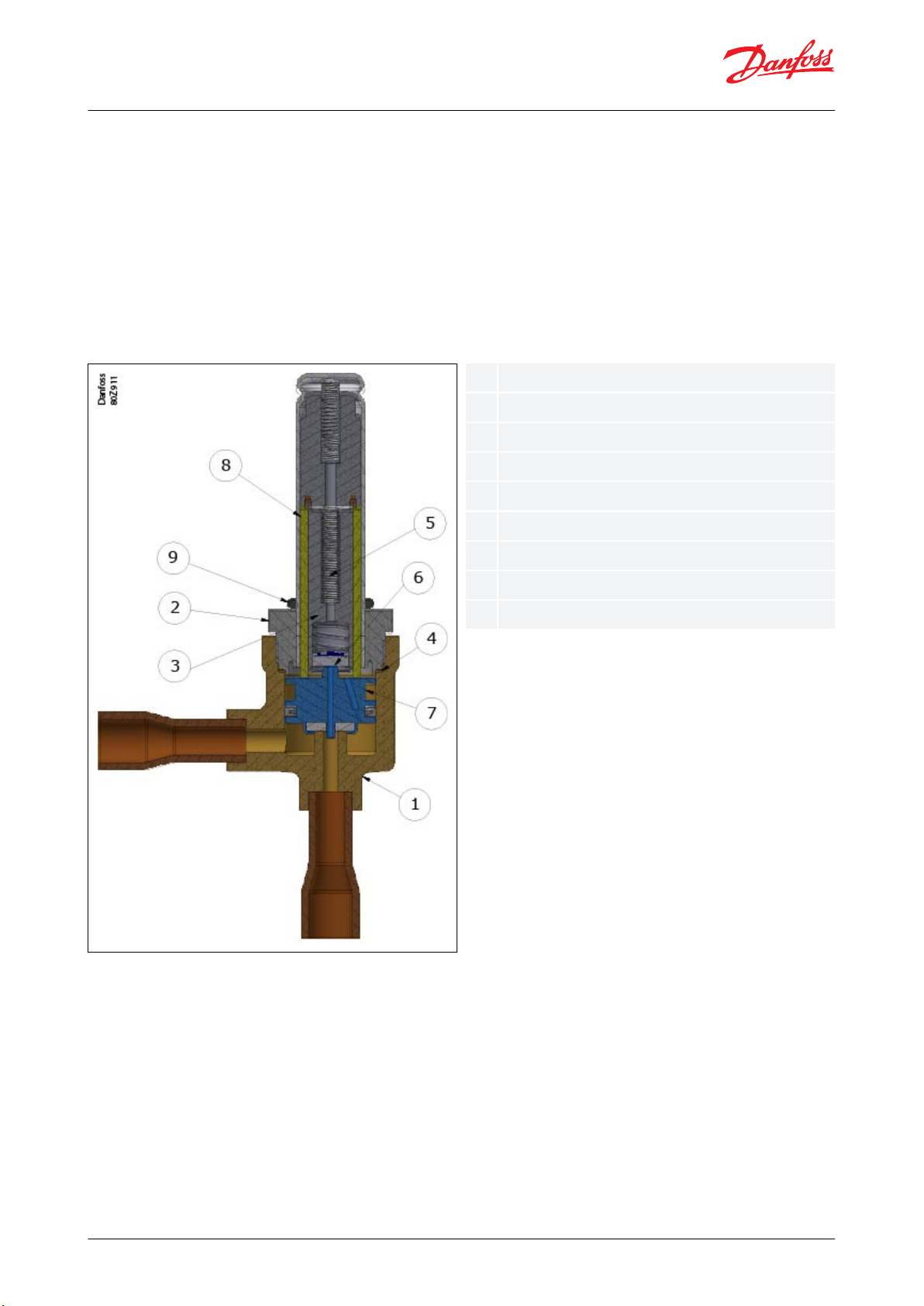

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 3

Page 4

123456789

Valve housing

Cover

Armature assembly

Gasket

Armature spring

Seat plate

Piston assembly

Guide pin

Coil O-ring

Solenoid Valve, Type EVT

When the coil is disconnected, the armature (3) with seat plate (6) is pressed down against the pilot orice by the

armature spring (8). Via the equalization orice in the piston (5), the pressure above the piston rises to the same

value as the inlet pressure and the piston closes the main orice. The valve will be closed for as long as the coil is

disconnected.

Coil voltage connected (open):

When current is applied to the coil, the armature (3) is drawn up into the magnetic eld and opens the pilot orice.

This relieves the pressure above the piston (7), i.e. the space above the piston becomes connected to the outlet side

of the valve. The dierential pressure between inlet and outlet sides then presses the piston away from the main

orice and now the main orice opens for full ow. Therefore, a minimum dierential pressure of 2 bar is necessary

to open the valve and 0.4 bar to keep it open.

Figure 2: Servo operated

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 4

Page 5

Refrigerants

R744 (CO2)

Oil

POE 60cST, 85cST (piston compressors);

PAG 68cST, 100cST (piston and rotary compressors)

Media temperature range

-40 - 150 °C / -40 - 302 °F

Max. working pressure (PS/MWP)

140 bar / 2030.5 psi

Solenoid Valve, Type EVT

Media

Table 2: Media

NOTE:

• Media temperature of 0°C or higher when operating the valve for oil management lines.

• Danfoss recommends that a suitable lter or lter drier (< 40 microns) should be installed ahead of each solenoid

valve to keep scale, solder material and other foreign dirt and particles out of the valve.

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 5

Page 6

A

1

2

3

4

5

6

7

1

2

3

4

5

6

7

MOPD and MWP

Country of origin

Point of contact

Serial number

Code number

Media temperature

Ambient temperature

068F0611

Max. media TEMP 150 °C / 302 °C

Max. AMB TEMp 50 °C / 122°F

MOPD 110 bar / 1595, 4psi PS 140 / SWP 2030, 5

MADE IN DENMARK

Danfoss A/S 6430 Nordborg Denmark

068F0611F171D00001

A (2 : 1)

Type

Opening dierential pressure with standard coil ΔP [bar]

Min.

Max. (=MOPD) liquid

220V-230V 50Hz / 018F6176

EVT 1.2 NC

0

110

EVT 2.0 NC

2

110

EVT 3.0 NC

2

110

Pos. no.

Descriptions

Materials

1

Valve housing

ECO Brass

2

Cover

Stainless steel

3

Armature assembly

Stainless steel

4

Gasket

Copper

5

Spring

Stainless steel

6

Seat plate

PEEK7Piston

ECO Brass

8

Guide pin

Stainless steel

Solenoid Valve, Type EVT

Product specication

Technical data

Ambient temperature

-40°C to 50°C

Max. working pressure

140 bar with copper connections and stainless steel connections.

Flow capacity

• For Kv values please refer to the tables in Ordering.

• The Kv value of the water ow in [m3/h] at a pressure drop across valve of 1 bar, ρ = 1000 kg/m3.

Opening dierential pressure range

Table 3: MOPD

NOTE:

EVT 2.0 and 3.0 need 0.4 bar to keep open and can’t be used as relief valve if the dierential pressure is lower than

0.4 bar.

Valve selection based on capacity calculation

As for extended capacity calculations and valve selection based on capacities and refrigerants, please refer to

Coolselector®2. Rated and extended capacities are calculated with Coolselector®2 calculation engine to ARI

standards with the ASEREP equations based on laboratory measurements of selected valves.

Identication

Figure 3: Identication

Figure 4: Identication

Materials

Table 4: Materials

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 6

Page 7

8

0

m

m

[

3

,

2

i

n

]

4

3

m

m

[

1

,

7

i

n

]

15Ø mm

[0,6 in]

51 mm

[2 in]

1

3

Ø

m

m

[

1

/

2

i

n

]

6

5

m

m

[

2

,

6

i

n

]

17 mm

[0,7 in]

15 mm

[0,6 in]

6

5

m

m

[

2

,

9

i

n

]

51 mm

[2 in]

15 mm

[0,6 in]

6

m

m

[

1

/

4

i

n

]

8

0

m

m

[

3

,

2

i

n

]

17 mm

[0,7 in]

4

3

m

m

[

1

,

7

i

n

]

15 mm

[0,6 in]

Type

Net weight without coil

[kg]

EVT 1.2

0.22 kg

EVT 2.0

0.24 kg

EVT 3.0

0.24 kg

Solenoid Valve, Type EVT

Dimension and Weight

Figure 5: EVT ODF

Figure 6: EVT ODM

Table 5: Dimension and weight

NOTE:

Net weight of coil 018F6176 is approx. 0.27 kg.

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 7

Page 8

Type

Connection size

Kv value [m3/h]

Code no.

Packing

ODF [in]

ODM [mm]

Copper

Stainless Steel

EVT 1.2

3/8

-

0.05

068F0600

Multi-pack

068F0625

I-pack

-

6

068F0622

Multi-pack

068F0626

I-pack

EVT 2.0

3/8

-

0.1

068F0601

Multi-pack

068F0627

I-pack

-

6

068F0621

Multi-pack

068F0628

I-pack

EVT 3.0

3/8

-

0.23

068F0611

Multi-pack

068F0629

I-pack

-

6

068F0620

Multi-pack

068F0630

I-pack

Type

Tambient

Supply voltage

Voltage variation

Frequency

Power consumption

Code no.

[°C]

[V]

[Hz]

BE230AS

-40T50

220

-15%, +10%

50

11 W

018F6176

230

-15%, +10%

50

12 W

Solenoid Valve, Type EVT

Ordering

Parts program

Coils

Table 6: Coils

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 8

Page 9

1.

2.

A

B

1.

2.

A

B

C

D

E

Type

EVT 1.2

EVT 2.0 & 3.0

Seal Kit

068F0697

068F0697

Service Kit

068F0698

068F0699

1

2

B

A

Danfoss

068F0600_EX

1

2

A

B

C

D

E

Danfoss

068F0611_EX

Seal kit contains:

Coil O-ring

Gasket

Service kit contains:

Spring

Armature

Seal kit contains:

Coil O-ring

Gasket

Service kit contains:

Spring

Spring

Guided pins

Armature

Piston

Solenoid Valve, Type EVT

Accessories

Spare parts kits

Table 7: Spare part kits

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 9

Page 10

File name

Document type

Document topic

Approval authority

033F0688

EU declaration

LVD, EMC

Danfoss

033F1035

EU declaration

PED

Danfoss

Solenoid Valve, Type EVT

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Valid approvals

Table 8: Valid approvals

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.08 AI383432144920en-000101 | 11

Loading...

Loading...