Page 1

Data Sheet

Solenoid valve

Type EVRS 3-20 and EVRST 10-20

Stainless steel solenoid valves used in liquid, suction, hot gas and oil return lines

EVRS and EVRST are valves made of stainless

steel.

• EVRS 3 is direct operated.

• EVRS 10, 15 and 20 are servo operated.

• EVRST 10,15 and 20 are forced servo

operated.

The valves are used in liquid, suction, hot gas

and oil return lines with ammonia or

uorinated refrigerants.

EVRS 3 and EVRST are designed for keeping

open at a pressure drop of 0 bar.

EVRS/EVRST 10, 15 and 20 are equipped with

spindel for manual opening.

EVRS and EVRST are supplied as components,

i.e. valve body and coil must be separately

ordered.

Features

• Stainless steel valve body and connections

• Max. working pressure 50 barg

• Applicable to HCFC, HFC, R717 (Ammonia)

and R744 (CO2)

• MOPD up to 38 bar with 20 watt a.c. coil

• Wide choice of a.c. and d.c. coils

• Designed for temperatures of media up to

105°C

• Manual stem on EVRS and EVRST 10, EVRST

15 and EVRST 20

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

72886419420en-000601

Page 2

Danfoss

32F418.11.15

37

36

4

16

28

49

51

18

29

Danfoss

32F417.11.15

24

4

16

18

28

49

29

Danfoss

32F419.13.13

28

14

8

6

16

45

5

EVRST EVRS

53

44

49

29

83

84

73

45

43

28

16

4

82

80

18

40

Pg13.5

20

36

Danfoss

32F476.11.12

4.

16.

18.

20.

24.

28.

29.

36.

40.

43.

44.

45.

49.

51.

53.

73.

80.

82.

83.

84.

Coil

Armature

Pilot valve plate

Earth terminal

Connection for exible steel

hose

Gasket

Pilot orice

DIN plug

Terminal box

Valve cover

O-ring

Valve cover gasket

Valve body

Cover

Manual operating spindle

Equalization hole

Diaphragm

Support washer

Valve seat

Main valve plate

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Function

Figure 1: EVRS 3, pipe thread

Figure 3: EVRS / EVRST 10 and 15

Figure 2: EVRS 3, weld

Figure 4: EVRS / EVRST 20

The solenoid valve design is based on three dierent principles:

1.

Direct operation

2.

Servo operation

3.

Forced servo operation

1. Direct operation

EVRS 3 is directly operated. The valve opens direct for full ow when the armature (16) moves up into the magnetic

eld of the coil. This means that the valve operates with a min. dierential pressure of 0 bar. The valve plate (18)

made of teon and is tted direct to the armature (16).

Inlet pressure acts from above on the armature and with it the valve plate. Thus, inlet pressure, spring force and the

weight of the armature act to close the valve when the coil is currentless.

2. Servo operation

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 2

Page 3

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

EVRS 10, 15 and 20 are servo operated with a "oating" diaphragm (80). The pilot orice (29), which is of stainless

steel, is placed in the centre of the diaphragm. The teon pilot valve plate (18) is tted direct to the armature (16).

With the coil currentless, the main orice and pilot orice are closed. The pilot orice and main orice are held

closed by the weight of the armature, the armature spring force and the dierential pressure between inlet and

outlet sides.

When current is applied to the coil the armature is drawn up into the magnetic eld and opens the pilot orice. This

relieves the pressure above the diaphragm because the space above the diaphragm becomes connected to the

outlet side of the valve. The dierential pressure between inlet and outlet sides then presses the diaphragm away

from the main orice which opens to full ow. Thus a certain minimum dierential pressure is necessary to open the

valve and keep it open. For EVRS 10, 15 and 20 valves this dierential pressure is 0.05 bar. When current is switched

o, the pilot orice closes. Then the pressure above the diaphragm rises, via the equalization holes (73) in the

diaphragm, to the inlet pressure and causes the diaphragm to close the main orice.

3. Forced servo operation

EVRST 10, 15 and 20 are forced servo operated solenoid valves. Forced servo operation diers from servo operation

in that in a forced servo operated valve the armature and the diaphragm are connected by a spring. Thus the

armature helps to lift the diaphragm (80) and keep it lifted so that the pressure drop in the open valve is the least

possible. These types of valves therefore require no dierential pressure to keep them open.

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 3

Page 4

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Media

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2).

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 4

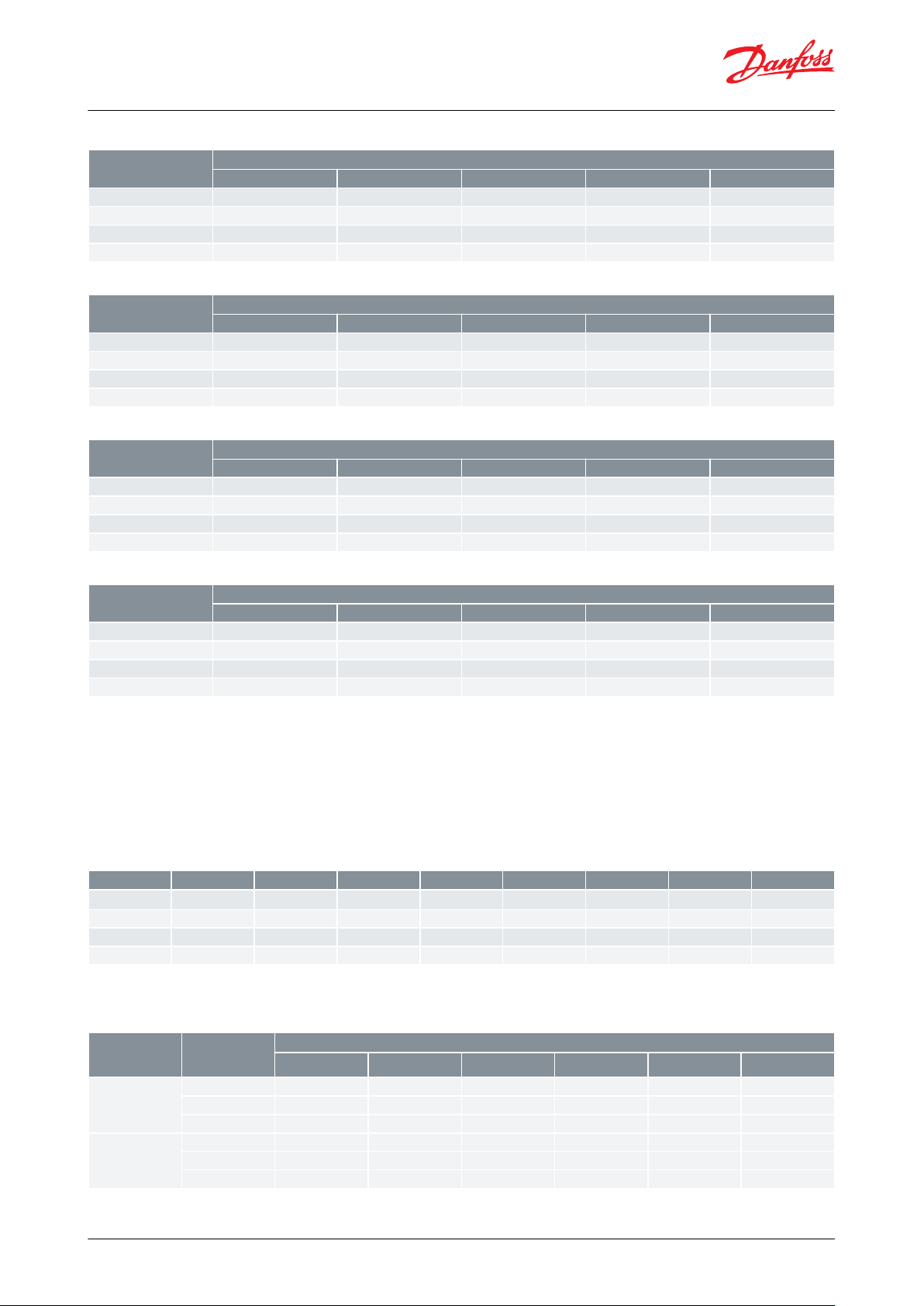

Page 5

Type

Opening dierential pressure ∆p bar

kv value

(2)

m3/h

Max. working

pressure Ps

Min.

Max. (MOPD) liquid

(1)

10 W a.c.

12 W a.c.

20 W a.c.

20 W d.c.

EVRS 3

0.021253814

0.23

50 bar(g)

EVRS 10

0.0521253818

1.5

EVRST 10

0.014213816

1.5

EVRS 15

0.0521253818

2.7

EVRST 15

0.014213818

2.7

EVRS 20

0.0521253813

4.5

EVRST 20

0.014213813

4.5

Type

Rated capacity

(3)

kW

Liquid

Suction vapour

Hot gas

R717

R22

R134a

R404A

R410A

R717

R22

R134a

R404A

R410A

R717

R22

R134a

R404A

R410A

EVRS 3

21.8

4.6

4.3

3.2

4.5

6.5

2.1

1.7

1.7

2.3

EVRS/EVRST 10

142

30.2

27.8

21.1

29.793.4

2.5

3.1

4.3

42.6

13.91111.3

14.9

EVRS/EVRST 15

256

54.4

50.13853.5

16.1

6.2

4.4

5.5

7.7

76.7

24.9

19.8

20.3

26.7

EVRS/EVRST 20

426

90.6

83.5

63.3

89.1

26.9

10.3

7.3

9.212128

41.5

32.9

33.9

44.5

Type

R 744 Rated capacity kW

(4)

Liquid

Suction

EVRS 3

6.65

-

EVRS/ EVRST 10

43.3

6.9

EVRS/ EVRST 15

78

12.4

EVRS/ EVRST 20

130

20.7

Type

Liquid capacity Q

e

kW at pressure drop across valve ∆p bar

0.1

0.2

0.3

0.4

0.5

EVRS 3

17.8

25.1

30.8

35.6

39.8

EVRS/EVRST 10

116.0

164.0

201.0

232.0

259.0

EVRS/EVRST 15

209.0

295.0

362.0

418.0

467.0

EVRS/EVRST 20

348.0

492.0

603.0

696.0

778.0

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Product specication

Technical data

Temperature of medium

-40 °C / +105 °C for 10 or 12 watt coil. Max. 130 °C during defrosting. -40 °C / +80 °C for 20 watt coil.

Ambient temperature and enclosure for coil: See "Coils for solenoid valves", lit.no. AI237186440089

Table 1: Technical data

(1)

(1)

MOPD for media in gas form is approx. 1 bar greater.

MOPD for media in gas form is approx. 1 bar greater.

(2)

(2)

The kv value is the water ow in m3/h at a pressure drop in the valve of 1 bar, ρ = 1000 kg/m3.

The kv value is the water ow in m3/h at a pressure drop in the valve of 1 bar, ρ = 1000 kg/m3.

Table 2: Rated capacity

(3)

(3)

Rated liquid and suction vapour capacity is based on evaporating temperature te = -10 °C, liquid temperature ahead of valve tl = +25 °C, and

Rated liquid and suction vapour capacity is based on evaporating temperature te = -10 °C, liquid temperature ahead of valve tl = +25 °C, and

pressure drop across valve ∆p = 0.15 bar. Rated hot gas capacity is based on condensing temperature tc = +40 °C, pressure drop across valve ∆p

pressure drop across valve ∆p = 0.15 bar. Rated hot gas capacity is based on condensing temperature tc = +40 °C, pressure drop across valve ∆p

= 0.8 bar, hot gas temperature th = +60 °C, and subcooling of refrigerant ∆t

= 0.8 bar, hot gas temperature th = +60 °C, and subcooling of refrigerant ∆t

sub

sub

= 4 K.

= 4 K.

Table 3: Rated capacity

(4)

(4)

Rated liquid and suction vapour capacity is based on evaporating temperature te = -40 °C, liquid temperature ahead of the vale tl = - 8 °C and

Rated liquid and suction vapour capacity is based on evaporating temperature te = -40 °C, liquid temperature ahead of the vale tl = - 8 °C and

pressure drop across the valve ∆p = 0.15 bar For other condition please refer to DIR-Calc or contact your local Danfoss oce.

pressure drop across the valve ∆p = 0.15 bar For other condition please refer to DIR-Calc or contact your local Danfoss oce.

Capacity

Liquid capacity Ql kW

Table 4: R717 (NH3)

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 5

Page 6

Type

Liquid capacity Qe kW at pressure drop across valve ∆p bar

0.1

0.2

0.3

0.4

0.5

EVRS 3

3.8

5.3

6.6

7.6

8.5

EVRS/EVRST 10

24.7

34.9

42.7

49.3

55.1

EVRS/EVRST 15

44.4

62.8

76.9

88.8

99.2

EVRS/EVRST 20

73.9

105.0

128.0

148.0

165.0

Type

Liquid capacity Qe kW at pressure drop across valve ∆p bar

0.1

0.2

0.3

0.4

0.5

EVRS 3

3.5

4.9

6.0

7.0

7.8

EVRS/EVRST 10

22.7

32.2

39.4

45.5

50.8

EVRS/EVRST 15

40.9

57.9

70.9

81.8

91.5

EVRS/EVRST 20

68.2

96.5

118.0

136.0

153.0

Type

Liquid capacity Qe kW at pressure drop across valve ∆p bar

0.1

0.2

0.3

0.4

0.5

EVRS 3

2.6

3.7

4.6

5.3

5.9

EVRS/EVRST 10

17.2

24.3

29.8

34.4

38.5

EVRS/EVRST 15

31.0

43.8

53.7

62.0

69.3

EVRS/EVRST 20

51.7

73.0

89.5

103.0

116.0

Type

Liquid capacity Qe kW at pressure drop across valve ∆p bar

0.1

0.2

0.3

0.4

0.5

EVRS 3

3.7

5.3

6.4

7.5

8.3

EVRS/EVRST 10

24.3

34.44248.6

54.3

EVRS/EVRST 15

43.7

61.8

75.6

87.5

97.7

EVRS/EVRST 20

72.9

103

126

146

163

t

v

°C

-100+10

+20

+25

+30

+40

+50

R717 (NH

3

)

0.84

0.88

0.92

0.9711.03

1.09

1.16

R22, R134a

0.76

0.81

0.88

0.9611.05

1.16

1.31

R404A

0.7

0.76

0.84

0.9411.07

1.24

1.47

R410A

0.73

0.79

0.86

0.9511.06

1.23

1.47

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Q

e

kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 10

0.1

3.4

4.5

5.9

7.3

8.9

10.6

0.15

4.0

5.4

7.0

9.0

10.9

13.0

0.2

4.5

6.1

7.9

10.0

12.6

15.0

EVRS/EVRST 15

0.1

6.1

8.1

10.7

13.2

16.0

19.1

0.15

7.2

9.7

12.5

16.1

19.6

23.4

0.2

8.0

11.0

14.2

18.0

22.6

27.0

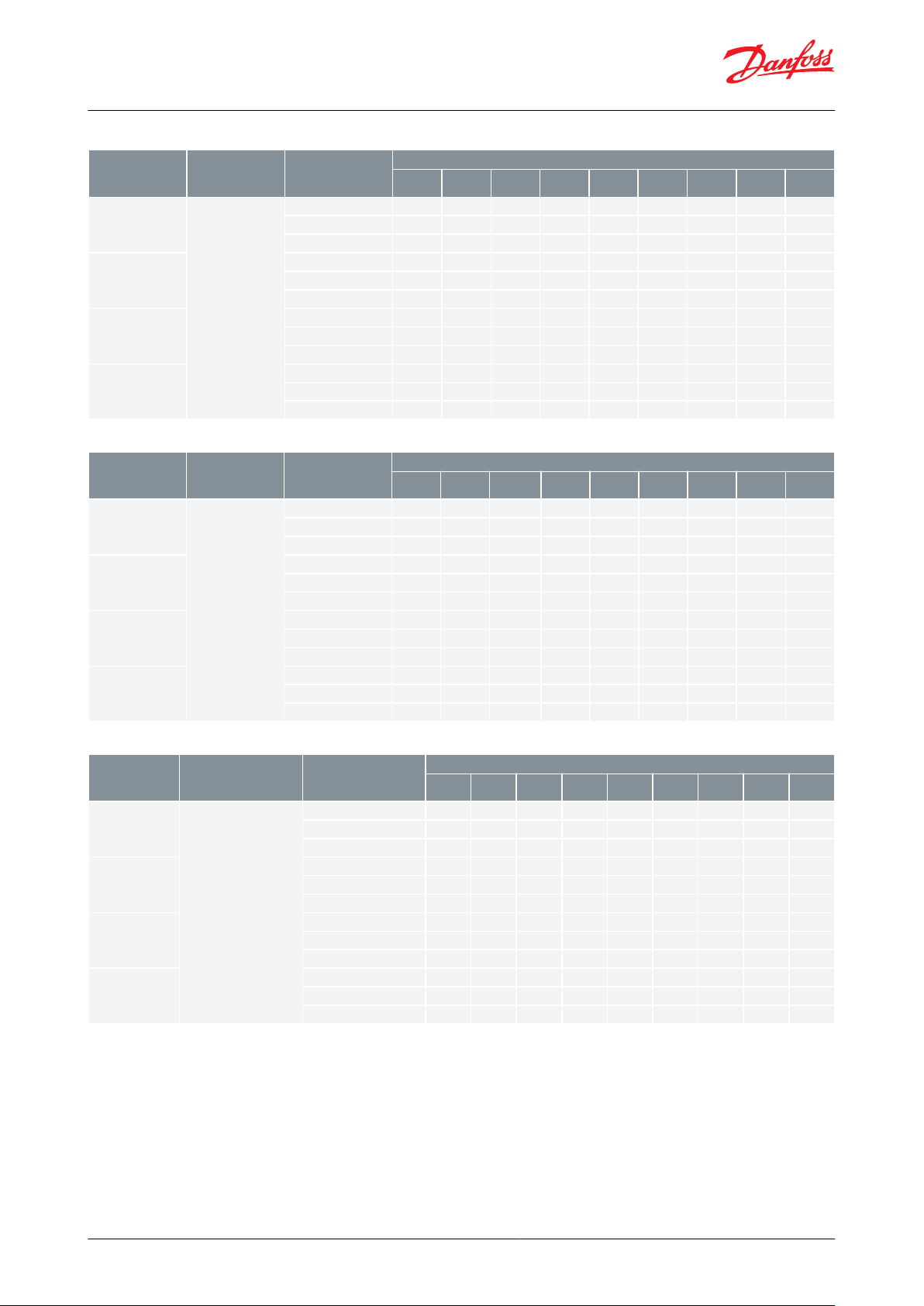

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Table 5: R22

Table 6: R134a

Table 7: R404A

Table 8: R410A

NOTE:

Capacities are based on liquid temperature tl = + 25 °C ahead of valve, evaporating temperature te = -10 °C, and

superheat 0 K.

Correction factors

When sizing valves, the table value must be multiplied by a correction factor depending on evaporating

temperature te.

Table 9: Correction factors

Suction vapour capacity Qe kW

Table 10: R717 (NH3)

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 6

Page 7

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Qe kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 20

0.1

10.2

13.5

17.8

21.9

26.6

31.9

0.15

12.1

16.1

20.9

26.9

32.6

39.0

0.2

13.4

18.3

23.7

29.9

37.7

45.1

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Qe kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 10

0.1

1.4

1.8

2.3

2.8

3.4

4.0

0.15

1.6

2.1

2.7

3.4

4.1

4.9

0.2

1.8

2.4

3.1

3.8

4.8

5.6

EVRS/EVRST 15

0.1

2.5

3.2

4.1

5.0

6.1

7.2

0.15

2.9

3.8

4.8

6.2

7.4

8.8

0.2

3.3

4.3

5.5

6.8

8.6

10.2

EVRS/EVRST 20

0.1

4.1

5.3

6.8

8.4

10.1

12.0

0.15

4.9

6.4

8.1

10.3

12.3

14.7

0.2

5.5

7.2

9.2

11.4

14.3

16.9

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Qe kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 10

0.1

0.87

1.2

1.6

2.1

2.6

3.2

0.15

0.99

1.4

1.9

2.4

3.2

3.9

0.2

1.1

1.6

2.1

2.8

3.5

4.5

EVRS/EVRST 15

0.1

1.6

2.1

2.8

3.8

4.7

5.7

0.15

1.8

2.5

3.4

4.4

5.7

7.0

0.2

2.0

2.8

3.8

5.0

6.3

8.1

EVRS/EVRST 20

0.1

2.6

3.6

4.7

6.3

7.8

9.6

0.15

3.0

4.2

5.6

7.3

9.5

11.7

0.2

3.3

4.7

6.4

8.3

10.5

13.5

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Qe kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 10

0.1

1.2

1.5

2.0

2.5

3.1

3.7

0.15

1.4

1.8

2.4

3.1

3.8

4.6

0.2

1.6

2.1

2.7

3.4

4.3

5.3

EVRS/EVRST 15

0.1

2.1

2.7

3.6

4.5

5.5

6.6

0.15

2.5

3.3

4.3

5.5

6.8

8.2

0.2

2.8

3.7

4.9

6.1

7.8

9.5

EVRS/EVRST 20

0.1

3.5

4.6

6.0

7.5

9.2

11.1

0.15

4.1

5.5

7.1

9.2

11.3

13.6

0.2

4.6

6.2

8.1

10.2

13.0

15.8

Type

Pressure drop

across valve ∆p

bar

Suction vapour capacity Qe kW at evaporating temperature te °C

-40

-30

-20

-100+10

EVRS/EVRST 10

0.1

1.9

2.3

2.9

3.5

4.2

5.0

0.15

2.2

2.9

3.5

4.3

5.1

6.1

0.2

2.6

3.3

4.0

5.0

5.9

7.0

EVRS/EVRST 15

0.1

3.3

4.2

5.2

6.3

7.6

9.0

0.15

4.0

5.1

6.3

7.7

9.2

11.0

0.2

4.7

5.9

7.3

8.9

10.7

12.7

EVRS/EVRST 20

0.1

5.6

7.0

8.6

10.5

12.6

15.0

0.15

6.7

8.6

10.5

12.9

15.4

18.4

0.2

7.8

9.9

12.2

14.9

17.8

21.2

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Table 11: R22

Table 12: R134a

Table 13: R404a

Table 14: R410A

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 7

Page 8

tv°C

-100+10

+20

+25

+30

+40

+50

R717 (NH3)

0.84

0.88

0.92

0.97

1.0

1.03

1.09

1.16

R22, R134a

0.76

0.81

0.88

0.96

1.0

1.05

1.16

1.31

R404A

0.70

0.76

0.84

0.94

1.0

1.07

1.24

1.47

R410A

0.76

0.80

0.89

0.96

1.0

1.05

1.18

1.37

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆t

sub

= 4 K

Condensing temperature tc °C

+20

+30

+40

+50

+60

EVRS 3

0.1

1.8

2.1

2.3

2.5

2.6

0.2

2.6

2.9

3.2

3.5

3.7

0.4

3.8

4.2

4.6

4.9

5.3

0.8

5.1

6.0

6.5

7.1

7.6

1.6

7.4

8.3

9.1

9.9

10.9

EVRS/EVRST 10

0.1

12.0

3.4

14.7

16.0

17.2

0.2

17.1

19.0

20.9

22.7

24.4

0.4

24.5

27.1

29.7

32.2

34.7

0.8

34.0

39.0

42.6

46.1

49.5

1.6

48.5

53.8

59.1

64.3

1.3

EVRS/EVRST 15

0.1

21.7

24.1

26.4

28.8

31.0

0.2

30.8

34.2

37.5

40.8

44.0

0.4

44.1

48.8

53.5

58.0

62.4

0.8

61.2

70.3

76.7

83.0

89.1

1.6

87.4

96.9

106.0

116.0

128.0

EVRS/EVRST 20

0.1

36.1

40.1

44.0

48.0

51.7

0.2

51.4

57.0

62.6

68.0

73.2

0.4

73.5

81.3

89.1

96.7

104.0

0.8

102.0

117.0

128.0

138.0

148.0

1.6

146.0

161.0

177.0

193.0

214.0

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆tsub = 4 K

Condensing temperature tc °C

+20

+30

+40

+50

+60

EVRS 3

0.1

0.68

0.72

0.76

0.78

0.79

0.2

0.97

1.0

1.1

1.1

1.1

0.4

1.4

1.5

1.5

1.6

1.6

0.8

1.9

2.0

2.1

2.3

2.3

1.6

2.7

2.9

3.0

3.1

3.2

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

NOTE:

• Capacities are based on liquid temperature tl = +25 °C ahead of evaporator.

• The table values refer to the evaporator capacity and are given as a function of evaporating temperature te and

pressure drop ∆p in valve.

• Capacities are based on dry, saturated vapour ahead of valve. During operation with superheated vapour ahead of

valve, the capacities are reduced by 4% for each 10 K superheat.

Correction factors

When sizing valves, the evaporator capacity must be multiplied by a correction factor depending on liquid

temperature tl ahead of expansion valve.

When the corrected capacity is known, the selection can be made from the table.

Table 15: Correction factors

Table 16: R717 (NH3)

Table 17: R22

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 8

Page 9

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆tsub = 4 K

Condensing temperature tc °C

+20

+30

+40

+50

+60

EVRS/EVRST 10

0.1

4.4

4.7

4.9

5.1

5.2

0.2

6.3

6.7

7.0

7.2

7.3

0.4

9.0

9.6

10.0

10.3

10.4

0.8

12.4

13.2

13.9

14.7

14.9

1.6

17.5

18.6

19.6

20.2

20.5

EVRS/EVRST 15

0.1

8.0

8.5

8.9

9.2

9.3

0.2

11.4

12.1

12.6

13.0

13.2

0.4

16.3

17.2

18.0

18.5

18.7

0.8

22.3

23.1

24.9

26.5

26.8

1.6

31.5

33.5

35.2

36.4

36.9

EVRS/EVRST 20

0.1

13.3

14.1

14.8

15.3

15.5

0.21920.12121.7

22.0

0.4

27.1

28.73030.9

31.2

0.8

37.1

38.4

44.5

44.2

44.6

1.6

52.5

55.9

58.6

60.6

61.5

t

o

°C

-40

-30

-20

-100+10

R717 (NH

3

)

0.89

0.91

0.96

1.0

1.06

1.10

R22

0.90

0.94

0.97

1.0

1.03

1.05

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Q

h

Kw

Evaporating temp. t

e

= -10 °C. Hot gas temp. ts = tc + 25 °C. Subcooling ∆t

sub

= 4 K

Condensing temperature t

c

°C

+20

+30

+40

+50

=60

EVRS 3

0.1

0.54

0.57

0.6

0.61

0.6

0.2

0.77

0.82

0.85

0.86

0.85

0.4

1.1

1.2

1.2

1.2

1.2

0.8

1.5

1.6

1.7

1.8

1.8

1.6

2.2

2.3

2.4

2.5

2.4

EVRS/EVRST 10

0.1

3.5

3.7

3.9

4.0

3.9

0.2

5.0

5.3

5.5

5.6

5.6

0.4

7.0

7.7

7.9

8.0

7.9

0.8

9.9

10.5

11.0

11.6

11.4

1.6

14.3

15.1

15.7

16.0

15.9

EVRS/EVRST 15

0.1

6.4

6.7

7.0

7.1

7.1

0.2

9.1

9.6

10.0

10.1

10.0

0.4

12.6

13.8

14.2

14.4

14.3

0.8

17.9

19.0

19.8

20.8

20.5

1.6

25.7

27.2

28.2

28.8

28.6

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

NOTE:

• An increase in hot gas temperature th of 10 K reduces valve capacity approx. 2% and vice versa.

• A change in evaporating temperature te changes valve capacity; see correction factor table below.

Correction factors

When sizing valves, the table value must be multiplied by a correction factor depending on evaporating

temperature te.

Table 18: Correction factors

Hot gas capacity Qh kW

Table 19: R134a

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 9

Page 10

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. ts = tc + 25 °C. Subcooling ∆t

sub

= 4 K

Condensing temperature tc °C

+20

+30

+40

+50

=60

EVRS/EVRST 20

0.1

10.6

11.2

11.7

11.8

11.8

0.2

15.1

16.0

16.6

16.8

16.7

0.4

21.0

22.9

23.7

24.0

23.8

0.8

29.8

31.6

33.0

34.7

34.2

1.6

42.8

45.3

47.1

47.9

47.6

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆tsub = 4 K

Condensing temperature tc °C

+20

+30

+40

+50

+60

EVRS 3

0.1

0.62

0.63

0.62

0.59

0.54

0.2

0.87

0.89

0.88

0.83

0.76

0.4

1.2

1.3

1.3

1.2

1.1

0.8

1.7

1.7

1.7

1.7

1.5

1.6

2.4

2.5

2.4

2.3

2.1

EVRS/EVRST 10

0.1

4.0

4.1

4.0

3.8

3.5

0.2

5.7

5.8

5.7

5.5

5.0

0.4

8.1

8.2

8.2

7.8

7.0

0.8

11.1

11.4

11.3

11.1

10.1

1.6

15.7

16.0

15.8

15.2

13.9

EVRS/EVRST 15

0.1

7.3

7.4

7.3

6.9

6.3

0.2

10.2

10.4

10.3

9.8

8.9

0.4

14.6

14.8

14.7

14.0

12.7

0.8

20.1

20.4

20.3

20.0

18.1

1.6

28.3

28.8

28.4

27.4

25.0

EVRS/EVRST 20

0.1

12.1

12.3

12.1

11.5

10.5

0.2

17.1

17.3

17.2

16.3

14.9

0.4

24.4

24.7

24.5

23.3

21.1

0.8

33.4

34.0

33.9

33.3

30.2

1.6

47.1

48.0

47.4

45.6

41.6

t

o

°C

-40

-30

-20

-100+10

R404A

0.86

0.88

0.9311.03

1.07

R134a

0.88

0.92

0.9811.04

1.08

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Q

h

Kw

Evaporating temp. t

e

= -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆tsub = 4 K

Condensing temperature t

c

°C

+20

+30

+40

+50

+60

EVRS 3

0.1

0.8

0.8

0.8

0.8

0.7

0.2

1.1

1.1

1.1

1.110.4

1.6

1.6

1.6

1.6

1.5

0.8

2.2

2.7

2.2

2.2

2.1

1.6

3.1

3.2

3.2

3.2

2.9

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Table 20: R404A

NOTE:

An increase in hot gas temperature th of 10 K reduces valve capacity approx. 2% and vice versa.

A change in evaporating temperature te changes valve capacity; see correction factor table below.

Correction factors

When sizing valves, the table value must be multiplied by a correction factor depending on evaporating

temperature te.

Table 21: Correction factors

Table 22: R410A

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 10

Page 11

Type

Pressure drop across

valve ∆p bar

Hot gas capacity Qh Kw

Evaporating temp. te = -10 °C. Hot gas temp. th = tc + 25 °C. Subcooling ∆tsub = 4 K

Condensing temperature tc °C

+20

+30

+40

+50

+60

EVRS/EVRST 10

0.1

5.1

5.2

5.3

5.2

4.8

0.2

7.2

7.4

7.4

7.3

6.8

0.4

10.2

10.4

10.5

10.3

9.6

0.8

14.4

14.8

14.9

14.5

13.7

1.6

20.3

20.82120.5

19.1

EVRS/EVRST 15

0.1

9.2

9.4

9.4

9.3

8.6

0.21313.3

13.3

13.1

12.2

0.4

18.4

18.8

18.9

18.5

17.2

0.8

25.9

26.6

26.7

26.1

24.6

1.6

36.6

37.5

37.8

36.9

34.5

EVRS/EVRST 20

0.1

15.3

15.7

15.8

15.5

14.4

0.2

21.6

22.1

22.2

21.8

20.3

0.4

30.6

31.3

31.5

30.8

28.7

0.8

43.2

44.3

44.6

43.5411.66162.66361.6

57.4

t

o

°C

-40

-30

-20

-100+10

R410A

0.92

0.95

0.9811.02

1.03

Type

Hot gas

temperature

th °C

Condensing

temperature

tc °C

Hot gas capacity G

h

kg/s at pressure drop across valve ∆p bar

0.512345678

EVRS 3

90

25

0.003

0.005

0.006

0.007

0.007

0.007

0.007

0.007

0.007350.004

0.005

0.007

0.009

0.009

0.01

0.01

0.01

0.01450.005

0.006

0.009

0.01

0.011

0.012

0.013

0.013

0.013

EVRS/EVRST 10

25

0.022

0.03

0.04

0.045

0.048

0.048

0.048

0.048

0.048350.026

0.036

0.048

0.056

0.061

0.064

0.065

0.065

0.065450.03

0.041

0.056

0.066

0.074

0.079

0.083

0.085

0.086

EVRS/EVRST 15

25

0.04

0.054

0.072

0.081

0.086

0.087

0.087

0.087

0.087350.046

0.064

0.086

0.100

0.109

0.115

0.117

0.117

0.117450.053

0.074

0.101

0.120

0.133

0.142

0.149

0.153

0.155

EVRS/EVRST 20

25

0.066

0.09

0.12

0.12

0.144

0.145

0.145

0.145

0.145350.077

0.107

0.144

0.167

0.182

0.191

0.195

0.195

0.195450.089

0.124

0.169

0.199

0.211

0.237

0.248

0.255

0.258

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

NOTE:

An increase in hot gas temperature th of 10 K reduces valve capacity approx. 2% and vice versa.

A change in evaporating temperature te changes valve capacity; see correction factor table below.

Correction factors

When sizing valves, the table value must be multiplied by a correction factor depending on evaporating

temperature te.

Table 23: Correction factors

Table 24: R717 (NH3)

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 11

Page 12

Type

Hot gas

temperature

th °C

Condensing

temperature

tc °C

Hot gas capacity Gh kg/s at pressure drop across valve ∆p bar

0.512345678

EVRS 3

90

25

0.008

0.011

0.014

0.016

0.017

0.017

0.017

0.017

0.017350.009

0.012

0.017

0.019

0.021

0.022

0.022

0.022

0.022450.01

0.014

0.019

0.022

0.025

0.026

0.027

0.028

0.028

EVRS/EVRST 10

25

0.051

0.069

0.092

0.104

0.109

0.111

0.111

0.111

0.111350.058

0.08

0.108

0.125

0.136

0.142

0.144

0.144

0.144450.066

0.092

0.125

0.146

0.162

0.172

0.179

0.183

0.183

EVRS/EVRST 15

25

0.091

0.125

0.165

0.187

0.197

0.199

0.199

0.199

0.199350.105

0.144

0.194

0.225

0.244

0.256

0.258

0.258

0.258450.119

0.165

0.224

0.263

0.291

0.31

0.322

0.329

0.33

EVRS/EVRST 20

25

0.152

0.208

0.275

0.311

0.328

0.332

0.332

0.332

0.332350.174

0.241

0.323

0.375

0.407

0.425

0.431

0.431

0.431450.193

0.275

0.374

0.439

0.485

0.516

0.537

0.548

0.55

Type

Hot gas

temperature

th °C

Condensing

temperature

tc °C

Hot gas capacity Gh kg/s at pressure drop across valve ∆p bar

0.512345678

EVRS 3

60

25

0.007

0.009

0.011

0.012

0.012350.009

0.011

0.014

0.016

0.016

0.016

0.016450.01

0.012

0.018

0.02

0.021

0.021

0.021

0.021

0.021

EVRS/EVRST 10

25

0.048

0.06

0.074

0.077

0.077350.055

0.071

0.092

0.103

0.104

0.104450.06

0.084

0.111

0.127

0.134

0.135

0.135

0.135

0.135

EVRS/EVRST 15

25

0.081

0.108

0.134

0.14

0.14350.094

0.129

0.166

0.192

0.187

0.187

0.187450.108

0.151

0.2

0.228

0.241

0.244

0.244

0.244

0.244

EVRS/EVRST 20

25

0.134

0.18

0.223

0.233

0.233350.157

0.215

0.276

0.307

0.312

0.312

0.312450.181

0.252

0.333

0.381

0.403

0.407

0.407

0.407

0.407

Type

Hot gas

temperature

th °C

Condensing

temperature

tc °C

Hot gas capacity Gh kg/s at pressure drop across valve ∆p bar

0.512345678

EVRS 3

60

25

0.01

0.013

0.018

0.021

0.022

0.023

0.023

0.023

0.023350.011

0.015

0.02

0.024

0.027

0.028

0.029

0.029

0.03450.012

0.017

0.023

0.028

0.032

0.034

0.035

0.036

0.037

EVRS/EVRST 10

25

0.063

0.087

0.116

0.134

0.145

0.148

0.149

0.149

0.149350.072

0.1

0.134

0.158

0.174

0.184

0.19

0.19

0.192450.081

0.112

0.153

0.182

0.203

0.228

0.228

0.237

0.239

EVRS/EVRST 15

25

0.113

0.157

0.21

0.242

0.26

0.267

0.269

0.269

0.269350.129

0.18

0.242

0.285

0.313

0.332

0.341

0.342

0.346450.146

0.202

0.275

0.327

0.365

0.393

0.411

0.424

0.431

EVRS/EVRST 20

25

0.189

0.262

0.350

0.403

0.433

0.445

0.449

0.449

0.449350.215

0.300

0.404

0.474

0.521

0.552

0.569

0.57

0.576450.243

0.337

0.459

0.545

0.609

0.656

0.684

0.707

0.719

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Table 25: R22

Table 26: R134a

Table 27: R404A

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 12

Page 13

Danfoss

A32F668.10.10

4

5

7

1

Danfoss

A32F670.10.10

Type

Hot gas

temperature

th °C

Condensing

temperature

tc °C

Hot gas capacity Gh kg/s at pressure drop across valve ∆p bar

0.512345678

EVRS 3

90

25

0.009

0.013

0.018

0.022

0.025

0.028

0.031

0.031

0.031350.01

0.014

0.02

0.025

0.029

0.032

0.035

0.038

0.038450.012

0.016

0.023

0.029

0.033

0.037

0.04

0.044

0.047

EVRS/EVRST 10

25

0.059

0.083

0.117

0.144

0.166

0.185

0.201

0.201

0.201350.067

0.094

0.133

0.163

0.189

0.211

0.231

0.249

0.249450.076

0.108

0.152

0.186

0.215

0.241

0.263

0.285

0.304

EVRS/EVRST 15

25

0.106

0.15

0.211

0.259

0.3

0.334

0.361

0.361

0.361350.12

0.17

0.24

0.294

0.34

0.38

0.416

0.449

0.449450.137

0.194

0.274

0.335

0.387

0.433

0.474

0.513

0.548

EVRS/EVRST 20

25

0.177

0.149

0.352

0.431

0.498

0.556

0.602

0.602

0.602350.2

0.283

0.4

0.49

0.566

0.633

0.693

0.748

0.748450.228

0.323

0.456

0.558

0.645

0.722

0.79

0.854

0.913

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Table 28: R410A

NOTE:

An increase in hot gas temperature th of 10 K reduces valve capacity approx. 2% and vice versa.

Material specication

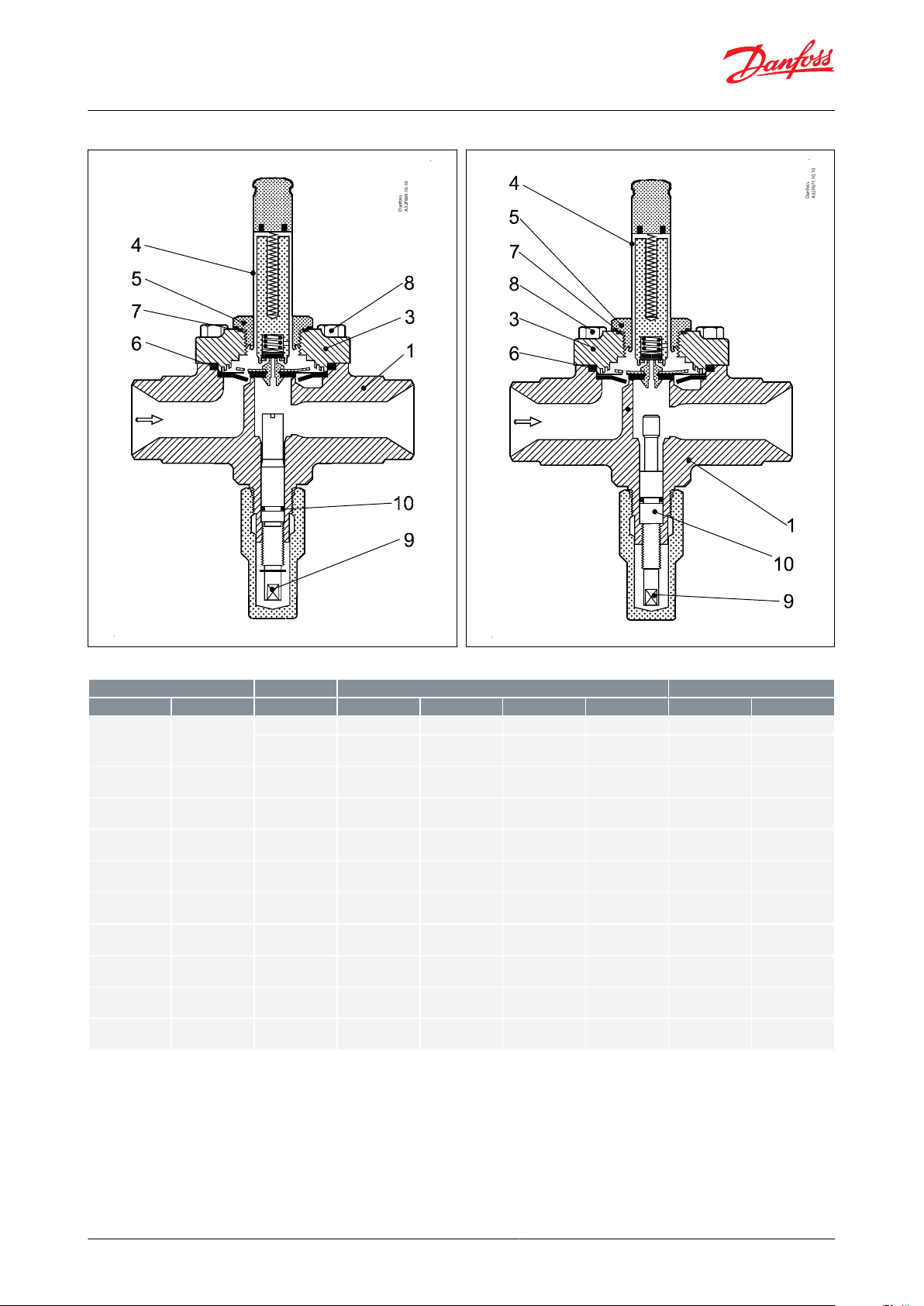

Figure 5: EVRS 3, Pipe thread

Figure 6: EVRS 3, welded

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 13

Page 14

Danfoss

A32F669.10.10

Danfoss

A32F671.10.10

Solenoid valves

Standard

No.

Description

Type

Material

Analysis

Mat.no.

W.no.

DIN

EN

1

Valve housing

EVRS 3

Stainless steel

X8 CrNiS 18-9

1.4305

10088

EVRS (T )

10/15/20

Stainless steel

X6 CrNi 18-9

1.4308

17455

2

Welding tube

EVRS 3

Stainless steel

X2 CrNiMo

17-12-2

1.4404

174553Cover

EVRS (T )

10(15/20

Stainless steel

X6 CrNi 18-9

1.4308

17455

4

Armature tube

EVRS(T )

3/10/15/20

Stainless steel

X2 CrNi 19-11

1.4306

10088

5

Armature tube

nut

EVRS(T )

3/10/15/20

Stainless steel

X8 CrNi 19-11

1.4305

100886Gasket

EVRS(T )

3/10/15/20

RubberCr7

Gasket armature

tube

EVRS(T )

10/15/20

Al gasket

Al 99.5

3.0255

102108Screws

EVRS(T )

10/15/20

Stainless steel

A2-70

3506

9

Spindle for man.

oper.

EVRS(T )

10/15/20

Stainless steel

X8 CrNiS 18-9

1.4305

1008810Gasket

EVRS(T )

10/15/20

Rubber

Cr

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Figure 7: EVRS/ EVRST 10 and 15

Figure 8: EVRS/ EVRST 20

Table 29: Material specication

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 14

Page 15

Danfoss

A32F414.11

Danfoss

A32F415.11

Danfoss

A32F416.11

Danfoss

A32F474.11

Type

L

5

max.

Weight with coil

10 W

12 W

20 W

mmmmkg

EVRS 3, pipe thread

75850.7

EVRS 3, weld

75850.6

EVRS/EVRST 10

75851.2

EVRS/EVRST 15

75851.3

EVRS/EVRST 20

75852

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Dimensions and weights

Figure 9: EVRS 3, pipe thread

Figure 10: EVRS 3, weld

Figure 12: Coil with DIN plugs Figure 13: EVRS / EVRST 10 and 15

Coil with terminal box

Figure 11: Coil with cable

Figure 14: EVRS / EVRST 20 Coil with

terminal box

NOTE:

Weight of coil:

• 10 W: approx. 0.3 kg

• 12 and 20 W: approx. 0.5 kg

Table 30: Weight of coil

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 15

Page 16

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

NOTE:

Above weight is approximated.

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 16

Page 17

Type

Max. working pressure

Ps bar

Connection

Code no.

Weld in.

Pipe thread ISO 228/1

With manual stem

Without manual stem

EVRS 3

50

3

⁄8

032F3080

EVRS 350G 1/4

032F3081

EVRS 10

50

1

⁄2

032F3082

EVRST 10

50

1

⁄2

032F3083

EVRS 15

50

3

⁄4

032F3084

EVRST 15

50

3

⁄4

032F3085

EVRS 20501

032F5437

EVRST 20501

032F5438

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Ordering

Figure 15: Ordering

Table 31: Separate valve bodies

Coils See "Coils for solenoid valves", data sheet. AI237186440089

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 17

Page 18

File name

Document type

Document topic

Approval authority

0C14029.523467890YTN

Pressure - Safety Certicate

CRN

TSSA

Solenoid valve, Type EVRS 3-20 and EVRST 10-20

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 32: Valid approvals

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 18

Page 19

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 72886419420en-000601 | 19

Loading...

Loading...