Page 1

Data Sheet

Electronic thermostat control

Type ETC 1H

For simple commercial refrigeration applications

The ETC 1H is introducing a exible platform

due to onboard micro-controller and software

dedicated product conguration, perfect for

light commercial refrigeration applications.

Standard versions with similar functionality as

the traditional electro-mechanical thermostats

as well as several customized high performance

software versions for various applications are

available.

The ETC 1H is developed for applications such

as:

• Refrigerators

• Bottle coolers

• Freezers

• No-frost freezers with heating element

• Medicine coolers

AI215986425643en-000501

Page 2

Product

specication

120 V, 60 Hz

230 V, 50/60 Hz

Power supply

115 V AC +/- 10% 60 Hz

220 V AC – 240 V DC +/- 10% 50 Hz

Energy consumption

Max 0.5 Watt

Max 0.5 Watt

Operating conditions

Ambient temp.

32 – 122 °F

0 – 50 °C

Humidity

Max 90% RH, Non-condensing

Max 90% RH, Non-condensing

Measuring range

NTC sensor

-40 – +185 °F

-40 – +85 °C

Relay output 1

Compressor

UL 60730: LRA96, FLA16

IEC/EN 60730: 16(16) A

UL 60730: LRA 60/ FLA 10

Relay output 2

Heater

5 A

5 A

Relay output 3

Fan

UL 60730: LRA 6/ FLA1

IEC/EN 60730: 5 A

UL 60730: LRA 6/ FLA 1

Accuracy

NTC sensor

+/- 1 K

+/- 1 K

ETC 1H

+/- 0.5 K

+/- 0.5 K

Temperature sensors

NTC- 5K

NTC- 5K

Life time

Relay 1

+350,000 cycles

+350,000 cycles

Relay 2

+30,000 cycles

+30,000 cycles

Relay 3

+30,000 cycles

+30,000 cycles

Connections

Power

6.3 x 0.8 mm tabs, RAST 5

6.3 × 0.8 mm tabs, RAST 5

Signal/remote

3-pole RAST 2,5 edge connector

2-Pole RAST 2,5 edge connector

3-pole RAST 2,5 edge connector

2-Pole RAST 2,5 edge connector

Temperature indication

Through optional remote display

Through optional remote display

Approvals

UL-C, NSF

Semko, CE, CQC, EAC

EMC Category

------

Category-1

IP class

IP 00

IP 00

Remote control

Optional remote display with Control. 1wire protocol

Optional remote display with Control. 1wire protocol

Number of sensors

2 (optional 3)

2 (optional 3)

Start-up-time

< 2 seconds

< 2 seconds

Electronic thermostat control, type ETC 1H

Features

• ETC 1H can control the cabinet temperature directly

• ETC 1H has low energy consumption

• 1 or 2 sensors (Air, evaporator) and optional remote display can be connected

• Using NTC temperature sensors

• Temperature control independent of barometric pressure

• High accuracy combined with close dierentials and narrow tolerances ensures improved control

• Built in timers enhances functionality

• Optional alarm for over or under temperature in both cold and warm

• Auxiliary relays: 5 Amp for heater, fan, light etc. Eventually with delayed start or/and stop

• Under voltage and over voltage compressor protection (brown-out protection)

• Pressure equalisation protection on starting the device or when voltage drops out (blackout protection)

• Diagnostics and self check of sensors and potentiometer

• Several defrosting methods can be handled:

◦ Time controlled defrosting

◦ Time controlled defrosting with evaporator sensor

◦ Temperature controlled defrosting

• Dual band control of outdoor bottle coolers

• Quick Parameter Programming using PC software tool and Gateway

• Hydrocarbon refrigerant compatible relay outputs

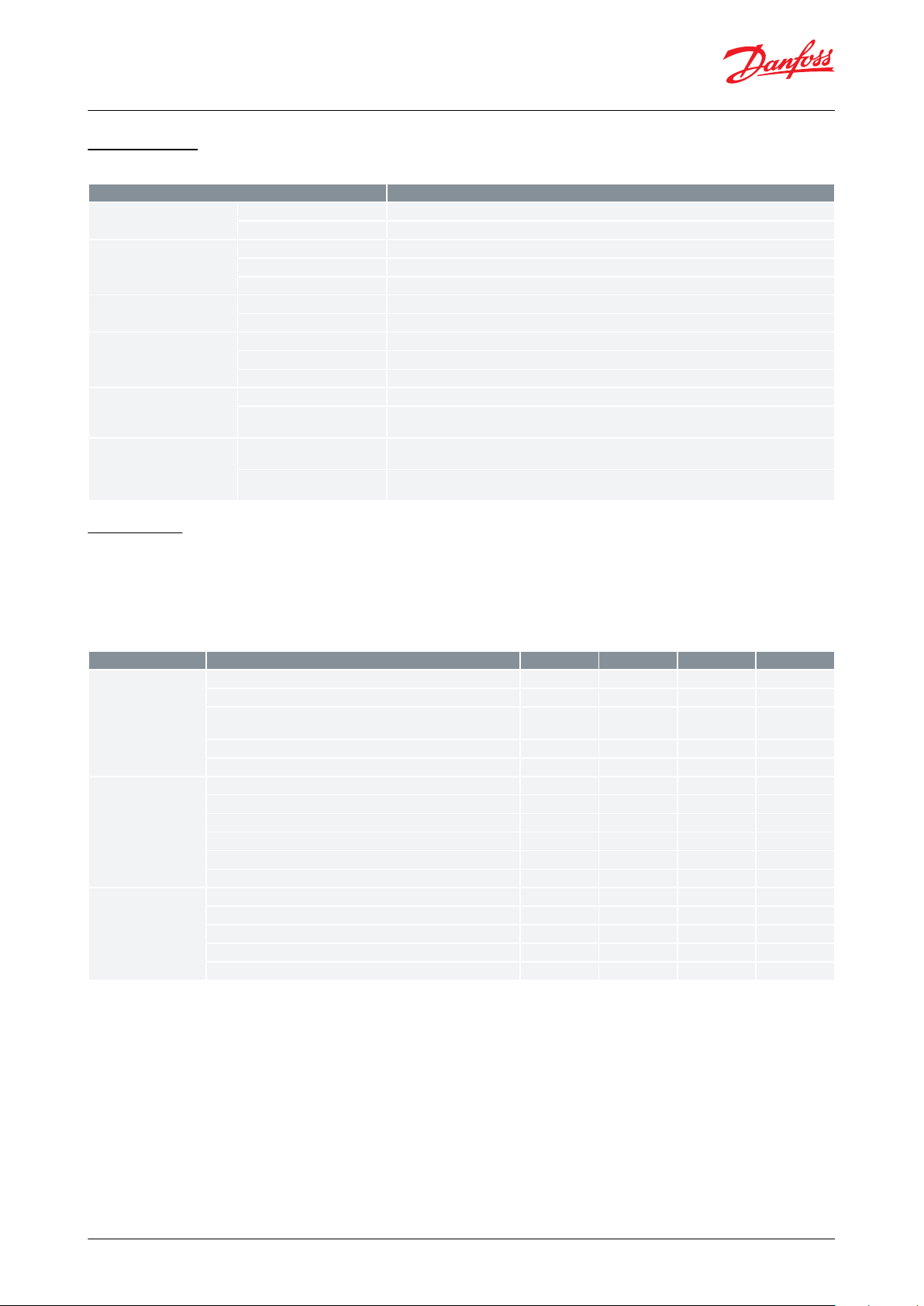

Product specication

Technical data

Table 1: Technical data

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 2

Page 3

Product specication

Description

Temperature

Settings

Dierential: -1 – 10 K , Range: 0 – 30 K, Defrost: 0 – 10 °C

Adjustment

Knob with stop 210° +/-5°. Stop 45°+/-5° o Knob angle without stop 255°+/-5°

Diagnostics

Visual indication

On-board LED (Red)

Function

Self check of sensors and potentiometer

Sensor fault

Air sensor

Compressor protection

Brown-out

Under-voltage and over-voltage protection

Black-out

Based on temperature at cabinet sensor

Defrost

Mode 1

Start by Time- Stop by Cabinet Temperature (1 sensor)

Mode 2

Start by Time- Stop by Defrost Sensor (2 sensors)

Mode 3

Start and Stop by Defrost Sensor (2 sensors)

Alarm

Types

Over or/and under temperature in cold or warm

Indication

Flashing LED on the ETC 1H or by an external connected remote module or optionally to one of

the relays to control a buzzer

Blocked condenser

On customer request only

Function

Monitor the condenser temperature and stop the compressor until the temperature goes below

the condenser warning temperature

Indication

Flashing LED on the ETC 1H or by an external connected remote module or optionally to one of

the relays to control a buzzer

Parameter

Min

Max

Default

Unit

Thermostat

Cold cut-out

-65500

°C

Warm cut-out

-655010

°C

Default temp set also used as remote setpoint

0

1023

512

0: cold

1023: warm

Cold

dierential

-1201

K

Warm

dierential

-1201

K

Compressor

Min runtime01800

300

Sec

Min stoptime

0

1800

300

Sec

Max runtime

0

10800

3600

Sec

Max stoptime

0

10800

5400

Sec

Error runtime

0

1800

600

Sec

Error Stoptime

0

1800

900

Sec

Alarm on relay

Cold overtemp alarm

-655015

°C

Warm overtemp alarm

-655015

°C

Cold undertemp alarm

-65502

°C

Warm undertemp alarm

-65502

°C

Alarm delay012060Min

Electronic thermostat control, type ETC 1H

Functionality

Table 2: Functionality

Parameters

It is possible to adjust the following parameters in the controller using Danfoss PC software tool ‘KoolProg’ and

Gateway.

For more information please visit: KoolProg

Table 3: Parameters

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 3

Page 4

Parameter

Min

Max

Default

Unit

Defrost

Defrost method

0: No defrost

030

Num

1: Time start, Control T stop

2: Time start, Evap T stop

3: Evap T start , Evap T stop

Defrost terminate temperature

0505

°C

Defrost start temperature

-250-10

°C

Drip-o time

0

18000Sec

Minimum defrost time

0

3600

900

Sec

Maximum defrost time

0

7200

1800

Sec

Minimum defrost interval

0

720

360

Min

Maximum defrost interval

0

2160

720

Min

Fan on during defrost

Disable

Enable

Disable

Hot-gas defrost

Disable

Enable

Disable

Timer reset on cutout

Disable

Enable

Disable

Fan

Fan start delay

0

18000Sec

Fan stop delay

0

18000Sec

Fan stop on cutout

Disable

Enable

Disable

Blocked condenser

(optional)

Condenser warning temperature

508570

°C

Condenser stop temperature

508580

°C

Condenser watch

Disable

Enable

Disable

Voltage protection

Minimum cut-in voltage

80

210

185

Vrms

Voltage threshold

02015

Vrms

Maximum cut-in voltage

130

264

260

Vrms

Voltage protection

Disable

Enable

Disable

Miscellaneous

Factory test065535

0

Boolean

D0: Comp relay

D1: Fan relay

D2: Heater relay

D6: LED 1/10 blinking

D7: LED _ blinking

D15: Factory test

Sensor Type

0: Epcos

-100

100

Epcos

Num

% of 1/4 period

1: Shibuara Zero-cross switching

0

Thermostat ID low D0-32

0

2320Num

Typenumber

0

100000Num

D14-15 group number

D0-13 number

SW version0999

100

Zero switch

Disable

Enable

Disable

Stop function

Disable

Enable

Disable

Remote display

Fahrenheit in display

Disable

Enable

Disable

Boolean

Decimal point

Disable

Enable

Enable

Show setpoint

Disable

Enable

Disable

Display lock at defrost

Disable

Enable

Disable

Remote sensor oset

-10100

Remote sensor deviation

-10

10

Remote sample time

0

100

10

Remote display lock

0

14400Min

Electronic thermostat control, type ETC 1H

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 4

Page 5

Danfoss

80G8133

Warm

cut-out

Default

cut-out

Cold

cut-out

Cold

differential

Temperature

Knob position

Default

position

Cold

position

Warm differential

compressor

Cold differential

compressor

Compressor

cutout warm

position

Compressor

cutout cold

position

Heat cutin warm

position

Heat cutin cold

position

Warm differential

heat

Cold differential

heat

Warm

position

Danfoss

80G8134

Electronic thermostat control, type ETC 1H

Variants

Figure 1: Temperature cut-out

In order to optimize the eciency and ensure the reliability of the Danfoss products in your specic applications

and systems, always contact Danfoss prior to initiating the use of any Danfoss products.

• You can have the ETC1H with optional 2 or 3 relays, for controlling heaters, fans etc.

• You can have the ETC1H with standard software or optionally with special customized software for optimized

functionality. Please contact Danfoss regarding this.

Danfoss does not accept any responsibility for ETCs placed in environments outside our design specications. Use of

the ETCs in such cases must be veried via relevant eld-tests, and always remains the responsibility of the buyer.

Figure 2: Temperature dierential chart

Dual band control of compressor and cabinet heater for outdoor bottle coolers placed in cold environment.

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 5

Page 6

Danfoss

80G8135

Electronic thermostat control, type ETC 1H

Dimensions and Mounting

Figure 3: Dimensions and Mounting

The controls can be mounted using the nut shown or it can be mounted using 2 screws type EJOT DURO-PT dia. 3 ×

7 mm.

WARNING:

By using screw types dierent than the above mentioned, there is a risk of short circuiting the line potential.

NOTE:

All Danfoss knobs have been designed to sit ush against the housing, relieving the load on the spindle arm.

Maximum mounting force of knob: 60 N. Whenever using non-Danfoss knobs, please ensure that they are mounted

as described above and that the maximum mounting force of knob: 60 N is not exceeded.

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 6

Page 7

Description

Code number

Comment

ETC 1H1 (120 V/ 240 V)

077F1396/99

Project specic

ETC 1H2 (120 V/ 240 V)

077F1395/98

ETC 1H3 (120 V/ 240 V)

077F1394/97

Black knob

077F8562

Mechanical options

Washer, Black, White print 0-9, I-Pack

077F8577

Description

Cable length

Port

Code

Cabinet sensor

(1)

470S1077F8751

Cabinet sensor

(1)

1.0S1077F8757

Cabinet sensor

(1)

1.5S1077F8761

Cabinet sensor

(1)

2.0S1077F8765

Cabinet sensor

(1)

2.5S1077F8767

Cabinet sensor

(1)

3.0S1077F8769

Cabinet sensor

(1)

3.5S1077F8723

Cabinet sensor

(1)

6.0S1080G2019

Evaporator sensor

(2)

1.0S2077F8786

Evaporator sensor

(2)

1.5S2077F8790

Evaporator sensor

(2)

2.0S2077F8794

Evaporator sensor

(2)

3.0S2077F8798

Evaporator sensor

(2)

6.0S2080G2029

Condenser sensor

(3)

1.0S3077F8756

Condenser sensor

(3)

1.5S3077F8760

Condenser sensor

(3)

3.0S3077F8768

Electronic thermostat control, type ETC 1H

Ordering

Table 4: Ordering for ETC-1H

Table 5: Ordering for sensors

(1)

(1)

NTC temp sensor w/o color marking Typical cabinet temperature sensor (depending on assignment).

NTC temp sensor w/o color marking Typical cabinet temperature sensor (depending on assignment).

(2)

(2)

NTC temperature sensor with 2'' color marking Typical evaporator temperature sensor (depending on assignment).

NTC temperature sensor with 2'' color marking Typical evaporator temperature sensor (depending on assignment).

(3)

(3)

NTC temperature sensor with 1'' color marking Typical condenser temperature sensor (depending on assignment).

NTC temperature sensor with 1'' color marking Typical condenser temperature sensor (depending on assignment).

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 7

Page 8

Regulatory and Compliance

Directive

Standards

Country

Electrical Safety (Class I & Class II equipment)

Low Voltage Directive: 2014/35/EU

EN 60730-1:2000 +A12+A13+A1+A14+A16+A2

Europe

Electrical Safety (Class I & Class II equipment)

Low Voltage Directive: 2014/35/EU

EN 60730 2-9 : 2010

Europe

Electrical Safety (Class I & Class II equipment)

-

GB 14536.1:2008, GB 14536.10:2008

China

Electrical Safety (Class I & Class II equipment)

-

UL 60730-1, UL 60730 2-9

US

Electrical Safety (Class I & Class II equipment)

-

CAN/CSA-E60730-1, CAN/CSA-E60730 2-9

Canada

Electrical Safety (Class I & Class II equipment)

-

CU TR 004/2011

Eurasia

Electromagnetic Compatibility

EMC Directive: 2014/30/EU

EN 61000 6-2:2005, EN61000 6-3:2007 +A1:2011

Europe

RoHS

RoHS Directive: 2011/65/EU & 2015/863/EU

EN 50581:2012, EN IEC 63000 : 2018

Europe

Food Safety

-

NSF/ANSI-2

US

Approved for use in Flammable Refrigerants

-

EN 60335 2-89: 2010 Annex BB, EN 60335 2-24:

2010 Annex CC

Europe

Approved for use in Flammable Refrigerants

-

UL 471, UL 60335 2-24, UL 60079-15 ed.4

US

Enclosure material ammable class

-

UL 94

US

Certication and Manufacturer Declarations on

Conformity

CE, C-UL-US, CQC, UA , EAC, ENEC, NSF, S Mark, RoHS

Electronic thermostat control, type ETC 1H

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 6: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI215986425643en-000501 | 9

Loading...

Loading...