Page 1

Datasheet

ESBE VTC 511

3-Way Thermic Valve

Applications:

Typical Applications:

• High mass non-condensing boiler coupled

with low return water situations, i.e. snow

melt systems or high mass concrete

radiant floor heating

• Gravity hot water conversion systems

• Solid fuel boilers feeding storage tanks or

a heating system

• Solar heating and stratification control for

storage tank

The ESBE VTC thermic valve is a thermostatic

by-pass valve which regulates the

temperature of either the supply out or the

return of water in a hydronic heating system.

In a conventional application, the VTC valve

safeguards non-condensing boilers against

corrosion from condensation that would

result if a minimum flue gas temperature

is not maintained. With the VTC the boiler

is able to recover and keep up with the

drop in water temperature. The VTC valve

can also be used on a solid fuel boiler or

a solar application where a minimum or

maximum water temperature is trying to be

maintained.

Features:

• Thermostatically maintains a high and steady

return temperature increasing the life and

efficiency of the heat source

• Protection from thermal shock within non-

condensing boilers

• Self contained thermostatic element with no

adjustment required

• Interchangeable thermostat elements, to

meet temperature requirements

• Low leakage rate through the ports of

the valve

Ordering Information:

AI000086403224

* Valve body and thermostat sold separately. Order one valve body and

VTC Valve Body, Without Thermostat*

Code No. Series Cv Valve Size

193 B1701 V TC511 16.2 1-1¼” FNPT

Internal VTC Temperature Element

Code No. Series Typical Application

193 B1702 122 °F (50°C)

193 B170 4 140 °F (60°C)

193 B1709 149 °F (65°C)

193 B170 6 176 °F (80°C)

Spare Parts

Code No. Description

98060150 O-ring for brass plug

one temperature element to assemble a complete valve

Return line boiler protection193 B1703 131°F (55°C)

Boiler outlet, storage tank feed193 B1705 158 °F (70°C)

Connection

© Danfoss | 02/2022 | 1

Page 2

ESBE VTC 511 3-Way Thermic Valve Datasheet

ESBE VTC 511 3-Way Thermic Valve Datasheet

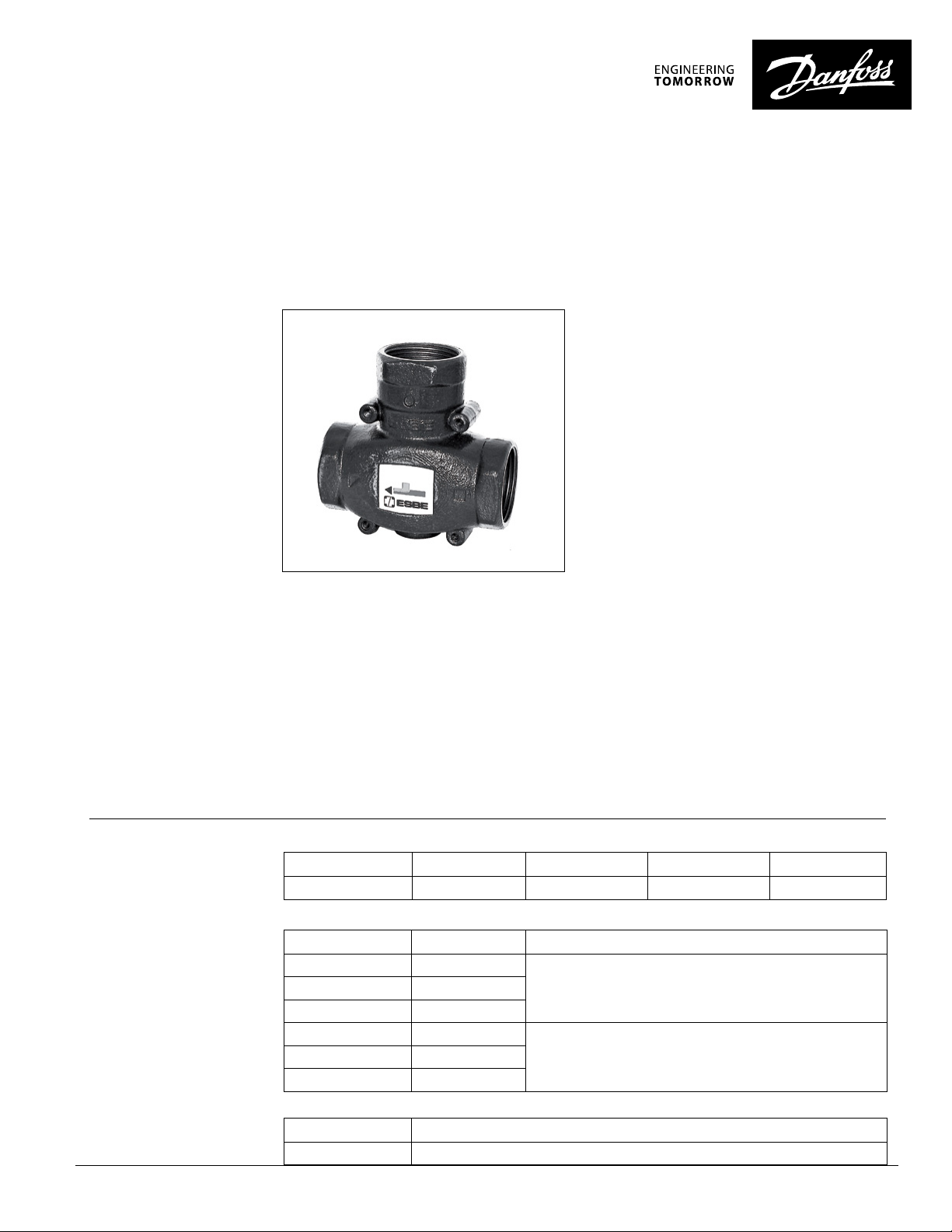

Valve Selection:

Piping Orientation:

Supply Mounted

(149 °F (65°C), 158°F (70°C), 167°F (75°C) elements)

Circulator

VTC valve

Other location for circulator

Return Mounted

(122 °F (50°C), 131°F (55°C), 140°F (60°C) elements)

Circulator

When the VTC is piped on the supply

side out from the heat source, the valve

will begin to allow water out to the

system when the temperature of the fluid

meets the temperature of the inserted

thermostat element.

The VTC valve, when placed on the return

side will open when the minimum return

temperature of the element is reached.

When the fluid temperature reaches

18°F (10°C) higher than the element’s

temperature, the return port from the

system will be fully open.

Technical Specifications:

Max. system pressure 145psi (10 bar)

Max. medium temperature 230°F (110 °C)

Min. medium temperature 32°F (0°C)

Fully open temperature differential 18°F (10°C) higher than temperature element

Max. differential pressure across:

B - AB & A - AB 14.5psi (1 bar)

B (О)

AB( )

Max. leakage rate

A(∆)

B - A 4.35psi (0.35 bar)

A - AB 1% of Cv

B - AB 3% of Cv

Allowable medium Closed loop system, Glycol mixture up to 50%

VTC

valve

Other location for circulator

2 | © Danfoss | 02/2022

AI000086403224

AI000086403224

© Danfoss | 02/2022 | 3

Page 3

ESBE VTC 511 3-Way Thermic Valve Datasheet

Systems Applications:

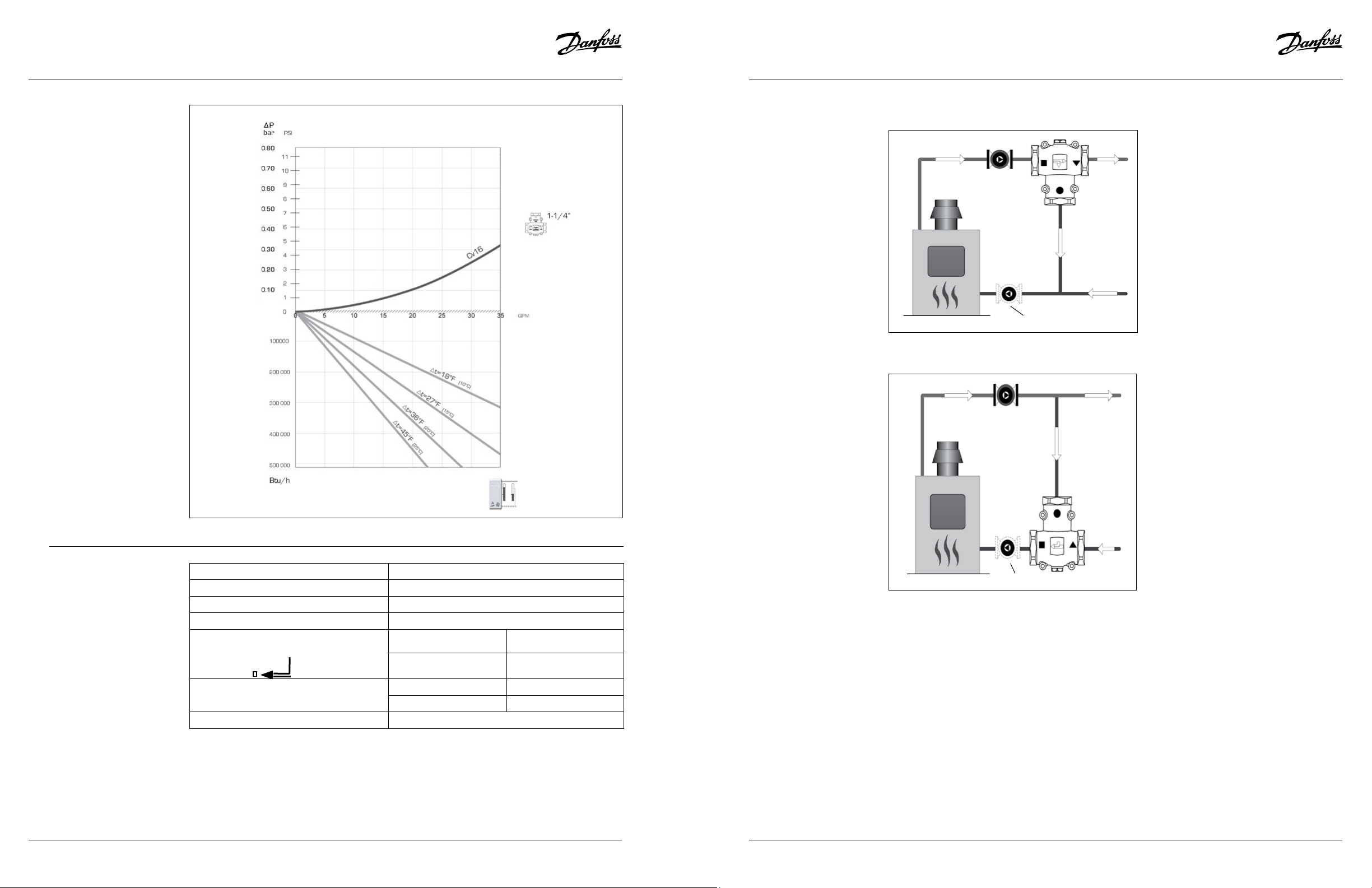

VTC Thermic Valve on Gravity Conversion System

Because gravity conversion systems contain

an enormous volume of water, the water

returning to the heat source could be

significantly cooler, leading to condensation

and a shorter life for the heat source.

Adding a thermic valve to the system will

prevent the boiler from sustained operation

at temperatures below the dew point of

their flue gases.

VTC Valve

VTC Valve on Multi-zone Systems with Circulators

Where a high mass non condensing

heat source is matched with a large low

temperature system, a situation could occur

where the heat source is unable to keep up

with the rate of demand from the system.

The use of the thermic valve provides the

opportunity for the heat source to catch-up.

VTC Valve

Charging of Storage Tank through Solar Heating

With the thermic VTC valve, an efficient

method of charging a tank can be done.

To achieve efficiency through the solar

panel, cool water should enter allowing

for a higher differential temperature across

the panel. Additionally heated fluid from

the panel should be properly distributed

within the tank to reduce stratification i.e.

even temperature distribution, within the

tank.

4 | © Danfoss | 02/2022

AI000086403224

Page 4

Dimensions:

A B C Depth Weight

Size in (mm) in (mm) in (mm) in (mm) lbs (kg)

1-¼” 4.13 (105) 1.50 (38) 2.95 (75) 2.17 (55) 3.04 (1.38)

Construction:

Valve body Nodular iron

O-ring EPDM

Thermostat cover Brass

Thermostat Copper

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other technical data in product manuals, catalogues descriptions, advertisements, etc.

and whether made available in writing, orally, electronically, online or via download, shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order confirmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to products ordered but not delivered provided that such alterations can be made without

5 | © Danfoss | 02/2022

changes to form, fit or function of the product. All trademarks in this material are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

AI000086403224

Loading...

Loading...