Page 1

ESBE VTA Series Lead-Free Thermostatic Mixing Valves Datasheet

Keep water temperatures safe in point

of source applications with thermostatic

mixing valves.

Low maintenance, easy-to-install thermostatic mixing valves

(TMV) are designed to protect against accidental scalding, &

increase amounts of available hot water.

HIGH

Temperatures within

source reduce growth

of Legionella while

safeguarding against

scalding.

heating.danfoss.us

Page 2

ESBE VTA Series Lead Free Thermostatic Mixing Valves Datasheet

Applications:

Specifications:

The compact ESBE VTA series are lead-free (LF)

thermostatic mixing valves (TMV) designed for

point of source in domestic hot water distribution

systems and/or regulation of supply in hydronic

heating systems. The series of LF valves meet

the NSF/ANSI 372 standards for ‘lead free’

requirements.

The VTA series of valve replaces the legacy 20

Series and 30MR Series of valves. The VTA Series

are available in four temperature ranges:

• 85 to 120°F (30 to 49°C) (Domestic/ Hydronic)

• 95 to 140°F (35 to 60°C) (Domestic/ Hydronic)

• 70 to 110°F (20 to 45°C) (Hydronic)

• 85 to 160°F (30 to 70°C) (Hydronic)

As a point of source for domestic hot water

application, the thermostatic control within

the VTA valve accommodates increased water

• Conforms to ASSE-1017*

* Ranges 85°-120° F & 95°-140° F only

• Anti-scald function

• Designed for mixing purposes

• Long life and easy maintenance

• Quiet operation

• Compact design and lightweight snap-

on cover for dirt protection and to prevent

unauthorized adjustment or tampering

• Cover label for recording setting

information including recorded outlet

temperature and date installed

• Available connections:

• Threaded body (FNPT)

• Solder (Union connection)

• CPVC (Union connection)

• Maximum working pressure:

150 psi (10 bar) / CPVC: 80 psi (5.5 bar)

temperature at the source while maintaining

appropriate water temperatures out to the

fixtures. With a higher temperature at the source,

the installation benefits of the VTA series include:

• Additional volume of domestic hot water

to the fixtures at an appropriate regulated

temperature

• Preventative measures to reduce

growth of Legionella by maintaining a

high temperature within the source &

safeguarding against scalding down stream

In the event there is a cold-water supply failure,

the hot water supply closes automatically.

The angle flow pattern of the ESBE VTA series

tmvs combine high quality performance with

remarkable ease of installation and servicing.

• Maximum differential pressure between hot

and cold ports:

44 psi (3 bar)

• Maximum system differential pressure

between outlet and inlet ports:

72 psi (5 bar)

• Maximum hot water inlet temperature:

19 4°F (90°C)

• Minimum required flow for proper

temperature regulation:

• All valves except 1” NPT: 0.9 GPM

• 1“ NPT valve size: 2.0 GPM

• Up to a 50% glycol mixture for closed loop

hydronic system

2 | © Danfoss | 03/2020

AI189286403251

Page 3

ESBE VTA Series Lead Free Thermostatic Mixing Valves Datasheet

Ordering

Information:

Valve Connection Type Valve Size Temperature Range Cv Code No.

¾” 70° t o 110 °F (20° to 45°C) 1.9 065B8868LF

¾” 85° to 120°F (30° to 49°C) 1.9 065B8869LF

Female NPT

¾” 95° to 140 °F (35° to 60°C) 1.9 065B8870LF

¾” 85° to 160°F (30° to 70°C) 1.9 065B8871LF

1” 85° to 120°F (30° to 49°C) 4.1 3162 2111LF

1” 95° to 140°F (35° to 60°C) 4.1 31622011LF

85° to 120°F (30° to 49°C) 1.9 065B8877LF

Union Solder & CPVC

(Requires tailpiece kits, sold seperately. See below.)

-

95° to 140 °F (35° to 60°C) 1.9 065B8878LF

85° to 160°F (30° to 70°C) 1.9 065B8872LF

Accessories Size Description Code No.

½” solder tailpieces 065B8901

Tailpiece Kits

(for Sold er & CPVC)

¾” solder tailpieces 065B8892

¾” CPVC

(follow pipe manufacturers instructions) 065B8898

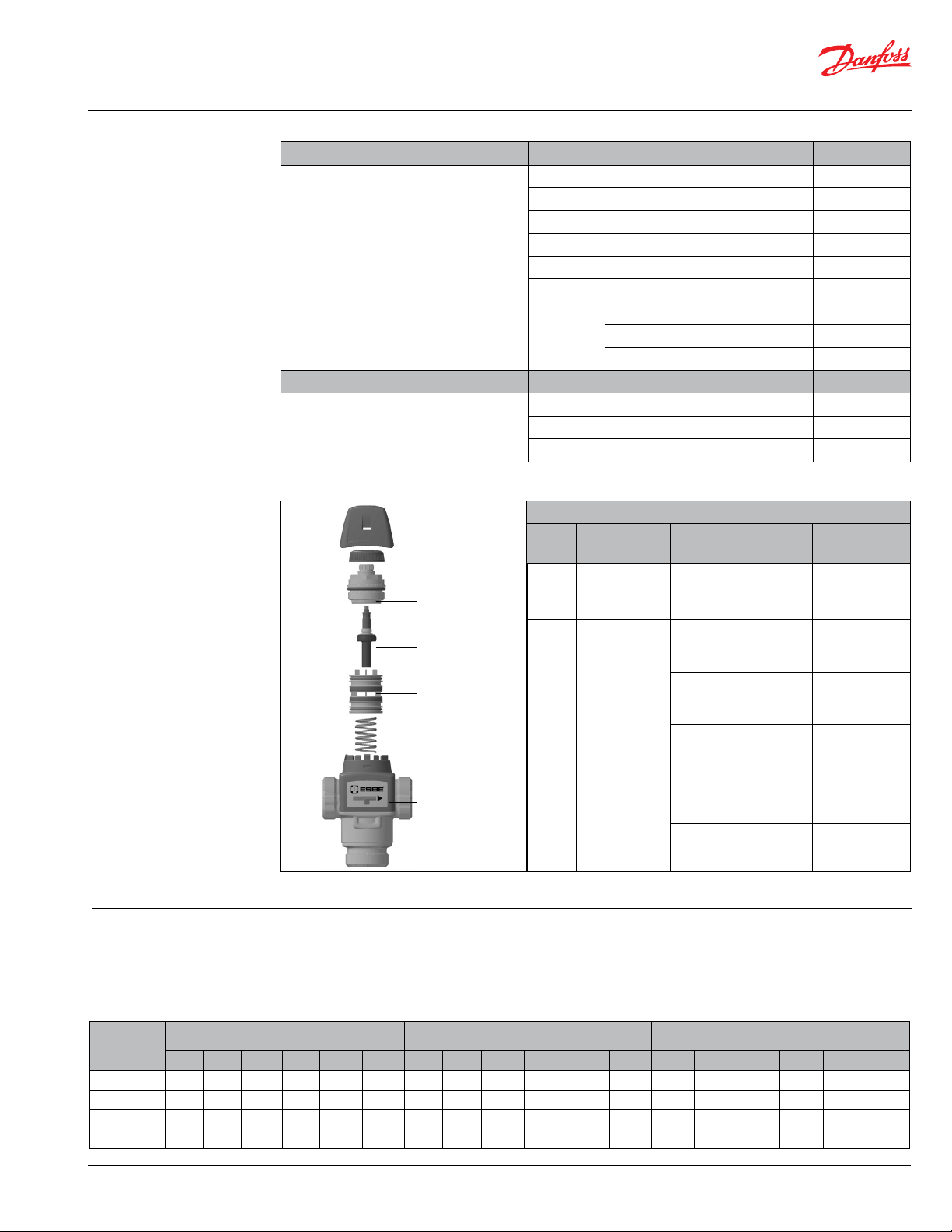

Spare Parts

1- Cap

Item

No.

Description Temperature Range Code No.

Cap for All

2- Adjustment

Bonnet

1

Except

-

1” NPT

065B8846

3- Thermostat

70° to 110°F (20° to 45°C)

065B8842

Repair Kit for

4- Shuttle

All Except

85° to 120°F (30° to 49°C)

065B8843

1” NPT

5- Spring

6- Body

1-5

Repair Kit for

95° to 140°F (35° to 60°C)

85° to 120°F (30° to 49°C)

065B8844

37101600

1” NPT

Temperature

Setting:

95° to 140°F (35° to 60°C)

VTA series of tmvs will provide a mixed water temperature according to the following table. The outlet

temp. stated are approximate, based on the given hot water supply temp. & a cold water supply of 50°F

3710140 0

(10°C). For other cold water temp. correct the outlet temp. by 1°F for every 10°F (or 1°C for every 10°C)

deviation from 50°F (10°C), up or down.

Hot Water

Tem p.

120 °F (49°C) 67(19) 74(2 3) 81(27 ) 87(31) 94(3 4) 109(43) 8 0(27) 90(32) 97(36) 102(39) 107(42 ) 115( 46 ) 95(35) 10 6(41) 115( 46 ) 11 9(4 8) 120(49) 120(49)

140 °F (60°C) 68 (20) 75( 24) 82(28) 90(32) 97(36) 113(45) 81(27 ) 91(3 3) 9 9(37) 104 (40) 109(43) 117(4 7) 97(36) 108 (42) 117 (47 ) 126(52) 133(56) 140 (60)

160° F (70°C) 69( 21) 76( 24) 8 4(29) 92(33) 100 (38) 118 (4 8) 82(28) 93(34) 100(3 8) 10 6(41) 112( 44) 118 (48 ) 9 9(37) 109 (43) 118 (48 ) 127(53) 135(57) 14 5(63)

180° F (82°C) 70( 21) 77(25) 86(30) 95( 35) 102(39) 12 2(50 ) 82(28) 95(35) 102(39) 10 8(42) 11 4(4 6) 120(49) 100( 38) 111(4 4) 120(49) 12 9(5 4) 13 6(5 8) 149 (65)

70° - 110°F (20° to 45°C) 85°- 120 °F (30°- 49°C) 95°- 140 °F (35° - 60°C)

1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4 5 6

AI189286403251

© Danfoss | 03/2020 | 3

Page 4

ESBE VTA Series Lead Free Thermostatic Mixing Valves Datasheet

Flow Pattern &

Capacity:

Hot (DHW) / Supply (Hydronic)

Cold (DHW) / Return (Hydronic)

Flow vs. Pressure Drop for VTA Series

Mixed

Pattern:

The VTA series provides a mixing

flow pattern for both a domestic

hot water (DHW) application and

for hydronic heating systems. If a

diverting flow pattern is required

refer to the VTA572 datasheet

located on heating.danfoss.us

(Code No.31700200).

1” NPT

Cv 4 .1

All others

Cv 1.9

Capacity:

The flow rate through the VTA

series valve at any given pressure

drop can be determined from the

capacity diagram.

4 | © Danfoss | 03/2020

AI189286403251

Page 5

ESBE VTA Series Lead Free Thermostatic Mixing Valves Datasheet

Domestic Hot Water

Sizing:

For domestic hot water systems the VTA series

can be sized based on the number of fixture

units the valve will supply.

Valve selection process:

1. Determine the type and number of fixtures

to be supplied by the mixing valve.

2. Assign fixture units from Table 1 for each

fixture type.

3. Add the total number of fixture units.

4. Confirm the mixing valve has sufficient

capacity from Table 2.

Example:

A residential home with 2-1/2 baths (3 bathroom

sinks and 2 baths or 7 fixture units), kitchen

(1 kitchen sink and a dish washer or 3 fixture

units), and a clothes washer (2 fixture units).

Hot water supply from the water heater is ¾”.

The total is 12 fixture units.

Table 1. Fixture Units

Bathroom sink 1

Kitchen Sink 2

Bath 2

Shower 2

Clothes Washer 2

Dish Washer 1

Table 2. VTA Series Capacity

Valve Size Max. Fixture Units

All except 1” NPT 16

1” NPT 30

Note: Cer tain fixtures such as hot tubs, roman tubs or spa

showers may require a high volume of hot water. The V TA

series may not be capable of providing sufficient hot water to

these fixtures.

Typical Piping:

Central mixing

Radiant floor

Domestic water

VTA series of tmvs can be used to safely supply domestic hot water in residential, commercial, institutional,

and industrial installations.

The VTA series are also well suited for use in hydronic heating systems requiring a reduced hot water

temperature such as in radiant heating systems, heat pumps, and solar heating systems.

Radiant floor heating Take off for radiant floor he ating Return water tem p. control & mixing for radiant flo or

Recirculated do mestic water

AI189286403251

© Danfoss | 03/2020. | 5

Page 6

ESBE VTA Series Lead Free Thermostatic Mixing Valves Datasheet

Dimensions & Weights:

C

B

C

B

D

A

Threaded (FPT)

Union Solder & Union CPVC

Description

union valve w/ ½” solder tailpcs 4.1” (10 4) 2.3” (59) 2.1” (53) 2.0” (52) 1.7 (0.8)

union valve w/ ¾” solder tailpcs 4.8” (122) 2.7” (69) 2.1” (53) 2.4” (61) 1.7 (0.8)

union valve w/ ¾” CPVC 4.7” (119 ) 2.6” (66) 2.1” (53) 2.4” (83) 1.5 (0.7)

¾” valve female NPT connections 2.8” (71) 1.7” (43) 2.1” (53) 1.4” (36) 1.1 (0.5)

1” valve female NPT connections 3.75” (95) 2.5” (63) 2.4” (61) 1.9” (48) 2 (0.95)

A B C D

Dimensions, in (mm)

A

Weight

lbs (kg)

Typical Specification:

6 | © Danfoss | 03/2020

A Thermostatic Mixing Valve shall be installed on

the outlet of the water heater for the distribution

of tempered water to the fixtures. The

thermostatic mixing valve shall have an internal

self regulating element housed within a brass

lead free constructed valve body. The valve shall

have a protective plastic body cover and snap-on

cap to prevent unauthorized tampering. The

valve shall be an ESBE VTA thermostatic mixing

valve series.

A Thermostatic Mixing Valve for hydronic

heating applications shall be installed prior

to the circulator for the system or zone. The

thermostatic mixing valve shall have an internal

self regulating element housed within a brass

lead free constructed valve body. The valve shall

have a protective plastic body cover and snap-on

cap to prevent unauthorized tampering. The

valve shall be an ESBE VTA series thermostatic

mixing valve series.

AI189286403251

Page 7

Learn how VTA thermostatic mixing valves helped

provide year-round comfort & reduced water

temperatures for offices in New York City.

Read the Interchurch Center case story: bit.ly/Interchurch

VDKIS422

© Danfoss | 09/2019. | 7

Page 8

VTA Series Features:

Snap-on cover prevents debris as well as

unauthorized adjustment or tampering

Compact lightweight design used in domestic

& radiant heating applications

Suitable for HWC (hot water circulation)

Quiet operation with long lifespan &

easy maintenance

Conforms to ASSE-1017

(Valve ranges: 85°-120 °F & 95°-140°F only)

Anti-scald & anti-legionella protection

A variety of connections available:

• Threaded body (FNPT)

• Solder Union

• CPVC Union

Danfoss Heating | Tel.: 1-888-DANFOSS (326-3677) | Fax: 416-352-5981 | Website: heating.danfoss.us

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A /S. All rights reserved.

8 | © Danfoss | 03/2020

AI189286403251

Loading...

Loading...