Page 1

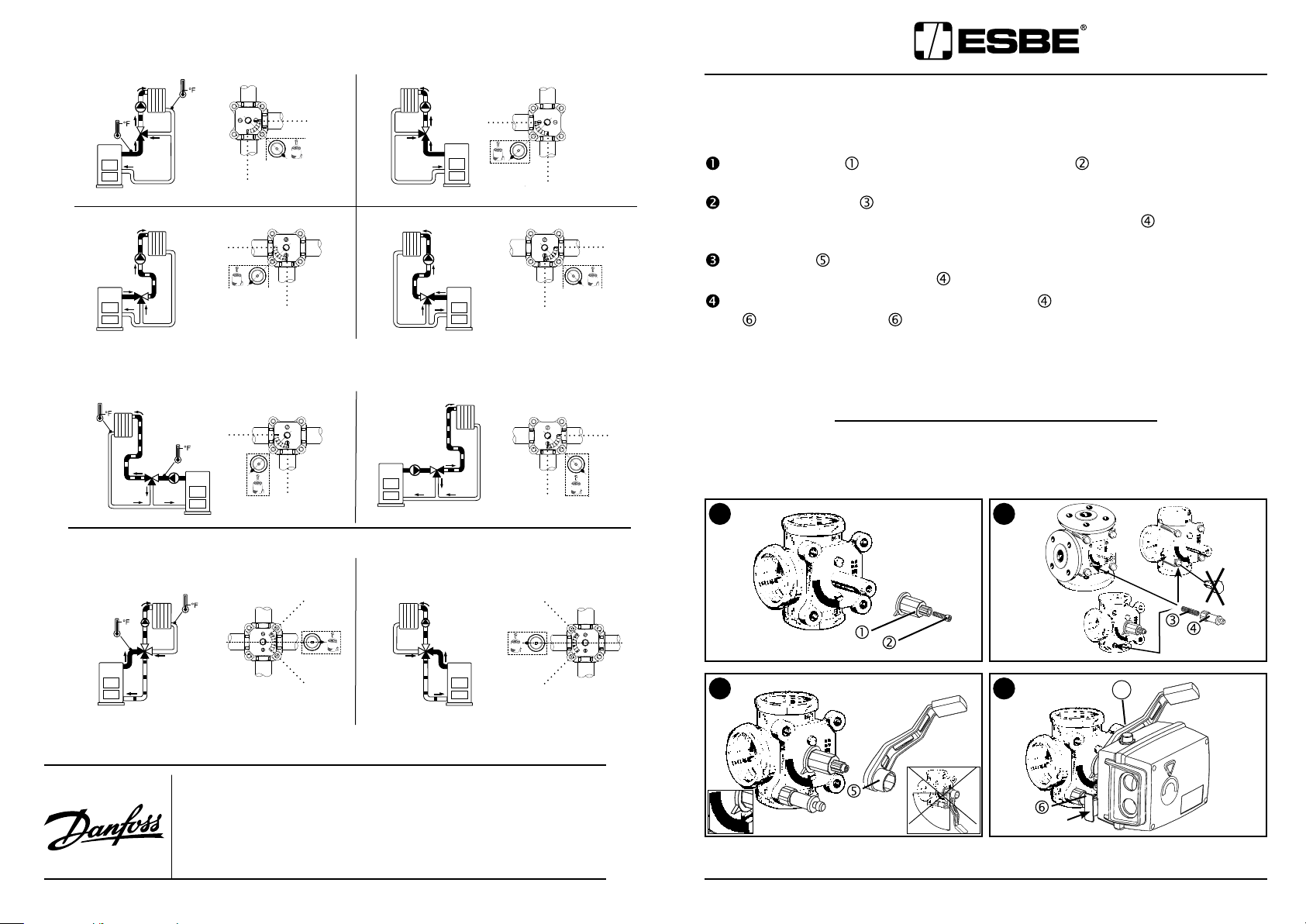

TYPICAL 3- & 4-WAY VALVE APPLICATIONS

5

5

5

5

5

5

5

5

5

5

3-WAY MIXING –

Two temperature inputs, one blended outpu

t

A) B)

10

0

C)

0

10

3-WAY DIVERTING –

Configurations shown below are suitable for boiler return

water control

E)

0

10

D)

F)

10

10

10

ESBE Series 90 Actuator

INSTALLATION INSTRUCTIONS

Place drive sleeve onto shaft and secure with screw . Rotate the sleeve and

0

0

0

valve shaft until the pointer is aligned to position 5 on scale plate.

Mount threaded stud in the lower left threaded hole. For 1½ and 2" valves replace

one of the cover bolts with the threaded stud. Tighten mounting piece

onto threaded

stud.

Mount handle over drive sleeve. Handle must be mounted opposite to the pointer of

the drive sleeve, & facing away from

Mount actuator onto sleeve so that mounting piece

piece

. Push locking piece

.

fits into the locking

to lock in place. Labels are supplied to indicate the direction of rotation. Determine the direction of rotation and mount the correct label under the

plastic front cover of actuator.

Note: Always test rotation of the valve in manual position mode to ensure that the handle

does not interfere with the actuator mounting stud and mounting piece.

Manual Operation: Always disconnect power before operating by hand.

Note position of drive sleeve pointer to be returned to. Depress the gray button, “A”, on

the side to release the handle. The valve can now be operated manually.

Never manually operate when gears are engaged.

1 2

3G

4-WAY MIXING AND DIVERTING

A)

10

0

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss

A/S. All rights reserved.

For technical support or additional product information, contact:

Danfoss Inc.

7941 Corporate Drive

Baltimore, MD USA 21236

Telephone: (433) 512 - 0266

Fax: (443) 512 - 0270

E-mail: heatinginfo@danfoss.com

www.na.heating.danfoss.com

B)

Danfoss Inc.

6711 Mississauga Road · Suite 410

Mississauga, ON, L5N 2W3 Canada

Telephone: (905) 285 - 2050

Fax: (905) 285 - 2055

E-mail: heatinginfo@danfoss.com

www.na.heating.danfoss.com

10

3F

3MG

0

3 4

A

”CLICK”

Art.nr. 98140172 Ritn.nr 3459 Utg PD4

Page 2

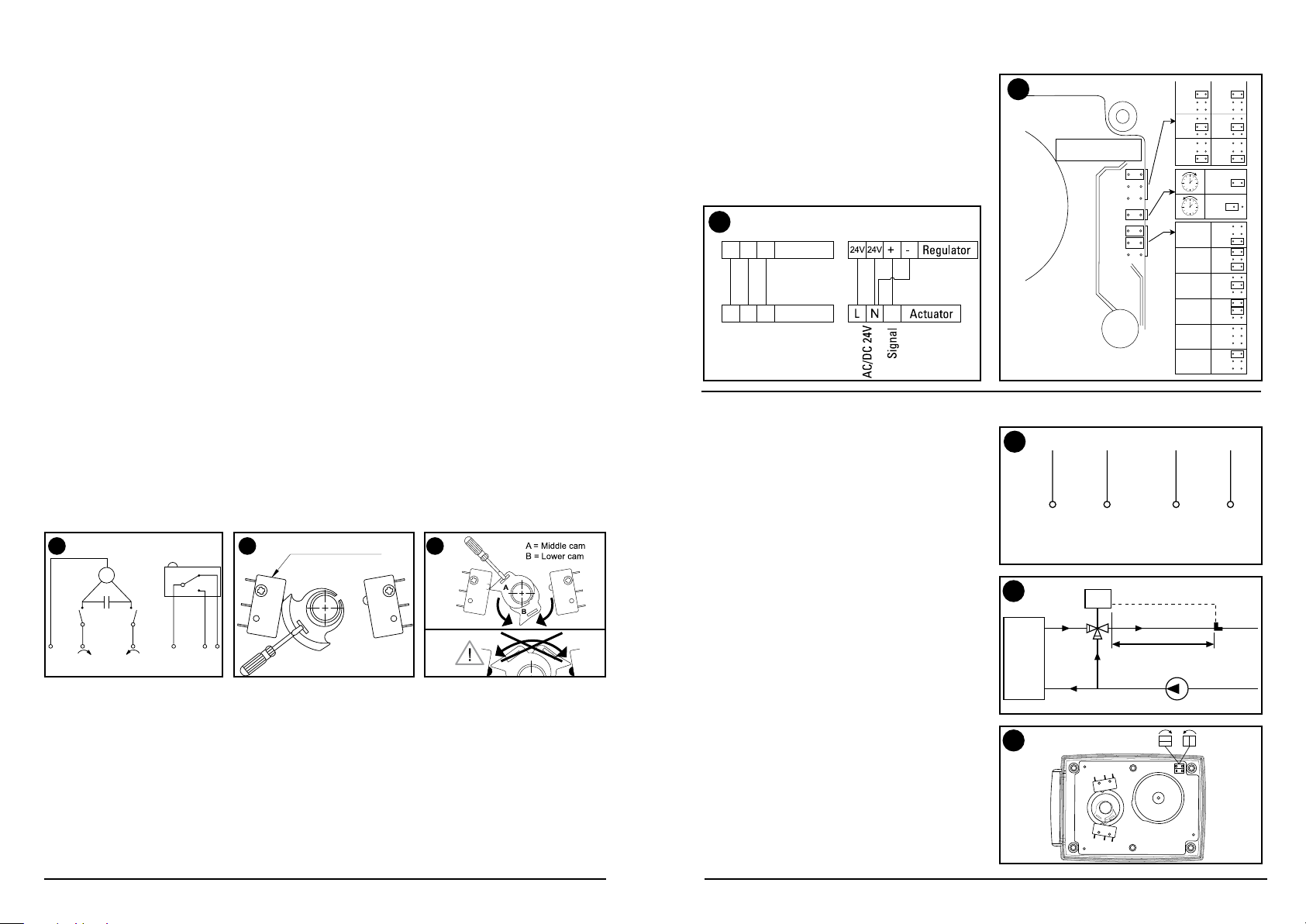

Wiring: Type 91EM, 92EM, 92-2EM and 93EM for “Floating” Signals - see fig. 5. For

M

L1

L1

N

1 2 3

1

2 3

Regulator

Actuator

Signal

L N

AC/DC 24V

92 P

60 s

90 s

120 s

92 P2

120 s

180 s

240 s

60 s

90 s

120 s

120 s

180 s

240 s

60 s

90 s

120 s

120 s

180 s

240 s

OFS

DIV

CUR

OFS

DIV

CUR

OFS

DIV

CUR

OFS

DIV

CUR

OFS

DIV

CUR

OFS

DIV

CUR

90 s

120 s

Reverse

OFS

DIV

CUR

60 s

Reverse

Reverse

0-20 mA

4-20 mA

0-10 V

2-10 V

0-5 V

1-5 V

L1

N

2

3

ESBE Type 92P - see fig. 8 and 92K2 actuators, see fig. 10 in separate sections.

Warning: Always turn off all electrical power before removing or servicing the actuator.

– The actuator is powered using a 24VAC transformer, 3VA minimum.

– Remove the four cover screws and lift the cover off the actuator.

– Remove one (or two) of the wiring knockouts and install one (or two) of the “conduit

fittings”. All wires must go through these fittings.

– Attach the “common” from the control (or transformer) to terminal “N”.

– Connect the control output for clockwise rotation to “Upper terminal L1”, and connect

the control output for counterclockwise rotation to “Lower terminal L1”.

Auxiliary Switch

– ESBE 91EM, 92EM, 92-2EM and 93EM actuators include one fully adjustable auxiliary

switch. The wiring should be connected as shown in fig. 5. To set the switching position,

turn the cam (see fig. 6).

Reinstall the cover and secure it, before turning on the power.

Adjusting the Degree of Rotation

– ESBE 90 series actuators do not

require adjustment when used with ESBE valves.

However if the actuator is used for an application that requires a different degree of rotation, the middle and lower cams can be adjusted to provide between 30° and 180° of

rotation. For access to the cams, the cam operating the auxiliary switch must be removed

(see fig. 7).

Always turn off all power before adjustments are made.

Test: Test the valve rotation to ensure the valve is allowed to fully open and

fully close. Rotations of 30° to 180° are possible via middle and lower cams for

applications that require them. For access, aux. switch cam must be removed.

Auxiliary

switch

Motor Speed and Signal Selection, Type 92P Only, for “Proportional” Signals

– With power turned off, follow instructions for removing the cover.

– The 92P is designed for operating signals of 0-5VDC, 1-5VDC, 0-10VDC, 2-10VDC,

0-20mA and 4-20mA signals. The factory default setting is 0-10VDC.

– Running speed for 90° rotation is factory set at 60s, but can be changed to 90s or

120s.

– If required, the motor speed and operating signal can be changed to different values,

as shown on the PCB card (see fig. 9).

Wiring, Type 92P Only

– Connect the 24V AC or DC power supply to terminals 1 and 2 (see fig. 8).

– Connect the control signal to terminal 3.

Auxiliary switch

(Upper switch)

C

C= Auxiliary switch upper cam

765

Direction of Rotation, Type 92P Only

– The 92P is factory set to rotate in the clockwise direction. To change the direction of rotation to Counter-clockwise, change the position

of the jumper as shown on the PCB card (see

fig. 9). Reinstall the cover and secure it,

before turning on the power.

8

3-wire 4-wire

ESBE Regulator Type 92K2 – a complete

unit for constant temperature regulating.

Handling

For the best control the sensor shall be

placed about 3’ (1 m) downstream from

the valve (see fig. 11). The sensor must be

carefully insulated from the ambient temperature.

Wiring

See fig. 10.

Adjusting

The function of the regulator 92K2 is

adjusted by two knobs:

Right hand knob for temperature setting

from 59 – 158° F (+ 15° C to + 70° C)

Left hand knob for selection of intervals

between control signals from 1 to 70 seconds. Normally 30 seconds is suitable but

depending on installation characteristics a

longer or shorter interval can be used.

Direction of rotation

The direction of rotation can be reversed

by changing the position of the two jumpers (fig. 12).

Note: The installation shall include an

approved means to disconnect the power.

9

10

92K2=24 VAC Sensor

11

92K2

3' (1 m)

12

Sensor

Jumpers

Loading...

Loading...