Page 1

User Guide

Controller for temperature control

EKC 202C-MS

Page 2

Introduction

Application

• The controller is used for temperature control refrigeration

appliances and cold room in supermarkets

• Control of defrost, fans, alarm and light

• For front panel mounting

• Signal from NTC sensors

Principle

The controller contains a temperature control where the signal

can be received from one temperature sensor.

The sensor is placed in the cold air ow after the evaporator or in

the warm air ow just before the evaporator.

The controller controls the defrost with either natural defrost or

electric defrost. Renewed cutin after defrost can be accomplished

based on time or temperature.

A measurement of the defrost temperature can be obtained

directly through the use of a defrost sensor.

Four relays will cut the required functions in and out – the application determines which:

• Refrigeration (compressor or solenoid valve)

• Defrost

• Fan

• Alarm or light

Advantages

• Integrated refrigeration-technical functions

• Defrost on demand in 1:1 systems

• Buttons and seal imbedded in the front

• IP65 density from the front panel

• Digital input for either:

- Door contact function with alarm

- Defrost start

- Start/stop of regulation

- Night operation

- Change-over between two temperature reference

- Case cleaning function

• Instant programming via programming key

• Sensor signal from NTC sensor (adjustable)

• HACCP

Calibration option so that the EN 441-13 standard can be fullled.

Extra module

• The controller can afterwards be tted with an insertion module

if the application requires it.

The controller has been prepared with plug, so the module

simply has to be pushed in

- Battery module

The module guarantees voltage to the controller if the supply

voltage should drop out for more than four hours. The clock

function can thus be protected during a power failure.

- Data communication

If you require operation from a PC, a data communication module has to be placed in the controller.

- Coordinated defrost via data communication

Contents

Introduction ....................................................................................................... 2

Operation ............................................................................................................ 5

Menu survey ....................................................................................................... 6

2 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Functions ............................................................................................................. 8

Connections ..................................................................................................... 14

Data ..................................................................................................................... 15

Ordering ............................................................................................................16

Page 3

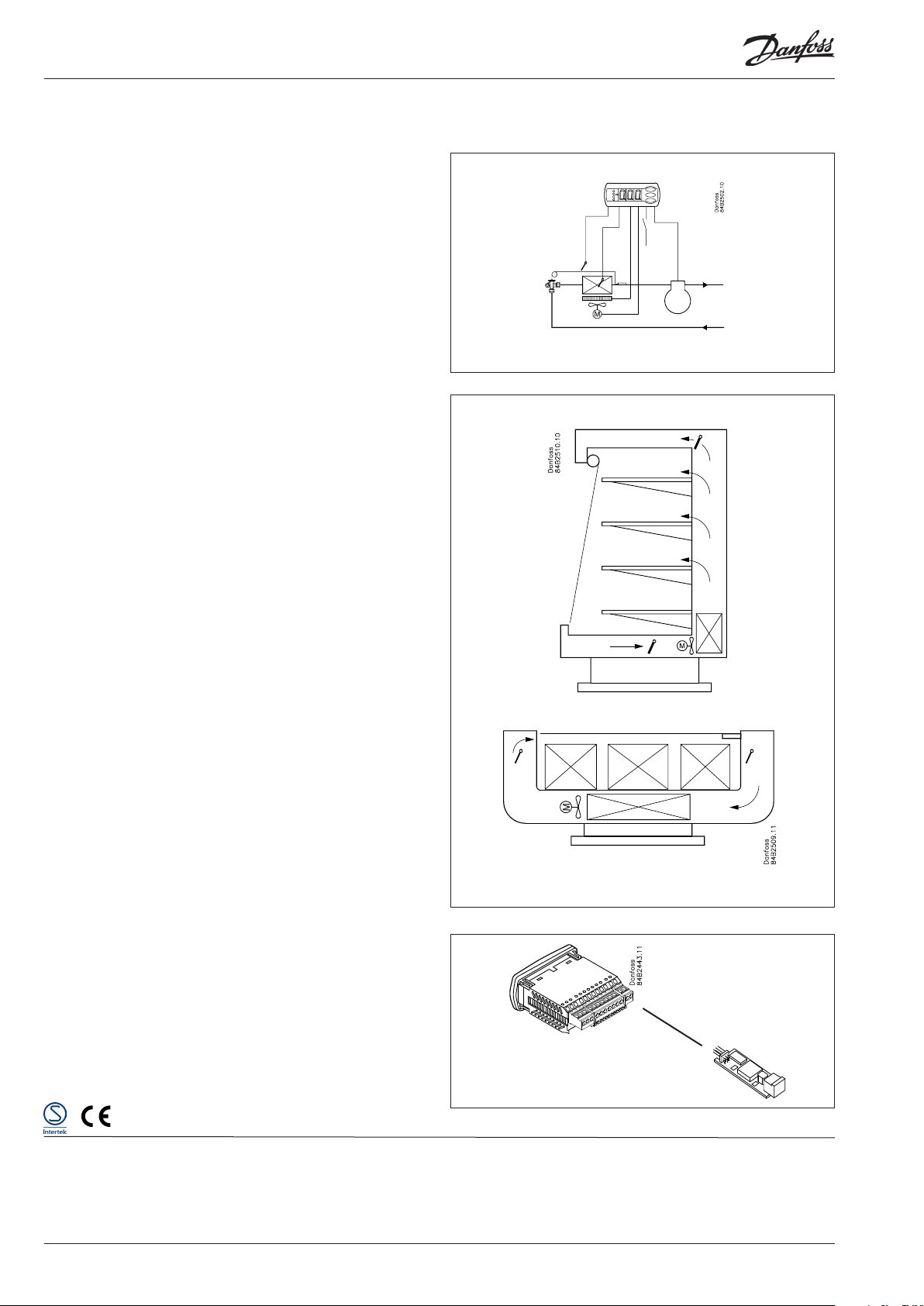

Outputs and Inputs

Controller with four relay outputs, two temperature sensors and

digital input.

• Temperature control at start/stop of compressor / solenoid valve

• Defrost sensor must be connected when defrosting stop is

performed by temperature

• If defrosting stop is performed on time, the sensor can be used

either for monitoring the condenser temperature or as a product

sensor

• Electrical defrost / gas defrost

• Control of fan

• Relay output 4 can be used for an alarm function or for a light

function.

Sensors

One or two NTC sensors of the same type must be connected.

The following can be selected:

NTC 5000 Ω @ 25°C. M2020 (Danfoss Type = EKS 211)

NTC 10000 Ω @ 25°C. Beta 3435 (Danfoss Type = EKS 221)

NTC 3000 Ω @ 25°C

NTC 2500 Ω @ 0°C

NTC 10000 Ω @ 25°C

NTC 2000 Ω @ 25°C

Set the type in menu o06.

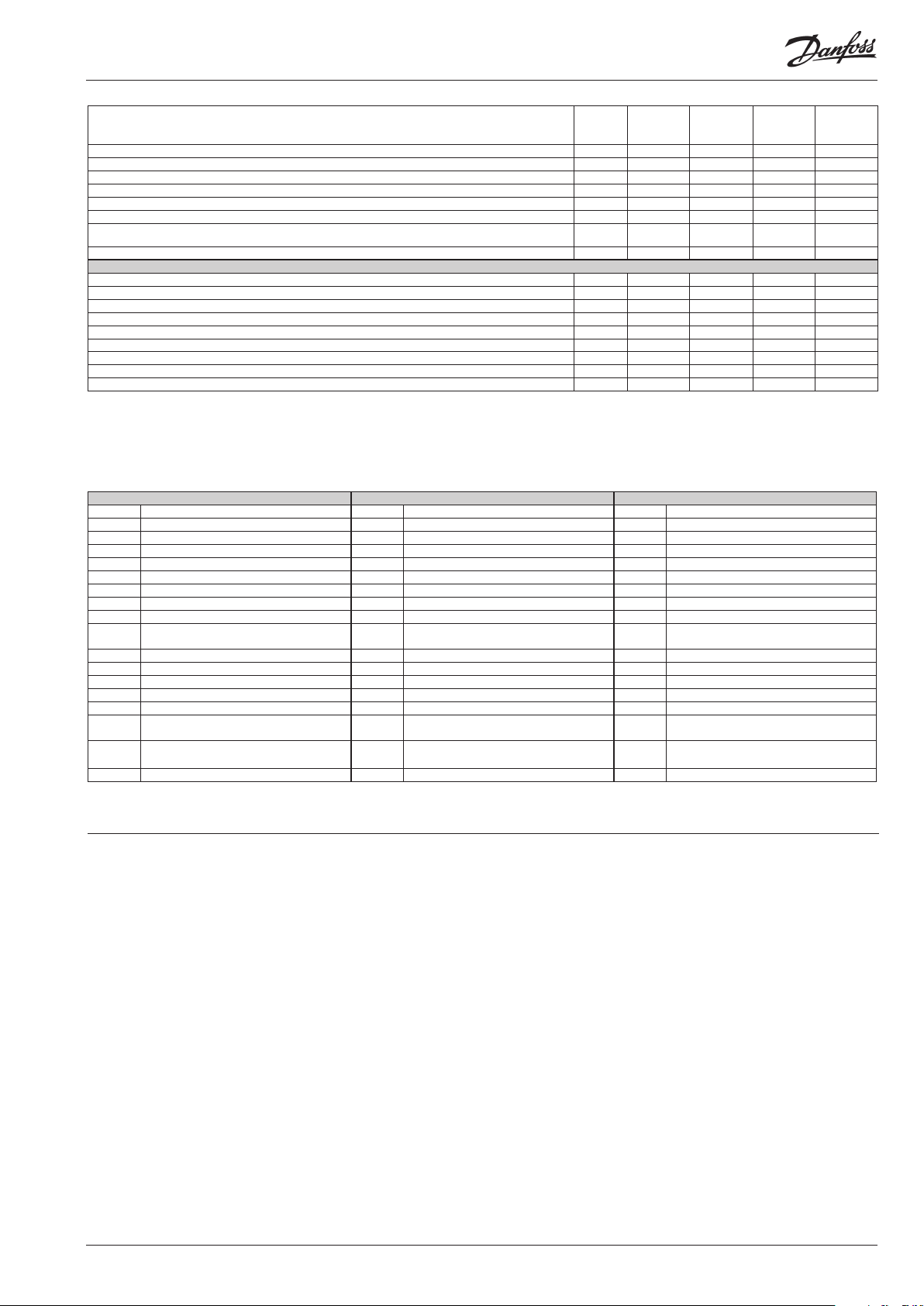

Type NTC 5000 Ω

@ 25°C (M2020)

Danfoss NTC EKS 211 EKS 221 - - - -

°C Ω Ω Ω Ω Ω Ω

30 4029 8313 2417 - 8300 1651

25 5000 10000 3000 883 10000 2000

20 6246 12091 3747 1074 12271 2437

15 7855 14695 4712 1313 15146 2987

10 9951 17958 5970 1616 18809 3682

5 12696 22068 7617 2000 23504 4571

0 16330 27278 9798 2492 29564 5716

−5 21166 33922 12700 3124 37441 7198

−10 27681 42450 16608 3947 47754 9133

−15 36503 53468 21902 5019 61357 11644

−20 48614 67801 29168 6434 79440 14961

−25 65333 86580 39200 8306 103676 19402

−30 88766 111364 53259 10822 136428 25388

−35 121795 144324 73077 14217 181078 33505

−40 169157 188500 101490 18848 242495 44657

Alternativer

Alternatives

Alternativen

Alternatives

Alternativas

o06 n01 n02 n03 n04 n05 n06

NTC 10000 Ω

@ 25°C (Beta 3435)

Carel:

HP/WF/WP/INF

Dixell:

NS/NG/NX/NY/NT

Eliwell:

SN8

Lae:

SN4K..P

NTC 3000 Ω

Frigo:

M841

@ 25°C

NTC 2500 Ω

Wurm:

TRK 277

@ 0°C

NTC 10000 Ω

@ 25°C

Wurm:

T2000

Lae:

SN2K..P

NTC 2000 Ω

@ 25°C

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 3

Page 4

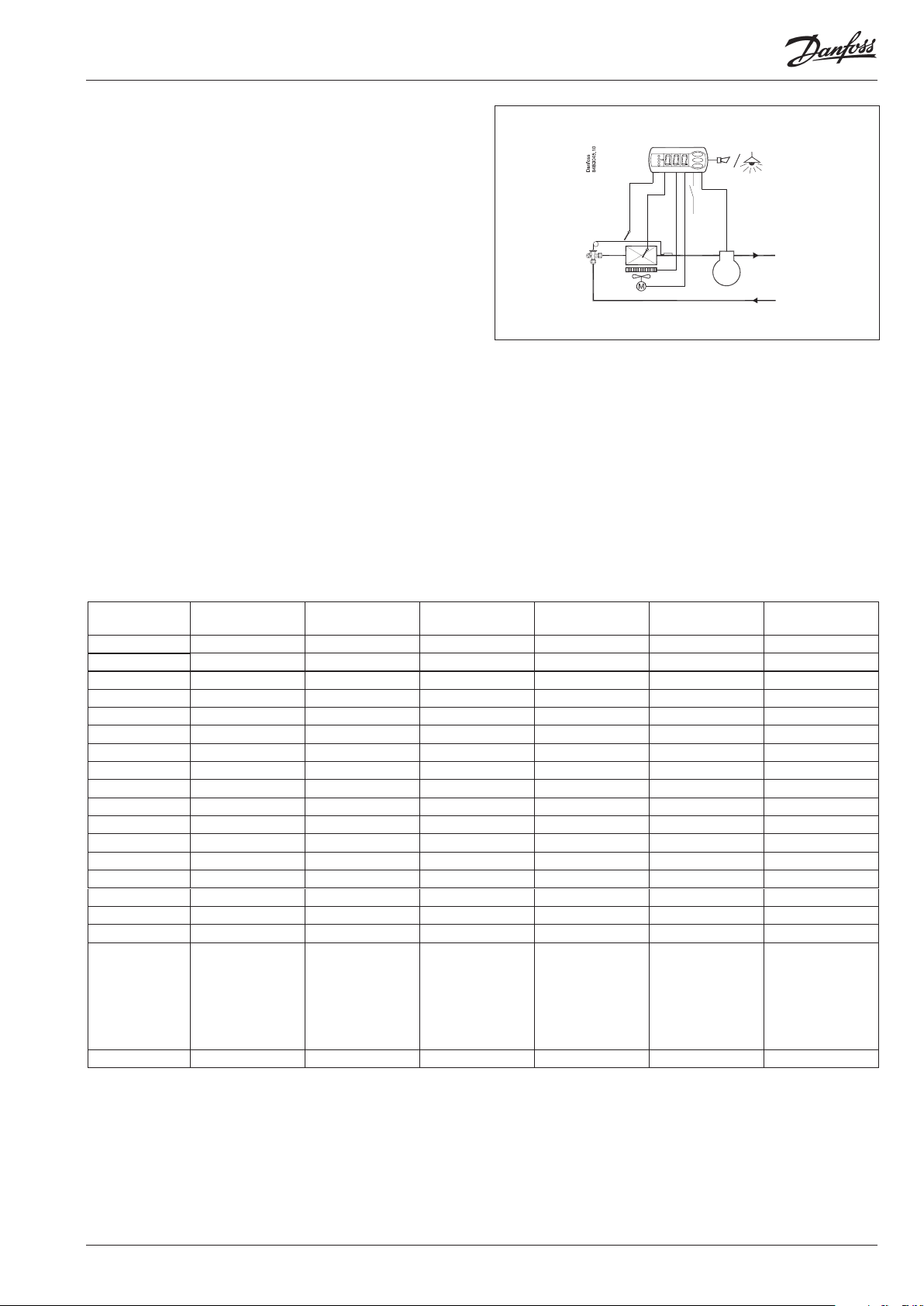

Start of defrost

A defrost can be started in dierent ways

Interval: Defrost is started at xed time intervals, say, every

eight hour

Refrigeration time:

Defrost is started at xed refrigeration time inter-

vals, in other words, a low need for

refrigeration will ”postpone” the coming defrost

Contact Defrost is started here with a pulse signal on a

digital input.

Manual: An extra defrost can be activated from the control ler’s lower-most button

S5-temp. In 1:1 systems the eciency of the evaporator can

be followed. Icing-up will start a defrost.

Schedule Defrost here can be started at xed times of the

day and night. But max. six defrosts

Network A defrost can be started via data communication

All the mentioned methods can be used at random – if just one

them is activated a defrost will be started. When the defrost starts

the defrost timers are set at zero

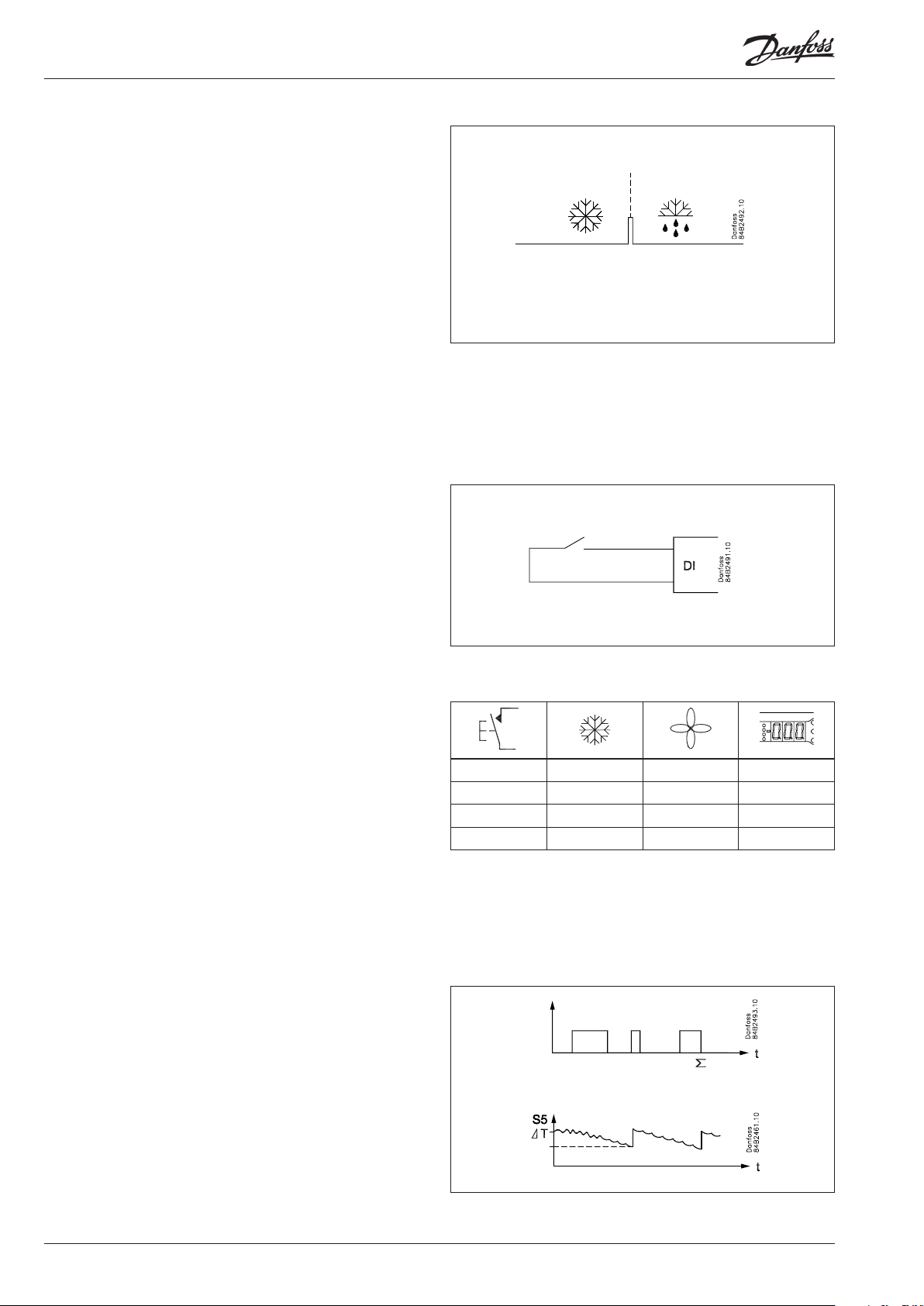

Digital input

The digital input can be used for the following functions:

- Door contact function with alarm if the door has been open for

too long.

- Defrost start

- Start/stop of regulation

- Change-over to night operation

- Case cleaning

- Change to another temperature reference

- Inject on/o

A pulse signal

starts the

defrost

Case cleaning function

This function makes it easy to steer the refrigeration appliance

through a cleaning phase. Via three pushes on a switch you

change from one phase to the next phase.

The rst push stops the refrigeration – the fans keep working

”Later”: The next push stops the fans

”Still later”: The next push restarts refrigeration

The dierent situations can be followed on the display.

There is no temperature monitoring during case cleaning.

On the network a cleaning alarm is transmitted to the system unit.

This alarm can be ”logged” so that proof of the sequence of events

is provided.

Defrost on demand

1 Based on refrigeration time

When the aggregate refrigeration time has passed a xed time,

a defrost will be started.

2 Based on temperature

The controller will constantly follow the temperature at S5.

Between two defrosts the S5 temperature will become lower

the more the evaporator ices up (the compressor operates for a

longer time and pulls the S5 temperature further down). When

the temperature passes a set allowed variation the defrost will

be started.

This function can only be used in 1:1 systems

- + + °C

1 ÷ + Fan

2 ÷ ÷ O

3 + + °C

4 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 5

Operation

Display

The values will be shown with three digits, and with a setting you

can determine whether the temperature are to be shown in °C or

in °F.

Light-Emitting Diodes (LED) on front panel

There are LED’s on the front panel which will light up when the

belonging relay is activated.

= Refrigeration

= Defrost

= Fan

The light-emitting diodes will ash when there is an alarm.

In this situation you can download the error code to the display

and cancel/sign for the alarm by giving the top button a brief

push.

Defrost

During defrost a –d– is shown in the display. This view will

continue up till 15 min. after the cooling has resumed.

However the view of –d– will be discontinued if:

- The temperature is suitable within the 15 minutes

- The regulation is stopped with “Main Switch”

- A high temperature alarm appears

Examples

Set menu

1. Push the upper button until a parameter r01 is shown

2. Push the upper or the lower button and nd that parameter you

want to change

3. Push the middle button until the parameter value is shown

4. Push the upper or the lower button and select the new value

5. Push the middle button again to enter the value.

Cutout alarm relay / receipt alarm/see alarm code

• Push briey the upper button

If there are several alarm codes they are found in a rolling stack.

Push the uppermost or lowermost button to scan the rolling

stack.

Set temperature

1. Push the middle button until the temperature value is shown

2. Push the upper or the lower button and select the new value

3. Push the middle button to select the setting

Manual start or stop of a defrost

• Push the lower button for four seconds.

See the temperature at the defrost sensor

• Push briey the lower button

If no sensor has been mounted, ”non” will appear.

The buttons

When you want to change a setting, the upper and the lower

buttons will give you a higher or lower value depending on the

button you are pushing. But before you change the value, you

must have access to the menu. You obtain this by pushing the

upper button for a couple of seconds - you will then enter the column with parameter codes. Find the parameter code you want to

change and push the middle buttons until value for the parameter

is shown. When you have changed the value save the new value

by once more pushing the middle button

100% tight

The buttons and the seal are imbedded in the front.

A special moulding technique unites the hard front plastic, the

softer buttons and the seal, so that they become an integral

part of the front panel. There are no openings that can receive

moisture or dirt.

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 5

Page 6

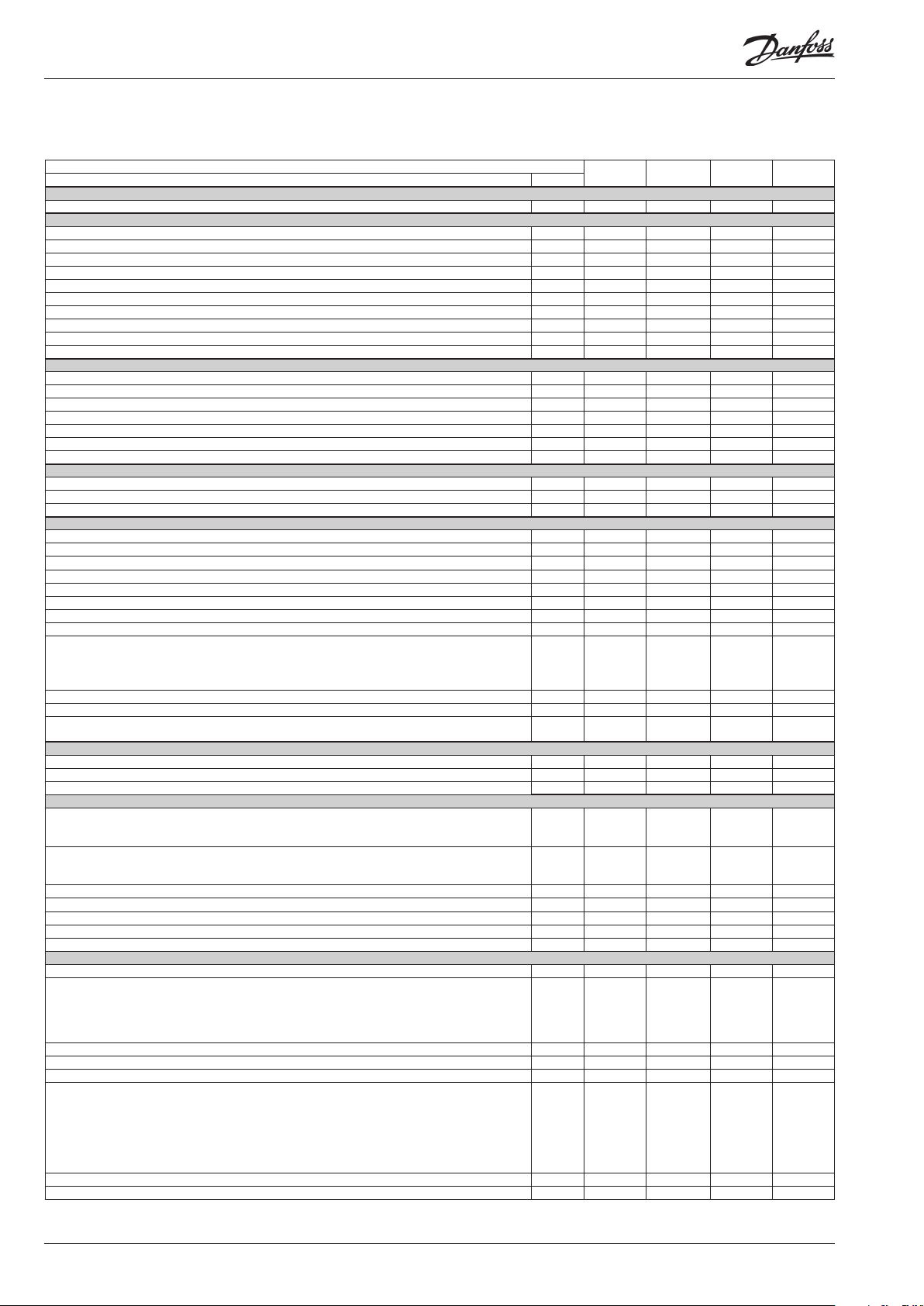

Menu survey

Function Codes

Parameters

Normal operation

Temperature (set point) --- -50°C 50°C 2°C

Thermostat

Dierential r01 0,1 K 20 K 2 K

Max. limitation of setpoint setting r02 -49°C 50°C 50°C

Min. limitation of setpoint setting r03 -50°C 49°C -50°C

Adjustment of temperature indication r04 -20 K 20 K 0.0 K

Temperature unit (°C/°F) r05 °C °F °C

Correction of the signal from Sair r09 -10 K 10 K 0 K

Manual service(-1), stop regulation(0), start regulation (1) r12 -1 1 1

Displacement of reference during night operation r13 -10 K 10 K 0 K

Activation of reference displacement r40 r39 OFF on OFF

Value of reference displacement (activation by r39 or DI) r40 -50 K 50 K 0 K

Alarm

Delay for temperature alarm A03 0 min 240 min 30 min

Delay for door alarm A04 0 min 240 min 60 min

Delay for temperature alarm after defrost A12 0 min 240 min 90 min

High alarm limit A13 -50°C 50°C 8°C

Low alarm limit A14 -50°C 50°C -30°C

Alarm delay DI1 A27 0 min 240 min 30 min

High alarm limit for condenser temperature (o70) A37 0°C 99°C 50°C

Compressor

Min. ON-time c01 0 min 30 min 0 min

Min. OFF-time c02 0 min 30 min 0 min

Compressor relay must cutin and out inversely (NC-function) c30 0 / OFF 1 / on 0 / OFF

Defrost

Defrost method (none/EL/gas) d01 no Gas EL

Defrost stop temperature d02 0°C 25°C 6°C

Interval between defrost starts d03 0 hours 240 hours 8 hours

Max. defrost duration d04 0 min 180 min 45 min

Displacement of time on cutin of defrost at start-up d05 0 min 240 min 0 min

Drip o time d06 0 min 60 min 0 min

Delay for fan start after defrost d07 0 min 60 min 0 min

Fan start temperature d08 -15°C 0°C -5°C

Fan cutin during defrost

Min.-value Max.-value

d09 0 2 1

0: Stopped

1: Running

2: Running during pump down and defrost

Defrost sensor (0=time, 1=S5, 2=Sair) d10 0 2 0

Max. aggregate refrigeration time between two defrosts d18 0 hours 48 hours 0 hours

Defrost on demand - S5 temperature’s permitted variation during frost build-up. On central plant choose

20 K (=o)

Fans

Fan stop at cutout compressor F01 no yes no

Delay of fan stop F02 0 min 30 min 0 min

Fan stop temperature (S5) F04 -50°C 50°C 50°C

Real time clock

Six start times for defrost.

Setting of hours.

0=OFF

Six start times for defrost.

Setting of minutes.

0=OFF

Clock - Setting of hours t07 0 timer 23 timer 0 timer

Clock - Setting of minute t08 0 min 59 min 0 min

Clock - Setting of date t45 1 31 1

Clock - Setting of month t46 1 12 1

Clock - Setting of year t47 0 99 0

Miscellaneous

Delay of output signals after start-up o01 0 s 600 s 5 s

Input signal on DI1. Function:

0=not used. 1=status on DI1. 2=door function with alarm when open. 3=door alarm when open. 4=defrost

start (pulse-signal). 5=ext.main switch. 6=night operation 7=change reference (r40 will be activated)

8=alarm function when closed. 9=alarm function when open. 10=case cleaning (pulse signal). 11=Inject o

when open.

Network address o03 0 119 0

On/O switch (Service Pin message) o04 OFF ON OFF

Access code 1 (all settings) o05 0 100 0

Used sensor types

n01: NTC 5000 Ω @ 25°C. M2020 (Danfoss Type = EKS 211)

n02: NTC 10000 Ω @ 25°C. Beta 3435 (Danfoss Type = EKS 221)

n03: NTC 3000 Ω @ 25°C

n04: NTC 2500 Ω @ 0°C

n05: NTC 10000 Ω @ 25°C

n06: NTC 2000 Ω @ 25°C

Display step = 0.5 (normal 0.1 at Pt sensor) o15 no yes no

Max hold time after coordinated defrost o16 0 min 60 min 20

d19 0 K 20 K 20 K

t01-t06 0 timer 23 timer 0 timer

t11-t16 0 min 59 min 0 min

o02 0 11 0

o06 n01 n06 n02

Factory

setting

SW = 1.3x

Actual set-

ting

6 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 7

Conguration of light function (relay 4)

1=ON during day operation. 2=ON / OFF via data communication. 3=ON follows the DI-function, when DI

is selected to door function or to door alarm

Activation of light relay (only if o38=2) o39 OFF ON OFF

Case cleaning. 0=no case cleaning. 1=Fans only. 2=All output O. o46 0 2 0

Access code 2 (partly access) o64 0 100 0

Save the controllers present settings to the programming key. Select your own number. o65 0 25 0

Load a set of settings from the programming key (previously saved via o65 function) o66 0 25 0

Replace the controllers factory settings with the present settings o67 OFF On OFF

Re alternative application for the S5 sensor (maintain the setting at 0 if it is used as defrost sensor, other-

wise 1 = product sensor and 2 = condenser sensor with alarm)

Select application for relay 4: 1=light, 2= alarm o72 1 2 2

Service

Temperature measured with S5 sensor u09

Status on DI1 input. on/1=closed u10

Status on night operation (on or o) 1=closed u13

Read the present regulation reference u28

Status on relay for cooling (Can be controlled manually, but only when r12=-1) u58

Status on relay for fans (Can be controlled manually, but only when r12=-1) u59

Status on relay for defrost. (Can be controlled manually, but only when r12=-1) u60

Temperature measured with Sair sensor u69

Status on relay 4 (alarm, light).(Can be controlled manually, but only when r12=-1) u71

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep upper and lower button depressed at the same time as you recon nect the

supply voltage

Fault code display Alarm code display Status code display

E1 Fault in controller A 1 High temperature alarm S0 Regulating

E6 Change battery + check clock A 2 Low temperature alarm S1 Waiting for end of the coordinated defrost

E 27 S5 sensor error A 4 Door alarm S2 ON-time Compressor

E 29 Sair sensor error A 5 Max. Hold time S3 OFF-time Compressor

A 15 DI 1 alarm S4 Drip-o time

A 45 Standby mode S10 Refrigeration stopped by main switch

A 59 Case cleaning S11 Refrigeration stopped by thermostat

A 61 Condenser alarm S14 Defrost sequence. Defrosting

o38 1 3 1

o70 0 2 0

S15 Defrost sequence. Fan delay

S16 Refrigeration stopped because of open DI

input

S17 Door open (open DI input)

S20 Emergency cooling

S25 Manual control of outputs

S29 Case cleaning

S32 Delay of output at start-up

non The defrost temperature cannot be dis-

played. There is stop based on time

-d- Defrost in progress / First cooling after

defrost

PS Password required. Set password

Start-up:

Regulation starts when the voltage is on.

1 Go through the survey of factory settings. Make any necessary changes

in the respective parameters.

2 For network. Set the address in o03 and then transmit it to the gateway/

system unit with setting o04.

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 7

Page 8

Functions

Here is a description of the individual functions.

Function Para-

meter

Normal display

Normally the temperature value from thermostat sensor Sair is displayed. Display air (u69)

Thermostat Thermostat control

Set point

Regulation is based on the set value plus a displacement, if applicable. The value is set via a push

on the centre button.

The set value can be locked or limited to a range with the settings in r02 and r 03.

The reference at any time can be seen in ”u28 Temp. ref”

Dierential

When the temperature is higher than the reference + the set dierential, the compressor relay

will be cut in. It will cut out again when the temperature comes down to the set reference.

Ref. Dif.

Setpoint limitation

The controller’s setting range for the setpoint may be narrowed down, so that much too high or

much too low values are not set accidentally - with resulting damages.

To avoid a too high setting of the setpoint, the max. allowable reference value must be lowered. r02 Max cutout °C

To avoid a too low setting of the setpoint, the min. allowable reference value must be increased. r03 Min cutout °C

Correction of the display’s temperature showing

If the temperature at the products and the temperature received by the controller are not identical, an oset adjustment of the shown display temperature can be carried out.

Temperature unit

Set here if the controller is to show temperature values in °C or in °F.

Parameter by operation via data communication

Cutout °C

r01 Dierential

r04 Disp. Adj. K

r05 Temp. unit

°C=0. / °F=1

(Only °C on AKM, whatever the setting)

Correction of signal from Sair

Compensation possibility through long sensor cable

Start / stop of refrigeration

With this setting refrigeration can be started, stopped or a manual override of the outputs can

be allowed.

Start / stop of refrigeration can also be accomplished with the external switch function connected to the DI input.

Stopped refrigeration will give a ”Standby alarm”.

Night setback value

The thermostat’s reference will be the setpoint plus this value when the controller changes over

to night operation. (Select a negative value if there is to be cold accumulation.)

Value of reference displacement

The thermostat reference and the alarm values are shifted the following number of degrees

when the displacement is activated. Activation can take place via r39 or input DI

Value of reference displacement

The thermostat reference and the alarm values are shifted the following number of degrees

when the displacement is activated. Activation can take place via r39 or input DI

r09 Adjust Sair

r12 Main Switch

1: Start

0: Stop

-1: Manual control of outputs allowed

r13 Night oset

r39 Th. oset

r40 Th. oset K

Night setbck

(start of night signal)

8 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 9

Alarm Alarm settings

The controller can give alarm in dierent situations. When there is an alarm all the light-emitting

diodes (LED) will ash on the controller front panel, and the alarm relay will cut in.

Alarm delay (short alarm delay)

If one of the two limit values is exceeded, a timer function will commence. The alarm will not

become active until the set time delay has been passed. The time delay is set in minutes.

With data communication the importance

of the individual alarms can be dened.

Setting is carried out in the “Alarm destinations” menu.

A03 Alarm delay

Time delay for door alarm

The time delay is set in minutes.

The function is dened in o02.

Time delay for cooling (long alarm delay)

This time delay is used during start-up, during defrost, immediately after a defrost.

There will be change-over to the normal time delay (A03) when the temperature has dropped

below the set upper alarm limit.

The time delay is set in minutes.

Upper alarm limit

Here you set when the alarm for high temperature is to start. The limit value is set in °C (absolute

value). The limit value will be raised during night operation. The value is the same as the one set

for night setback, but will only be raised if the value is positive.

The limit value will also be raised in connection with reference displacement r39.

Lower alarm limit

Here you set when the alarm for low temperature is to start. The limit value is set in °C (absolute

value).

The limit value will also be raised in connection with reference displacement r39.

Delay of a DI alarm

A cut-out/cut-in input will result in alarm when the time delay is passed. The function is dened

in o02.

High alarm limit for condenser temperature

If the S5 sensor is used for monitoring the condenser’s temperature you must set the value at

which the alarm is to become activated. The value is set in °C.

The denition of S5 as condenser sensor is accomplished in o70. The alarm is zeroset again 10 K

below the set temperature.

Compressor Compressor control

The compressor relay works in conjunction with the thermostat. When the thermostat calls for

refrigeration will the compressor relay be operated.

Running times

To prevent irregular operation, values can be set for the time the compressor is to run once it has

been started. And for how long it at least has to be stopped.

The running times are not observed when defrosts start.

Min. ON-time (in minutes) c01 Min. On time

Min. OFF-time (in minutes) c02 Min. O time

Reversed relay function for compressor relay

0: Normal function where the relay cuts in when refrigeration is demanded

1: Reversed function where the relay cuts out when refrigeration is demanded (this wiring pro-

duces the result that there will be refrigeration if the supply voltage to the controller fails).

Defrost Defrost control

The controller contains a timer function that is zeroset after each defrost start.

The timer function will start a defrost if/when the interval time is passed.

The timer function starts when voltage is connected to the controller, but it is displaced the rst

time by the setting in d05.

If there is power failure the timer value will be saved and continue from here when the power

returns.

This timer function can be used as a simple way of starting defrosts, but it will always act as

safety defrost if one of the subsequent defrost starts is not received.

The controller also contains a real-time clock. By means of settings of this clock and times for the

required defrost times, defrost can be started at xed times of the day. If there is a risk of power

failure for periods longer than four hours, a battery module should be mounted in the controller.

Defrost start can also be accomplished via data communication, via contact signals or manual

start-up.

All starting methods will function in the controller. The dierent functions have to be set, so that

defrosts do not ”come tumbling” one after the other.

Defrost can be accomplished with electricity, hotgas or brine.

The actual defrost will be stopped based on time or temperature with a signal from a temperature sensor.

A04 DoorOpen del

A12 Pulldown del

A13 HighLim Air

A14 LowLim Air

A27 AI.Delay DI

A37 Condtemp Al.

Reset alarm

c30 Cmp relay NC

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 9

Page 10

Defrost method

Here you set whether defrost is to be accomplished with electricity or "non".

During defrost the defrost relay will be cut in.

When gas defrosting the compressor relay will be cut in during defrost.

Defrost stop temperature

The defrost is stopped at a given temperature which is measured with a sensor (the sensor is

dened in d10).

The temperature value is set.

Interval between defrost starts

The function is zeroset and will start the timer function at each defrost start. When the time has

expired the function will start a defrost.

The function is used as a simple defrost start, or it may be used as a safeguard if the normal

signal fails to appear.

If master/slave defrost without clock function or without data communication is used, the interval time will be used as max. time between defrosts.

If a defrost start via data communication does not take place, the interval time will be used as

max. time between defrosts.

When there is defrost with clock function or data communication, the interval time must be set

for a somewhat longer period of time than the planned one, as the interval time will otherwise

start a defrost which a little later will be followed by the planned one.

In connection with power failure the interval time will be maintained, and when the power

returns the interval time will continue from the maintained value.

The interval time is not active when set to 0.

Max. defrost duration

This setting is a safety time so that the defrost will be stopped if there has not already been a

stop based on temperature or via coordinated defrost.

(The setting will be the defrost time if d10 is selected to be 0)

Time staggering for defrost cutins during start-up

The function is only relevant if you have several refrigeration appliances or groups where you

want the defrost to be staggered in relation to one another. The function is furthermore only

relevant if you have chosen defrost with interval start (d03).

The function delays the interval time d03 by the set number of minutes, but it only does it once,

and this at the very rst defrost taking place when voltage is connected to the controller.

The function will be active after each and every power failure.

Drip-o time

Here you set the time that is to elapse from a defrost and until the compressor is to start again.

(The time when water drips o the evaporator).

Delay of fan start after defrost

Here you set the time that is to elapse from compressor start after a defrost and until the fan

may start again. (The time when water is “tied” to the evaporator).

Fan start temperature

The fan may also be started a little earlier than mentioned under “Delay of fan start after defrost”,

if the defrost sensor S5 registers a lower value than the one set here.

Fan cut in during defrost

Here you can set whether fan is to operate during defrost.

0: Stopped (Runs during pump down)

1: Running (stopped during "fan delay")

2: Running during pump down and defrost. After that stopped

Defrost sensor

Here you dene the defrost sensor.

0: None, defrost is based on time

1: S5

2: Sair

Defrost on demand – aggregate refrigeration time

Set here is the refrigeration time allowed without defrosts. If the time is passed, a defrost will be

started.

With setting = 0 the function is cut out.

Defrost on demand – S5 temperature

The controller will follow the eectivity of the evaporator, and via internal calculations and

measurements of the S5 temperature it will be able to start a defrost when the variation of the

S5 temperature becomes larger than required.

Here you set how large a slide of the S5 temperature can be allowed. When the value is passed,

a defrost will start.

The function can only be used in 1:1 systems when the evaporating temperature will become

lower to ensure that the air temperature will be maintained. In central systems the function

must be cut out.

With setting = 20 the function is cut out

If you wish to see the temperature at the S5 sensor, push the controller’s lowermost button. Defrost temp.

If you wish to start an extra defrost, push the controller’s lowermost button for four seconds.

You can stop an ongoing defrost in the same way

d01 Def. method

d02 Def. Stop Temp

d03 Def Interval

(0=o)

d04 Max Def. time

d05 Time Stagg.

d06 DripO time

d07 FanStartDel

d08 FanStartTemp

d09 FanDuringDef

d10 DefStopSens.

d18 MaxTherRunT

d19 CutoutS5Dif.

Def Start

Here you can start a manual defrost.

10 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 11

Hold After Def

Shows ON when the controller is

operating with coordinated defrost.

Defrost State

Status on defrost

1= pump down / defrost

Fan Fan control

Fan stopped at cut-out compressor

Here you can select whether the fan is to be stopped when the compressor is cut out

Delay of fan stop when compressor is cut out

If you have chosen to stop the fan when the compressor is cut out, you can delay the fan stop

when the compressor has stopped.

Here you can set the time delay.

Fan stop temperature

The function stops the fans in an error situation, so that they will not provide power to the appliance. If the defrost sensor registers a higher temperature than the one set here, the fans will be

stopped. There will be re-start at 2 K below the setting.

The function is not active during a defrost or start-up after a defrost.

With setting +50°C the function is interrupted.

Internal defrosting schedule/clock function

(Not used if an external defrosting schedule is used via data communication.)

Up to six individual times can be set for the defrost start throughout the day.

Defrost start, hour setting t01-t06

Defrost start, minute setting (1 and 11 belong together, etc.)

When all t01 to t16 equal 0 the clock will not start defrosts.

Real-time clock::

Setting the clock is only necessary when there is no data communication.

In the event of a power failure of less than four hours, the clock function will be saved.

When mounting a battery module the clock function can preserved longer

Clock: Hour setting t07

Clock: Minute setting t08

Clock: Date setting t45

Clock: Month setting t46

Clock: Year setting t47

F01 Fan stop CO

(Yes = Fan stopped)

F02 Fan del. CO

F04 FanStopTemp.

t11-t16

Miscellaneous Miscellaneous

Delay of output signal after start-up

After start-up or a power failure the controller’s functions can be delayed so that overloading of

the electricity supply network is avoided.

Here you can set the time delay.

Digital input signal - DI

The controller has a digital input which can be used for one of the following functions:

O: The input is not used

1) Status display of a contact function

2) Door function. When the input is open it signals that the door is open. The refrigeration and

the fans are stopped. When the time setting in “A04” is passed, an alarm will be given and

refrigeration will be resumed.

3) Door alarm. When the input is open it signals that the door is open. When the time setting in

“A04” is passed, there will be alarm.

4) Defrost. The function is started with a pulse signal. The controller will register when the DI

input is activated. The controller will then start a defrost cycle. If the signal is to be received by

several controllers it is important that ALL connections are mounted the same way (DI to DI

and GND to GND).

5) Main switch. Regulation is carried out when the input is short-circuited, and regulation is

stopped when the input is put in pos. OFF.

6) Night operation. When the input is short-circuited, there will be regulation for night operation.

7) Reference displacement when DI1 is short-circuited. Displacement with “r40”.

8) Separate alarm function. Alarm will be given when the input is short-circuited.

9) Separate alarm function. Alarm will be given when the input is opened. (For 8 and 9 the time

delay is set in A27)

10) Case cleaning. The function is started with a pulse signal. Cf. also description on page 4.

11) Inject on/o. O when DI is open.

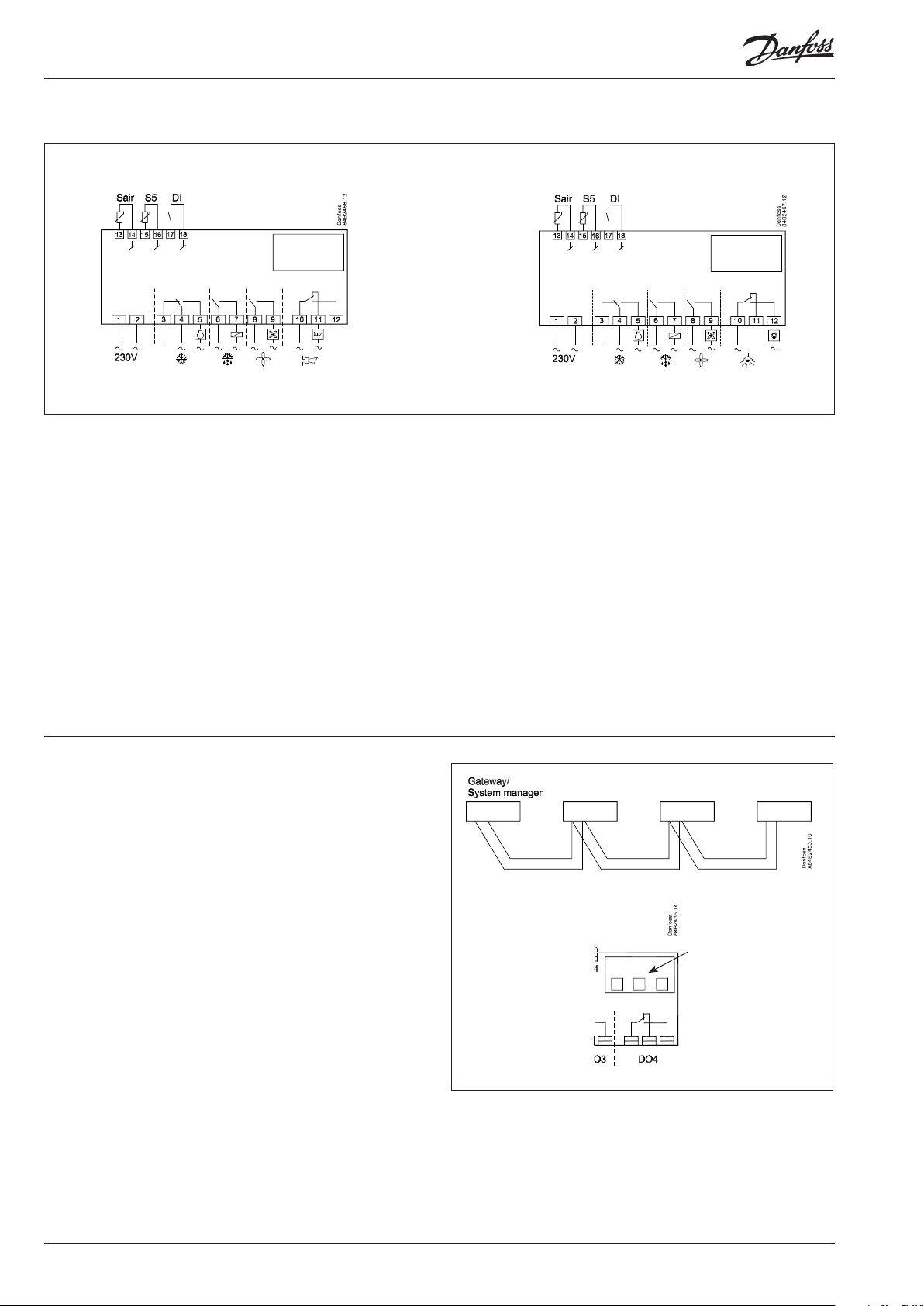

Address

If the controller is built into a network with data communication, it must have an address, and

the master gateway of the data communication must then know this address.

These settings can only be made when a data communication module has been mounted in the

controller and the installation of the data communication cable has been nished.

This installation is mentioned in a separate document “RC8AC”.

o01 DelayOfOutp.

o02 DI 1 Cong.

Denition takes place with the numerical

value shown to the left.

(0 = o)

DI state

(Measurement)

The DI input’s present status is shown here.

ON or OFF.

After installation of a data communication

module the controller can be operated on

an equal footing with the

other controllers in ADAP-KOOL® refrigeration controls.

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 11

Page 12

The address is set between 1 and 240, gateway determined o03

The address is sent to the gateway when the menu is set in pos. ON o04

Access code 1 (Access to all settings)

If the settings in the controller are to be protected with an access code you can set a numerical

value between 0 and 100. If not, you can cancel the function with setting 0. (99 will always give

you access).

Sensor type

n01: NTC 5000 Ω @ 25°C. M2020 (Danfoss type = EKS 211)

n02: NTC 10000 Ω @ 25°C. M3435 (Danfoss type = (EKS 221)

n03: NTC 3000 Ω @ 25°C

n04: NTC 2500 Ω @ 0°C

n05: NTC 10000 Ω @ 25°C

n06: NTC 2000 Ω @ 25°C

All the mounted sensors must be of the same type.

Display step

Yes: Gives steps of 0.5°

No: Gives steps of 0.1°

Max. standby time after coordinated defrost

When a controller has completed a defrost it will wait for a signal which tells that the refrigeration may be resumed. If this signal fails to appear for one reason or another, the controller will

itself start the refrigeration when this standby time has elapsed.

Conguration of light function

1) The relay cuts in during day operation

2) The relay to be controlled via data communication

3) The relay to be controlled by the door switch dened in either o02 where the setting is

selected to either 2 or 3. When the door is opened the relay will cut in. When the door is closed

again there will be a time delay of two minutes before the light is switched o.

Activation of light relay

The light relay can be activated here (if 038=2)

Case cleaning

The status of the function can be followed here or the function can be started manually.

0 = Normal operation (no cleaning)

1 = Cleaning with fans operating. All other outputs are O.

2 = Cleaning with stopped fans. All outputs are O.

If the function is controlled by a signal at the DI input, the relevant status can be seen here in the

menu.

Access code 2 (Access to adjustments)

There is access to adjustments of values, but not to conguration settings. If the settings in the

controller are to be protected with an access code you can set a numerical value between 0 and

100. If not, you can cancel the function with setting 0. If the function is used, access code 1 (o05)

must also be used.

Copy the controller’s present settings

With this function the controller’s settings can be transferred to a programming key. The key

can contain up to 25 dierent sets. Select a number. All settings except for Address (o03) will be

copied. When copying has started the display returns to o65. After two seconds you can move

into the menu again and check whether the copying was satisfactory.

Showing of a negative gure spells problems. See the signicance in the Fault Message section.

Copy from the programming key

This function downloads a set of settings earlier saved in the controller. Select the relevant

number.

All settings except for Address (o03) will be copied. When copying has started the display

returns to o66. After two seconds you can move back into the menu again and check whether

the copying was satisfactory. Showing of a negative gure spells problems. See the signicance

in the Fault Message section.

Save as factory setting

With this setting you save the controller’s actual settings as a new basic setting (the earlier factory settings are overwritten).

Other application for S5 sensor

Maintain the setting at 0 if the sensor has been dened as defrost sensor in D10. If D10 has been

set at 0 or 2 the S5 input can be used as product sensor or condenser sensor. Here you dene

which:

0: Defrost sensor

1: Product sensor

2: Condenser sensor with alarm

Relay 4

Here you dene the application for relay 4:

1: Light

2: Alarm

o05 -

o06

o15

o16 Max HoldTime

o38 Light cong

o39 Light remote

o46 Case clean

o64 -

o65 -

o66 -

o67 -

o70 S5 Cong

o72 DO4 Cong

SensorCong

NTC 5000 Ω @ 25°C (EKS 211) = 15

NTC 10000 Ω @ 25°C (EKS 221) = 16

NTC 3000 Ω @ 25°C = 17

NTC 2500 Ω @ 0°C = 18

NTC 10000 Ω @ 25°C = 19

NTC 2000 Ω @ 25°C = 20

Disp. Step = 0.5

12 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 13

- - - Night Setback

0=Day

1=Night

Service Service

Temperature measured with S5 sensor u09 S5 temp.

Status on DI input. on/1=closed u10 DI1 status

Status on night operation (on or o) 1=closed

Read the present regulation reference u28 Temp. ref.

Status on relay for cooling

Status on relay for fan

Status on relay for defrost

Temperature measured with Sair sensor u69 Sair temp

Status on relay 4 (alarm or light function) u71 DO4 status

Fault message Alarms

In an error situation the LED’s on the front will ash and the alarm relay will be activated. If you

push the top button in this situation you can see the alarm report in the display. If there are

further push again to see them.

There are two kinds of error reports - it can either be an alarm occurring during the daily operation, or there may be a defect in the installation.

A-alarms will not become visible until the set time delay has expired.

E-alarms, on the other hand, will become visible the moment the error occurs.

(An A alarm will not be visible as long as there is an active E alarm).

Here are the messages that may appear: 1 = alarm

A1: High temperature alarm High t. alarm

A2: Low temperature alarm Low t. alarm

A4: Door alarm Door Alarm

A5: Information. Parameter o16 is expired Max Hold Time

A15: Alarm. Signal from DI input DI1 alarm

A45: Standby position (stopped refrigeration via r12 or DI input) Standby mode

A59: Case cleaning. Signal from DI input Case cleaning

A61: Condenser alarm Cond. alarm

E1: Faults in the controller EKC error

E6: Fault in real-time clock. Check the battery / reset the clock. -

E27: Sensor error on S5 S5 error

E29: Sensor error on Sair Sair error

When copying settings to or from a copying key with functions o65 or o66, the following information may appear:

0: Copying concluded and OK

4: Copying key not correctly mounted

5: Copying was not correct. Repeat copying

6: Copying to EKC incorrect. Repeat copying

7: Copying to copying key incorrect. Repeat copying

8: Copying not possible. Order number or SW version do not match

9: Communication error and timeout

10: Copying still going on

(The information can be found in o65 or o66 a couple of seconds after copying has been

started).

u13 Night Cond.

u58 Comp1/LLSV

u59 Fan relay

u60 Def. relay

Alarm destinations

The importance of the individual alarms

can be dened with a setting (0, 1, 2 or 3)

Warning ! Direct start of compressors *

To prevent compressor breakdown parameter c01 and c02 should be set according to suppliers requirements or in general :

Hermetic Compressors c02 min. 5 minutes

Semihermetic Compressors c02 min. 8 minutes and c01 min. 2 to 5 minutes ( Motor from 5 to 15 KW )

* ) Direct activating of solenoid valves does not require settings dierent from factory (0)

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 13

Page 14

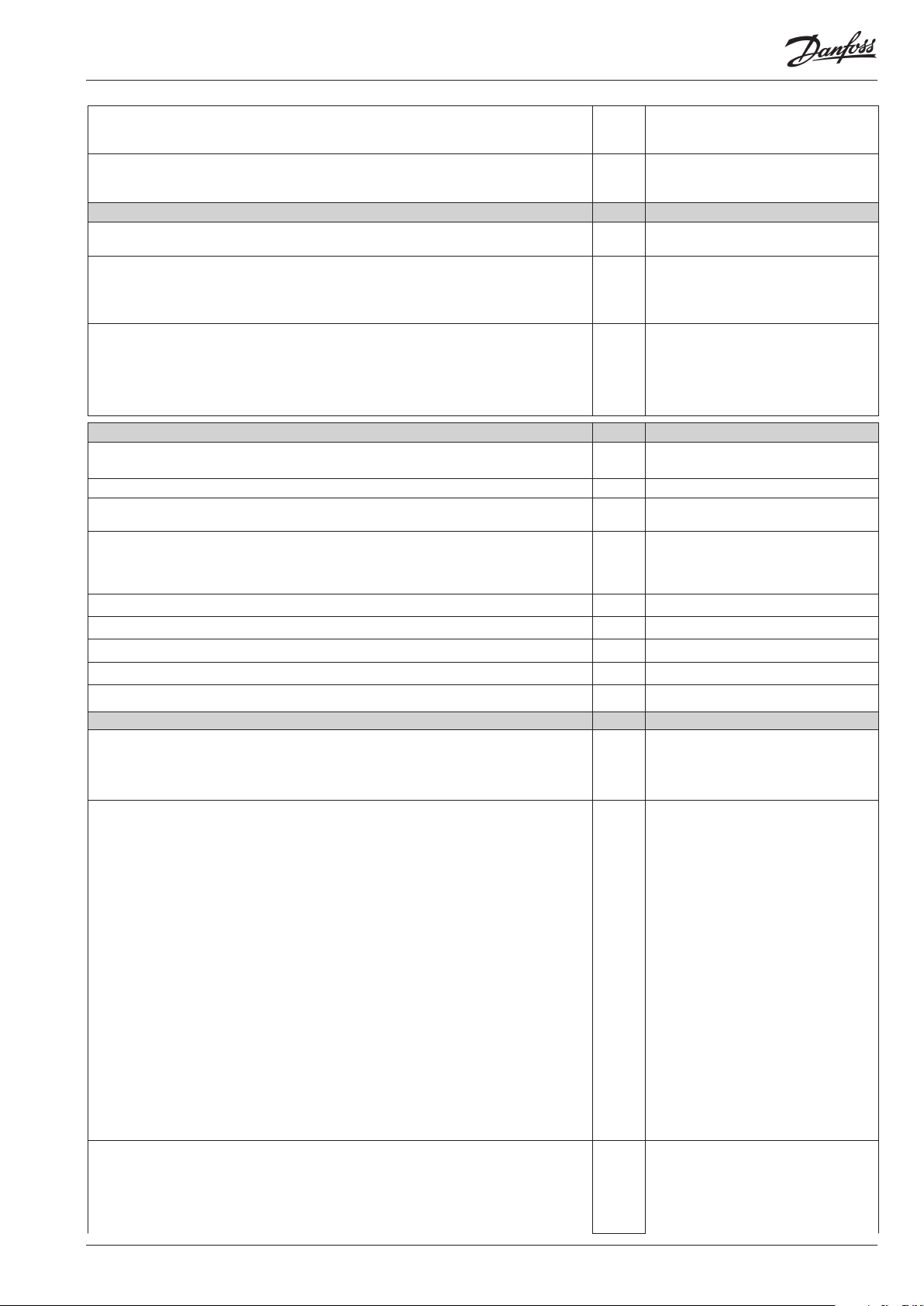

Connections

or

Power supply

230 V a.c.

Sensors

Sair is thermostat sensors.

S5 is a defrost sensor and is used if defrost has to be stopped

based on temperature. It may however also be used as product

sensor or condenser sensor.

Digital On/O signal

A cut-in input will activate a function. The possible functions are

described in menu o02.

Data communication

If data communication is used, it is important that the installation

of the data communication cable is performed correctly.

See separate literature No. RC8AC..

Relays

The general connections are:

Refrigeration. The contact will cut in when the controller demands

refrigeration

Defrost.

Fan.

Alarm. The relay is cut out during normal operation and cuts

in in alarm situations and when the controller is dead

(de-energised)

Light. The contact will cut in when the controller

demands light.

Electric noise

Cables for sensors, DI inputs and data communication must be

kept separate from other electric cables:

- Use separate cable trays

- Keep a distance between cables of at least 10 cm

- Long cables at the DI input should be avoided

Data communication

14 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

Page 15

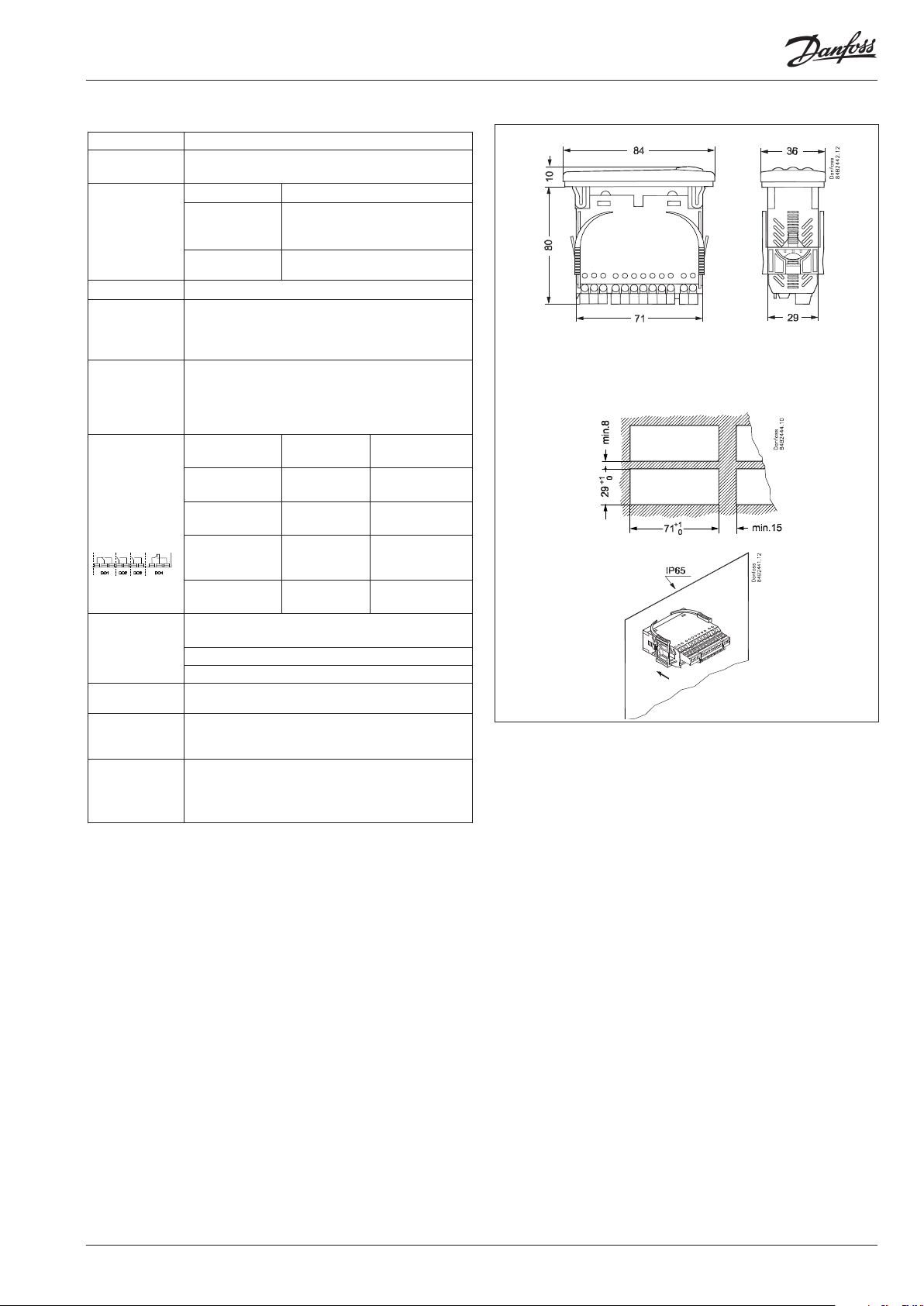

Data

Supply voltage 230 V a.c. +10/-15 %. 1,5 VA, 50/60 Hz

Sensors NTC

Measuring range -40 to +30°C

Accuracy

Controller

Sensor

Display LED, 3 digits

Signal from contact functions

Digital inputs

Requirements to contacts: Gold plating

Cable length must be max. 15 m

Use auxiliary relays when the cable is longer

Max.1,5 mm2 multi-core cable on supply and relays.

Electrical connection cable

Power current terminals are mounted on the circuit

board.

Max. 1 mm2 on sensors - and DI inputs.

Low current terminals are with plugs

DO1.

Refrigeration

Relays

DO2. Defrost 8 (6) A

DO3. Fan 6 (3) A

DO4. Alarm or

light

0 to +55°C, During operations

Environments

-40 to +70°C, During transport

20 - 80% Rh, not condensed

No shock inuence / vibrations

Enclosure

IP 65 from front.

Buttons and packing are imbedded in the front.

Escapement

reserve for the

4 hours

clock

EU Low Voltage Directive and EMC demands re CE-

Approvals

marking complied with

LVD tested acc. EN 60730-1 and EN 60730-2-9, A1, A2

EMC tested acc. EN 61000-6-3 and EN 61000-6-2

* DO1 and DO2 are 16 A relays. The mentioned 8A can be increased up to 10A, when the ambient

temperature is kept below 50 ° C.

DO3 and DO4 are 8 A relays. Max. load must be kept.

** Gold plating ensures make function with small contact loads

*** UL-approval based on 30000 couplings

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such as LEDs and on/o

control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or similar.

±1 K below -35°C

±0,5 K between -35 to +25°C

±1 K above +25°C

Sensor determined. Please see the

data for the actual sensor

CE

(250 V a.c.)

8 (6) A

UL ***

(240 V a.c.)

10 A Resistive

5FLA, 30LRA

10 A Resistive

5FLA, 30LRA

6 A Resistive

3FLA, 18LRA

131 VA Pilot duty

4 (1) A

Min. 100 mA**

4 A Resistive

131 VA Pilot duty

Weight = 200 g

EKC 202C-MS User Guide RS8GH202 © Danfoss 2015-08 15

Page 16

Ordering

Type Function Code no.

EKC 202C-MS Refrigeration controller 084B8543

EKA 178A

EKA 179A

EKA 181C

Data communication module

MOD-bus

Data communication module

RS 485 - LON

Battery module that will protect the clock in case of

lengthy power failure

084B8564

084B8565

084B8577

EKA 182A Copy key EKC - EKC 084B8567

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

16 User Guide RS8GH202 © Danfoss 2015-08 EKC 202C-MS

ADAP-KOOL®

Loading...

Loading...