Page 1

Technical brochure

EKA 183A Programming key

EKA 183A is the tool allowing fast installation

of the EKC, AK-CC and AK-CT refrigeration

controllers both in field and in production,

thanks to the easy setting of the parameters

with a simple plug and play action.

Features

y OEM and Service tool for quickly setting up a

controller

y Bidirectional communication from and to the

connected controller

y USB connection to PC

Page 2

General features

EKA 183A is used to copy setting to an EKC, AK-CC and AK-CT

controller.

It can be used to copy settings from one controller to another

controller of the same type. i.e. the same code number and software

version.

Can be used for:

EKC 102, EKC 202, EKC 204 and AK-CC 210.

EKC 3xx (but not EKC 301), EKC 4xx, EKC 5xx, AK-CC 450,

AK-CC 550 and AK-CT.

(ERC 10x and ERC11x only through docking station. Set the Data

Transfer “MODE=A” in this case as described in the last page.)

Function

Principle

EKA 183A is put into the controller. The controller is connected to the

mains.

Data can be copied from the programming key to the controller or

vice versa by operating the push button.

Pre-programming

EKA 183A is put into the PC’s USB port. The actual file is then set.

The settings are done using the “Microsoft Excel” program. (See next

page).

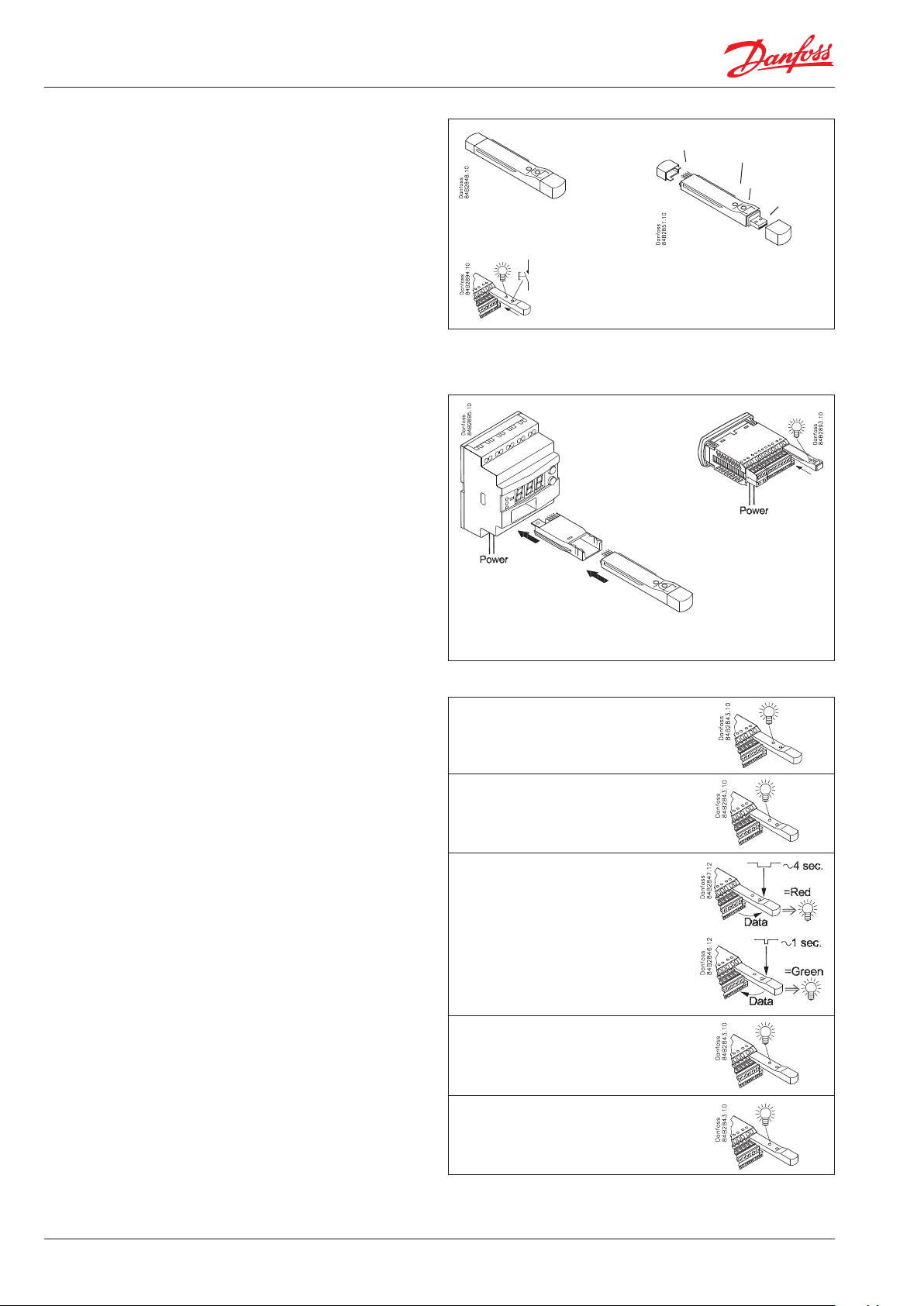

EKC-plug

LED

Push button

USB-plug

LED

1. The LED will flash yellow

when the programming key is put into the controller.

Here it is checked whether the data can be transferred.

2. Shortly afterwards

the LED constant light up yellow and the data transfer can start.

3. and 4. transfer of data:

• pushing the button briefly (1 sec.) will transfer data to the

controller (green LED flashes).

• a long push (at least 4 sec.) will transfer data from the controller to

the programming key (red LED flashes).

• (The transfer of data to the controller will start immediately

(i.e. without push the button), if this function has been activated.

See page 4.)

5. the LED light up constant

the transfer has finished.

If the LED flashes alternately red and green (and remains), an error

has occurred in the transfer. Put the programming key into the PC

and read the error code.

The two usual errors will be:

• the controller’s order number and software version do not match

the file that you are trying to copy to the controller.

• the programming key already contains a write-protected file of

the type you are trying to extract from the controller.

For EKC 3xx, EKC 4xx, EKC 5xx, AK-CC 450, AK-CC 550 and

AK-CT 200 the enclosed adapter must be used.

Yellow

1. Flashes

(checking)

Yellow

2. Light up constant

(await push)

3. Push

ashes

4. Flashes

(transfer data)

constant

5. Ligh up constant

(transfer finisched)

Danfoss A/S (ADAP-KOOL®/DF) | February 2017 DKRCC.PD.R1.07.022

Page 3

1

All parameters are transferred

All the set parameters are transferred. This also applies to the Main

Switch, refrigerant type, application number, address, etc.

There are no exceptions.

Ordering

Type Description Code no.

EKA 183A Programming key 084B8582

Principles and settings via PC

The programming key can only contain one file for each order

number, but there is room for many order numbers.

8020.ekc 8522.ekc 084B8942_.xls cong.cfg EKA183A.log

An example of the contents of a programming key.

The two first files (and similar types) will not be available before they have been

uploaded to the programming key.

By limiting it to one file, you control what is copied. Numerous files

with different settings, e.g. settings for cooling, frost, etc., will not be

mixed up.

When the file is transferred to a controller, the programming key will

check both the order number and the software version.

Both the order number and the software version on the controller

must match the file on the programming key, otherwise the transfer

will not work. The LED will flash to indicate an incomplete transfer.

In order to progress with an incomplete transfer, you must have a

file that corresponds to the one in the controller. But before this, you

must take into account the file that is already on the programming

key.

• If the file is write-protected, you cannot copy another one to the

programming key. The LED will indicate this by flashing.

• If it is not write-protected, it will be overwritten.

You can move the file to a PC, making it accessible later.

And then we go back to the incomplete transfer. If you have a file

with the correct software version, it must be copied over onto the

programming key and then to the controller.

• If you do not have the file, and want to save it for later, you can

copy the file from the controller to the programming key.

If you have several files for the same controller, we recommend that

you save them in different folders, so that they are kept apart from

each other. The programming key can only accept files if the name is:

XXXX.EKC, where XXXX is the last four digits in the order number, e.g.

084B8522.

Setting with “Microsoft Excel” program

The file is on the programming key.

084B8942_xxx.xls (xxx = software version)

Open the file and enable Macros.

The control screen is shown below.

At the bottom, you can save the file as a “Read-Only” file.

If you forget to do this, the file will be overwritten if you do a

“long push” on the programming key, thus transferring data from an

EKC to the programming key.

EKA 183A - Parameter editor

Ver. 1.02

Open Parameter file

File: C:\8520.ekc

Software version: 2.07

Model number: 8520 0

Text

--- Cutout °C 1 -50 50

r01 Differential 1 0.1 20

r02 Max cutout °C 1 -49 50

r03 Min cutout °C 1 -50 49

o17 Disp. S4 % 10 0 100

r04 Disp. Adj. K 1 -20 20

r05 Temp. unit 1 0

r09 Adjust S4 1 -10 10

Value MinMax

Edit parameter

Save file

Save file as “Read Only”

Danfoss A/S (ADAP-KOOL®/DF) | February 2017 DKRCC.PD.R1.07.02 3

Page 4

Data transfer

Two methods can be selected for transferring data:

• A: data transfer from the programming key to the controller occurs

at the same time as the programming key is pushed into the

controller.

• B: the unit is checked and the transfer takes place when the button

is pushed. (B= factory setting).

• P: reserved function.

Connect the programming key to a PC and find the file “Config.cfg”.

The file can be opened using the “WordPad” program.

Set the MODE line to either A or B.

## Sw. version. 1.xx

# Advanced users only

# EKA183A configuration file

#

# EKA183A configuration file

#

# MODE=A: EKA183A will automatically start uploading of parameters to EKC.

# MODE=B: EKA183A function is controlled by the push button.

# MODE=P: EKA183A is controlled by “EKA183A PC Toolkit”.

#

MODE=B

# End of configuration file

Error and status messages

If the LED flashes after a data transfer, the transfer is unsatisfactory.

Look at the error code in the log.

Description of errors and messages found in log:

001 Connection initialized to EKC, mode = button action

002 Connection initialized to EKC, mode = auto

003 Connection initialized to EKC, mode = PC/HID

004 Starting to copy from EKC to Programming Key

005 Done copying from EKC to Programming Key

006 Starting copy from Programming Key to EKC

007 DONE copy from Programming Key to EKC

008 A new configuration has been created

100 Unspecified E1 error

101 E2 error. Mode set to PC action, but no PC is connected

103 E2 error. Mode not set to BUTTON, AUTO or PC

103 E2 error. Tr ying to upload to a illegal PNU number.

Filename and line number specified in log

104 E2 error. Illegal value to upload, eg. out of range.

Filename and line number specified in log

105 E2 error. Tr ying to write “read only value”.

Filename and line number specified in log

106 E2 error. [PNU] section not found in parameter.

Filename specified in log

107 E2 error. Syntax error in PNU line.

Filename and line number specified in log

108 E2 error. No parameter file found to upload

109 E2 error. No configuration file found

110 E2 error. Syntax error in configuration file

111 E2 error. A parameter file for the current EKC is already

present and it is write protected

112 E2 error. A parameter file for the connected EKC exists, but

the software version in the file is different from the connected EKC

113 Not enough free space left on device

If the transferred data has to be used as “New factory setting”, add the

following text: FAC = Y

# MODE=P: EKA183A is controlled by “EKA183A PC Toolkit”.

#

MODE=B

FAC=Y

# End of configuration file

Modes vary based on product and connected device.

Please pay attention to choose the following modes, while the

Programming key is connected.

Mode Settings for Programming Key

Product Type

ERC 10X Series Mode A Not applicable

ERC 11X Series Mode A Not applicable

Plugged in Docking

Station

Connected to ERC prod-

uct directly

Read the log

Connect the programming key to a PC and find the file

“EKA183A. log”. The file can be opened using the “WordPad” program.

It displays the following information: No. of last event (here, line 23).

The last event will always be the last line. If there are more than

50 events, the first ones will be overwritten, so that the last 50 can

always be seen.

Latest line:23

001;00:00 01-01-00;8520;2.0.5;0;;

004;00:00 01-01-00;8520;2.0.5;0;;

005;00:00 01-01-00;8520;2.0.5;0;8520-000.ekc;

001;00:52 01-01-00;8020;1.1.6;0;;

001;01:03 01-01-00;8020;1.1.6;0;;

004;01:03 01-01-00;8020;1.1.6;0;;

005;01:03 01-01-00;8020;1.1.6;0;8020-000.ekc;

001;02:04 01-01-00;8020;1.1.6;0;;

006;02:04 01-01-00;8020;1.1.6;0;;

107;02:04 01-01-00;8020;1.1.6;0;8020-000.ekc;182

001;02:07 01-01-00;8020;1.1.6;0;;

006;02:07 01-01-00;8020;1.1.6;0;;

107;02:07 01-01-00;8020;1.1.6;0;8020-000.ekc;182

001;02:09 01-01-00;8020;1.1.6;0;;

004;02:09 01-01-00;8020;1.1.6;0;;

005;02:09 01-01-00;8020;1.1.6;0;8020-000.ekc;

001;03:22 01-01-00;8020;1.1.6;0;;

004;03:22 01-01-00;8020;1.1.6;0;;

005;03:22 01-01-00;8020;1.1.6;0;8020-000.ekc;

001;00:01 01-01-00;8520;2.0.5;0;;

004;00:01 01-01-00;8520;2.0.5;0;;

005;00:01 01-01-00;8520;2.0.5;0;8520-000.ekc;

• The first number is a code.

- Numbers below 100 are event codes.

- Numbers above 100 are error codes.

• The next number is the date and time of the event (It is the time

set in the controller that is used).

• Again, the next number is the last 4 digits of the controller’s order number.

• Then comes the software version — e.g. 2.05

• And the address set in o03.

• Then the recipient’s data. — Order number, address and “EKC”.

• If the event is an error, the last number in the line (e.g. 182) will be

information for Danfoss about where the error has occurred.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S (ADAP-KOOL®/DF) | February 2017 DKRCC.PD.R1.07.024

Loading...

Loading...