Page 1

Data Sheet

Eco-Damper

ICD damper, ICC Check valve

and ICS control valve

(3 valve) system build on the ICV modular concept

The Danfoss Eco-damper solution is a 3

component (3 valve) system build on the ICV

modular concept.

Each component consists of an ICV housing

and 1 of 3 modules performing the functions

Dampening (ICD), Non-return (ICC) and Control

(ICS 1 or 3 pilots) respectively.

The Danfoss Eco-damper solution is used in the

economizer line of typical screw compressors

to dampen the pulsations from the compressor.

The Eco damper system is designed for high

damping eciency over a broad band of low

frequencies with neglectable pressure drop.

It comes in sizes 32 and 50 and is oered from a

parts program giving a wide variety of

connection types and sizes.

The ICD is a unique damping system combining

the Helmholz, Quarter wave and Expansion

chamber principles into a broad band damper,

able to reduce the Ammonia pulsations by 30%

to 80% for critical frequencies in the frequency

range of 100 to 500 Hz.

AI310433586905en-000201

Page 2

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Features

• Designed for Industrial Refrigeration applications for a maximum working pressure of 52 bar / 754 psig.

• Applicable to R717 (Ammonia)

• Direct welded connections

• Connection types include butt weld, socket weld and solder connections

• Low temperature steel body

• Low weight and compact design

• The 3 top covers can be turned in any of 4 orientations without aecting the individual functions

• Manual opening of the solenoid valve (ie. the line) possible

• Robust PTFE seat secures long lasting solenoid valve function

• Service friendly design

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 2

Page 3

Description

ICD, ICC, ICS 32

ICD, ICC, ICS 50

Valve body/connection material

Steel

Steel

Connection standard

EN 10220

ANSI (B 36.10)

ANSI (B 16.11)

EN 1254-1

ANSI (B 16.22)

EN 10220

ANSI (B 36.10)

ANSI (B 16.11)

EN 1254-1

ANSI (B 16.22)

Connection type

Butt weld

Socket weld

Solder connection

Butt weld

Socket weld

Solder connection

Min. opening dierential pressure

ICS = 0,07 bar (1 psi)

ICC = 0,04 bar (0.6 psi)

ICS = 0,07 bar (1 psi)

ICC = 0,04 bar (0.6 psi)

Pressure dierential for fully opening of the ICS

and ICC valves

ICS = 0,2 bar (2.9 psi)

ICC = 0,08 bar (1.2 psi)

ICS = 0,2 bar (2.9 psi)

ICC = 0,08 bar (1.2 psi)

Kv (m3/h)

ICC = 16.6

ICD = 17.7

ICC = 40.4

ICD = 39.4

Cv (USgal/min)

ICC = 19.3

ICD = 20.6

ICC = 47

ICD = 45.9

Temperature range

ICD Temp. Range from -20 °C – 150 °C / - 4 °F – 302 °F

ICC Temp. Range from -60 °C – 120 °C / -76 °F – 248 °F

ICS Temp. Range from -60 °C– 120 °C / -76 °F – 248 °F

ICD Temp. Range from -20 °C – 150 °C / - 4 °F – 302 °F

ICC Temp. Range from -60 °C – 120 °C / -76 °F – 248 °F

ICS Temp. Range from -60 °C – 120 °C / -76 °F – 248 °F

Max. working pressure

52 bar / 754 psig

52 bar / 754 psig

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Portfolio overview

ICD, ICC, ICS 32 & 50

Table 1: Portfolio overview

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 3

Page 4

ICD

ICC

ICS

A

B B

Mass flow direction

Pulsation direction

Compressor

Fixation Rod

Pipe Clamp

Y

Z

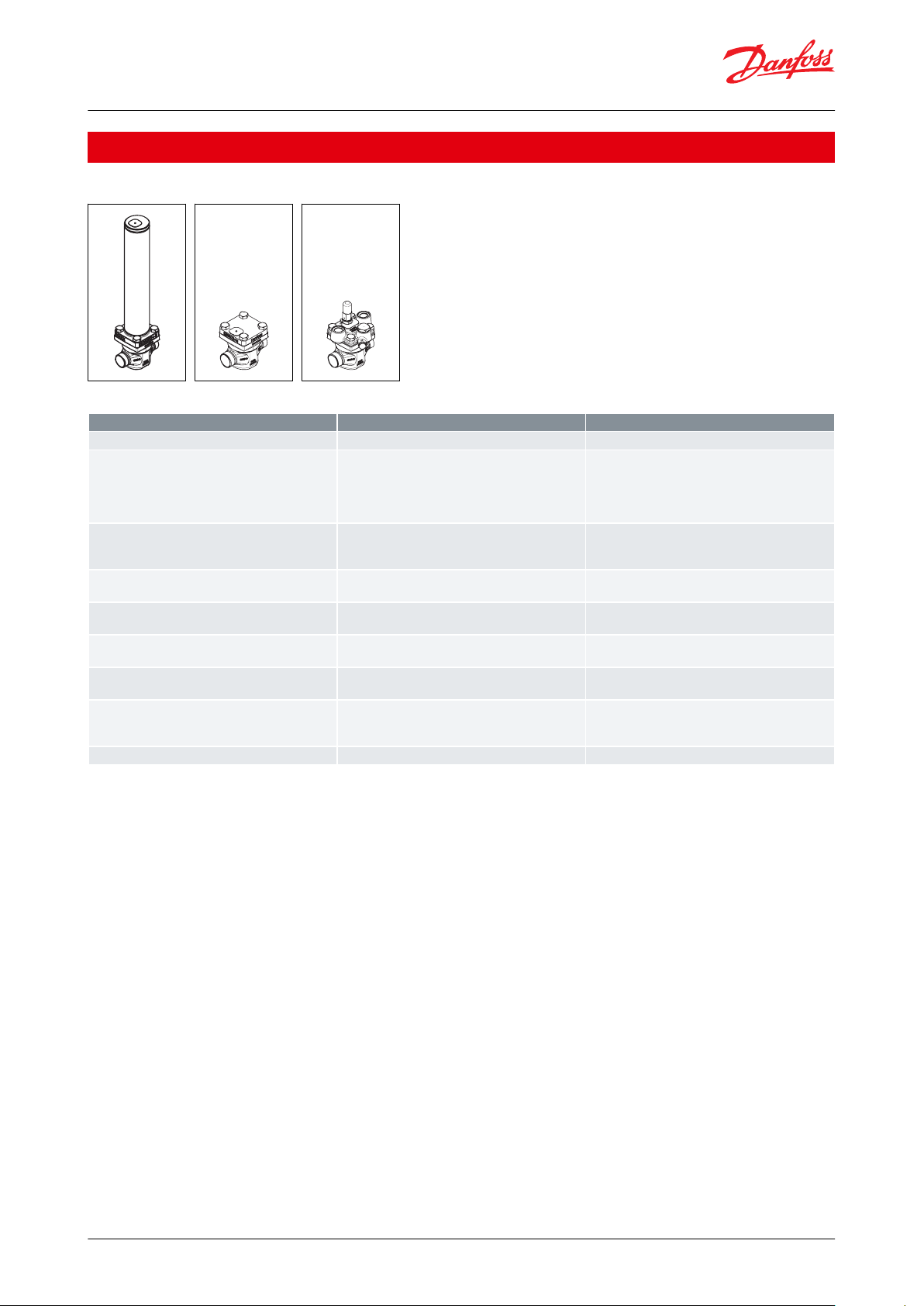

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Functions

Figure 1: Functional diagram

Though the refrigerant ow in the economizer line is towards the compressor, the pulsations moves in the opposite

direction. Due to this phenomenon the sequence of the 3 components is important. Seen from the compressor the

dampening comes rst followed by ow alignment and ow control.

It is equally important to orientate the valve housings with the arrow pointing in the mass ow direction (pointing

towards the compressor).

Distances between the single components are of great importance and recommendations must be followed.

The Eco damper is designed for high eciency dampening of pulsation pressure peeks and creating unidirectional

ow in economizer lines of Ammonia systems.

Depending on the RPM’s and geometry of the typical screw compressor the frequency and amplitude of the

pulsations in the economizer lines will vary.

The ICD damper is specically designed for dampening of the critical Ammonia pulsations in the broad band of 100

to 500 Hz.

A simple calculation will clarify if a certain compressor set-up will result in pulsation frequencies between 100 and

500 Hz and this clarication should be made before considering the Eco damper solution. Please look into the

Selection section.

The ICD is a unique damping system combining the Helmholz, Quarter wave and Expansion chamber principles into

a broad band damper, able to reduce the Ammonia pulsations by 30% to 80% for critical frequencies in the specied

frequency band.

The ICC non-return/check valve is a robust valve optimized to withstand pulsations in the same low frequency band.

The ICC features the ability to reduce small pulsating movements in the wrong direction with an overall low

pressure drop for the main ow direction.

The ICS control valve is the ordinary valve used for allround control purposes. In the Eco-Damper application the 3

pilot version is oered to be able to include more functions like solenoid and/ or pressure control. The solenoid

function is the on/o function for the entire Eco-Damper.

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 4

Page 5

In N/mmAB

X

275.000

375.000

Y

14.000

36.000Z14.000

36.000

In N/mmAB

X

275.000

36.000Y14.000

375.000

Z

14.000

36.000

Equalizer por t

Female Male

Housing size

ICD connection size

ICC connection size

32

DN32

DN32

DN40

DN4050DN50

DN50

DN65

DN65

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

The Eco-Damper solution must be assembled like shown in the above gure with the ICD next to the compressor

followed by the ICC and nally the ICS.

NOTE:

In order to prevent exceeding vibrations caused by the ICD eigenfrequency, pipe clamps for fastening the

ICD must be installed, and the max distances have to be followed (Figure 1: Functional diagram. Pos. A and B

are mandatory). The pipe clamp for pos. A is included in the box. The B pipe clamps and the support must be

strong and robust xation points to help reduce vibrations.

As a guideline the values for stiness of the clamp support can be found in following tables. For reference of

coordinate system see Figure 1: Functional diagram. The pipe clamps at A and B have to provide the

following minimum stiness if the xation rod is pointing in x-direction:

The pipe clamps at B have to provide the following minimum stiness if the xation rod is pointing in ydirection (clamp at A remains unchanged):

Selection

To determine the actual pulsation frequency of a compressor use this formula:

Frequency = RPM (female) * number of grooves (female) / 60 [Hz]

Example: Frequency = 2000 * 6 / 60 = 200 Hz

If 100 Hz < Frequency < 500 Hz dampening is possible with the Eco damper.

Further selection should be based on housing size, connection size and capacity.

Capacity

Once the frequency range is conrmed to be within damper range, the next step is to nd the right valve capacity.

For selection and capacity calculation please refer to Coolselector®2

For application and compressor model conrmation please contact Danfoss.

These criteria should be used for selection.

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 5

Page 6

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

• Complete Eco-Damper solution (ICD+ICC): Lowest pressure drop @ min. and max. capacity

• Check ICC: Pressure drop min. @ minimum capacity (to be outside un-stable area) Check pressure drop max. @

maximum capacity

• Control/solenoid valve: Pressure drop @ min. and max. capacity

• Check control/solenoid valve: Pressure drop min. @ minimum capacity (to be outside un-stable area) Check

pressure drop max. @ maximum capacity

NOTE:

For assistance in relation to selection of right valve capacity please contact Danfoss.

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 6

Page 7

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Media

Refrigerants

Applicable to R717 (Ammonia)

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 7

Page 8

Max. temperature range

Media: -60 °C – 120 °C / -76 °F – 248 °F.

Max. working pressure

52 bar / 754 psig

Min. opening dierential pressure

ICS = 0,07 bar (1 psi)

ICC = 0,04 bar (0.6 psi)

Pressure dierential for fully opening of the ICS and ICC valves

ICS = 0,2 bar (2.9 psi)

ICC = 0,08 bar (1.2 psi)

Kv (m3/h)

Size 32: 17

Size 50: 44

Cv (USgal/min)

Size 32: 20

Size 50: 51

Coil requirement for ICS+EVM

Coils to be IP67

Damping frequency range

100 – 500Hz

Surface protection

For excellent corrosion protection all valve outer surfaces are zinc-chromated.

The Damper module is painted.

1

3

2

4

5

1

3

2b

2a

2

4

6c

C

6

7

11

12

2

4

8

9

10

6c

C

6a

6b

D

E

A

B

1

No

Part

Material

EN

ASTM

JIS

1

Body

Low temperature steel

G20Mn5QT

EN 10213-3

LCC A352

SCPL1 G5151

2

Top assembly

Low temperature steel

G20Mn5QT,

EN 10213-3

P285QH+QT 10222-4

LCC A352

LF2, A350

SCPL1 G5151

2a

O-ring

Cloroprene (Neoprene)

2b

O-ring

Cloroprene (Neoprene)

3

Gasket

Fiber, non-asbestos

4

Bolts

Stainless steel

A2-70, EN 1515-1

Grade B8 A320

A2-70, B 1054

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Product specication

Pressure and temperature

Table 2: Pressure and temperature

Material specication

Table 3: Material specication

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 8

Page 9

No

Part

Material

EN

ASTM

JIS

5

Pipe support

Stainless Steel

6

Function module (assembled)6ao-ring

Cloroprene (Neoprene)

6b

o-ring

Cloroprene (Neoprene)

6c

Washer plate

SteelACylinder

SteelBPiston

SteelCValve plate

PTFEDSpring

SteelECone

Steel7Gasket

Fiber, non-asbestos

8

Plug

Steel9Gasket

Aluminium

10

Manual operating spindle

Steel11Plug

Steel12Gasket

Aluminium

ICV 32

ICV 50

DASOCSDSA

L

ID

Butt-weld DIN

Butt-weld ANSI

Socket weld ANSI

Solder DIN

Solder ANSI

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Connections

The Eco-Damper concept

The Eco-Damper concept is developed to highest exibility of direct welded connections. For valve sizes ICV 32 and

50 a wide range of connection sizes and types is available.

The direct welded (non-anged) connections secures low risk of leakage.

Table 4: There are two valve bodies available

There is a wide range of connection types available:

• D: Butt weld, EN 10220

• A: Butt weld, ANSI (B 36.10)

• SOC: Socket weld, ANSI (B 16.11)

• SD: Solder connection, EN 1254-1

• SA: Solder connection, ANSI (B 16.22)

Table 5: Design (valve)

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 9

Page 10

H₁ H₂

L

Connection

H1H

2

L

Weight

32 D (1 1/4 in.)

mm

40

482.57

145

7 Kg

in.

1.57

18.99

5.71

15.4 lbs

40 D (1 1/2 in.)

mm

40

482.57

145

6.8 Kg

in.

1.57

18.99

5.71

14.9 lbs

32 A (1 1/4 in.)

mm

40

482.57

145

6.8Kg

in.

1.57

18.99

5.71

15 lbs

40 A (1 1/2 in.)

mm

40

482.57

145

6.8 Kg

in.

1.57

18.99

5.71

15.1 lbs

32 SOC (1 1/4 in.)

mm

40

482.57

148

6.9 Kg

in.

1.57

18.99

5.83

15.3 lbs

35 SD (1 3/8 in. SA)

mm

40

482.57

148

6.8 Kg

in.

1.57

18.99

5.83

14.9 lbs

42 SD (1 5/8 in.)

mm

40

482.57

148

6.8 Kg

in.

1.57

18.99

5.83

14.9 lbs

42 SA (1 5/8 in.)

mm

40

482.57

148

6.8 Kg

in.

1.57

18.99

5.83

14.9 lbs

50 D (2 in.)

mm

59

503.74

200

12.2 Kg

in.

2.32

19.83

7.87

26.9 lbs

65 D (2 1/2 in.)

mm

59

503.74

210

12.6 Kg

in.

2.32

19.83

8.27

27.8 lbs

50 A (2 in.)

mm

59

503.74

200

12.3 Kg

in.

2.32

19.83

7.87

27.1 lbs

65 A (2 1/2 in.)

mm

59

503.74

210

12.6 Kg

in.

2.32

19.83

8.27

27.8 lbs

50 SOC (2 in.)

mm

59

503.74

216

13.4 Kg

in.

2.32

19.83

8.5

29.6 lbs

54 SD (2 1/8 in. SA)

mm

59

503.74

216

12.4 Kg

in.

2.32

19.83

8.5

27.2 lbs

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Dimensions and weights

ICD 32 and 50

Table 6: Housing with module

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 10

Page 11

H₁ H₂

L

Connection

H1H

2

L

Weight

32 D (1 1/4 in.)

mm

40

86.8

145

6.5 Kg

in.

1.57

3.42

5.71

14.4 lbs

40 D (1 1/2 in.)

mm

40

86.8

145

6.6 Kg

in.

1.57

3.42

5.71

14.6 lbs

32 A (1 1/4 in.)

mm

40

86.8

145

6.6 Kg

in.

1.57

3.42

5.71

14.6 lbs

40 A (1 1/2 in.)

mm

40

86.8

145

6.7 Kg

in.

1.57

3.42

5.71

14.7 lbs

32 SOC (1 1/4 in.)

mm

40

86.8

148

6.8 Kg

in.

1.57

3.42

5.83

14.9 lbs

35 SD (1 3/8 in. SA)

mm

40

86.8

148

6.6 Kg

in.

1.57

3.42

5.83

14.6 lbs

42 SD (1 5/8 in.)

mm

40

86.8

148

6.6 Kg

in.

1.57

3.42

5.83

14.6 lbs

42 SA (15/8 in.)

mm

40

86.8

148

6.6Kg

in.

1.57

3.42

5.83

14.6 lbs

50 D (2 in.)

mm

59

111.25

200

9.1 Kg

in.

2.32

4.38

7.87

20 lbs

65 D (2 1/2 in.)

mm

59

111.25

210

9.5 Kg

in.

2.32

4.38

8.27

20.9 lbs

50 A (2 in.)

mm

59

111.25

200

9.1 Kg

in.

2.32

4.38

7.87

20.2 lbs

65 A (2 1/2 in.)

mm

59

111.25

210

9.5 Kg

in.

2.32

4.38

8.27

20.9 lbs

50 SOC (2 in.)

mm

59

111.25

216

10.3 Kg

in.

2.32

4.38

8.5

22.7 lbs

54 SD (2 1/8 in. SA)

mm

59

111.25

216

9.2 Kg

in.

2.32

4.38

8.5

20.3 lbs

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

ICC 32 and 50

Table 7: Housing with top cover

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 11

Page 12

H₁

H₂

H₄

L₁

H₃

L

Connection

H1H2H3H

4

L

L1L2B1B

2

Weight

ICS 1 Pi‐

lot

Weight

ICS 3 Pi‐

lots

32 D (1 1/4 in.)

mm

40

160

1007414551155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.7120.5923.43

9.9 lb.

11 lb.

40 D (1 1/2 in.)

mm

40

160

1007414551155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.7120.5923.43

9.9 lb.

11 lb.

32 A (1 1/4 in.)

mm

40

160

1007414551155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.7120.5923.43

9.9 lb.

11 lb.

40 A (1 1/2 in.)

mm

40

160

1007414551155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.7120.5923.43

9.9 lb.

11 lb.

32 SOC (1 1/4 in.)

mm

40

160

1007414851155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.8320.5923.43

9.9 lb.

11 lb.

35 SD (1 3/8 in. SA)

mm

40

160

1007414851155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.8320.5923.43

9.9 lb.

11 lb.

42 SD (1 5/8 in.)

mm

40

160

1007414851155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.8320.5923.43

9.9 lb.

11 lb.

42 SA (1 5/8 in.)

mm

40

160

1007414851155187

4.5 kg

5 kg

in.

1.57

6.3

3.93

2.91

5.8320.5923.43

9.9 lb.

11 lb.

50 D (2 in.)

mm

59

181

1209320051156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

7.8720.59

2.48

3.58

19.6 lb.

20.2 lb.

65 D (2 1/2 in.)

mm

59

181

1209321051156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

8.2720.59

2.48

3.58

19.6 lb.

20.2 lb.

50 A (2 in.)

mm

59

181

1209320051156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

7.8720.59

2.48

3.58

19.6 lb.

20.2 lb.

65 A (2 1/2 in.)

mm

59

181

1209321051156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

8.2720.59

2.48

3.58

19.6 lb.

20.2 lb.

50 SOC (2 in.)

mm

59

181

1209321651156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

8.520.59

2.48

3.58

19.6 lb.

20.2 lb.

54 SD (2 1/8 in. SA)

mm

59

181

1209321651156391

8.9 kg

9.2 kg

in.

2.32

7.13

4.72

3.66

8.520.59

2.48

3.58

19.6 lb.

20.2 lb.

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

ICS 32 and 50

Table 8: Housing with module

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 12

Page 13

ICS 3

3 x Valve body

32 D (1 1/4 in.)

027H3120

Table 10

1 x Function module set

ICD & ICC

027H3201

Table 11

1 x Function module ICS 32

027H3200

Table 12

1 x Top cover

3 pilots

027H3173

Table 13

32 D (1

1

⁄4 in.)

40 D (1

1

⁄2 in.)

42 SA (1

5

⁄8 in.)

42 SD (1

5

⁄8 in.)

027H3120

027H3125

027H3127

027H3128

35 SD (1

3

⁄8 in. SA)

32 A (1

1

⁄4 in.)

32 SOC (1

1

⁄4 in.)

40 A (1

1

⁄2 in.)

027H3123

027H3121

027H3122

027H3126

Description

Code Number

ICD & ICC 32

027H3201

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Ordering

ICD, ICC, ICS 32

Ordering from the parts programme

Table 9: Example (select from table 10 to 13)

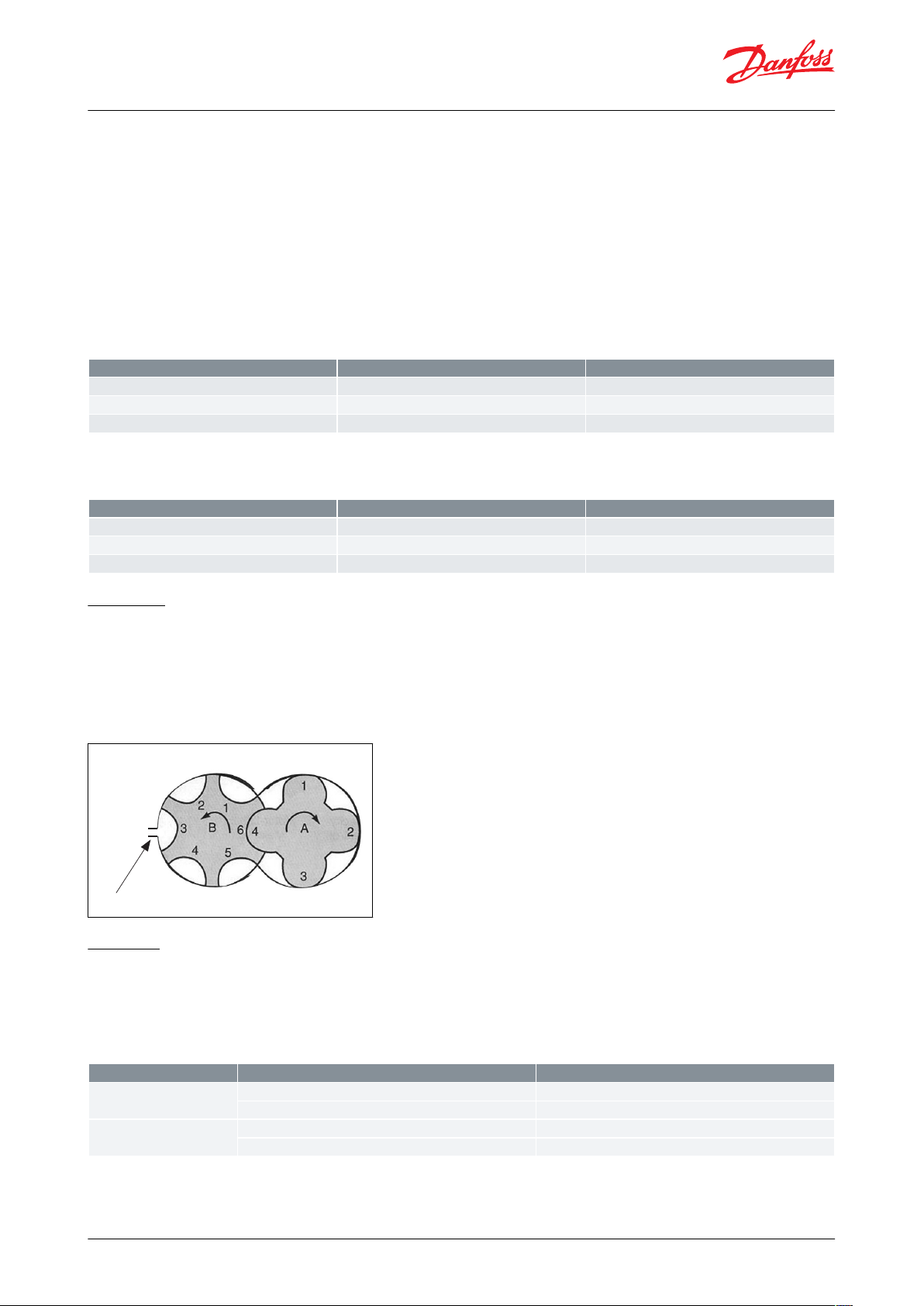

Figure 2: ICV 32 valve body

Table 10: ICV 32 valve body w/dierent connections

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 3: ICD & ICC

Table 11: ICD & ICC function module set

NOTE:

Including bolts, gaskets and o-rings

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 13

Page 14

ICS 1

ICS 3

Description

Code Number

ICS 32

027H3200

Description

Code Number

Top cover 1 Pilot

027H3172

(1)

Top cover 3 Pilots

027H3173

(2)

ICS 3

3 x Valve body

50 D (2 in.)

027H5120

Table 15

1 x Function module set

ICD & ICC

027H5201

Table 16

1 x Function module ICS 50

027H5200

Table 17

1 x Top cover

3 pilots

027H5173

Table 18

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Figure 4: ICS 32

Table 12: ICS 32 function module

NOTE:

Including gasket and O-rings

Figure 5: Top cover 1 Pilot

Figure 6: Top cover 3 Pilots

Table 13: ICS 32 top cover

(1)

(1)

Including bolts

Including bolts

(2)

(2)

Including bolts and one blanking plug

Including bolts and one blanking plug

ICD, ICC, ICS 50

Ordering from the parts programme

Table 14: Example (select from table 15 to 18)

Figure 7: ICV 50 valve body

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 14

Page 15

ICS 1

ICS 3

50 D (2 in.)

65 D (2

1

⁄2 in.)

54 SD (2

1

⁄8 in. SA)

50 A (2 in.)

027H5120

027H5124

027H5123

027H5121

50 SOC (2 in.)

65 A (2

1

⁄2 in.)

027H5122

027H5125

Description

Code Number

ICD & ICC 50

027H5201

Description

Code Number

ICS 50

027H5200

Description

Code Number

Top cover 1 Pilot

027H3172

(1)

Top cover 3 Pilots

027H3173

(2)

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Table 15: ICV 50 valve body w/dierent connections

NOTE:

D = Butt-weld DIN ; A = Butt-weld ANSI ; J = Butt-weld JIS ; SOC = Socket weld ANSI ; SD = Solder DIN ; SA =

Solder ANSI ; FPT = Female Pipe Thread

Figure 8: ICD & ICC

Table 16: ICD & ICC function module set

NOTE:

Including bolts, gaskets and o-rings

Figure 9: ICS 50

Table 17: ICS 50 function module

NOTE:

Including gasket and O-rings

Figure 10: Top cover 1 Pilot

Figure 11: Top cover 3 Pilots

Table 18: ICS 50 top cover

(1)

(1)

Including bolts

Including bolts

(2)

(2)

Including bolts and one blanking plug

Including bolts and one blanking plug

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 15

Page 16

Description

Code Number

ICC 32 function module

027H3202

ICC 50 function module

027H5202

Description

Code Number

ICC 32 repair kit

027H3039

ICC 50 repair kit

027H5017

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Spare parts and accessories

Figure 12: Function module

Table 19: Function module

Figure 13: Repair kit

Table 20: Repair kit

NOTE:

Including bolts, gaskets and o-rings

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 16

Page 17

ICD, ICC and ICS valves

Nominal bore

DN 32 - 50 (1 1/4 - 2 in.)

Classied for

Fluid group I

Category

II

Eco-Damper - ICD damper, ICC Check valve and ICS control valve

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

The ICV valve concept is designed to full global refrigeration requirements.

The individual components are CE, CRN and UL approved. For specic approval information, please contact Danfoss.

Table 21: Compliance

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 17

Page 18

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.12 AI310433586905en-000201 | 18

Loading...

Loading...