Data Sheet

Hermetic filter drier

Type DML and DCL

For uniow liquid line

All ELIMINATOR® driers have a solid core with

binding material held to an absolute minimum.

There are two types of ELIMINATOR® cores. Type

DML driers have a core composition of 100%

Molecular Sieve, while type DCL contain 80%

Molecular Sieve with 20% activated alumina.

ELIMINATOR® type DML driers are designed for

applications requiring the highest moisture

capacity.

ELIMINATOR® type DCL driers are designed for

applications requiring high moisture capacity

and acid adsorption capacity.

Available with solder (cu-plated steel

connectors) and are connections.

For other connections please contact your

Danfoss Sales Representative.

AI192386435941en-001401

Hermetic lter drier Type DML and DCL

Features

The Core type DML

• 100% Molecular Sieve core

• High drying capacity minimizing the risk of acid formation (hydrolysis)

The Core type DCL

• 80% Molecular Sieve with 20% activated alumina

• Perfect core blend for systems that operate at high condensing temperatures and require high drying capacity

The Shell

• PED approved for PS 46 bar

• Available with solder (Cu-plated steel connectors) and are connections

• Corrosion resistant powder-painted nish. Special coating for marine applications available upon request

• Allows installation with any orientation provided the arrow is in the ow direction

• Available in sizes 3 – 75 cubic inches

The Filter

• 25 μm (0.001 in.) lter provides high retention with minimal pressure drop

• Thermally stable up to 120 °C

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 2

Danfoss

R64-2107.10

EVR

SGN

AKS

EKC

TCAE

GBC

GBCDML / DCL

Hermetic lter drier Type DML and DCL

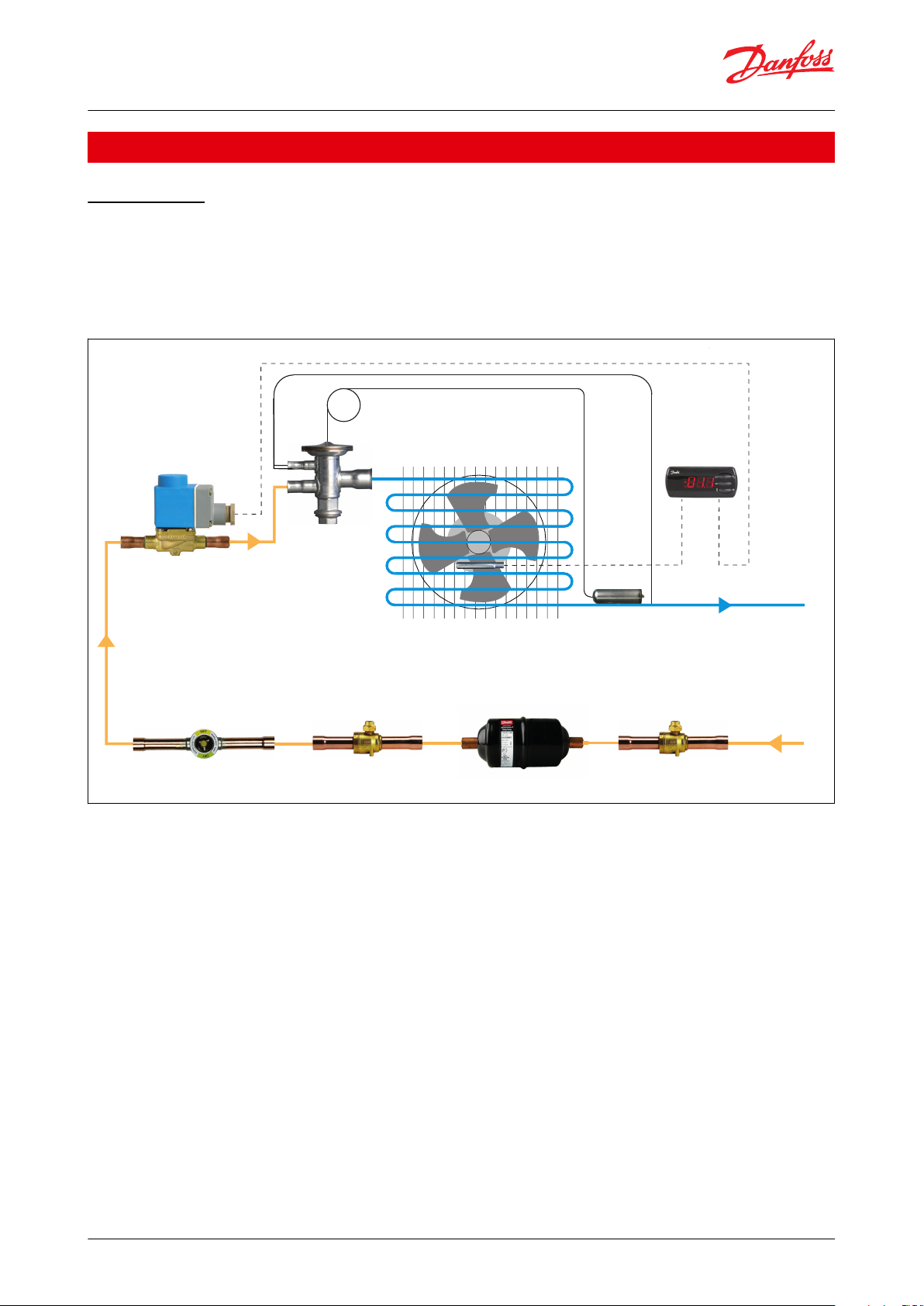

Application

Intro-diagram

ELIMINATOR® Hermetic lter driers protect refrigeration and air-conditioning systems from moisture, acids, and solid

particles.

With these contaminants eliminated, systems are safer from harmful chemical reactions and from abrasive

impurities.

Figure 1: Application

DML Filter drier

Recommended for use with R134a, R404A, R32,R410A,R407C, R23, R600, R600a,R1234yf, R1234ze, R407f,R290,

R452A,R444B, R449A, R448A and R450A refrigerants. Will not deplete oil additives

DCL Filter Drier

Recommended for use with Applicable to R22, R134a, R404A, R32,R410A, R407C, R23, R600, R600a,R1234yf, R1234ze,

R407f, R290, R452A,R444B, R449A, R448A and R450A refrigerants

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 3

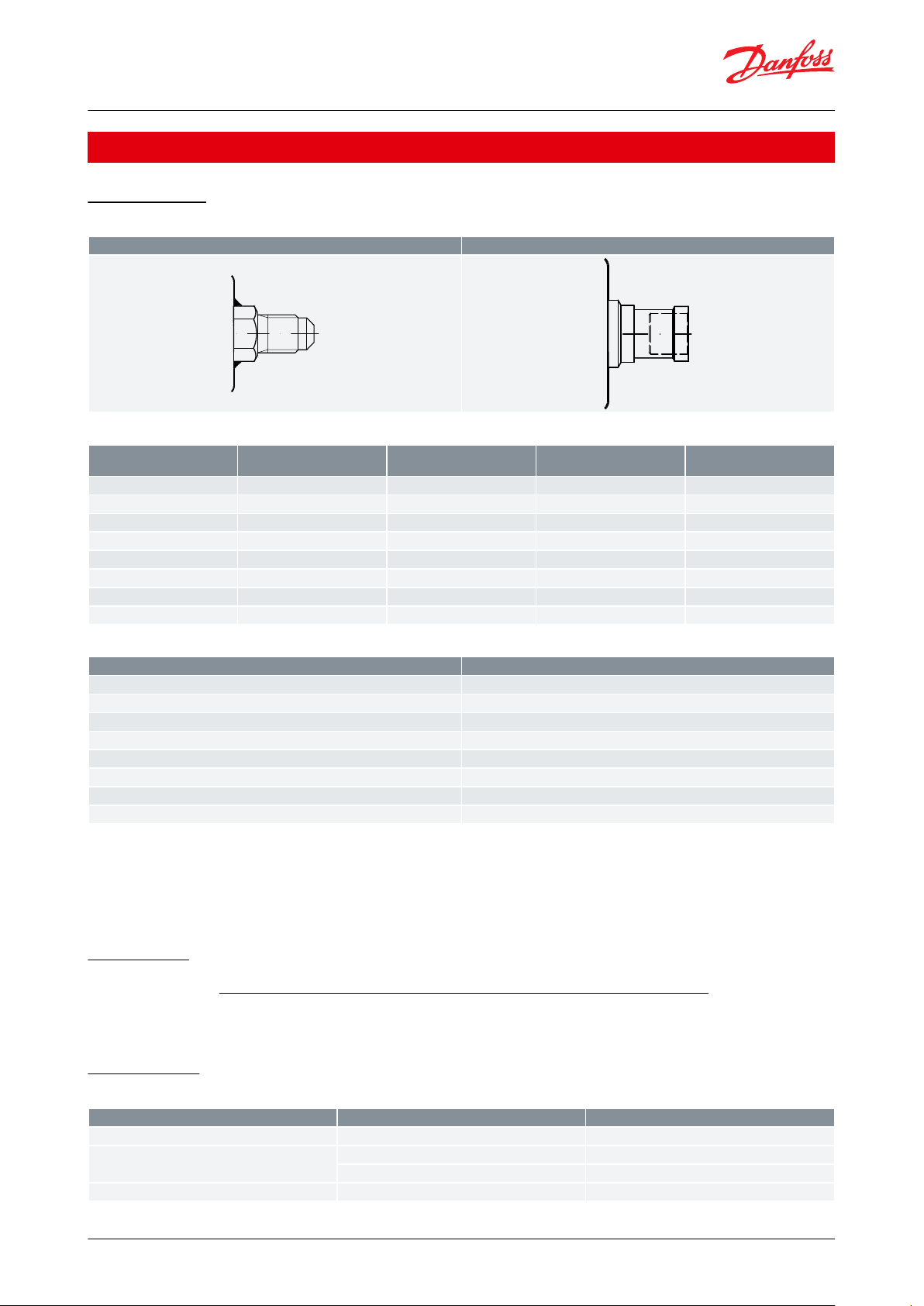

Flare connection

Solder connection(cu-plated steel connectors)

Filter

Solid core surface[cm2]

Solid core volume[cm3]

Filter drier volume (shell vol‐

ume)[l]

Filter drier volume (net vol‐

ume)[l]

DML/DCL 038229

0.08

0.051

DML/DCL 059535

0.12

0.085

DML/DCL 08

131560.17

0.114

DML/DCL 16

220

134

0.36

0.226

DML/DCL 30

378

256

0.72

0.464

DML/DCL 41

510

350

0.97

0.62

DML/DCL 60

756

513

1.34

0.827

DML/DCL 75

1019

702

1.81

1.108

Filter

Acid capacity

(1)

[g]

DCL 03

0.5

DCL 05

0.8

DCL 08

1.3

DCL 16

2.9

DCL 30

6.1

DCL 41

8.3

DCL 60

12.2

DCL 75

16.6

Type

Codes

Description

Filter drier

D

Drier

Solid core

C

80% Molecular Sieve / 20% activated alumina

M

100% Molecular Sieve core

Application

L

Liquid line

Hermetic lter drier Type DML and DCL

Product specication

Technical data

Table 1: Technical data

Table 2: Surface and volume

Table 3: Acid capacity

(1)

(1)

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Temperature range:

Temperature range:

-40 – 70 °C

-40 – 70 °C

Maximum working pressure:

Maximum working pressure:

PS 46 bar

PS 46 bar

Conversions

Drops of water =

See ARI standard 710-86 for recommended initial and nal PPM values for dierent refrigerants.

[1 kg of refrigerant× (Initial PPM of water−Final PPM of water)]

50

Identication

Table 4: Identication

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 4

DCL053

s

Type

Codes

Description

Size (volume)

3

3 in.

3

5

5 in.

3

8

8 in.

3

16

16 in.

3

30

30 in.

3

38

38 in.

3

41

41 in.

3

60

60 in.

3

75

75 in.

3

Connection (lter connection in 1⁄8 of an inch increments)

2

1⁄4 in. / 6 mm

2.5

5⁄16 in. / 8 mm

3

3⁄8 in. / 10 mm

4

1⁄2 in. / 12 mm

5

5⁄8 in. / 16 mm

6

3⁄4 in. / 18 (19) mm

7

7⁄8 in. / 22 mm

9

1

1

⁄8 in. / 28 mm

Connection type

(blank)

Flare connection

s

Solder connection

DCL053

s

Filter drier

Solid core

Application

Size (volume)

Connection (lter connection in 1⁄8 of an inch increments)

Connection type

Refrigerant and oil types

DCL

DML

Refrigerant

HFO

Recommended

Recommended

HC

(1)

Recommended

Recommended

HFC

Recommended

Recommended

HCFC

Recommended

Recommended

Oil

Mineral or AB

Recommended

Recommended

POE or PAG, pure

Recommended

Recommended

POE or PAG, with additives

Not recommended

(2)

Recommended

Hermetic lter drier Type DML and DCL

Example for type codes

Selection

Type selection is made considering the application

Table 5: Selection

(1)

(1)

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for

(2)

(2)

DCL Hermetic

DCL Hermetic

substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not

substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not

harmful to the system.

harmful to the system.

lter driers contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar

lter driers contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar

Filter drier selection based on capacity calculation

Drier selection based on capacities and refrigerants, please refer to Coolselector®2. Rated and extended capacities

are calculated with the Coolselector®2 calculation engine to ARI standards with the ASEREP equations based on

laboratory measurements of selected valves.

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 5

ammable refrigerants now.

ammable refrigerants now.

1234567

DML / DCL 03

DML / DCL 05

DML / DCL 08, DML / DCL 16

DML / DCL 30, DML / DCL 41

Danfoss

23Z22.11

.13

DML / DCL 60, DML / DCL 75

Inlet

Spring

Solid core

Polyester mat

Perforated plate

Seal cap, are connection

Seal cap, solder connection

Hermetic lter drier Type DML and DCL

Download Coolselector®2 for free at coolselector.danfoss.com.

Design

Table 6: Design

The relatively large diameter of the hermetic lter drier means that the liquid ow velocity is suitably low and the

pressure drop minimal.

Powder formation is eliminated because the solid core grains are bonded and cannot move against each other.

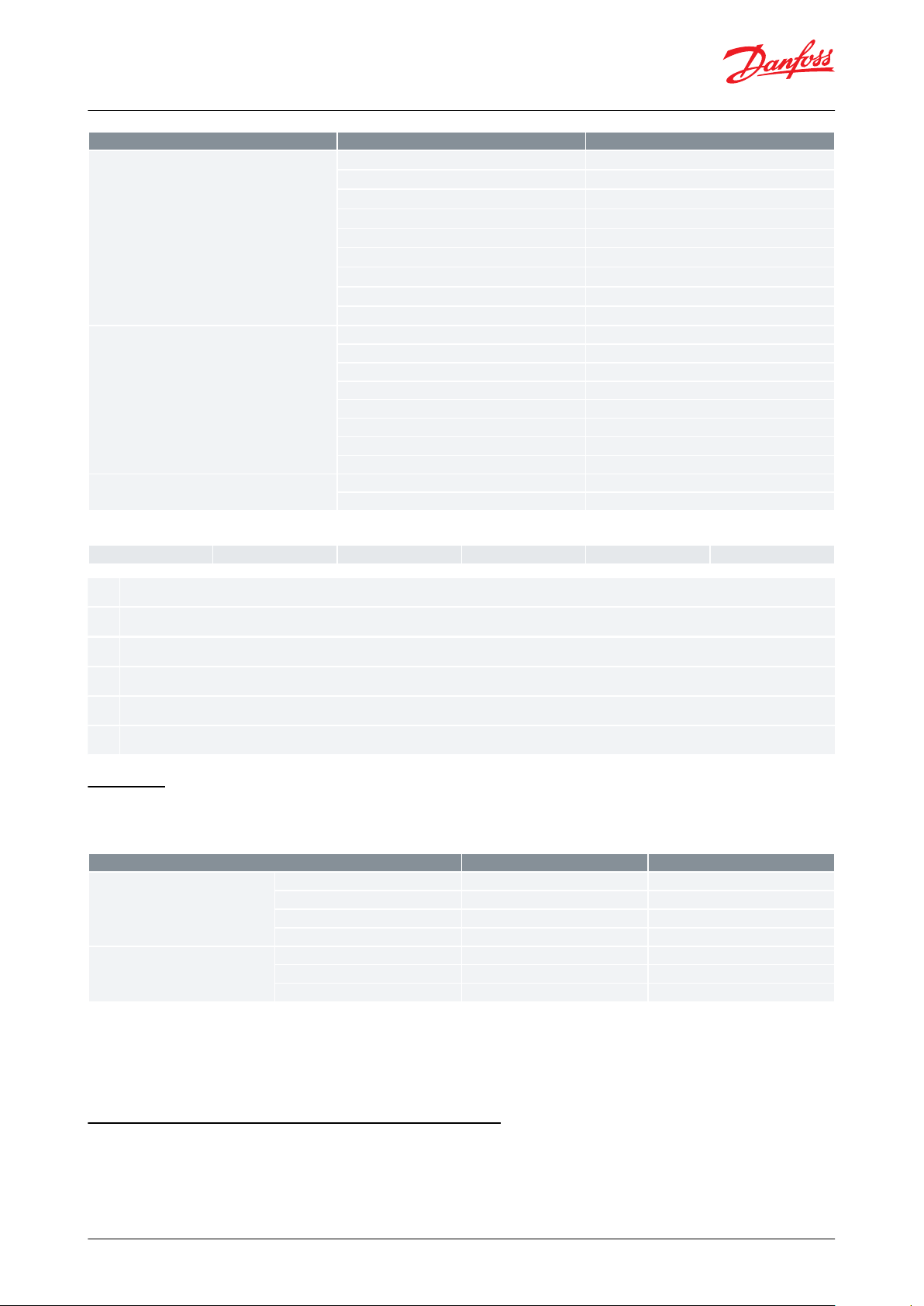

Dimensions and weights

Flare connections

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 6

Type

AA1A2LD1

D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 0326633331104643

0.17

DCL / DML 0336633331234643

0.19

Type

AA1A2LD1

D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 052

75

24.5

50.5

1195854

0.24

DCL / DML 053

75

24.5

50.5

1325854

0.27

Type

AA1A2LD1

D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 082

101

50.5

50.5

1455854

0.31

DCL / DML 083

101

50.5

50.5

1585854

0.35

DCL / DML 084

101

50.5

50.5

1665854

0.37

DCL / DML 085

101

50.5

50.5

1755854

0.4

DCL / DML 162

1105555

1548076

0.65

DCL / DML 163

1105555

1678076

0.67

DCL / DML 164

1105555

1758076

0.74

DCL / DML 165

1105555

1848076

0.74

DCL / DML 166

1105555

1828076

0.84

Type

ALD1

D2

Net weight

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 303

186

2438076

1.28

DCL / DML 304

186

2518076

1.32

DCL / DML 305

186

2608076

1.35

DCL / DML 306

186

2588076

1.45

DML 385

151

2259389

1.59

DCL / DML 413

187

2449389

1.79

DCL / DML 414

187

2529389

1.82

DCL / DML 415

187

2619389

1.87

Hermetic lter drier Type DML and DCL

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 7

Danfoss

23Z80.10

Type

AA1A2BLD1D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 032s

66333384984643

0.17

DCL / DML

032.5s

663333851014643

0.16

DCL / DML 033s

663333861044643

0.16

DCL / DML 034s

663333841084643

0.16

Danfoss

23Z81.10

Type

AA1A2BLD1D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 052s

75

24.5

50.5931075854

0.24

DCL / DML

052.5s

75

24.5

50.5941105854

0.24

DCL / DML 053s

75

24.5

50.5951135854

0.23

DCL / DML 054s

75

24.5

50.5971175854

0.24

DCL / DML 055s

75

24.5

50.5

101

1255854

0.26

Danfoss

23Z82.10

Type

AA1A2BLD1D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 082s

101

50.5

50.5

119

1335854

0.3

DCL / DML

082.5s

101

50.5

50.5

120

1365854

0.3

DCL / DML 083s

101

50.5

50.5

121

1395854

0.3

DCL / DML 084s

101

50.5

50.5

123

1435854

0.31

DCL / DML 085s

101

50.5

50.5

127

1515854

0.32

DCL / DML 162s

1105555

128

1428076

0.64

DCL / DML

162.5s

1105555

129

1458076

0.64

Hermetic lter drier Type DML and DCL

Solder connection (cu-plated steel connectors)

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 8

Type

AA1A2BLD1D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 163s

1105555

130

1488076

0.65

DCL / DML 164s

1105555

132

1528076

0.65

DCL / DML 165s

1105555

136

1608076

0.66

DCL / DML 166s

1105555

136

1648076

0.69

DCL / DML 167s

1105555

136

1708076

0.7

Danfoss

23Z83.10

Type

ABLD1D2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DCL / DML 303s

186

206

2248076

1.28

DCL / DML 304s

186

208

2288076

1.26

DCL / DML 305s

186

212

2368076

1.27

DCL / DML 306s

186

212

2408076

1.3

DCL / DML 307s

186

212

2468076

1.32

DCL / DML 309s

186

196

2508076

1.37

DCL / DML 414s

187

209

2299389

1.84

DCL / DML 415s

187

213

2379389

1.85

DCL / DML 417s

187

213

2479389

1.88

DCL / DML 419s

187

197

2519389

1.9

DCL / DML 604s

337

359

3798076

2.98

DCL / DML 606s

337

363

3918076

2.21

DCL / DML 607s

337

363

3978076

2.21

DCL / DML 609s

337

347

4018076

2.32

DCL / DML 757s

338

364

3989389

3.1

DCL / DML 759s

338

348

4029389

3.1

Hermetic lter drier Type DML and DCL

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 9

Danfoss

23Z8403

Type

Connection size

Multi pack

Industrial pack for OEM only

[in.]

[mm]

Code no.

Qty.

Code no.

Qty.

DCL 032

1⁄4

6

023Z5000

(1)(2)

32––

DCL 032

1⁄4

6

023Z5075

(2)

32––

DCL 033

3⁄8

10

023Z5001

(1) (2)

32––

DCL 033

3⁄8

10

023Z5089

(2)

32––

DCL 052

1⁄4

6

023Z5002

(2)

24

023Z8002

(2)

16

DCL 053

3⁄8

10

023Z5003

(2)

24

023Z8003

(2)

16

DCL 082

1⁄4

6

023Z5004

(2)

24

023Z8004

(2)

16

DCL 083

3⁄8

10

023Z5005

(2)

24

023Z8005

(2)

16

DCL 084

1⁄2

12

023Z5006

(2)

24––

DCL 162

1⁄4

6

023Z5007

(2)

12

023Z8007

(2)

12

DCL 163

3⁄8

10

023Z5008

(2)

12

023Z8008

(2)

12

DCL 164

1⁄2

12

023Z5009

(2)

12

023Z8009

(2)

12

DCL 165

5⁄8

16

023Z5010

(2)

12

023Z8010

(2)

12

DCL 166

3⁄4

19

023Z5011

(2)

12––

DCL 303

3⁄810023Z00128–

–

DCL 304

1⁄212023Z0013

8

023Z3013

8

DCL 305

5⁄816023Z0014

8

023Z3014

8

DCL 306

3⁄419023Z01568–

–

DCL 414

1⁄212023Z01028–

–

DCL 415

5⁄816023Z01038–

–

Danfoss

23Z8403

Type

Connection size

Multi pack

Industrial pack for OEM only

[in.]

[mm]

Code no.

Qty.

Code no.

Qty.

DML 032

1⁄4

6

023Z5035

(1) (2)

32

023Z8035

(1) (2)

28

DML 033

3⁄8

10

023Z5036

(1) (2)

32

023Z8036

(1)

28

DML 033

3⁄8

10

023Z5090

(2)

32––

DML 052

1⁄4

6

023Z5037

(2)

24

023Z8037

(2)

16

DML 053

3⁄8

10

023Z5038

(2)

24

023Z8038

(2)

16

DML 082

1⁄4

6

023Z5039

(2)

24

023Z8039

(2)

16

DML 083

3⁄8

10

023Z5040

(2)

24

023Z8040

(2)

16

DML 084

1⁄2

12

023Z5041

(2)

24

023Z8041

(2)

16

DML 085

5⁄8

16

023Z5073

(2)

24––

DML 162

1⁄4

6

023Z5042

(2)

12

023Z8042

(2)

12

DML 163

3⁄8

10

023Z5043

(2)

12

023Z8043

(2)

12

DML 164

1⁄2

12

023Z5044

(2)

12

023Z8044

(2)

12

DML 165

5⁄8

16

023Z5045

(2)

12

023Z8045

(2)

12

DML 166

3⁄4

19

023Z5046

(2)

12––

Hermetic lter drier Type DML and DCL

Ordering

Type DCL Flare

Figure 2: DCL Flare

Table 7: DCL Flare

(1)

(1)

Wire mesh in lter drier outlet

Wire mesh in lter drier outlet

(2)

(2)

India make is available with code 023ZXXXX91

India make is available with code 023ZXXXX91

Type DML Flare

Figure 3: DML Flare

Table 8: DML Flare

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 10

Type

Connection size

Multi pack

Industrial pack for OEM only

[in.]

[mm]

Code no.

Qty.

Code no.

Qty.

DML 303

3⁄810023Z0049

8

023Z3049

8

DML 304

1⁄212023Z0050

8

023Z3050

8

DML 305

5⁄816023Z0051

8

023Z3051

8

DML 306

3⁄419023Z0193

8

023Z3193

8

DML 385

5⁄816023Z01898–

–

DML 413

3⁄810023Z01088–

–

DML 414

1⁄212023Z01098–

–

DML 415

5⁄816023Z0110

8

023Z3110

6

DML 416

3⁄419023Z0195

8

023Z0210

6

Danfoss

23Z8405

Type

Conn. Size

Multi pack

Industrial pack for OEM

only

Conn. Size

Multi pack

Industrial pack for OEM

only

[in.]

Code no.

Qty.

Code no.

Qty.

[mm]

Code no.

Qty.

Code no.

Qty.

DCL 032s

1⁄4

023Z4501

(1)

32

023Z4801

(1)

28

6

023Z4500

(1)

32

023Z4800

(1)

28

DCL 032.5s

5⁄16

023Z4502

(1)

32

023Z4803

(1)

288–––

–

DCL 033s

3⁄8

023Z4504

(1)

32––10023Z4503

(1)

32––

DCL 052s

1⁄4

023Z4506

(1)

24

023Z4805 2)166

023Z4505

(1)

24

023Z4804

(1)

16

DCL 052s

5⁄16

023Z4507

(1)

24––10–––

–

DCL 053s

3⁄8

023Z4509

(1)

24

023Z4807

(1)

16

10

023Z4508

(1)

24––

DCL 082s

1⁄4

023Z4511

(1)

24––6023Z4510

(1)

24––

DCL 082s

5⁄16

023Z4512

(1)

28––6–––

–

DCL 083s

3⁄8

023Z4514

(1)

24

023Z4811

(1)

16

10

023Z4513

(1)

24

023Z4809

(1)

16

DCL 084s

1⁄2

023Z4516

(1)

24

023Z4813

(1)

16

12

023Z4515

(1)

24––

DCL 162s

1⁄4

023Z4518

(1)

12––6023Z4517

(1)

12––

DCL 163s

3⁄8

023Z4521

(1)

12––10023Z4519

(1)

12

023Z4814

12

DCL 164s

1⁄2

023Z4523

(1)

12

023Z4815

(1)

12

12

023Z4522

(1)

12––

DCL 165s

5⁄8

023Z4524

(1)

12

023Z4816

(1)

1212–––

–

DCL 166s

3⁄4

023Z4525

(1)

12––––––

–

DCL 167s

7⁄8

023Z4526

(1)

12––––––

–

DCL 303s

3⁄8

023Z4528

8

023Z4817810

023Z45278–

–

DCL 304s

1⁄2

023Z45308––12

023Z45298–

–

DCL 305s

5⁄8

023Z4531

8

023Z4819816–8––

DCL 306s

3⁄4

023Z45338––18

023Z45328–

–

DCL 307s

7⁄8

023Z4534

8

023Z4820822–8––

DCL 309s

11⁄8

023Z45368––28

023Z45358–

–

DCL 414s

1⁄2

023Z45388––12–8––

DCL 415s

5⁄8

023Z45398––16–8––

DCL 417s

7⁄8

023Z45408––22–8––

DCL 419s

11⁄8

023Z45428––28

023Z45418–

–

DCL 604s

1⁄2

023Z454412––22––––

DCL 607s

7⁄8

023Z45456––22––––

DCL 609s

11⁄8–12––28023Z45466–

–

DCL 757s

7⁄8

023Z454812––22––––

DCL 759s

11⁄8

023Z455012––28

023Z454912–

–

Hermetic lter drier Type DML and DCL

(1)

(1)

Wire mesh in lter drier outlet

Wire mesh in lter drier outlet

(2)

(2)

India make is available with code 023ZXXXX91

India make is available with code 023ZXXXX91

Type DCL Solder (cu-plated steel connectors)

Figure 4: DCL Solder

Table 9: DCL Solder

(1)

(1)

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 11

India make is available with code 023ZXXXX91

India make is available with code 023ZXXXX91

Danfoss

23Z8405

Type

Conn. Size

Multi pack

Industrial pack for OEM

only

Conn. Size

Multi pack

Industrial pack for OEM

only

[in.]

Code no.

Qty.

Code no.

Qty.

[mm]

Code no.

Qty.

Code no.

Qty.

DML 032s

1⁄4

023Z4552

(1)

32

023Z4822

(1)

28

6

023Z4551

(1)

32

023Z4821

(1)

28

DML 032.5s

5⁄16

023Z4553

(1)

32

023Z4823

(1)

288–––

–

DML 033s

3⁄8

023Z4555

(1)

32

023Z4825

(1)

28

10

023Z4554

(1)

32

023Z4824

(1)

28

DML 034s

1⁄2

023Z4556

(1)

32––12023Z455732–

–

DML 052s

1⁄4

023Z4559

(1)

24

023Z4849

(1)

16

6

023Z4558

(1)

24

023Z4826

(1)

16

DML 052.5s

5⁄16

023Z4560

(1)

24––6–––

–

DML 053s

3⁄8

023Z4562

(1)

24

023Z4828

(1)

1610023Z4561

28

023Z4827

(1)

16

DML 054s

1⁄2

023Z4564

(1)

24––12023Z4563

(1)

12

023Z4845

(1)

16

DML 055s

5⁄8

023Z4565

(1)

24

023Z4838

(1)

1616–––

–

DML 082s

1⁄4

023Z4567

(1)

24

023Z4847

(1)

16

6

023Z4566

(1)

24

023Z4866

(1)

16

DML 082.5s

5⁄16

023Z456824––8––––

DML 083s

3⁄8

023Z4570

(1)

24

023Z4835

(1)

1610023Z4569

24

023Z4839

(1)

16

DML 084s

1⁄2

023Z4572

(1)

24

023Z4829

(1)

16

12

023Z4571

(1)

24

023Z4840

(1)

16

DML 085s

5⁄8

023Z4573

(1)

24––16–––

–

DML 162s

1⁄4

023Z4575

(1)

12––6023Z4574

(1)

12––

DML 163s

3⁄8

023Z4578

(1)

12

023Z4836

(1)

12

10

023Z4577

(1)

12

023Z4842

(1)

12

DML 164s

1⁄2

023Z4580

(1)

12

023Z4830

(1)

12

12

023Z4579

(1)

12

023Z4843

(1)

12

DML 165s

5⁄8

023Z4581

(1)

12

023Z4831

(1)

1216–––

–

DML 166s

3⁄4

023Z4582

(1)

12

023Z4832

(1)

1219–––

–

DML 167s

7⁄8

023Z4583

(1)

12––22–––

–

DML 303s

3⁄8

023Z45858––10

023Z45848–

–

DML 304s

1⁄2

023Z4587

8

023Z4837812

023Z4586

8

023Z4844

8

DML 305s

5⁄8

0023Z4588

8

023Z4833816––––

DML 306s

3⁄4

023Z4589

8

023Z4848819––––

DML 307s

7⁄8

023Z4590

8

023Z4834822––––

DML 309s

11⁄8

023Z45928––28

023Z45918–

–

DML 414s

1⁄2

023Z45948––12

023Z45938–

–

DML 415s

5⁄8

023Z45958––16––––

DML 417s

7⁄8

023Z4596

8

023Z4896622––––

DML 419s

11⁄8

023Z4598

8

023Z4898628

023Z45978–

–

DML 604s

1⁄2

023Z460012––12

023Z459912–

–

DML 605s

1⁄2––––18023Z46016–

–

DML 607s

7⁄8

023Z4602

6

023Z4902–22––––

DML 609s

11⁄8

023Z460412––28

023Z460312–

–

DML 757s

7⁄8

023Z4605

12

023Z4905422––––

DML 759s

11⁄8

023Z4607

12

023Z4907428

023Z460612–

–

Hermetic lter drier Type DML and DCL

Type DML Solder (cu-plated steel connectors)

Figure 5: DML Solder

Table 10: DML Solder

(1)

(1)

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 12

India make is available with code 023ZXXXX91

India make is available with code 023ZXXXX91

Document type

Approval authority

Manufacturer declaration for PED/ROHS/ATEX

Danfoss

UL certicate

UL

EAC document

EAC

Manufacturer declaration for china ROHS

Danfoss

Hermetic lter drier Type DML and DCL

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 11: Certicates, declarations, and approvals

WARNING:

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for ammable

refrigerants now.

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI192386435941en-001401 | 14

Loading...

Loading...