Page 1

Data Sheet

Hermetic bi-flow filter drier

Type DMB and DCB

DMB and DCB are for use in liquid lines on heat pumps.

Hermetic bi-ow lter driers, types DMB and

DCB are for use in liquid lines on heat pumps.

Hermetic bi-ow lter driers have built-in check

valves which ensure that refrigerant liquid

always ows through the lter driers from the

outer side of the lter core towards the center.

Thus all dirt particles are retained irrespective

of ow direction.

DMB and DCB lter driers ensure fast and

eective adsorption of moisture as well as

organic and inorganic acids.

When building heat pump systems, the use of

bi-ow lters can, depending on the type of

system, save up to ten solder connections. This

reduces production costs and the number of

potential leakage points.

Available with are and solder (cu-plated steel)

connections.

For other connections please contact your

Danfoss Sales Representative.

AI192386436430en-000401en-000401

Page 2

Filter

Solid core surface

Solid core volume

Filter drier volume

(shell volume)

Filter drier volume

(net volume)

[cm

2

]

[cm

3

]

[l]

[l]

DMB/DCB 087380

0.10

0.088

DMB/DCB 16

100

145

0.30

0.234

DMB/DCB 30

250

365

0.49

0.322

Hermetic bi-ow lter drier, Type DMB and DCB

Features

The Core type DMB

• 100% 3Å Molecular Sieve core

• High drying capacity minimizing the risk of acid formation (hydrolysis)

• Recommended for use with HFO, HC, HFC and HCFC refrigerants

• Will not deplete oil additives

The Core type DCB

• 80% 3Å Molecular Sieve with 20% activated alumina

• Perfect core blend for systems that operate at high condensing temperatures and require high drying capacity

• Recommended for use with HFO, HC, HFC and HCFC refrigerants

The Shell

• PED approved for PS 46 bar

• Available with are and solder (cu-plated steel) connections

• Optimum ow characteristics and dirt retention

• The check valves are not sensitive to dirt and give minimum restriction, irrespective of ow direction

The Filter

• Eective dirt removal to 25 μm

• No dirt released by reversing the ow direction

• Available in sizes 8 – 30 cubic inches

Construction

Figure 1: Flow direction

Product specication

Technical data

Figure 2: Flare connection

Table 1: Surface and volume

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 2

Page 3

DMB164

s

Filter

Acid capacity

(1)

[g]

DCB 08

0.96

DCB 16

1.29

DCB 30

3.16

Type

Codes

Description

Filter drier

D

Drier

Solid core

C

80% Molecular Sieve / 20% activated alumina

M

100% Molecular Sieve core

Application

B

Bi-ow

Filter housing volume (approx.)

08

8 in.

3

16

16 in.

3

30

30 in.

3

Connection (lter connection in 1⁄8 of an inch increments)

2

1

⁄4

in. / 6 mm

3

3

⁄8

in. / 10 mm

4

1

⁄2

in. / 12 mm

5

5

⁄8

in. / 16 mm

7

7

⁄8

in. / 22 mm

9

1

1

⁄8 in.

Connection type

(blank)

Flare connection

s

Solder connection (cu-plated steel connector)

Filter drier

Solid core

Application

Size (volume)

Connection (lter connection in 1⁄8 of an inch increments)

Connection type

Hermetic bi-ow lter drier, Type DMB and DCB

Figure 3: Solder connection (cu-plated steel)

Table 2: Acid capacity

(1)

(1)

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Temperature range:

-40 – 70 °C

Dirt retention

Particles > 25 μm

Identication

Table 3: Type codes

Example for type codes

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 3

Page 4

Refrigerant and oil types

DCB

DMB

Refrigerant

HFO

Recommended

Recommended

HC

(1)

Recommended

Recommended

HFC

Recommended

Recommended

HCFC

Recommended

Recommended

Oil

Mineral or AB

Recommended

Recommended

POE or PAG, pure

Recommended

Recommended

POE or PAG, with additives

Not recommended

(2)

Recommended

Type

Drying capacity [kg] refrigerant 1) Liquid capacity [kW] 2) Max.

Working

Pressure

PS

R134a R404A R507 R22 R407C R410A

R134a R404A R507 R22 R407C R410A

[°C]

24 52 24 52 24 52 24 52 24 52 24 52

[bar]

DMB 082/082s 9.1 8.6 9.7 9.2 9.9 9.2 9.2 8.5 9.1 8.4 8.3 7.6 3.9 2.8 2.8 4.3 4.3 4.3 46

DMB 083/083s 9.1 8.6 9.7 9.2 9.9 9.2 9.2 8.5 9.1 8.4 8.3 7.6 7.4 5.3 5.3 8.2 8.2 8.2 46

DMB 084/084s 9.1 8.6 9.7 9.2 9.9 9.2 9.2 8.5 9.1 8.4 8.3 7.6 8.3 6.0 6.0 9.2 9.2 9.2 46

DMB 162 17.1 16.2 18.4 17.4 18.7 17.3 17.3 16.0 17.1 15.8 15.6 14.4 7.6 5.3 5.3 8.8 8.8 8.8 46

DMB 163/163s 17.1 16.2 18.4 17.4 18.7 17.3 17.3 16.0 17.1 15.8 15.6 14.4 18.0 13.0 13.0 20.0 20.0 20.0 46

DMB 164/164s 17.1 16.2 18.4 17.4 18.7 17.3 17.3 16.0 17.1 15.8 15.6 14.4 28.0 20.0 20.0 32.0 32.0 32.0 46

DMB 165/165s 17.1 16.2 18.4 17.4 18.7 17.3 17.3 16.0 17.1 15.8 15.6 14.4 37.0 29.0 29.0 40.0 40.0 40.0 46

DMB 303 42.0 39.7 45.2 42.8 46.0 42.5 42.5 39.3 42.1 38.9 38.3 35.3 19.0 15.0 15.0 21.0 21.0 21.0 46

DMB 304/304s 42.0 39.7 45.2 42.8 46.0 42.5 42.5 39.3 42.1 38.9 38.3 35.3 28.0 20.0 20.0 31.0 31.0 31.0 46

DMB 305/305s 42.0 39.7 45.2 42.8 46.0 42.5 42.5 39.3 42.1 38.9 38.3 35.3 38.0 28.0 28.0 42.0 42.0 42.0 46

DMB 307s 42.0 39.7 45.2 42.8 46.0 42.5 42.5 39.3 42.1 38.9 38.3 35.3 43.0 32.0 32.0 47.0 47.0 47.0 46

Type

A

L

D1D

2

Net weight

[mm]

[mm]

[mm]

[mm]

[Kg]

DMB/DCB 082

103

1475854

0.50

DMB/DCB 083

103

1605854

0.50

DMB/DCB 084

103

1685854

0.60

Hermetic bi-ow lter drier, Type DMB and DCB

Selection

Table 4: Type selection is made considering the application

(1)

(1)

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for ammable refrigerants now

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for ammable refrigerants now

(2)

(2)

DCB Hermetic lter driers contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar

DCB Hermetic lter driers contain activated alumina, which is a polar material used for acid adsorption. Many oil additives are also polar

substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not

substances and can be adsorbed by the activated alumina, rendering them useless, and reducing the drier’s acid capacity, though this is not

harmful to the system

harmful to the system

Selection example

Select the appropriate type (DMB or DCB) based on refrigerant and oil type. Then select the drier size based on the

adsorption and liquid capacity required.

• Amount of charge: 15 kg R134a at tL = 24 °C To dry 15 kg R134a at 24 °C from 1050 to 60 ppm moisture, a DMB 16

is necessary

• Cooling capacity: Qe = 25 kW, To obtain a mass ow corresponding to 25 kW cooling capacity with a DMB 16 lter

drier, a 1⁄2 inch connection must be chosen. Larger connections can be chosen in accordance with the liquid line

dimension

• Result DMB 164 or DMB 165 can be used

If the initial moisture content is very small or a planned change of the lter drier is considered, a smaller lter drier

size can be chosen.

Dimensions and weights

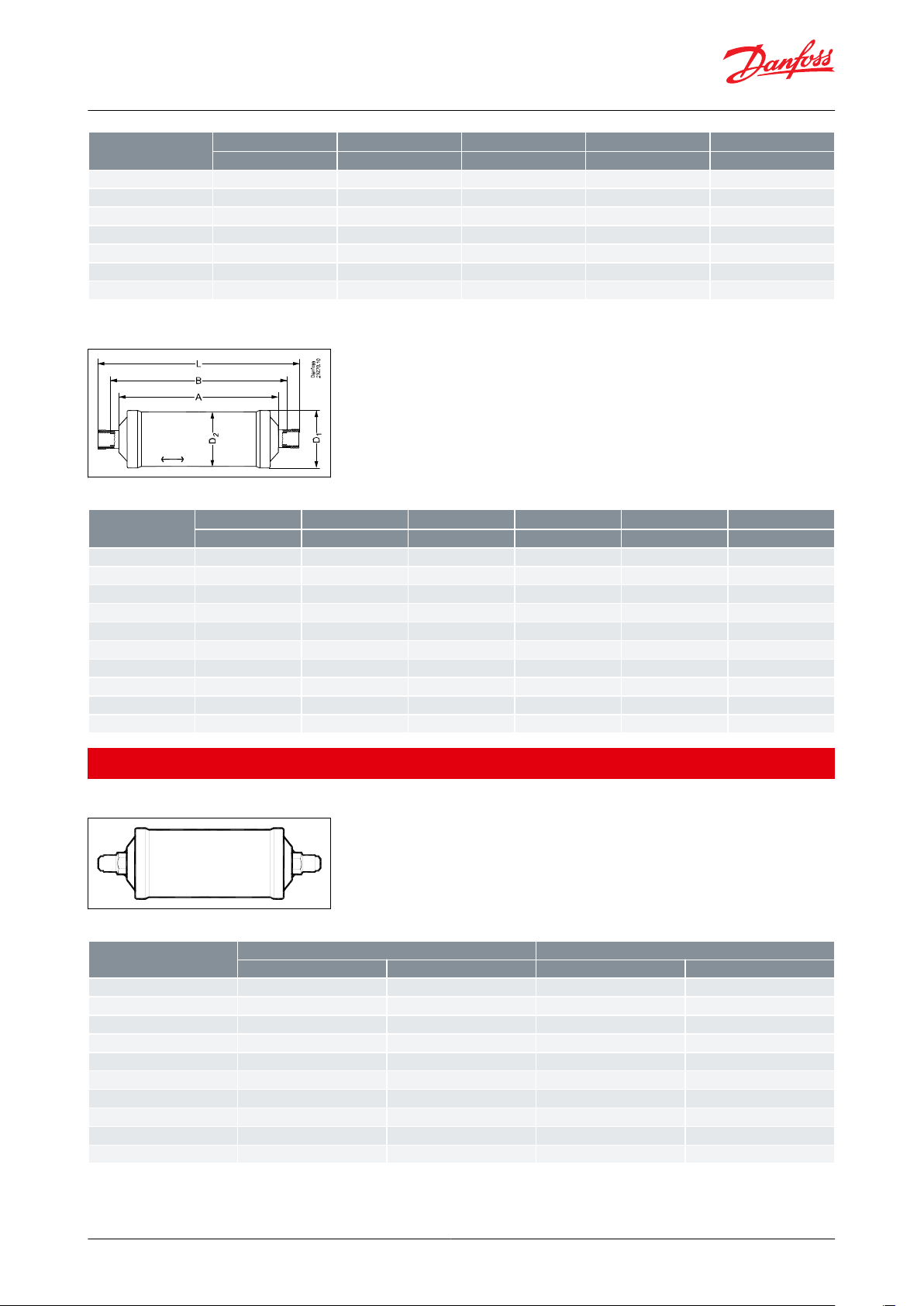

Figure 4: Flare connections

Table 5: DMB and DCB

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 4

Page 5

Type

A

L

D1D

2

Net weight

[mm]

[mm]

[mm]

[mm]

[Kg]

DMB/DCB 162

112

1568076

0.80

DMB/DCB 163

112

1698076

0.80

DMB/DCB 164

112

1778076

0.90

DMB/DCB 165

112

1868076

0.90

DMB/DCB 303

188

2458076

1.10

DMB/DCB 304

188

2538076

1.2

DMB/DCB 305

188

2628076

1.2

Type

ABL

D1D

2

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DMB/DCB 082s

103

119

1355854

0.50

DMB/DCB 083s

103

122

1415854

0.50

DMB/DCB 084s

103

124

1455854

0.60

DMB/DCB 163s

112

131

1508076

0.80

DMB/DCB 164s

112

133

1548076

0.80

DMB/DCB 165s

112

136

1608076

0.90

DMB/DCB 304s

188

209

2308076

1.00

DMB/DCB 305s

188

212

2368076

1.10

DMB/DCB 307s

188

214

2508076

1.10

DMB 309s

188

198

2528076

1.44

Type

Conn.

Multi pack

[in.]

[mm]

Qty.

Code no.

DMB 082

1

⁄4

624023Z1412

DMB 083

3

⁄8

1024023Z1411

DMB 084

1

⁄2

1224023Z1410

DMB 162

1

⁄4

612023Z1416

DMB 163

3

⁄8

1012023Z1415

DMB 164

1

⁄2

1212023Z1414

DMB 165

5

⁄8

1612023Z1413

DMB 303

3

⁄8

108023Z1419

DMB 304

1

⁄2

128023Z1418

DMB 305

5

⁄8

168023Z1417

Hermetic bi-ow lter drier, Type DMB and DCB

Figure 5: Solder connection (cuplated steel connectors)

Table 6: DMB and DCB

Ordering

Figure 6: Flare connection

Table 7: Type DMB are

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 5

Page 6

Type

Conn.

Multi pack

[in.]

[mm]

Qty.

Code no.

DCB 082

1

⁄4

624023Z1402

DCB 083

3

⁄8

1024023Z1401

DCB 084

1

⁄2

1224023Z1400

DCB 162

1

⁄4

612023Z1406

DCB 163

3

⁄8

1012023Z1405

DCB 164

1

⁄2

1212023Z1404

DCB 165

5

⁄8

1612023Z1403

DCB 303

3

⁄8

108023Z1409

DCB 304

1

⁄2

128023Z1408

DCB 305

5

⁄8

168023Z1407

Type

Conn.

Multi pack

Industrial pack

Conn.

Multi pack

[in.]

Qty.

Code no.

Qty.

Code no.

[mm]

Qty.

Code no.

DMB 082s

1

⁄4

24

023Z1473––624

023Z1461

DMB 083s

3

⁄8

24

023Z1472

16

023Z16721024

023Z1459

DMB 084s

1

⁄2

24

023Z1471

16

023Z16711224

023Z1457

DMB 163s

3

⁄8

12

023Z1476

12

023Z16761012

023Z1455

DMB 164s

1

⁄2

12

023Z1475

12

023Z16751212

023Z1453

DMB 165s

5

⁄8

12

023Z1474

12

023Z1674––

–

DMB 303s

3

⁄8

8

023Z1481––––

–

DMB 304s

1

⁄2

8

023Z1479––128

023Z1451

DMB 305s

5

⁄8

8

023Z1478

8

023Z1487––

–

DMB 307s

7

⁄8

8

023Z1477

8

023Z1498––

–

DMB 309s

1

1

⁄8

––8

023Z1493––

–

Type

Conn.

Multi pack

Industrial pack

Conn.

Multi pack

[in.]

Qty.

Code no.

Qty.

Code no.

[mm]

Qty.

Code no.

DCB 082s

1

⁄4

24

023Z1464––––

–

DCB 083s

3

⁄8

24

023Z1463––1024

023Z1458

DCB 084s

1

⁄2

24

023Z1462––––

–

DCB 163s

3

⁄8

12

023Z1467––––

–

DCB 164s

1

⁄2

12

023Z1466

12

023Z16661212

023Z1452

DCB 165s

5

⁄8

12

023Z1465

12

023Z1665––

–

DCB 304s

1

⁄2

8

023Z1470––––

–

DCB 305s

5

⁄8

8

023Z1469––––

–

DCB 307s

7

⁄8

8

023Z1468––––

–

Hermetic bi-ow lter drier, Type DMB and DCB

Table 8: Type DCB are

Figure 7: Solder (cu-plated steel

connectors)

Table 9: Type DMB Solder (cu-plated steel connectors)

Table 10: Type DCB Solder (cu-plated steel connectors)

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 6

Page 7

Document name

Document type

Document topic

Approval authority

SA 6398

UL Certicate

Mechanical Safety Certicate

UL

023Z9601.AF

Manufacturer's Declaration

ATEX/PED/RoHS

Danfoss

023Z9610.AA

Manufacturer's Declaration

China RoHS

Danfoss

RU Д-DK.АИ08.B.00828_19

EAC Declaration

Machinery & Equipment

EAC

Hermetic bi-ow lter drier, Type DMB and DCB

Table 11: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 7

Page 8

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.08 AI192386436430en-000401en-000401 | 8

Loading...

Loading...