Technical Information

PLUS+1® Mobile Machine Displays

DM430M Series

www.danfoss.com

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

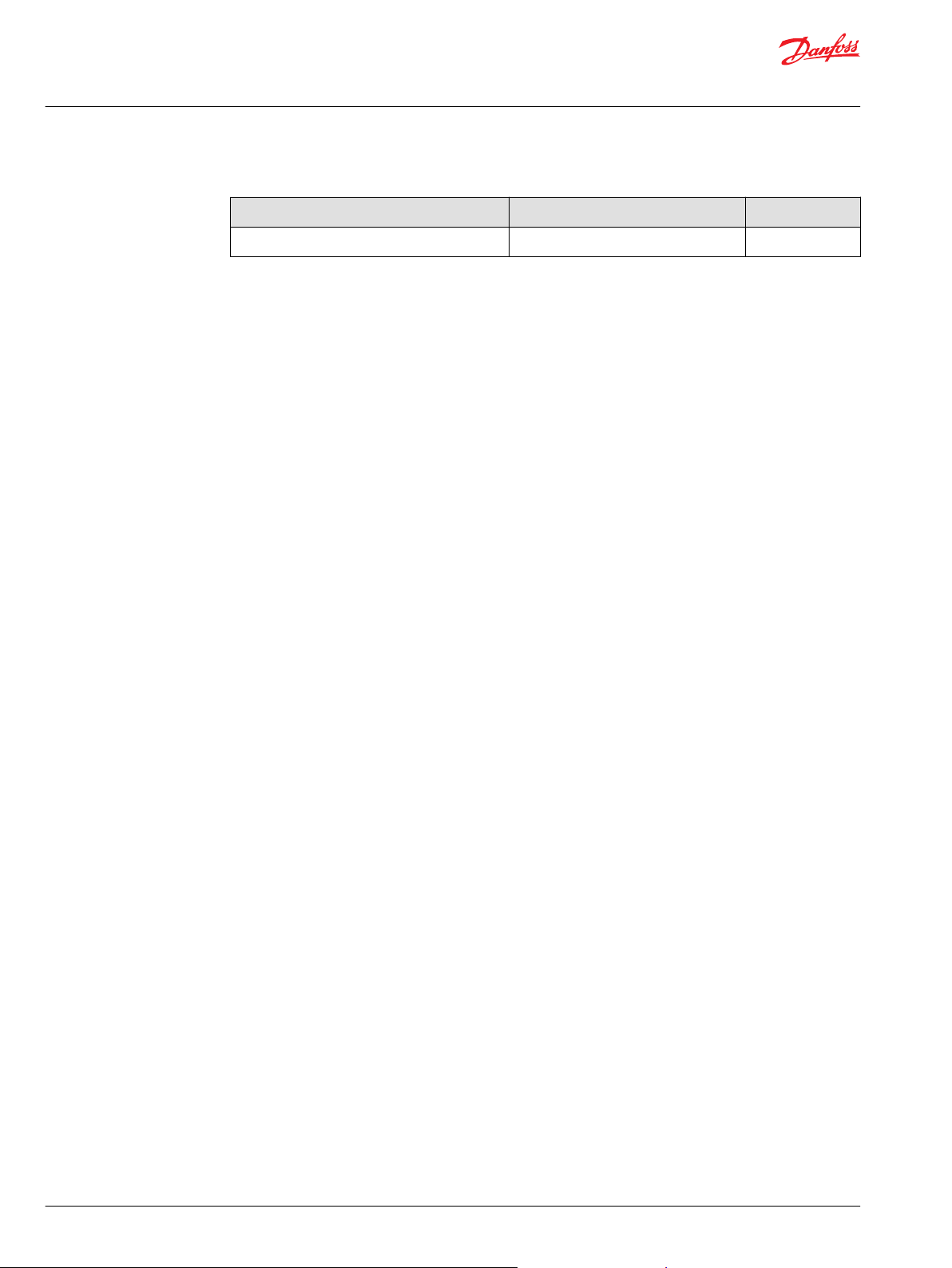

Revision history Table of revisions

Date Changed Rev

February 2021 First edition 0101

2 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Contents

DM430M literature references

Technical Information (TI)............................................................................................................................................................. 4

Data Sheet (DS)................................................................................................................................................................................. 4

PLUS+1® GUIDE User Manual....................................................................................................................................................... 4

Latest version of technical literature.........................................................................................................................................4

User liability and safety statements

OEM responsibility........................................................................................................................................................................... 5

Safety statements.............................................................................................................................................................................5

Display operation guidelines..................................................................................................................................................5

Machine wiring guidelines...................................................................................................................................................... 6

Machine welding guidelines...................................................................................................................................................6

Overview

DM430M Series Displays................................................................................................................................................................7

PLUS+1® GUIDE............................................................................................................................................................................ 7

LCD features..................................................................................................................................................................................7

Ordering information

Model variants...................................................................................................................................................................................8

Model code.........................................................................................................................................................................................8

Model code key.................................................................................................................................................................................8

Related products...............................................................................................................................................................................9

Input/output types and specifications

Input types........................................................................................................................................................................................10

Digital/analog..................................................................................................................................................................................10

Multifunction inputs..................................................................................................................................................................... 11

CAN shield and analog input.....................................................................................................................................................13

Alarm output................................................................................................................................................................................... 13

CAN communication.....................................................................................................................................................................13

USB communication..................................................................................................................................................................... 14

RS232 communication.................................................................................................................................................................14

Product ratings

DM430M environmental testing criteria............................................................................................................................... 15

Supply voltage/maximum current ratings........................................................................................................................... 15

Ingress Protection (IP) rating .................................................................................................................................................... 16

Installation

DM430M Series Displays dimensions.....................................................................................................................................17

Pin assignments..............................................................................................................................................................................17

Mounting.......................................................................................................................................................................................... 18

Fastening...........................................................................................................................................................................................20

Visibility and viewing radius...................................................................................................................................................... 21

Display faulty application recovery.........................................................................................................................................21

Cleaning............................................................................................................................................................................................ 21

©

Danfoss | February 2021 BC370081692721en-000101 | 3

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

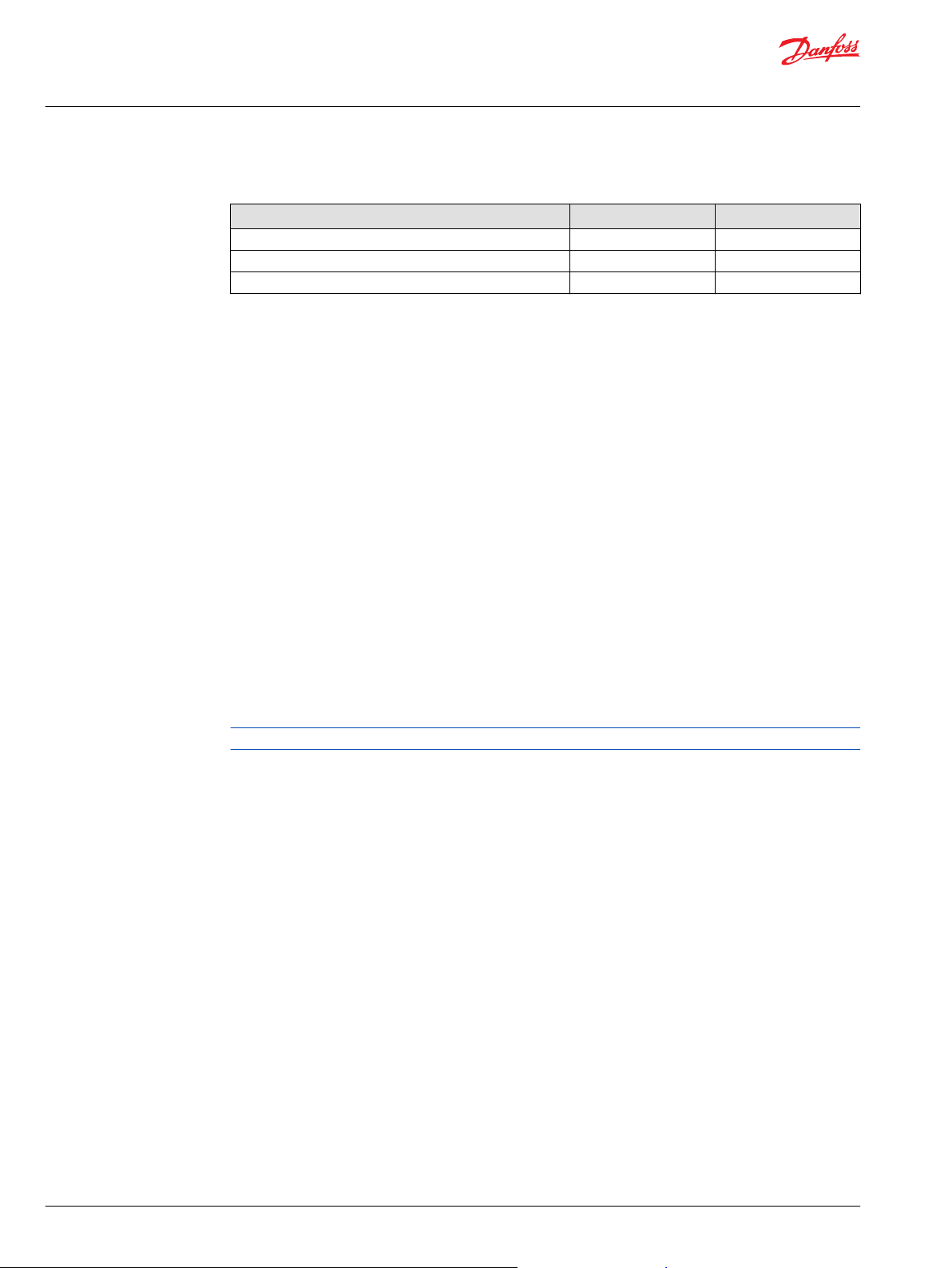

DM430M literature references

Reference literature

Literature title Literature type Literature number

DM430M Series PLUS+1® Mobile Machine Displays Technical Information BC370081692721

DM430M Series PLUS+1® Mobile Machine Displays Data Sheet AI370083437722

PLUS+1® GUIDE Software User Manual AQ152886483724

Technical Information (TI)

A TI is comprehensive information for engineering and service personnel to reference.

Data Sheet (DS)

A DS is summarized information and parameters that are unique to a specific model.

PLUS+1® GUIDE User Manual

The Operation Manual (OM) details information regarding the PLUS+1® GUIDE tool used in building PLUS

+1® applications. This OM covers the following broad topics:

How to use the PLUS+1® GUIDE graphical application development tool to create machine

•

applications

How to configure module input and output parameters

•

How to download PLUS+1® GUIDE applications to target PLUS+1® hardware modules

•

How to upload and download tuning parameters

•

How to use the PLUS+1® Service Tool

•

Latest version of technical literature

Comprehensive technical literature is online at www.danfoss.com

4 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

User liability and safety statements

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

Safety statements

Display operation guidelines

•

Disconnect your machine's battery power before connecting power and signal cables to the display.

•

Before doing any electrical welding on your machine, disconnect all power and signal cables

connected to the display.

•

Do not exceed the display power supply voltage ratings. Using higher voltages may damage the

display and can create a fire or electrical shock hazard.

•

Do not use or store the display where flammable gases or chemicals are present. Using or storing the

display where flammable gases or chemicals are present may cause an explosion.

•

Software configures the keypad buttons on the display. Do not use these buttons to implement

critical safety features. Use separate mechanical switches to implement critical safety features such as

emergency stops.

•

Design systems that use the display so that a communication error or failure between the display and

other units cannot cause a malfunction that might injure people or damage material.

•

The protective glass over the display screen will break if hit with a hard or heavy object. Install the

display to reduce the possibility of it being hit by hard or heavy objects.

•

Storing or operating a display in an environment that exceeds the display specified temperature or

humidity rating may damage the display.

•

Always clean the display with a soft, damp cloth. Use a mild dishwashing detergent as needed. To

avoid scratching and discoloring the display, do not use abrasive pads, scouring powders, or solvents

such as alcohol, benzene, or paint thinner.

•

Keep ambient light sensor area clean and uncovered for best operation.

•

Danfoss graphical displays are not user serviceable. Return the display to the factory in case of failure.

©

Danfoss | February 2021 BC370081692721en-000101 | 5

W

C

W

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

User liability and safety statements

Machine wiring guidelines

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Improperly protected power input lines against over current conditions may cause damage to the

hardware. Properly protect all power input lines against over-current conditions. To protect against

unintended movement, secure the machine.

Caution

Unused pins on mating connectors may cause intermittent product performance or premature failure.

Plug all pins on mating connectors.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

Machine welding guidelines

Warning

High voltage from power and signal cables may cause fire or electrical shock, and cause an explosion if

flammable gasses or chemicals are present.

Disconnect all power and signal cables connected to the electronic component before performing any

electrical welding on a machine.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

6 | © Danfoss | February 2021 BC370081692721en-000101

C

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Overview

DM430M Series Displays

The DM430M series 4.3" displays are the first ruggedized displays that Danfoss is introducing to the

marine market after many years of experience building rugged equipment.

The DM430M series displays come marine pre-certified with the American Bureau of Shipping (ABS) Type

Approval, decreasing machine certification time and reducing time to market.

As the visual interface for the machine, the DM430M series provide customers with a modern, yet rugged

design. As well as supreme screen viewing quality and a wide range of features.

The optically-bonded and anti-glare coated screen is optimized for usage in all lighting conditions. It

provides outstanding sunlight viewability and wide wide viewing angles. In darker settings, the light

sensor automatically adjusts screen brightness and switches between day and night display themes.

With the Engine Information Center (EIC) application, the DM430M series displays can be set up in a

matter of minutes with pre-defined screen graphics and without any programming.

PLUS+1® GUIDE

PLUS+1® GUIDE (Graphical User Integrated Development Environment) is a complete toolbox that

generates downloadable applications for all programmable PLUS+1® Compliant products.

A screen editor allows easy development of applications by programmers without formal software

development training. The expertise from a software engineer is not needed to find your way around in

PLUS+1® GUIDE.

Caution

Unwanted system failure may occur.

Refer to PLUS+1® GUIDE Software User Manual, AQ152886483724 for best programming practices.

https://www.danfoss.com/en/products/software/dps/plus1-software/plus1-guide/#tab-overview

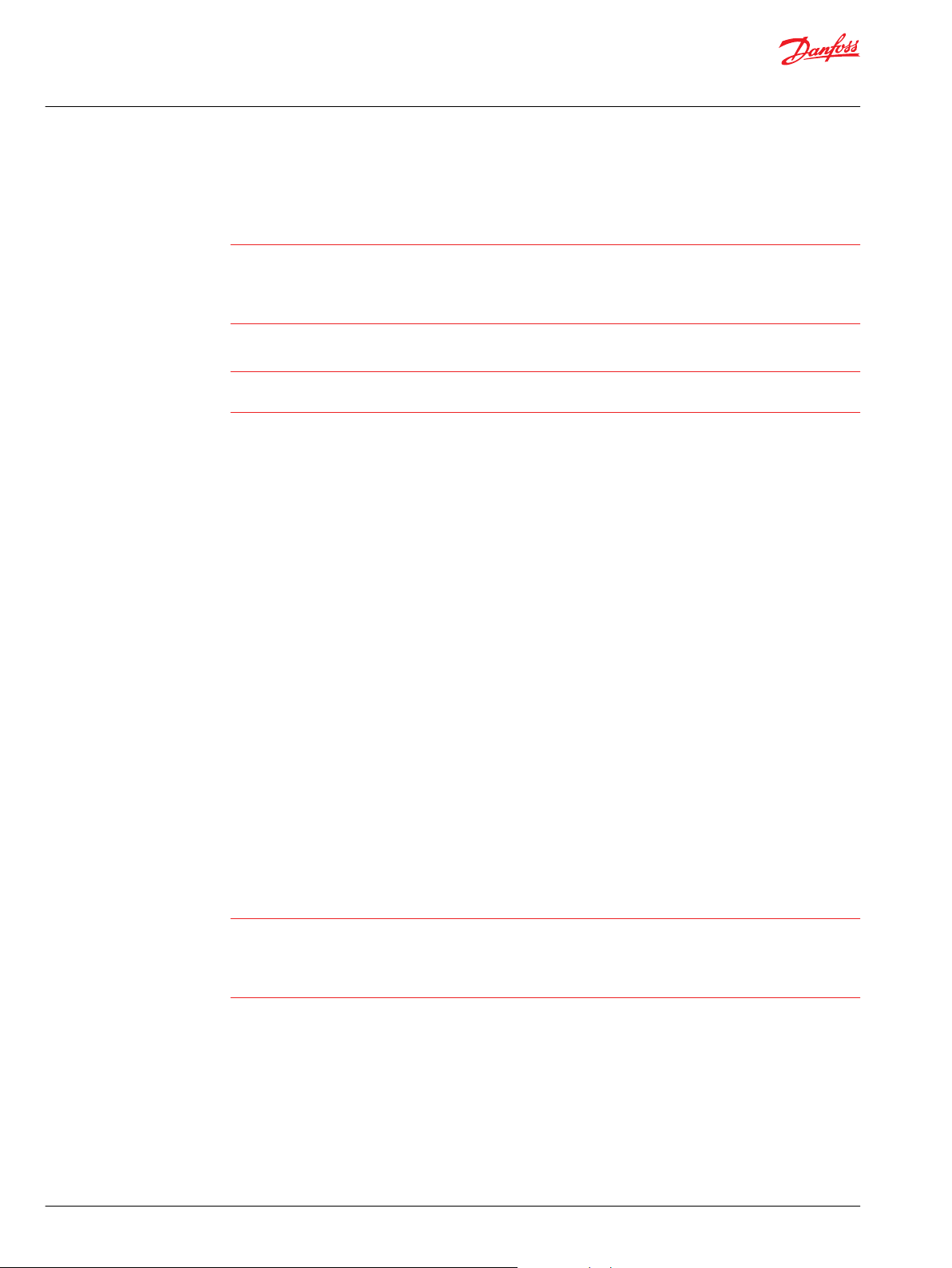

LCD features

DM430M Series Display LCD

Description Values Unit Notes

Min. Typ. Max.

Screen size 4.3 Inch

Resolution 480 x 272 Pixels

Aspect ratio WQVGA Wide Quarter

Luminance 700 800 cd/m

Contrast ratio 500:1

Viewing angle ± 70 Degree Top, bottom, left,

Color depth 24 Bits 8 bits per color

Programmable

ambient light

sensor

2

Video Graphics

Array

right

OSRAM SFH3410

©

Danfoss | February 2021 BC370081692721en-000101 | 7

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

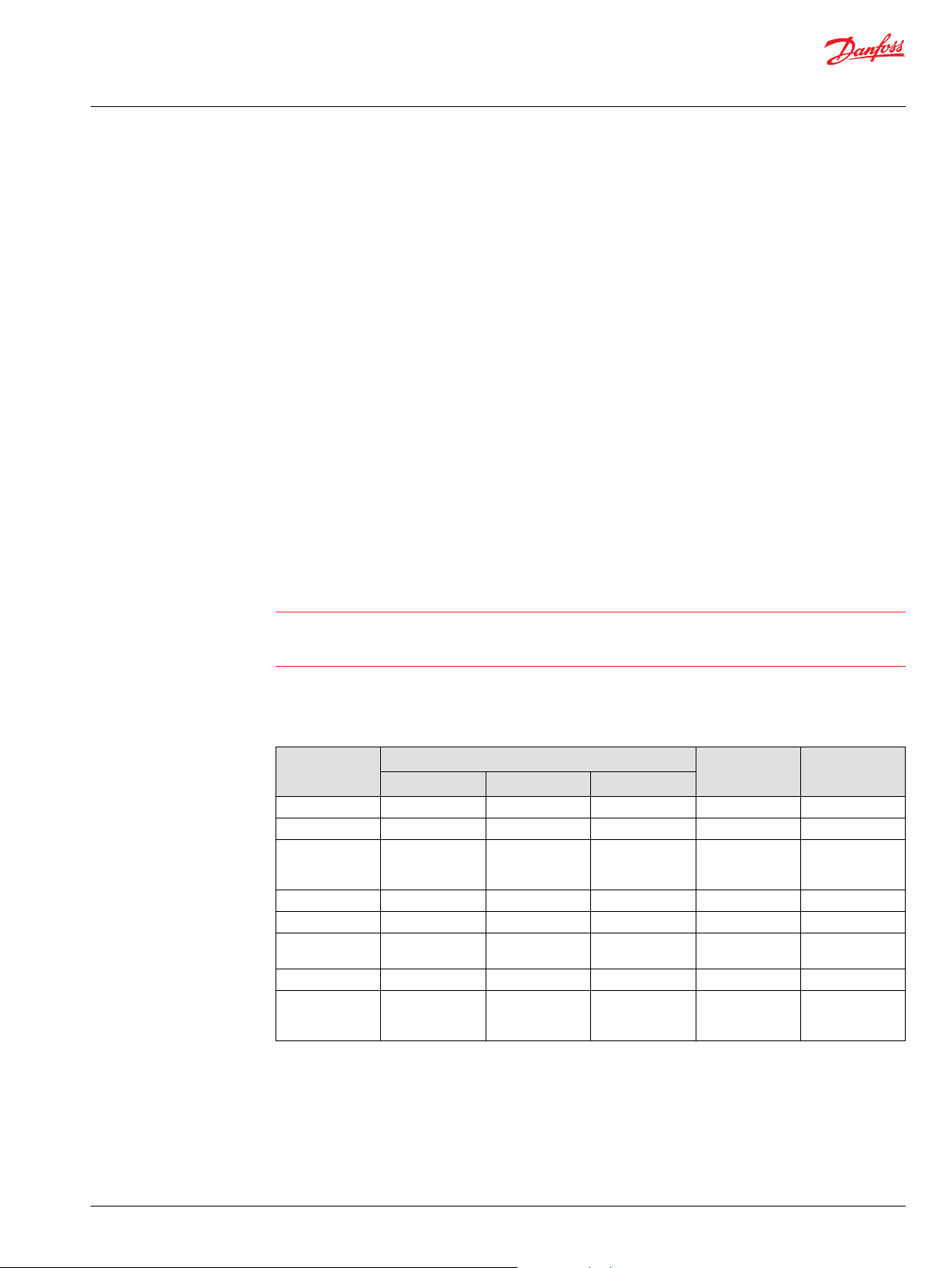

Ordering information

Model variants

Model code Part number

DM430M-0-0-0-0 11267564

DM430M-0-0-1-0 11267565

DM430M-0-1-0-0 11267566

DM430M-0-1-1-0 11267567

DM430M-1-0-0-0 11267568

DM430M-1-0-1-0 11267569

DM430M-1-1-0-0 11267570

DM430M-1-1-1-0 11267571

DM430M-2-0-0-0 11267592

DM430M-2-0-1-0 11267593

DM430M-2-1-0-0 11267594

DM430M-2-1-1-0 11267595

DM430M-0-0-0-1 11267541

DM430M-0-0-1-1 11267602

DM430M-0-1-0-1 11267603

DM430M-0-1-1-1 11267604

DM430M-1-0-0-1 11267605

DM430M-1-0-1-1 11267591

DM430M-1-1-0-1 11267612

DM430M-1-1-1-1 11267574

DM430M-2-0-0-1 11267606

DM430M-2-0-1-1 11267607

DM430M-2-1-0-1 11267608

DM430M-2-1-1-1 11267609

Model code

A B C D E

DM430M

Model code key

A—Model name Description

DM430M 4.3" Color Graphical Display

B—Inputs/Outputs Description

0 1 CAN Port, 4DIN/AIN, 2 MFIN

1 2 CAN Port, 2DIN/AIN, 2 MFIN

2 1 CAN Port, 2DIN/AIN, 2 MFIN, Sensor Power

C—M12 connector Description

0 No USB Device, No RS232

1 USB Device, RS232

8 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Ordering information

D—Button Pads Description

0 4 Buttons, 6 LEDs

1 Navigation buttons, 2 Dual-color LEDs

Related products

E—Application key

(EIC Application)

0 No Application Key

1 Application Key (EIC Application)

Description

Related product part numbers

DEUTSCH 12-pin Connector Kit (DTM06-12SA)

Mounting Bracket Kit

CG150-2 CAN/USB Gateway (Sold separately)

PLUS+1® GUIDE Professional

Cable, M12 8-Pin to USB Device

Cable, M12 8-Pin to Lead Wires

Connection tools part numbers

DEUTSCH stamped contacts terminal crimp tool, size 20

DEUTSCH solid contacts terminal crimp tool

10100944

11198661

11153051

11179523

11130518

11130713

10100744

10100745

©

Danfoss | February 2021 BC370081692721en-000101 | 9

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Input/output types and specifications

Input types

DM430M Series displays support the following pin types:

Digital or Analog (DIN/AIN)

•

Multifunction (Din/AIN/FreqIN, Rheo, 4–20 mA)

•

Fixed Range Analog or CAN shield (AIN/CAN shield)

•

Each PLUS+1® Module input pin supports one of the above functional types. For pins with multiple

functions, input configurations are user programmable using PLUS+1® GUIDE templates.

When using inputs in digital mode, it is advised to use the software selectable pull-up or pull-down

resistors.

Digital/analog

Middle range

Description Unit Minimum Typical Maximum Comment

Minimum

discernible

voltage

Minimum

discernible

voltage

Resolution mV — 1.4 — —

Worst case offset

and gain error

Non-linearity mV — — ±8.5 —

Input impedance kΩ 230 233 236 No pull up or pull

Input impedance

(5V/GND)

Input impedance

(2.5V)

mV —

mV 5.64 5.78 5.92 —

mV — — ±0.14 V

kΩ 13.9 14.1 14.3 Pull up or pull

kΩ 7.1 7.3 7.4 Pull up and pull

—

0.03 —

down

down

down

Measure

= 5.78 V

High range

Description Unit Minimum Typical Maximum Comment

Minimum

discernible

voltage

Minimum

discernible

voltage

Resolution mV — 9.5 — —

Worst case offset

and gain error

Non-linearity mV — — ±56.8 —

Input impedance kΩ 108.2 109.3 110.4 No pull up or pull

mV —

mV 37.5 38.8 40.1 —

mV — — ±1.3 V

—

0.16 —

down (Vin < 5.7

V)

Measure

= 38.8 V

10 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Input/output types and specifications

High range (continued)

Description Unit Minimum Typical Maximum Comment

Input impedance

(5V/GND)

Pull up and pull

down input

impedance (2.5V)

Multifunction inputs

Low range analog

Description Unit Minimum Typical Maximum Comment

Minimum discernible

voltage

Maximum discernible

voltage

Resolution mV — 0.1 — —

Worst case offset and gain

error

Non-linearity mV — — ±26 —

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

kΩ 13.0 13.2 13.4 Pull up or pull

kΩ 6.9 7.0 7.1 Pull up and pull

mV — — 13 —

mV 379 404 430 —

mV — — ±0.6 V

Measure

down (Vin < 5.7

V)

down (Vin < 5.7

V)

= 404 mV

Middle range analog

Description Unit Minimum Typical Maximum Comment

Minimum discernible

voltage

Maximum discernible

voltage

Resolution mV — 1.4 — —

Worst case offset and gain

error

Non-linearity mV — — ±8.5 —

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

V — — 0.03 —

V 5.69 5.78 5.88 —

V — — ±0.14 V

Measure

= 5.78 V

High range analog

Description Unit Minimum Typical Maximum Comment

Minimum discernible

voltage

Maximum discernible

voltage

Resolution mV — 9.5 — —

Worst case offset and gain

error

Non-linearity mV — — ±56.8 —

V — — 0.16 —

V 37.9 38.8 39.7 —

V — — ±0.95 V

Measure

= 38.8 V

©

Danfoss | February 2021 BC370081692721en-000101 | 11

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Input/output types and specifications

High range analog (continued)

Description Unit Minimum Typical Maximum Comment

Input impedance kΩ 109.1 109.3 109.5 No pull up or pull down

Input impedance (5V/GND) kΩ 13.0 13.2 13.4 Pull up or pull down (Vin <

Input impedance (2.5V) kΩ 6.9 7.0 7.1 Pull up and pull down (Vin

Low range frequency (PPU)

Description Unit Minimum Typical Maximum Comment

Range Hz 0 — 10000 In steps of 1 Hz

Rising voltage threshold mV — — 314

Falling voltage threshold mV 55 — —

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

(Vin < 5.7 V)

5.7 V)

< 5.7 V)

Middle range frequency (PPU)

Description Unit Minimum Typical Maximum Comment

Range Hz 0 — 10000 In steps of 1 Hz

Range (phase and quad) Hz 0 — 5000 In steps of 1 Hz

Rising voltage threshold V — — 4.25 Voltage required for

Falling voltage threshold V 0.97 — — Voltage required for

Input impedance kΩ 232 233 234 No pull up or pull down

Input impedance (5V/GND) kΩ 13.9 14.1 14.3 Pull up or pull down

Input impedance (2.5V) kΩ 7.1 7.3 7.4 Pull up and pull down

frequency input

frequency input

Resistance input

Description Unit Minimum Typical Maximum Comment

Range Ω 6 — 10000 In steps of 1 Ω

Measurement error % — — 7.1 100Ω

— — 2.1 1kΩ

— — 5.4 10kΩ

Input impedance Ω 1320 1320 1330 No pull up or pull down

Current input (4-20 mA)

Description Unit Minimum Typical Maximum Comment

Minimum discernible

current

Maximum discernible

current

Resolution µA — 7 — —

Worst case offset and gain

error

mA — — 0.12 —

mA 28.2 28.9 29.7 —

µA — — ±743 I

Measure

= 28.9 mA

12 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Input/output types and specifications

Current input (4-20 mA) (continued)

Description Unit Minimum Typical Maximum Comment

Non-linearity µA — — ±42 —

Input impedance Ω 197 200 202 No pull up or pull down

CAN shield and analog input

CAN Shield

Description Unit Minimum Typical Maximum Comment

Input impedance — — 0.68µF+1Ω — —

Analog input

Description Unit Minimum Typical Maximum Comment

Minimum discernible

voltage

Maximum discernible

voltage

Resolution mV — 1.4 — —

Worst case offset and gain

error

Non-linearity mV — — ±8.5 —

Input impedance kΩ 230 233 236

V — — 0.03 —

V 5.64 5.78 5.92 —

V — — ±0.14 V

Measure

= 5.78 V

Alarm output

CAN communication

Low side digital output

Description Unit Minimum Typical Maximum Comment

Voltage V 0 — Vin —

Current mA 0 — 500 —

Description Unit Minimum Typical Maximum Comment

Available Baud rates kbps 50

100

125

250

500

1000

Maximum input voltage

range

V -27 — 40 CAN+ and CAN-

With 120 Ω termination.

The default baud rate is 250

kbps.

Software updates using CG150 are supported via CAN0 and CAN1 channels.

©

Danfoss | February 2021 BC370081692721en-000101 | 13

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Input/output types and specifications

USB communication

Description Unit Minimum Typical Maximum Comment

Available Baud

rates

Maximum input

voltage

RS232 communication

Description Unit Minimum Typical Maximum Comment

Available Baud

rates

Maximum input

voltage

Mbps — 12 — —

V -0.3 — 7.3 D+, D-, and VBUS

bps — 2400 — The default baud

V -25 — 25 Rx

4800

9600

19200

38400

57600

115200

-13.2 — 13.2 Tx

rate is 9600 bps.

14 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Product ratings

DM430M environmental testing criteria

Climate environment

Description Applicable standard Comment

Storage temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bb

Operating temperature IEC 60068-2-1, test Ab, IEC 60068-2-2 test Bd

Thermal and humidity

cycle

Degree of protection IEC 60529

Chemical environment

Description Applicable standard Comment

Chemical resistance ISO 16750-5

Mechanical environment

Description Applicable standard Comment

Vibration IEC 60068-2-64 test Fh 7.67g

Bump IEC 60068-2-27 test Eb

Shock IEC 60068-2-27 test Ea

Free fall IEC 60068-2-31 test Ed

IEC 60068-2-38 (partial)

Electrical/electromagnetic

Description Applicable standard Comment

EMC emissions ISO 13766

EMC immunity ISO 13766

ESD EN61000-4-2

Auto electrical transients ISO 7637-2, ISO 7637-3

Short circuit protection Danfoss test

Reversed polarity

protection

Supply voltage/maximum current ratings

DM430M graphical displays are designed to operate with a nominal 9 to 36 Vdc power supply with

reverse polarity protection.

Supply voltage/maximum current ratings

Description Unit Minimum Typical Maximum Comment

Operating temperature °C -30 — +70

Storage temperature °C -40 — +85

DC supply voltage V 9 — 36 Normal operation.

Danfoss test

Electromagnetic compatibility for earth

moving machinery.

Electromagnetic compatibility for earth

moving machinery.

Inputs and outputs survive continuous

short circuit. Normal function resumes

when short is removed.

Survives reverse polarity at supply

voltage for at least five minutes.

6 — 36 Cranking; reduced

functionality.

-36 — 36 Short circuit and reversed

polarity protection.

©

Danfoss | February 2021 BC370081692721en-000101 | 15

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Product ratings

Supply voltage/maximum current ratings (continued)

Description Unit Minimum Typical Maximum Comment

DC supply current mA — 202 — Vin = 9V

+5V output voltage V 4.75 5 5.09 Normal operation over

+5V output current mA — — 100

Short circuit pin voltage V 0 — 36 All DEUTSCH connector

Ingress Protection (IP) rating

DM430M displays carry a full Ingress Protection rating of IP66 and IP67 only if the rear USB mating

connector or seal plug and DEUTSCH mating connector is in place.

— 144 — Vin = 13.5V

— 92 — Vin = 27V

— 86 — Vin = 36V

temperature.

0 — 36 Short circuit protection.

pins.

16 | © Danfoss | February 2021 BC370081692721en-000101

96.04 [3.78]

110.61 [4.30]

54.87 [2.16]

6.7 [0.26]

9.3 [0.37]

46.45 [1.83]

123.6 [4.87]

114.9 [4.52]

104 [4.09]

75 [2.95]

48.56 [1.91]

32.46 [1.28]

52.76 [2.08]

50 [1.97]

99 [3.90]

107 [4.21]

115 [4.53]

C1

C2

(RAM mount)

6x M4

Surface B

Surface A

Pin 1

Pin 6

Pin 12Pin 7

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Installation

DM430M Series Displays dimensions

mm [in]

Pin assignments

12 pin DEUTSCH connector

DEUTSCH DTM06-12SA 12 pin

C1 pin DM430M-0-x-x-x DM430M-1-x-x-x DM430M-2-x-x-x

1 Power ground - Power ground - Power ground 2 Power supply + Power supply + Power supply +

3 CAN 0 + CAN 0 + CAN 0 +

4 CAN 0 - CAN 0 - CAN 0 5 AnIn/CAN 0 Shield AnIn/CAN 0 Shield AnIn/CAN 0 Shield

6 DigIn/AnIn DigIn/AnIn DigIn/AnIn

7 DigIn/AnIn DigIn/AnIn DigIn/AnIn

8 DigIn/AnIn CAN 1+ Sensor power 5 V/100 mA

9 DigIn/AnIn CAN 1- Secondary power input

10 Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

11 Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

12 Digital out (0.5A sinking) Digital out (0.5A sinking) Digital out (0.5A sinking)

*

From controller (requires surge protection).

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

*

©

Danfoss | February 2021 BC370081692721en-000101 | 17

Pin 6

Pin 8

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 7

4 x R3

R13

115.40 [4.54]

107.50 [4.23]

104.50 [4.11]

99.50 [3.92]

1

2

3

A B

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Installation

8 pin M12 connector

M12-A 8 pin

C2 pin Function

1 Device Vbus

2 Device data 3 Device data +

4 Ground

5 Ground

6 RS232 Rx

7 RS232 Tx

8 NC

Mounting

Recommended mounting procedure

mm [in]

Callout Description

A Panel opening for mounting on surface A

B Panel opening for mounting on surface B

1 Panel seal

2 Panel bracket

3 Four screws

18 | © Danfoss | February 2021 BC370081692721en-000101

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Installation

Panel thickness: 2.5 to 5 mm

Panel thickness: 1 to 6 mm

Panel thickness: 1 to 4.5 mm

©

Danfoss | February 2021 BC370081692721en-000101 | 19

C

7.5 [0.3]

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Installation

Fastening

Caution

•

Use of non-recommended screws can cause damage to housing.

•

Excessive screw torque force can cause damage to housing. Maximum torque: 0.9 N m (8 in-lbs).

•

Reassembly with self-tapping screws can damage existing threads in housing.

•

Oversized panel cutouts can jeopardize product IP rating.

•

Ensure the vent is not covered. This excludes the RAM mount option.

Fastening hole depth

mm [in]

Fastening hole depth: 7.5 mm (0.3 in). Standard M4x0.7 screw may be used.

Maximum torque: 0.9 N m (8 in-lbs).

20 | © Danfoss | February 2021 BC370081692721en-000101

70°

Technical Information

PLUS+1 Mobile Machine Displays DM430M Series

Installation

Visibility and viewing radius

Due to the display nature of the TFT-LCD screen, the optimal viewing angle for the DM430M series

graphical display is at a maximum radius of 70° from either side of the screen.

Optimal viewing angle

Display faulty application recovery

The boot loader is always executed when the unit is powered. The boot loader checks if the application

has the completely downloaded flag set and in that case starts to execute it after a delay of 200 ms. The

delay gives an opportunity for the PLUS+1® Service Tool to prevent the call to the application. This allows

a non functional application to be replaced by the boot loader. This recovery function is activated by the

Communication > Recover ECU menu in the PLUS+1® Service Tool.

Cleaning

Do not pressure wash. Clean using a dry, soft, lint-free cloth, such as a micro-fiber cloth.

©

Danfoss | February 2021 BC370081692721en-000101 | 21

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | February 2021 BC370081692721en-000101

Loading...

Loading...