Page 1

User Manual

Engine Information Center (EIC)

DM430E Series Display

www.danfoss.com

Page 2

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

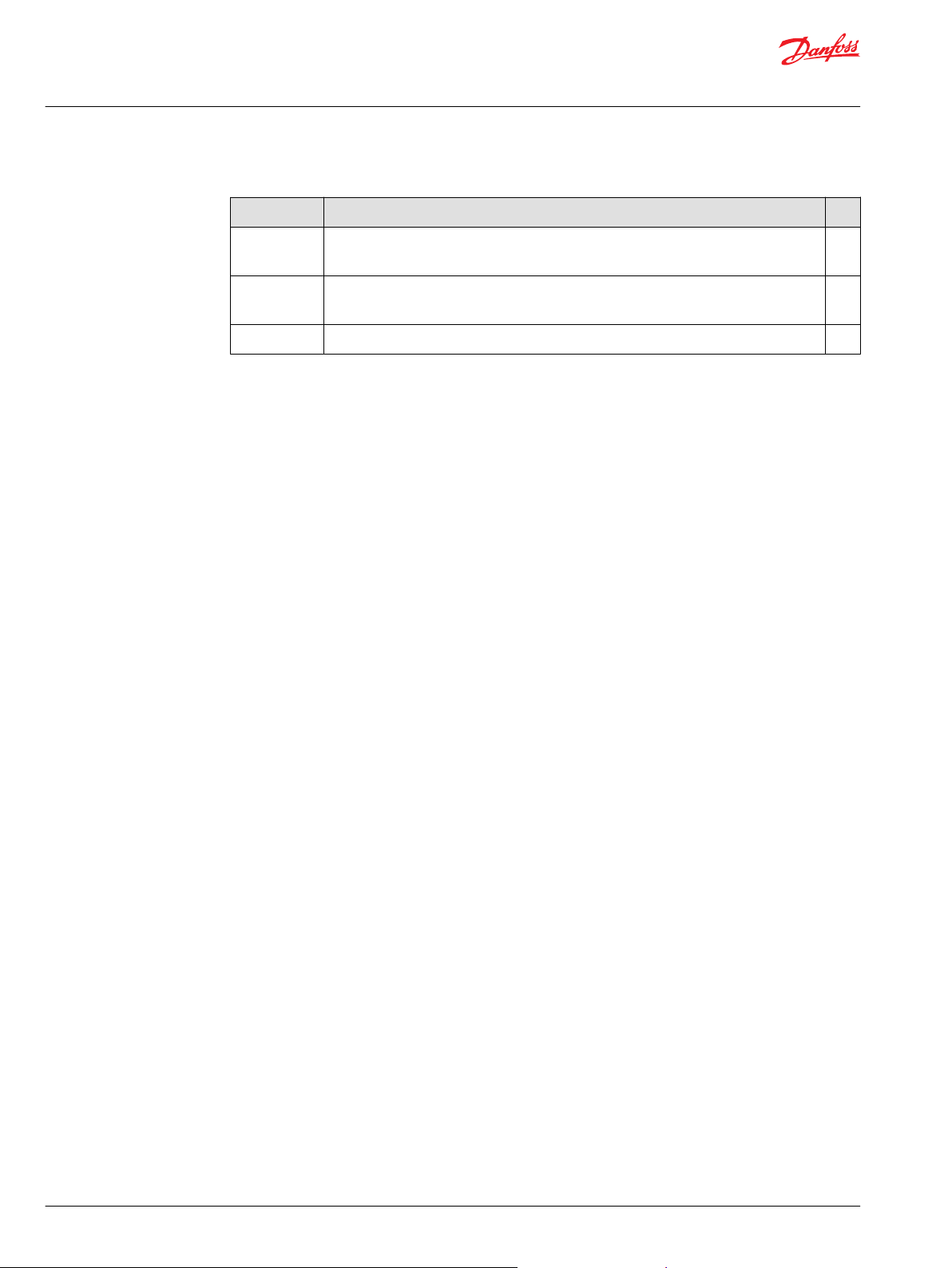

Revision history Table of revisions

Date Changed Rev

December 2018 Minor change for print on demand, removed 2 blank pages at end of the manual for

required total pages divisive by 4.

December 2018 Added note in regards to keeping ambient light sensor area clean and uncovered for best

operation.

December 2018 First edition 0101

0103

0102

2 | © Danfoss | December 2018 AQ288937102741en-000103

Page 3

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Contents

User liability and safety statements

OEM responsibility........................................................................................................................................................................... 4

Safety statements.............................................................................................................................................................................4

Display operation guidelines..................................................................................................................................................4

Machine wiring guidelines...................................................................................................................................................... 5

Machine welding guidelines...................................................................................................................................................5

Overview

DM430E Series Display package................................................................................................................................................. 6

DM430E literature references.................................................................................................................................................6

Technical Information (TI)...................................................................................................................................................6

Data Sheet (DS).......................................................................................................................................................................6

API Specifications (API)........................................................................................................................................................6

PLUS+1® GUIDE User Manual.............................................................................................................................................6

Latest version of technical literature.............................................................................................................................. 6

The Engine Information Center (EIC).........................................................................................................................................6

Navigation using soft keys............................................................................................................................................................ 7

Initiate and inhibit regeneration.................................................................................................................................................7

Inhibit Regeneration action.....................................................................................................................................................8

Initiate Regeneration action....................................................................................................................................................8

TSC1 RPM setpoint......................................................................................................................................................................8

Main Menu

Basic Setup menu.............................................................................................................................................................................9

Brightness....................................................................................................................................................................................10

Color Theme............................................................................................................................................................................... 10

Time & Date................................................................................................................................................................................ 10

Language.....................................................................................................................................................................................11

Units...............................................................................................................................................................................................11

Diagnostics menu..........................................................................................................................................................................11

System Info................................................................................................................................................................................. 12

Fault Log...................................................................................................................................................................................... 12

Device List................................................................................................................................................................................... 12

Screen Setup menu.......................................................................................................................................................................13

Select Screens............................................................................................................................................................................ 13

Number of Screens...................................................................................................................................................................13

System Setup menu......................................................................................................................................................................14

Reset Defaults............................................................................................................................................................................ 14

CAN................................................................................................................................................................................................14

Display.......................................................................................................................................................................................... 15

PIN Setup..................................................................................................................................................................................... 15

Trip Reset..................................................................................................................................................................................... 16

Setup to monitor signals

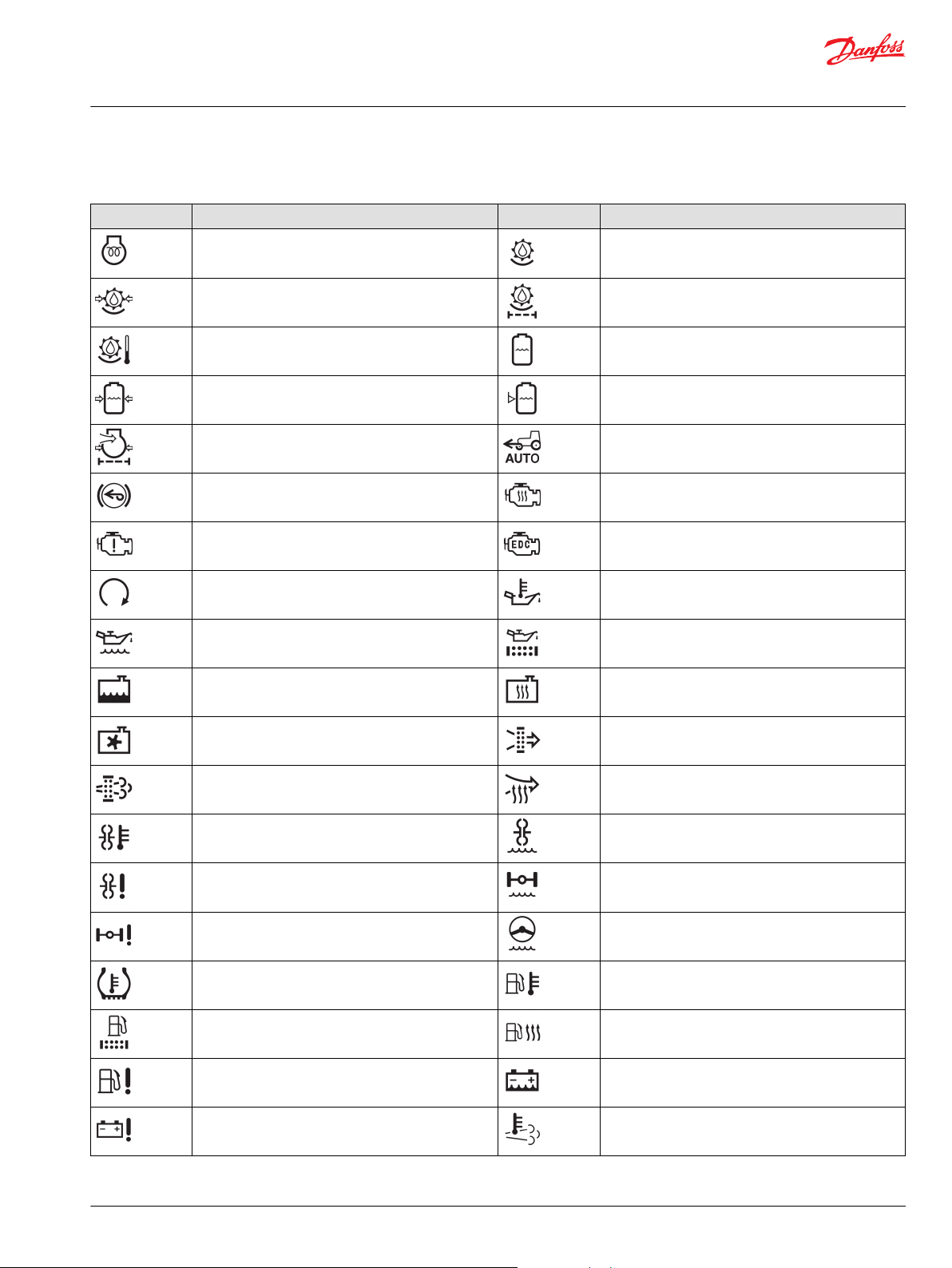

Symbols for J1939 parameters..................................................................................................................................................21

LED indicators

Particulate filter lamp................................................................................................................................................................... 25

High exhaust system temperature lamp...............................................................................................................................25

Regeneration disabled lamp......................................................................................................................................................25

Installation and mounting

Mounting.......................................................................................................................................................................................... 26

Fastening...........................................................................................................................................................................................27

Pin assignments..............................................................................................................................................................................27

Ordering information

Model variants.................................................................................................................................................................................29

Model code.......................................................................................................................................................................................29

Model code key...............................................................................................................................................................................29

Related products............................................................................................................................................................................30

©

Danfoss | December 2018 AQ288937102741en-000103 | 3

Page 4

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

User liability and safety statements

OEM responsibility

The OEM of a machine or vehicle in which Danfoss products are installed has the full responsibility for all

consequences that might occur. Danfoss has no responsibility for any consequences, direct or indirect,

caused by failures or malfunctions.

Danfoss has no responsibility for any accidents caused by incorrectly mounted or maintained

•

equipment.

Danfoss does not assume any responsibility for Danfoss products being incorrectly applied or the

•

system being programmed in a manner that jeopardizes safety.

All safety critical systems shall include an emergency stop to switch off the main supply voltage for

•

the outputs of the electronic control system. All safety critical components shall be installed in such a

way that the main supply voltage can be switched off at any time. The emergency stop must be easily

accessible to the operator.

Safety statements

Display operation guidelines

•

Disconnect your machine's battery power before connecting power and signal cables to the display.

•

Before doing any electrical welding on your machine, disconnect all power and signal cables

connected to the display.

•

Do not exceed the display power supply voltage ratings. Using higher voltages may damage the

display and can create a fire or electrical shock hazard.

•

Do not use or store the display where flammable gases or chemicals are present. Using or storing the

display where flammable gases or chemicals are present may cause an explosion.

•

Software configures the keypad buttons on the display. Do not use these buttons to implement

critical safety features. Use separate mechanical switches to implement critical safety features such as

emergency stops.

•

Design systems that use the display so that a communication error or failure between the display and

other units cannot cause a malfunction that might injure people or damage material.

•

The protective glass over the display screen will break if hit with a hard or heavy object. Install the

display to reduce the possibility of it being hit by hard or heavy objects.

•

Storing or operating a display in an environment that exceeds the display specified temperature or

humidity rating may damage the display.

•

Always clean the display with a soft, damp cloth. Use a mild dishwashing detergent as needed. To

avoid scratching and discoloring the display, do not use abrasive pads, scouring powders, or solvents

such as alcohol, benzene, or paint thinner.

•

Keep ambient light sensor area clean and uncovered for best operation.

•

Danfoss graphical displays are not user serviceable. Return the display to the factory in case of failure.

4 | © Danfoss | December 2018 AQ288937102741en-000103

Page 5

W

C

W

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

User liability and safety statements

Machine wiring guidelines

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Improperly protected power input lines against over current conditions may cause damage to the

hardware. Properly protect all power input lines against over-current conditions. To protect against

unintended movement, secure the machine.

Caution

Unused pins on mating connectors may cause intermittent product performance or premature failure.

Plug all pins on mating connectors.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

Machine welding guidelines

Warning

High voltage from power and signal cables may cause fire or electrical shock, and cause an explosion if

flammable gasses or chemicals are present.

Disconnect all power and signal cables connected to the electronic component before performing any

electrical welding on a machine.

The following is recommended when welding on a machine equipped with electronic components:

•

Turn the engine off.

•

Remove electronic components from the machine before any arc welding.

•

Disconnect the negative battery cable from the battery.

•

Do not use electrical components to ground the welder.

•

Clamp the ground cable for the welder to the component that will be welded as close as possible to

the weld.

©

Danfoss | December 2018 AQ288937102741en-000103 | 5

Page 6

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Overview

DM430E Series Display package

Prior to use, ensure the following are included in the display package:

•

DM430E Series Display

•

Panel Seal Gasket

•

DM430E Series Display - Engine Information Center (EIC) User Manual

DM430E literature references

Reference literature

Literature title Literature type Literature number

DM430E Series PLUS+1® Mobile Machine Displays Technical Information BC00000397

DM430E Series PLUS+1® Mobile Machine Displays Data Sheet AI00000332

DM430E Series Display - Engine Information Center (EIC)

Software

PLUS+1® GUIDE Software User Manual AQ00000026

Technical Information (TI)

A TI is comprehensive information for engineering and service personnel to reference.

User Manual AQ00000253

Data Sheet (DS)

A DS is summarized information and parameters that are unique to a specific model.

API Specifications (API)

An API is specifications for programming variable settings.

API specifications are the definitive source of information regarding pin characteristics.

PLUS+1® GUIDE User Manual

The Operation Manual (OM) details information regarding the PLUS+1® GUIDE tool used in building PLUS

+1® applications. This OM covers the following broad topics:

How to use the PLUS+1® GUIDE graphical application development tool to create machine

•

applications

How to configure module input and output parameters

•

How to download PLUS+1® GUIDE applications to target PLUS+1® hardware modules

•

How to upload and download tuning parameters

•

How to use the PLUS+1® Service Tool

•

Latest version of technical literature

Comprehensive technical literature is online at www.danfoss.com

The Engine Information Center (EIC)

The DM430E comes installed with the powerful and flexible Danfoss Engine Information Center (EIC)

J1939 engine monitor software application. Use the application to customize the look and feel of your

individual engine monitoring needs by creating and controlling analog and digital display information in

the screen configurations that work best for your performance requirements.

Navigate through diagnostic information and configuration screens with ease by using the four contextdependent soft keys located at the front of the display. Choose from more than 4500 different

monitoring parameter profiles to customize the DM430E.

6 | © Danfoss | December 2018 AQ288937102741en-000103

Page 7

Inhibit

Switch

Initiate

Switch

TSC1RPM

Set Point

Exit/Back

One Screen

Exit/Back

One Screen

NavigateUpNavigate

Down

Select

Next

Menu

NavigateUpNavigate

Down

Main

Menu

Decrement Increment

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Overview

Up to four signals can be monitored on each screen. Use the EIC software to configure the DM430E for

alarms and alerts.

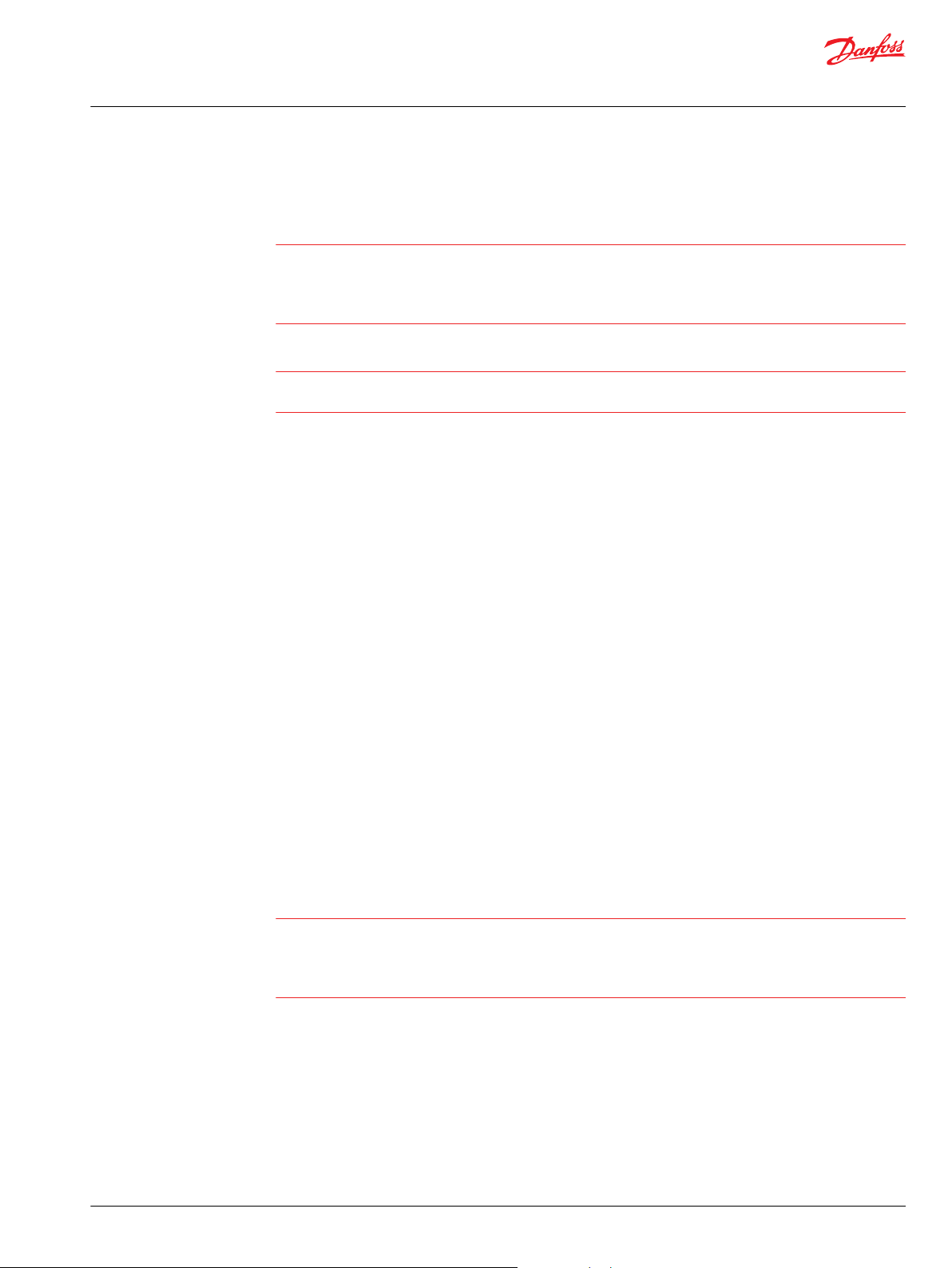

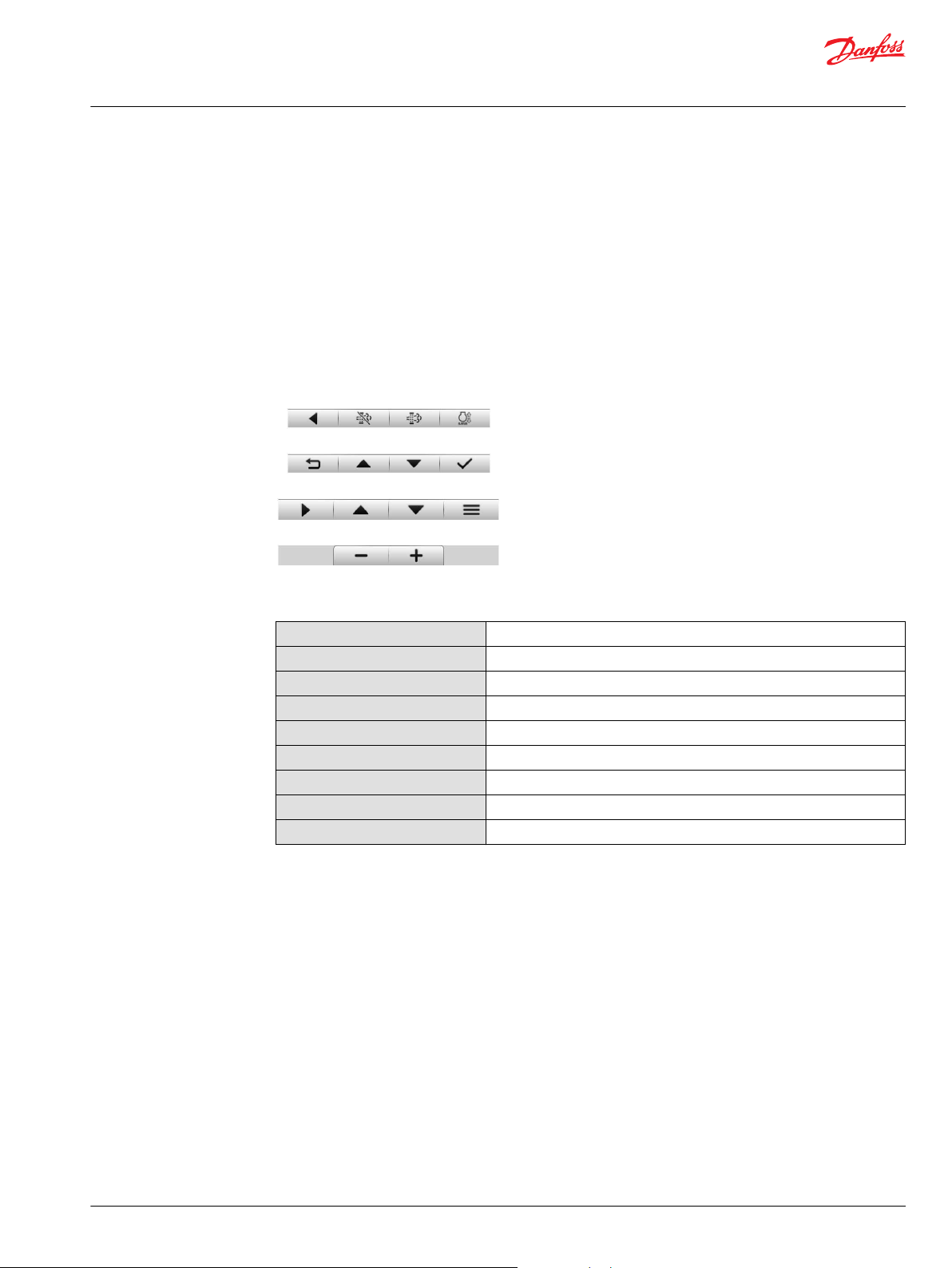

Navigation using soft keys

The DM430E is controlled by navigation through a set of four soft keys located at the lower front of the

display. The keys are context dependent. Soft key selection options are displayed above each key and are

dependent on the current navigation location within the engine monitor software program. As a general

rule, the far right soft key is the selector button and the far left soft key is the step back one screen key. To

optimize full screen use, the on-screen selections are not displayed when not in use. Press any soft key to

display current selection options.

Navigation using soft keys

Initiate and inhibit regeneration

Screen navigation

Navigate Up

Navigate Down

Main Menu

Exit/Back one screen

Select

Next Menu

Inhibit Regen

Initiate Regen

Increment/decrement

Press to move up through menu items or screens

Press to move down through menu items or screens

Press to go to Main Menu screen

Press to go back one screen

Press to accept selection

Press to select next digit or screen element

Press to force regeneration of particulate filter

Press to inhibit particulate filter regeneration

Press to increment or decrement value

While EIC DM430E is displaying one of the monitor screens, pressing any soft key will show the available

navigation actions in an action menu. There are two separate action menus on this level, the first one to

appear contains the following actions (from left to right).

Next Menu

•

Navigate Up

•

Navigate Down

•

Main Menu

•

Selecting Next Menu will display the second action menu with Inhibit switch (Inhibit Regeneration),

Initiate switch (Initiate Regeneration) and RPM Set Point. Pressing it again will show the first set of

actions once more. Selecting Navigate Up and Navigate Down will allow navigation between signal

monitoring screens. Selecting Main Menu will display the DM430E set up options. If no soft keys are

pressed and released for 3 seconds while the action menu is shown, the menu will disappear and the

actions are no longer available. Pressing (and releasing) any soft key will activate the first menu once

more.

©

Danfoss | December 2018 AQ288937102741en-000103 | 7

Page 8

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Overview

Inhibit Regeneration action

If the user selects the Inhibit Regeneration action while the action menu is being displayed the same

function as described in Initiate Regeneration action will be executed, with the following.

Bit 0 (out of 0-7) in byte 5 (out of 0-7) is set to 1 (true).

•

The pop up reads Inhibit Regen.

•

The acknowledgment lights up the Regeneration Inhibit LED.

•

Initiate Regeneration action

If the user selects the Initiate Regeneration action while the action menu is being displayed; bit 2 (out of

0-7) in byte 5 (out of 0-7) will be set to 1 (true) in the J1939 message PGN 57344 bound for the engine.

This change prompts the message to be transmitted. The bit will stay like this for the duration of the soft

key press or for the 3 second countdown to soft key inactivity, whichever occurs first. The bit is then reset

to 0 (false).

The soft key press also prompts the display to show a pop up lasting for 3 seconds. This popup simply

says Initiate Regen. If the display does not receive an acknowledgment from the engine on the change

to message PGN 57344 the last half of the pop up will read No Engine Signal. This acknowledgment is

the command that lights up the Initiate Regeneration LED on the display unit housing.

TSC1 RPM setpoint

The TSC1 message sends the RPM requirement for the engine.

8 | © Danfoss | December 2018 AQ288937102741en-000103

Page 9

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

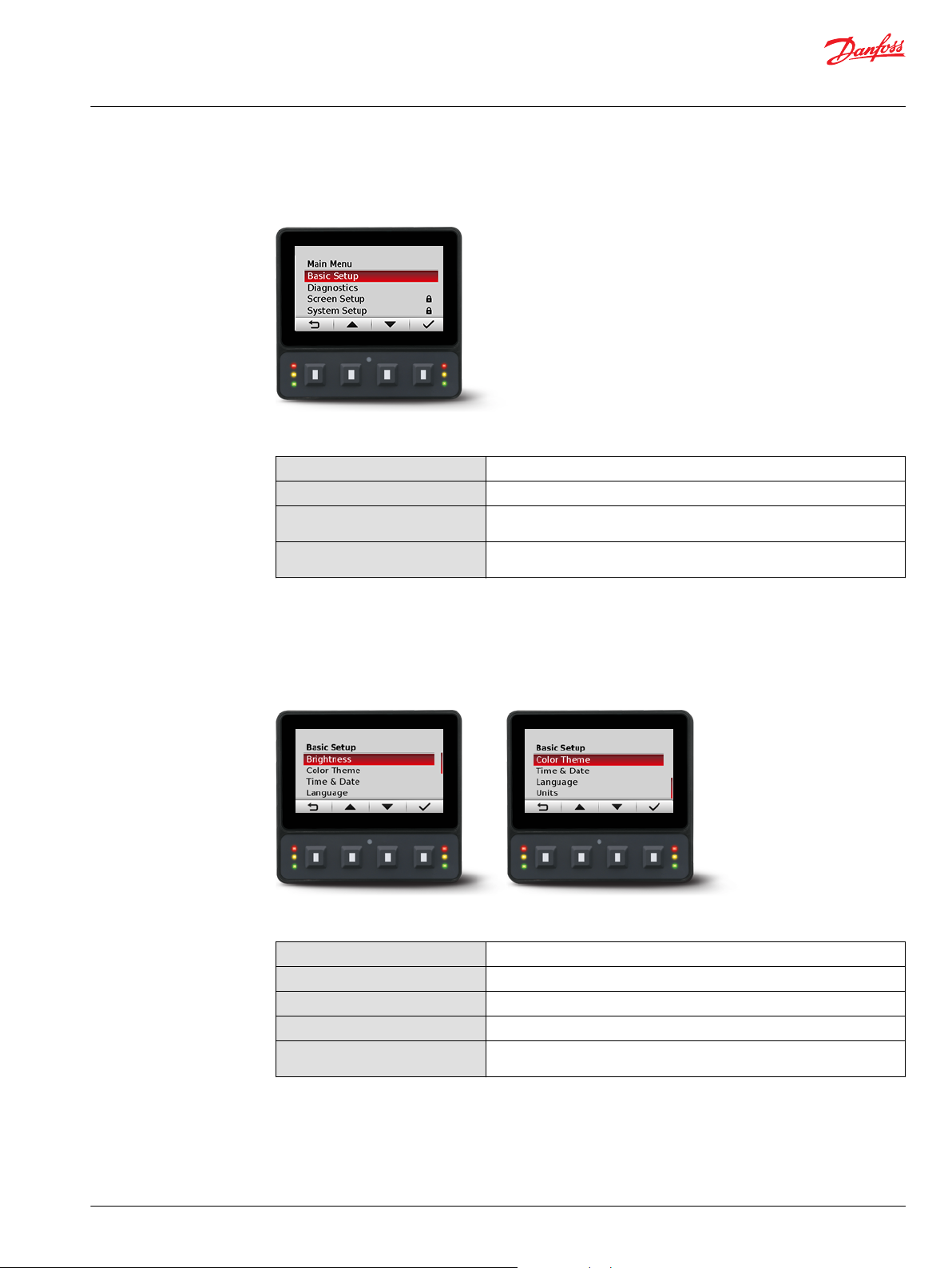

Use the Main Menu as the starting point for configuring the DM430E Series Display.

Main Menu screen

Main Menu

Basic Setup

Diagnostics

Screen Setup

System Setup

Use to set Brightness, Color Theme, Time & Date, Language, Units

Use to view system, fault log and device information

Use to select screens, number of screens and parameters (can be PIN

protected)

Use to reset defaults and trip information, access CAN information, select

display settings, and configure PIN settings

Basic Setup menu

Use Basic Setup to set brightness, color theme, time & date, language, and units for the DM430E Series

Display.

Basic Setup screen

Basic Setup menu

Brightness

Color Theme

Time & Date

Language

Units

Use to adjust brightness level of the screen

Use to set background color of display

Use to set time, date, and time and date styles

Use to set the system language, default language is English

Use to set speed, distance, pressure, volume, mass, temperature and flow

settings

©

Danfoss | December 2018 AQ288937102741en-000103 | 9

Page 10

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

Brightness

Use the minus (-) and plus (+) soft keys to adjust display screen brightness. After 3 seconds of inactivity

the screen will go back to basic setup.

Brightness screen

Color Theme

Use to select between 3 options of Light, Dark and Automatic.

Color Theme screen

Time & Date

Use up, down, select, and next soft keys to set time style, time, date style, and date.

Time & Date screen

10 | © Danfoss | December 2018 AQ288937102741en-000103

Page 11

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

Language

Use up, down and select soft keys to select program language. Available languages are English, Spanish,

French, German, Italian, Swedish and Portuguese.

Language screen

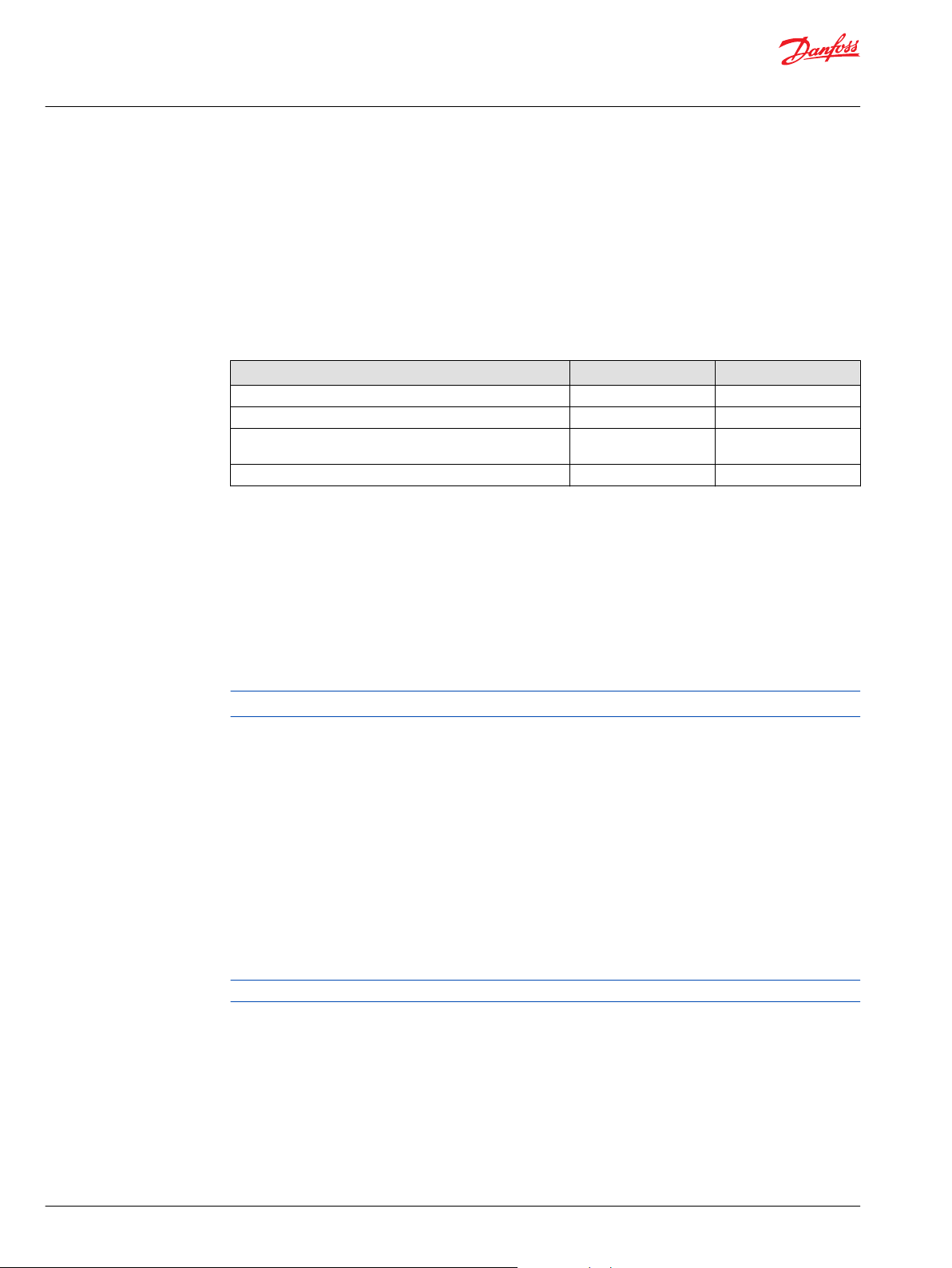

Units

Use up, down, and select soft keys to define units of measurement.

Diagnostics menu

Units of measurement

Speed

Distance

Pressure

Volume

Mass

Temperature

Flow

kph, mph

km, miles

kPa, bar, psi

litre, gal, igal

kg, lbs

°C, °F

lph, gph, igph

Use to obtain system info, fault log entries, and device information.

Diagnostics screen

Diagnostics menu

System Info

Fault Log

Device List

©

Danfoss | December 2018 AQ288937102741en-000103 | 11

Use to display hardware, software, system, and node information for

connected devices

Use to view and monitor current and previous fault information

Use to display list of all currently connected J1939 devices

Page 12

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

System Info

The System Info screen contains hardware serial number, software version, node number and ROP

version.

System Info screen example

Fault Log The Fault Log screen contains saved and stored fault information. Select either Active Faults or Previous

Faults to monitor fault activity. Select specific faults to list more information.

Fault Log screen

Active faults

Select Active Faults to display all active faults on the CAN network.

Previous faults

Select Previous Faults to display all previously active faults on the CAN network.

Device List

The Device List screen lists J1939 devices and addresses that are currently being monitored on the

network.

12 | © Danfoss | December 2018 AQ288937102741en-000103

Page 13

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

Screen Setup menu

Use Screen Setup to select individual screens for setup, and number of signal screens.

Screen Setup menu

Select Screens

Number of Screens

Select screen to set up signal information, screens available are dependent

on Number of Screens selection

Select 1 to 4 screens for information display

Select Screens

Select screen to customize. For screen set up details, see Setup to monitor signals.

Select Screens example

Number of Screens

Select number of screens for display. Choose from 1 to 4 screens. For screen set up details, see Setup to

monitor signals.

Number of Screens example

©

Danfoss | December 2018 AQ288937102741en-000103 | 13

Page 14

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

System Setup menu

Use System Setup to monitor and control application systems.

System Setup menu

Reset Defaults

CAN

Display

PIN Setup

Trip Reset

Use to reset all system information to the default settings

Use to customize CAN settings

Use to customize display settings

Use to customize PIN settings

Use to reset trip information

Reset Defaults

Select Reset Defaults to reset all EIC settings to original factory default settings.

CAN

Use the CAN settings screen to make the following selections.

14 | © Danfoss | December 2018 AQ288937102741en-000103

Page 15

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

CAN settings menu

Fault Popup

Conversion Method

Engine Address

Engine Type

Engine DMs Only

Transmit TSC1

JD Interlock

Display

Select on/off to enable/disable pop-up messages.

Select 1, 2 or 3 to determine how to interpret nonstandard fault messages. Consult engine manufacturer

for correct setting.

Select engine address. Selection range is 0 to 253.

Select from a list of predetermined engine types.

Only accepts fault codes or J1939 DM messages from the

engine.

Enable to send the TSC1 (Torque Speed Control 1)

message.

Transmit John Deere Interlock message required for

regeneration.

Display Setting

Startup Screen

Buzzer Output

Force Return to Gauges

Demo Mode

Select to enable/disable logo display at startup.

Select to enable/disable warning buzzer functionality.

After 5 minutes of inactivity returns to main Gauge.

Select on/off to enable demonstration mode.

PIN Setup

To reduce the potential for errors, Screen Setup and System Setup menu options can only be accessed

after entering a PIN code.

The default code is 1-2-3-4. To change PIN code go to System Setup > PIN Setup > Change PIN Code.

PIN Setup

©

Danfoss | December 2018 AQ288937102741en-000103 | 15

Page 16

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Main Menu

Trip Reset

Select Yes to reset all trip data.

16 | © Danfoss | December 2018 AQ288937102741en-000103

Page 17

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

The following steps are for screen setup. Steps 1 through 3 are for selecting number of screens and

screen types and 4 through 7 are for selecting J1939 monitor controls.

For J1939 parameters available, function and symbols, reference Symbols for J1939 parameters.

1. Navigate to Main Menu > Screen Setup > Number of Screens. Select from one to four screens for

signal monitoring.

2. Navigate to Main Menu > Screen Setup > Select Screens and select screen to customize.

3. Select screen type for each of the screens selected. There are four screen variants.

Screen type 1

Type 1 is a two-up screen view with two signal capacity.

Screen type 2

©

Danfoss | December 2018 AQ288937102741en-000103 | 17

Page 18

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

Type 2 is a three-up view with one large signal display capacity and behind it, partially visible, are two

small signal display capacities.

Screen type 3

Type 3 is a three-up view with one large and two small signal display capacities.

Screen type 4

Type 4 is a four-up view with four small signal display capacities.

For more screen type customization it is possible to configure the small signal displays by choosing from

three styles.

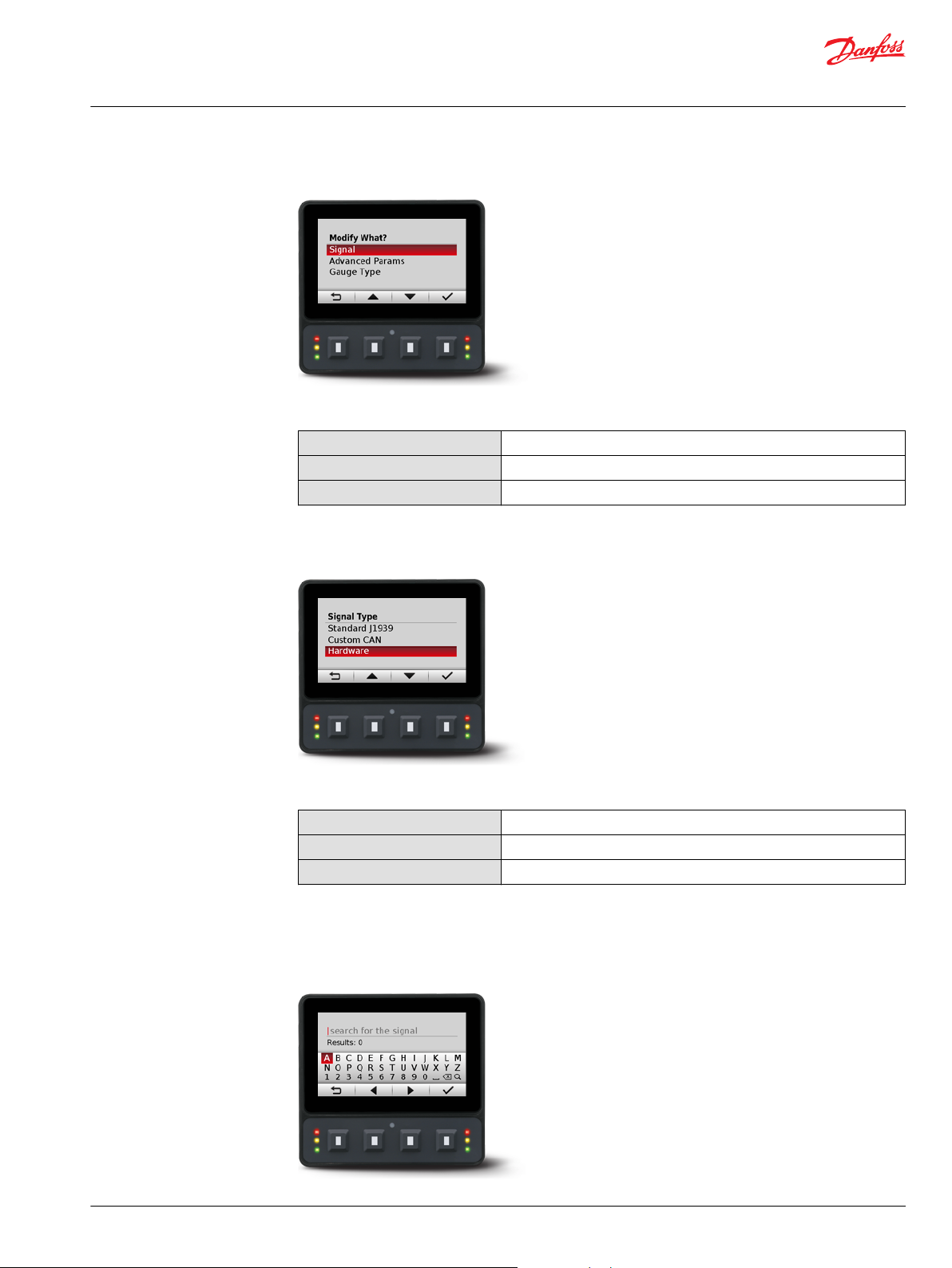

4. After choosing the gauge to modify, press select key, a screen called Modify What? will open.

Within this screen it is possible to modify the signal and advanced parameters. Additionally, for

screen type 3 and 4, the gauge type can also be modified.

18 | © Danfoss | December 2018 AQ288937102741en-000103

Page 19

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

Modify What? screen

Modify What?

Signal

Advanced Parameters

Gauge Type

5. When modifying signal, 3 signal types are available.

Signal Type screen

Use to define the signal you would like to display.

Use to define gauge icon, range, multiplier and tick settings.

Use to define gauge appearance.

Signal Type

Standard J1939

Custom CAN

Hardware

Choose from over 4500 signal types.

Choose a CAN signal.

Choose hardware specific signals.

6. When choosing Standard J1939, it is possible to search for available signals. Choose between Text,

PGN and SPN search types. Use the left and right arrow soft keys to cycle through the alphabet and

enter the signal.

Search for the signal screen

©

Danfoss | December 2018 AQ288937102741en-000103 | 19

Page 20

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

7. After making a signal selection, press the right arrow soft key to go to the next selection area.

Use left arrow, right arrow, and next soft keys to select signal monitoring screen.

•

Use the right arrow soft key to rotate through the selections in a clockwise rotation.

•

Examples of screen signal selections

Complete screen signal selections then press the back symbol soft key to return to previous menus.

8.

Navigate back for more screen selections or press the back soft key until you reach the Main Screen.

Example of screen setup

20 | © Danfoss | December 2018 AQ288937102741en-000103

Page 21

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

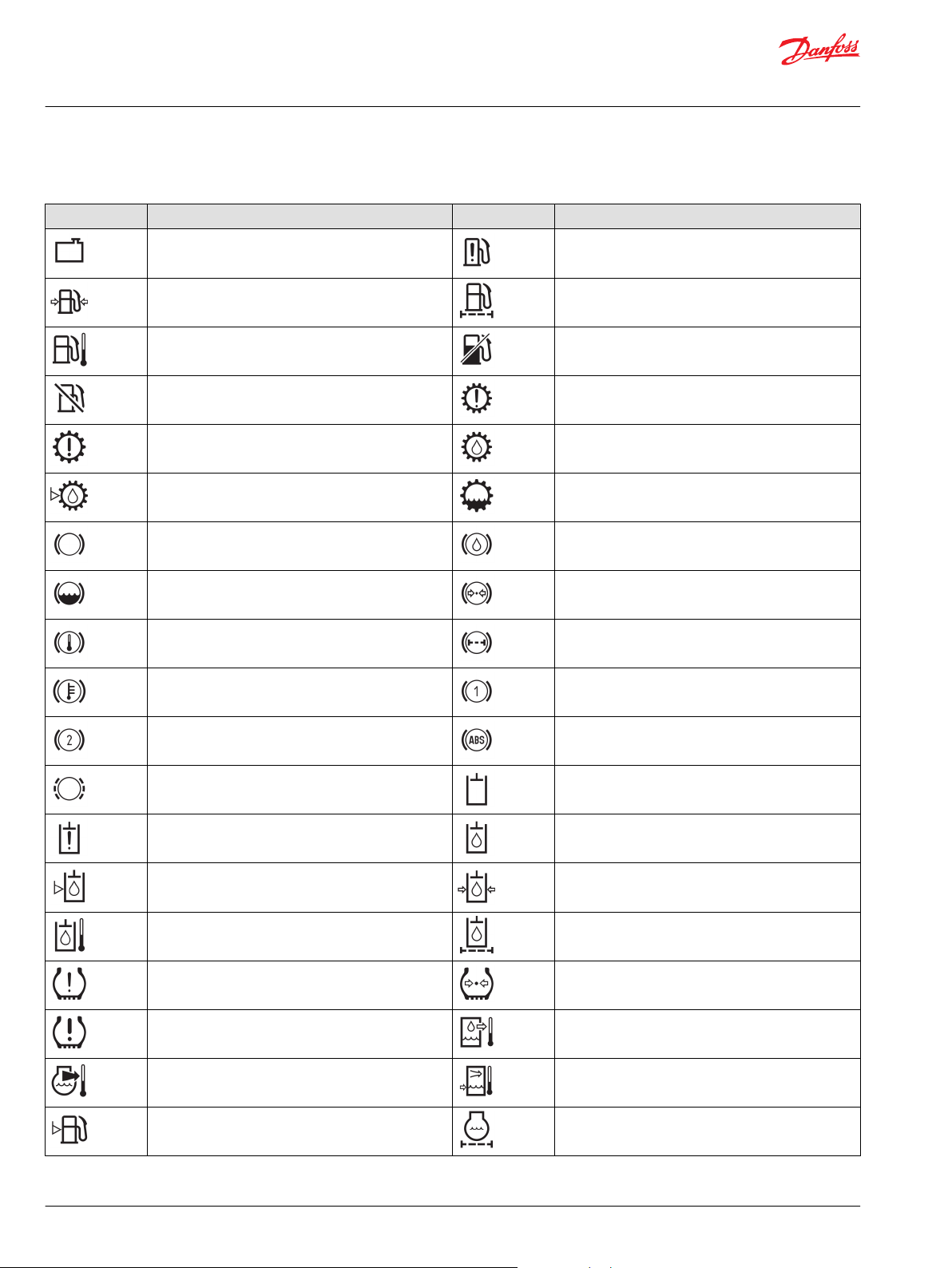

Symbols for J1939 parameters

The following table lists symbols for the J1939 engine and transmission parameters that are available and

can be monitored.

Symbols for the J1939 engine and transmission parameters

Symbol Name/Function Symbol Name/Function

Temperature Engine coolant temperature

Battery charging condition Engine oil

Engine Fuel economy

Primary voltage Oil; fluid

Transmission Transmission

Transmission oil pressure Transmission oil temperature

Transmission oil temperature Transmission oil filter

Engine intake air filter; engine combustion air filter Hour meter; elapsed operating hours

Hand accelerator control; hand throttle Engine failure; engine malfunction

Engine lubricating oil Engine lubricating oil level

Engine lubricating oil pressure Engine lubricating oil temperature

Engine lubricating oil filter Engine coolant

Engine coolant level Engine coolant pressure

Engine coolant temperature Engine intake; combustion air

Engine intake; combustion air pressure Engine intake; combustion air temperature

Engine exhaust gas Engine exhaust gas pressure

Engine exhaust gas temperature Engine start

Engine stop Engine rotational speed (revolutions per minute)

©

Danfoss | December 2018 AQ288937102741en-000103 | 21

Page 22

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

Symbols for the J1939 engine and transmission parameters (continued)

Symbol Name/Function Symbol Name/Function

Heat exchanger, coolant fluid radiator; radiator Fuel system failure; malfunction

Fuel pressure Fuel filter

Fuel temperature Fuel shut-off

Fuel shut-off Transmission failure/malfunction

Transmission failure/malfunction Transmission oil

Transmission oil level Transmission oil level

Brake system Brake oil/fluid

Brake fluid level Brake system pressure

Brake system temperature; brake temperature Brake system filter

Brake system temperature; brake temperature Brake system, first circuit

Brake system, second circuit Anti-lock brake system, failure

Worn brake linings Hydraulic system

Hydraulic system failure/malfunction Hydraulic oil

Hydraulic oil level Hydraulic oil pressure

Hydraulic oil temperature Hydraulic oil filter

Tire failure/malfunction Tire pressure

Tire failure/malfunction Liquid cooled oil cooler, oil outlet temperature

Engine-exhaust-gas coolant temperature Charge air cooler, coolant inlet temperature

Fuel level Engine coolant filter

22 | © Danfoss | December 2018 AQ288937102741en-000103

Page 23

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

Symbols for the J1939 engine and transmission parameters (continued)

Symbol Name/Function Symbol Name/Function

Engine, electrical preheat (low temperature start aid) Separator-drive oil

Separator-drive oil pressure Separator-drive oil filter

Separator-drive oil temperature Spray solution tank

Spray solution tank pressure Spray solution tank level

Engine air filter pressure Tractor, front-wheel drive, automatic operation

Tractor, front-wheel drive, braking Road vehicle, engine heating

Road vehicle, engine failure/malfunction Road vehicle, electronic diesel control

Road vehicle, engine start Road vehicle, engine oil temperature

Road vehicle, engine oil level Road vehicle, engine oil filter

Road vehicle, engine coolant level Road vehicle, engine coolant heating

Road vehicle, engine coolant fan Road vehicle, engine inlet air filter

Road vehicle, engine emission filter Road vehicle, engine inlet air preheat

Transmission converter temperature Transmission converter fluid level

Transmission converter failure Axle fluid level

Axle failure Steering fluid level

Tire temperature Road vehicle, fuel temperature

Road vehicle, fuel filter Fuel heating

Road vehicle, fuel system failure Battery fluid level

Battery failure Engine emission system temperature; diesel particulate

©

Danfoss | December 2018 AQ288937102741en-000103 | 23

filter, regeneration underway

Page 24

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Setup to monitor signals

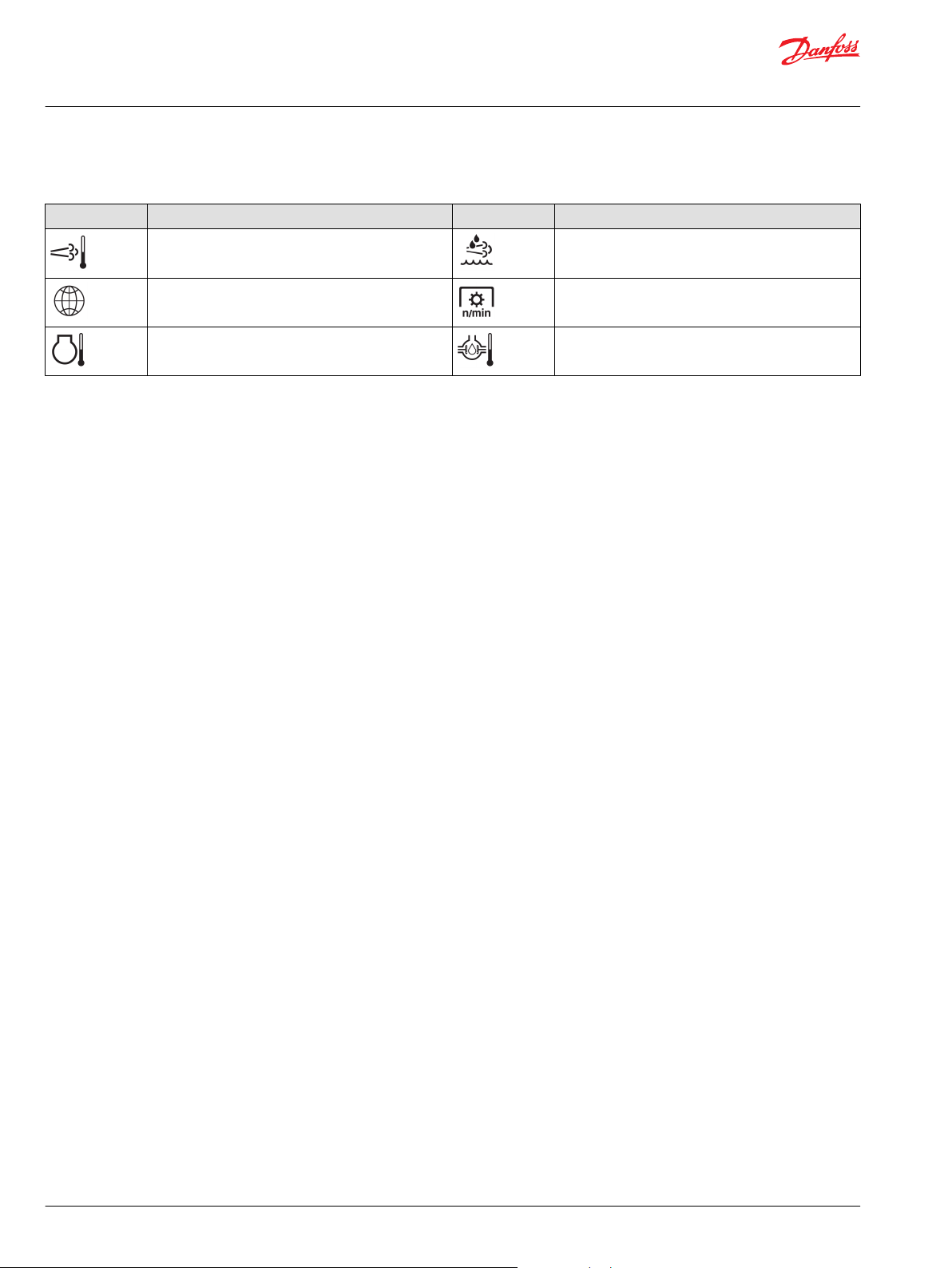

Symbols for the J1939 engine and transmission parameters (continued)

Symbol Name/Function Symbol Name/Function

Engine emissions system temperature; diesel

particulate filter, regeneration underway

Latitude and longitude Power take-off (PTO), rotational speed

Engine system temperature Differential gear oil temperature

Diesel exhaust fluid (DEF); selective catalyst reduction

(SCR) fluid

24 | © Danfoss | December 2018 AQ288937102741en-000103

Page 25

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

LED indicators

Particulate filter lamp

Stage 1 The right Amber LED indicates the initial need for regeneration.

The lamp is on solid.

Stage 2 The right Amber LED indicates an urgent regeneration.

Lamp flashes with 1 Hz.

Stage 3 Same as Stage 2 but check engine lamp will also turn on.

High exhaust system temperature lamp

The left Amber LED indicates the increase of exhaust system temperature due to regeneration.

Regeneration disabled lamp

The left Amber LED indicates that the regeneration disabled switch is active.

©

Danfoss | December 2018 AQ288937102741en-000103 | 25

Page 26

4 x R3

R13

115.40 [4.54]

107.50 [4.23]

104.50 [4.11]

99.50 [3.92]

1

2

3

A B

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Installation and mounting

Mounting

Recommended mounting procedure

mm [in]

Callout Description

A Panel opening for mounting on surface A

B Panel opening for mounting on surface B

1 Panel seal

2 Panel bracket

3 Four screws

26 | © Danfoss | December 2018 AQ288937102741en-000103

Page 27

C

7.5 [0.3]

Pin 1

Pin 6

Pin 12Pin 7

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Installation and mounting

Fastening

Caution

•

Use of non-recommended screws can cause damage to housing.

•

Excessive screw torque force can cause damage to housing. Maximum torque: 0.9 N m (8 in-lbs).

•

Reassembly with self-tapping screws can damage existing threads in housing.

•

Oversized panel cutouts can jeopardize product IP rating.

•

Ensure the vent is not covered. This excludes the RAM mount option.

Fastening hole depth

mm [in]

Fastening hole depth: 7.5 mm (0.3 in). Standard M4x0.7 screw may be used.

Maximum torque: 0.9 N m (8 in-lbs).

Pin assignments

12 pin DEUTSCH connector

DEUTSCH DTM06-12SA 12 pin

C1 pin DM430E-0-x-x-x DM430E-1-x-x-x DM430E-2-x-x-x

1 Power ground - Power ground - Power ground 2 Power supply + Power supply + Power supply +

3 CAN 0 + CAN 0 + CAN 0 +

4 CAN 0 - CAN 0 - CAN 0 5 AnIn/CAN 0 Shield AnIn/CAN 0 Shield AnIn/CAN 0 Shield

6 DigIn/AnIn DigIn/AnIn DigIn/AnIn

©

Danfoss | December 2018 AQ288937102741en-000103 | 27

Page 28

Pin 6

Pin 8

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 7

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Installation and mounting

DEUTSCH DTM06-12SA 12 pin (continued)

C1 pin DM430E-0-x-x-x DM430E-1-x-x-x DM430E-2-x-x-x

7 DigIn/AnIn DigIn/AnIn DigIn/AnIn

8 DigIn/AnIn CAN 1+ Sensor power

9 DigIn/AnIn CAN 1- Secondary power input

10 Multifunction input (DigIn/AnIn/Freq/4-20

11 Multifunction input (DigIn/AnIn/Freq/4-20

12 Digital out (0.5A sinking) Digital out (0.5A sinking) Digital out (0.5A sinking)

*

From controller (requires surge protection).

mA/Rheostat)

mA/Rheostat)

8 pin M12 connector

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

Multifunction input (DigIn/AnIn/Freq/4-20

mA/Rheostat)

*

M12-A 8 pin

C2 pin Function

1 Device Vbus

2 Device data 3 Device data +

4 Ground

5 Ground

6 RS232 Rx

7 RS232 Tx

8 NC

28 | © Danfoss | December 2018 AQ288937102741en-000103

Page 29

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Ordering information

Model variants

Part number Order code Description

11197958 DM430E-0-0-0-0 4 Buttons, I/O

11197973 DM430E-1-0-0-0 4 Buttons, 2-CAN

11197977 DM430E-2-0-0-0 4 Buttons, Sensor Power, Secondary Power Input

11197960 DM430E-0-1-0-0 4 Buttons, I/O, USB/RS232

11197974 DM430E-1-1-0-0 4 Buttons, 2-CAN, USB/RS232

11197978 DM430E-2-1-0-0 4 Buttons, Sensor Power, Secondary Power Input, USB/RS232

11197961 DM430E-0-0-1-0 Navigation Buttons, I/O

11197975 DM430E-1-0-1-0 Navigation Buttons, 2-CAN

11197979 DM430E-2-0-1-0 Navigation Buttons, Sensor Power, Secondary Power Input

11197972 DM430E-0-1-1-0 Navigation Buttons, I/O, USB/RS232

11197976 DM430E-1-1-1-0 Navigation Buttons, 2-CAN, USB/RS232

11197980 DM430E-2-1-1-0 Navigation Buttons, Sensor Power, Secondary Power Input, USB/RS232

11197981 DM430E-0-0-0-1 4 Buttons, I/O, EIC Application

11197985 DM430E-1-0-0-1 4 Buttons, 2-CAN, EIC Application

11197989 DM430E-2-0-0-1 4 Buttons, Sensor Power, Secondary Power Input, EIC Application

11197982 DM430E-0-1-0-1 4 Buttons, I/O, USB/RS232, EIC Application

11197986 DM430E-1-1-0-1 4 Buttons, 2-CAN, USB/RS232, EIC Application

11197990 DM430E-2-1-0-1 4 Buttons, Sensor Power, Secondary Power Input, USB/RS232, EIC Application

11197983 DM430E-0-0-1-1 Navigation Buttons, I/O, EIC Application

11197987 DM430E-1-0-1-1 Navigation Buttons, 2-CAN, EIC Application

11197991 DM430E-2-0-1-1 Navigation Buttons, Sensor Power, Secondary Power Input, EIC Application

11197984 DM430E-0-1-1-1 Navigation Buttons, I/O, USB/RS232, EIC Application

11197988 DM430E-1-1-1-1 Navigation Buttons, 2-CAN, USB/RS232, EIC Application

11197992 DM430E-2-1-1-1 Navigation Buttons, Sensor Power, Secondary Power Input, USB/RS232, EIC Application

Model code

A B C D E

DM430E

Model code key

A—Model name Description

DM430E 4.3" Color Graphical Display

B—Inputs/Outputs Description

0 1 CAN Port, 4DIN/AIN, 2 MFIN

1 2 CAN Port, 2DIN/AIN, 2 MFIN

2 1 CAN Port, 2DIN/AIN, 2 MFIN, Sensor Power

C—M12 connector Description

0 No USB Device, No RS232

1 USB Device, RS232

©

Danfoss | December 2018 AQ288937102741en-000103 | 29

Page 30

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

Ordering information

D—Button Pads Description

0 4 Buttons, 6 LEDs

1 Navigation buttons, 2 Dual-color LEDs

Related products

E—Application key

(EIC Application)

0 No Application Key

1 Application Key (EIC Application)

Description

Connector bag assembly

10100944

DEUTSCH 12-pin Connector Kit (DTM06-12SA)

Connector and cable kit

11130518

11130713

Cable, M12 8-Pin to USB Device

Cable, M12 8-Pin to Lead Wires

Connection tools

10100744

10100745

DEUTSCH stamped contacts terminal crimp tool, size 20

DEUTSCH solid contacts terminal crimp tool

Mounting kit

11198661

Panel mounting kit

Software

11179523

(annual renewal with

11179524 to keep the

software updates)

Online

*

Requires a model with Application Key. See Model variants for model codes.

PLUS+1® GUIDE Professional Software (includes 1 year of software updates, a single user

license, Service and Diagnostic Tool and Screen Editor)

J1939 CAN EIC Engine Monitor Software

*

30 | © Danfoss | December 2018 AQ288937102741en-000103

Page 31

User Manual

DM430E Series Display - Engine Information Center (EIC) Software

©

Danfoss | December 2018 AQ288937102741en-000103 | 31

Page 32

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | December 2018 AQ288937102741en-000103

Loading...

Loading...