Page 1

Application guidelines

DC Compressors

DL19H / DL22H / DL30H

Compressors for mobile applications

12 - 24V Direct Current Compressor

www.danfoss.com

Page 2

Page 3

Application Guidelines

Content

DL compressors ...................................................................................................................................4

Compressor Overview .............................................................................................................................................................................4

Technical specification ............................................................................................................................................................................4

Performance data ................................................................................................................................5

Operating envelope ............................................................................................................................6

Electronic Driver controlled through resistance ...............................................................................7

General rules and wiring connections ...............................................................................................................................................7

Voltage drop in the power leads ..........................................................................................................................................................7

Terminal lay out wiring Diagram..........................................................................................................................................................7

Operating voltage .....................................................................................................................................................................................8

Battery protection system ......................................................................................................................................................................8

Temperature Switch .................................................................................................................................................................................8

Speed determination ..............................................................................................................................................................................9

Protections and alarms ............................................................................................................................................................................9

Ordering and packaging .................................................................................................................. 10

3BC346145660120en-000101

Page 4

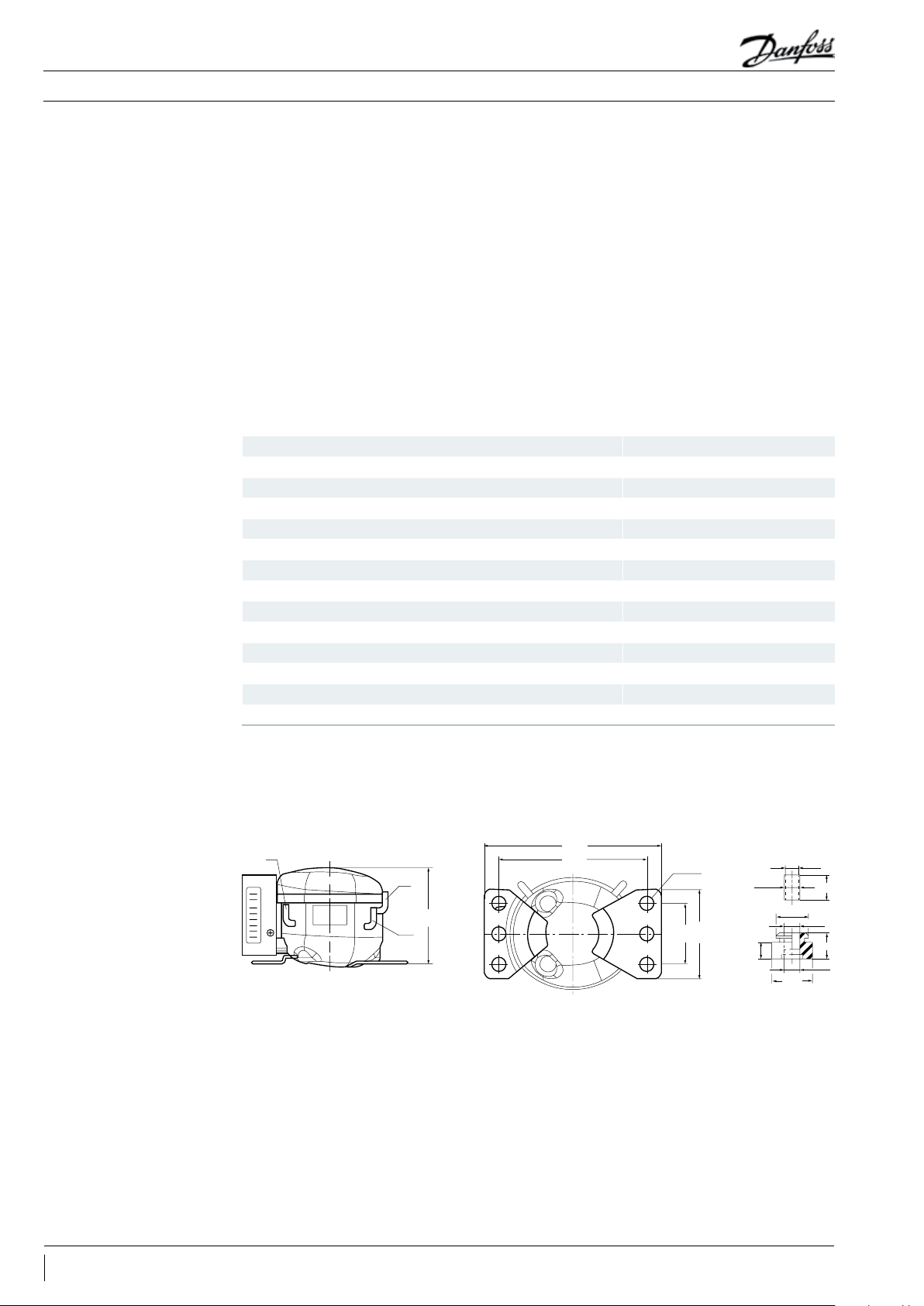

202

16.5

Application Guidelines

DL compressors

Compressor Overview

Technical specification

Many vehicles for transportation of goods or

recreation, such as trucks, caravans, boats, cars,

etc. are often equipped with cooling appliances.

These compressors are designed to operate

silently, efficiently and reliably even up to angles

of tilt of 30º, working with refrigerant R134a.

The compressors for such mobile applications

must be designed to operate from a low voltage

DC power supply. These compressors must also

be compact in their dimensions, highly reliable

and yield high performances.

The DL series of compressors are not designed for

off-road applications. Special approval is required

by Danfoss Commercial Compressors for this type

of application. The maximum tilt angle allowed in

DL compressors (stopped or running) is 30º.

DL19H, DL22H and DL30H are the answer to the

users’ needs requiring comfort and reliability in

their travelling, either on holidays, at work or in

any other circumstance where Direct current is

DL19H, DL22H and DL30H can be powered at any

voltage within the 12 to 24V DC range, and are

designed for capillary tube expansion.

required for cooling.

Refrigerant R134a *

Oil type / charge ISO VG 15 ESTER / 120cm

Expansion capilary tube

Application LBP/ MBP / HBP

Evaporation temperature range -35ºC to +10ºC.

Condensation temperature range up to 65ºC (Pull-down peak: 70ºC).

Ambient temperature range -10 to 43ºC **

voltage range DC 9.6 - 17 / 21.3 - 31.5 VDC

Motor speed range 2000 - 3500 rpm

Consumption of the electronic driver when the compressor is stopped 0.5W

Comp. dispalcement DL19H/DL22H/DL30H 1.9cm3 / 2.2cm3 / 3cm

Weight DL19H/DL22H/DL30H+ Electronic unit 3.9kg / 4.2kg /4.2 kg + 0.2 kg

Suction connector I.D. 6.2 mm (1)

Service connector I.D. 6.2 mm (2)

Discharge connector I.D. 4.9 mm (3)

* Compatible refriger. R1234yf

** In case of ambi ent temperature lower than 0 ºC. an oil heate r will be needed.

3

3

Fixings and Silent blocks (Mounting Accessories) Standard

6 holes Ø16

1

1. Suction 6.2 mm

2. Service 6 .2 mm

3. Discharge 4.9 mm

4. 6 holes Ø16 (170 X 70 net)

170

4

3

129

2

70

102

(170 X 70 net)

Ø10.2

Ø21

11

Ø26

Ø8.6

Ø10.5

17

Ø9.8

4 BC346145660120en-000101

Page 5

Application Guidelines

Performance data

Table 1: Cooling Capacity [W] ASHRAE

Type / Code rpm

2000 10 16 26 29 37 52 70 91 114 141 154 171

DL19H /

123F1905

DL22H /

123 F190 6

DL30H /

123 F1907

2500 13 22 35 40 50 69 91 115 144 174 190 209

3000 15 25 38 44 57 79 103 135 168 208 227 253

3500 16 30 50 57 73 100 131 167 208 252 273 301

2000 14 22 34 38 49 66 87 110 138 169 183 201

2500 17 27 40 45 57 78 104 133 165 202 220 243

3000 22 33 48 54 68 93 123 158 196 241 262 289

3500 28 41 59 66 83 113 148 190 236 288 314 348

2000 21 30 45 49 64 88 116 149 187 229 103 276

2500 24 37 56 63 79 108 144 184 230 283 306 340

3500 34 53 79 89 110 147 188 235 287 344 369 407

-35 -30 -25 -23. 3 -20 -15 -10 -5 0 5 7. 2 10

Table 2: Power consumption [W] ASHRAE

Type / Code rpm

DL19H /

123F1905

DL22H /

123 F190 6

DL30H /

123 F1907

2000 0.58 0.75 0.99 1.08 1.26 1.56 1.88 2.22 2.56 2.91 3.07 3.27

2500 0.56 0.80 1.07 1.16 1.35 1.65 1.95 2.25 2.56 2.87 3.01 3.18

3500 0.54 0.83 1.12 1.21 1.4 1. 68 1.95 2.22 2.48 2.74 2.85 2.99

2000 0.66 0.85 1.08 1.16 1.33 1.6 0 1.89 2.18 2.49 2.80 2.95 3 .13

2500 0.67 0.86 1.10 1.19 1.37 1.66 1.96 2.25 2. 55 2.84 2.97 3.13

3500 0.80 0.94 1.15 1.23 1. 39 1.65 1.93 2.21 2.50 2.78 2.97 3.07

2000 0.78 0.93 1.14 1. 22 1.38 1.64 1.90 2.17 2.43 2.69 2.80 2.94

2500 0.74 0.93 1.17 1.26 1.43 1.71 1.99 2.26 2.53 2.79 2.9 3.04

3500 0.77 0.96 1.17 1.24 1.39 1.62 1.87 2.12 2.39 2.66 2.79 2.95

-35 -30 -25 -23. 3 -20 -15 -10 -5 0 5 7. 2 10

Cooling Capacity [W] ASHRAE ºC

Power consumption [W] ASHRAE ºC

Table 3: COP [W/W] ASHRAE

Type / Code rpm

DL19H /

123F1905

DL22H /

123 F190 6

DL30H /

123 F1907

2000 0.58 0.75 0.99 1.08 1.26 1.56 1. 88 2.22 2.56 2.91 3.07 3.27

2500 0.56 0.80 1.07 1.16 1. 35 1.65 1.95 2.25 2.56 2.87 3.01 3.18

3500 0.54 0.83 1.12 1.21 1.4 1. 68 1.95 2.22 2.48 2.74 2.85 2.99

2000 0.66 0.85 1.08 1.16 1.33 1.6 0 1.89 2.18 2.49 2.80 2.95 3 .13

2500 0.67 0.86 1.10 1.19 1.37 1.66 1.96 2.25 2. 55 2.84 2.97 3.13

3500 0.80 0.94 1.15 1.23 1. 39 1.65 1.93 2.21 2.50 2.78 2.97 3.07

2000 0.78 0.93 1.14 1. 22 1.38 1.64 1.90 2.17 2.43 2.69 2.80 2.94

2500 0.74 0.93 1.17 1.26 1.43 1.71 1.99 2.26 2.53 2.79 2.9 3.04

3500 0.77 0.96 1.17 1.24 1.39 1.62 1.87 2.12 2.39 2.66 2.79 2.95

COP [W/W] ASHRAE ºC

-35 -30 -25 -23. 3 -20 -15 -10 -5 0 5 7. 2 10

5BC346145660120en-000101

Page 6

Application Guidelines

Operating envelope

6 BC346145660120en-000101

Page 7

Application Guidelines

Electronic Driver controlled through resistance

General rules and wiring connections

Voltage drop in the power leads

DL series must always be powered through the

dedicated electronic driver, which is supplied

with the compressor as a separate device.

• Never connect the compressor’s hermetic pins

(fusite) to the terminals of a battery or any

other dc or ac source directly.

• Do not try to fit an electronic driver different

than the electronic driver supplied with the

compressor. the compressor will not operate

and irreversible damage may occur.

the power input terminals of the electronic

driver

• “-“ Power input terminal of the electronic driver

should be connected to the chassis of the

vehicle as well as the appliance frame

• A fuse must be placed between the “+” pole

of the battery or dc power supply and the “+”

power input terminal of the electronic driver:

- 12V systems: 12A fuse

- 24V systems: 7.5A fuse

• Always respect the polarity of the battery with

To avoid excessive voltage drop in the leads, their length and cross section must be related to the

voltage supply as indicated in Table below.

Table 4

Cross section Rated Operating Range

2

mm

2.5 2.5 5

4 4 8

6 6 12

10 10 20

12V 24V

Length (m)

Terminal lay out Wiring Diagram

The electronic driver features a terminal board where all connections are made. The terminal lay out is

described in the wiring diagram.

34

2

+

–

+

6

–

+

5

–

–

+

F+

F–

D

1

C

7

8

P

T

Legend

1 Electronic driver

2 Battery

3 Fuse

4 Main switch

5 External Fan*

6 LED

7 Thermostat

8 Resistor (speed selection)

9 Resistor (battery protection )

9

* The positive side of the fan is connected to the (F +) end of the controller, and the negative terminal of the controller is connected to the

(F-) terminal of the controller. A terminal of the controller (F +) and (F-) can be connected with a 12V DC fan The When the input voltage of

the controller exceeds 12V, the output value between the terminals (F +) and (F-) is always kept at 12V.

Regardless of whether the input voltage system is 12V or 24V, the fan must be a 12V DC fan. B, the controller can continue to output 0.5A

fan drive capability.

7BC346145660120en-000101

Page 8

Application Guidelines

Electronic Driver controlled through resistance

Operating voltage

Battery protection system

DL series are designed to operate in a wide range of DC voltages, supplied either by a battery or by

any other kind of filtered DC power supply.

DC voltage supply allowed: 9.6V to 31.5V. Controller itself detect if is connected to 12V or 24V.

Table 5: Operating Voltage Setting Table

External

resistance

KΩ V V V V V V

0 9.6 10.9 17.0 21.3 22.7 31.5

1.6 9.7 11.0 17.0 21.5 22.9 31.5

2.4 9.9 11.1 17.0 21.8 23.2 31.5

3.6 10.0 11.3 17.0 22.0 23.4 31.5

4.7 10.1 11.4 17.0 22.3 23.7 31.5

6.2 10.2 11.5 17.0 22.5 23.9 31.5

8.2 10.4 11.7 17.0 22.8 24.2 31.5

11 10.5 11.8 17.0 23.0 24.5 31.5

14 10.6 11.9 17.0 23.3 24.7 31.5

18 10.8 12.0 17.0 23.6 25.0 31.5

24 10.9 12.2 17.0 23.8 25.2 31.5

33 11.0 12.3 17.0 24.1 25.5 31.5

47 11.1 12.4 17.0 24.3 25.7 31.5

82 11.3 12.5 17.0 24.6 26.0 31.5

220 9.6 10.9 17.0 21.3 22.7 31.5

12V Stop

value

12V Boot

value

12V High pressure

stop value

24V Stop

value

24V Boot

value

24V High pressure

stop value

There is a protection system for the battery that prevents the compressor from operating if the

available voltage becomes too low. The electronic driver will start and stop the compressor as needed

by detection of the voltage between the input terminals (+) and (-) to protect the different power

supply batteries.

Temperature Switch

The recommended standard battery protection values are listed in table 6. Other voltage can be set by

adjusting the controller terminal (C) and (P) connection resistance (9), the specific value of Table 5.

Table 6: Limits of battery protection parameters

12V Cut-out 12V Cut-in 24V Cut-out 24V Cut-in

V V V V

10.4 11.7 22.8 24.2

The temperature switch (7) e.g. mechanical or electronic thermostat is connected to C and T pins and

determine compressor ON and OFF operation.

8 BC346145660120en-000101

Page 9

Application Guidelines

Electronic Driver controlled through resistance

Speed determination

Protections and alarms

If there is no resistor between C an T pins compressor running speed will be 2000rpm. Table 3 shows

the compressor running speed according to the resistance value connected between pins C and T.

Table 7

Compressor speed C/T Resistance C/T Current

rpm Ω mA

2000 0 5

2100 51 4.8

2200 100 4.6

2300 150 4.4

2400 200 4.2

2500 277 4

2600 330 3.8

2700 400 3.6

2800 490 3.4

2900 586 3.2

3000 692 3

3100 816 2.8

3200 963 2.6

3300 1137 2.4

3400 1331 2.2

3500 1523 2

DL series are electronically protected against a number of possible malfunctions and failures. As

shown in Terminal lay out Wiring Diagram:

• The controller terminal (+) and (D) can be connected between a 10mA LED (6) for the display fault,

LED anode connected to the controller (+) side, the cathode connected to the controller (D) end.

• When the failure occurs, LED every 3 seconds for the cycle, continuous flash in each cycle, according

to different failures flash different times, each flashing for 0.4 seconds, continuous flashing for 3.2

minutes. The number of specific codes and blinks is shown in Table 8.

Table 8: Alarm codification

No. of blinks Fault type

1 Voltage fault - The input voltage is outside the set range

2 Fan current fault - fan current output current greater than 1A

3 Compressor start fault - compressor motor stall or system pressure too large

4 Compressor minimum speed fault - The compressor is overloaded or the motor speed is too small.

5 Controller temperature fault - controller housing temperature too high (> 85 ° C)

6 Controller hardware failure - The controller has detected an abnormal parameter

9BC346145660120en-000101

Page 10

Application Guidelines

Ordering and packaging

Compressors are packed in industrial pack on polyester trays (25pcs each) on the pallet.Packaging and Ordering

Model

DL19H including electronic driver 25 6 150 1135 830 123F1905

DL22H including electronic driver 25 6 150 1135 830 123F1906

DL30H including electronic driver 25 6 150 1135 830 123F1907

Qty/Level Nb of levels Qty/Pallet Length Wight

Industrial pack Pallet dimensions (mm)

code

10 BC346145660120en-000101

Page 11

Page 12

Danfoss Commercial Compressors

Danfoss Inverter Scrolls

is a worldwide manufacturer of compressors and condensing units for refrigeration and HVAC applications. With a wide range

of high quality and innovative products we help your company to find the best possible energy efficient solution that respects

the environment and reduces total life cycle costs.

We have 40 years of experience within the development of hermetic compressors which has brought us amongst the global

leaders in our business, and positioned us as distinct variable speed technology specialists. Today we operate from engineering

and manufacturing facilities spanning across three continents.

Danfoss Turbocor Compressors

Danfoss Scrolls

Danfoss Optyma Condensing Units

Danfoss Maneurop Reciprocating Compressors

Danfoss Light Commercial Refrigeration

Compressors

Our products can be found in a variety of applications such as rooftops, chillers, residential air conditioners,

heatpumps, coldrooms, supermarkets, milk tank cooling and industrial cooling processes.

http://cc.danfoss.com

Danfoss Commercial Compressors, BP 331, 01603 Trévoux Cedex, France | +334 74 00 28 29

BC346145660120en-000101 © Danfoss | DCS (CC) | 2020.06

Loading...

Loading...