Page 1

Data sheet DBC

Air Eliminators

For Heating and Cooling Systems

Features:

Performance Principal /

Induced Turbulence:

DBC air eliminators allow hydronic heating and

cooling systems to operate at their maximum

performance by quickly removing dissolved gas

particles and microscopic air bubbles from the

system. This translates to reduced corrosion,

higher system efficiencies, quicker start-ups and

decreased maintenance call backs.

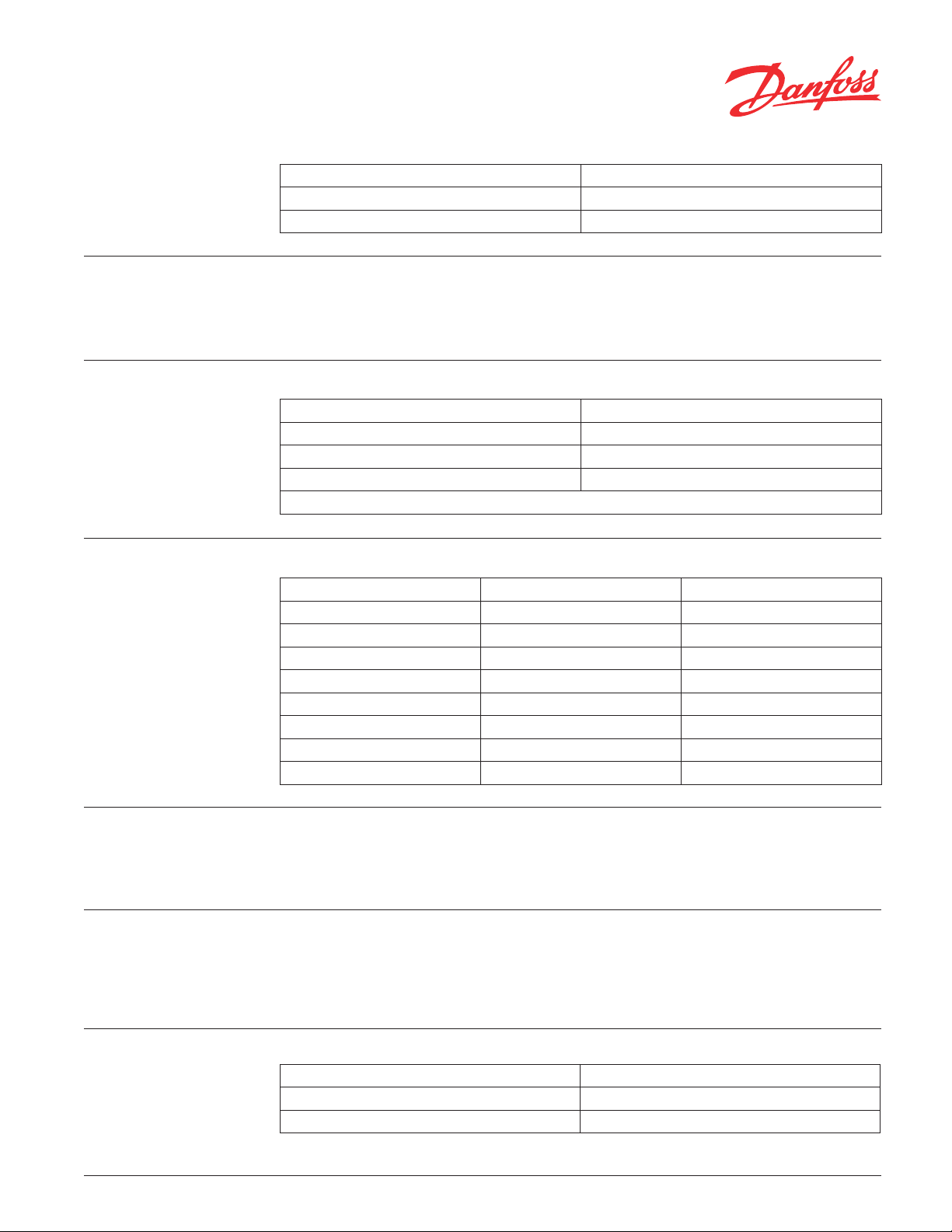

As system fluid enters the air separating

chamber containing a metal lattice matrix,

the flow of the fluid becomes turbulent. The

turbulent flow causes variations in velocity and

pressure resulting in the accumulation of microair bubbles on the surface of the lattice.

As the bubbles merge, the buoyancy force

on the bubbles cause them to float to the

upper chamber of the air eliminator where it is

regulated and released by a float mechanism.

Vent Chamber:

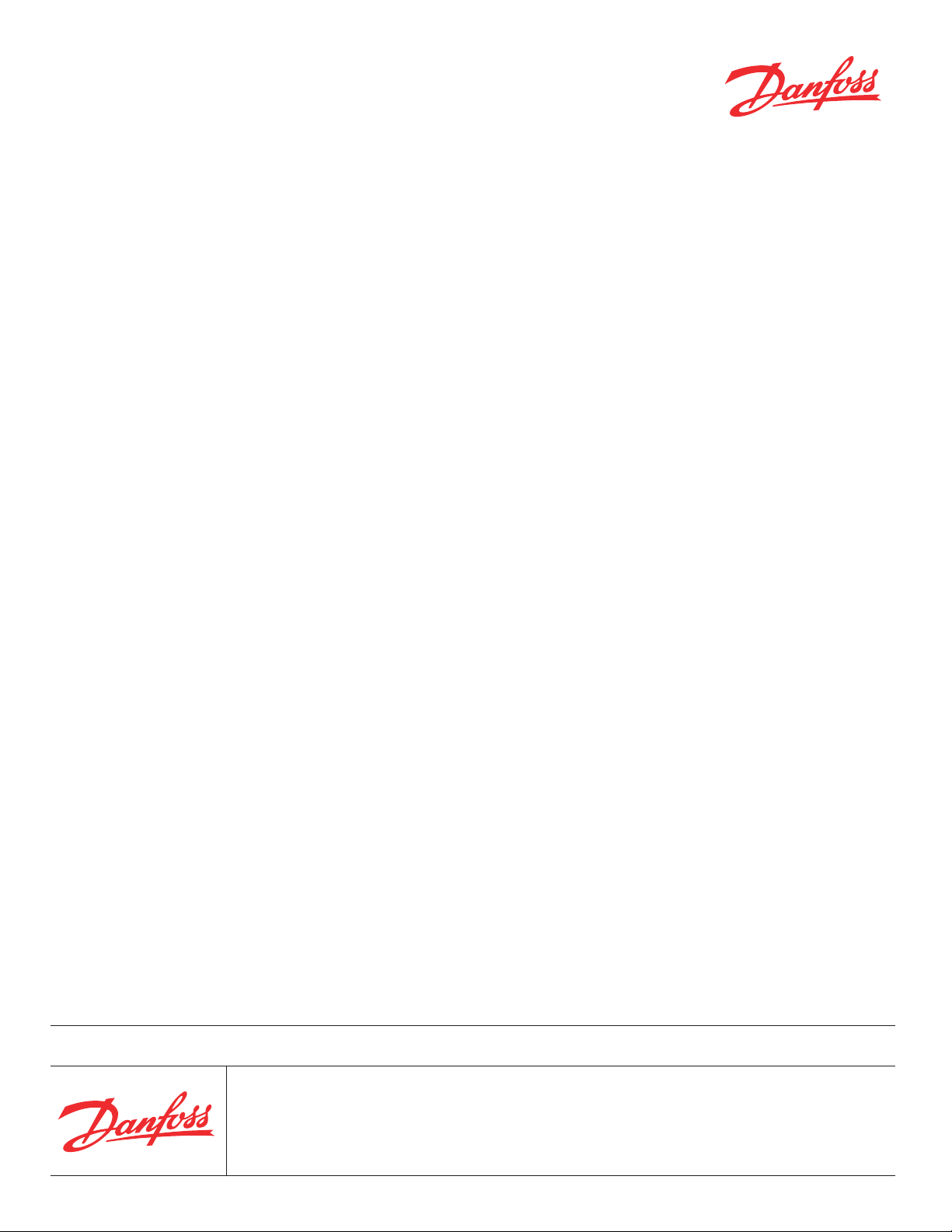

Installation Examples:

The float mechanism maintains a proper

air chamber at the top of the unit allowing

maximum performance of the vent valve.

VDFMA122 © Danfoss 05/09

1

Page 2

Data sheet

DBC

Air Eliminators

For Heating and Cooling Systems

System Connections:

Servicing:

Service Connections:

Ordering Information:

Size Connection

3/4” to 2” FNPT

2-1/2” to 4” ANSI Flange

The construction of DBC air eliminator allows

maintenance and cleaning without removal of

eliminator from the system. Brass models allow

Feature Size

Drain Plug (Models 3/4” - 2”) 1/2”

Drain Plug (Models 2-1/2” - 4) 1”

Purge Connection (Models 2-1/2” - 4”) 3/8”

Removable Vent (All Models)

Code Size Connections

551045DNF 3/4” NPT

551046DNF 1” NPT

551047DNF 1-1/4” NPT

551048DNF 1-1/2” NPT

551049DNF 2” NPT

551060DNF 2-1/2” ANSI Flange

551080DNF 3” ANSI Flange

551100DNF 4” ANSI Flange

for complete access to working internals. Steel

units allow access to vent assembly and blow

down valve for internal flushing.

Installation:

Preferred Location of

Separator:

Air Separator:

2

Orientation

DBC air eliminators are designed to be installed

with the float chamber in the vertical position.

Heating

Upstream of the circulator (Suction Side), downstream of the boiler. (ie: highest temperature,

lowest pressure)

Lattice Matrix Material Stainless Steel - All Models

Removable Lattice Brass Models Only

Rapid Manual Venting Ball valve on 2-1/2” to 4” models

VDFMA122 © Danfoss 05/09

Cooling

Upstream of the circulator (Suction Side) and

chiller (Return Side). (ie: highest temperature,

lowest pressure)

Page 3

Data sheet

DBC

Air Eliminators

For Heating and Cooling Systems

Materials of Construction:

Dimensions:

A

3/4” to 2”

2-1/2” to 4”

C

1/2”

B

Brass Body

EDPM Seals

NPT Connections

Stainless Steel Lattice Matrix

Steel, Enameled Painted

EDPM Seals

ANSI Flanges

Stainless Steel Lattice Matrix

F

C

D

E

A

Figure 1 Figure 2

B

D

E

Figure 1

Code No. A

551045D NF 3/4” 110.0 (4.3) 55.0 (2.2) 146.0 (5.7) 191.0 (7.5) N/A 1.7 (3.7)

551046 DNF 1” 110.0 (4.3) 55.0 (2.2) 146.0 (5.7) 191.0 (7.5) N/A 1.7 (3.7)

551047DNF 1-1/4” 124.0 (4.9) 55.0 (2.2) 166.0 (6.5) 211.0 (8.3) N/A 2.2 (4.9)

551048 DNF 1-1/2” 124.0 (4.9) 55.0 (2.2) 166.0 (6.5) 211.0 (8.3) N/A 2.2 (4.9)

551049DN F 2” NPT 127.0 (5.0) 55.0 (2.2) 160.0 (6.3) 211.0 (8.3) N/A 2.5 (5.5)

Figure 2

Code No. A

551060 DNF 2-1/2” ANSI 350.0 (13.8) 55.0 (2.2) 373.5 (14.7) 506.0 (20.0) 168.5 (6.6) 15.6 (34.4)

55108 0DN F 3” ANSI 466.0 (18.4) 55.0 (2.2) 435.5 (17.2) 595.0 (23.5) 219.0 (8.6) 28.0 (61.7)

551100DN F 4” ANSI 470.0 (18.5) 55.0 (2.2) 435.5 (17.2) 595.0 (23.5) 219.0 (8.6) 30.0 (66.1)

Flow Characteristics:

Connections 3/4” 1” 1-1/ 4” 1 -1/2 ” 2” NPT 2-1/2” ANSI 3” ANSI 4” ANSI

L/min 22.7 35.2 57.9 90.4 141.2 238.7 361.5 564.8

Gal/min 6.0 9.3 15.3 23.9 37.3 63.1 95.5 149.3

3

/h 1.4 2.1 3.5 5.4 8.5 14.3 21.7 33.9

m

Gal/h 359.0 558.0 917.0 1,432.0 2,238.0 3,784.0 5,732.0 8,956.0

B

in (mm)

B

in (mm)

C

in (mm)

C

in (mm)

D

in (mm)

D

in (mm)

E

in (mm)

E

in (mm)

F

in (mm)

F

in (mm)

Weight

kg (lb)

Weight

kg (lb)

VDFMA122 © Danfoss 05/09

3

Page 4

Data sheet

DBC

Air Eliminators

For Heating and Cooling Systems

Danfoss can accept no responsibility for possible errors in printed materials and reserves the right to alter its products without notice.

All trademarks in this material are property of the respective companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss Inc.

Toronto, ON

Tel.: 905-285-2050, Fax: 905-285-2055

www.na.heating.danfoss.com

4

VDFMA122 © Danfoss 05/09

Danfoss Inc.

Baltimore, MD

Tel.: 443-512-0266, Fax: 443-512-0270

www.na.heating.danfoss.com

Loading...

Loading...