Page 1

Data Sheet

Hermetic burn-out filter drier

Type DAS

Used in the suction line to clean up refrigeration and air conditioning systems

Hermetic burn-out lter driers type DAS are

used in the suction line to clean up

refrigeration and air conditioning systems after

a compressor motor burn-out.

The solid core, which is composed of 70%

activated alumina and 30% Molecular Sieve,

adsorbs harmful acids as well as moisture.

Available with are and solder (pure copper)

connections.

AI192386433066en-000601

Page 2

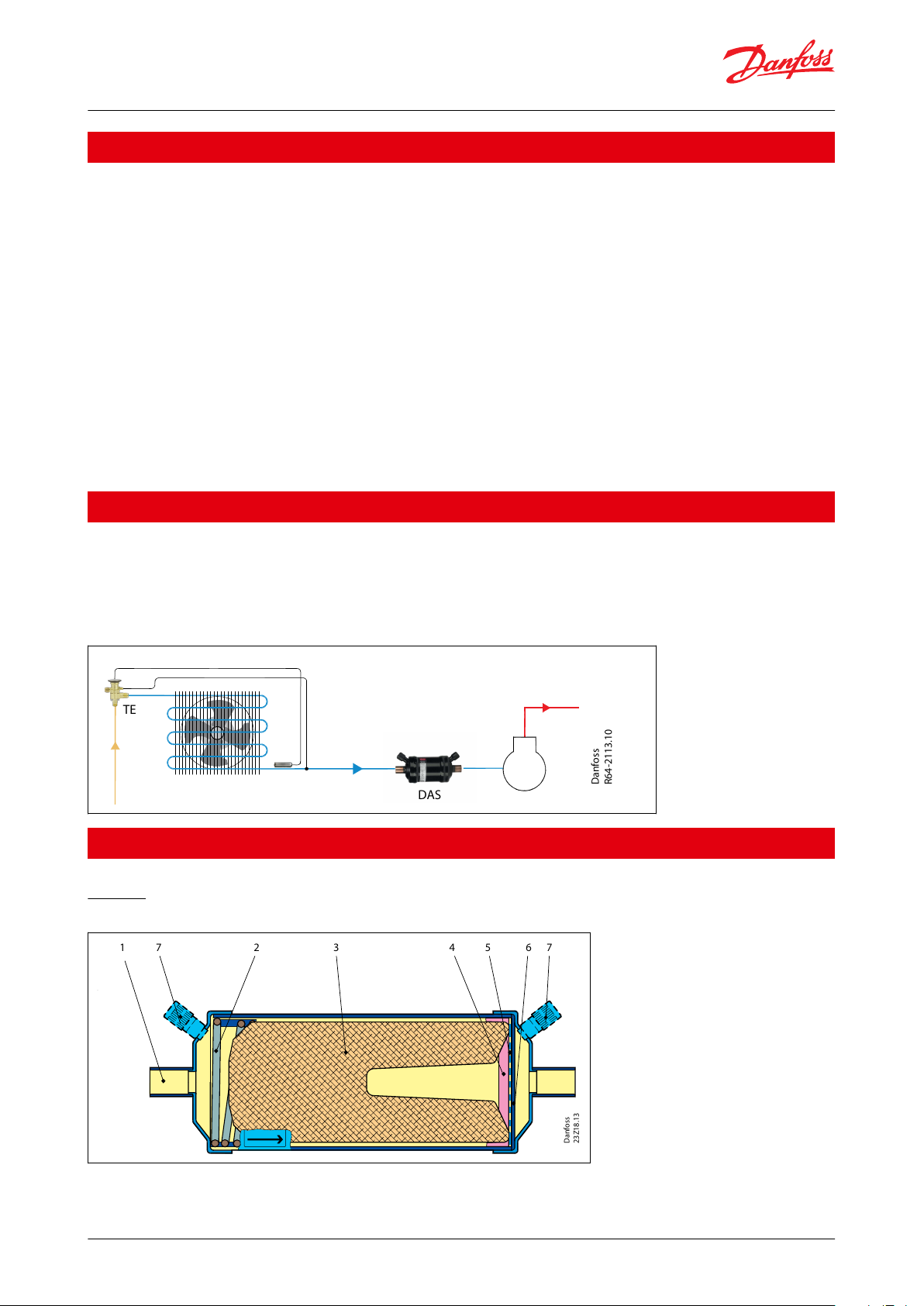

TE

DAS

Danfoss

R64-2113.10

Danfoss

23Z18.13

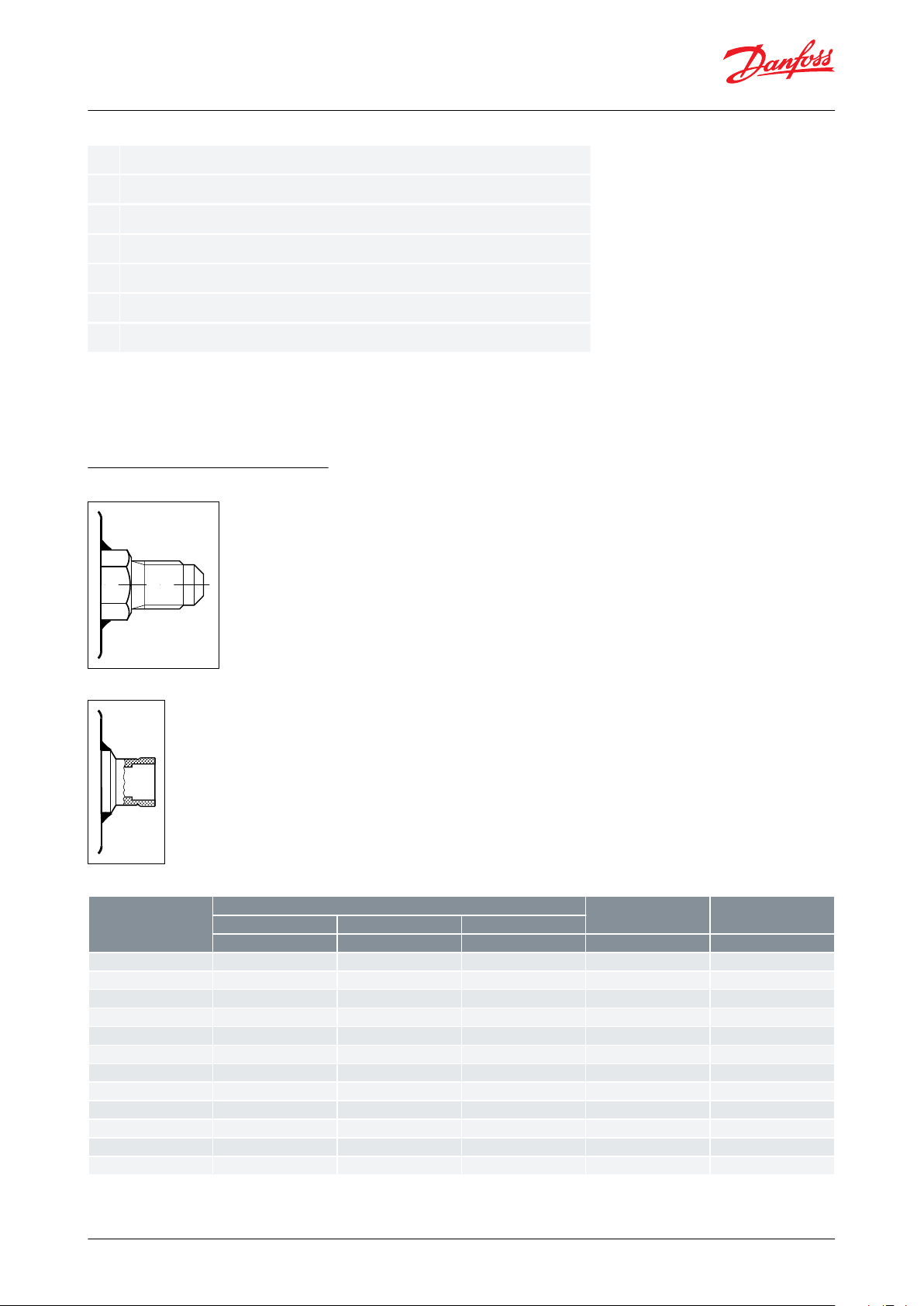

7 2 3 4 5 6 7 1

Hermetic burn-out lter drier, type DAS

Features

The Core type DAS

• Solid core with 70% activated alumina and 30% Molecular Sieve for adsorption of acid and moisture

• Recommended for use with HFO, HC, HFC and HCFC refrigerants

The Shell

• PED approved for PS 35 bar

• Available with are and solder (pure copper) connections

• Corrosion resistant powder-painted nish

• Allows installation with any orientation provided the ow is in the arrow direction

• 2 Schrader access valves to measure pressure drop across the drier

• Available in sizes 8 – 60 cubic inches

The Filter

• 120 mesh wire mesh provides solid particle retention with minimal pressure drop

Functions

Hermetic lter driers protect refrigeration and air-conditioning systems from moisture, acids, and solid particles.

By adsorbing harmful acids after a compressor motor damage, the DAS hermetic burn-out lter drier protects the

new compressor against premature failure.

Figure 1: Functional diagram

Product specication

Design

Figure 2: Type DAS

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 2

Page 3

1234567

Inlet

Spring

Solid core

Polyester ma

Metal mesh

Perforated plate

Schrader valve

Type

Rated capacity, Q

n

(1)

Acid capacity

(2)

Max.Working Pressure

PS

R22/R407C/R410A

R134a

R404A/R507

[kW]

[kW]

[kW]

[g]

[bar]

DAS 08363.5

4.5

3.8

35

DAS 084105.583.8

35

DAS 085

14.5912.5

3.8

35

DAS 0861911.5

16.5

3.8

35

DAS 164

10.568.5

8.6

35

DAS 165159.5138.6

35

DAS 1662012178.6

35

DAS 1672213.5198.6

35

DAS 30518111518.2

35

DAS 30622141918.2

35

DAS 30726162218.2

35

DAS 30931202718.2

35

Hermetic burn-out lter drier, type DAS

The large diameter of the hermetic burn-out lter drier means that ow velocity is suitably low and the pressure

drop minimal.

Powder formation is eliminated because the solid core grains are bonded and cannot move against each other.

Technical data and capacities

Figure 3: Flare connection

Figure 4: Solder connection (pure copper)

Table 1: Type DAS

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 3

Page 4

Qe/FeQeQnF

e

Type

Rated capacity, Qn

(1)

Acid capacity

(2)

Max.Working Pressure

PS

R22/R407C/R410A

R134a

R404A/R507

[kW]

[kW]

[kW]

[g]

[bar]

DAS 41730182524.3

35

DAS 41935223024.3

35

DAS 60720121736.5

35

QNActual evaporator capacity

Nominal capacity

Correction factor

[°C]40-5-10

-15

-20

-25

-30

-35

-40

F

e

1

0.9

0.75

0.6

0.5

0.4

0.35

0.25

0.2

0.15

Type

Codes

Description

Filter drier

D

Drier

Solid core

A

Burn-out, 70% activated alumina / 30% Molecular Sieves

Application

S

Suction line

Size (volume)

8

8 in

3

16

16 in

3

30

30 in

3

41

41 in

3

60

60 in

3

Connection

(lter connection in

1

⁄8 of an

inch increments)

3

3

⁄8

in. / 10 mm

4

1

⁄2

in. / 12 mm

5

5

⁄8

in. / 16 mm

6

3

⁄4

in. / 18 (19) mm

7

7

⁄8

in. / 22 mm

9

1

1

⁄8 in. / 28 mm

Connection type

(blank)

Flare connection

s

Solder connection (pure copper)

Hermetic burn-out lter drier, type DAS

(1)

(1)

Rated capacity is stated at: evaporating temperature te = 4 °C pressure drop Δp = 0.21 bar

Rated capacity is stated at: evaporating temperature te = 4 °C pressure drop Δp = 0.21 bar

(2)

(2)

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Adsorption capacity of oleic acid at 0.05 TAN (Total Acid Number).

Temperature range: -40 – 70 °C

Selection

Capacities for other temperatures than 4 °C are calculated by use of correction factors. Divide your actual evaporator

capacity with the correction factor given for your actual evaporating temperature.

Look up the capacity table for the necessary rated capacity:

Table 2: Correction factors Fe for evaporating temperatures [°C]

Example

To select a hermetic burn-out lter drier for a R22 plant with an evaporator capacity at 8.5 kW at -20 °C you may use

a burn-out

lter drier with a rated capacity of 8.5/0.4 = 21.25 kW or bigger.

For example DAS 306.

Identication

Table 3: Type codes

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 4

Page 5

DAS083svv

Type

Codes

Description

Access valves

Inlet:

Outlet:

(blank)

No access valves

No access valves

V

Schrader valve

No access valves

VV

Schrader valve

Schrader valve

Filter drier

Solid core

Application

Size (volume)

Connection (lter connection in

1

⁄8 of an inch increments)

Connection type

Access valves

Type

ABLD1D2

F

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DAS 083sVV

101

120

1395854400.47

DAS 084sVV

101

122

1435854400.5

DAS 085sVV

101

125

1495854400.5

DAS 086sVV

101

131

1615854400.5

DAS 164sVV

110

131

1528076500.83

DAS 165sVV

110

134

1588076500.84

DAS 166sVV

110

140

1708076500.84

DAS 167sVV

110

141

1728076500.84

DAS 169sVV

110

142

1738076501.9

DAS 305sVV

186

210

2348076501.31

DAS 306sVV

186

216

2468076501.31

DAS 307sVV

186

217

2488076501.33

DAS 309sVV

186

218

2498076501.35

DAS 417sVV

187

218

2499389552.08

DAS 419sVV

187

219

2509389552.08

DAS 607sVV

337

363

3998076502.39

DAS 609sVV

337

358

4008076502.4

Hermetic burn-out lter drier, type DAS

Example for type codes

Dimensions and weights

Figure 5: Solder connections

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 5

Page 6

Type

ALD1D2F

Net weight

[mm]

[mm]

[mm]

[mm]

[mm]

[Kg]

DAS 083VV

101

1585854400.51

DAS 084VV

101

1665854400.62

DAS 164VV

110

1758076400.91

DAS 165VV

110

1848076400.95

Danfoss

23Z8406

Type

Connection

Multi pack

[in.]

Qty.

Code no.

DAS 083VV

3

⁄8

24

023Z1001

DAS 084VV

1

⁄2

24

023Z1002

DAS 164VV

1

⁄2

12

023Z1007

DAS 165VV

5

⁄8

12

023Z1008

Danfoss

23Z8407

Type

Connection

Multi pack

[in.]

Qty.

Code no.

DAS 083sVV

3

⁄8

24

023Z1003

DAS 084sVV

1

⁄2

24

023Z1004

DAS 085sVV

5

⁄8

24

023Z1005

DAS 086sVV

3

⁄4

24

023Z1006

DAS 164sVV

1

⁄2

12

023Z1009

DAS 165sVV

5

⁄8

12

023Z1010

DAS 166sVV

3

⁄4

12

023Z1011

DAS 167sVV

7

⁄8

12

023Z1012

DAS 305sVV

5

⁄8

8

023Z1013

DAS 306sVV

3

⁄4

8

023Z1014

DAS 307sVV

7

⁄8

8

023Z1015

DAS 309sVV

1

1

⁄8

8

023Z1016

DAS 417sVV

7

⁄8

8

023Z1017

Hermetic burn-out lter drier, type DAS

Figure 6: Flare connections

Ordering

Figure 7: Flare connection

Table 4: Flare

Figure 8: Solder connection

Table 5: Solder

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 6

Page 7

Type

Connection

Multi pack

[in.]

Qty.

Code no.

DAS 419sVV

1

1

⁄8

8

023Z1018

DAS 607sVV

7

⁄8

12

023Z1019

DAS 609sVV

1

1

⁄8

12

023Z1020

Document name

Document type

Document topic

Approval authority

SA 6398

UL Certicate

Mechanical Safety Certicate

UL

023Z9601.AF

Manufacturers Declaration

ATEX/PED/RoHS

Danfoss

023Z9610.AA

Manufacturers Declaration

China RoHs

Danfoss

RU Д-DK.БЛ08.B.00828_19

EAC Declaration

Machinery & Equipment

EAC

Hermetic burn-out lter drier, type DAS

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 6: Certicates, declarations, and approvals

NOTE:

Only solder versions (cu-plated / pure copper) and connection sizes below 25 mm are approved for ammable

refrigerants now.

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 7

Page 8

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.09 AI192386433066en-000601 | 8

Loading...

Loading...