Page 1

INSTRUCTIONS

INSTALLATION OF TOP SECTION BACK-CHANNEL COOLING KIT FOR

FRAMES D3, D4 & E2

This instruction sheet is for the installation of the top section only of the back-channel cooling

kits available for the VLT

estal is required.

The minimum enclosure depth is 500 mm (600 mm for E2 frame) and the minimum enclosure

width is 600 mm (800 mm for E2 frame). The maximum depth and width are as required by

the installation. When using multiple drives in one enclosure mount each drive on its own

back panel and support along the mid-section of the panel. The back-channel cooling kits

are very similar in construction for all frames. The D3 and D4 kits do not support “in frame”

mounting of the drives. The E2 kit is mounted “in frame” for additional support of the drive.

These kits can be used with IP00/Chassis drives as listed in Table 1.

Using these kits as described removes 85% of the losses via the back channel using the

drive’s main heat sink fan. The remaining 15% must be removed via the door of the enclosure. (Refer to Note 2 for air flow requirements.)

®

series drives. In addition to the enclosure a 200 mm vented ped-

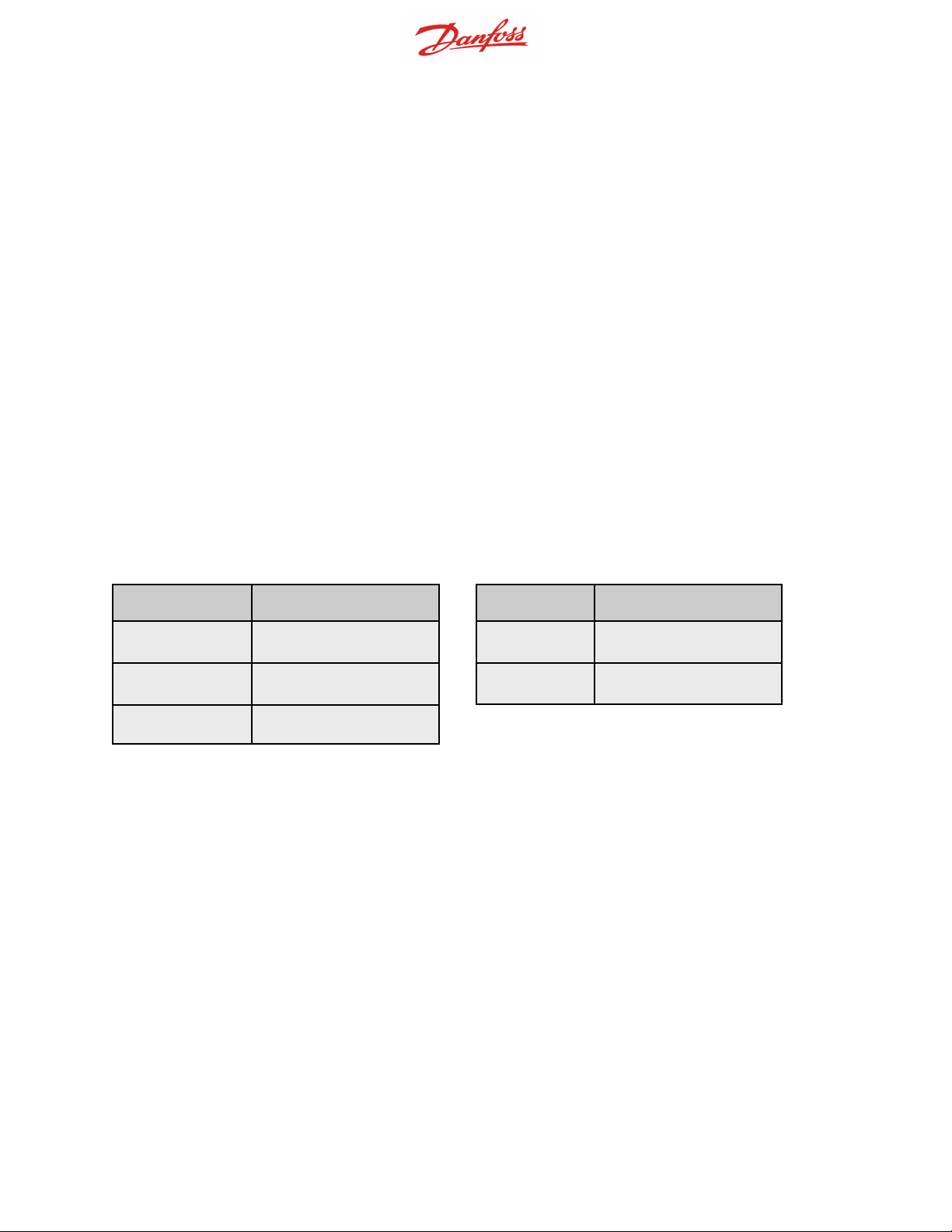

Table 2. Kit Part Numbers Table 1. Applicable Drives and Frames

VLT Drive Frame

HVAC D3, D4, E2

Aqua D3, D4, E2

VLT Frame Kit Part Number

D3 and D4 176F1775

E2 176F1776

Automation D3, D4, E2

Notes:

1. The photos in this instruction are based on a D4 Frame installation. D3 and E2 frames use

parts similar to those in the photos however they are sized appropriately for those frames.

2. A doorfan(s) is required on the enclosure to remove the heat losses not contained in the

backchannel of the drive. The minimum airflow required (at the maximum rated ambient

3

temperature) for the D3 and D4 frame drives is 391 m

required (at the maximum rated ambient temperature) for the E2 frame drive is 782 m

(460 cfm). If additional heat losses are added within the enclosure a calculation must be

made to ensure the proper airflow is provided to cool the inside of the enclosure.

3. The end user is responsible for ensuring the enclosure rating of the system after the toponly duct kit is installed.

/h (230 cfm). The minimum airflow

3

/h

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 1

Page 2

Kit Contents

• Ductwork components

• Mounting hardware

• Gasket material

• 175R5631 View of Ductwork components, D3 and D4 frames

• 175R1037 View of Ductwork components, E2 frame

Required Tools

• Metric Socket Set, 7-19mm

• Socket Extensions

• Torx Driver Set T10-T40

• Torque Wrench 6-50 in-lbs (.7-6 N-M)

Torque Requirements

1. 10 mm, M5 Nuts torque to 20 in-lbs (2.3 N-M)

2. T25 Torx screws torque to 20 in-lbs (2.3 N-M)

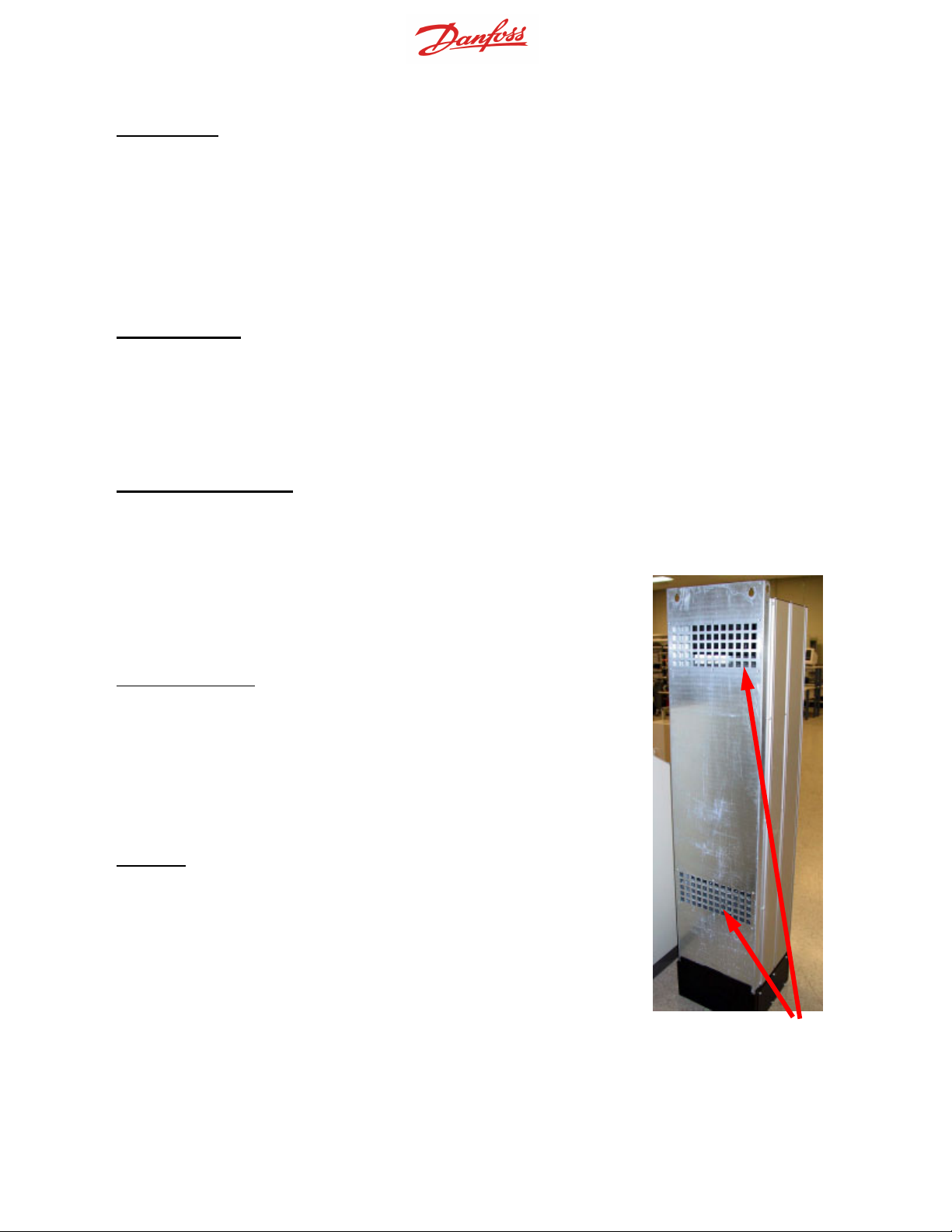

Install gasket material on the back openings of

the drive (Photo 1) prior to installation on the enclosure back panel.

D3 and D4 frames

: Use the template provided

with the kit (175R5639) to determine the drive

location on the back panel of the enclosure. The

template is referenced to the top-left corner of the

back panel. Therefore the template may be used

with any size back panel and both the 1800 mm

and 2000 mm high enclosures.

E2 frame

: Use the measurements on Drawing

175R1037, Sheet 2 to determine the drive location.

Photo 1. Drive openings o n rear are not

used in this application.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 2

Page 3

Prior to installing the back panel in the enclosure,

apply the gasket on both sides of the bottom duct

adapter as shown in Photos 2 and 3.

Photo 2. Bottom duct adapter

Before installing the back panel with the drive in

the enclosure, remove and discard the rear-most

screws (Photo 4) that are located on the top cover

of the drive. The holes will be used to fasten the

top ductwork with longer screws provided with the

kit.

Photo 3. Bottom duct adapter w/

Photo 4. Top of IP00/Chassis drive.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 3

Page 4

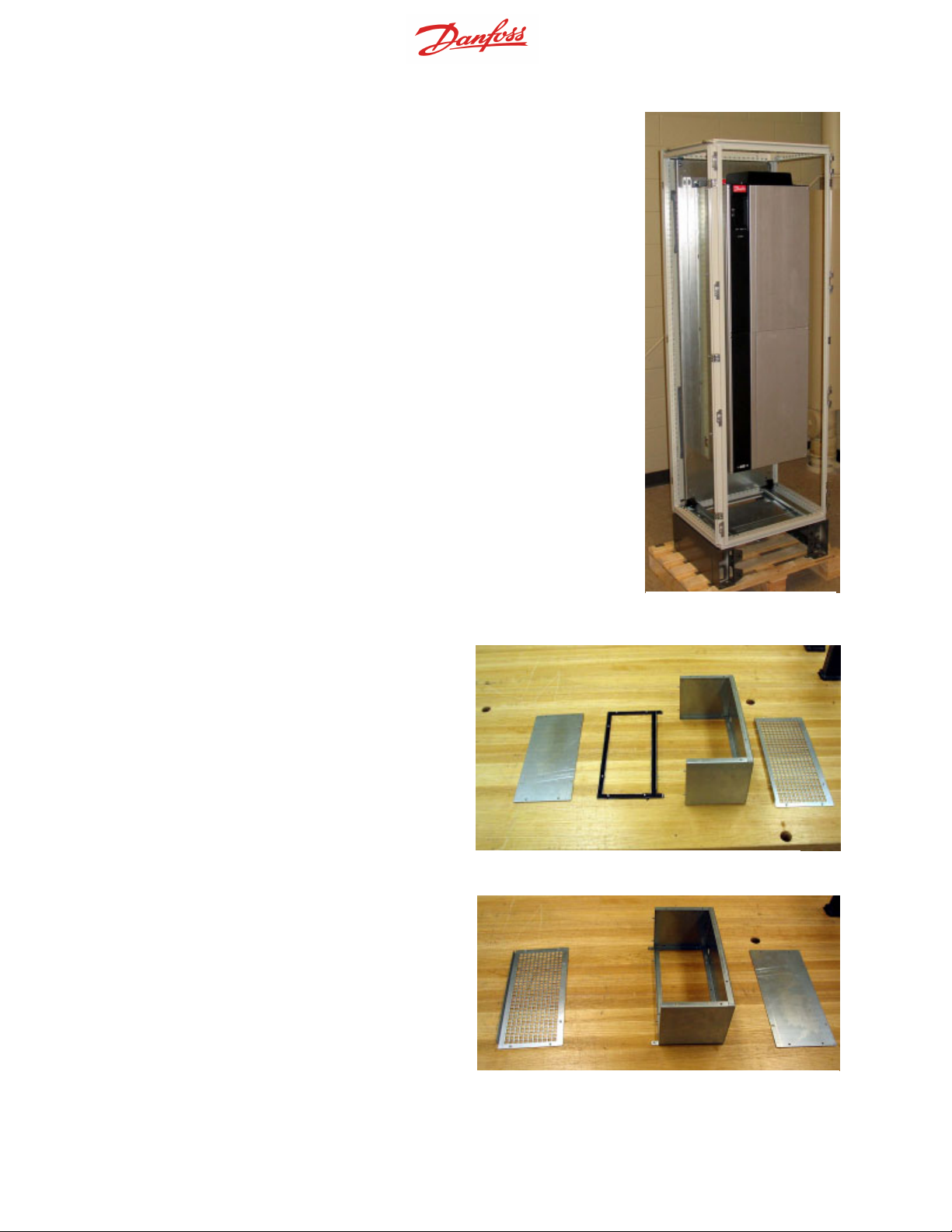

Install the backpanel in the enclosure (Photo 5). Use brackets

supplied by the enclosure manufacturer (minimum one per side

at the middle of the drive) with appropriate support strip for

additional support of the backpanel. For the D4 frame use two

supports per side. Consult the enclosure manufacturer manual

for additional support requirements if additional components are

mounted on the same back panel.

The top duct work cover is composed of

the following pieces as shown in Photo 6.

From left to right:

• top duct closing plate

• drive bracket

• duct

• vented top cover

Install the drive bracket onto the duct.

Photo 5. Drive installed

in cabinet—D4 Frame.

Photo 6. Top duct assembly.

Photo 7. The top duct work partially assembled with bottom flange.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 4

Page 5

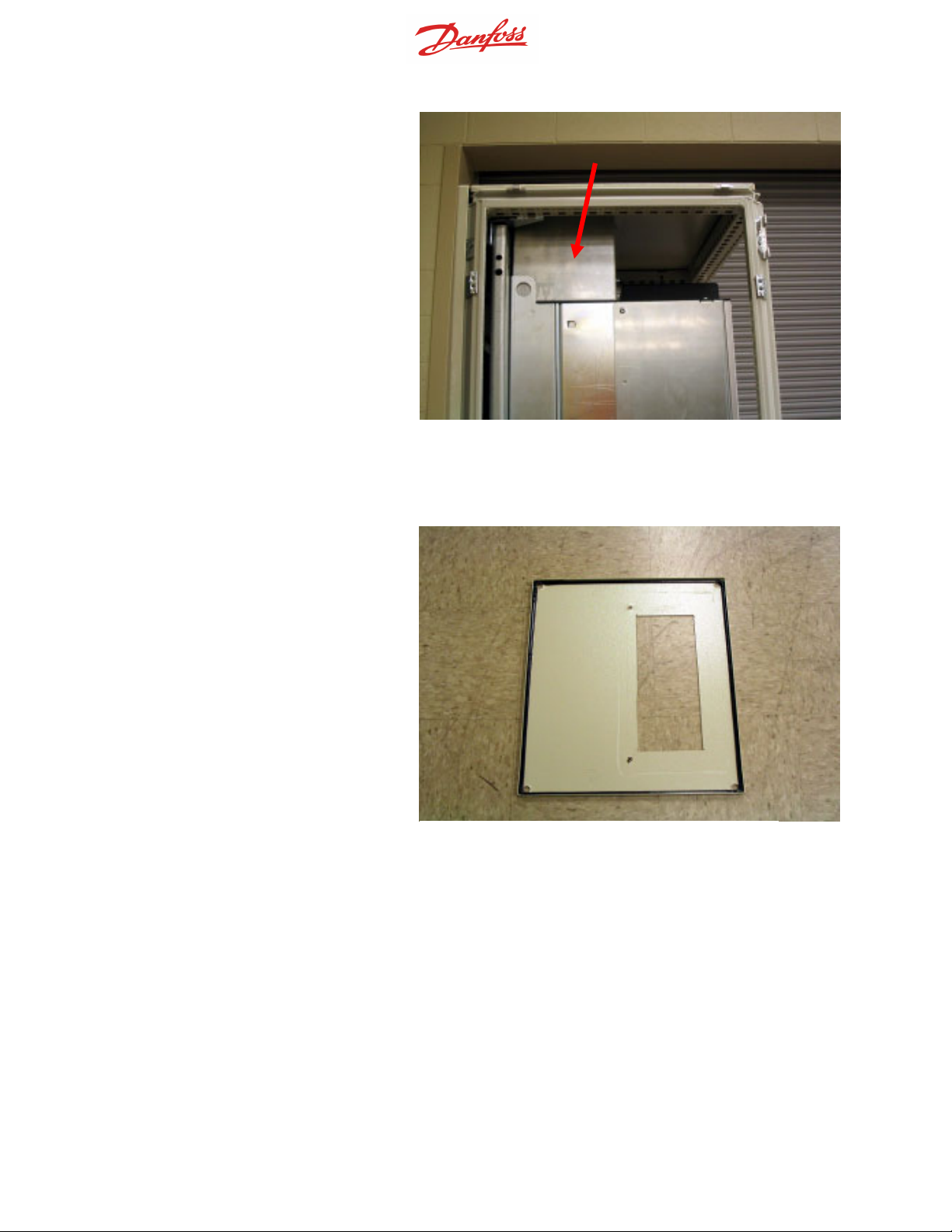

Temporarily install the top duct section as shown in Photo 8. Use the

top duct cover piece to mark the enclosure top for the opening. Alternately, Drawing 175R5639 can be

used to mark the enclosure for cut-

Cut the enclosure top. Do not apply

gasket to enclosure top (the gasket

is part of the duct work).

Photo 8. Top duct work and enclosure top installed.

Photo 9. Enclosure top with cutout.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 5

Page 6

Assemble the top duct as shown in

Photos 10, 11 and 12. Gasket is applied to several surfaces as shown

(refer to drawing 175R5631 Sheet 2,

exploded view of components). The

top duct closing plate is left off for the

installation of the duct work on the

drive.

Closing plate

Photo 10. Top duct assembled with gasket.

Photo 11. Gasket applied to both sides drive

bracket and grated cover.

Photo 12. Top duct ready to be installed on drive.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 6

Page 7

The top duct work is attached to the

drive using existing holes on the top

cover of the drive. Use the 5 longer

screws (supplied with kit) to install

the top duct work. The duct work will

fit over the drive mounting bolts.

Once the duct work is attached to the

drive, the duct closing plate can be

attached. The top duct work assembly is complete.

Photo 13. Gasket folds over the edge to form seal

between the duct and top vented cover.

Photo 14. Top duct installed.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 7

Page 8

Install top duct-cover assembly using the longer T25 screws provided

with the kit in the drive top cover

holes. Reference Photos 15.

Apply the gasket to the top duct

closing plate. Reference Photo 16.

Photo 15. Top duct installed.

Install the duct closing plate. Reference Photo 17.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 8

Photo 16. Top duct closing plate with gasket.

Photo 17. Top duct closing plate installed.

Page 9

Install the top of the enclosure. Reference Photos 18 and 19.

Top duct installation is complete.

Photo 18. Enclosure top installed.

Photo 19. Top view of enclosure.

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 9

Page 10

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 10

Page 11

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 11

Page 12

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 12

Page 13

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 13

Page 14

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 14

Page 15

MI.38.H1.02 - VLT® is a Danfoss Registered Trademark 15

Loading...

Loading...