Page 1

Technical Information

ATEX certified

Axial piston pump, variable displacement

D1P130/D1P145/193/260

www.danfoss.com

Page 2

Technical Information

ATEX certified D1P 130/145/193/260

Revision history Table of revisions

Date Changed Rev

September 2021 Fixed typo 0202

August 2021 Added size 193/260, updated model code, and replaced the nameplate 0201

February 2020 Updated cover image and changed document number from BC00000404 0102

July 2018 first edition 0101

2 | © Danfoss | September 2021 BC274750280114en-000202

Page 3

Technical Information

ATEX certified D1P 130/145/193/260

Contents

General information

ATEX Introduction............................................................................................................................................................................4

Explosive atmosphere.....................................................................................................................................................................4

Explosion triangle....................................................................................................................................................................... 4

General zone classification...................................................................................................................................................... 4

Equipment category and zones.............................................................................................................................................5

Contents of marking.................................................................................................................................................................. 6

Marking of Danfoss D1 pumps...............................................................................................................................................7

Production place and date of pump....................................................................................................................................8

Example ATEX label - D1P........................................................................................................................................................8

Maximum surface temperature

Viscosity and temperature for D1P pump.............................................................................................................................10

Model Code

Model code.......................................................................................................................................................................................11

Displacement, rotation and product version.......................................................................................................................12

Control types................................................................................................................................................................................... 12

Input shaft options........................................................................................................................................................................ 12

Mounting flange options............................................................................................................................................................ 13

End cap and main port options................................................................................................................................................ 13

Auxiliary mounting flange options..........................................................................................................................................13

Power control settings.................................................................................................................................................................14

Pressure compensated control settings................................................................................................................................14

Load sensing control settings................................................................................................................................................... 15

Hydraulic displacement control setting................................................................................................................................ 15

Maximum and minimum displacement settings............................................................................................................... 15

Minimum displacement settings..............................................................................................................................................15

Special hardware and features..................................................................................................................................................15

Tandem pump information........................................................................................................................................................16

Technical specifications

Ambient temperature.................................................................................................................................................................. 17

Oil types / Operating fluids.........................................................................................................................................................17

Mineral oils..................................................................................................................................................................................17

Oil temperature.........................................................................................................................................................................17

Viscosity........................................................................................................................................................................................17

Displacement Limiter

Displacement limiter setting..................................................................................................................................................... 18

©

Danfoss | September 2021 BC274750280114en-000202 | 3

Page 4

Ignitable

substance (Gas)

Oxygen Source of ignition

(Spark or heat)

P301 800

Technical Information

ATEX certified D1P 130/145/193/260

General information

ATEX Introduction

The ATEX Directive 2014/34/EU specifies the minimum safety requirements for equipment intended for

use in potentially explosive atmospheres in European Union member states. ATEX is derived from the

French term ATmosphères EXplosives.

Hydraulic pump are designed for mobile and stationary applications. Some pump are used in related

applications, where locations are classified as hazardous areas.

The equipment intended for use in hazardous areas are divided into two groups:

Group I: Equipment intended for use in underground parts of mines (mining equipment).

Group II: Equipment intended for use in other places than mines (non-mining equipment).

The Danfoss hydraulic pump, type D1P are intended for use in Group II applications.

Explosive atmosphere

Explosion triangle

A “hazardous area” is defined as an area in which the atmosphere contains, or may contain in sufficient

quantities, flammable or explosive gases, dusts or vapours. In such an atmosphere a fire or explosion is

possible when three basic conditions are met. This is often referred to as the “hazardous area” or

“explosion” triangle.

An atmosphere with the potential to become an explosive atmosphere during operating conditions

and/or under the influence of the surroundings is defined as a potentially explosive atmosphere.

Products covered by directive 2014/34/EU are defined as intended for use in potentially explosive

atmospheres. Removing one of the elements eliminates all risk of explosion.

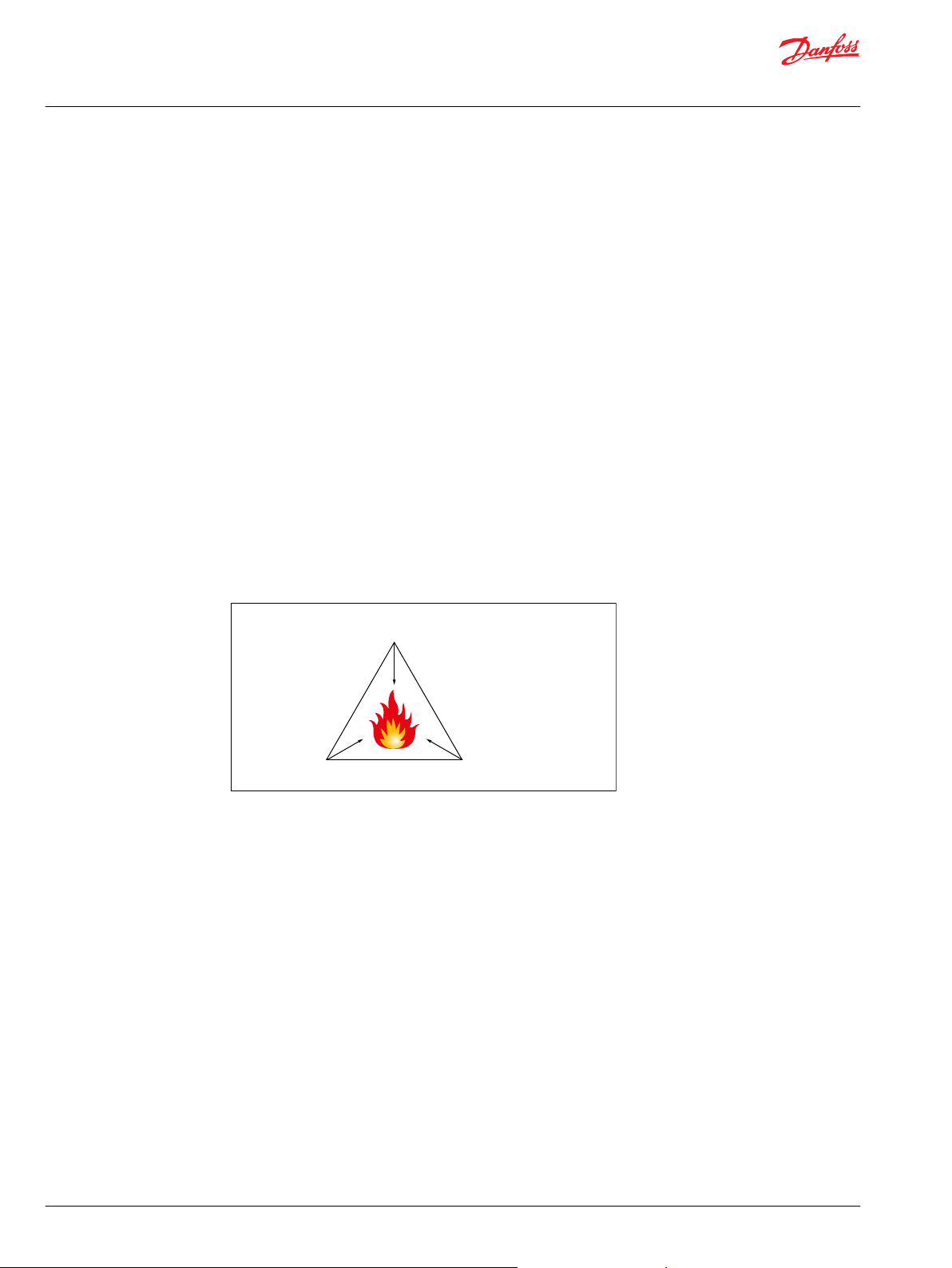

General zone classification

Directive 99/92/EC divides the Hazardous areas into zones and defines criteria by which products are

categorized within these zones; Zone 0 / 20 is the most restrictive and Zones 1 / 21 and 2 / 22 are less

restrictive. The following table describes the zones in an installation where there is a potential for

explosive atmospheres. The owner of the installation must analyze and assess the area in which the

explosive gas/dust mixture may occur, and if necessary must divide it into zones. This process of zoning

then allows the correct plant and equipment to be selected for use in the area.

4 | © Danfoss | September 2021 BC274750280114en-000202

Page 5

Zone 0

Zone 0

Zone 2

Zone 1

F301 801

Degree of protection Protection

Category

Very high Two independent protection measures or safe if two errors occur

independently

Category 1

High

Safe in normal operation and in anticipated case of commonly

occurring errors

Category 2

Normal Safe in normal operation

Category 3

P301 802

Technical Information

ATEX certified D1P 130/145/193/260

General information

Zones Presence of potentially explosive atmosphere Type of risk

Gas (G) Dust (D)

0 20 Present continuously or for long periods Permant

1 21 Likely to occur in normal operation occasionally Potential

2 22 Not likely to occur in normal operation but. If it does

occur, will persist for a short period of time

Minimal

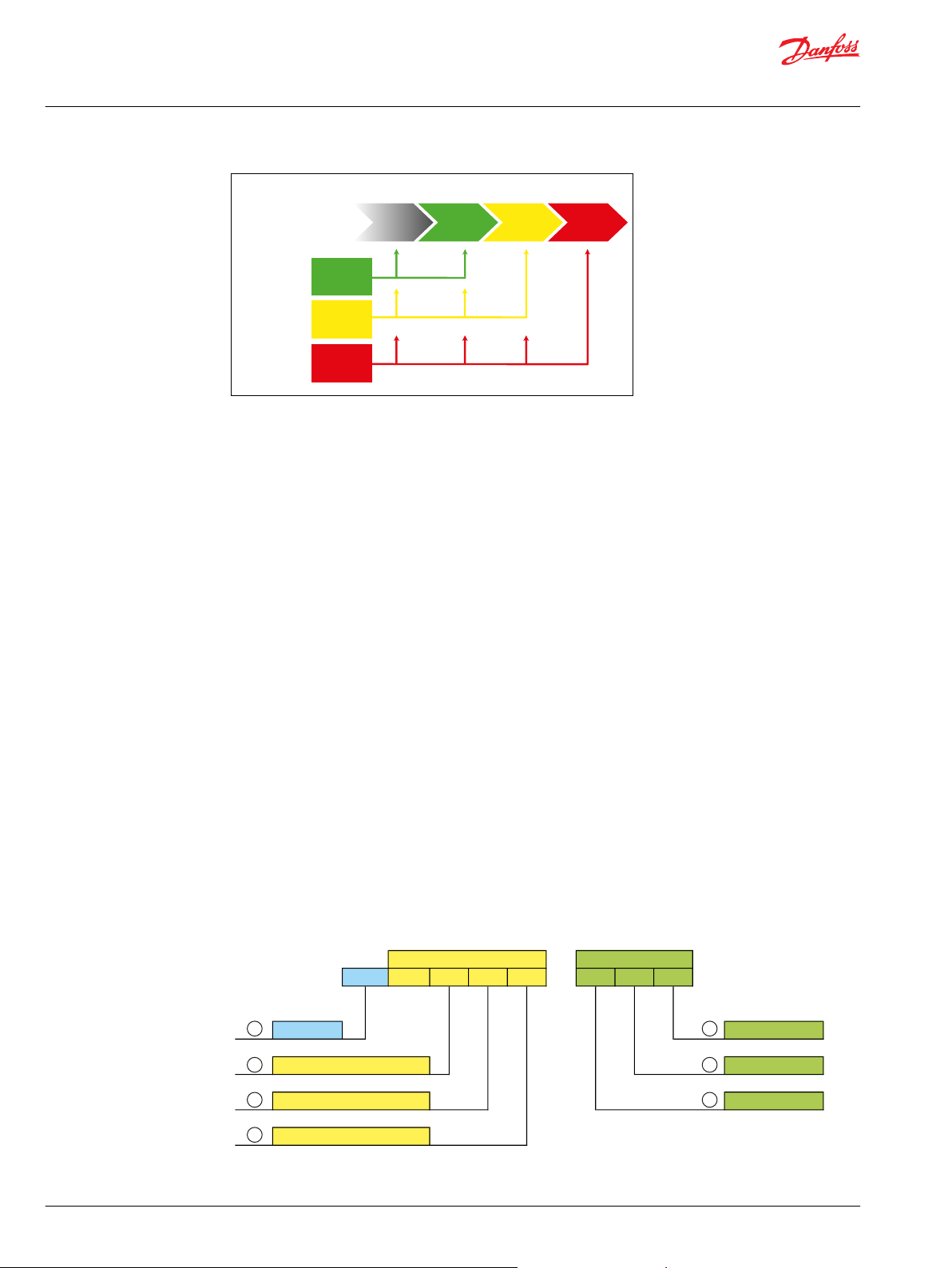

Equipment category and zones

Mechanical components with potential ignition sources e.g. components containing non-conductive

materials or layers or components with hot surface are covered by the ATEX-directive.

Non-mining equipment for potentially explosive atmosphere is classified as:

Equipment Group II – this group comprises three categories according to the level of safety provided:

•

Category 1

•

Category 2

•

Category 3

Category 1 equipment has the highest degree of protection – see the following below.

These products have to fulfil all requirements in the ATEX directive, and have to be marked with the

required “Ex” marking.

Equipment located in zone specified areas must fulfil the following requirements (see also the following

figure):

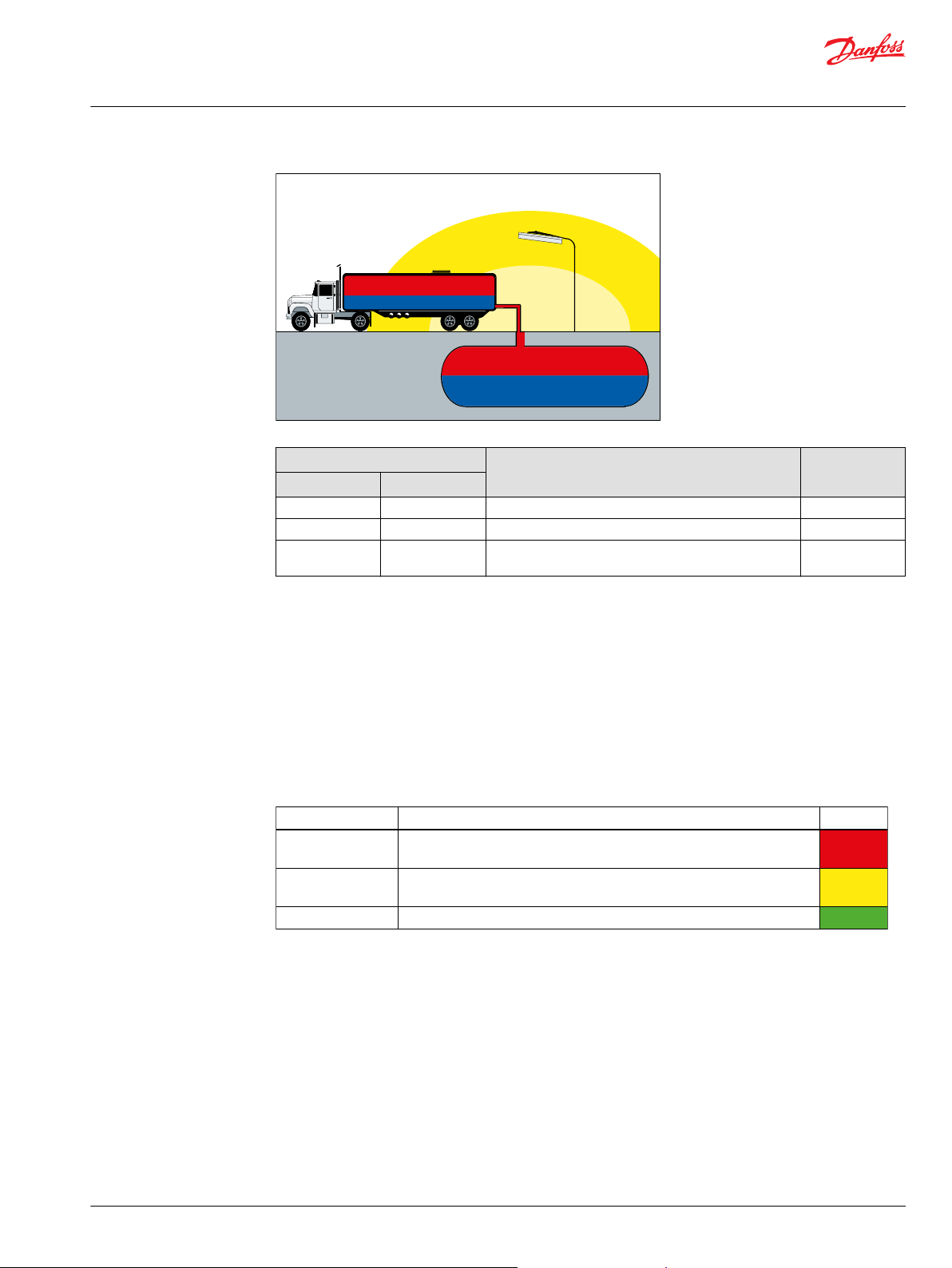

Category 3 – approved equipment can be installed in hazardous areas zone 2 / 22 and outside zone

•

categorized areas.

Category 2 – approved equipment can be installed in hazardous areas zone 1 / 21, zone 2 / 22 and

•

outside zone categorized areas.

©

Danfoss | September 2021 BC274750280114en-000202 | 5

Category 1 – approved equipment can be installed in hazardous areas zone 0 / 20, zone 1 / 21, zone

•

2 / 22 and outside zone categorized areas.

Page 6

Zone 0Zone 1Zone 2

No requirementsts

Hazards area

Catagory

3

Catagory

2

Catagory

1

ATEX

Directive

Equipment

group II

P301 803

Ex

CE-marking Temperature class

Equipment group Gas Group

Equipment Category Protection type

Nature of atmosphere

Spe cifi c markin g Add itiona l m arki ng

CE II 2 G c II C T4

1

2

3

7

6

5

4

P301 805

Technical Information

ATEX certified D1P 130/145/193/260

General information

Contents of marking

The rules for the marking of systems, equipment and components are uniformly defined in the standards

relating to the general technical requirements – EN 13463-1 for mechanical equipment.

A priority for all Ex equipment and protective systems is that the marking should show the areas of their

designated use. Components covered within the scope of the ATEX directive have to be CE-marked, and

marked with the specific “Ex”-sign.

Principle

The marking must indicate the following:

•

The manufacturer who has put the item of equipment on the market

•

Manufacturer’s type identification

•

Year in which the equipment was manufactured

•

A serial number

And further the ignition protection marking

•

Symbol of the equipment group and category (M1 or M2 for group I mining equipment, or 1 or 2 or 3

for Group II non-mining equipment).

Additionally for Group II equipment only:

1. The letter “G” where explosive atmospheres caused by gases, vapours or mists are concerned;

and/or

2. The letter “D” where explosive atmospheres caused by dusts are concerned.

•

Type of ignition protection system.

•

Where appropriate, symbol of explosion group of the equipment.

•

For Group II equipment, the symbol indicating the temperature class or the maximum surface

temperature in °C, or both.

6 | © Danfoss | September 2021 BC274750280114en-000202

Page 7

Technical Information

ATEX certified D1P 130/145/193/260

General information

Callout Description

1 CE marking

Specific marking

2 Equipment group I - Mining

3 Equipment category 1 (zone 0/20)

4 Nature of atmosphere G - Gas

Additional marking

5 Protection type fr - Protection by flow restricting enclosure

6 Gas group IIA

7 Temperature class

II - Non-mining

2 (zone 1/21)

3 (zone 2/22)

D - Dust

d - Protection by flameproof enclosure

c - Protection by constructional safety

b - Protection by control of ignition sources

p - Protection by pressurized enclosures

k - Protection by liquid immersion

IIB

IIC

Equipment without any explosion group maring can be used for

explosive atmosphere of explosive group IIA, IIB and IIC provided

the equipment is not marked for specific atmosphere.

T1 to T6

TX; where the maximum surface temperature depends not on

the equipment itself, but mainly on operating conditions (like

heated fluid) the relevant information shall be given in the

instruction for use in order to inform the user about this special

situation.

Marking of Danfoss D1 pumps

The Danfoss hydraulic pumps are marked as equipment for Group II, category 2 for gas and dust

environment and with ignition protection constructional safety and liquid immersion.

Temperature class/Maximum surface temperature depends on the operating conditions (ambient and

fluid temperature).

ATEX marking

Marking For model code option

CE Ex II 3G Ex h IIA T3 Gc AN3 (temperature class T3)

CE Ex II 3G Ex h IIA T4 Gc AN4 (temperature class T4)

CE Ex II 3G Ex h IIA T5 Gc AN5 (temperature class T5)

1

See Model Code for additional information.

1

See Viscosity and temperature for D1P pump on page 10 for more information about temperature classes.

For detailed information on selecting the appropriate T-codes, please see D1P ATEX User Manual,

BC376161003883.

©

Danfoss | September 2021 BC274750280114en-000202 | 7

Page 8

Technical Information

ATEX certified D1P 130/145/193/260

General information

Production place and date of pump

The production location and date of the pump is shown at the first 5 digits of the serial no.

Example: Serial no: N45123094

Five first digits are N4512

N is the manufacturing location (N=Nordborg ; H = Haiyan(China))

4 is the year (It stands for the last digit in the possible decade).

51 is the week

2 is the day (2 = Tuesday)

The last four digits are a consecutive number.

The ATEX certification of the units are done under the scope of:

"Directive 2014/34/EU of the European Parliament and of the Council of 26 February 2014 on the

harmonisation of the laws of the Member States relating to equipment and protective systems intended for use

in potentially explosive atmospheres."

With following parameters:

•

Equipment group: II

•

Zone: 2 (gas)

•

Equipment Category: 3G

•

Temperature class: T3...T5

•

Explosion protection group: II A

According to this classification, the Conformity Assessment Procedure has to be executed according to

Directive 2014/34/EU, annex VIII, Modul A: Internal Production Control (see article 13, section 1 (c)) The EU

declaration of conformity has to be prepared and issued with regard to annex X of /1/. The “Essential

Health and Safety Requirements” defined by /1/, annex II, have to be considered.

Example ATEX label - D1P

Examples of ATEX pump labels – Pump produced in People's republic of China

1. Manufacturer

2. Location of production

3. ATEX code

8 | © Danfoss | September 2021 BC274750280114en-000202

Page 9

Technical Information

ATEX certified D1P 130/145/193/260

General information

4. Material number

5. Model code, including unit and displacement

6. Production code

©

Danfoss | September 2021 BC274750280114en-000202 | 9

Page 10

W

W

Technical Information

ATEX certified D1P 130/145/193/260

Maximum surface temperature

Viscosity and temperature for D1P pump

Features Data

Viscosity

Temperature

1)

Intermittent = Short term t < 3 min per incident.

2)

Cold start = Short term t < 3 min; p ≤ 30 bar; n ≤ 1000 min-1(rpm); please contact Danfoss Power Solutions

especially when the temperature is below -25 °C [-13 °F].

3)

Must not be exceeded locally either (e.g. in the bearing area) . The temperature in the bearing area is (depending

on pressure and speed ) up to 5 °C [41 °F] higher than the average case drain temperature.

Above maximum surface temperatures are without any deposited dust on the product. The possible

insulation effect of a dust layer on the surface has to be taken into account by the safety margin to the

minimum ignition temperature of the dust concerned. For up to 5 mm [1.97 in] layer thickness the safety

margin is 75°C [167°F]. For further information please see IEC 60079-14.

Intermittent

Minimum 7 mm2/sec [49 SUS]

Recommended range 16-36 mm2 [81-168 SUS]

Maximum (cold start)

Minimum (cold start)

Maximum intermittent

1)

2)

2)

1)

5 mm2/sec [42 SUS]

1600 mm2/sec [7416 SUS]

-40°C [-40°F]

115°C [239°F]

3)

Warning

The above operating temperatures (ambient and oil) of the pump must be guaranteed by the end user.

Warning

It is compulsory to use oils whose inflammable degree is at least 50K above the maximum surface

temperature of the pump. See also Oil types / Operating fluids on page 17.

10 | © Danfoss | September 2021 BC274750280114en-000202

Page 11

D 1 P 2 6 0 R A T P E 2 T E 4 Y 3 B 1 1 1 5 3 4 0 N N N N F S 0 5 N N N NN N

Series

Product

type

Displacement

A B C D E F G H J K L M N P R S

Rotation

Product version

Control type

Input shaft

Endcap

Power control setting

Pressure compensated control setting

Load sensing control setting

Hydraulic disp control start pressure setting

Max displacement setting

Min displacement setting

Special hardware

Special feature

Mounting flange

Auxiliary flange

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

D1P model code

The below illustration and the following sections describe how to identify parts of the model code and

availability of certain part options based on frame size.

Example model code; D1P 260 shown

©

Danfoss | September 2021 BC274750280114en-000202 | 11

Page 12

W

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

D1P 130-260 displacement, rotation and product version

Displacement

Code Description 130 145 193 260

130 130 cm3 [7.93 in3] max. displacement per revolution

145 145 cm3 [8.85 in3] max. displacement per revolution

193 193 cm3 [11.78 in3] max. displacement per revolution

260 260 cm3 [15.87 in3] max. displacement per revolution

Rotation

Code Description 130 145 193 260

R Clockwise [CW]

L Counter Clockwise [CCW]

Product Version

Code Description 130 145 193 260

A

D1P 130-260 control types

Code Description 130 145 193 260

NPNN Pressure Compensated Control

NPSN Pressure Compensated Control + Load Sensing Control

NPNR Pressure Compensated Control + Remote Pressure Compensated Control

TPSN Power Control + Pressure Compensated Control + Load Sensing Control

TPH1 Power Control + Pressure Compensated Control

Control Code Explanation:

•

First digit: Power control (Torque control) , "N" means no power control.

•

Second digit: Pressure compensated control, "N" means no pressure compensated control.

•

Third & Fourth digits: Proportional displacement control or Load sensing control , "NN" means no

control in either category.

Warning

A relief valve is required to be installed in the pump outlet for additional system protection. Failure to

install the relief valve can lead to system damage and/or injury.

D1P 130-260 input shaft options

Code Description 130 145 193 260

T 130/145/193: Spline, DIN 5480 W50 x 2 x 30 x 24 x 9g;

260: Spline, DIN 5480 W60 x 2 x 30 x 28 x 9g;

Shaft Seal Material: FKM

S Spline, SAE J744 1 3/4in, 13T 8/16 DP;

Shaft Seal Material: FKM

12 | © Danfoss | September 2021 BC274750280114en-000202

Page 13

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

Code Description 130 145 193 260

A 193: Spline, SAE J744 2in, 15T 8/16 DP;

260: Spline, SAE J744 2 1/4in, 17T 8/16 DP;

Shaft Seal Material: FKM

P Straight Keyed DIN 6885,

130/145: AS14 x 9 x 80

193: AS16 x 10 x 100

260: AS18 x 11 x 100

Shaft Seal Material: FKM

*

K

SAE J744 (D/E) 3in straight keyed shaft

0.4375x3.000in

*

There is no impeller option for sizes 130 and 145 with this shaft.

D1P 130-260 mounting flange options

Code Description 130 145 193 260

D4 SAE J744 152-4 (D)

E4 SAE J744 165-4 (E)

D1P 130-260 end cap and main port options

End cap and main ports

Code Description Rotation 130 145 193 260

Y1 Radial, side, flange ports

Inlet: 3in port, M16 x 2;

Outlet: 1 1/4in port, M14 x 2 SAE J518

With impeller

Y2 Radial, side, flange ports

Inlet: 3 1/2in port, M16 x 2;

Outlet: 1 1/2in port, M16 x 2 SAE J518

With impeller

Y3 Radial, side, flange ports

Inlet: 4in port, M16 x 2;

Outlet: 1 1/2in port, M16 x 2 SAE J518

With impeller

CW [R]

CCW [L]

CW [R]

CCW [L]

CW [R]

CCW [L]

D1P 130-260 auxiliary mounting flange options

Auxiliary mounting flange (through-drive flange)

Code Description 130 145 193 260

NN No auxiliary flange

A1 SAE J744 82-2 (A); Spline coupling: 5/8in 9T 16/32DP

A2 SAE J744 82-2 (A); Spline coupling: 3/4in 11T 16/32DP

A3 SAE J744 82-2 (A); Spline coupling: 7/8in 13T 16/32DP

B1 SAE J744 101-2 (B) ; Spline coupling: 7/8in 13T 16/32DP

B2 SAE J744 101-2 (B); Spline coupling: 1in 15T 16/32DP

BA SAE J744 101-2 (B); Spline coupling: 7/8in 13T 16/32DP; Adapter 90°

BB SAE J744 101-2 (B); Spline coupling: 7/8in 13T 16/32DP; Cover 45°

©

Danfoss | September 2021 BC274750280114en-000202 | 13

Page 14

P

setting@1500 rpm

= P

actual *

n

actual

1500

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

Auxiliary mounting flange (through-drive flange) (continued)

Code Description 130 145 193 260

C5 SAE J744 127-2&4 (C) ; Spline coupling:1 1/4in 14T 12/24DP

C9 SAE J744 127-2&4 (C); Spline coupling: 1 3/4in 13T 8/16DP

D2 SAE J744 152-4 (D); Spline coupling: 1 3/4in 13T 8/16DP

D5 SAE J744 152-4 (D) ; Spline coupling: N50x2x30x24x9H

E2 SAE J744 165-4 (E) ; Spline coupling: N50 x 2 x 30 x 24 x 9H

E3 SAE J744 165-4 (E) ; Spline coupling: N60 x 2 x 30 x 28 x 9H

D1P 130-260 power control settings

Power control setting at 1500rpm (kW), “3 digit code”

1

Code

NNN No Power Control

XXX xxx kW between ranges specified below (For example: Code "090" means 90kW)

030-115 30-115 kW [40-154 hp] at 1500 rpm

035-155 35-155 kW [47-208 hp] at 1500 rpm

040-210 40-210 kW [54-282 hp] at 1500 rpm

1

For settings out of these ranges, please contact Danfoss Power Solutions.

2

Only increments of 5kW [6.7 hp] are allowed. E.g. 035, 040, 045, etc.)

Description 130 145 193 260

at 1500 rpm

2

2

2

If the speed is not 1500rpm, please make a conversion using the following formula, assuming constant

torque:

For example:

If actual power is 110 kW at 2100 rpm, the conversion to obtain the power control setting at 1500 rpm

should be 110*1500/2100=79, choose 080 option (round to closest 5 kW increment option).

D1P 130-260 pressure compensated control setting

Pressure compensated control setting (bar), “3 digit code”

*

Code

NNN No Pressure compensated control

XXX xxx bar between the range specified below (For example: Code "320" means 320

150~350 150~350 bar [2176~5076 psi] (Please select pressure compensated control setting

*

For settings out of these ranges, please contact Danfoss Power Solutions.

Description 130 145 193 260

bar [4641 psi])

in increments of 10 bar [145 psi]. E.g. 150 or 160 or 170, etc.)

14 | © Danfoss | September 2021 BC274750280114en-000202

Page 15

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

D1P 130-260 load sensing control settings

L - Load Sensing Control Setting (bar), "2 digit code"

Code Description 130 145 193 260

NN No load sensing control

XX xx bar between the range specified below (For example: Code "25" means 25 bar

10~35*10~35 bar [145~508 psi] (Please select load sensing control setting in increments

*

For settings out of these ranges, please contact Danfoss Power Solutions. Range allowed for NPNR (Pressure compensated + Remote Pressure

compensated control) is 15-35 bar

D1P 130-260 hydraulic displacement control setting

Hydraulic displacement control start pressure setting, “2 digit code”

Code Description 130 145 193 260

NN No hydraulic displacement control

04-10 4-10 bar

[363 psi])

of 1 bar [14.5 psi]. E.g. 10 or 11 or 12, etc.)

D1P 130-260 maximum displacement settings

Maximum displacement setting, “2 digit code”

Code Description 130 145 193 260

FS Factory setting : 100%

1

XX

1

Please consider frame sizing and increments when selecting a maximum displacement setting (see displacement limiter for more information).

2

Only increments of 5% are allowed. (E.g. 70, 75, 80 etc.)

XX% of maximum displacement (For example: Code "90" means 90% of maximum

displacement)

2

D1P 130-260 minimum displacement settings

Minimum displacement setting, “2 digit code”

Code Description 130 145 193 260

FS 0% of maximum displacement limit setting

XX XX% of maximum displacement limit setting

1

Only increments of 5% are allowed. (E.g. 70, 75, 80 etc.)

1

If a different minimum displacement setting is required, please contact Danfoss Power Solutions.

D1P ATEX special hardware and features

Special features

Code Description 130 145 193 260

AN3 Factory Setting (black paint, ATEX tag T3, format A w/o filter)

AN4 Factory Setting (black paint, ATEX tag T4, format A w/o filter)

AN5 Factory Setting (black paint, ATEX tag T5, format A w/o filter)

©

Danfoss | September 2021 BC274750280114en-000202 | 15

Page 16

P400282

Control

Pump

Endcap

Control

Pump

Endcap

P400282

Control

Pump

Endcap

Control

Pump

Endcap

Control

Pump

Endcap

Technical Information

ATEX certified D1P 130/145/193/260

Model Code

D1P tandem pump information

Information about tandem pump direction and ordering instructions are found below.

Pump direction

Auxiliary pump

INDEX = 0°

Auxiliary pump

INDEX = 90°

When assembling a system the first

pump is always to be considered at 0°

INDEX as shown below.

Auxiliary pump

INDEX = 270°

Auxiliary pump

INDEX = 180°

For gear pump tandem angle information, please contact Danfoss Power Solutions.

Ordering tandem pumps

When ordering tandem pumps, the type designations of the 1st and 2nd pumps must be connected by a

“+”, and tandem pump angle should be given as indicated below.

Ordering example:

D1P193RATPE2TE4Y2E2090320NNNNFSFSNNNNNN +

D1P193RATPE2TE4Y2NN090320NNNNFSFSNNNNNN

Tandem angle 0° + 180°

16 | © Danfoss | September 2021 BC274750280114en-000202

Page 17

W

Technical Information

ATEX certified D1P 130/145/193/260

Technical specifications

Ambient temperature

Maximum ambient temperature depends on the requested ATEX class needed.

In general the ambient temperature should lie between -30 °C [-22 °F] and +90 °C [+210 °F] to ensure that

the shaft seal retains its sealing capacity.

Oil types / Operating fluids

In a hydraulic system the most important task of the oil is to transfer energy. At the same time the oil

must lubricate moving parts in hydraulic components, protect them from corrosion, and transport dirt

particles and heat out of the system. To ensure that hydraulic components operate without problems

and have long operating life it is therefore vital to select the correct oil type with the necessary additives.

Ratings and performance data are based on operating with hydraulic fluids containing oxidation, rust

and foam inhibitors. These fluids must possess good thermal and hydrolytic stability to prevent wear,

erosion and corrosion of pump components.

Mineral oils

For systems containing Danfoss hydraulic pumps, type D1P, mineral hydraulic oil with anti-wear

additives, type HLP [DIN 51524] or HM (ISO 11158) must be used. Mineral oils without anti-wear additives

or engine oils can also be used, provided operating conditions are suitable.

Warning

It is compulsory to use oils whose inflammable degree is at least 50K above the maximum surface

temperature of the pump. Maximum surface temperature for Group IIG and IID can be found under:

Viscosity and temperature for D1P pump on page 10.

Oil temperature

Maximum oil temperature depends on the requested ATEX class needed (in this case T3)..

Under normal operating conditions it is recommended to keep the temperature in the range of 30 °C [86

°F] and 60 °C [140 °F].

Fluid temperature affects the viscosity of the fluid and resulting lubricity and film thickness. High

temperatures can also limit seal life, at most non-metallic materials are adversely affected by use at

elevated temperatures.

Fluids may break down or oxidize at high temperature, reducing their lubricity and resulting in reduced

life of the unit. Oil life is greatly reduced if its temperature exceeds +60 °C [+140 °F]. As a general rule, oil

life is halved for each 8 °C [46 °F] its temperature exceeds +60 °C [+140 °F].

Viscosity

Maintain fluid viscosity within the recommended range for maximum efficiency and bearing life.

Minimum viscosity should only occur during brief occasions of maximum ambient temperature and

severe duty cycle operation. Maximum viscosity should only occur at cold start. Limit speeds until the

system warms up.

Fluid viscosity limits

Conditions mm2/s (cSt) SUS

Minimum 12 66

Continuous 20 - 80 98 - 370

Maximum 1500 6950

We recommend the use of an oil type having a viscosity of 35 mm2/s at the actual operating temperature.

©

Danfoss | September 2021 BC274750280114en-000202 | 17

Page 18

P400281

Maximum

displacement

limiter

Minimum

displacement

limiter

Technical Information

ATEX certified D1P 130/145/193/260

Displacement Limiter

D1P displacement limiter

Series D1 pumps feature maximum and minimum displacement limiters, which limit displacement

mechanically.

Maximum Displacement Limiter

Frame Setting range Displacement change per turn

130

145

193

260

Minimum Displacement Limiter

Frame Setting range Displacement change per turn

130

145

193

260

72 cm3 – 130 cm

72 cm3 – 145 cm

0 cm3 – 193 cm

56 cm3 – 260 cm

0 cm3 – 124 cm

0 cm3 – 124 cm

0 cm3 – 193 cm

0 cm3 – 260 cm

3

3

3

3

3

3

3

3

11 cm3/rev

11 cm3/rev

16 cm3/rev

19 cm3/rev

9 cm3/rev

9 cm3/rev

15 cm3/rev

18 cm3/rev

Displacement Limiter Cross-Section View

18 | © Danfoss | September 2021 BC274750280114en-000202

Page 19

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Cartridge valves

•

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydraulic integrated

•

circuits (HICs)

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | September 2021 BC274750280114en-000202

Loading...

Loading...