Page 1

Service Manual

D1 High Power Open Circuit Pumps

Size 130/145/193/260

www.danfoss.com

Page 2

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

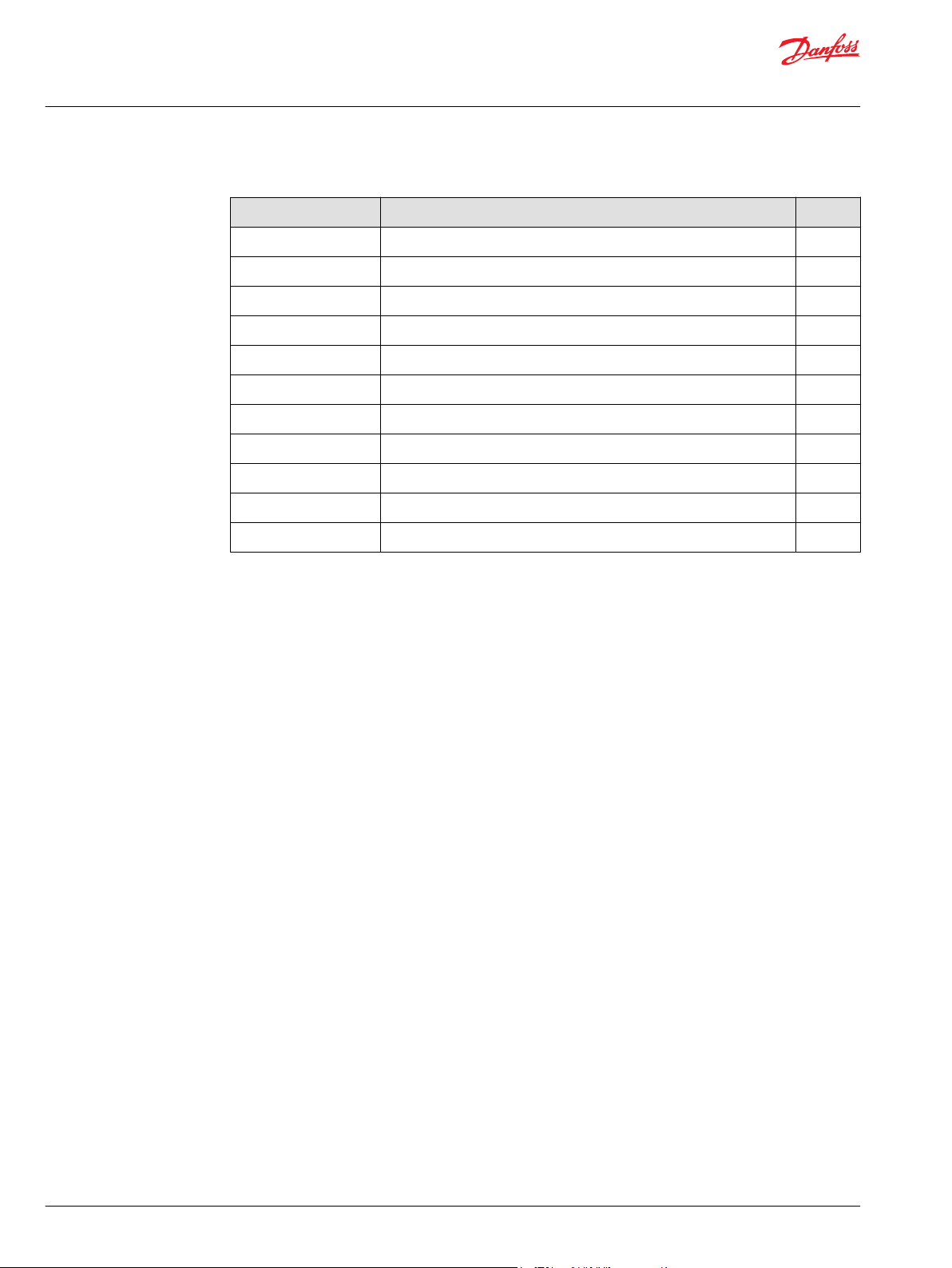

Revision history Table of revisions

Date Changed Rev

October 2019 Fixed EDC control adjustments for clarity 0301

August 2019 Fixed typo 0202

July 2019 Various updates 0201

October 2018 Added Shaft Replacement 0106

July 2018 Fixed layout 0105

June 2018 Major Update 0104

October 2017 Added Size 130 0103

June 2016 Added Size 260 0102

April 2016 Converted to Danfoss layout - DITA CMS 0101

July 2015 Added 145 cc information AB

January 2014 First edition AA

2 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 3

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Contents

Introduction

Overview..............................................................................................................................................................................................5

General instructions........................................................................................................................................................................ 5

Remove the unit.......................................................................................................................................................................... 5

Keep it clean..................................................................................................................................................................................5

Replace all O-rings and gaskets............................................................................................................................................. 5

Secure the unit.............................................................................................................................................................................5

Safety precautions............................................................................................................................................................................5

Unintended Machine Movement..........................................................................................................................................5

Flammable Cleaning Solvents................................................................................................................................................6

Fluid Under Pressure..................................................................................................................................................................6

Personal Safety.............................................................................................................................................................................6

Symbols used in Danfoss literature............................................................................................................................................6

Design...................................................................................................................................................................................................6

Cross-section view........................................................................................................................................................................... 8

Operation

NPNN (Pressure Compensated Control).................................................................................................................................. 9

NPSN (Pressure Compensated Control + Load Sensing Control).................................................................................11

NPNR (Pressure Compensated Control + Remote Pressure Compensated Control)............................................ 13

TPSN (Power Control + Pressure Compensated Control + Load Sensing Control)................................................15

NNES (Electric Displacement Control + Load Sensing Control)....................................................................................17

Solenoid Specification............................................................................................................................................................ 19

Standard EDC Valve................................................................................................................................................................. 20

NNES Priority.............................................................................................................................................................................. 20

TPE2/TPE5 (Power Control + Pressure Compensated Control + Electric Displacement Control).................... 21

TPE2/TPE5 Priority....................................................................................................................................................................21

NPE2/NPE0 (Pressure Compensated Control + Electric Displacement Control).....................................................22

Operating parameters

Pressure............................................................................................................................................................................................. 23

Speed..................................................................................................................................................................................................23

Fluid.................................................................................................................................................................................................... 23

Viscosity........................................................................................................................................................................................24

Temperature...............................................................................................................................................................................24

Fluid velocity.............................................................................................................................................................................. 24

Technical specifications

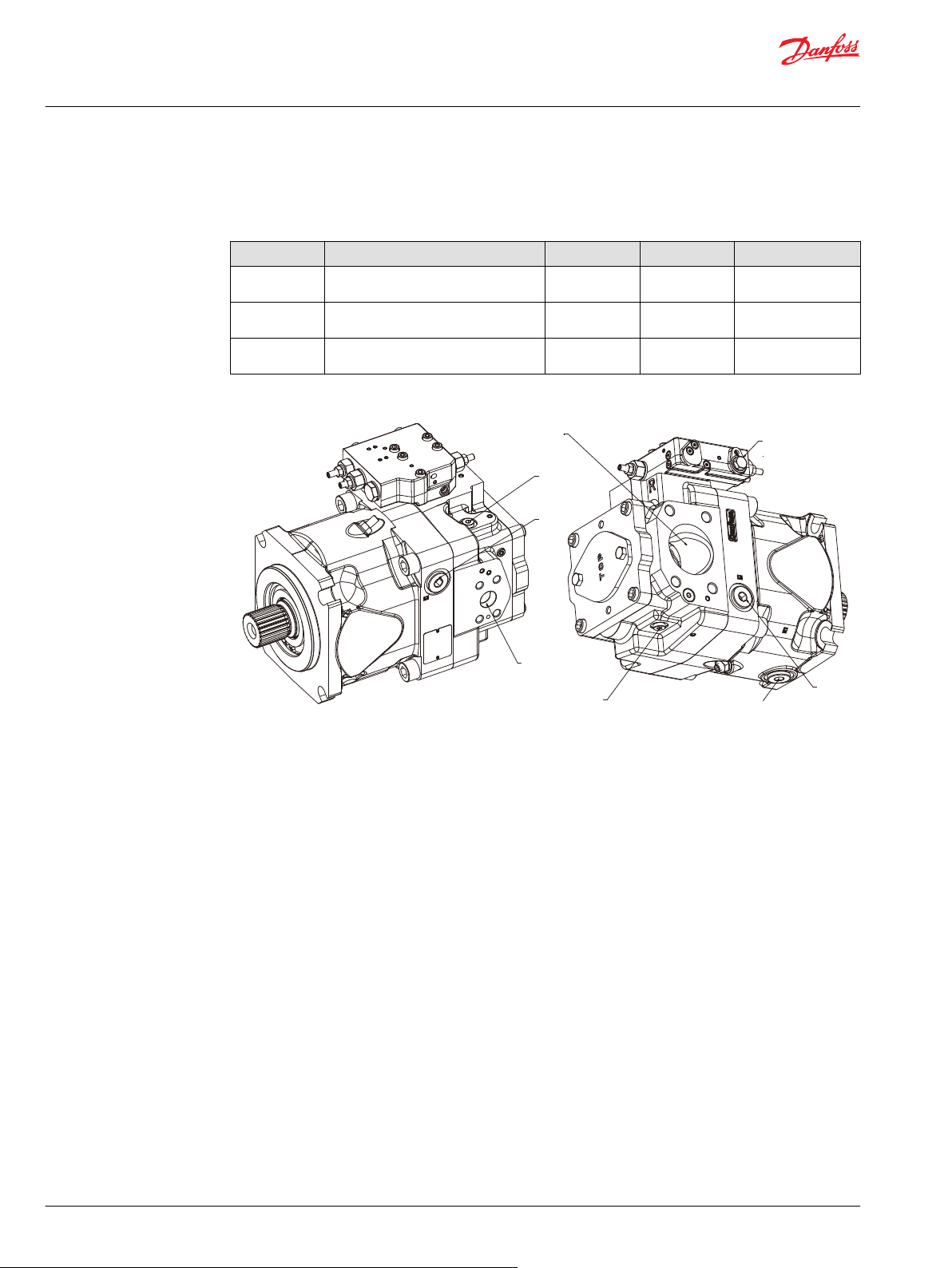

D1 130-260 pump specifications..............................................................................................................................................25

D1P fluid specifications................................................................................................................................................................26

Fluid and filter maintenance

Recommendations of Fluid and Filter Maintenance.........................................................................................................27

Pressure measurements

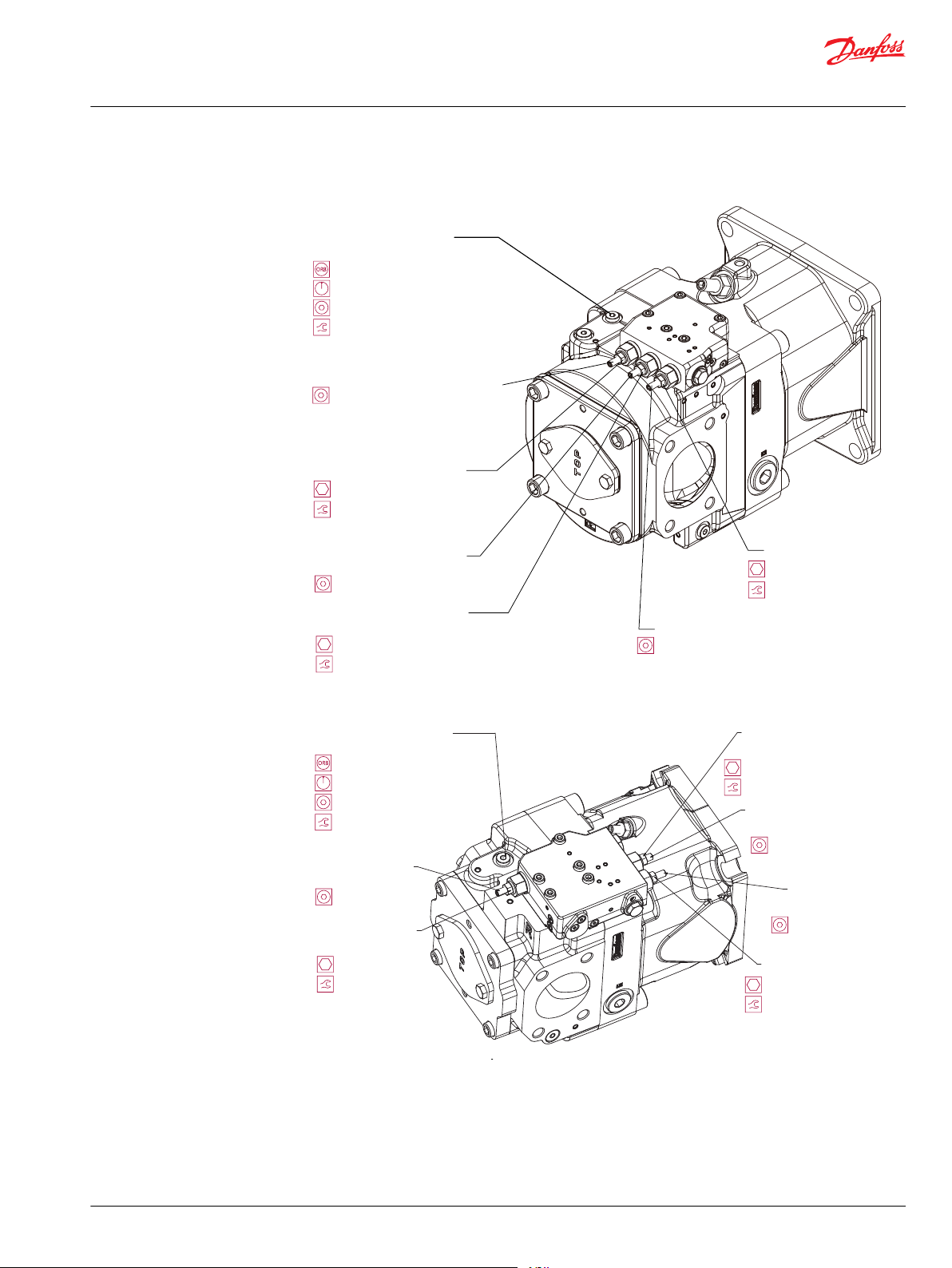

Port Locations and Gauge Installation (130/145)...............................................................................................................28

Port Locations and Gauge Instalation (193/260)................................................................................................................29

Initial start-up procedures

General...............................................................................................................................................................................................30

Start-up Procedure........................................................................................................................................................................ 30

Troubleshooting

Excessive Noise and /or Vibration............................................................................................................................................31

Low Pump Output Flow...............................................................................................................................................................31

No or Low System Pressure........................................................................................................................................................31

Actuator Response is Sluggish..................................................................................................................................................32

Pressure or Flow Instability.........................................................................................................................................................32

System Operating Hot..................................................................................................................................................................33

High Inlet Vacuum.........................................................................................................................................................................33

Adjustments

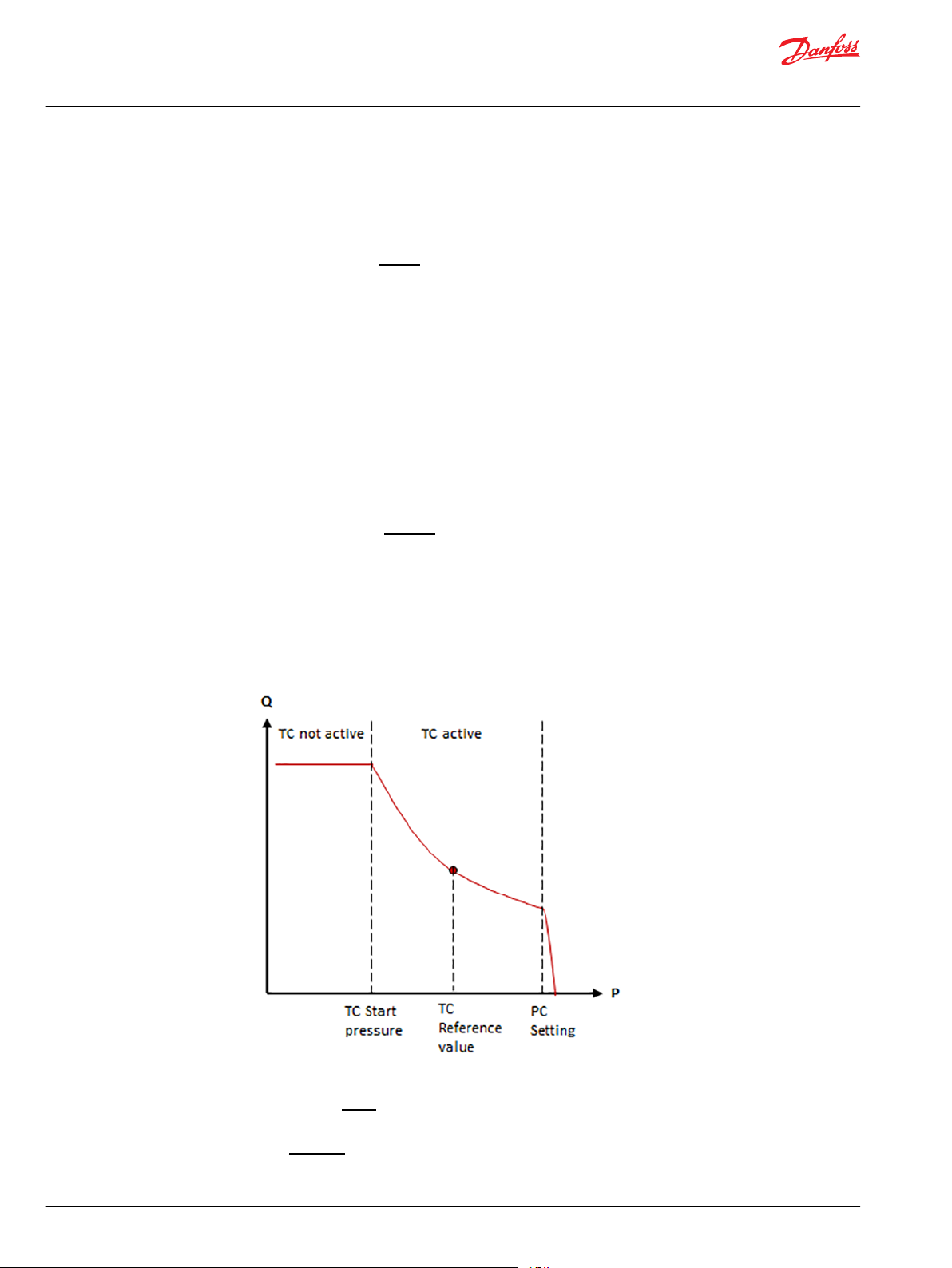

Calculate Power Control Start Point Pressure and Corresponding Flow in Advance........................................... 34

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 3

Page 4

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Contents

Electric Displacement Control Adjustment .........................................................................................................................35

Pressure Compensated Control Adjustment.......................................................................................................................37

Power Control Adjustment.........................................................................................................................................................37

Load Sensing Control Adjustment...........................................................................................................................................37

Displacement Limiters Adjustment.........................................................................................................................................40

Adjust Displacement Limiters..............................................................................................................................................40

Minor repairs

Shaft replacement......................................................................................................................................................................... 41

Shaft removal.............................................................................................................................................................................41

Shaft installation....................................................................................................................................................................... 42

Shaft Seal Replacement...............................................................................................................................................................43

Removal........................................................................................................................................................................................43

Installation...................................................................................................................................................................................43

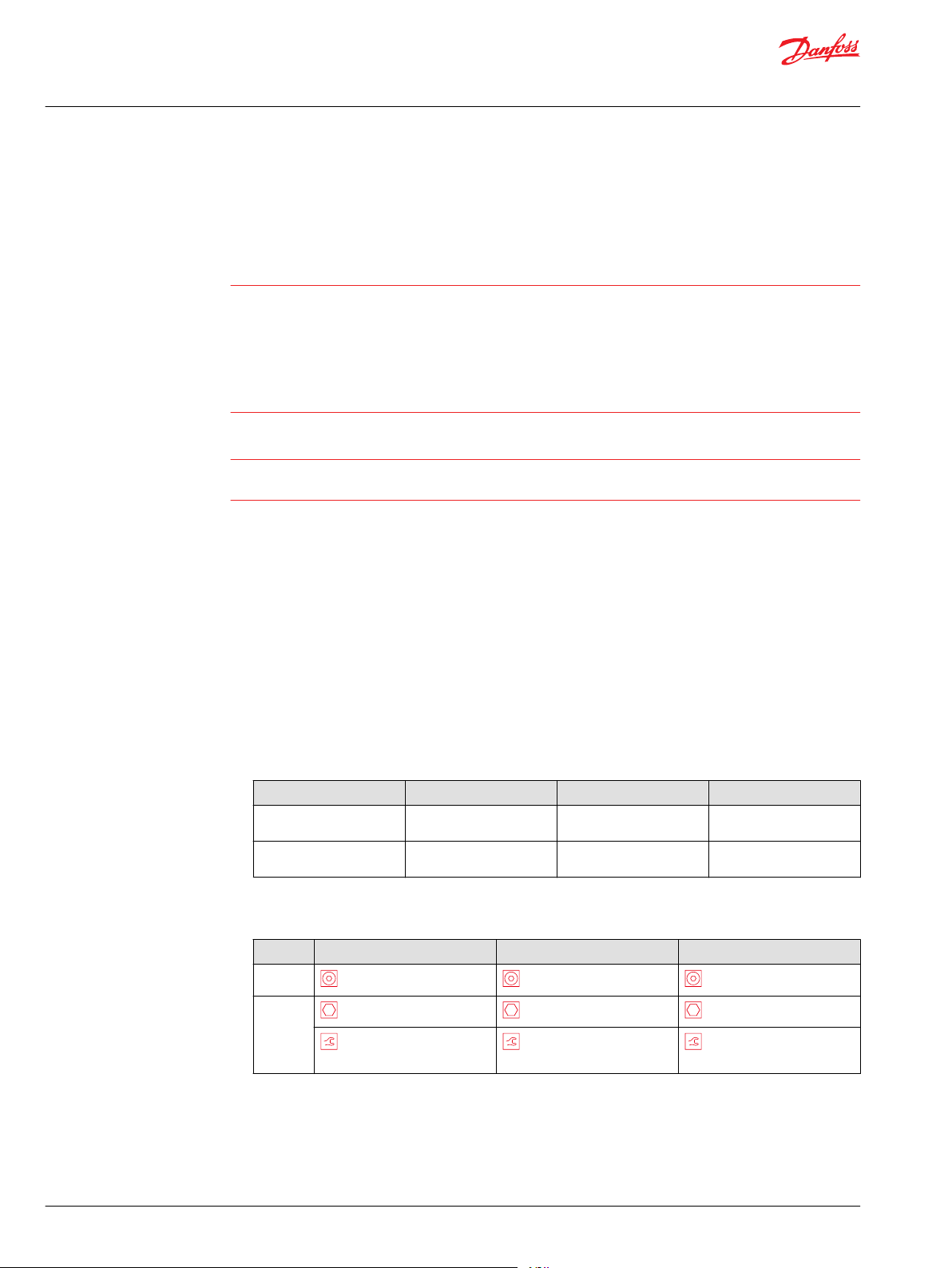

Auxiliary Flange and Charge Pump Replacement............................................................................................................. 44

Auxiliary flange removal........................................................................................................................................................ 44

Auxiliary flange installation...................................................................................................................................................44

130/145........................................................................................................................................................................................ 45

193/260........................................................................................................................................................................................ 46

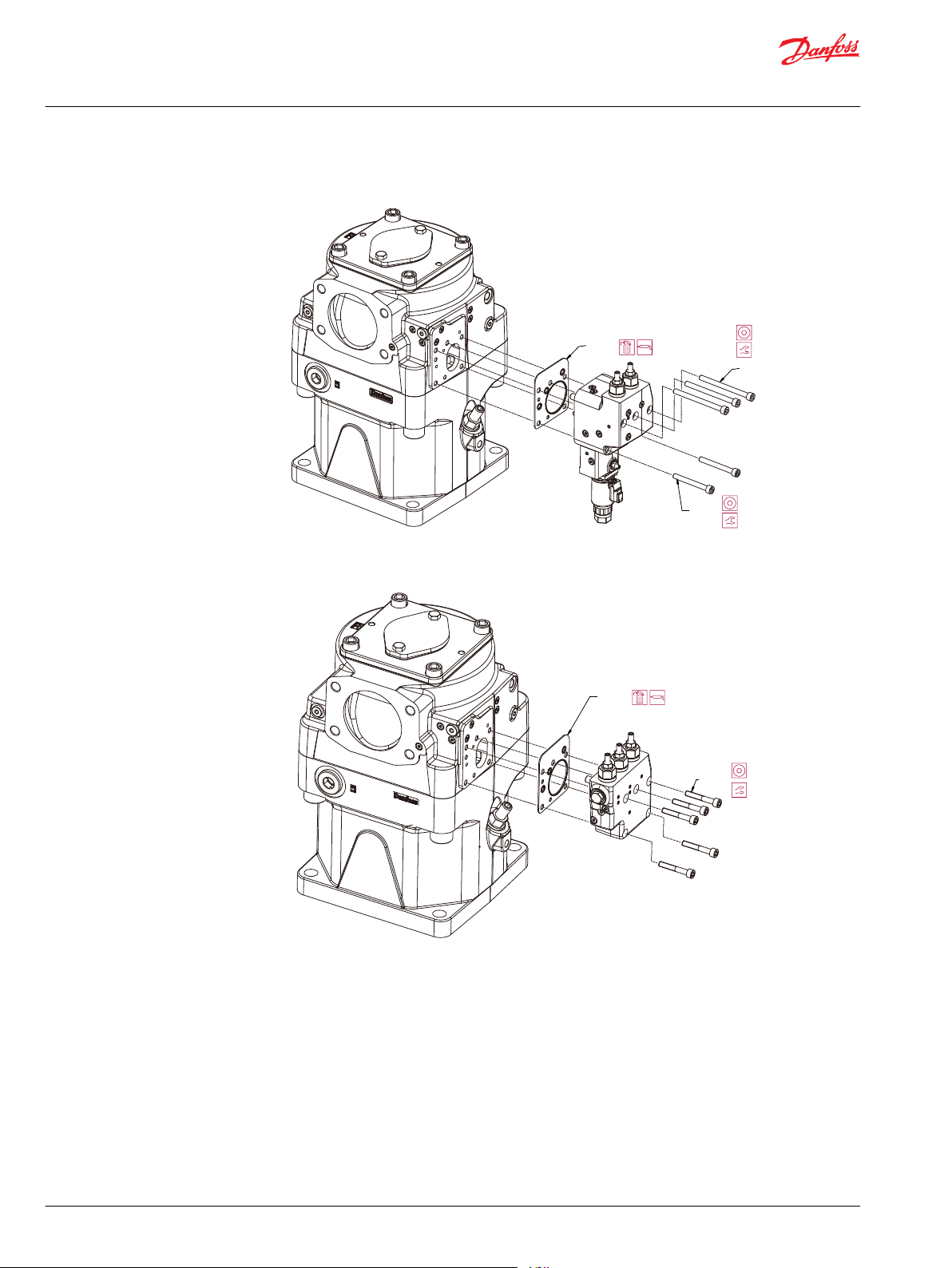

Control (193/260)...........................................................................................................................................................................47

Removal........................................................................................................................................................................................47

Installation...................................................................................................................................................................................47

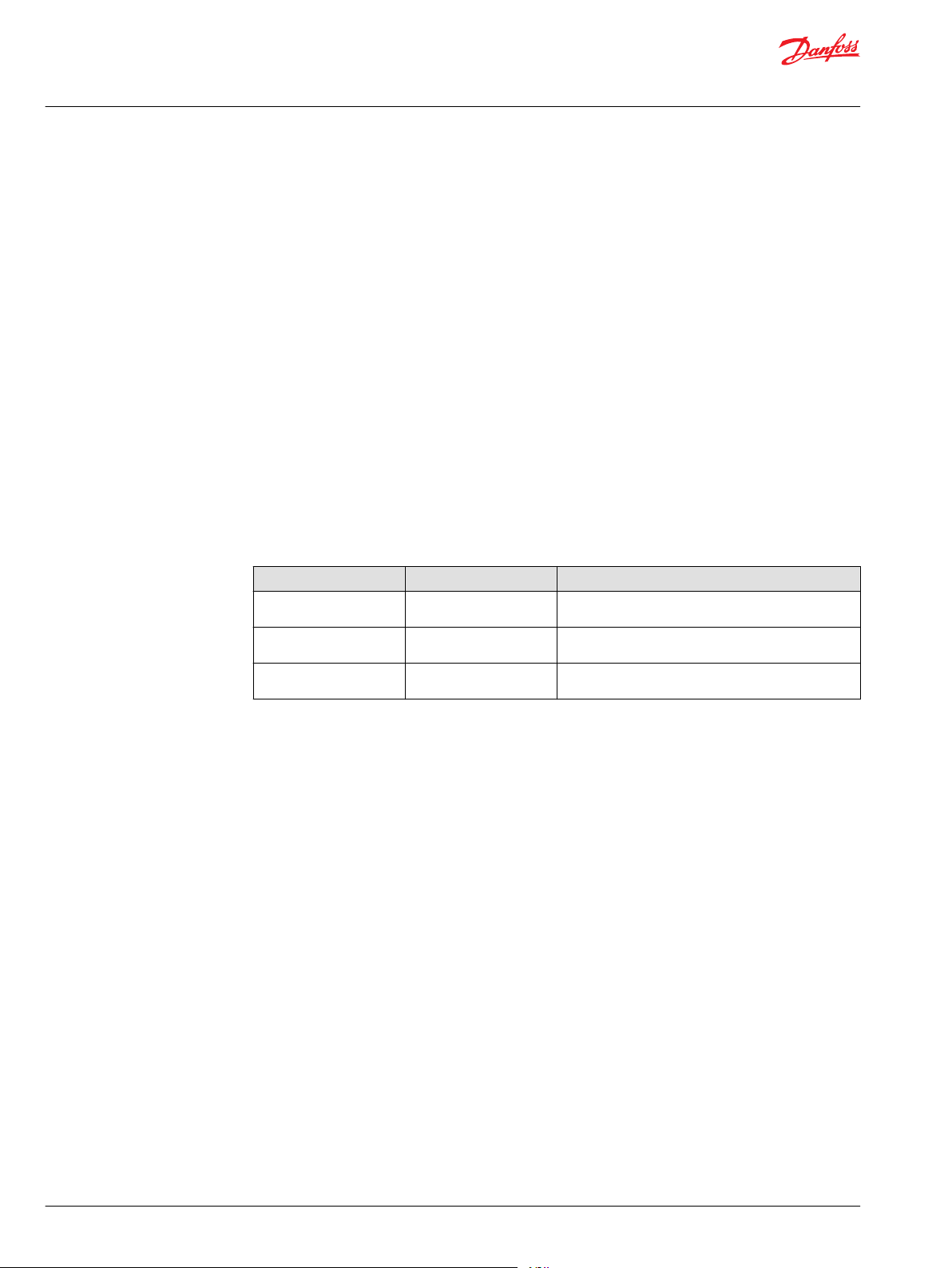

Control (130/145)...........................................................................................................................................................................49

Shuttle Valve or Plug.....................................................................................................................................................................50

Shuttle valve or plug removal..............................................................................................................................................50

Shuttle valve or plug installation........................................................................................................................................50

Edge Filter (260)..............................................................................................................................................................................50

Edge filter removal...................................................................................................................................................................50

Edge filter installation.............................................................................................................................................................50

Displacement Limiters................................................................................................................................................................. 52

Displacement limiter screw removals...............................................................................................................................52

Displacement limiter screws installation......................................................................................................................... 52

Plug and fitting installation........................................................................................................................................................54

193 TPE2 control....................................................................................................................................................................... 54

260 TPE2 control....................................................................................................................................................................... 55

130/145 TPSN control............................................................................................................................................................. 56

Plugs and fasteners....................................................................................................................................................................... 57

Fastener and torque chart.....................................................................................................................................................57

Plug size and torque chart.....................................................................................................................................................58

4 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 5

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Introduction

Pump service overview

This manual includes information on maintenance, troubleshooting, and minor repair of D1P pumps.

Performing minor repairs may require removal from the vehicle/machine. Thoroughly clean the unit

before beginning maintenance or repair activities. Since dirt and contamination are the greatest enemies

of any type of hydraulic equipment, follow cleanliness requirements strictly. This is especially important

when changing the system filter and when removing hoses or plumbing.

A worldwide Global Service Partner Network is available for major repairs. Major repairs require the

removal of the unit’s endcap, which voids the warranty unless done by a Global Service Partner. Danfoss

Global Service Partners are trained by the factory and certified on a regular basis. You can locate your

nearest Global Service Partner using the distributor locator at www.danfoss.com.

For detailed technical information, refer to the Technical Information manual.

General instructions

Remove the unit

If necessary, remove the unit from the vehicle/machine. Chock the wheels on the vehicle or lock the

mechanism to inhibit movement. Be aware that hydraulic fluid may be under high pressure and/or hot.

Inspect the outside of the pump and fittings for damage. Cap hoses after removal to prevent

contamination.

Safety precautions

Keep it clean

Cleanliness is a primary means of assuring satisfactory pump life on either new or repaired units.

Clean the outside of the pump thoroughly before disassembly. Take care to avoid contamination of the

system ports. Cleaning parts by using a clean solvent wash and air drying is usually adequate.

As with any precision equipment, you must keep all parts free of foreign material and chemicals. Protect

all exposed sealing surfaces and open cavities from damage and foreign material. If left unattended,

cover the pump with a protective layer of plastic.

Replace all O-rings and gaskets

Danfoss recommends that you replace all O-rings, seals and gaskets. Lightly lubricate all O-rings with

clean petroleum jelly prior to assembly.

Secure the unit

If removed from machine, place the unit in a stable position with the shaft pointing downward. It

will be necessary to secure the pump while removing and torquing fasteners and components.

Unintended Machine Movement

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

Secure the machine or disable/disconnect the mechanism while servicing to protect against unintended

movement.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 5

Page 6

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Introduction

Flammable Cleaning Solvents

Some cleaning solvents are flammable.

Do not use cleaning solvents in an area where a source of ignition may be present to avoid possible fire.

Fluid Under Pressure

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing serious

injury and/or infection. This fluid may also be hot enough to cause burns.

Relieve pressure in the system before removing hoses, fittings, gauges, or components. Never use your

hand or any other body part to check for leaks in a pressurized line. Use caution when dealing with

hydraulic fluid under pressure. Seek medical attention immediately if you are cut by hydraulic fluid.

Personal Safety

Protect yourself from injury whenever servicing a hydraulic system.

Use proper safety equipment, including safety glasses, at all times.

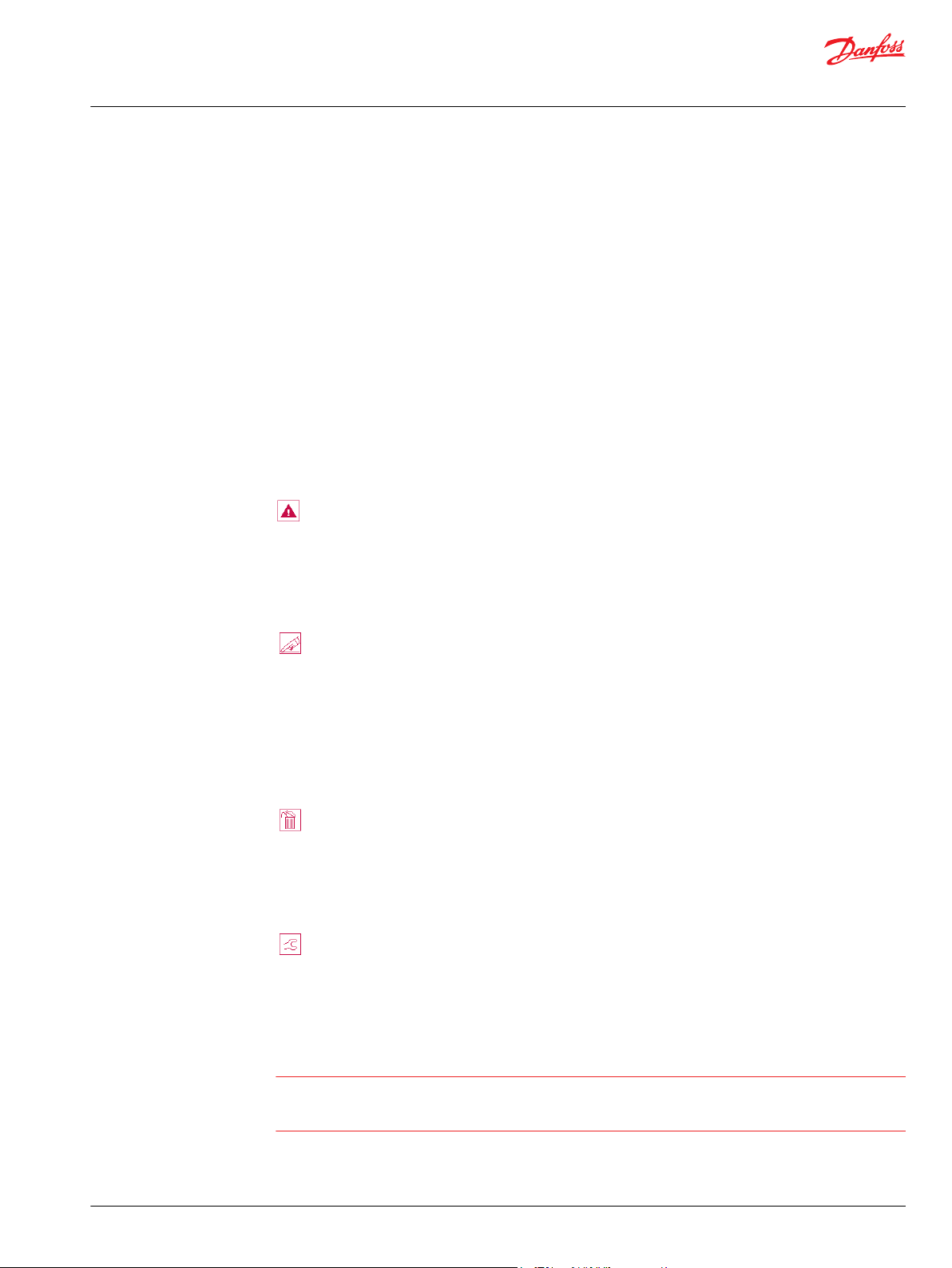

Symbols used in Danfoss literature

WARNING may result in injury Tip, helpful suggestion

CAUTION may result in damage to product or

property

Reusable part Apply grease / petroleum jelly

Non-reusable part, use a new part Apply locking compound

Non-removable item Inspect for wear or damage

Option - either part may exist Clean area or part

Superseded - parts are not interchangeable Be careful not to scratch or damage

Measurement required Note correct orientation

Flatness specification Mark orientation for reinstallation

Parallelism specification Torque specification

External hex head Press in - press fit

Internal hex head Pull out with tool – press fit

Torx head Cover splines with installation sleeve

O-ring boss port Pressure measurement/gauge location or

Lubricate with hydraulic fluid

specification

The symbols above appear in the illustrations and text of this manual. They are intended to communicate

helpful information at the point where it is most useful to the reader. In most instances, the appearance

of the symbol itself denotes its meaning. The legend above defines each symbol and explains its purpose.

D1 pumps design

Danfoss D1 high power open circuit piston pumps convert input torque into hydraulic power. Rotational

force is transmitted through the input shaft to the cylinder block. The input shaft is supported by roller

6 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 7

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Introduction

bearings at the front and rear of the pump and is splined into the cylinder block . A lip-seal at the front

end of the pump prevents leakage where the shaft exits the pump housing. The spinning cylinder block

contains nine reciprocating pistons. Each piston has a brass slipper connected at one end by a ball joint.

The slippers are held to the swashplate by the retainer. The block spring holds the cylinder block to the

valve plate. The reciprocating movement of the pistons occurs as the slippers slide against the inclined

swashplate during rotation. Via the valve plate, one half of the cylinder block is connected to pump inlet

and the other half to pump outlet. As each piston cycles in and out of its bore, fluid is drawn from the

inlet and displaced to the outlet thereby imparting power into the system circuit. A small amount of fluid

is allowed to “leak” from the cylinder block / valve plate and slipper / swashplate interfaces for lubrication

and cooling. Case drain ports are provided to return this fluid to the reservoir.

The volume of fluid displaced into the system circuit is controlled by the angle of the swashplate. The

swashplate is forced into an inclined position (into stroke) by the bias piston and spring. The servo piston

opposes the action of the bias piston and spring forcing the swashplate out of stroke.

The pump control, by varying the pressure at the servo piston, controls the displacement of fluid in the

system circuit.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 7

Page 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Introduction

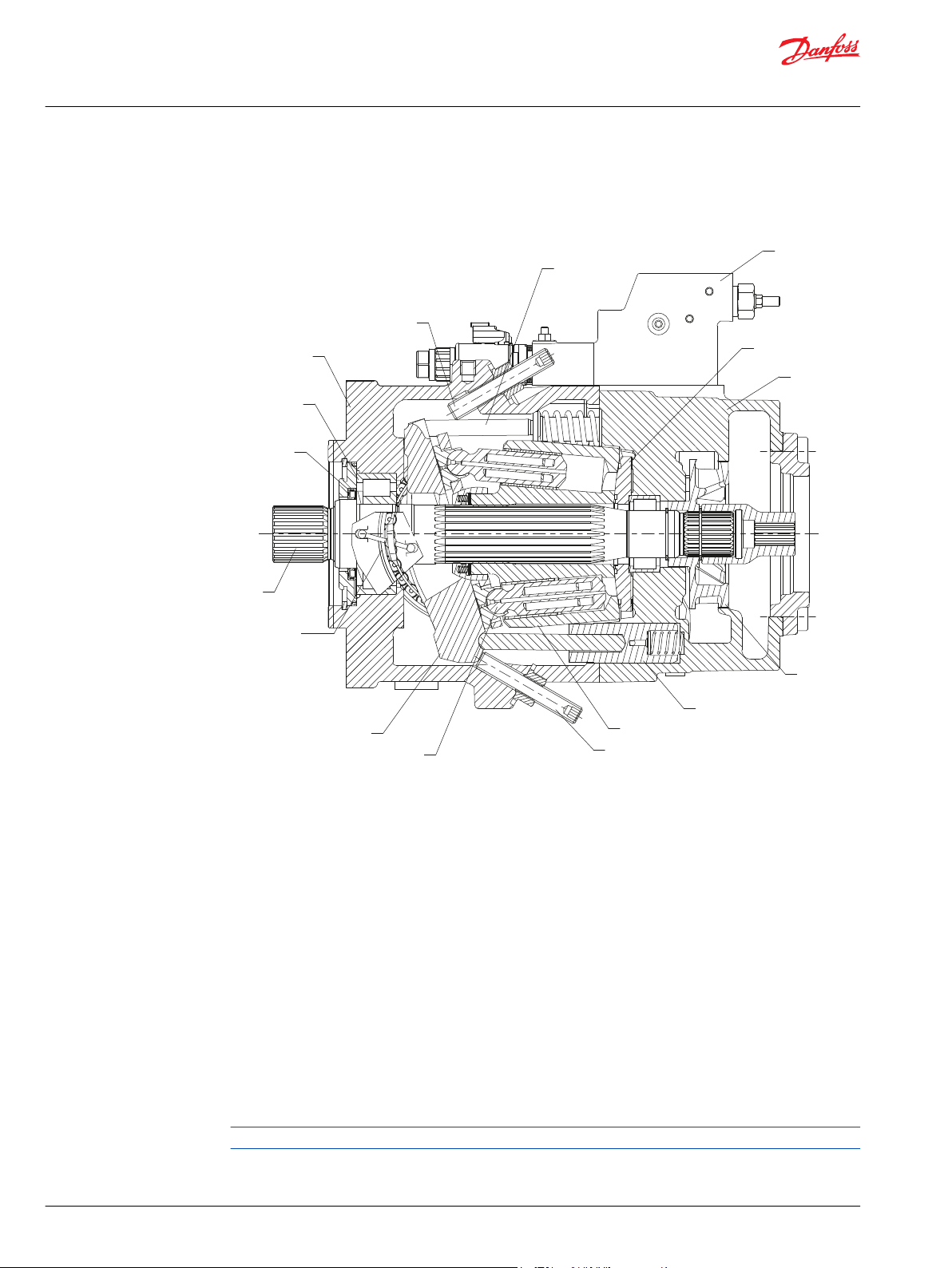

D1 pump cross-section view

D1 pump

1. Shaft seal

2. Roller bearing

3. Housing

4. Minimum displacement limiter

5. Bias piston

6. Control

7. Valve plate

8. Endcap

9. Charge pump

10. Servo piston

11. Cylinder block

12. Maximum displacement limiter

13. Piston

14. Swashplate

15. Swashplate Bearing

16. Input shaft

Some internal parts may be different depending on the pump size.

8 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 9

0

0

Q max

Flow

Pressure

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

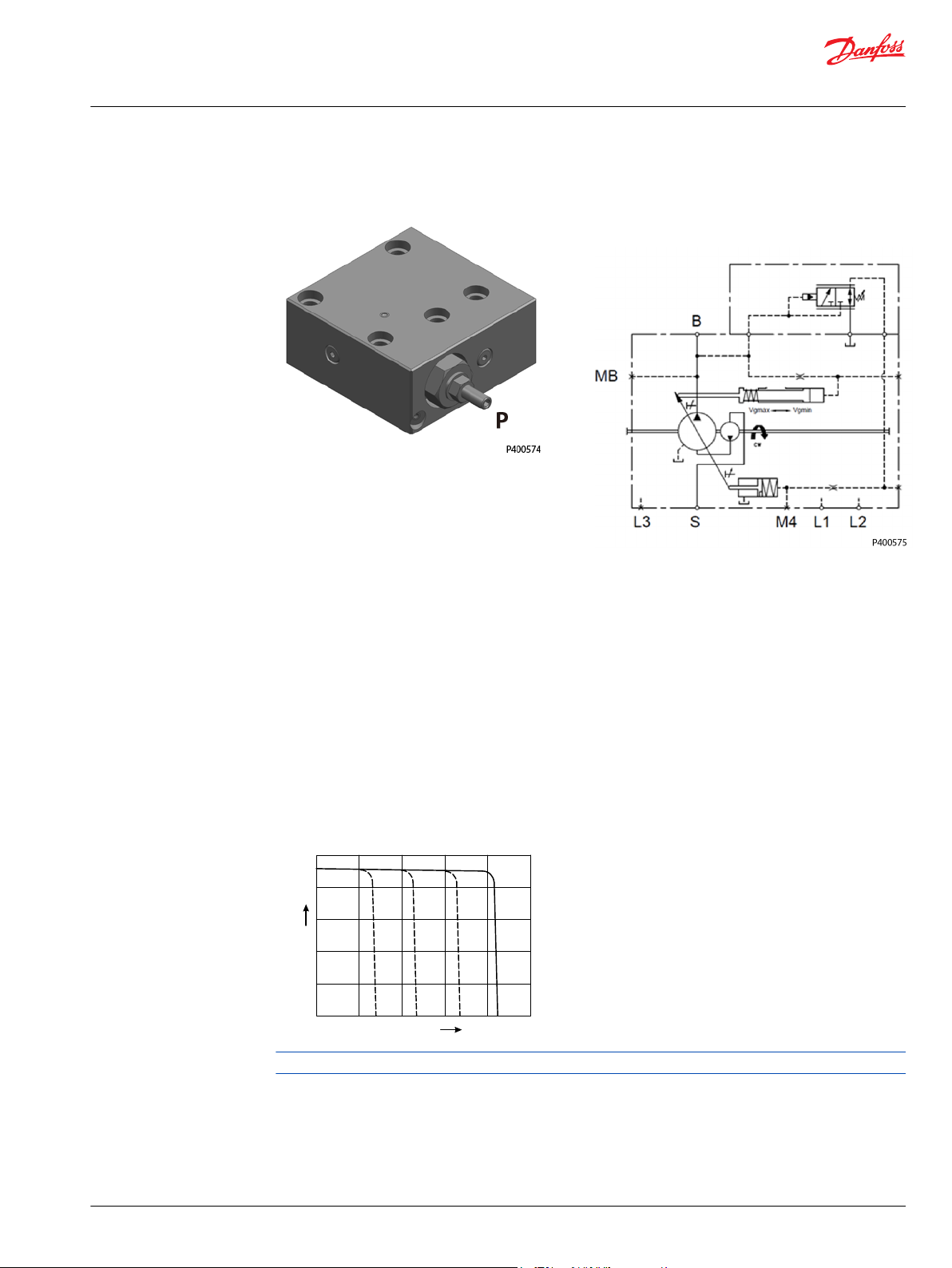

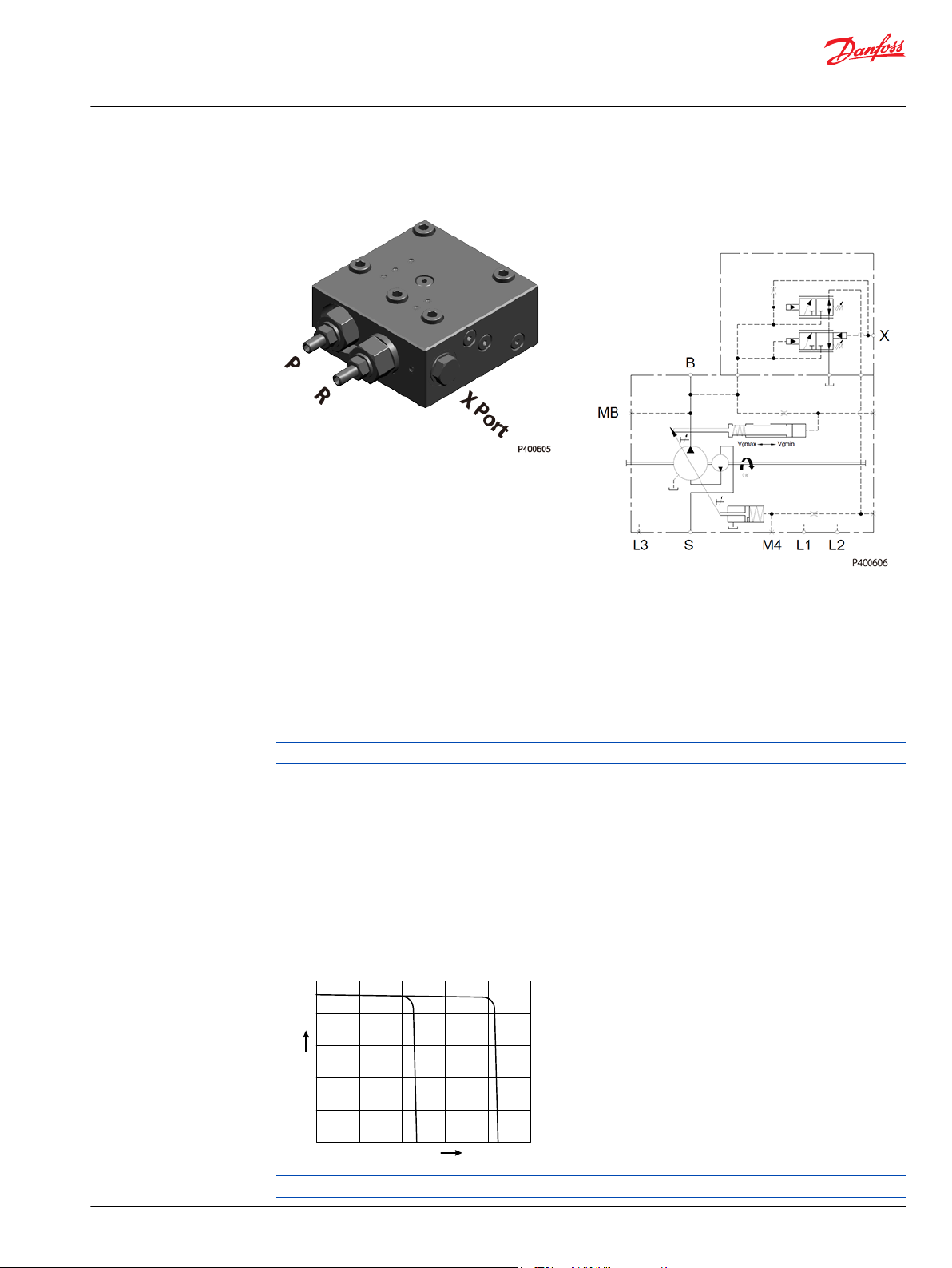

NPNN (Pressure Compensated Control)

D1P 130/145/193/260+NPNN

Pressure Compensated Control (P) Principle

The P control design maintains a constant pressure in the hydraulic circuit as flow varies. The P control

modulates pump flow accordingly to maintain system pressure at the P setting as the P adjusting screw

and spring defines.

Pressure Compensated Control (P) Operation

When system pressure, acting on the non-spring end of the P spool, overcomes the force of the P spring,

the spool shifts porting system pressure to the servo piston and the swashplate angle decreases. When

system pressure drops below the P setting, the P spring shifts the spool in the opposite direction

connecting the servo piston to pump case and the swashplate angle increases. The swashplate is

maintained at whatever angle is required to keep system pressure at the P setting.

P characteristic

It is recommended that a relief valve be installed in the pump outlet for additional system protection.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 9

Page 10

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

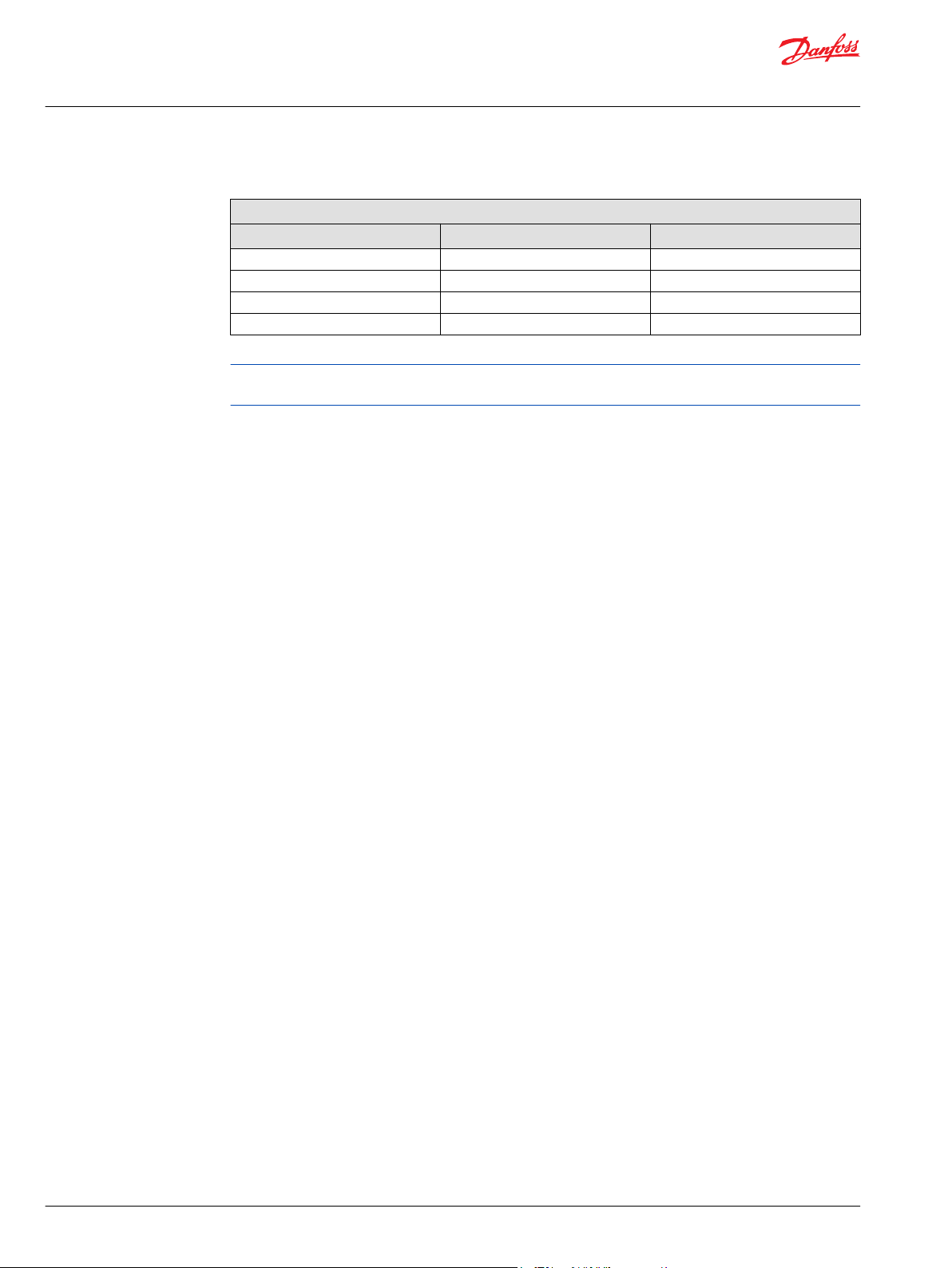

Response/Recovery

Pressure Compensated (PC) Control Response/Recovery Times* @80°C, 350 bar, 1500rpm

Frame Size Response (msec) Recovery (msec)

130cc 150 270

145cc 150 270

1

193cc

260cc 154 327

1

Tested at 1800rpm

Values may vary depending on application conditions. For more information, please contact Danfoss

Power Solutions.

280 500

10 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 11

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

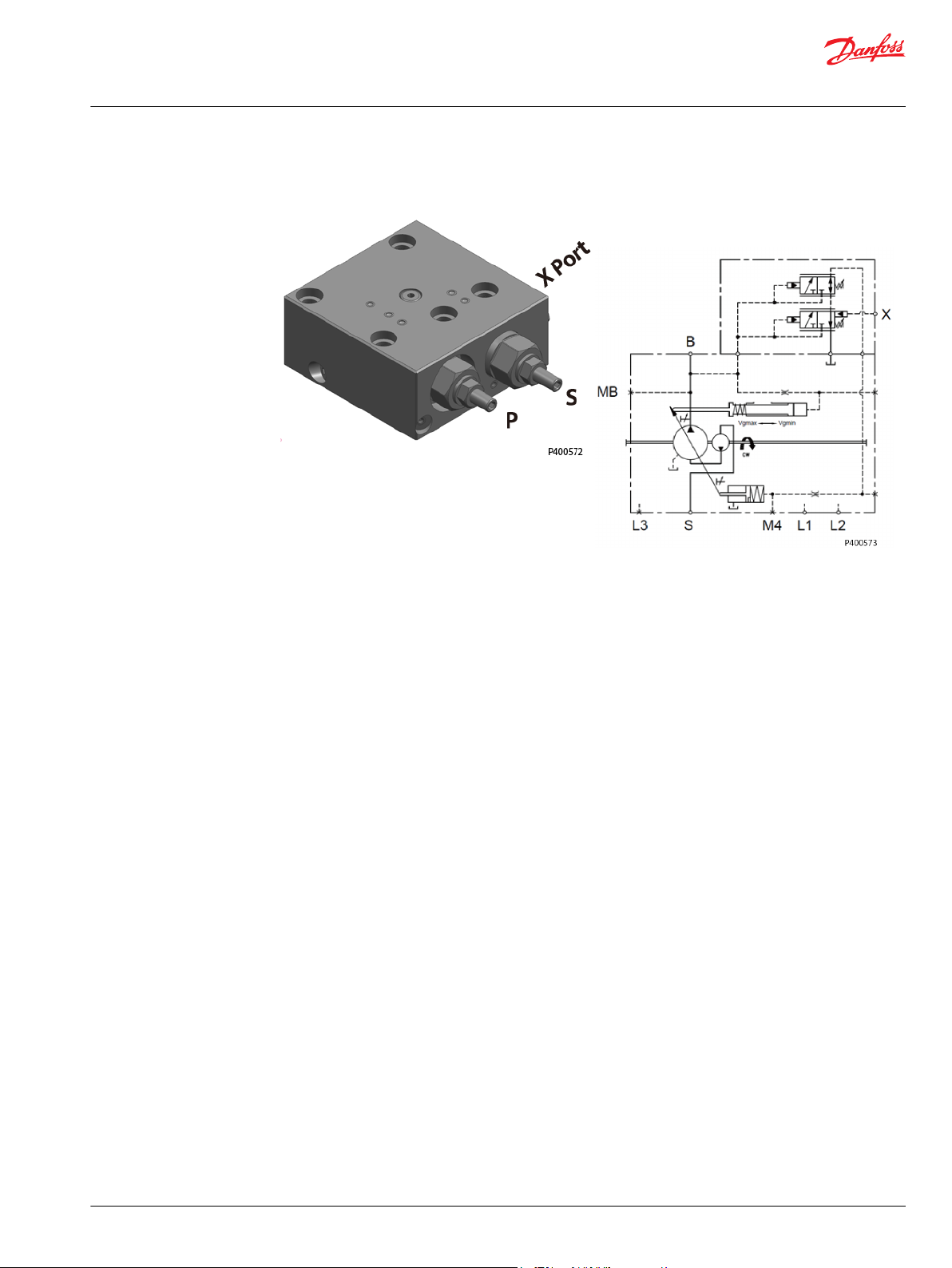

NPSN (Pressure Compensated Control + Load Sensing Control)

D1P 130/145/193/260+NPSN

Pressure Compensated Control (P) Principle and Operation

Please refer to NPNN (Pressure Compensated Control) on page 9

Load Sensing Control (S) Principle

The S control design matches pump flow with system demand. The S control senses the flow demand of

the system as a pressure drop across the external control valve (1).

As (1) opens and closes, the pressure difference (delta) across the valve changes. When opening, the delta

decreases. When closing, the delta increases. The S control then increases or decreases pump flow to the

system until the pressure delta becomes equal to the S setting as defined by the S adjusting screw and

spring.

Load Sensing Control (S) Operation

Through internal porting, system pressure [upstream of (1)] is applied to the non-spring end of the S

spool, and through hydraulic line connected at port X, load pressure [downstream of (1)] is applied to the

spring end. This arrangement allows the S spool to act on the delta between system pressure and load

pressure. The S spring sets the threshold of operation (S setting).

Because the swashplate is biased to maximum angle, the pump attempts to deliver full flow to the

hydraulic system. When the flow being delivered exceeds demand, the pressure delta across the (1) is

great enough to overcome spring force and shift the S spool porting system pressure to the servo piston.

The pump de-strokes reducing flow until the delta across the (1) becomes equal to the S setting.

When flow being delivered is less than demand, the delta across the (1) drops below the S setting and the

S spring shifts the spool connecting the servo piston to pump case. The pump strokes increasing flow

until the delta across the (1) becomes equal to the S setting.

When the external control valve (1) is placed in neutral, it connects the LS signal line to drain. With no LS

pressure acting on the non-spring end of the LS spool, the pump adjusts stroke to whatever position

necessary to maintain system pressure at the LS setting. The pump is now in low pressure standby mode.

(1) is not in the scope of supply.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 11

Page 12

0

0

Q max

Flow

Pressure

P setting

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

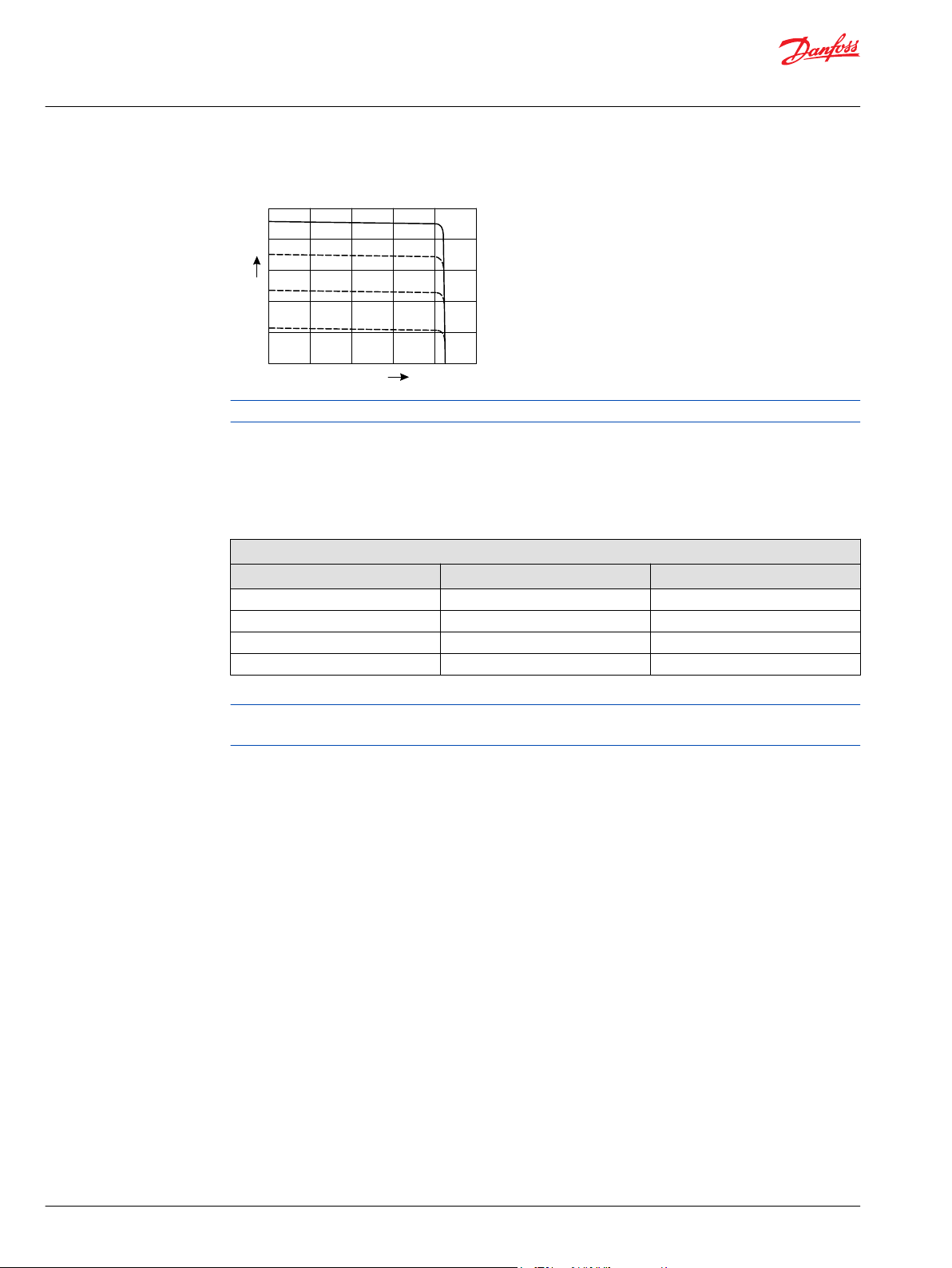

S characteristic

For additional system protection, install a relief valve in the pump outlet line.

NPSN Priority

The Pressure Compensated Control (P) has priority over the Load Sensing Control (S).

Response/Recovery

Load Sensing (LS) Response/Recovery Times @80°C, 1500rpm, LS Setting at 25 bar

Frame Size Response (msec) Recovery (msec)

130cc 260 360

145cc 260 360

1

193cc

260cc 309 327

1

Tested with a LS setting of 20bar

233 264

Values may vary depending on application conditions. For more information, please contact Danfoss

Power Solutions

12 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 13

0

0

Q max

Flow

Pressure

RP setting

PC setting

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

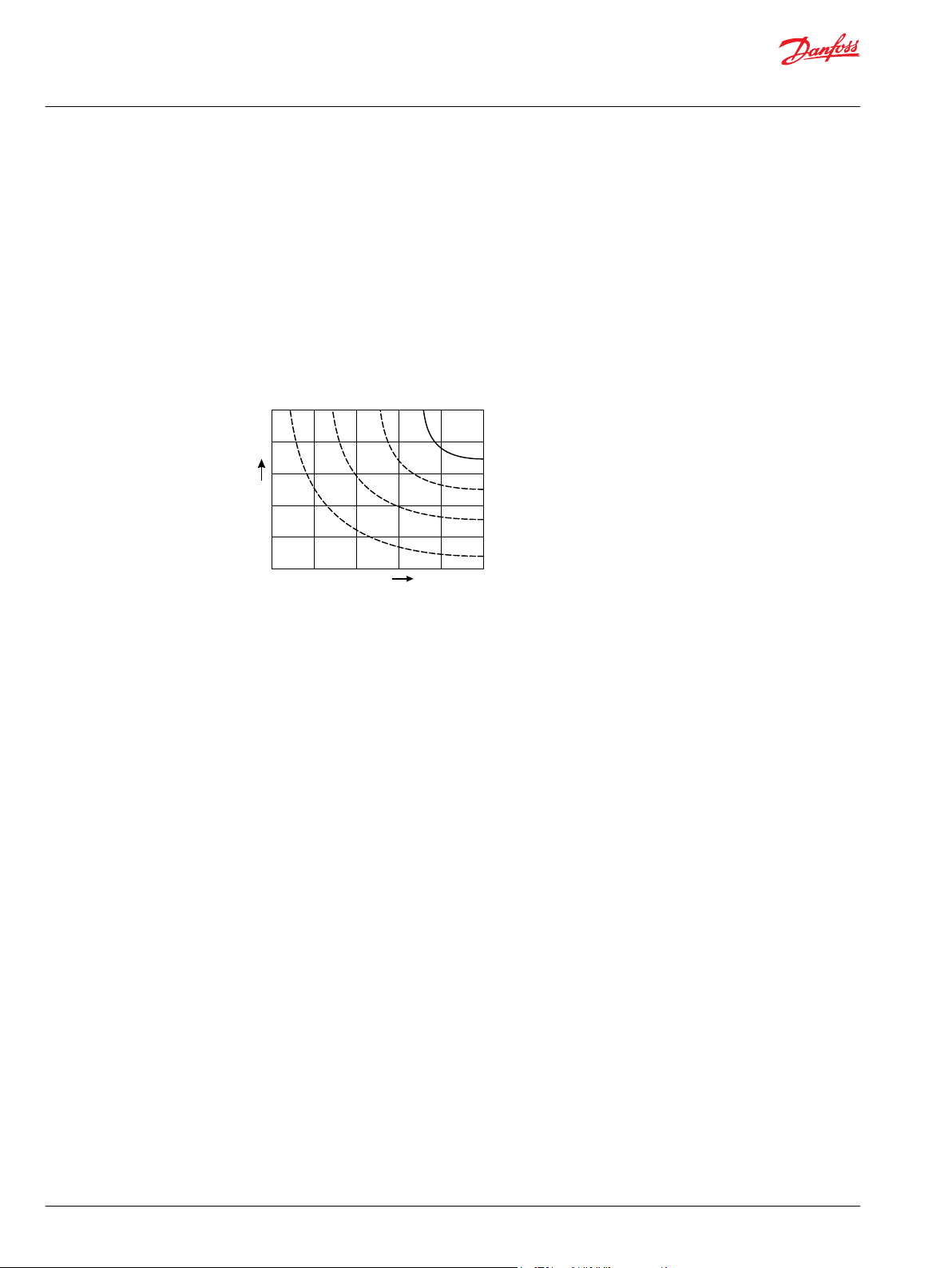

NPNR (Pressure Compensated Control + Remote Pressure Compensated Control)

D1P 130/145/193/260+NPNR

Pressure Compensated Control (P) Principle and Operation

Please refer to NPNN (Pressure Compensated Control) on page 9.

Remote Pressure Compensated Control (R) Principle

The remote PC control is a two-stage control that allows multiple PC settings. Remote PC controls are

commonly used in applications requiring low and high pressure PC operation.

For this control, Danfoss recommends a load sense setting of 20bar.

Remote Pressure Compensated Control (R) Operation

The remote PC control uses a pilot line connected to an external hydraulic valve. The external valve

changes pressure in the pilot line, causing the PC control to operate at a lower pressure. When the pilot

line is vented to reservoir, the pump maintains pressure at the load sense setting. When pilot flow is

blocked, the pump maintains pressure at the PC setting. An on-off solenoid valve can be used in the pilot

line to create a low-pressure standby mode. A proportional solenoid valve, coupled with a

microprocessor control, can produce an infinite range of operating pressures between the low pressure

standby setting and the PC setting.

R characteristic

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 13

For additional system protection, install a relief valve in the pump outlet line.

Page 14

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

NPNR Priority

When the pump’s X-port is vented to tank, or limited to some pressure setting via a remote valve, the

remote pressure compensator function will control the maximum outlet pressure of the pump. If the

pump’s outlet pressure reaches the pressure setting of the pressure compensator (PC) function, the PC

function will take priority and limit the pump’s maximum pressure.

14 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 15

X

MB

B

(1)

P400251

Vg min

Vg max

L3

S M4 L1 L2

P400080

X

Vg min

CW

Vg max

MB

B

L3

S M4 L1 L2

(1)

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

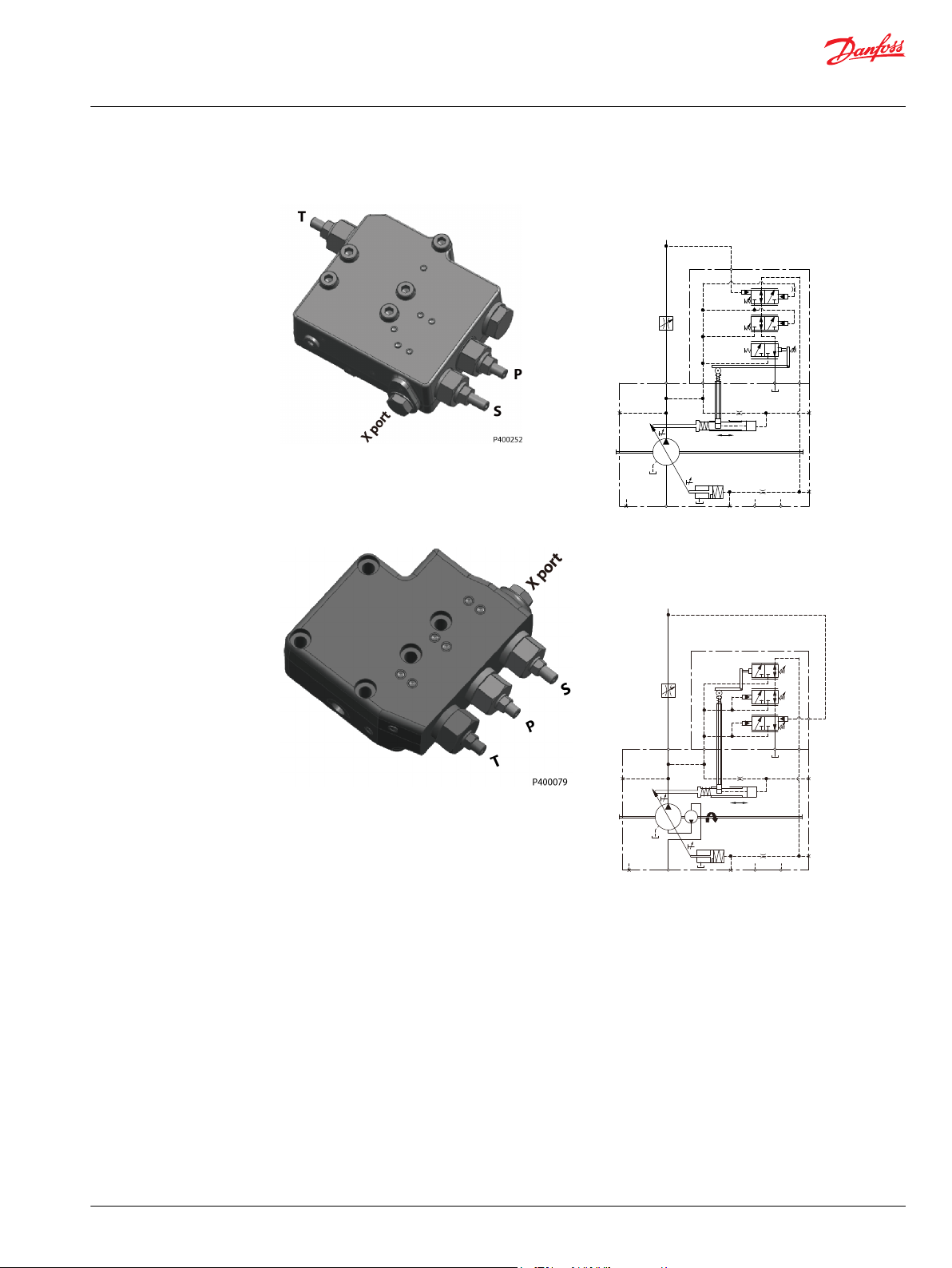

TPSN (Power Control + Pressure Compensated Control + Load Sensing Control)

D1P 130/145+TPSN

D1P 193/260+TPSN

*Control oil filter is optional

Power Control (T) Principle

The power control regulates the displacement of the pump depending on the working pressure so that a

given drive power is not exceeded at constant drive speed, this function can prevent engine stall or

protect electric generator.

©

PB = working pressure

PB • Vg = C Vg = displacement

C = constant

The precise control with a hyperbolic control characteristic, provides an optimum utilization of available

power.

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 15

Page 16

Q max

0

0

Flow

Pressure

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

Power Control (T) Operation

The working pressure acts on a rack-pivot via a roller jack which produces a rotating torque, an externally

adjustable spring force counteracts this which determines the power setting.

If the moment generated by working pressure exceeds the moment generated by spring force, the

control valve is actuated by the rack-pivot, and pump reduces displacement. The lever length at the rackpivot is shortened and the working pressure can increase at the same rate as the displacement decreases

without the drive powers being exceeded.

(PB • Vg = C).

The hydraulic output power (characteristic T) is influenced by the efficiency of the pump.

T characteristic

Pressure Compensated Control (P) Principle and Operation

Please refer to NPNN (Pressure Compensated Control) on page 9

Load Sensing Control (S) Principle and Operation

Please refer to NPSN (Pressure Compensated Control + Load Sensing Control) on page 11

TPSN Priority

The Pressure Compensated Control (P) has priority over the Power Control (T), Power Control has priority

over Load Sensing Control (S).

16 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 17

W

X

E

B

Vgmax Vgmin

B

MB

S

M4

L3

L1 L2

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

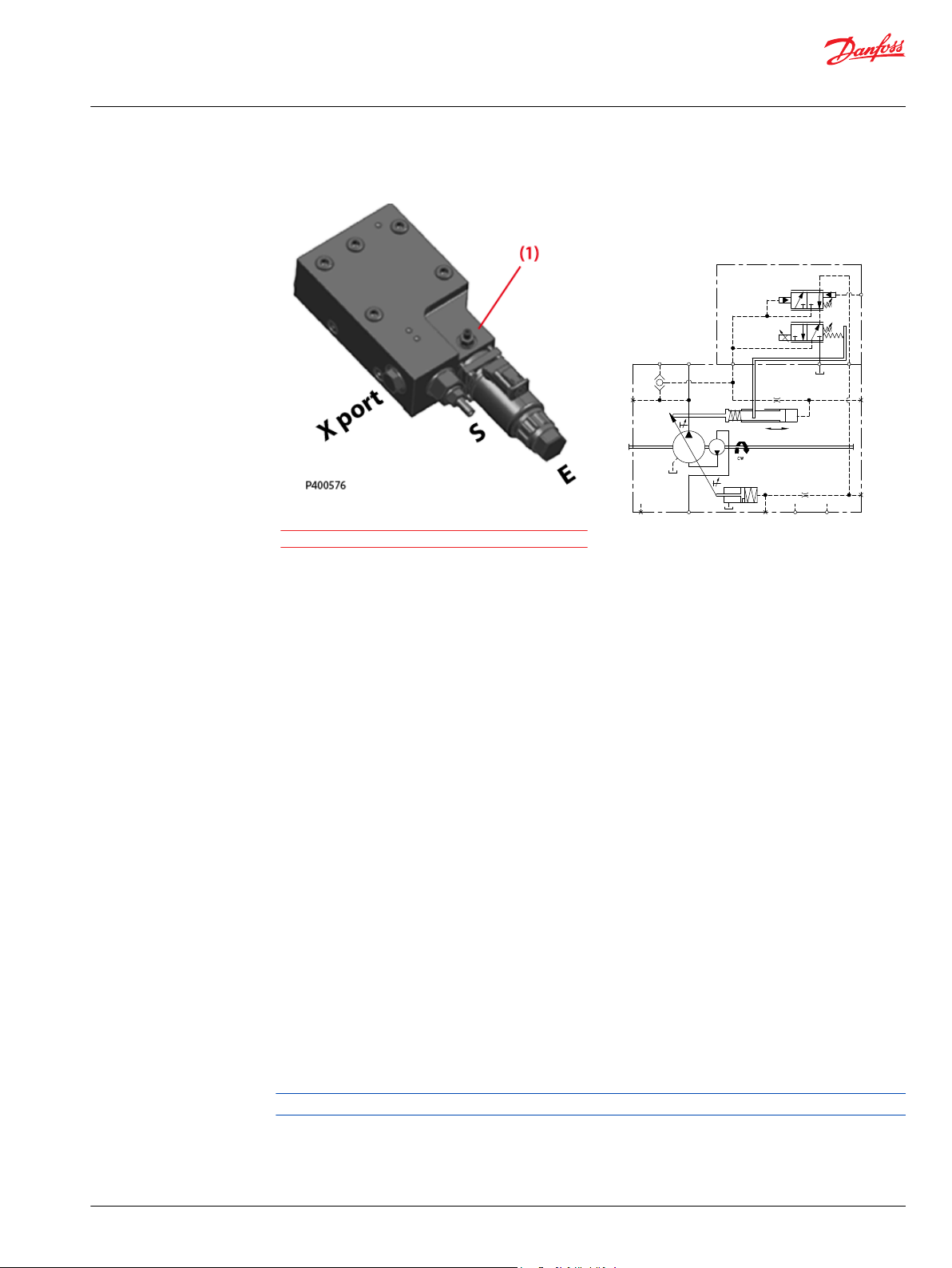

NNES (Electric Displacement Control + Load Sensing Control)

Warning

(1) Adjustment is not permissible

D1P 130/145/193/260 NNES

Electric Displacement Control (E) Principle

The electric displacement control uses an electric proportional solenoid valve to vary the pump’s

displacement from minimum displacement to maximum displacement or from maximum displacement

to minimum displacement. The swashplate angle (pump displacement) is proportional to the electrical

input signal (control current).

Electric Displacement Control (E) Operation

This control is current driven, requiring a Pulse Width Modulated (PWM) signal. Pulse width modulation

allows more precise control of current to the solenoid. The PWM signal causes the solenoid pin to push

against the E spool, which depressurizes the end of servo piston, the swashplate angle increases under

the force of the bias piston

A swashplate feedback link provides swashplate position force to the solenoid through the E spool’s

linear spring. The control reaches equilibrium when the position of the swashplate spring feedback force

exactly balances the input command solenoid force from the operator. As working pressure changes with

load, the control and servo/swashplate system work constantly to maintain the commanded position of

the swashplate.

Electric Displacement Control (E) Operating Instruction

To make sure the electric displacement control works properly, a minimum control pressure of 30 bar

[435 psi] is required. The required control pressure is taken either from the working pressure, or from the

externally applied control pressure at the E port.

If you can’t make sure that the working pressure is above 30 bar all the time, then a minimum of 30bar

[435 psi] pressure supply at the E port is mandatory in order to control the displacement of the pump at

all times. This pressure supply can be provided from different sources, such as an additional small gear or

piston pump and a relief valve, or an accumulator.

If E port is not connected, remove the shuttle valve

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 17

Page 18

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

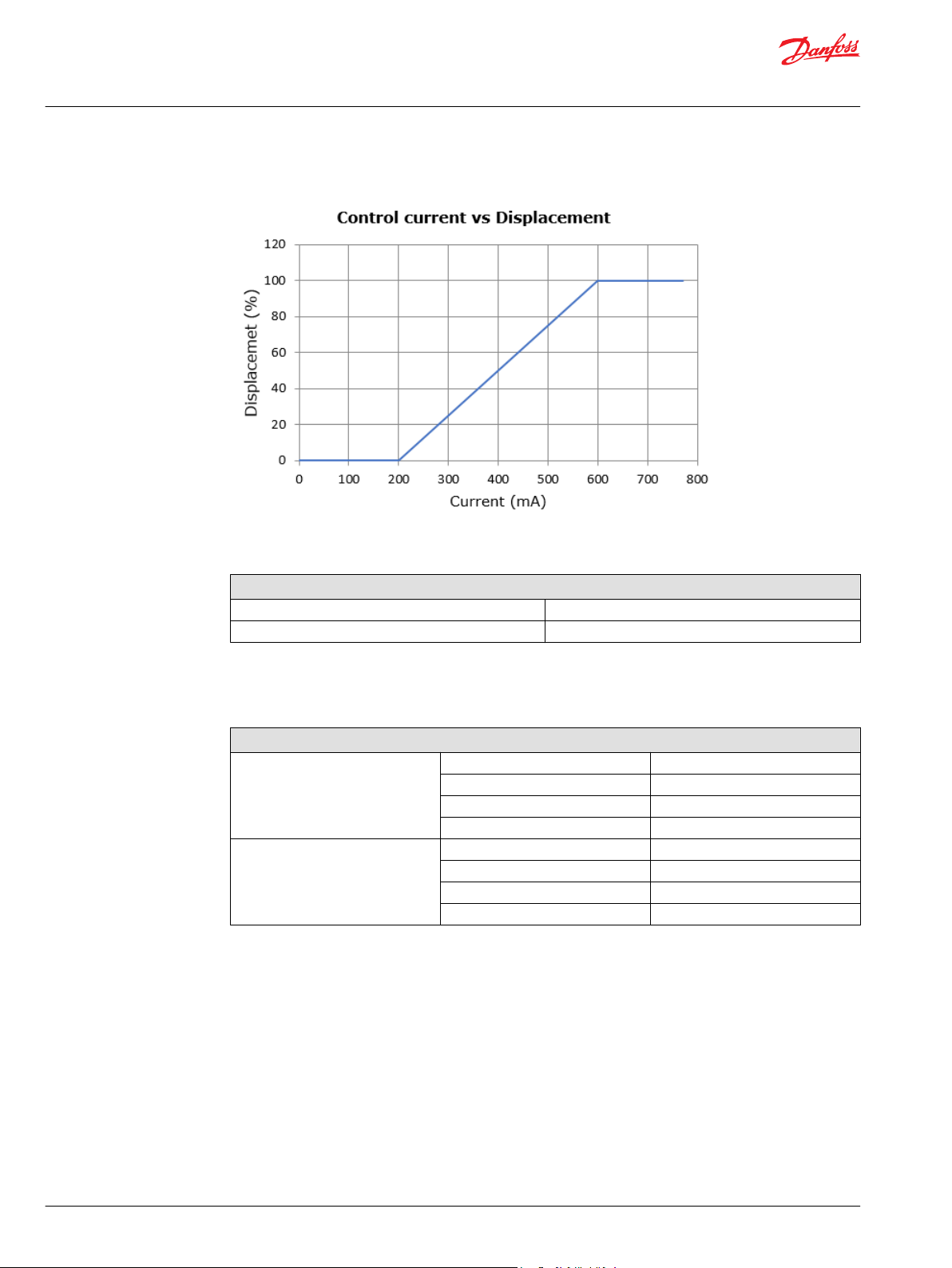

Typical operating curve

Hysteresis

EDC Hysteresis

Input hysteresis <4.5%

Output hysteresis @50% displacement <4.0%

1

Values may vary depending on application conditions. For more information, please contact Danfoss Power

Solutions

1

Response/Recovery

Response/Recovery Times @ 1500rpm (50°C)

Response 0%-100% 130cc (263 bar) 260 msec

Response 100%-0% 130cc (263 bar) 390 msec

1

145cc (263 bar) 260 msec

193cc (160 bar) 272 msec

260cc (200 bar) 370 msec

145cc (263 bar) 390 msec

193cc (160 bar) 186 msec

260cc (200 bar) 390 msec

MOR

Each Electric Displacement Control (EDC) is equipped with a Manual Over Ride (MOR) function for

temporary actuation of the control to aid in diagnostics, even if insufficient or no current is supplied to

the solenoid actuator. Initial activation of the MOR function will require a higher force to overcome the

sticking effect between the pin and O-ring seal. Repeated activation of this functionality should provide

better controllability.

18 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 19

W

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

Warning

Do not actuate the MOR unless the machine is in a “SAFE” mode. Unintended MOR operation will cause

the pump to go into stroke, use only for diagnosis purposes.

Solenoid Specification

Technical data - Solenoid

Voltage

Start current at Vg min.

End Current at Vg max.

Maximum current

Coil Resistance @ 20 °C [70 °F]

PWM Range

PWM Frequency (preferred)

IP Rating (IEC 60 529) + DIN 40 050, part 9

IP Rating (IEC 60 529) + DIN 40 050, part 9 with

mating connector

*

PWM signal required for optimum control performance

*

24V (±20%)

200 mA

600 mA

770 mA

22.7 Ω

70~200 Hz

100 Hz

IP 67

IP 69K

Mating connector for Solenoid

Description Ordering Number Quantity

Mating Connector DEUTSCH DT06-2S 1

Wedge Lock DEUTSCH W2S 1

Socket contact (16 and 18 AWG) DEUTSCH 0462-201-16141 2

Danfoss mating connector kit K29657 1

The mating connector is not included in the delivery contents, this can be delivered by Danfoss on request.

Compatible PLUS+1® controllers(see below):

MC012 L1301095

MC024 L1315302

MC038 11051653

MC050 L1301752

MC088 11006645

For further information: please visit: http://www.danfoss.com/Products/MobileElectronics/index.htm

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 19

Page 20

DEUTSCH DT04-2P

74.5 4.5

(3)

A

(2)

(1)

45°

Ø37.1

36.7

Ø4

Ø13

M18x1.5

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

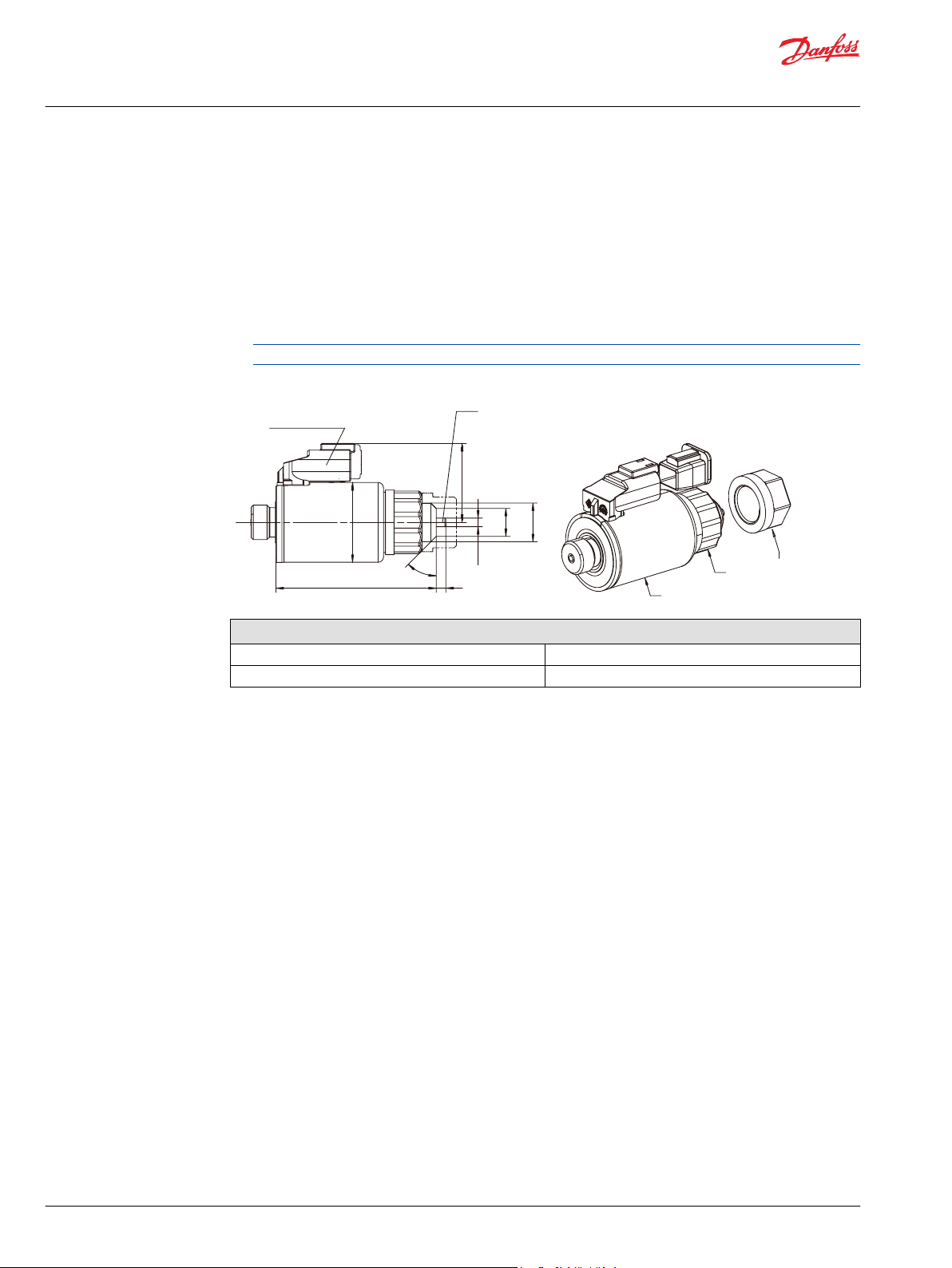

Standard EDC Valve

The position of the connector can be changed by turning the solenoid body. Proceed as follows:

1. Loosen protection cap (1).

2. Loosen lock nut (2).

3. Turn the solenoid body (3) to the desired position.

4. Tighten the lock nut (2).

5. Tighten the protection cap (1).

Tightening Torque of lock nut: 5 ± 1 N•m [44.25 ± 8.85 lbf•in]

Standard EDC Valve

A - Actuation Forces

Breakaway Force (First actuation) 45 N [10.12 lbf] max.

Repeat of Actuation 25 N [5.62 lbf] max.

NNES Priority

Both the Electric Displacement Control (EDC) and the Load Sensing Control (LS) are used to control the

pump’s displacement. The pump will output the smallest displacement when both control functions are

given control instruct.

20 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 21

W

MB

E B

L3

S M4 L1 L2

Vg min

Vg max

P400074

*

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

TPE2/TPE5 (Power Control + Pressure Compensated Control + Electric Displacement Control)

D1P 130/145+TPE5

D1P 193/260+TPE2

*Control oil filter is optional

Warning

(1) Adjustment is not permissible

Power Control (T) Principle and Operation

Please refer to TPSN (Power Control + Pressure Compensated Control + Load Sensing Control) on page 15

Pressure Compensated Control (P) Principle and Operation

Please refer to NPNN (Pressure Compensated Control) on page 9

Electric Displacement Control (E2/E5) Principle and Operation

Please refer to NNES (Electric Displacement Control + Load Sensing Control) on page 17

TPE2/TPE5 Priority

The Pressure Compensated Control (P) has priority over the Power Control (T), and the Power Control (T)

has priority over Electric Displacement Control (EDC).

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 21

Page 22

B

MB

S

M4

L3

L1 L2

Vgmax Vgmin

E

Vgmax Vgmin

B

MB

S

M4L3L1 L2

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operation

NPE2/NPE0 (Pressure Compensated Control + Electric Displacement Control)

D1P 260 with NPE2 (left); D1P 260 with NPE0 (right)

Pressure Compensated Control (P) Principle and Operation

Please refer to NPNN (Pressure Compensated Control) on page 9.

Electric Displacement Control (E2/E0) Principle and Operation

Please refer to NNES (Electric Displacement Control + Load Sensing Control) on page 17.

Shuttle Valve/Pilot Supply

Please refer to Electric Displacement Control (E) Operating Instruction section at NNES (Electric

Displacement Control + Load Sensing Control) on page 17.

To determine if an external control pilot supply is needed, please consult your Danfoss Power Solutions

representative.

D1P pumps configured with an NPE2 control will come with a shuttle valve installed at the E port. D1P

pumps with an NPE0 control will not include the shuttle valve.

22 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 23

0.8

0.9

Speed

n

max

/

n

max1

0.9

1.0

Displacement Vg/Vgmax

1.0

1.1

1.2

Pabs=1 bar [14.5 psi]

Pabs=1.5 bar [21.8 psi]

P400076

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operating parameters

D1P pressure overview

D1P speed overview

Maximum

working

pressure

The highest recommended outlet (application). Operating at or below this pressure

should yield satisfactory product life. For all applications, the load should move below

this pressure. This corresponds to the maximum allowable pressure compensated

control setting.

Maximum

(peak) pressure

The highest intermittent (t<1s) outlet pressure allowed. Maximum machine load

should never exceed this pressure, and pressure overshoots should not exceed this

pressure.

Inlet pressure The absolute pressure in the pump suction port, it is related to pump speed. Make

sure it is in the allowable range, see D1 pump specifications.

Case pressure The case pressure at the ports L1 and L2 may be a maximum of 1.2 bar [17.4 psi]

higher than the inlet pressure at the port S but not higher than 2 bar. Size drain

plumbing accordingly and connect it to tank directly. The housing must always be

filled with hydraulic fluid.

Rated

speed

The fastest recommended operating speed at full displacement and at least 0.6 bar [8.7

psi] abs with charge pump (0.8 bar [11.6 psi] abs without charge pump) inlet pressure.

Operating at or below this speed should yield satisfactory product life.

Maximum

speed

The highest recommended operating speed at full power conditions. Operating at or

beyond maximum speed requires positive inlet pressure and/or a reduction of pump

outlet flow. Refer to Inlet pressure vs. speed on page 23, chart below.

Inlet pressure vs. speed

Minimum

speed

The lowest operating speed allowed. Operating below this speed will not yield

satisfactory performance.

Caution! Threat to pump life!

Working outside of the pump's operating parameters may result in shortened life expectancy of the

pump.

Always work within the operating conditions of the pump application.

With accurate duty cycle information, your Danfoss Power Solutions representative can assist you in

calculating expected pump life.

D1P fluid overview

Ratings and performance data for D1 pumps are based on operating with premium hydraulic fluids

containing oxidation, rust, and foam inhibitors. These include premium turbine oils, API CD engine oils

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 23

Page 24

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Operating parameters

per SAE J183, M2C33F or G automatic transmission fluids (ATF), Dexron II (ATF) meeting Allison C-3 or

Caterpillar T0‑2 requirements, and certain specialty agricultural tractor fluids. For more information on

hydraulic fluid selection, see Danfoss Power Solutions publications 520L0463 Hydraulic Fluids and

Lubricants, Technical Information, and 520L0465 Experience with Biodegradable Hydraulic Fluids,

Technical Information.

D1P viscosity

Minimum Viscosity This should only occur during brief occasions of maximum ambient temperature

and severe duty cycle operation.

Maximum

Viscosity

This should only occur at cold start. Pump performance will be reduced. Limit

speeds until the system warms up.

Maintain fluid viscosity within the recommended range for maximum efficiency and pump life.

D1P temperature overview

Minimum

Temperature

Relates to the physical properties of the component materials. Cold oil will not

affect the durability of the pump components. However, it may affect the ability of

the pump to provide flow and transmit power

Maximum

Temperature

Relates to material properties. Don’t exceed it. Measure maximum temperature at

the hottest point in the system. This is usually the case drain.

D1P fluid velocity

Choose piping sizes and configurations sufficient to maintain optimum fluid velocity, and minimize

pressure drops. This reduces noise, pressure drops, overheating and maximizes system life and

performance.

Recommended fluid velocities

System lines

Suction line

Case drain

6 to 9 m/sec

1 to 2 m/sec

3 to 5 m/sec

Typical guidelines; obey all pressure ratings.

Velocity equations

SI units

Q = flow (l/min)

A = area (mm²)

Velocity = (16.67•Q)/A (m/sec)

24 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 25

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Technical specifications

D1 130-260 pump specifications

(Theoretical values, without efficiency and tolerances; value rounded)

130 145 193 260

Features Unit

Displacement

Available Rotation

Maximum

Minimum 0 0 0 0 0 0

cm3 [in3]

CCW [L]

CW [R]

Min.

Rated at max.

Input Speed

Flow at max. speed & displacement (n max.

& Vg max.)

displacement (Vg

max.)

Maximum at Vg < Vg

3

max.

rpm

l/min

[US gal/

min]

System (Working)

4

Pressure

Inlet Pressure

(Absolute)

Case Pressure

(Absolute)

Max. Working

Pressure

bar [psi]

Max. Pressure 400 [5802]

Minimum

Maximum 30 [435]

Maximum above inlet

Maximum 2 [29]

bar [psi]

bar [psi]

Filling Capacity L [US gal] 2.9 [0.77] 2.9 [0.77] 3.8 [1] 4.6 [1.3]

Torque at Vg max. & Δp = 350 bar N•m [lbf•in] 724 [6408] 808 [7151] 1075 [9515] 1448 [12816]

Power at Q max. (max. flow) & Δp = 350 bar kW [hp] 159 [213] 190 [255] 186 [249] 211 [283] 281 [377] 349 [468]

Mass Moment of Inertia of internal rotating

components

2

kg•m

[slug•ft2]

Mass kg [lb] 68 [150] 74 [163] 68 [150] 74 [163] 106 [234] 141 [311]

External Shaft Loads External Moment MeN•m [lbf•in] 476 [4213] 476 [4213] 822 [7275] 1081 [9568]

Vibratory

Mounting Flange

Load Moments

1

The values apply at absolute pressure (Pabs) of at least 0.8 bar [11.6psi] at the suction port S and mineral hydraulic fluid.

2

The values apply at absolute pressure (Pabs) of at least 0.6 bar [8.7psi] at the suction port S and mineral hydraulic fluid.

3

The values apply at Vg ≤ Vg max or in case of an increase in the inlet pressure (Pabs) at the suction port S. Please refer to Inlet Pressure vs Speed Graph

(continuous)

Shock (maximum) 8692 [76930] 8692 [76930] 13782

N•m [lbf•in]

at D1P speed overview on page 23

4

Applied pressures above maximum working pressure requires Danfoss application approval. Maximum (peak) pressure is the highest intermittent

(t<1s) outlet pressure allowed.

5

If the application requires the higher inlet pressure than 5 bar [72.5psi] (up to 30 bar [435psi]), please contact.Danfoss Power Solutions.

W/O Charge

Pump

W/ Charge

Pump

W/O Charge

Pump

W/ Charge

Pump

W/Charge

Pump

W/Charge

Pump

130 [7.93] 130 [7.93] 145 [8.85] 145 [8.85] 193 [11.78] 260 [15.87]

500 500 500 500 500 500

2200

1

2500

2

2200

2

2500

3

2500

3

2300

3

2500 2500 2200 2500 2500 2300

286 [76] 325 [86] 319 [84] 363 [96] 483 [128] 598 [158]

350 [5076]

0.8 [11.6] 0.6 [8.7] 0.8 [11.6] 0.6 [8.7] 0.6 [8.7] 0.6 [8.7]

5

2 [29] 30 [435] 2 [29] 2 [29] 2 [29]

1.2 [17.4]

0.0299

[0.0221]

0.0306

[0.0226]

0.0299

[0.0221]

0.0306

[0.0226]

0.0576

[0.0426]

0.2080

[0.1537]

4553 [40297] 4553 [40297] 6286 [55636] 8477 [75027]

16338

[121980]

[144603]

Counterclockwise (CCW) & Clockwise (CW) directions as viewed from the shaft end of the pump.

Exceeding the permissible values could cause a loss of function, reduced life or the destruction of the

pump.

Do not exceed the values shown in the table above.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 25

Page 26

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Technical specifications

D1P fluid specifications

Features Units Value

Intermittent

Viscosity

Minimum 7 [49]

Recommended range 16 - 36 [81 - 168]

Maximum (cold start)

Temperature range

Minimum (cold start)

Maximum intermittent

Temperature Range: -40 - 90 °C

Filtration (minimum)

Cleanliness per ISO 4406

[-40 - 194°F]

Temperature Range: 90 - 115 °C

[194 - 239°F]

1)

Intermittent = Short term t < 3min per incident.

2)

Cold start = Short term t < 3min, p ≤ 30 bar [435 psi], n ≤ 1000 min-1(rpm) , please contact Danfoss Power Solutions

especially when the temperature is below -25 °C [-13 °F].

3)

Must not be exceeded locally either (e.g. in the bearing area) . The temperature in the bearing area is (depending

on pressure and speed ) up to 5 °C [41 °F] higher than the average case drain temperature.

1)

5 [42]

mm2/sec

[SUS]

2)

2)

1)

°C [°F]

1600 [xxxxx]

-40 [-40 °F]

115 [239 °F]

3)

20/18/15

19/17/14

26 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 27

C

W

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Fluid and filter maintenance

Recommendations of Fluid and Filter Maintenance

To ensure optimal product life, perform regular maintenance of the fluid and filter. Contaminated fluid is

the main cause of unit failure. Take care to maintain fluid cleanliness when servicing.

Check the reservoir daily for proper fluid level, the presence of water, and rancid fluid odor. Water in the

fluid may be noted by a cloudy or milky appearance or free water in the bottom of the reservoir. Rancid

odor indicates the fluid has been exposed to excessive heat. Change the fluid immediately if these

conditions occur. Correct the problem immediately.

Inspect vehicle for leaks daily.

Change the fluid and filter per the vehicle / machine manufacturer’s recommendations or at these

intervals: Change the fluid more frequently if it becomes contaminated with foreign matter (dirt, water,

grease, etc.) or if the fluid is subjected to temperature levels greater that the recommended maximum.

Fluid and filter change interval

Reservoir type Maximum change interval

Sealed 2000 hours

Breather 500 hours

Caution

High temperatures and pressures accelerate fluid aging. These conditions will require more frequent fluid

changes.

Change filters whenever the fluid is changed or when the filter indicator shows that it is necessary to

change the filter. Replace all fluid lost during filter change.

Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state, and federal environmental regulations. Never reuse hydraulic fluid.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 27

Page 28

P400254

MB

L1

B : Outlet port

X : Load sensing

signal port

S : Inlet port

M4

L3

L2

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Pressure measurements

Port Locations and Gauge Installation (130/145)

The following table and drawing show the port locations and gauge sizes needed. When testing system

pressures, calibrate pressure gauges frequently to ensure accuracy. Use snubbers to protect gauges.

Port Purpose Port size Wrench size Range of gauge

L1, L2, L3 Case drain M26x1.5 12 mm 0-60 bar [0-870.23

M

B

M

4

130/145 Port locations, Control type: TPSN

Outlet M12x1.5 6 mm 0-600 bar [0-8702.26

Servo piston chamber M12x1.5 6 mm 0-600 bar [0-8702.26

psi]

psi]

psi]

28 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 29

MB

E : External Control

Port

L1

S : Inlet Port

B : Outlet Port

M4

L3

L2

MB

L1

X : Load Sensing

Signal Port

M4

L3

L2

B : Outlet Port

S : Inlet Port

P400092

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Pressure measurements

Port Locations and Gauge Instalation (193/260)

Port Purpose Port size Wrench size Range of gauge

L1, L2, L3 Case drain M33x2 17 mm 0-60 bar [0-870.23

M

B

M

4

193/260 Port location, Control type: TPE2

Outlet M12x1.5 6 mm 0-600 bar [0-870.23

Servo piston chamber M12x1.5 6 mm 0-600 bar [0-870.23

psi]

psi]

psi]

193/260 Port location, Control type: TPSN

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 29

Page 30

C

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Initial start-up procedures

General

Follow this procedure when starting-up a new D1 installation or when restarting an installation in which

the pump has been removed.

Prior to installing the pump, inspect for damage incurred during shipping. Make sure all system

components (reservoir, hoses, valves, fittings, heat exchanger, etc.) are clean prior to filling with fluid.

Start-up Procedure

1. Connect the pump to the prime mover.

Ensure that the pump shaft is properly aligned with the shaft of the prime mover. Alignment should

be within 0.25 mm and the angle must not exceed 0.2°.

Caution

Incorrect shaft alignment may result in damage to drive shaft, bearings, or seal which can cause

external oil leakage.

2. Fill the reservoir with a recommended hydraulic fluid.

Always filter fluid through a 10 micron filter while pouring into the reservoir. Never reuse hydraulic

fluid.

3. Fill the main pump housing with clean hydraulic fluid. Pour filtered oil directly into the upper most

case drain port.

4. Fill the inlet line leading from the pump to the reservoir. Check the inlet line for properly tightened

fittings and be certain it is free of restrictions and air leaks.

5. To ensure the pump stays filled with oil, install the case drain line in the upper most case drain port.

6. Install a gauge at port MB to monitor system pressure during start up.

Follow recommendations in the vehicle / machine operator’s manual for prime mover start up

procedures.

7. Switch system to free circulation or to lowest pressure, jog the prime mover or run at the lowest

possible speed until pump and all pipes are filled and free from air bubbles. Raise pressure setting

only when all air is removed.

Let the pump work at reduced pressure for 5 - 10 min, check if all pipes and connections are leak-free

and tight.

8. Check the suction pressure at port S of the axial piston pump at nominal speed and maximum flow,

make sure it is in allowable range.

9. Check the case drain pressure at the connected port L1 or L2 at maximum pressure, make sure it is in

allowable range.

10. Shut down the prime mover and remove the pressure gauge. Replace plug at port MB.

11. Check the fluid level in the reservoir; add clean filtered fluid if necessary.

The pump is now ready for operation.

30 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 31

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Troubleshooting

Excessive Noise and /or Vibration

Item Description Action

Check fluid level in reservoir. Insufficient hydraulic fluid causes

Check for air in system. Air in system causes noisy, erratic

Check pump inlet pressure / vacuum. Improper inlet conditions cause

Inspect shaft couplings. A loose or incorrect shaft coupling

Check shaft alignment. Misaligned shafts create excessive

Hydraulic fluid viscosity above

acceptable limits.

Low Pump Output Flow

cavitation.

control.

erratic behavior and low output flow.

causes excessive noise and / or

vibration.

noise and / or vibration.

Hydraulic fluid viscosity above

acceptable limits or low fluid

temperature will not allow the pump

to fill or control to operate properly.

Fill the reservoir to proper level.

Purge air and tighten fittings. Check

inlet for leaks.

Correct pump inlet pressure /

vacuum conditions.

Repair or replace coupling and

ensure that correct coupling is used.

Correct shaft misalignment.

Allow system to warm up before

operating, or use fluid with the

appropriate viscosity grade for

expected operating temperatures.

Item Description Action

Check fluid level in reservoir. Insufficient hydraulic fluid will limit

Hydraulic fluid viscosity above

acceptable limits.

Check external system relief valve

setting.

Check pressure compensate (PC),

load sensing (LS) and power (T)

control setting.

Check LS control signal pressures. Incorrect LS signal will not allow

Check Pilot pressure for hydraulics

displacement control and input

current for electric displacement

control.

Check pump inlet pressure / vacuum. High inlet vacuum causes low output

Check input speed. Low input speeds decrease flow. Adjust input speed.

Check pump rotation. Incorrect rotational configuration

output flow and cause internal

damage to pump.

Fluid viscosity above acceptable

limits or low fluid temperature will

not allow the pump to fill or control

to operate properly.

External relief valve set below PC

setting causes low output flow.

Low PC setting prevents the pump

from achieving full stroke. Low LS

setting limits output flow. Low T

setting limits output flow.

pump to operate correctly.

Incorrect input signal causes low

output flow.

flow.

causes low flow.

Fill the reservoir to proper level.

Allow system to warm up before

operating, or use fluid with the

appropriate viscosity grade for

expected operating temperatures.

Adjust external relief valve following

manufacturer’s recommendation.

External relief valve setting must be

above PC setting to operate properly.

Contact Danfoss Service.

Inspect system to ensure that proper

LS signal transmit to pump.

Adjust input hydraulic or electric

signal to right value.

Correct inlet pressure conditions.

Use pump with appropriate

rotational configuration.

No or Low System Pressure

Item Description Action

Check pressure compensate (PC) and

power (T) control setting.

Check external relief valve. External relief valve setting below PC

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 31

Low PC and T setting leads to low

system pressure.

setting.

Contact Danfoss Service.

Adjust external relief valve according

to manufacturer’s recommendations.

External relief valve must be set

above PC setting to operate properly.

Page 32

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Troubleshooting

Item Description Action

Check pilot pressure or control

pressure.

Internal system leaks. Worn internal parts don’t allow the

Actuator Response is Sluggish

Item Description Action

Check external system relief valve

setting.

Check pressure compensate (PC),

load sensing (LS) and power (T)

control setting.

Check LS control signal pressures. Incorrect LS signal will not allow

Check Pilot pressure for hydraulics

displacement control and input

current for electric displacement

control.

Internal system leaks. Worn internal parts don’t allow the

Hydraulic fluid viscosity above

acceptable limits.

Check external system valving. Malfunctioning valving may not allow

Check pump case pressure. High case pressure causes the system

Check pump inlet pressure / vacuum. High inlet vacuum causes low output

Insufficient pilot pressure or control

pressure.

pump to operate properly.

Low external relief valve setting slows

down system.

Low PC setting prevents the pump

from achieving full stroke. Low LS

setting limits output flow. Low T

setting limits output Torque.

pump to operate correctly.

Incorrect input signal causes low

output flow.

pump to operate properly.

Hydraulic fluid viscosity above

acceptable limits or low fluid

temperature will not allow the pump

to fill or control to operate properly.

system to respond properly.

to be sluggish.

flow.

Increase them to appropriate value.

Refer to Authorized Service Center for

required repair.

Adjust external relief valve setting

following manufacturer’s

recommendations. External relief

setting must be above PC setting to

operate properly.

Contact Danfoss Service.

Inspect system to ensure that proper

LS signal transmit to pump.

Adjust input hydraulic or electric

signal to right value.

Refer to Authorized Service Center for

required repair.

Allow system to warm up before

operation or sue fluid with the

appropriate viscosity grade for

expected operating temperatures.

Repair or replace system valving as

required.

Correct case drain line restrictions.

Correct inlet pressure conditions.

Pressure or Flow Instability

Item Description Action

Check for air in system. Air in system causes erratic operation. Activate PC allowing system to bleed

Check LS setting. Low LS setting may cause instability. Contact Danfoss Service.

Check LS signal line. Blocked LS signal line interferes with

Check external relief valve and PC

setting.

Check external relief valve. Chattering external relief valve may

proper LS operation.

Insufficient pressure differential

between PC setting and external

relief valve.

cause unstable feedback to pump

control.

air. Check inlet line for leaks and

eliminate source of air ingression.

Remove blockage.

Adjust external relief valve or PC

control settings to appropriate level.

Relief valve setting must be above PC

setting to operate properly.

Adjust or replace relief valve.

32 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 33

C

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Troubleshooting

System Operating Hot

Item Descriptin Action

Check fluid level in reservoir. Insufficient volume of hydraulic fluid

Inspect heat exchanger. Check air

flow and input air temperature for

the heat exchanger.

Check external system relief valve

setting.

Check pump inlet pressure / vacuum. High inlet vacuum adds heat to

High Inlet Vacuum

Item Description Action

Check fluid temperature. Low temperature increases viscosity.

Inspect inlet screen. Blocked or restricted inlet screen

Check inlet piping. Too many fittings, bends, or long

Hydraulic fluid viscosity above

acceptable limits.

will not meet cooling demands of

system.

Insufficient air flow, high input air

temperature, or undersized heat

exchanges will not meet cooling

demands of the system.

Fluid passing through relief valve

adds heat to system.

system.

High fluid viscosity causes high inlet

vacuum.

causes high inlet vacuum.

piping causes high inlet vacuum.

High fluid viscosity causes high inlet

vacuum.

Fill reservoir to proper level. Verify

proper size of reservoir.

Clean, repair, or replace heat

exchanger as required. Verify proper

size of heat exchanger.

Adjust external system relief valve

setting following manufacturer’s

recommendations. External relief

valve setting must be above PC

setting for proper operation.

Correct inlet pressure / vacuum

conditions.

Allow system to warm up before

operating.

Clean screen / remove blockage.

Eliminate fittings to make path more

direct.

Select fluid with appropriate viscosity

for expected operating temperature.

Caution

High inlet vacuum causes cavitation which can damage internal pump components.

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 33

Page 34

Power = P • n • Vg •

10

-3

600

• η

90 = P • 1500 • 193 •

10

-3

600

• (.912)

Power [kW] =

P • Q

600

• η

90 =

245 • Q

600

• (.912)

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Adjustments

Calculate Power Control Start Point Pressure and Corresponding Flow in Advance

If Power/Torque control is used:

1. Calculate the power control start point pressure according to the formula:

P Power control start point pressure [bar]

n Pump input speed [rpm]

Vg Pump theoretical displacement [cc]

η Total efficiency, set at 91.2%

The start point pressure is the point in the Pressure vs Flow performance curve in which the Torque

control becomes active. The PC setting must be higher than this value, otherwise the PC function will

take priority before the MTC function becomes active. If the desired power setting is 90kW, the pump

input speed is 1500 rpm and the pump’s theoretical displacement is 193cc, then solve for start point

Pressure:

Start point Pressure is calculated to be 170bar.

2. Use the average value between the start point Pressure and the Pressure Compensated Control

setting as a reference value; this value must be inside the "TC active" region. For example: Power

control start point Pressure is 170 bar, and the Pressure compensated control setting desired is 320

bar. Use the average value (170+320)/2=245 bar.

Flow vs Pressure curve during torque limiting

3. Calculate corresponding flow by using the following formula:

34 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

Page 35

W

C

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Adjustments

Q=201 l/min

Adjustments

Control 130/145 193 260

NPNN PC [bar per turn] 163.2 163.2 163.2

NPSN & NPNR PC [bar per turn] 163.2 163.2 163.2

LS [bar per turn] 26.4 26.4 26.4

TPSN PC [bar per turn] 271 163.2 163.2

LS [bar per turn] 50 26.4 26.4

MTC [kW per

turn]@1500rpm

NNES LS [bar per turn] 26.4 26.4 26.4

EDC [mA offset per

turn]

TPE5 PC [bar per turn] 163.2 N/A N/A

MTC [kW per

turn]@1500rpm

EDC [mA offset per

turn]

TPE2 PC [bar per turn] N/A 163.2 163.2

MTC [kW per

turn]@1500rpm

EDC [mA offset per

turn]

39 73.5 99

263 263 263

50.8 N/A N/A

263 N/A N/A

N/A 73.5 99

N/A 263 263

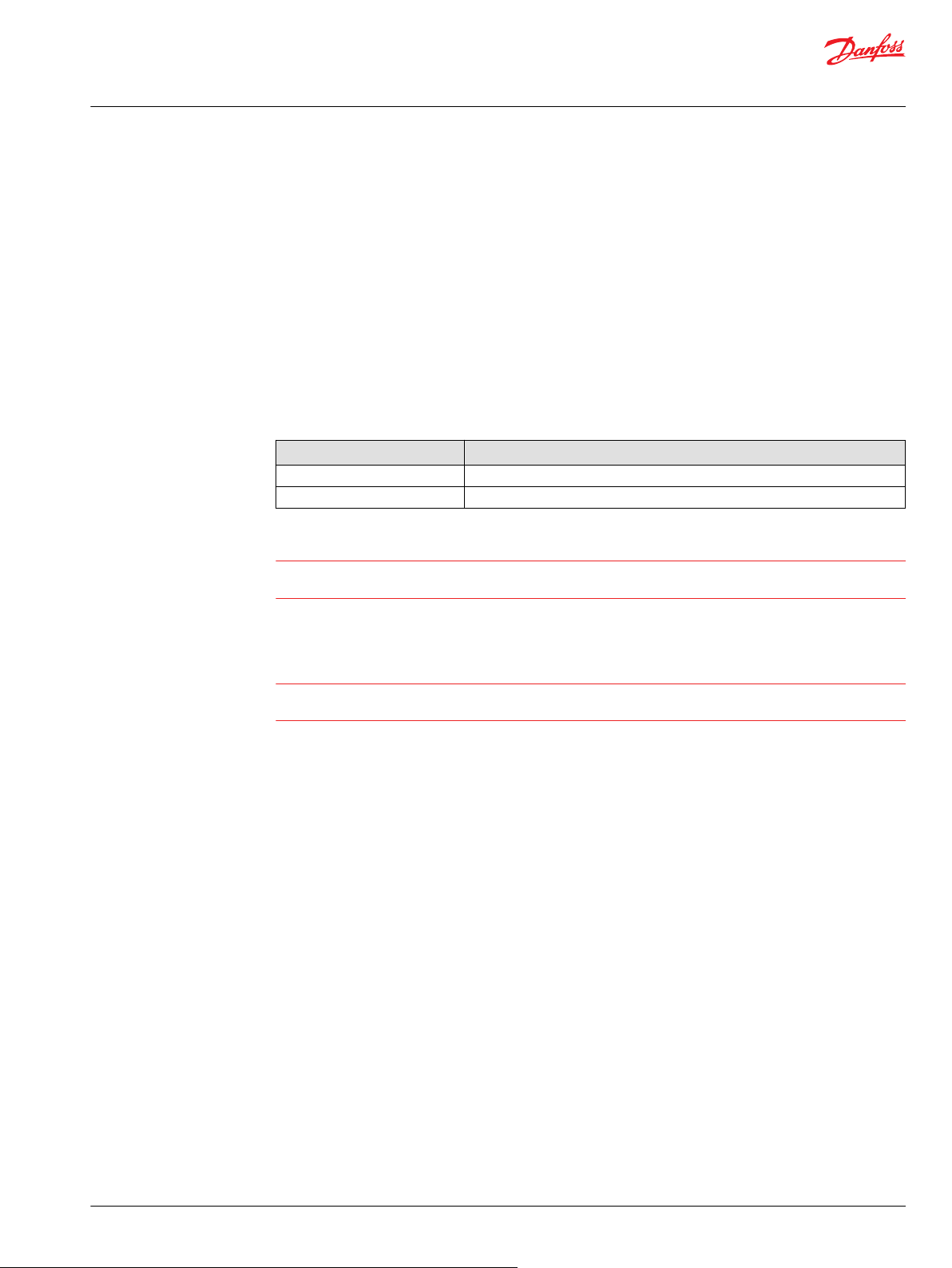

Electric Displacement Control Adjustment

1. Install a pressure gauge in port MB to measure outlet pressure. Install a flow meter in outlet line to

measure pump flow.

Warning

Escaping hydraulic fluid under pressure can have sufficient force to penetrate your skin causing

serious injury and/or infection. Relieve pressure in the system before removing hoses, fittings,

gauges, or components.

Unintended movement of the machine or mechanism may cause injury to the technician or

bystanders. To protect against unintended movement, secure the machine or disable / disconnect

the mechanism while servicing.

Caution

Contamination can damage internal components and void the manufacturer’s warranty. Take

precautions to ensure system cleanliness when removing and reinstalling system lines.

2. Locate the Electric Displacement Control Adjustment screw (see below).

The reference starting length, A, of the screw must be approximately 5-6mm. Adjusting this screw will

offset the Displacement vs Current curve and change the start current. The reference length is useful

in minimizing adjustment time (see the Adjustments table above for gain per turn information).

©

Danfoss | October 2019 L1527453 | AX00000292en-000301 | 35

Page 36

A

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Adjustments

Reference starting screw length for EDC adjustment

3. Start the prime mover and input 700 mA to electric displacement control solenoid valve, then allow

fluid to reach normal operating temperature. The pump must be at full displacement at this point.

If the pump does not provide flow with maximum current in the solenoid, the EDC adjustment screw

might need to be re-adjusted.

a) Back out the screw to the reference length mentioned in the previous step and adjust carefully to

ensure proper function. Danfoss recommends a prime mover speed of 1500rpm for testing (unless

specified otherwise).

The testing setup must be plumbed in a way so the EDC function works properly. Please refer to

Electric Displacement Control (E) Operating Instruction.

4. Totally lock the LS control (if used) to avoid interference with EDC adjustment.

a) Loosen the LS control lock nut and turn the LS control adjusting screw clockwise all the way to the

end, while holding the LS control adjusting screw.

b) Torque the control lock nut to 21.6~24.6 N•m [191-218 lbf•in].

5. Load the pump's outlet pressure to 50 bar and input 400mA to electric displacement control, then

loosen the electric displacement control lock nut and turn its adjusting screw until the pump

displacement achieves (see Displacement table below), which can calculated by monitoring pump

outlet flow and pump speed.

Clockwise turning the adjustment screw decreases pump displacement, counterclockwise turning

increases pump displacement. The displacement - current curve will offset (see Adjustments table) per

turn.

The EDC adjustment screw is only sensitive in a limited area around the starting reference length of

the set screw.

6. While holding the position of the electric displacement control adjusting screw, torque the lock nut

to 9.5 N•m [84 lbf•in].

7. Test another current value.

a) Input 500 mA to electric displacement control.

b) Check if the displacement is within the range specified in the below table at this moment.

If the displacement is within the proper range, the electric displacement control adjustment

complete. If it is not, please re-adjust.

8. Stop the prime mover, remove the pressure gauge and flow meter, and return the system to its

normal operating configuration.

Displacement

Input Current Size 130 Size 145 Size 193 Size 260

400mA+/-8 mA 67.5cc+/-5cc 67.5cc+/-5cc 92.5 cc+/-5cc 140.5 cc+/-5cc

36 | © Danfoss | October 2019 L1527453 | AX00000292en-000301

500mA+/-8 mA 101cc+/-5cc 101cc+/-5cc 115.5 cc+/-5cc 172.5 cc+/-5cc

Page 37

Service Manual

D1 High Power Open Circuit Pumps Size 130/145/193/260

Adjustments

Pressure Compensated Control Adjustment

1. Install a pressure gauge in port MB to measure outlet pressure.

2. Ensure the pump is operating at maximum displacement. If the control has Electric Displacement

Control, input 700mA to obtain maximum displacement.

3. Load the pump outlet pressure to at least 30 bar higher than the expected pressure compensated

control setting. This may be achieved by operating a hydraulic function to its full extension, putting

the pump in a dead-head condition.

4. Loosen the Pressure compensated control lock nut and turn the Pressure compensated control

adjusting screw until the desired setting is indicated on the pressure gauge at port MB. Clockwise

rotation increases pressure, counterclockwise rotation decreases; approximate gain per turn (see

Adjustments table). Once the PC adjustment is complete, hold the position of the adjustment screw

and torque the PC control lock nut to 21.6-24.6 N·m [lbf·in].

5. Stop the prime mover, remove the pressure gauge, and return the system to its normal operating

configuration.

If the pressure does not increase, an external system relief valve may require adjustment. External

system relief valve must be set above the Pressure compensated control setting for proper operation.

Power Control Adjustment

1. Install a pressure gauge in port MB to measure outlet pressure. Install a flow meter in outlet line to

2. Start the prime mover and make sure the pump is operating at maximum displacement. If the control

3. Load the pump outlet pressure to the reference pressure value previously obtained in the calculation,

4. Stop the prime mover, remove the pressure gauge and flow meter, and return the system to its

Load Sensing Control Adjustment

1. Install a pressure gauge in port MB to measure outlet pressure, Tee-in a pressure gauge to the LS

2. Start Prime mover and allow fluid to reach normal operating temperature.

3. Totally lock the LS control; to do this first loosen the LS control lock nut and turn the LS control

4. Adjust Power control and pressure compensated control (if used).

measure pump flow.

has Electric Displacement Control, input 700mA to obtain maximum displacement. By doing this, the

functions will not interfere with each other, if maximum displacement is commanded by the EDC at

all times, the MTC function will take priority once the start point pressure is reached.

loosen the power control lock nut and turn the power control adjusting screw and monitor the flow

meter, when the flow meter shows the flow corresponding to the previous calculation, stop turning,