Page 1

MAKING MODERN LIVING POSSIBLE

User Manual

PLUS+1 Compliant

CYPR1

www.powersolutions.danfoss.com

Function Block

Page 2

User Manual

PLUS+1 Compliant CYPR1 Function Block

2

AQ00000201 · 00-00 · July 2015

©

All trademarks in t

PLUS+1, GUIDE, and Sauer

PLUS+1 GUIDE, PLUS+1 Compliant, and Sauer

Company

Revision History

Revision Date Comment

Rev 00-00 July 2015

2015 Danfoss Power Solutions (US) Company. All rights reserved.

his material are properties of their respective owners.

-Danfoss are trademarks of Danfoss Power Solutions (US) Company. The Danfoss,

-Danfoss logotypes are trademarks of Danfoss Power Solutions (US)

.

Page 3

User Manual

PLUS+1 Compliant

AQ00000201 · Rev 00-00 · July 2015

3

CYPR1 Function Block

Contents

CYPR1 Function Block ........................................................................................................................................ 4

Overview ......................................................................................................................................................... 4

Inputs ............................................................................................................................................................... 4

Outputs ............................................................................................................................................................ 5

About Function Block Connections...................................................................................................... 7

Fault and Status Logic ............................................................................................................................... 8

Function Block Parameter Values........................................................................................................ 10

Page 4

User Manual

PLUS+1 Compliant

AQ00000201 · Rev 00-00 · July 2015

4

Overview

CYPR1 Function Block

CYPR1 Function Block

This function block outputs X, Y, and Z position data based on measurements from the

CYPR1 Sensor. All signals are received via the CAN communication bus.

See About Function Block Connections on page 7 for an overview of this function block’s

connections and signals.

Inputs

CYPR1 Function Block Inputs

Input Type Range Description

CAN Bus ——

SrcAddr U8 0 to 253

CAN port that receives messages from the CYPR1 sensor.

Source address of the CYPR1 sensor.

Page 5

User Manual

PLUS+1 Compliant

CYPR1Function Block

AQ00000201 · Rev 00-00 · July 2015

5

Outputs

CYPR1Function Block Outputs

Output Type Range Description

Status U16 ——

Reports the function block’s status.

• 0x0000 = Block is OK.

• 0x8008 = SrcAddr or Timeout value is out of range.

CYPR1 Function Block

Fault U16 ——

Mode U8 ——

Output Bus ——

X_Axis S32 Mode 0: 0 to 35999

Mode 1: -17999 to

18000

Mode 2: -9000 to

9000

Mode 3:-10000 to

10000

Y_Axis S32 Mode 0: 0 to 35999

Mode 1: -17999 to

18000

Mode 2: -9000 to

9000

Mode 3:-10000 to

10000

Reports the function block’s faults.

This function block uses a non-standard bitwise scheme to report its status and faults.

• 0x0000 = Block is OK.

• 0x0001 = CAN message not received since startup.

• 0x0002 = CAN message was received, but now has timed out.

• 0x0004 = Received data is reported using an unsupported mode.

• 0x0008 = Received data mode does not match XID.

• 0x0010 = Received axis data is out of range.

• 0x0020 = Sensor reporting that data is degraded.

Indicates the X, Y, and Z data range, units, and sensing mode.

• 0 = Angle Sensing Mode 1, range reported 0 to 359.99 degrees

• 1 = Angle Sensing Mode 1, range reported -179.99 to 180.00 degrees

• 2 = Angle Sensing Mode 2, -90.00 to 90.00 degrees

• 3 = Orientation Mode, -1.0000 to 1.0000 vector

• 255 =Device is in an invalid or unsupported mode.

Bus containing output signals.

X Axis orientation according to reported mode.

1 = 0.01 Degrees for modes 0, 1, 2

1 = 0.0001 Unit Vector for mode 3

Y Axis orientation according to reported mode.

1 = 0.01 Degrees for modes 0, 1, 2

1 = 0.0001 Unit Vector for mode 3

Page 6

User Manual

PLUS+1 Compliant

CYPR1Function Block

6

AQ00000201 · Rev 00-00 · July 2015

CYPR1Function Block Outputs

Output Type Range Description

Z_Axis S32 Mode 0: 0 to 35999

Mode 1: -17999 to

18000

Mode 2: -9000 to

9000

Mode 3:-10000 to

10000

Z Axis orientation according to reported mode.

1 = 0.01 Degrees for modes 0, 1, 2

1 = 0.0001 Unit Vector for mode 3

CYPR1Function Block

Page 7

User Manual

PLUS+1 Compliant

CYPR1Function Block

AQ00000201 · Rev 00-00 · July 2015

7

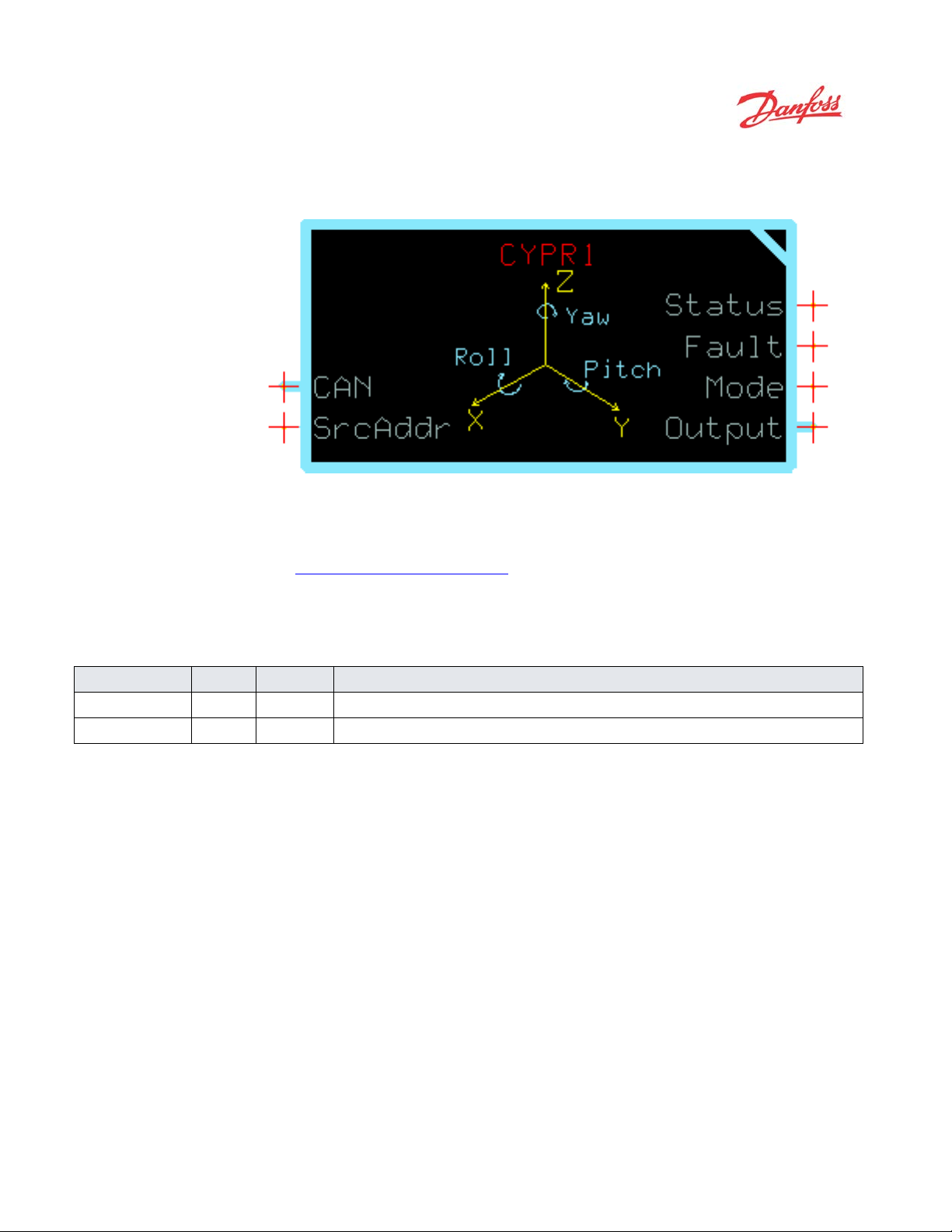

About Function Block Connections

1

2

unction Block Connections

F

Item Description

1.

2.

3.

4.

5.

6.

CYPR1 Function Block

3

4

5

6

Determines the CAN port connected to the sensor.

Configures the function block to listen for CAN data from the sensor’s network address.

Reports the status of the function block.

Reports the fault of the function block.

Reports the active mode of the CYPR1 sensor and indicates how the position data is formatted.

Output bus containing the X, Y, and Z axis position information.

Page 8

User Manual

PLUS+1 Compliant

CYPR1Function Block

8

AQ00000201 · Rev 00-00 · July 2015

Fault Logic

CYPR1Function Block

Fault and Status Logic

Unlike most other PLUS+1 compliant function blocks, this function block uses non-standard fault

codes.

Fault Hex Binary Cause Response Delay† Latch‡ Correction

No message

received

Timeout 0x0002 00000010 Valid message not

Unsupported

Mode

Mode does

not match

XID

Invalid CAN

Data

Data

Degraded

†

A delayed fault is reported if the detected fault condition persists for a specified delay time. A delayed fault cannot be cleared until the fault

condition remains undetected for the delay time.

‡

The function block maintains a latched fault report until the latch releases.

0x0001 00000001 No valid CAN

message from

specified source

address has been

received since

startup.

received within

expected time

window.

0x0004 00000100 Received message

indicates data

reported using an

unsupported mode.

0x0008 00001000 Received message

indicates data

reported using an

unsupported mode

and XID

combination.

0x0010 00010000 Received data is

outside expected

ranges.

0x0020 00100000 Sensor elements are

unable to report

with optimal

accuracy.

Outputs remain at

zero.

Previous outputs are

reported.

Outputs set to zero. N N Use fault signal to trigger

Outputs set to zero. N

Outputs set to zero. N N Use fault signal to trigger

Outputs reported,

but data is less

accurate.

N

N Use fault signal to trigger

application response. Check that

sensor is properly connected to

CAN bus and correct value for

SrcAddr has been set. Check bus

for physical failure or overload.

Y N Use fault signal to trigger

application response. Check bus

for physical failure or overload.

application response. Verify

attached sensor is set to a

compatible mode. Check bus for

conflicting data from other

sources.

N Use fault signal to trigger

application response. Verify

attached sensor is set to a

compatible mode. Check bus for

conflicting data from other

sources.

application response. Verify

attached sensor is set to a

compatible mode. Check bus for

conflicting data from other

sources.

N

N Check CYPR1 technical

documentation for application

limits and further details on

operation.

Page 9

User Manual

PLUS+1 Compliant

CYPR1Function Block

AQ00000201 · Rev 00-00 · July 2015

9

CYPR1 Function Block

Status Logic

Status Hex Binary Cause Response Delay† Latch‡ Correction

Parameter

out of range

†

A delayed fault is reported if the detected fault condition persists for a specified delay time. A delayed fault cannot be cleared until the fault

condition remains undetected for the delay time.

‡

The function block maintains a latched fault report until the latch releases.

0x8008 10001000 SrcAddr or

Timeout value is

outside the allowed

range.

Function Block

operates using the

closest valid value.

Data may not be

properly received.

N N Use fault signal to trigger

application response. Adjust the

values to be within their allowed

range, make sure the proper

SrcAddr is set.

Page 10

User Manual

PLUS+1 Compliant

CYPR1Function Block

10

AQ00000201 · Rev 00-00 · July 2015

Function Block Parameter Values

Enter the top-level page of the CYPR1 function block to view and change this function

block's parameters.

CYPR1Function Block

Function Block Parameters

Input Type Range Description

Timeout U16 10 to 10000

The Timeout signal specifies the maximum acceptable period between receiving two consecutive

messages from the CYPR1 sensor. It is recommended to set this value at least 1.5 times the sensor’s

specified transmission period.

10 = 10 ms.

Page 11

User Manual

PLUS+1 Compliant CYPR1 Function Block

(This page is intentionally blank.)

Page 12

AQ00000201 · 00-00 · July 2015

www.danfoss.com

©2015 Danfoss Power Solutions (US) Company

Products we offer:

•

•

•

•

•

•

•

•

•

•

•

•

•

• Sensors

Danfoss

Power Solutions

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239

Danfoss

Power Solutions

Krokamp 35

D

Phone: +49 4321 871

Danfoss

Power Solutions

Nordborgvej 81

DK

Phone: +45 7488 4444

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd

Building #22, N

Hai Rd

Jin Qiao, Pudong New

District

Shanghai, China 201206

Phone: +86 21 3418 5200

Comatrol

www.comatrol.com

Schwarzmüller

www.schwarzmueller

Turolla

www.turollaocg.com

Hydro

www.hydro

Daikin

www.

Danfo

electronic components. We specialize in providing

excel in the harsh operating conditions of the mobile off

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad ran

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss

Go to www.

Wherever off

customers, ensuring the best possible solutions for outstanding performance. And with an extensive

network of Global Service Partners, we also provide c

components.

Please contact the

Danfoss can accept no responsibility for possibl e errors in cata logues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

All trademarks i n this material are property of the res pective companies. Danfoss an d the Danfoss logotype are trademarks of Danfoss Power Solutions (US) Company. All rights reserved.

Bent Axis Motors

Closed Circuit Axial Piston

Pumps and Motors

Displays

Electrohydraulic Power

Steering

Electrohydraulics

Hydraulic Power Steering

Integrated Systems

Joysticks and Control

Handles

Microcontrollers and

Software

Open Circuit Axial Piston

Pumps

Orbital Motors

PLUS+1™ GUIDE

ss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

state-of-the-art technology and solutions that

-highway market. Building on our extensive

ge of off-highway vehicles.

—Your Strongest Partner in Mobile Hydraulics.

powersolutions.danfoss.com for further product information.

-highway vehicles are at work, so is Danfoss. We offer expert worldwide support for our

omprehensive global service for all of our

Danfoss Power Solution representative nearest you.

Proportional Valves

-Gear

- Sauer-Danfoss

daikin-sauer-danfoss.com

already on order provided that such alterations can be made without subsequential changes being necessary in specifcations already agreed.

-Inverter

-gear.com

US Company

-6000

-inverter.com

Local address:

GmbH & Co. OHG

-24539 Neumünster, Germany

0

ApS

-6430 Nordborg, Denmark

.

o. 1000 Jin

Loading...

Loading...