Page 1

Installation guide

Multi Ejector

type CTM 6

Refrigerant:

R744 with oil

032R9797

Ambient temp. range:

-10 °C – +50 °C / 14 °F – 122 °F

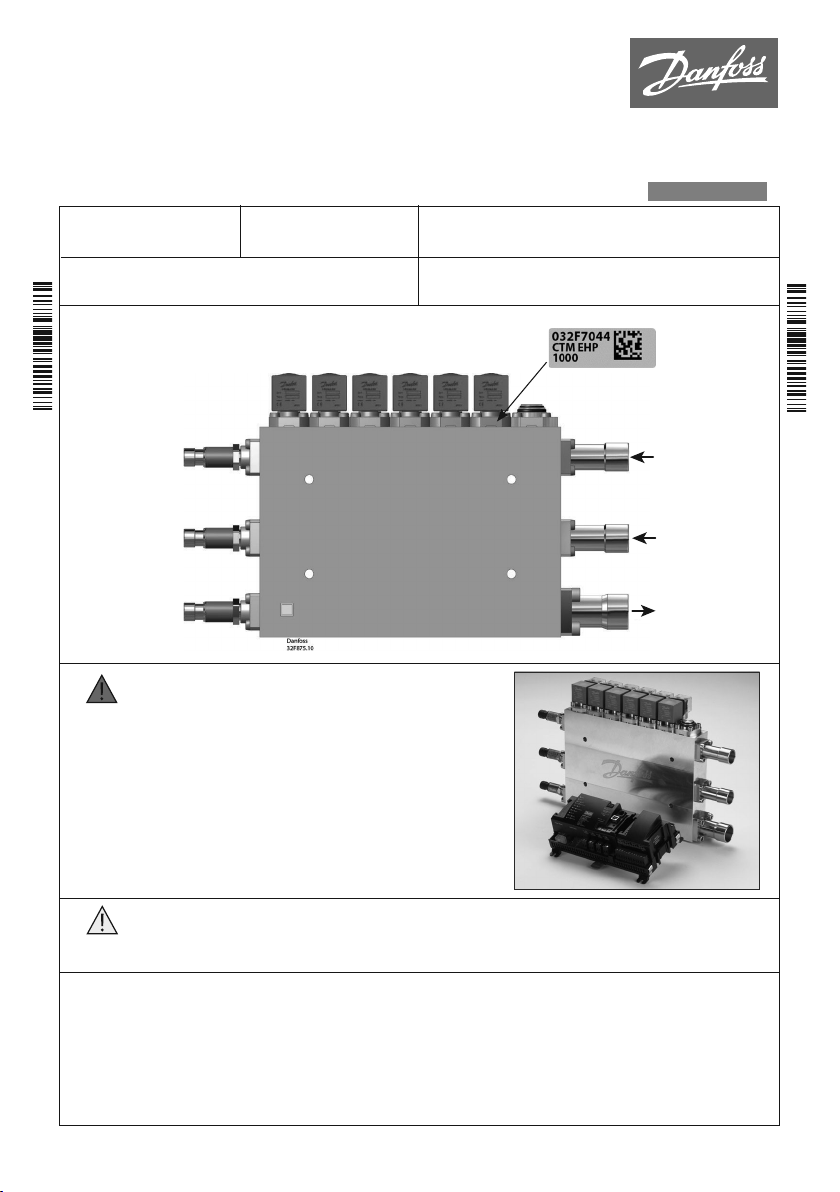

Connector positions

CTM 6

Pressure

transmitter

B

(Pgc)

Pressure

transmitter

)

(P

D

0

Pressure

transmitter

)

(P

rec

Max. Working Pressure:

140 bar / 2031 psi

Ejector Ejector Ejector Ejector Ejector Ejector

1 2 3 4 5 6

Media temp. range:

-10 °C – +50 °C / 14 °F – 122 °F

Max. OPD: 90 bar / 1305 psi

Min. OPD: 0.1 bar / 1.45 psi

ENGINEERING

TOMORROW

Label

Strainer

English

High pressure inlet

A

Suction inlet

C

Receiver

EF

032R9797

The CTM Multi Ejector valve is approved for use only with

WARNING!

DISCLAIMER

WARNING!

General installation

•

• Coils available in 110-120V AC and 230V AC, 50/60Hz.

• It is recomended to place shut-off valves on all 3 connections.

• C and D connections can be moved from one side to the other if needed. Please be aware of the torque

of the screws.

• Evacuating the ejector is recommended to do on the outlet and on the high pressure side.

• Pressurizing the ejector should be done from the suction side first (Suction inlet C).

• It is recommended to install ejector after suction filter (Suction inlet C).

© Danfoss | DCS (rm) | 2019.11

Danfoss controller type AK-PC 78x, AK-CC 550A or

AK-CC 750A and AK-SM 8xx.

Danfoss expressly disclaims, and any responsibility or

liability, whether based on contract, breach of warranty,

tort, statute or otherwise, shall be excluded, if the CTM

Multi Ejector valve is used with any controller other than

a Danfoss controller type AK-PC 78x, AK-CC 550A or

AK-CC 750A and AK-SM 8xx.

For further information on AK-PC,

please see separate document.

• Do not disassemble / assemble the parts unnecessarily to avoid risk of breaking the O-ring,

dirt in the valve etc.

• Avoid high mechanical stress in connection with tube mounting / welding.

• Do not remove connectors during welding / brazing.

Always place the ejector with the coils upwards so the check valve inside can use gravity to close.

DKRCC.PI.VM0.A2.02 | 1

Page 2

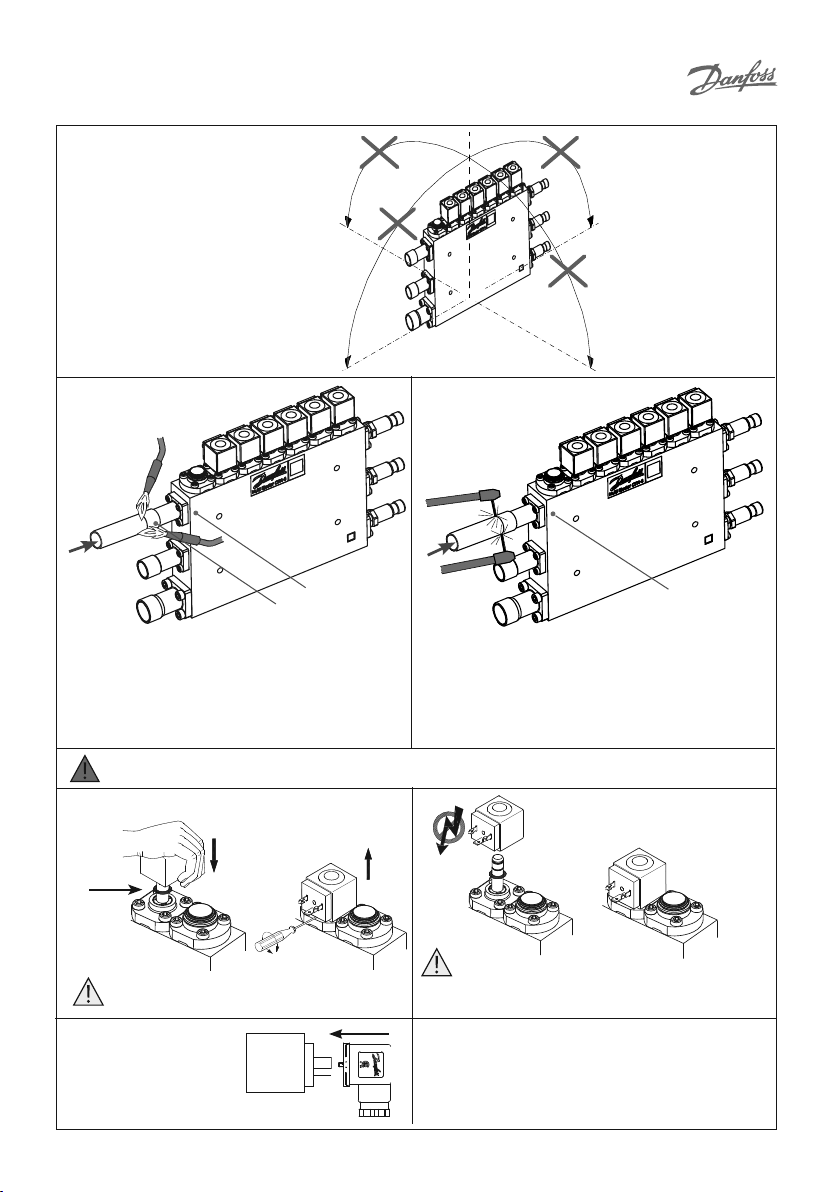

Mounting: With coils upwards

CTM Multi Ejector needs to be fixed to the

rack frame using 4 holes in the aluminum

block do avoid stress on the connectors

Brazing Welding

Danfoss

32F876.10

N

2

Danfoss

032F842.11

N

2

Max. 75 °C / 167 °F

Max. 700 °C / 1300 °F

Recommendation for brazing

Recommendation: brazing nozzle 4 - 6 mm ( 5/32 in - 15/64 in)

Materials used for brazing:

• Flux: Metalli tenacity No. 5 Powder or Braze Tec

special h paste.

• Filler: Silver-Flo 55 (BS:AG 14/ DIN L-Ag55 Sn) or Silver-Flo

56 (AWS B Ag-7).

Recommendation for TIG welding

• Power approximately 60 A.

• Use Shield gas charge - Argon.

• Material for welding - approximately

2 mm thick stainless steel alloy.

Warnin g: Filler metals containing Phosphor i.e. BS: CP 1/ DIN L-Ag 15P or BS: CP 3/ DIN L-Ag P7 must not be used.

Coil

On Off

Click!

Danfoss

Danfoss

Warning

Be sure that the O-ring is in place.

32F1002.10

Mounting D IN plug / LED DIN plug.

© Danfoss | DCS (rm) | 2019.11

Danfoss

32F1004.10

Armature tubes are sensitive and have to be protected

during the installation:

• do not damage the armature tubes with strokes or

forces

• do not lift or handle the block by lifting the armature

tubes etc.

• avoid pull-forces on the wires connected to the coils

32F882.10

Warning

Never switch on power to the coil when it is

dismounted from the valve. There is a danger the coil

may be damaged and a risk of injuries and burns.

DKRCC.PI.VM0.A2.02 | 2

Danfoss

032F841.11

Max. 75 °C / 167 °F

Danfoss

32F1004.10

Page 3

Starting up /Operation:

Opening sequence:

1 - connector A

2 - connector C

3 - connector E

Follow the opening sequence to avoid too

high NRV differential pressure.

Service

Mounting and service of ejectors

Liquid ejectors* and then high pressure

ejectors with the highest capacities (longest

ejectors) must be placed closest to the suction

connector C.

Any blank ejector must be placed closest to

the suction connector C.

*aplicable only for CTM 6 Combi

For mounting of pressure transmitter

MBS 8250 (064G1136)

B

Starting up the system: open all connection ball valves slowly

(avoiding liquid hammer that can damage

internal check valve (NRV) and build-in strainer.

It is mandatory to clean the strainer after 2 days of running the

system. O-rings needs to be replaced with the two new ones placed

on the strainer top. Removed O-rings to be placed on the strainer

top and reused after return to initial shape during next strainer

maintenance. Strainer cleanliness is important for proper operation

of Multi Ejector and the cleaning shall be repeated if necessary every

2-3 weeks to remove the dirt circulating in the system.

A: Inlet connector

Gas cooler outlet - Ball valve - inlet connector

Combi brazing

B: Inlet measurement port G

C: Suction connector

MT evaporator outlet - Ball valve - suction connector

Combi brazing

D: Suction measurement port G

E: Outlet connector

Outlet connector - Ball valve - Receiver

Combi brazing 1 inch ODF - weld 1

F: Outlet measurement port G

Pressure transmitter connections

A

AB

7

/8 inch ODF - weld 3/4 inch (EN10220)

7

/16 inch - 20 UNF

7

/8 inch ODF- weld 3/4 inch (EN10220)

7

/16 inch - 20 UNF

1

7

/8 inch (EN10220)

/16 inch - 20 UNF

D

Warning:

C

EF

C

Danfoss

32F880.10

Pressure transmitter

Type MBS 8250

Ratiometric

Pin 1 (A): + supply

Pin 2 (B): - supply/common

Pin 3 (C): output

Do not disassemble / assemble the parts unnecessarily to avoid risk of breaking the O-ring, dirt in the valve etc.

Insulation of Multi Ejector

Requirements for materials used for insulation:

• has to be based on a synthetic rubber base

or ex Polyurethane

• water vapor diffusion resistance number μ

≤7000

Exchange of connectors

and pressure transmitters

A

D

Tightening sequence

Torque 6 mm screws: 10 Nm ± 1 Nm

Allen key 5 mm

Torque 6 mm screws: 10 Nm ± 1 Nm

Allen key 5 mm

Torque 8 mm screws: 27.5 Nm ± 2.5 Nm

Allen key 6 mm

© Danfoss | DCS (rm) | 2019.11

C

B

• thermal conductivity ≤ 0,033 W/(m·K)

• insulations material thickness ≥ 5 mm

• for use at low temperature -10°C or lower

• for use at high temperature +50°C or higher

• glue or adhesive made of Poly chloroprene or it is Silicone type

Do not insulate the coils of Multi Ejector

Torque for mounting

pressure transmitters

32,5 Nm ± 2,5

Wrench 22 mm

oss

Danf

32F1000.10

DKRCC.PI.VM0.A2.02 | 3

Page 4

Service

= compressor oil

B

B

C

Danfoss

32F855.10

D

A

Tightening sequence

8

Mount the strainer

with screws

C

Danfoss

D

A

Tightening sequence

32F877.20

Mount the ejector with screws

Allen key 5 mm

Torque 10 Nm ± 1

Oil O-rings and place

strainer in valve

Allen key 5 mm

Torque 10 Nm ± 1

7

Oil O-rings and place ejector

5 mm allen key

Torque 6 Nm ± 1

6

Assemble strainer

5

5 mm

allen key

3

Allen key 5 mm

Service on strainer

© Danfoss | DCS (rm) | 2019.11

Clean or replace strainer

and replace O-ring

4

Dismount strainer

3

2

2

1

1

Remove strainer

from valve body

Allen key 5 mm

Remove ejector from valve body Replace complete ejector

Servi ce on ejector

DKRCC.PI.VM0.A2.02 | 4

Loading...

Loading...