Data sheet

CI-TI™ Contactors and motor starters

Types CI 61 - CI 98

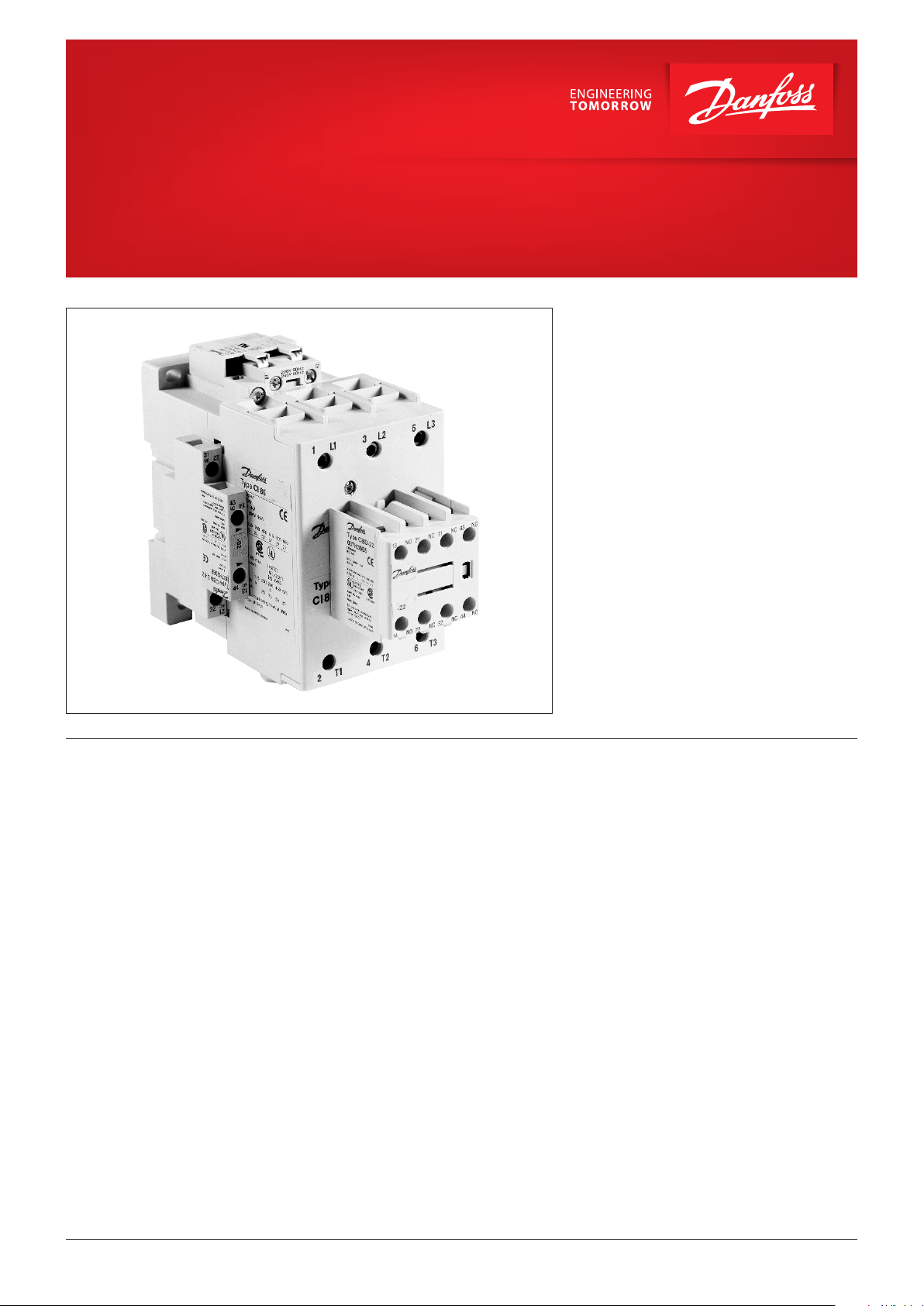

Contactors CI 61, CI 73, CI 86 and CI 98 switch

powers of up to 30 kW, 37 kW, 45 kW and 55 kW

respectively under 3 × 380 V AC-3 loads.

Accessories include a wide selection of auxiliary

contacts, mechanical interlocks and RC elements.

Auxiliary contacts for mounting on the side or

top are available. The auxiliary contacts have

force-actuated contacts and can form part of

safety switching.

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 1

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Ordering

CBD 11

BD S-

CBD 22

Mechanical

interlock

Contactors CI 61, CI 73, CI 86, CI 98

Main circuit

Type

U

e

220 – 240 V

AC-3 load

U

e

380 – 690 V

2

I

)

th

I

e

(AC-1)

Open

I

the

(AC-1)

Encl.

3

)

[kW] [kW] [A] [A] [A] Number Number

CI 61 18.5 30 60 100 100 3 1-8 037H3061

CI 73 22 37 72 100 100 3 1-8 037H3062

CI 86 25 45 85 100 100 3 1-8 037H3063

CI 98 30 55 97 130 110 3 1-8 037H3040

1

) Coil voltage / frequency or Suffix no. (see table below) must be added to the Danfoss code no.

2

) The thermal current Ith gives the maximum load at 40 °C, which corresponds to installing the contactor in air (open).

3

) The thermal current I

gives the maximum load at 60 °C, which corresponds to installing the contactor in an enclosure.

the

Main

contacts

(make)

Add-on

options

Code no.1)

Coil voltages and coils for CI 61, CI 73, CI 86, C 98

Coil voltage 1) - (sufix no.)

Contactor Code no.

CI 61 037H3061

CI 73 037H3062

CI 86 037H3063

CI 98 037H3040 - -

Available

Special order

Unavailable

-

24 V 50/60 Hz

(13)

110 V, 50/60 Hz

(23)

220 – 230 V, 50/60 Hz

(32)

380 – 400 V, 50/60 Hz

(39)

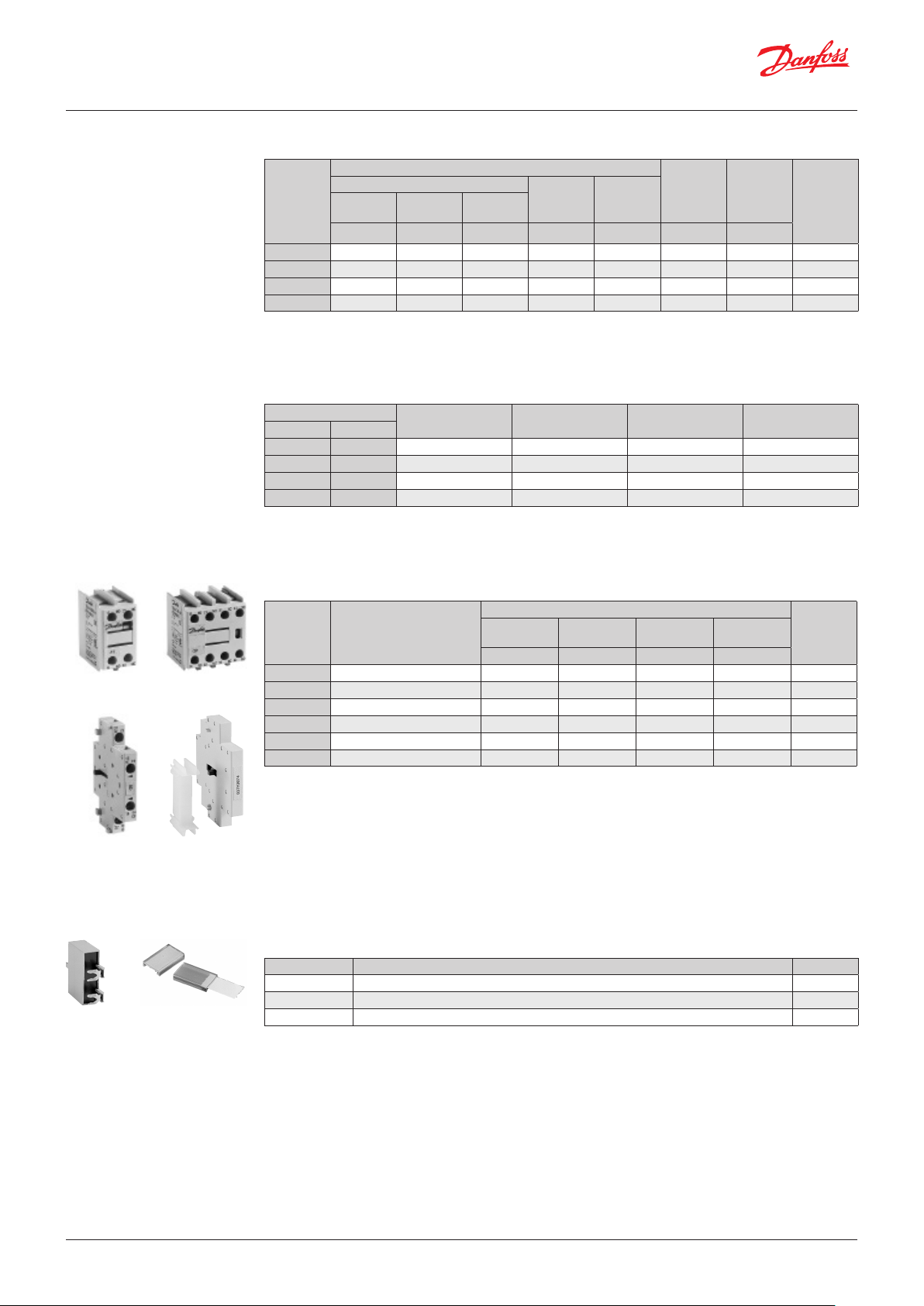

Auxiliary contact block CBD for CI 61, CI 73, CI 86 and CI 98 contactors

Load

Type Contact function 1)

I

e

(AC-15)

2

I

)

th

(AC-1) Open

3

I

)

the

(AC-1) Encl.

U

e

Code no.

[A] [A] [A] [V]

CBD-11 1 make (NO) + 1 break (NC) 5.5 10 6 690 037H3064

CBD-22 2 make (NO) + 2 break (NC) 5.5 10 6 690 037H3065

CBD S-NC 1 break (NC) 3 10 6 690 037H3066

CBD S-NO 1 make (NO) 3 10 6 690 037H3067

CBD S-11 1 make (NO) + 1 break (NC) 3 10 6 690 037H3069

CBD S-20 2 make (NO) 3 10 6 690 037H3070

1

) Force-actuated contacts suitable for safety switching.

2

) The thermal current Ith gives the maximum load at

40 °C, which corresponds to installing the contactor

3

) The thermal current Ithe gives the maximum load at

60 °C, which corresponds to installing the contactor

in an enclosure.

in air (open).

In CBD auxiliary contact the silver tips are

cross-stamped.

Both contact types are PLC-compatible.

Min. load 24 V, 10 mA.

In CBD S auxiliary contact the silver tips are

H-shaped.

RCD-

Clip-on marker

© Danfoss | DCS (az) | 2018.02

Accessories for contactors CI 61, CI 73, CI 86, CI 98

Description Comments Code no.

Mech. interlock Mech. interlock can be established between pairs 037H3074

Type RCD 280 (110 – 280 V, 50/60 Hz) 037H3072

Clip-on markers Rating plate with cover 037H3142

IC.PD.C00.F6.02 | 2

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Description

Ordering

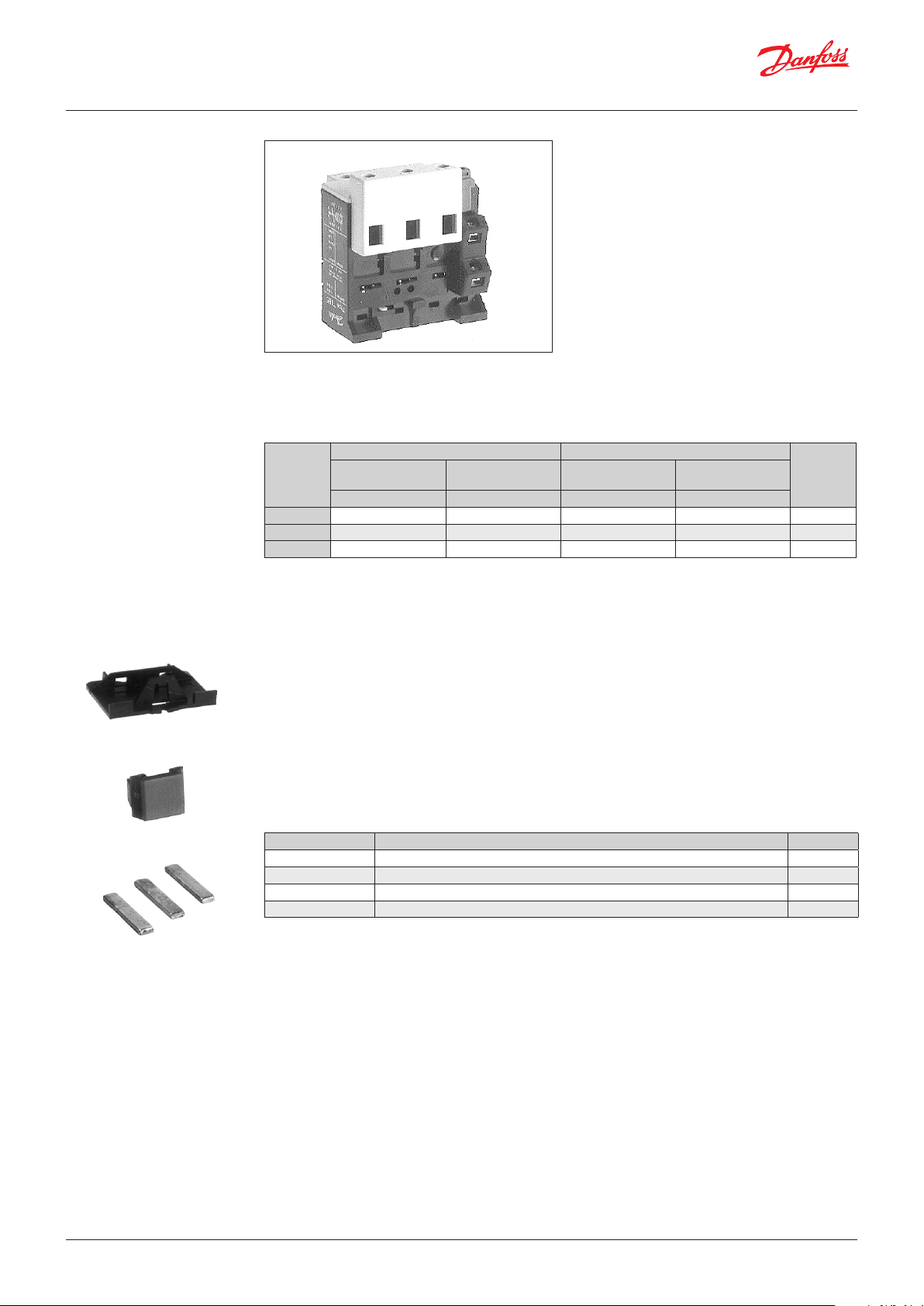

Thermal overload relays TI 80 - TI 86 are used with

contactors type CI 61, CI 73 and CI 86 to give

overload protection of squirrel-cage motors of

30 – 55 kW.

The relays trip under asymmetric load, i.e.

accelerated release if phase drop-out occurs.

Other features of TI 80 and TI 86:

• stop / reset button

• manual / automatic reset

• test button

• double scale for direct start or Y / D start

• signal contact with changeover

Thermal overload relays TI 80 and TI 86

Range Max. fuse 1)

Type

TI 80 42 – 63 75 – 109 100 100 047H1016

TI 80 60 – 80 105 – 138 125 125 047H1017

TI 86 74 – 85 130 – 147 125 125 047H1018

1

) To IEC 947-4 coordination types 1 and 2:

Coordination type 1: Any type of damage to the motor starter is permissible. If the motor starter is in an enclosure, no external

damage to the enclosure is permissible. After a short-circuit the thermal overload relay shall be partially or

wholly replaced.

Coordination type 2: No damage to the motor starter is permissible, but slight contact burning and welding is permissible.

Motor

starter

[A] [A] [A] [A]

Y / D

starter

gI, gL, gG

Type 2

BS 88, type T

Type 2

Code no.

Base

Push button extension

Current rail set

Selection of thermal overload relay

The selection of a thermal overload relay must

be based on the motor full load current and the

method of starting:

• With direct start the motor starter range applies

• With star-delta start Y / D starter range applies

Example:

Full load current: 85 A

• With direct start, the suitable motor starter

range is 74 – 85 A, i.e. thermal overload relay

047H1018

• With star-delta start, the suitable Y/D starter

range is 75 – 109 A, i.e. thermal overload relay

047H1016

Accessories for thermal overload relays TI 80 - TI 86

Description Comments Code no.

Clip-on markers For mounting on TI 80 - TI 86 (250-off )

Base For separate mounting of TI 80 - TI 86 047L045666

Pushbutton extension For TI 9C TI- TI 86 (3 mm) 047L040666

Current rail set For direct mounting of TI 80 / TI 86 on contactors CI 61-73-86 (set of 3 )

037H010566

037H010866

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 3

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Construction standards

• Contactors, thermal overload relays and

accessories are designed and tested in

accordance with IEC 947/EN 60947.

Pulse voltage

Type U

CI 61-CI 73-CI 86-CI 98 8 KV

imp

• Environment

• Temperate climate

• Tested and passed in accordance with

DIN 50 016 and 40 046 part 38 and IEC 68

• Max. installation height: 2000 NN, in accordance

with IEC 947

Ambient temperature

Type

CI 61-CI 73-CI 86-CI 98 -25 °C – 60 °C -55 °C – 80 °C

Operation Storage / Transport

Environment

Type

TI 86 -5 – 40 °C -50 – 60 °C 2 g at 200 Hz 9 g for 7.5 ms 30

Temperature

compensated

Ambient

temperature

Mounting direction

Ambient temperature

Vibration

Shock

perpendicular to

contact system

operations

per hour

Max.

Approvals

Rated life

Type EN 60947 LLC CDC TYSK

CI 61

CI 73

CI 86

CI 98

TI 80

TI 86

Approved

Type

CI 61-CI 73-CI 86-CI 98 10 x 10

Mechanical

life

Operations

6

Electrical life

AC-3

Operations

6

1 x 10

Duty cycles per hour

AC-3 load

Operations

300

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 4

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Electrical life curves

Contactors CI 61-73-86-98 load categories, AC-1

Contactors CI 61-73-86-98, load categories AC-3 & AC4

10% AC-4 Mixed operation of squirrel-cage motors;

Ue = 230…400…460 V

Contactors CI 61-73-86-98, load categories AC-4

Switching of squirrel-cage motors; Ue = 230…690 V

Contactors CI 61-73-86-98, load categories AC-3

Switching of squirrel-cage motors while starting;

Ue = 230…400…460 V

A: Electrical life in millions of make / break operations.

B: Rated Operating current (A).

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 5

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Tripping graphs

TI 80 / 86

Explanation of graphs

Mean value curves

Upper curve: 3-phase tripping and asymmetric load tripping at min. setting

Lower curve: Asymmetric load tripping at max. setting

When tripping from the operationally warm condition, the tripping times are approx. 30% of the

values shown. These values apply at an ambient temperature = 20 °C.

3-phase tripping: x =

rated motor current

Asymmetric load tripping: x =

max. scale value on overload relay

Tripping time 2 < Tp ≤ 10 s at 7.2 × Ie class 10 A

Note! In general, the thermal overload relay is always set on motor full load current.

3-phase overload

. Measure overload current

. Find the overload factor (x) by dividing the measured value by the set value of the thermal overload

relay (motor full load current).

. Find (x) on the horizontal axis and follow a line vertically up until it intersects the upper curve.

. From the intersection point, follow a horizontal line to the left and read off on the vertical axis the

time that will elapse before the thermal overload relay cuts out the motor.

Asymmetric load tripping

. Measure the current the motor draws from one of the intact phases.

. Find the overload factor (x) by dividing the measured value by the maximum scale value of the

thermal overload relay.

. Find (x) on the horizontal axis and follow a line vertically up until it intersects the lower curve.

. From the intersection point, follow a horizontal line to the left and read off on the vertical axis the

time that will elapse before the thermal overload relay switch off the motor.

measured current

measured current

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 6

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Contact symbols and

terminal marking

Auxiliary contacts

Auxiliary contacts

CBD - 11

Auxiliary contacts

CBD S - NO

Auxiliary contacts

CBD S - NC

Auxiliary contacts

CBD S - 11

Auxiliary contacts

CBD - 22

Auxiliary contacts

CBD S - 20

Contactors and thermal overload relay

Contactors

CI 61/73/86/98

Thermal overload relay

TI 80/86

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 7

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Connections

Loads

Connections, main contacts and contactor coils

EN 60947

Multicore

Type Connection method

CI 61, CI 73, CI 86, CI 98 Screw and box terminal 2.5 – 50 2.5 – 35 – 2 – 6

TI 80, TI 86 Screw and box terminal 1.5 – 35 1.5 – 25 – 0.8 – 3 – 5

Coil Screw and clamp washer 0.52 – 2.5 0.5 – 2.5 0.5 – 2.5 1 – 1.5

Single

[mm2] [mm2] [mm2] [Nm]

Without

terminal

sleeve

With terminal

sleeve

Tightening

torque

Direct start, load categories AC-2, AC-3, AC-4

Switching of 3-phase Motors; (50 Hz); Ambient temperature 60 °C, AC-2, AC-3, AC-4

Type

CI 61

CI 73

CI 86

CI 98

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 62 62 60 60 55 34

kW 18.5 18.5 32 32 37 32

A 72 72 72 72 67 42

kW 22 22 40 40 45 40

A 85 85 85 85 80 49

kW 25 25 45 45 55 45

A 96 95 97 97 78 57

kW 30 30 55 55 55 55

Rated loads at 50 Hz

Star-delta start, load category AC-3

Star-delta start, load category AC-3

Type

CI 61

CI 73

CI 86

CI 98

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 107 107 104 104 95 59

kW 32 32 55 55 63 55

A 125 125 125 125 116 73

kW 37 40 63 63 80 63

A 147 147 147 147 139 85

kW 45 50 80 80 90 80

A 166 165 168 168 135 99

kW 50 50 90 90 90 90

Rated Loads at 50 Hz

Three-phase ohmic load, load category AC-1

AC-1 Active Power Load (50 Hz)

Type

CI 61, CI73, CI86

CI 98

Operating temperatur max. 40 °C (open condition) Heat-resistant cable only (min 75 °C)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 100 100 100 100 100 100

kW 40 42 69 2 87 120

A 130 130 130 130 130 130

kW 52 54 90 93 113 155

Three-phase ohmic load, load category AC-1

AC-1 Active Power Load (50 Hz)

Type

CI 61, CI73, CI86

CI 98

Operating temperatur max. 60 °C (encl. condition) Heat-resistant cable only (min 75 °C)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 100 100 100 100 100 100

kW 40 42 69 72 87 120

A 110 110 110 110 110 110

kW 44 46 76 79 95 131

Switching three-phase power transformers (AC-6a)

Switching of Power Transformers; AC-6a (50 Hz)

Type

CI 61

CI 73

CI 86

CI 98

Transformer load, (factor n = 30, inrush current = n x rated transformer current)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 40.8 40.8 40.8 40.8 40.8 40.8

kW 16 17 28 29 35 49

A 40.8 40.8 40.8 40.8 40.8 40.8

kW 16 17 28 29 35 49

A 40.8 40.8 40.8 40.8 40.8 40.8

kW 16 17 28 29 35 49

A 48.5 48.5 48.5 48.5 48.5 48.5

kW 19.3 20.2 33.6 34.9 42 58

© Danfoss | DCS (az) | 2018.02

IC.PD.C00.F6.02 | 8

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Technical data

Switching lighting

Incandescent lamps

Type

CI 61 60 81 77 4000 2000 800

CI 73 70 85 81 4000 2000 800

CI 86 76 90 90 4700 2350 940

CI 98 90 115 100 4700 2350 940

(AC-5b)

Max. operating

current

[A]

Max. operating current [A] at

operating tempereature 1)

40 °C 60 °C 10 kA 20 kA 50 kA

Fluorescent lamps. individually compensated

(AC-5b)

Max. Capacity

[uF] at Icc=

Switching capacitor loads, individual capacitors (AC-6b)

Inductance in leads between capacitors connected in parallel min. 6µH

Type

CI 61 28 28 48 42 50 42 50 42

CI 73 28 28 48 48 55 50 55 50

CI 86 28 28 48 48 60 55 60 55

CI 98 28 28 48 48 60 55 60 55

220 – 240 V 380 – 415 V 500 V 690 V

40 °C 60 °C 40 °C 60 °C 40 °C 60 °C 40 °C 60 °C

Max. Reactive power [kVAr] 1)

Switching capacitor loads, regulating capacitors (AC-6b)

Inductance in leads between parallel-connected capacitors must be min.6µH

Type

CI 61 28 28 40 40 50 40 40 40

CI 73 28 28 48 48 50 50 50 50

CI 86 28 28 48 48 50 50 50 50

CI 98 28 28 48 48 50 50 50 50

220 – 240 V 380 – 415 V 500 V 690 V

40 °C 60 °C 40 °C 60 °C 40 °C 60 °C 40 °C 60 °C

Max. Reactive power [kVAr] 1)

Switching direct current load at 60 °C ambient temperature

Load categories DC-3 and DC-5, contacts connected in series

Type

CI 61 90 70 70 25 0.6 90 70 70 25 0.6

CI 73 90 70 70 25 0.6 90 70 70 25 0.6

CI 86 100 80 80 30 0.6 100 80 80 30 0.6

CI 98 100 80 80 30 0.6 100 80 80 30 0.6

Switching direct current load at 60 °C ambient temperature

Load category C-1, contacts connected in series

Type

CI 61 70 70 90 40 70 90 11 70 90 2 15 70 0.5 1.5 5

CI 73 80 80 90 40 80 90 11 80 90 2 15 80 0.5 1.5 5

CI 86 80 80 100 40 80 100 11 80 100 2 15 80 0.5 1.5 5

CI 98 80 80 100 40 80 100 11 80 100 2 15 80 0.5 1.5 5

24 V 48 V 110 V 220 V 440 V 24 V 48 V 110 V 220 V 440 V

1

pole2 poles3 poles1 pole2 poles3 poles1 pole2 poles3 poles1pole2 poles3 poles1 pole2 poles3 poles

DC-3. 3 poles in series DC-5. 3 poles in series

24 V 48 V 110 220 V 440 V

Max. operating current [A]

Max. operating current [A]

Contact resistance and power loss

Type

CI 61 0.9 9.7 4.5 14.2

CI 73 0.9 14 4.5 18.5

CI 86 0.9 19.5 4.5 24

CI 98 0.6 17 9 26

Typical impedance

per pole

[mΩ]

Power loss at

3 poles

AC-3 [W] AC-1 [W]

Coil consumption AC

[W]

Total power loss

© Danfoss | DCS (az) | 2018.02

Short-time withstand current I

Type

CI 61 700 20

CI 73 700 20

CI 86 700 20

CI 98 840 20

1

) 40 °C is defined as non-enclosed installation.

60 °C is defined as enclosed installation.

Short time withstand current in Amps (Icw)

cw

Current transfer time 10 sec.

Min cooling Time

[min.]

IC.PD.C00.F6.02 | 9

Data sheet | CI-TI™ Contactors and motor starters, Types CI 61 - CI 98

Technical data (continued)

Connections, auxiliary contacts

Single and

Type Connection method

CBD-, CBD S- For

CI 61- CI 73 - CI 86- CI 98

TI 80, TI 86 Screw and clamp washer 0.75 – 2.5 0.75 – 1.5 0.5 – 1.5 0.3 – 1

Screw and clamp washer 0.75 – 2.5 1 – 2.5 1 – 2.5 1 – 1.5

multi core

[mm2] [mm2] [mm2] [Nm]

High capacity

without term.

sleeve

with

term. sleeve

Tightening

torque

Auxiliary contacts, load categories AC-15 and AC-1

Max. operating current [A]

Type Comments

220 – 230 V

CBD-

CBD S- 3 3 2 2 1.6 0.75 10 6

1

) 40 °C is defined as non-enclosed installation.

60 °C is defined as enclosed installation.

For contactors CI 61- CI 73 CI 86 - CI 98

5.5 5 3 2.5 1.6 1 10 6

AC-15 AC-1

240 V 380

–

400 V 415 V 500 V 690 V 40 °C 1) 60°C 1)

Auxiliary contacts, load categories DC-12, DC-13, and DC-14

Type Comments

CBD- For contactors

CI 61- CI 73 - CI

CBD S- 6 3 0.45 0.18 0.1 3 1.5 0.6 0.3 0.2 2 1.6 0.3 0.12 0.15

86 - CI 98

24 V 48 V

12 9 3.5 0.55 0.2 5 2 0.7 0.25 0.12 9 5 2 0.4 0.16

DC-12 DC-13 DC-14

110 V 220 V 440 V

Max. operating current [A]

24 V 48 V

110 V 220 V 440 V

24 V 48 V

110 V 220 V

440 V

Coils, consumption and operating times

Type

CI 61- CI 73 -

CI 86 - CI 98

Inrush powerACHolding-power ACPull-in voltage ACDrop-out voltage ACMake time

[VA ] [W] [ VA] [W] [V] [V] [ms] [ms]

200 16 16 4.5 (0.85 – 1.1) x U

S

(0.3 – 0) x U

S

AC

18.5 – 30 10 – 60

Break time

AC

UL / CSA Specifications

RC Element (charge suppressor)

Overvoltage factor

Type Comments

RCD Suitable for contactors CI 61, CI 73, CI 86 1 – 3

n =

U

max

U

n

Max. load control circuit (contact system)

Type

TI 80 500 V, 2A, 200 VA 250 V, 2 A, 20 W 4 A 6 A

TI 86 500 V, 2A, 200 VA 250 V, 2 A, 20 W 4 A 6 A

AC-15 DC-13 gl, gL, gG BS 88 type T

Load Max. fuse

UL/CSA approved loads

Motor load (AC-3) [hp] Other loads (AC-1) [A]

Type

CI 61 5 10 15 20 40 50 90 90 90 90

CI 73 5 15 20 25 50 60 90 90 90 90

CI 86 7.5 15 25 30 60 60 100 100 100 100

CI 98 10 20 30 30 75 75 120 120 120 120

1

) 40 °C is defined as non-enclosed installation.

60 °C is defined as enclosed installation.

1-phase 3-phase UL CSA

115 V 230 V 200 V 240 V 460 V 575 V 40°C 1) 60°C 1) 40°C 1) 60°C 1)

Auxiliary contacts, UL/CSA approved loads

Load capacity

Type Comments

Category [VA] Category [W]

CBD For contactors CI 61- CI 73 - CI 86-CI 98 A600 720 Q600 69

CBD S For contactors CI 61- CI 73 - CI 86-CI 98 A600 720 Q600 69

[AC] [DC]

© Danfoss | DCS (az) | 2018.02

Connections, main contacts

Type Connection method

CI 61, CI 73, CI 86, CI 98 Screw and clamp washer 14 – 2 18 – 52

TI 80, TI 86 Screw and clamp washer 16 – 3 7 – 30

Single and multi core

[AWG ]

Tightening torque

[lb-in]

IC.PD.C00.F6.02 | 10

Dimensions

Contactor CI 61, 73, 86, 98 Contactor CI 61, 73, 86, 98 built together with thermal

overload relay TI 80-86

Drilling dimensions

CI 61, 73, 86, 98 with mechanical interlock

Thermal overload relays TI 80 and TI 86 for contactors CI 61, 73, 86 Thermal overload relays TI 80 and TI 86

Thermal overload relay TI 80 / TI 86 on base plate

© Danfoss | DCS (az) | 2018.02 IC.PD.C00.F6.02 | 11

Loading...

Loading...