Page 1

Data sheet

CI-TI™ Contactors and Motor Starters

Type CI 6 - 50

CI-TI™ contactors and motor starters

provide trouble-free switching and

maximum protection for costly motors

and other electrical equipment.

The components are compact, easy to

install and extremely reliable.

They are designed to meet demanding

requirements, based on comprehensive

application experience.

More than sixty years of manufacturing

experience ensure that our contactors

and motor starters stand out with regards

to quality and long life.

© Danfoss | DCS (az) | 2018.10 IC.PD.C10.1G.02 | 1

Page 2

Data sheet | Contactors, type CI 6 – CI 50

Contactors CI 6 – CI 50 for

AC coil voltage (no built-in

auxiliary contacts)

Danfoss contactors CI 6 – CI 50 cover the power

range 2.2 – 25 kW.

CI 6 is built up as a combined contactor/control

relay.

CI 9 DC – CI 30 DC and CI 9 EI – CI 30 EI are

contactors for DC coil voltage within the power

range 2.2 – 15 kW. The range CI 9 EI – CI 30 EI has

built-in interface relay for PLC application with

24 V DC output.

Accessories include a wide selection of clip-on

auxiliary contact blocks and timers, interface

modules and RC links.

The CI 6 – CI 50 range also includes thermal

overload relays for protection of squirrel-cage

motors.

Main circuit Auxiliary

Type

CI 6

CI 9

CI 12

CI 15

AC-3 load

U

e

220 –

240 V

[kW]

1.5 2.2 6 20 16 3 1 – 4 037H0015

2

)

1.5 2.2 6 20 16 4 1 – 4 037H0018

U

380 –

690 V

[kW]

e

I

e

[A]

2.2 4.0 9 25 16 3 1 – 4 037H0021

2.2 4.0 9 25 16 4 1 – 4 037H0022

3.0 5.5 12 25 20 3 1 – 4 037H0031

3.0 5.5 12 25 20 4 1 – 4 037H0032

4.0 7.5 3) 16 25 20 30 3 1 – 4 037H0049

4.0 7.5 3) 16 25 20 30 4 1 – 4 037H0050

4

I

th

(AC-1)

Open

[A]

)

I

the

(AC-1)

Encl.

[A]

CI 16 4.0 7.5 16 40 25 45 3 1 – 4 037H0041

CI 20 5.5 10.0 20 40 25 45 3 1 – 4 037H0045

CI 25 5.5 11.0 25 40 25 45 3 1 – 4 037H0051

CI 30 8.5 15.0 32 40 30 50 3 1 – 4 037H0055

CI 32 8.5 15.0 3) 32 63 63 3 1 – 4 037H0061

CI 37 10.0 18.5 3) 37 80 63 3 1 – 4 037H0056

CI 45 11.0 22.0 3) 45 80 80 90 3 1 – 4 037H0071

CI 50 15.0 25.0 3) 52 80 80 90 3 1 – 4 037H0080

1

) Suffix defining coil voltage/frequency must be added to the Danfoss code no. (see table on page 4).

2

) AC-15 operation: max. 500 VA / 6A

3

) Ue max.: 500 V

4

) The thermal current value lth represents the maximum load at 40 °C, which corresponds to installing the contactor in air (open).

5

) The thermal current value l

enclosure.

6

) Heat-resistant leads (min. 75 °C) must be used.

represents the maximum load at 60 °C, which corresponds to installing the contactor inside an

the

Max.

5

)

6

I

)

th

(AC-1)

Open

[A]

Main

contacts

(make)

Number

contacts

Add-on

options

Number

Code no. 1)

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 2

Page 3

Data sheet | Contactors, type CI 6 – CI 50

Contactors CI 6 – CI 30 for

AC coil voltage with AMP

connections

The CI 6 – CI 30 contactors are also available with

AMP connections in main circuits.

Coils are equipped with standard screw

connections.

This version can be especially useful in the

applications where contactors are installed in the

large number of standardized machines (welding

machines or A/C units).

Main circuit

AC-3 load AC-1 load

Type

U

e

220 – 240 V

[kW]

U

e

380 – 690 V

[kW]

[A]

I

e

4

l

)

th

Open

[A]

l

the

Encl.

[A]

5

)

CI 6 3) 1.5 2.2 6 20 16 – 037H4016

CI 9 2.2 4.0 9 25 16 – 037H4023

CI 12 3.0 5.5 12 25 20 – 037H4033

CI 20 5.5 10.0 20 40 25 45 037H4060

1

) Suffix defining coil voltage / frequency must be added to the Danfoss code no. (see table on page 4).

2

) The minimum order size is 30 pcs. for CI 6 to CI 15 and 25 pcs. for CI 16 to CI 30 in industrial packs.

Industrial packs should be ordered as 037H40xxxx.

3

) AC-15 Operation: max. 500 VA / 6A

4

) The thermal current value lth represents the maximum load at 40 °C, which corresponds to installing the contactor in air (open).

5

) The thermal current value lthe represents the maximum load at 60 °C, which corresponds to installing the contactor inside an

enclosure.

6

) Heat-resistant leads (min. 75 °C) must be used.

max.

6

l

)

th

(make)

[A]

Code no. 1) 2)

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 3

Page 4

Data sheet | Contactors, type CI 6 – CI 50

AC coil voltages and coils for

CI 6 – CI 30

AC coil voltages and coils for

CI 32 – CI 50

Coil voltage *) Sux no. Code no.

24 V, 50 – 60 Hz 13 037H6484

24 V, 50 Hz / 29 V, 60 Hz 16 037H6462

42 V, 50 Hz / 50 V, 60 Hz 17 037H6463

110 V, 50 Hz / 110 – 120 V, 60 Hz 23 037H6487

208 – 230 V, 60 Hz 28 037H6450

220 – 230 V, 50 Hz / 220 V, 60 Hz 32 037H6488

220 – 240 V, 50 Hz 31 037H6472

380 – 400 V, 50 Hz / 440 V, 60 Hz 37 037H6478

415 V, 50 Hz / 500 V, 60 Hz 38 037H6479

500 V, 50 Hz / 600 V, 60 Hz 94 037H6481

Coil voltage *) Sux no. Code no.

24 V, 50 – 60 Hz 13 037H6084

42 V, 50 Hz / 50 V, 60 Hz 17 037H6063

110 V, 50 Hz / 110 – 120 V, 60 Hz 23 037H6087

208 – 230 V, 60 Hz 28 037H6050

220 – 230 V, 50 Hz / 220 V, 60 Hz 32 037H6088

220 – 230 V, 50 Hz 31 037H6072

380 – 400 V, 50 Hz / 440 V, 60 Hz 37 037H6078

415 V, 50 Hz / 500 V, 60 Hz 38 037H6079

500 V, 50 Hz / 600 V, 60 Hz 94 037H6081

*) Standard coil voltage from -15% – 10%.

1

) Double frequency coil: voltage range ±10%.

Continuous operation: ambient temperature max. 55 °C, non-enclosed

Intermittent operation: energized for 30 min/hour: ambient temperature max. 65 °C

2

) Operating conditions and tolerances as for double frequency coils.

1

)

1

)

2

)

1

)

1

)

1

)

2

)

1

)

Correct ordering of contactors

Example: CI 9 with four main contacts and

24 V, 50 Hz coil voltage.

Select one of the following two forms of ordering:

1. Danfoss code no. + Sux no.:

037H002216

or

2. Danfoss code no. + coil voltage/frequency:

037H0022, 24 V/50 Hz

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 4

Page 5

Data sheet | Contactors, type CI 6 – CI 50

Interface contactors

CI 9 EI – CI 30 EI (no built-in

auxiliary contacts)

Contactors CI 9 EI – CI 30 EI cover the power

range 4 – 15 kW.

The operation of the coil is controlled by an

electronic circuit.

The range CI 9 EI – CI 30 EI has a built-in interface

relay for PLC application with 24 V DC output.

Accessories include a wide selection of clip- on

auxiliary contact blocks and timers.

The CI 9 EI – CI 30 EI range also includes thermal

overload relays for protection of squirrel-cage

motors.

Main circuit Control circuit

AC-3 load AC-1 load Coil PLC 5)

U

Type

CI 9 EI 24 2.2 4.0 9 25 16 24 DC 24 DC 037H801166

CI 9 EI 230 2.2 4.0 9 25 16 220 – 240 AC 4) 24 DC 037H806166

CI 15 EI 24 4.0 7.5 3) 15 25 20 24 DC 24 DC 037H801366

CI 15 EI 230 4.0 7.5 3) 15 25 20 220 – 240 AC 4) 24 DC 037H806366

CI 25 EI 24 5.5 11.0 25 40 25 24 DC 24 DC 037H801666

CI 25 EI 230 5.5 11.0 25 40 25 220 – 240 AC 4) 24 DC 037H806666

CI 30 EI 24 8.5 15.0 32 40 30 24 DC 24 DC 037H801766

CI 30 EI 230 8.5 15.0 32 40 30 220 – 240 AC 4) 24 DC 037H806766

1

) The thermal current value Ith gives the maximum load at 40 °C, which corresponds to installing the contactor in air (open).

2

) The thermal current value I

3

) Ue max 500 V

4

) Coils are dual frequency coils

5

) Cable length from PLC to B+ and B- max. 50 m because of risks of interference.

e

220 –

240 V

[kW]

U

e

380 –

690 V

[kW]

gives the maximum load at 60 °C, corresponding to installing the contactor inside an enclosure.

the

[A]

I

e

I

th

Open

[A]

1

)

I

the

Encl.

[A]

2

)

A1 – A2

[V]

B+ - B−

[V]

Code no.

Ordering example

CI 9 EI with 230 V AC coil

and 24 V DC PLC interface:

Danfoss code number:

037H806166

(Type: CI 9 EI230)

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 5

Page 6

Data sheet | Contactors, type CI 6 – CI 50

Contactors CI 9 DC – CI 30

DC (no built-in auxiliary

contacts)

Contactors CI 9 DC – CI 30 DC cover the range

4 – 15 kW.

The operation of the coil is controlled by an

electronic circuit.

The control voltage is 12 V DC or 24 V DC.

A typical application is transport cooling.

Accessories include a wide selection of clip-on

auxiliary contact blocks and timers.

The CI 9 DC – CI 30 DC range also includes

thermal overload relays for protection of

squirrel-cage motors.

Main circuit

AC-3 load AC-1 load

Type

CI 9 DC 24 2.2 4.0 9 25 16 24 DC 037H807166

CI 15 DC 12 4.0 7.5

CI 15 DC 24 4.0 7.5

CI 25 DC 24 5.5 11.0 25 40 25 24 DC 037H807666

CI 30 DC 24 8.5 15.0 32 40 30 24 DC 037H807766

1

) The thermal current value Ith gives the maximum load at 40 °C, which corresponds to installing the contactor in air (open).

2

) The thermal current value I

3

) Ue max 500 V.

4

) Standard coil voltage from -15% – 10%.

U

220 –

240 V

[kW]

e

U

e

380-690

V

[kW]

3)

3)

gives the maximum load at 60 °C, corresponding to installing the contactor inside an enclosure.

the

I

e

[A]

16 25 20 12 DC 037H800366

16 25 20 24 DC 037H807366

I

th

Open

[A]

1

)

I

the

Encl.

[A]

2

Control

circuit

4

Coil

)

)

A1 – A2

[V]

Code no.

Ordering example

CI 15 DC with 12 V DC coil:

Danfoss code number:

037H800366

(Type: CI 15 DC 12)

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 6

Page 7

Data sheet | Contactors, type CI 6 – CI 50

1

) The thermal current value Ith gives the maximal load at 40 °C, which corresponds to installing the contactor in air (open).

2

3

Auxiliary contact blocks CB

for CI 6 – CI 50

CB-

Auxiliary contact block

CB- with gold-plated

contacts (PLC-compatible)

Accessories for contactors

CI 6 – CI 50

Mech. interlock

CI 9 DC – CI 30 DC

CI 9 EI – CI 30 EI

Load

(AC-1)

Open

I

e

mA

1

I

)

th

[A]

Load

I

Type Contact function

CB-S start 6 10 10 500 green 037H0110

CB-I

CB-NO make 6 10 10 500 green 037H0111

CB-NC break 6 10 10 500 red 037H0112

CB-EM early make 6 10 10 500 white 037H0113

CB-LB late break 6 10 10 500 blue 037H0114

) The thermal current value I

) Without self-holding function.

Type Contact function

CB-NO make 1 – 30 5 – 30 white 037H0121

CB-NC break 1 – 30 5 – 30 blue 037H0122

start pulse

3

)

gives the maximal load at 60 °C, corresponding installing the contactor inside an enclosure.

the

e

(AC - 15)

[A]

6 10 10 500 green 037H0117

CB auxiliary contact blocks are force-actuated when

mounted on CI 6 – CI 30 and can therefore form part of

safety switching.

2

I

)

the

(AC-1)

Enc.

[V]

U

V

e

Colour code Code no.

U

e

Colour code Code no.

In the standard auxiliary contact CB - the silver tips

on the moreable contact is cross stamped and PLC compatible.

Min. load 24 V, 10 mA.

Description Comments Code no.

Mech. interlock

for CI 6 – CI 30

CI 9 DC – CI 30 DC,

CI 9 EI – CI 30 EI

Mech. interlock

for CI 32 – CI 50

RC Element

for CI 6 – CI 30

Rating plate for CI 6 - 50 Rating plate, can be mounted in auxiliary contact space (10-off ) 037H010166

Mech. interlock can be established between pairs (1-off ). 037H009166

Mech. interlock can be established between 037H010666

Reduces overvoltage on de-energization of coils

Type RC 250 (110 – 250 V, 50/60 Hz) 037H0076

Type RC 415 (380 – 415 V, 50/60 Hz) 037H0077

Mech. interlock

CI 32 – CI 50

RC Element

CI 6 – CI 30

RCB-

Rating plate

CI 6 – CI 50

Clip-on markers

CI 6 – CI 50 and CB-

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 7

Page 8

Data sheet | Contactors, type CI 6 – CI 50

ON-delay clip-on timers for

AC control voltage 50 / 60 Hz

ETB

Type Time range

0.5 – 20 s 24 – 65 047H0170

4 – 160 s 24 – 65 047H0171

ETB

0.5 – 20 s 110 – 240 047H0173

4 – 160 s 110 – 240 047H0174

0.5 – 20 min 110 – 240 047H0175

ETB electronic clip-on timers are for use with

Danfoss contactors to delay contactor close and

open.

The clip-on timers can be clipped direct onto

contactors CI 6 – CI 50 and occupy as little space

as one auxiliary contact.

Where separate mounting at the side of

contactors is required, a DIN rail mounting base

is available.

Voltage range

[V]

Code no.

OFF-delay clip-on timers for

AC control voltage 50 / 60 Hz

Accessory for ETB

Type Time range

0.5 – 20 s 24 – 65 047H0180

4 – 160 s 24 – 65 047H0181

ETB

Description Comments Code no.

DIN rail base for ETB For separate mounting of clip-on timers ETB 047H016466

0.5 – 20 min 24 – 65 047H0182

0.5 – 20 s 110 – 240 047H0183

4 – 160 s 110 – 240 047H0184

0.5 – 20 min 110 – 240 047H0185

Voltage range

[V]

Code no.

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 8

Page 9

Data sheet | Contactors, type CI 6 – CI 50

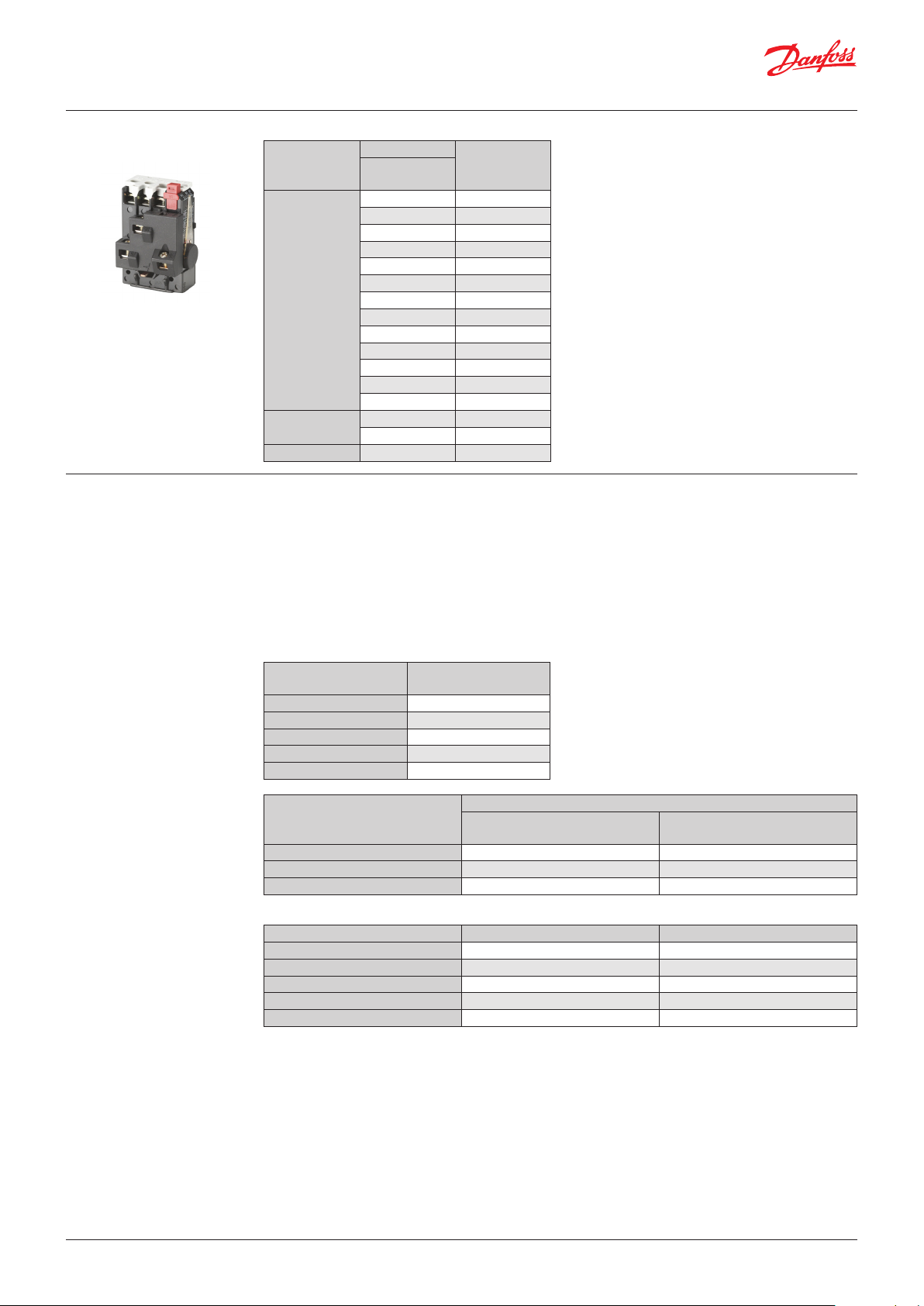

Thermal overload relays

TI 16C, TI 25C, TI 30C for

contactors CI 6 – CI 30

Thermal overload relays TI 16C, TI 25C and

TI 30C are used with contactors CI 6 – CI 30 to give

protection of squirrel-cage motors of 0.09 kW to

15 kW.

The relays have single-phase protection, i.e.

accelerated release if phase drop-out occurs.

This is particularly important for motors with

delta-connected windings.

Other features of TI 16C / 25C / 30C:

• stop/reset button

• manual/automatic reset

• test button

• double scale for direct start or Y/D start

• galvanically isolated signal contact

Range Max. fuse 1)

Type

TI 16C

TI 25C

TI 30C 24 – 32 41 – 55 80 63 80 63 60 047H0215

1

) To IEC 947-4 coordination types 1 and 2:

Coordination type 1: Any type of damage to the motor starter is permissible. If the motor starter is in an enclosure, no external

damage to the enclosure is permissible. After a short-circuit the thermal overload relay shall be partially or

wholly replaced.

Coordination type 2: No damage to the motor starter is permissible, but slight contact burning and welding is permissible.

2

) In accordance with HRC form II, TI 16C, TI 25C and TI 30C are suitable for operation in Canada and the USA.

3

) 50 A in Norway.

Motorstarter

[A]

0.13 – 0.20 – 25 – 32 – 1 047H0200

0.19 – 0.29 – 25 – 32 2 1 047H0201

0.27 – 0.42 – 25 2 32 2 1 047H0202

0.4 – 0.62 – 25 2 32 4 1 047H0203

0.6 – 0.92 – 25 4 32 6 3 047H0204

0.85 – 1.3 – 25 4 32 6 3 047H0205

1.2 – 1.9 – 25 6 32 10 6 047H0206

1.8 – 2.8 3.2 – 4.8 25 6 32 10 15 047H0207

2.7 – 4.2 4.7 – 7.3 25 16 32 20 15 047H0208

4.0 – 6.2 6.9 – 10.7 35 20 40 25 15 047H0209

6.0 – 9.2 10 – 16 50 20 50 25 35 047H0210

8.0 – 12 13 – 20.8 63 25 63 32 35 047H0211

11 – 16 19 – 27 80 25 80 32 50 047H0212

15 – 20 26 – 35 80 35

19 – 25 33 – 43 80 63 80 63 60 047H0214

Y/D-

starter

[A]

gl, gL, gG BS 88, type T

Type 1

[A]

Type 2

[A]

Type 1

3)

Type 2

[A]

80 40 60 047H0213

[A]

HRC 2)

II

[A]

Code no.

© Danfoss | DCS (az) | 2018.10

Selection of thermal overload relay

The selection of a thermal overload relay must

be based on the motor full load current and the

method of starting:

- With direct start the range for motor starter is

used.

- With star-delta start the range for Y/D starter is

used.

Example:

Full load current: 16 A

- With direct start, the suitable motor starter

range is 11 – 16 A, i.e. thermal overload relay

047H0212.

- With star-delta start, the suitable Y/D starter

range is 10 – 16 A, i.e. thermal overload relay

047H0210.

The range 13 – 20.8 A could also be used, but

thermal overload relay 047H0211 will not

release as quickly if one phase drops out.

IC.PD.C10.1G.02 | 9

Page 10

Data sheet | Contactors, type CI 6 – CI 50

Thermal overload relays

TI 80

Thermal overload relays TI 80 are used with

contactors CI 32 – 50 to give protection of

squirrel-cage motors of 7.5 kW to 25 kW.

The relays have single-phase protection, i.e.

accelerated release if phase drop-out occurs. This

is particularly important for motors with deltaconnected windings.

Other features of TI 80:

• stop/reset button

• manual/automatic reset

• test button

• double scale for direct start or Y/D start

• signal contact with changeover

Range Max. fuse 1)

Type

TI 80

1

) To IEC 947-4 coordination types 1 and 2:

Coordination type 1: Any type of damage to the motor starter is permissible. If the motor starter is in an enclosure, no external

damage to the enclosure is permissible. After a short-circuit the thermal overload relay shall be partially or

wholly replaced.

Coordination type 2: No damage to the motor starter is permissible, but slight contact burning and welding is permissible.

Motorstarter

[A]

16 – 23 28 – 40 125 63 125 63 047H1013

22 – 32 38 – 56 125 63 125 63 047H1014

30 – 45 52 – 78 125 100 125 100 047H1015

42 – 63 75 – 109 – 100 – 125 047H1016

Y/D-

starter

[A]

gl, gL, gG BS 88, type T

Type 1

[A]

Type 2

[A]

Type 1

[A]

Type 2

[A]

Code no.

Selection of thermal overload relay

The selection of a thermal overload relay must

be based on the motor full load current and the

method of starting:

- With direct start the range for motor starter is

used.

- With star-delta start the range for Y/D starter is

used.

Example:

Full load current: 45 A

- With direct start, the suitable motor starter

range is 30 – 45 A, i.e. thermal overload relay

047H1015.

- With star-delta start, the suitable Y/D starter

range is 38 – 56 A, i.e. thermal overload relay

047H1014.

Accessories for thermal overload relays TI 16C - 30C

Typ e Description Comments Code no.

Clip-on marker For thermal overload relays TI 16C, 25C and 30C (250-off) 037H010566

Holder for sep. mounting

Base for TI 16C Separate mounting of thermal overload relays TI 16C 047L040566

Base for TI 80 Separate mounting of thermal overload relays TI 80 (20-off ) 047L045666

Stop-pushbutton extension For thermal overload relays TI 16C-80 (3 mm) 047L040666

Mounting of thermal overload relays TI 16C, 25C and 30C

on 35 mm DIN rail

047H016566

Current rail set For direct mounting of thermal overload relay TI 80 on contactors 037H010866

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 10

Page 11

Data sheet | Contactors, type CI 6 – CI 50

Enclosures for the CI range

up to 30 A

Enclosures for the CI range up to 30 A are

made of plastic and oer a very high degree of

enclosure (IP 55 to IEC 529).

They are tted with a DIN rail and there is ample

space for a timer block (ETB) at the side of the

contactor. There is an earth terminal and a loop

terminal in the bottom of the enclosure. There

are versions with four knockouts for M20/25

cable entries.

Enclosure BCI and BCI 1: Up to four auxilliary

contact blocks can be tted on each contactor.

Box BCI 2: Ub addition to the start contact, two

auxiliary contact blocks can be tted to a

three-pole contactor.

Plastic enclosures for motor

starters up to 30 A (IP 55)

Type Application Pushbuttons Knockouts Code no.

BCI Control relay / Contactor None 4 M 20/4 M 25 047B010666

BCI 1 Motor starter Stop / reset 4 M 20/4 M 25 047B010466

BCI 2 Motor starter Start-Stop / reset 4 M 20/4 M 25 047B010266

Ordering of motor starter components

DOL starters (contactors CI 6 – CI 30 + thermal overload relays TI 16C – TI 30C + enclosure) 3 x 380-415 V

3)

Motor

Output

Fulload

current

[kW]

1

) To IEC 60947-4 coordination types 1 and 2:

Coordination type 1: Any type of damage to the motor starter is permissible. If the motor starter is in an enclosure, no external damage to the enclosure is permissible. After

Coordination type 2: No damage to the motor starter is permissible, but slight contact burning and welding is permissible.

2

) 50 A in Norway

3

) For each application, check full load current and start current of motor concerned.

4

) State the required coil voltage and frequency by suffix no.

[A]

0.09 0.35 0.27 – 0.42 TI 16C 047H0202 CI 6 037H0015 2 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.12 0.46 0.4 – 0.62 TI 16C 047H0203 CI 6 037H0015 2 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.18 0.62 0.4 – 0.62 TI 16C 047H0203 CI 6 037H0015 2 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.25 0.82 0.6 – 0.92 TI 16C 047H0204 CI 6 037H0015 4 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.37 1.3 0.85 – 1.3 TI 16C 047H0205 CI 6 037H0015 4 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.55 1.7 1.2 – 1.9 TI 16C 047H0206 CI 6 037H0015 6 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

0.75 2.1 1.8 – 2.8 TI 16C 047H0207 CI 6 037H0015 6 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

1.1 2.9 2.7 – 4.2 TI 16C 047H0208 CI 6 037H0015 16 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

1.5 3.7 2.7 – 4.2 TI 16C 047H0208 CI 6 037H0015 16 25 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

2.2 5.3 4.0 – 6.2 TI 16C 047H0209 CI 6 037H0015 20 35 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

3 7.0 6.0 – 9.2 TI 16C 047H0210 CI 9 037H0021 20 50 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

4 9.0 6.0 – 9.2 TI 16C 047H0210 CI 9 037H0021 20 50 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

5.5 12 8.0 – 12 TI 16C 047H0211 CI 12 037H0031 25 63 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

7.5 16 11 – 16 TI 16C 047H0212 CI 16 037H0041 25 80 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

10 20 15 – 20 TI 25C 047H0213 CI 20 037H0045 35 2) 80 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

11 22 19 – 25 TI 25C 047H0214 CI 25 037H0051 63 2) 80 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

15 32 24 – 32 TI 30C 047H0215 CI 30 037H0055 63 2) 80 BCI 1 047B010466 BCI 2 047B010266 CB-S 037H0110

a short-circuit the thermal overload relay shall be partially or wholly replaced.

Thermal overload relay Contactor Max. fuse 1) Enclosure Start contact

Range

[A] Type Code no. Type Code no. 4)

gI, gL,

gG

Type 2

[A]

gI, gL

gG

Type 1

[A]

with

stop-reset

Type Code no. Type Code no Type Code no.

with

start-stop/reset

Necessary only

with start-stop/reset

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 11

Page 12

Data sheet | Contactors, type CI 6 – CI 50

Thermal overload

relays

Construction standards

Range

Type

TI 16C

TI 25C

TI 30C 24 – 32 047H0215

Motor starter

[A]

0.13 – 0.20 047H0200

0.19 – 0.29 047H0201

0.27 – 0.42 047H0202

0.4 – 0.62 047H0203

0.6 – 0.92 047H0204

0.85 – 1.3 047H0205

1.2 – 1.9 047H0206

1.8 – 2.8 047H0207

2.7 – 4.2 047H0208

4.0 – 6.2 047H0209

6.0 – 9.2 047H0210

8.0 – 12 047H0211

11 – 16 047H0212

15 – 20 047H0213

19 – 25 047H0214

Code no.

Contactors, thermal overload relays and accessories

are designed and tested in accordance with

IEC 60947-4-1/EN 60947-4-1.

Environment

Temperate climate

Tested and passed in accordance with DIN 50 016

and 40 046 part 38 and IEC 68

Max. installation height: 2000 NN, in accordance

with IEC 60947-4-1

Pulse voltage

Ambient temperature

Vibration and shock

Tested and passed in

accordance with IEC 68-2-6

and IEC 68-2-7

U

Type

CI 6 – CI 15 8

CI 16 – CI 30 8

CI 32 – CI 50 8

CI 9 DC 8

CI 9 EI – CI 30 EI 8

Type

CI 6 – CI 50 -30 – 70 - 30 – 70

CI 9 DC – CI 30 DC -40 – 80 -40 – 80

CI 9 EI – CI 30 EI - 30 – 60 -40 – 80

Type Vibration 1) Shock 2)

CI 6 – CI 15 4 g, 10 – 200 Hz 9 g in 11 ms

CI 16 – CI 30 4 g, 10 – 200 Hz 9 g in 11 ms

CI 32 – CI 50 1 g, 5 – 1000 Hz 6 g in 11 ms

CI 9 DC – CI 30 DC 4 g, 5 – 200 Hz 10 g in 10 ms

CI 9 EI – CI 30 EI 4 g, 5 – 200 Hz 10 g in 10 ms

1

) Operating conditions: All directions with de-energized coil.

2

) Operating conditions: Parallel with armature and with de-energized coil

imp

[kV]

Operation

[°C]

Ambient temperature

Storage/Transport

[°C]

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 12

Page 13

Data sheet | Contactors, type CI 6 – CI 50

Environment

Electromagnetic

compatibility

Mounting direction

Temperature

Type

TI 16C -5 – 40 -50 – 60 2 g at 200 Hz 9 g for 7.5 ms 30

TI 25C -5 – 40 -50 – 60 2 g at 200 Hz 9 g for 7.5 ms 30

TI 30C -5 – 40 -50 – 60 2 g at 200 Hz 9 g for 7.5 ms 30

TI 80 -5 – 40 -50 – 60 2 g at 200 Hz 9 g for 7.5 ms 30

Type

CI 9 DC – CI 30 DC EN 50081-1 EN 50082-2

CI 9 EI – CI 30 EI EN 50081-1 EN 50082-2

compensated

[°C]

Emission Immunity

Ambient

temperature

[°C]

Vibration

Shock

perpendicular to

contact system

Max.

operations

per hour

Rated life

Approvals & Certicates

Mechanical life

Type

CI 6 – CI 30 10 x 10

CI 32 5 x 10

CI 37 – CI 50 5 x 10

Type

CI 6

CI 9

CI 12

CI 15

CI 16

CI 20

CI 25

CI 30

CI 32

CI 37

CI 45

CI 50

TI 16C / TI 25C / TI 30C

TI 80

CB-

ETB

CI 9DC – CI 30 DC

CI 9EI – CI 30 EI

Approved

No approval applied

CE marked in accordance

Operations

with LVD 2014/35/EU

Electrical life

AC-3 load

6

6

6

Operations

6

1 x 10

6

1 x 10

6

0.5 x 10

Approval authority

cULus EAC LLC CDC T YSK

Switching per hour

AC-3 load

Operations

1200

300

300

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 13

Page 14

Data sheet | Contactors, type CI 6 – CI 50

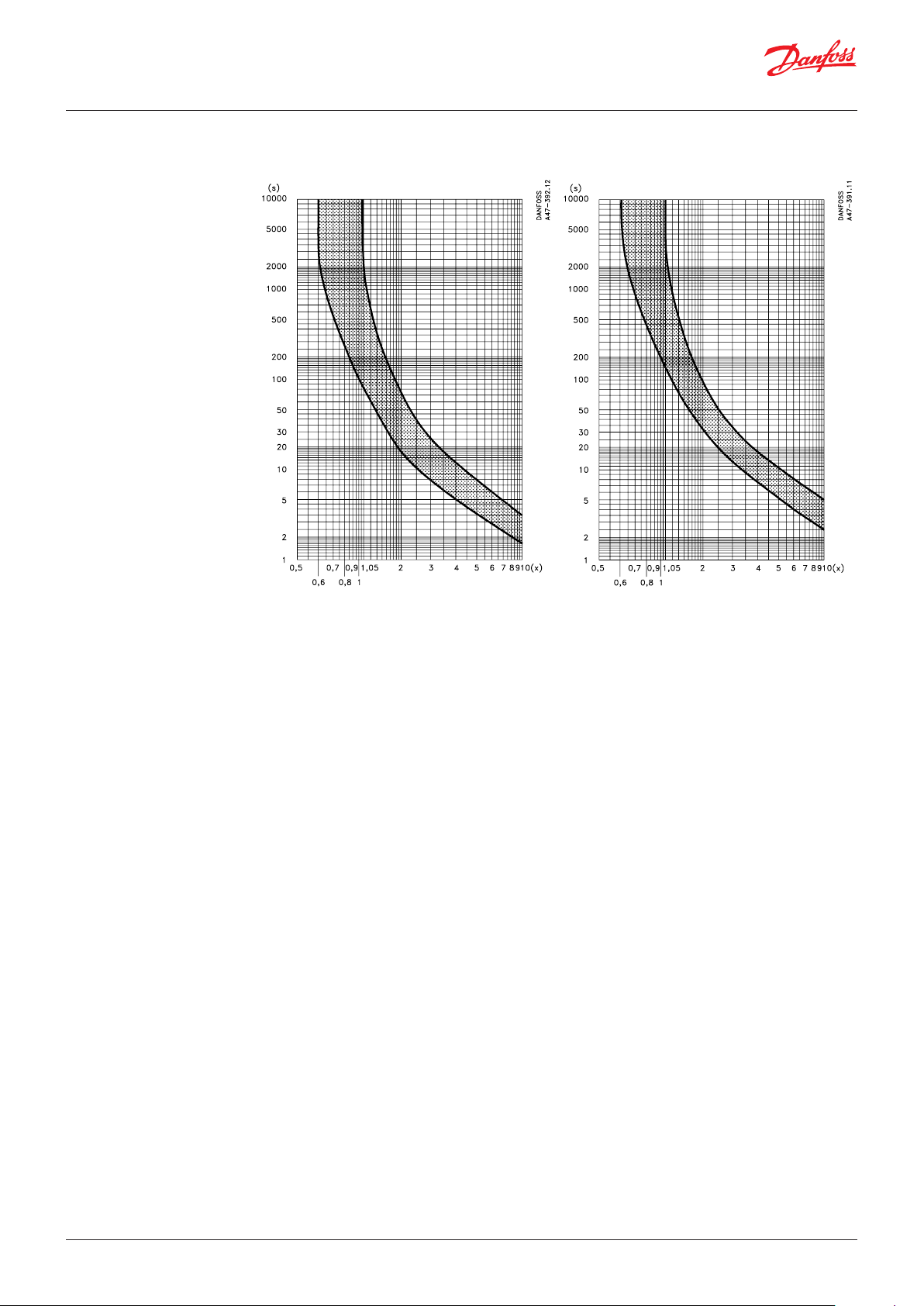

Electrical life curves

Contactors CI 6/9/12/15, CI 16/20/25/30, CI 37/45/50,

load categories AC-3

Contactors CI 6/9/12/15, CI 16/20/25/30, CI 37/45/50,

load categories AC-1

A: Electrical life in millions of make/break

operations

B: Breaking current (A)

Contactors CI 6/9/12/15, CI 16/20/25/30, CI 37/45/50,

load categories AC-4

A: Electrical life in millions of make/break

operations

B: Breaking current (A)

© Danfoss | DCS (az) | 2018.10

A: Electrical life in millions of make/break

operations

B: Breaking current (A)

IC.PD.C10.1G.02 | 14

Page 15

Data sheet | Contactors, type CI 6 – CI 50

Tripping graphs

TI16C, TI 25C, TI 30C

Explanation of graphs

Mean value curves

Upper curve: 3-phase tripping and asymmetric load

tripping at min. setting.

Lower curve: Asymmetric load tripping at max. setting.

When tripping from the operationally warm condition,

the tripping times are approx. 30% of the values shown.

These values apply at an ambient temperature = 20 °C.

3-phase tripping: x = measured current

rated motor current

Asymmetric load tripping: x = measured current

max. scale value on

overload relay

3-phase overload

1

) Measure overload current

2

) Find the overload factor (x) by dividing the measured

value by the set value of the thermal overload relay

(motor full load current).

3

) Find (x) on the horizontal axis and follow a line

vertically up until it intersects the upper curve.

4

) From the intersection point, follow a horizontal line

to the left and read o on the vertical axis the time

that will elapse before the thermal overload relay

cuts out the motor.

Asymmetric load tripping

1

) Measure the current the motor draws from one of

the intact phases.

2

) Find the overload factor (x) by dividing the measured

value by the maximum scale value of the thermal

overload relay.

3

) Find (x) on the horizontal axis and follow a line

vertically up until it intersects the lower curve.

4

) From the intersection point, follow a horizontal line

to the left and read o on the vertical axis the time

that will elapse before the thermal overload relay

switch o the motor.

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 15

Page 16

Data sheet | Contactors, type CI 6 – CI 50

Terminal marking

Relay marking

Terminal marking in Danfoss contactors conforms

to EN 50005. The idea of this marking is as

follows:

1. From the marking it is possible to read which

terminals are associated and which functions

the contacts have.

2. Control relays and contactors of dierent

makes but with the same number of

contacts must have identical terminal

markings.

Terminal markings on main contacts must have a

single-digit number.

Contact set with three main

contacts.

Thermal overload relay with

three bimetal elements.

Contactor marking

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 16

Page 17

Data sheet | Contactors, type CI 6 – CI 50

Terminal marking

Auxiliary contacts must be marked with a

two-digit number.

The rst digit = contact position (position digit)

The second digit = contact function (function

digit)

Function digits have been given the following

standardized designations:

Break contacts must have function digits

1 and 2.

Make contacts should have function

digits 3 and 4.

Special break contacts (early or late break)

must have function digits 5 and 6.

Special make contacts (early or late make)

must have function digits 7 and 8.

The placing of auxiliary contacts on contactors

is clearly indicated by the position digits stamped

on both parts.

Contact symbols and

terminal markings

Control relays and auxiliary contacts

Start contact (1 NO)

CB-S

Auxiliary contact (1 NO)

CB-NO

Auxiliary contact (1 EM)

CB-EM

Impulse contact (1 NO)

CB-I

Auxiliary contact (1 NO)

CB-NC

Auxiliary contact (1 LB)

CB-LB

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 17

Page 18

Data sheet | Contactors, type CI 6 – CI 50

Loads

Connections, main contacts

and contactor coils

Contactors

CI 6/9/12/15/16/20/25/30/32/37/45/50

Thermal overload relays

TI 16C/25C/30C

Type Connection method

CI 6, CI 9, CI 12, CI 15 Screw and clamp washer 0.75 – 2.5 0.75 – 2.5 0.5 – 2.5 0.8 – 2

CI 16, CI 20, CI 25, CI 30 Screw and clamp washer 1.5 – 10 2.5 - 6 1.5 – 4 0.8 – 2.5

CI 32, CI 37, CI 45, CI 50 Box terminal 1.5 – 35 1.5 – 25 – 0.8 – 5

CI 9 DC, CI 15 DC Screw and clamp washer 0.75 – 2.5 0.75 – 2.5 0.5 – 2.5 0.8 – 2

CI 25 DC, CI 30 DC Screw and clamp washer 1.5 – 10 2.5 – 6 1.5 – 4 0.8 – 2.5

CI 9 EI, CI 15 EI Screw and clamp washer 1.5 – 10 0.75 – 2.5 0.5 – 2.5 0.8 – 2

CI 25 EI, CI 30 EI Screw and clamp washer 1.5 – 10 2.5 – 6 1.5 – 4 0.8 – 2.5

TI 16C, TI 25C, TI 30C Screw and clamp washer 0.75 – 4 0.75 – 4 1 – 4 0.8 – 2

TI 80 Box terminal 1.5 – 35 1.5 – 25 – 0.8 – 3.5

Coils Screw and clamp washer 0.75 – 1.5 0.75 – 1.5 0.75 – 1.5 0.5 – 1.4

Contactor

CI 6/9/12/15

Thermal overload relay

TI 80

Single

core

[mm2]

without

terminal

sleeve

[mm2]

Multi core

with

terminal

sleeve

[mm2]

Recommended

Tightening

torque

[Nm]

Direct start, load categories

AC-2, AC-3, AC-4

Type

CI 6

CI 9

CI 9 EI / DC

CI 12

CI 15

CI 15 EI / DC

CI 16

CI 20

CI 25

CI 25 EI / DC

CI 30

CI 30 EI / DC

CI 32

CI 37

CI 45

CI 50

Rated loads at 50-60 Hz

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 6 6 6 6 4 2.7

kW 1.5 1.5 2.2 2.2 2.2 2.2

A 9 9. 9 9 7 5

kW 2.2 2.2 4 4 4 4

A 9 9 9 9 7 5

kW 2.2 2.2 4 4 4 4

A 12 12 12 12 9 7

kW 3 3 5.5 5.5 5.5 5.5

A 16 16 16 16 12 –

kW 4 4 7.5 7.5 7.5 –

A 16 16 16 16 12 –

kW 4 4 7.5 7.5 7.5 –

A 16 16 16 16 12 9

kW 4 4 7.5 7.5 7.5 7.5

A 20 20 20 20 15 11

kW 5.5 5.5 10 10 10 10

A 25 25 25 25 18 14

kW 5.5 5.5 11 11 11 11

A 25 25 25 25 18 14

kW 5.5 5.5 11 11 11 11

A 32 32 32 30 23 17

kW 8.5 8.5 15 15 15 15

A 32 32 32 30 23 17

kW 8.5 8.5 15 15 15 15

A 32 32 32 30 25 –

kW 8.5 9 15 15 15 –

A 37 37 37 37 29 –

kW 10 11 18.5 18.5 18.5 –

A 45 45 45 45 35 –

kW 11 12.5 22 22 22 –

A 52 52 52 52 40 –

kW 15 16 25 25 25 –

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 18

Page 19

Data sheet | Contactors, type CI 6 – CI 50

Table (continued)

Star-delta start, load

categories AC-3

Type

kgh

CI 9

CI 9 EI/ DC

CI 12

CI 15

CI 15 EI / DC

CI 16

CI 20

CI 25

CI 25 EI/ DC

CI 30

CI 30 EI/ DC

CI 32

CI 37

CI 45

CI 50

Rated loads at 50-60 Hz

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 10 10 10 10 7 5

kW 2.2 2.2 4 4 4 4

A 16 16 16 16 12 9

kW 4 4 7.5 7.5 7.5 7.5

A 16 16 16 16 12 9

kW 4 4 7.5 7.5 7.5 7.5

A 21 21 21 21 16 12

kW 5.5 5.5 10 10 10 10

A 27 27 27 27 21 –

kW 7.5 7.5 11 11 11 –

A 27 27 27 27 21 –

kW 7.5 7.5 11 11 11 –

A 27 27 27 27 21 16

kW 7.5 7.5 11 11 11 11

A 35 35 35 35 26 19

kW 10 10 15 15 15 15

A 43 43 43 43 31 24

kW 11 11 22 22 22 22

A 43 43 43 43 31 24

kW 11 11 22 22 22 22

A 52 52 52 52 40 30

kW 15 15 25 25 25 25

A 52 52 52 52 40 30

kW 15 15 25 25 25 25

A 56 56 56 56 43 –

kW 15 15 30 30 30 –

A 64 64 64 64 50 –

kW 18.5 18.5 33 33 33 –

A 78 78 78 78 55 –

kW 22 22 37 37 37 –

A 85 85 85 85 65 –

kW 25 25 45 45 45 –

Three phase ohmic load,

load category AC-1

Type

CI 6

CI 9 / CI 12 / CI 15

CI 9 EI / DC

CI 15 EI / DC

CI 16 / CI 20 /

CI 25 / CI 30

CI 25 EI / DC

CI 30 EI / DC

CI 32

CI 37 / CI 45 / CI 50

Operating temperature max. 40 °C (Open condition)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 20 20 20 20 20 20

kW 8 8 14 14 17 22

A 25 25 25 25 25 25

kW 9 10 16 17 20 28

A 25 25 25 25 25 25

kW 9 10 16 17 20 28

A 40 40 40 40 40 40

kW 15 16 26 27 33 45

A 40 40 40 40 40 40

kW 15 16 26 27 33 45

A 63 63 63 63 63 –

kW 23 24 41 43 51 –

A 80 80 80 80 80 –

kW 30 31 52 54 65 –

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 19

Page 20

Data sheet | Contactors, type CI 6 – CI 50

Table (continued)

Three phase ohmic load,

load category AC-1

Type

CI 6 / CI 9

CI 9 EI /

CI 9 DC

CI 12 / CI 15

CI 15 EI /

CI 15 DC

CI 16 / CI 20 / CI 25

CI 25 EI /

CI 25 DC

CI 30

CI 30 EI /

CI 30 DC

CI 32 / CI 37

CI 45 / CI 50

Operating temperature max. 60 °C (Enclosed condition)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 16 16 16 16 16 16

kW 6.4 6.7 11 12 14 18

A 16 16 16 16 16 16

kW 6.4 6.7 11 12 14 18

A 20 20 20 20 20 20

kW 7 8 13 14 16 22

A 20 20 20 20 20 20

kW 7 8 13 14 16 22

A 25 25 25 25 25 25

kW 9 10 16 17 20 28

A 25 25 25 25 25 25

kW 9 10 16 17 20 28

A 30 30 30 30 30 30

kW 11 12 19 20 24 35

A 30 30 30 30 30 30

kW 11 12 19 20 24 35

A 63 63 63 63 63

kW 23 24 41 43 51

A 80 80 80 80 80

kW 30 31 52 54 65

Three phase ohmic load,

load category AC-1

Switching three phase

power transformers (AC-6a)

Type

CI 15

CI 15 EI

CI 15 DC

CI 16 / CI 20 /

CI 25

CI 25 EI

CI 25 DC

CI 30

CI 30 EI

CI 30 DC

CI 45 / CI 50

Type

CI 6

CI 9

CI 9 EI

CI 9 DC

CI 12

CI 15

CI 15 EI

CI 15 DC

CI 16

CI 20

CI 25

CI 25 EI

CI 25 DC

CI 30

CI 30 EI

CI 30 DC

CI 32

CI 37

CI 45

CI 50

Operating temperature max. 40 °C (Open condition) Heat resistant cable only (min. 75 °C)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 30 30 30 30 30 30

kW 11 12 19 20 24 34

A 30 30 30 30 30 30

kW 11 12 19 20 24 34

A 45 45 45 45 45 45

kW 17 18 29 30 37 51

A 45 45 45 45 45 45

kW 17 18 29 30 37 51

A 50 50 50 50 50 50

kW 18 19 32 34 41 56

A 50 50 50 50 50 50

kW 18 19 32 34 41 56

A 90 90 90 90 90

kW 34 35 59 61 74

Transformer load, (factor n = 30, inrush current = n x rated transformer current)

220 – 230 V 240 V 380 – 400 V 415 V 500 V 690 V

A 3 3 3 30 3 3

kVA 1 1 2 2 2 3

A 4 4 4 4 4 4

kVA 1 1 2 2 3 4

A 4 4 4 4 4 4

kVA 1 1 2 2 3 4

A 5 5 5 5 5 5

kVA 2 2 3 3 4 5

A 6 6 6 6 6 6

kVA 2 2 4 4 5 7

A 6 6 6 6 6 6

kVA 2 2 4 4 5 7

A 7 7 7 7 7 7

kVA 2 2 4 5 6 8

A 9 9 9 9 9 9

kVA 3 3 6 6 7 10

A 11 11 11 11 11 11

kVA 4 4 7 7 9 13

A 11 11 11 11 11 11

kVA 4 4 7 7 9 13

A 13 13 13 13 13 13

kVA 5 5 9 9 11 15

A 13 13 13 13 13 13

kVA 5 5 9 9 11 15

A 14 14 14 14 14

kVA 5 5 9 10 12

A 17 17 17 17 17

kVA 6 7 11 12 14

A 20 20 20 20 20

kVA 7 8 13 14 17

A 23 23 23 23 23

kVA 9 9 15 16 19

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 20

Page 21

Data sheet | Contactors, type CI 6 – CI 50

Load category

Switching lighting

Switching capacitor loads,

individual capacitors

Inductance in leads between

capacitors connected in

parallel min. 6 µH.

Switching capacitor loads,

regulating capacitors

Inductance in leads

between parallel-connected

capacitors must be min. 6 µH

Incandescent

lamps

Type

CI 6 / CI 9 / CI 12 / CI 15 12 20 12 1000 500 200

CI 9 EI / CI 15 EI 12 20 12 1000 500 200

CI 9 DC / CI 15 DC 12 20 12 1000 500 200

CI 16 / CI 20 / CI 25 / CI 30 20 33 22 2700 1350 540

CI 25 EI / CI 30 EI 20 33 22 2700 1350 540

CI 25 DC / CI 30 DC 20 33 22 2700 1350 540

CI 32 35 40 27 3200 1600 540

CI 37 / CI 45 / CI 50 45 47 33 3200 1600 640

1

) 40 °C is dened as non-enclosed installation

60 °C is dened as enclosed installation

Type

CI 6 / CI 9 / CI 12 / CI 15 6 4 10 6 12 8 16 10

CI 9 EI / CI 15 EI 6 4 10 6 12 8 16 10

CI 9 DC / CI 15 DC 6 4 10 6 12 8 16 10

CI 16 / CI 20 / CI 25 / CI 30 10 6 16 10 22 15 30 20

CI 25 EI / CI 30 EI 10 6 16 10 22 15 30 20

CI 25 DC / CI 30 DC 10 6 16 10 22 15 30 20

CI 32 11 7 18 12 22 15 – –

CI 37 / CI 45 / CI 50 14 10 24 18 31 21 – –

1

) 40 °C is dened as non-enclosed installation

60 °C is dened as enclosed installation

Type

CI 6 / CI 9 / CI 12 / CI 15 5 4 6 6 6 6 6 6

CI 9 EI / CI 15 EI 5 4 6 6 6 6 6 6

CI 9 DC / CI 15 DC 5 4 6 6 6 6 6 6

CI 16 / CI 20 / CI 25 / CI 30 10 6 12 11 12 11 12 11

CI 25 EI / CI 30 EI 10 6 12 11 12 11 12 11

CI 25 DC / CI 30 DC 10 6 12 11 12 11 12 11

CI 32 11 7 12 12 12 12 – –

CI 37 / CI 45 / CI 50 14 10 18 16 18 16 – –

1

) 40 °C is dened as non-enclosed installation

60 °C is dened as enclosed installation

(AC-5b)

Max. operating

current

A 40 °C 60 °C 10 kA 20 kA 50 kA

220 – 240 V 380 – 415 V 500 V 690 V

40 °C 60 °C 40 °C 60 °C 40 °C 60 °C 40 °C 60 °C

220 – 240 V 380 – 415 V 500 V 690 V

40 °C 60 °C 40 °C 60 °C 40 °C 60 °C 40 °C 60 °C

Fluorescent lamps, individually compensated (AC-5a)

Max. operat. current [A]

at operat. temperature 1)

Max. reactive power [kVAr] 1)

Max. reactive power [kVAr] 1)

Max. capacity [µF]

at I

=

cc

Switching direct current load

Load categories DC-3 and

DC-5, contacts connected in

series

Type

CI 6 / CI 9 9 9 4.5 1.8 0.6 9 5 2 0.8 0.3

CI 9 EI / CI 15 EI 9 9 4.5 1.8 0.6 9 5 2 0.8 0.3

CI 9 DC / CI 15 DC 9 9 4.5 1.8 0.6 9 5 2 0.8 0.3

CI 12 / CI 15 16 16 6.5 2.5 0.6 16 8 3 1.2 0.4

CI 15 EI 16 16 6.5 2.5 0.6 16 8 3 1.2 0.4

CI 15 DC 16 16 6.5 2.5 0.6 16 8 3 1.2 0.4

CI 16 / CI 20 / CI 25 / CI 30

CI 25 EI / 30 EI 30 30 22 6 0.6 30 16 6 2.5 0.85

CI 25 DC / 30 DC 30 30 22 6 0.6 30 16 6 2.5 0.85

24 V 48 V 110 V 220 V 440 V 24 V 48 V 110 V 220 V 440 V

30 30 22 6 0.6 30 16 6 2.5 0.85

DC-3, 3-pole in series DC-5, 3-pole in series

Max. operating current [A]

Switching direct current load

Load category DC-1, contacts

connected in series

Type

CI 6 / CI 9 9 9 9 9 9 9 3.5 8 9 0.55 3.5 6 0.2 0.55 2

CI 9 EI 9 9 9 9 9 9 3.5 8 9 0.55 3.5 6 0.2 0.55 2

CI 9 DC 9 9 9 9 9 9 3.5 8 9 0.55 3.5 6 0.2 0.55 2

CI 12 / CI 15 16 16 16 16 16 16 5.2 15 16 0.8 5.2 10 0.2 0.8 3

CI 15 EI 16 16 16 16 16 16 5.2 15 16 0.8 5.2 10 0.2 0.8 3

CI 15 DC 16 16 16 16 16 16 5.2 15 16 0.8 5.2 10 0.2 0.8 3

CI 16 / CI 20 / CI 25 / CI 30 30 30 30 25 30 30 8 22 30 1.5 8 16 0.3 1.2 4.5

CI 25 EI / CI 30 EI 30 30 30 25 30 30 8 22 30 1.5 8 16 0.3 1.2 4.5

CI 25 DC / CI 30 DC 30 30 30 25 30 30 8 22 30 1.5 8 16 0.3 1.2 4.5

24 V 48 V 110 V 220 V 440 V

1-pole 2-pole 3-pole 1-pole 2-pole 3-pole 1-pole 2-pole 3-pole 1-pole 2-pole 3-pole 1-pole 2-pole 3-pole

Max. operating current [A]

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 21

Page 22

Data sheet | Contactors, type CI 6 – CI 50

Power loss

Contact resistance and

power losses

Short time withstand

current I

cw

Typical

Type

CI 6 2.1 0.2 2.5 2.7 2.9 5.2

CI 9 1.8 0.4 3.4 2.7 3.1 6.1

CI 12 1.6 0.7 3.0 2.7 3.4 5.7

CI 15 1.6 1.1 3.0 2.7 3.8 5.7

CI 16 1.1 0.8 5.3 2.7 3.5 8

CI 20 1.1 1.3 5.3 2.7 4 8

CI 25 1.1 2.1 5.3 2.7 4.8 8

CI 30 0.8 2.2 3.8 2.7 4.9 6.5

CI 32 0.9 2.8 11 3 5.8 14

CI 37 0.8 3.3 15 3 6.3 18

CI 45 0.8 4.9 15 3 7.9 18

CI 50 0.8 6.0 15 3 9 18

CI 9DC 1.8 0.4 3.4 1.5 1.9 5.3

CI 15DC 1.6 1.1 3 1.5 2.6 4.5

CI 25DC 1.1 2.1 5.3 1.5 3.6 6.8

CI 30DC 0.8 2.2 3.8 1.5 3.7 5.3

CI 9EI 1.8 0.4 3.4 1.5 1.9 5.3

CI 15EI 1.6 1.1 3 1.5 2.6 4.5

CI 25EI 1.1 2.1 5.3 1.5 3.6 6.8

CI 30EI 0.8 2.2 3.8 1.5 3.7 5.3

Type

TI 16C Typically 2.15 Typically 4.87

TI 25C Typically 2.15 Typically 4.87

TI 30C Typically 2.15 Typically 4.87

TI 80 Typically 5.17 Typically 10.8

Type

CI 6, CI 9, CI 12, CI 15 550 250 200 160 120 60 40 3

CI 9 EI, CI 15 EI 550 250 200 160 120 60 40 3

CI 9 DC, CI 15 DC 550 250 200 160 120 60 40 3

CI 16, CI 20, CI 25, CI 30 1000 700 500 360 240 110 80 6

CI 25 EI, CI 30 EI 1000 700 500 360 240 110 80 6

CI 25 DC, CI 30 DC 1000 700 500 360 240 110 80 6

CI 32 1000 800 580 380 200 100 12

CI 37, CI 45, CI 50 1300 1000 900 580 240 120 12

impedance

pr pole

[mΩ]

Power losses all 3 poles

AC-3

[W]

0.2 1 2 4 10 100 1000

AC-1

[W]

Min. setting

[W]

Current transfer time in sec.

Short time withstand current in Amps (Icw)

Coil

consumption

AC

[W]

Average power

Total power losses

AC-3

[W]

Max. setting

[W]

AC-1v

[W]

Min.

cooling

in min.

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 22

Page 23

Data sheet | Contactors, type CI 6 – CI 50

Connections, auxiliary

contacts

Type Connection method

CB- for CI 6 – CI 50 Screw and clamp washer 0.75 – 2.5 0.75 – 2.5 0.75 – 1.5 1 – 1.5

TI 16C, TI 25C, TI 30C, TI 80 Screw and clamp washer 0.75 – 1.5 0.75 – 1.5 0.5 –1.5 0.3 – 1

Coils, consumption and operating times

Inrush power Holding power Pull-in voltage Drop-out voltage Make time Break time

AC DC AC DC AC DC AC DC AC DC AC DC

Type

CI 6 – CI 30 75 65 9 2.7 (0.85 – 1.1) × U

CI 32 – CI 50 140 80 11 3 (0.85 – 1.1) × U

CI 9DC –

CI 30DC

CI 9 EI – CI

30 EI

VA W W VA W W V V V V ms ms ms ms

65 1.5 0.7-1.33 0.4-0.55 12 – 18 80 – 120

50 65 3.5 mA 2.8 1.5 3.5 mA (0.75 – 1.1) × Us(0.6 – 1.2)× Us(0.4 – 0.55) × Us(0.3 – 0.5) × U

RC Element (charge

suppressor)

Max. load control circuit

(contact system)

Type Comments

RC Suitable for contactors CI 6 – CI 30 1 – 1.5

RCB Suitable for contactors CI 32 – CI 50 1 – 2.0

Type

TI 16C 500 V

TI 30C

TI 80

Single core

[mm2]

s

s

AC-15 DC-13 gI, gL, gG BS 88 type T

2 A

200 VA

500 V

2 A

200 VA

(0.35 – 0.65) × U

(0.35 – 0.65) × U

Load Max fuse

s

s

250 V

2 A

20 W

250 V

2 A

20 W

terminal sleeve

Overvoltage factor

U

n =

Multi core

without

[mm2]

10 – 17 8 – 10

9 – 16 7 – 13

s

4 A 6 ATI 25C

4 A 6 A

with

terminal sleeve

[mm2]

12 – 18 10 – 16

U

Tightening

max

n

torque

[Nm]

UL/CSA specications

UL/CSA approved loads

Motor load (AC-3) [hp] Other loads (AC-1) [A]

Type

CI 6 0.5 1 1.5 2 3 5 16 16 20 20

CI 9 0.5 1.5 2 3 5 7.5 16 16 20 20

CI 12 0.75 2 3 4 7.5 10 20 20 20 20

CI 15 1 3 3 5 10 10 25 25 25 25

CI 16 1 3 5 5 10 15 40 40 40 40

CI 20 1.5 3 5 5 10 15 40 40 40 40

CI 25 2 4 7.5 7.5 15 20 40 40 40 40

CI 30 2 5 10 10 20 20 40 40 40 40

CI 32 3 5 10 10 20 25 70 63 70 63

CI 37 3 7.5 15 15 25 30 80 70 80 70

CI 45 4 7.5 15 15 30 30 80 70 80 70

CI 50 5 10 15 15 30 40 80 70 80 70

1

) 40 °C is dened as non-enclosed installation

60 °C is dened as enclosed installation

Auxiliary contacts,

UL/CSA-approved loads

1-phase 3-phase UL CSA

115 V 230 V 200 V 240 V 460 V 575 V 40 °C 1) 60°C 1) 40 °C 1) 60 °C 1)

Load capacity

Type Comments

Category [VA]

CB- For contactors CI 6..CI 50 A600 720

AC

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 23

Page 24

Data sheet | Contactors, type CI 6 – CI 50

Clip-on timer type ETB

Specication

Contact functions 1-pole contact without galvanic isolation (Triac)

Time ranges 0.5 – 20 s, 4 – 160 s, 0.5 – 20 min.

Voltage range AC 24 – 65 V / 50 – 60 Hz and 110 – 240 V / 50 – 60 Hz

Voltage range DC 24 – 65 V and 110 – 240 V

Voltage tolerance -15 – 10%

Ambient temperature (operation) -10 – 55%

Ambient temperature (storage and transport) -40 – 70 °C

Repeat accuracy ± 2% at constant voltage and temperature

Time for reset (dwell time) Min. 400 ms

Lead cross-section 0.75 – 2.5 mm

Load

Max. load AC lth = 0,5 A AC-15

Min. load AC 15 mA

Max. load DC lth = 0,5 A, I

Min. load DC 5 mA

Consumption

Delayed cut-in AC 65 300

Delayed cut-in AC 240 370

Delayed cut-out AC 65 720

Delayed cut-out AC 240 900

Delayed cut-in AC 65 520

Delayed cut-in AC 240 810

2

Voltage

[V]

= 7 A for 20 ms

max

Power

[mW]

Function description

ON delay

When voltage is applied to terminals 17 and A2,

the set time interval begins. When the set time

elapses, terminal 18 is powered and the contactor

is energised. When voltage to the Clip-on timer is

disconnected, the contactor drops out.

Set time

Supply on and triac made

OFF delay

Voltage is applied to terminals A1 and A2.

When terminal 15 receives voltage, terminal 16

is powered and the contactor is energised.

When terminal 15 is disconnected, the time

interval begins.

When the time interval elapses, the contactor is

de-energised.

If voltage to A1 – A2 is cut o, the contactor

drops out.

Set time

Supply on and triac made

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 24

Page 25

Data sheet | Contactors, type CI 6 – CI 50

Dimensions

Control relays, contactors and motor starters, CI 6, 9, 12, 15

Drilling dimensions

Contactors and motor starters CI 16, 20, 25, 30

Drilling dimensions

CI 6 – CI 30 with mechanical interlock

Drilling dimensions

Contactors and motor starters CI 32, 37, 45, 50

Drilling dimensions

Contactors and motorstarters

CI 9EI, 15EI, 9DC, 15DC

CI 32 – CI 50 with mechanical interlock

Drilling dimensions

Contactors and motor starters

CI 25EI, 30 EI, 25DC, 30DC

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 25

Page 26

Data sheet | Contactors, type CI 6 – CI 50

Dimensions,

Accessories

Auxiliary contact block CB Start contact block CB-S

Electronic clip-on timer ETB Separate mounting of electronic clip-on timer ETB

Electronic clip-on timer ETB Electronic clip-on timer ETB

clipped onto CI 6, 9, 12, 15 clipped onto CI 16, 20, 25, 30

Electronic clip-on timer ETB Separately mounted Interface module IFB on base

clipped onto CI 32, 37, 45, 50

© Danfoss | DCS (az) | 2018.10

RC Element for contactors

CI 6, 9, 12, 15, 16, 20, 25, 30

IC.PD.C10.1G.02 | 26

Page 27

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Dimensions

Thermal overload relays

TI 16C – TI 30C

Dimensions

Thermal overload relays

TI 80

Thermal overload relays for contactors CI 6,

9, 12, 15, 16, 20, 25, 30

Thermal overload relays TI 16C, 25C, 30C

Thermal overload relays for contactors CI 32, 37, 45, 50

Thermal overload relay TI 80

Holder for thermal overload relays TI 16C, 25C, 30C

Thermal overload relay TI 80 on base plate

Enclosures

Plastic enclosure BCI, BCI 1, BCI 2

for contactors CI 6, 9, 12, 15, 16, 20, 25, 30

Flush-mounted metal enclosure CITF 2

for contactors CI 6, 9, 12, 15, 16

© Danfoss | DCS (az) | 2018.10

IC.PD.C10.1G.02 | 27

Loading...

Loading...