Page 1

Installation guide

Danfoss

M148G0010_1

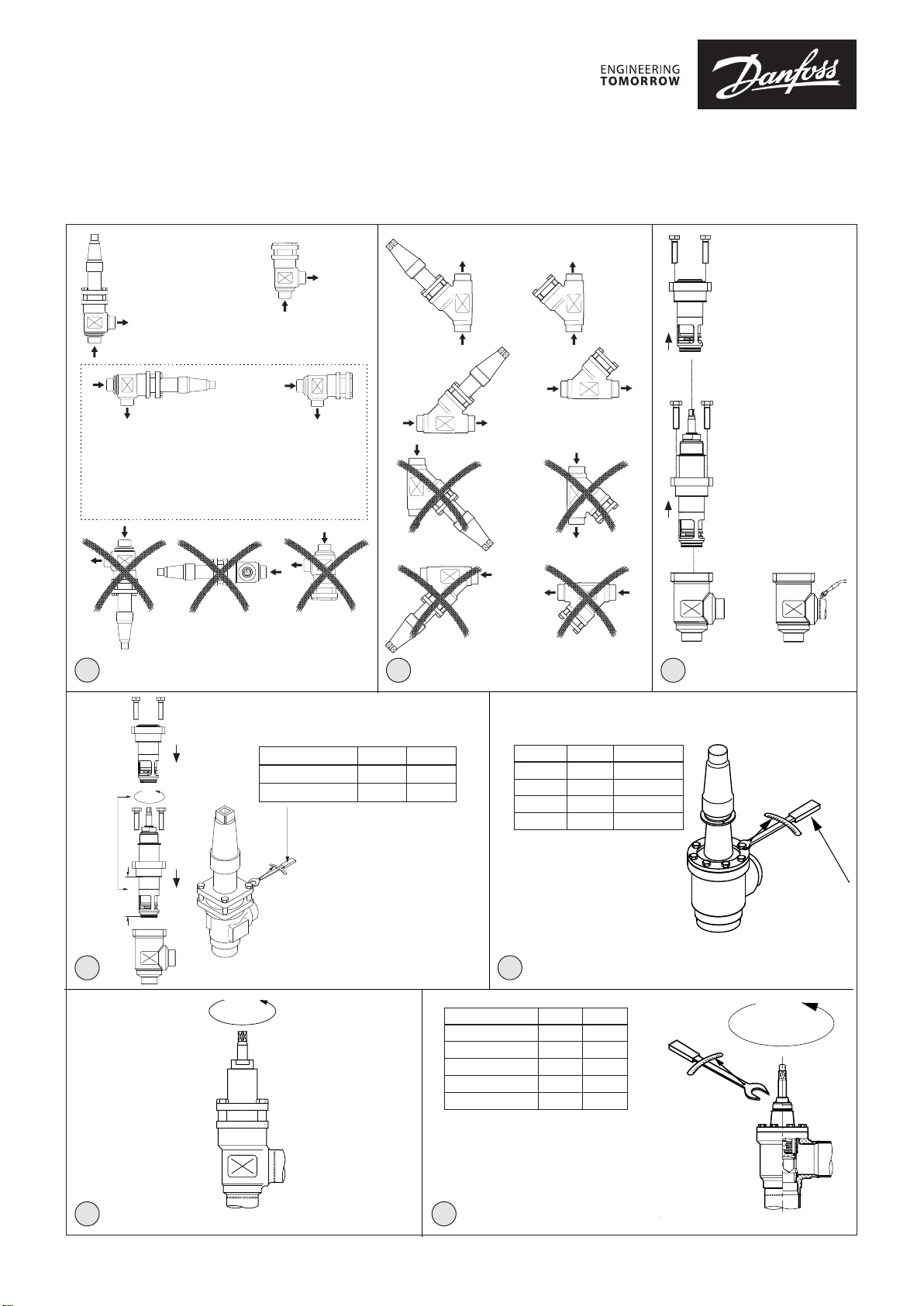

Check & stop valve / Check valves

SCA-X / CHV-X 15-125

148R9550

Only allowed for valve sizes 15-40

Gilt nur für Ventile DN 15 – 40

Permitido somente para tamanhos de válvula 15-40

Sólo permitido para válvulas de tamaños 15-40

Consentito solo per valvole di dimensioni 15-40

阀门尺寸仅限 15-40。

Tylko dla zaworów o wielkościach 15–40

Разрешается только для размеров клапанов 15-40

Permitido apenas para válvulas de tamanho 15-40

1a

148R9550

1b 2

Nm LB-feet

DN 15, 20 21 15

DN 25, 32, 40, 50 44 32

3

DN 15-20 50 37

DN 25-40 75 55

DN 50-65 95 70

DN 80-100 150 111

DN 125 250 184

DN 65 74 54

DN 80 44 32

DN 100 75 53

DN 125 183 135

3a

Nm Lb-feet

Nm LB-feet

4

© Danfoss | DCS (MWA) | 2018.05

4a

DKRCI.PI.FL1.T2.ML | 520H6172 | 1

Page 2

B

C

Danfoss

M148G0012_1

B

B

Danfoss

M148G0011_1

A

Danf

M148G0018_

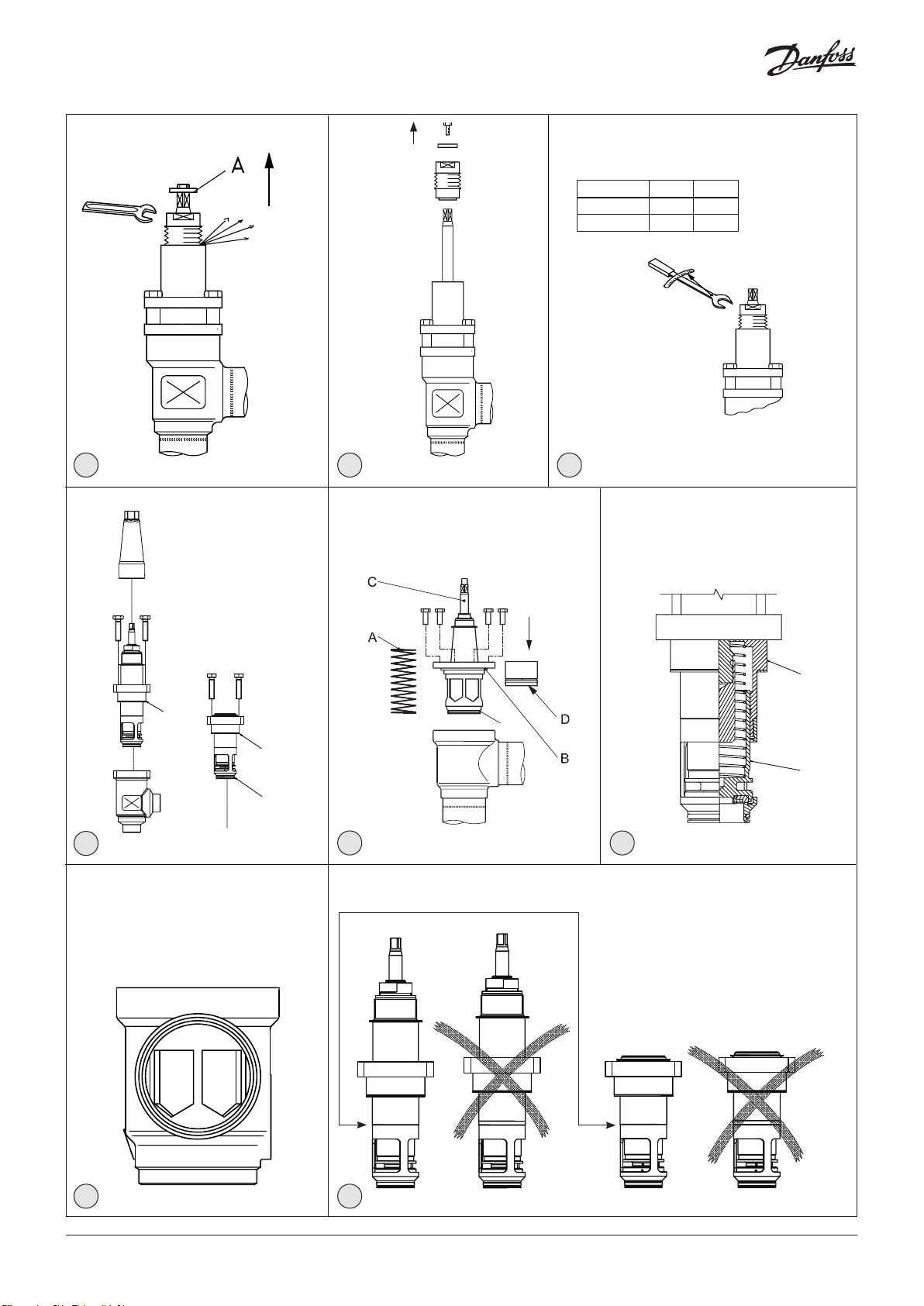

5 6 7

DN 15-40 DN 50-125 DN 15-40

Nm LB-feet

DN 15, 20 50 37

DN 25, 32, 40 75 55

8a

10 11

© Danfoss | DCS (MWA) | 2018.05

E

8b 9

Ensure tight screw connection.

Sicherstellen, dass die Schraubverbindung fest

angezogen sind

Assurez-vous que les vis sont bien serrées.

Garantizar el correcto apriete de las conexiones roscadas.

Assicurarsi che le viti siano ben serrate.

确保螺丝接口紧密.

Upewnić się, że wkręty są dokładnie dokręcone.

Обеспечьте плотное винтовое соединение.

1

oss

DKRCI.PI.FL1.T2.ML | 520H6172 | 2

Page 3

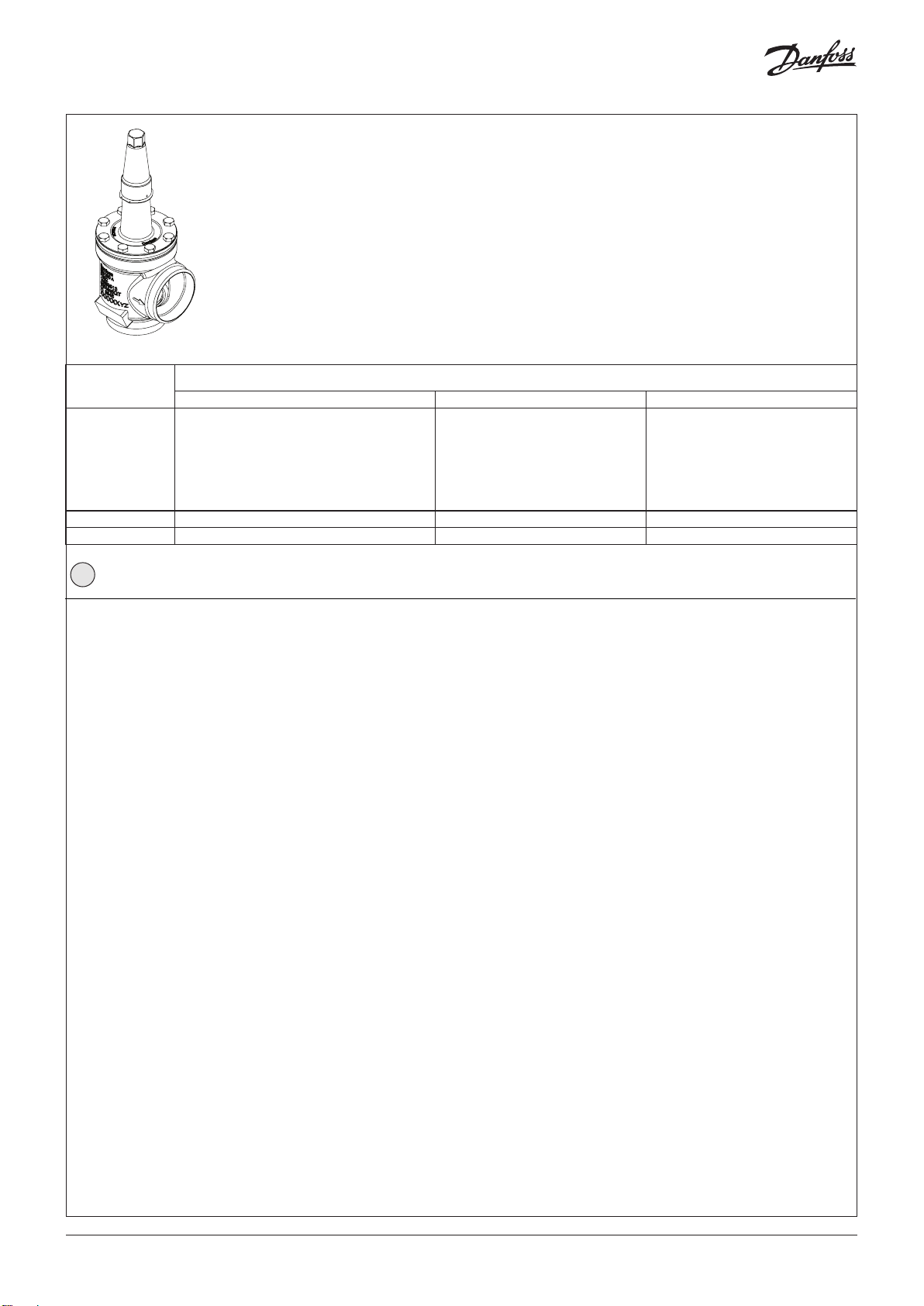

P2

P1

Flow direction Durchflussrichtung Sens du débit Sentido de flujo Direzione del flusso

P1 → P2 P2 → P1 P2 → P1

Valve size [DN]

Ventilgröße [DN]

Taille de vanne [DN]

Tamaño de la válvula [DN]

Dimensioni valvola [DN]

阀门规格 [DN]

Rozmiar zaworu [DN]

Размер клапана [DN]

Tamanho da válvula [DN]

100 44 bar / 638 psi 52 bar / 754 psi 44 bar / 638 psi

125 33 bar / 478 psi 52 bar / 754 psi 33 bar / 478 psi

Closing and opening pressure ΔP max. (P1-P2)

Max. Schließ- und Öffnungsdruck ΔP (P1-P2)

Pression de fermeture et d’ouverture ΔP max. (P1-P2)

ΔP máx. de apertura y cierre (P1-P2)

ΔP max. pressione di apertura e chiusura (P1-P2)

最大关闭与开启压力 ΔP(P1-P2)

Maks. ciśnienie różnicowe otwarcia i zamknięcia ΔP (P1–P2)

Давление закрытия и открытия ΔP макс. (P1-P2)

Pressão de abertura e fechamento ΔP máx. (P1-P2)

流向 Kierunek przepływu Направление потока Direção de fluxo

Closing pressure ΔP max. (P2-P1)

Max. Schließdruck ΔP (P2-P1)

Pression de fermeture ΔP max. (P2-P1)

ΔP máx. de cierre (P2-P1)

ΔP max. pressione di chiusura (P2-P1)

最大关闭压力 ΔP(P2-P1)

Maks. ciśnienie różnicowe zamknięcia ΔP (P2–P1)

Давление закрытия ΔP макс. (P2-P1)

Pressão de fechamento ΔP máx. (P2-P1)

Opening pressure ΔP max. (P2-P1)

Max. Öffnungsdruck ΔP (P2-P1)

Pression d’ouverture ΔP max. (P2-P1)

ΔP máx. de apertura (P2-P1)

ΔP max. pressione di apertura (P2-P1)

最大开启压力 ΔP(P2-P1)

Maks. ciśnienie różnicowe otwarcia ΔP (P2–P1)

Давление открытия ΔP макс. (P2-P1)

Pressão de abertura ΔP máx. (P2-P1)

12

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 3

Page 4

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia),

R744 (CO2), Propane, Butane, Iso-Butane and

Ethane.

The valve is only recommended for use in

closed circuits. For further information please

contact Danfoss.

Temperature range

–60/+150°C (–76/+302°F)

Pressure range

52 bar (754 psi)

The valve must be installed with the spindle

on top vertically upwards or in horizontal

position (fig. 1). SCA-X valves should be

opened by hand without the use of tools

or other devices. The valve is designed to

withstand a high internal pressure. However,

the piping system should be designed

to avoid liquid traps and reduce the risk

of hydraulic pressure caused by thermal

expansion. It must be ensured that the valve

is protected from pressure transients like

“liquid hammer” in the system.

Flow direction

Direct the flow towards the cone as indicated

by an arrow on the valve housing (fig. 1).

Welding

The bonnet should be removed before

welding (fig. 2) to prevent damage to the

O-rings in the packing gland and the gasket

between the valve body and bonnet, as

well as the teflon gasket in the valve seat.

Be careful not to damage the teflon cone

ring and make sure the complete bonnet is

protected from dirt and water while removed.

Only materials and welding methods,

compatible with the valve housing material,

must be applied to the valve housing. The

valve housing must be free from stresses

(external loads) after installation.

The valve should be cleaned internally to

remove welding debris on completion of

welding and before the valve is reassembled.

Avoid welding debris and dirt in the threads

of the housing and the bonnet.

Do NOT remove or service the dark colored

grease between the spindle thread and

the bonnet. In case the grease has been

contaminated with dirt, debris, particles

or water the complete top part must be

replaced.

Stop check valves must not be mounted in

systems where the outlet side of the valve

is open to atmosphere. The outlet side of

the valve must always be connected to the

system or properly capped off, for example

with a welded-on end plate.

Assembly

Remove welding debris and any dirt from

pipes and valve body before assembly. Check

that the cone has been fully screwed back

towards the bonnet before it is repositioned

in the valve body (SCA DN 50-125) (fig. 3).

Important for the SCA-X valves:

Full capacity is only obtained when the

spindle is screwed outward, “into bonnet”, i.e.

counterclockwise (fig. 3).

Tightening

Tighten the bonnet with a torque wrench, to

the values indicated in the table (fig. 3).

Please note that the table (fig. 3) containing

maximum torque must be adhered to and

never exceeded.

Important for SCA-X/CHV-X 50 - 125 valves:

For optimal flow the insert must be installed

as indicated in (fig. 10). Otherwise kv value

will be below indicated in the

technical brochure.

Colours and identification

The SCA-X and CHV-X valves are painted

with a red primer in the factory. Precise

identification of the valve is made via the

green coloured ID ring at the top of the

bonnet, as well as by the stamping on the

valve body. The external surface of the valve

housing must be protected against corrosion

with a suitable protective coating after

installation and assembly.

Protection of the name plate when repainting

the valve is recommended.

Maintenance

Packing gland (only SCA-X types)

When performing service and maintenance,

replace the complete packing gland only,

which is available as a spare part. As a

general rule, the packing gland must not be

removed if there is internal pressure in the

valve. However, if the following precautionary

measures are taken, the packing gland can be

removed with the valve still under pressure:

Backseating (fig. 4)

To backseat the valve, turn the spindle

counterclockwise until the valve is fully open.

Pressure equalization (fig. 5)

In some cases, pressure forms behind the

packing gland. Hence, a handwheel or a large

washer (pos. A) should be fastened on top of

the spindle while the pressure is equalized.

The pressure can be equalized by slowly

screwing out the gland.

Removal of packing gland (fig. 6)

Packing gland can now be removed.

Dismantling the valve (fig. 8)

Do not remove the bonnet while the valve is

still under pressure.

DN 15-40 (fig. 8a):

- Check that the gasket (pos. A+B) has not

been damaged.

- If the gasket (pos. A) has been exposed

to air or other refrigerants than listed in

this installation guide for more than

6 months it must be replaced.

- Check that the spindle is free of scratches

and impact marks.

- If the teflon cone ring has been damaged,

the whole cone assembly must be

replaced.

DN 50-125 (fig. 8b):

- Check that the spring (pos. A) is intact.

- Check that the gasket (pos. B+E) has not

been damaged.

- If the gasket (pos. A) has been exposed

to air or other refrigerants than listed in

this installation guide for more than

6 months it must be replaced.

- Check that the spindle (pos. C) is free of

scratches and impact marks.

- If the teflon cone ring (pos. D) has been

damaged, the whole cone assembly must

be replaced.

Replacement of the cone (fig. 9)

DN 15-40:

O-ring (pos. C) prevents the cone from falling

out. Pull the cone clear of the bonnet. Ensure

that the spring is not lost in the process.

Remove dirt, if any. Mount O-ring (pos. C) on

cone. Mount spring and cone in bonnet.

Do NOT remove or service the dark colored

grease between the spindle thread and

the bonnet. In case the grease has been

contaminated with dirt, debris, particles

or water the complete top part must be

replaced.

Assembly

Remove dirt, if any, from pipes and housing

before assembly. Important for the SCA-X

valves: Full capacity is only obtained when

the spindle is screwed outward, “into the

bonnet”, i.e. counterclockwise (fig. 3).

Note:

For SCA-X and CHV-X sizes DN 15-40 it

is important to ensure that the lower

and upper part of the insert is tightly

screwed together (fig. 11) and that this

screw connection is kept tight during

repositioning of the cone in the housing.

Use a to

rque wrench to tighten the bonnet

(fig. 3).

Tightening

Tighten the bonnet with a torque wrench,

to the values indicated in the table (fig. 3).

Tighten the packing gland with a torque

wrench, to the values indicated in the table

(fig. 7).

Use only original Danfoss parts, (including

packing glands and gaskets) for replacement.

Materials of new parts are certified for the

relevant refrigerant.

In cases of doubt, please contact your local

Danfoss sales office.

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 4

Page 5

DEUTSCH

Installation

Refrigerants

Anwendbar für HFCKW, HFKW, R717

(Ammoniak), R744 (CO2), Propan, Butan, IsoButan und Ethan.

Das Ventil ist nur für die Verwendung in

geschlossenen Kreisläufen empfohlen. Für

weitere Informationen wenden Sie sich bitte

an Danfoss.

Temperaturbereich

–60/+150°C (–76/+302°F)

Druckbereich

Die Ventile sind für einen max. Betriebsdruck

von 52 bar (754 psi) ausgelegt.

Das Ventil muss mit der Spindel senkrecht

nach oben (Abb. 1) eingebaut werden.

SCA-X sollten per Hand ohne Werkzeug oder

andere Vorrichtungen geöffnet werden.

Das Ventil ist für einen hohen Innendruck

ausgelegt. Das Verrohrungssystem

sollte jedoch ausgelegt sein, um

Flüssigkeitseinschlüsse zu verhindern und

das Risiko von Hydraulikdruck, verursacht

durch Wärmeausdehnung, zu senken. Es

muss sichergestellt werden, dass das Ventil

vor Druckstößen wie Flüssigkeitsschlag im

System geschützt ist.

Durchflussrichtung

Die Ventile müssen mit dem Durchfluss zum

Kegel in Pfeilrichtung auf dem Ventilgehäuse

eingebaut werden (Abb. 1).

Schweißen

Das Oberteil sollte vor dem Schweißen

entfernt werden (Abb. 2), um eine

Beschädigung der O-Ringe in der

Stopfbuchse und der Dichtung zwischen dem

Ventilkörper und dem Oberteil sowie der

Teflondichtung im Ventilsitz zu vermeiden.

Achten Sie darauf, den Teflon-Konusring

nicht zu beschädigen, und stellen Sie sicher,

dass das komplette demontierte Oberteil vor

Schmutz und Wasser geschützt ist.

Es dürfen nur Materialien und

Schweißmethoden verwendet werden,

die mit dem Material des Ventilgehäuses

kompatibel sind. Das Ventilgehäuse muss

nach der Installation frei von externen

Spannungen sein (keine äußeren Lasten).

Reinigen Sie das Ventil vor dem erneuten

Zusammenbauen von innen, um evtl.

Schweißrückstände zu entfernen. Vermeiden

Sie Schweißrückstände und Schmutz in den

Gewindebohrungen des Gehäuses und des

Oberteils.

Das dunkle Schmierfett zwischen dem

Spindelgewinde und dem Ventiloberteil darf

NICHT entfernt oder gewartet werden. Falls

das Schmierfett durch Schmutz, Rückstände,

Partikel oder Wasser verunreinigt wurde,

muss das Oberteil vollständig ausgetauscht

werden.

Absperrrückschlagventile dürfen nicht in

Systemen verwendet werden, bei denen

die Austrittsseite des Ventils nach außen hin

offen ist. Die Austrittsseite des Ventils muss

immer an die Anlage angeschlossen oder

ordnungsgemäß abgedeckt sein, z. B. mit

einer angeschweißten Endplatte.

Zusammenbau

Vor dem Zusammenbau Schweißüberreste

und Schmutz von Rohrleitungen und

Ventilgehäuse entfernen. Sicherstellen,

dass der Kegel vollständig zum Ventildeckel

hin zurückgeschraubt wurde, bevor er im

Ventilgehäuse eingesetzt wird (Abb. 3).

Wichtiger Hinweis für die SCA-X Ventile:

Volle Kapazität wird nur erreicht, wenn die

Spindel nach außen „in den Deckel“, d.h.

gegen den Uhrzeigersinn geschraubt ist (Abb.

3).

Anziehen

Den Ventildeckel mit einem

Drehmomentschlüssel anziehen (Werte bitter

in der Tabelle 3 entnehmen.

Bitte beachten, dass es sich hierbei um

Maximalwerte handelt, die niemals

überschritten werden dürfen.

Farben und Kennzeichnungen

Die SCA-X und CHV-X Ventile werden ab

Werk mit Rotoxid grundiert. Eindeutige

Kennzeichnung des Ventils erfolgt über

den Kennring oben am Ventildeckel

sowie die Prägung am Ventilgehäuse. Die

Außenfläche des Ventilgehäuses muss nach

dem Einbau und dem Zusammenbau mit

einer geeigneten Schutzbeschichtung gegen

Korrosion geschützt werden.

Beim Neulackieren des Ventils wird der Schutz

des Kennschilds empfohlen

Wartung

Stopfbuchse (nur SCA-X)

Bei Service- und Wartungsarbeiten ist

immer nur die komplette Stopfbuchse

auszutauschen, die als Ersatzteil erhältlich

ist. Grundsätzlich darf die Stopfbuchse

nur bei drucklosem Ventil entfernt

werden. Unter Berücksichtigung folgender

Vorsichtsmaßnahmen kann die Stopfbuchse

jedoch auch von einem unter Druck

stehenden Ventil entfernt werden:

Rücksitzdichtung (Abb. 4)

Zur Aktivierung der Rücksitzdichtung des

Ventils, die Spindel gegen den Uhrzeigersinn

drehen bis das Ventil völlig offen ist.

Druckausgleich (Abb. 5)

Unter Umständen entsteht Druck hinter

der Stopfbuchse. Daher sollte, während der

Druck ausgeglichen wird, am Spindelkopf ein

Handrad oder Ähnliches befestigt sein.

Der Druck lässt sich dann durch langsames

Herausdrehen der Stopfbuchse ausgleichen.

Ausbau der Stopfbuchse (Abb. 6)

Die Kappe und Stopfbuchse können jetzt

entfernt werden.

Zerlegen des Ventils (Abb. 8)

Den Ventildeckel nicht entfernen, während

das Ventil noch unter Druck steht.

DN 15 – 40 (Abb. 8a)

- Sicherstellen, dass der O-Ring (Pos. A+B)

nicht beschädigt wurde.

- Wenn die Dichtung (Pos. A) länger als

sechs Monate der Luft oder Kältemitteln,

die nicht in dieser Installationsanleitung

aufgelistet sind, ausgesetzt war, muss sie

ausgetauscht werden.

- Sicherstellen, dass die Spindel (Pos. C)

frei von Kratzern und Stoßspuren ist.

- Ist der Teflonring am Kegel

beschädigt, ist die gesamte Kegeleinheit

auszutauschen.

DN 50 – 125 (Abb. 8b)

- Sicherstellen, dass die Feder (Pos. A)

intakt ist.

- Sicherstellen, dass der O-Ring (Pos. B+E)

nicht beschädigt wurde.

- Wenn die Dichtung (Pos. A) länger als

sechs Monate der Luft oder Kältemitteln,

die nicht in dieser Installationsanleitung

aufgelistet sind, ausgesetzt war, muss sie

ausgetauscht werden.

- Sicherstellen, dass die Spindel (Pos. C)

frei von Kratzern und Stoßspuren ist.

- Ist der Teflonring am Kegel (Pos. D)

beschädigt, ist die gesamte Kegeleinheit

auszutauschen.

Ersatz des Kegel (Abb. 9)

DN 15-40:

O-Ring (Pos. C) verhindert das Herausfallen

des Kegels. Ziehen Sie den Kegel von der

Ventiloberteil ab. Stellen Sie sicher, dass die

Feder dabei nicht verloren geht. Entfernen Sie

eventuell vorhandenen Schmutz. O-Ring (Pos.

C) auf Kegel montieren. Feder und Kegel in

Ventiloberteil montieren.

Das dunkle Schmierfett zwischen dem

Spindelgewinde und dem Ventiloberteil darf

NICHT entfernt oder gewartet werden. Falls

das Schmierfett durch Schmutz, Rückstände,

Partikel oder Wasser verunreinigt wurde,

muss das Oberteil vollständig ausgetauscht

werden.

Zusammenbau

Schmutz, falls vorhanden, vor dem

Zusammenbau von Rohrleitungen und

Gehäuse entfernen. Wichtiger Hinweis für

die SCA-X Ventile: Volle Kapazität wird nur

erreicht, wenn die Spindel nach außen „in

den Deckel“, d. h. gegen den Uhrzeigersinn

geschraubt ist (Abb. 3).

Hinweis

Für SCA-X und CVH-X 15-40 ist es wichtig

sicherzustellen, dass das Oberteil fest mit

dem Unterteil verschraubt ist (Abb. 11)

und das diese Schraubverbindung beim

Wiedereinsetzen des Konus in das Gehäuse

fest verschraubt bleiben.

Den Ventildeckel mit einem

Drehmomentschlüssel anziehen (Abb. 3).

Festspannen

Den Ventildeckel mit einem

Drehmomentschlüssel festspannen,

für diesbezügliche Werte siehe Tabelle

(Abb. 3). Die Stopfbuchse mit einem

Drehmomentschlüssel festspannen, für

diesbezügliche Werte siehe Tabelle (Abb. 7).

Zum Austausch nur Originalteile von Danfoss,

einschließlich Stopfbuchsen, O-Ringe und

Dichtungen, benutzen. Die Werkstoffe

von Neuteilen sind für das betreffende

Kältemittel zertifiziert.

Im Zweifelsfall bitte mit Danfoss Kontakt

aufnehmen.

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 5

Page 6

FRANÇAIS

Installation

Fluides frigorigènes

Applicable aux fluides frigorigènes HCFC,

HFC, R717 (ammoniac), R744 (CO2), propane,

butane, isobutane et éthane.

Cette vanne est préconisée uniquement pour

les circuits fermés.

Pour plus d'informations, contactez Danfoss.

Plage de températures

-60/+150 °C

Plage de pressions

*52 bar

Installez la vanne de sorte que la tige se

trouve en position verticale ou horizontale

(fig. 1). Les vannes SCA-X doivent être

ouvertes

outils

conçues pour résister à une pression interne

élevée. Toutefois, il convient de concevoir le

circuit de façon à

réduire les risques de formation d’une

pression hydraulique sous l’effet de la

dilatation thermique. Veillez à ce que la vanne

soit protégée des variations de pression au

sein du circuit comme les « coups de bélier ».

Sens du débit

Dirigez le débit en direction du cône comme

indiqué par la flèche sur le corps de la vanne

(fig. 1).

Soudure

La partie interne doit être retirée avant le

soudage (fig. 2) afin de ne pas endommager

les joints toriques du presse étoupe, et le

joint entre le corps de vanne et la partie

supérieure, ainsi que le joint en téflon

du siège de la vanne. Veiller à ne pas

endommager la bague en téflon du cône.

Vérifier que la partie interne une fois retirée

est à l’abri de la saleté et de l’eau.

Seuls des matériaux et des méthodes de

soudage compatibles avec le matériau du

corps de la vanne, peuvent être soudés et

appliqués au corps de la vanne. Aucune

contrainte (charges externes) ne doit être

exercée sur le boîtier de la vanne après

l’installation.

L’intérieur de la vanne doit être nettoyé pour

éliminer les débris de soudage une fois le

soudage effectué et avant le montage de la

vanne. Éviter que des débris de soudage et

des salissures ne pénètrent dans les filetages

du boîtier et le capuchon.

Ne PAS enlever ou nettoyer l’excédent de

graisse foncée entre le filetage de la tige et

la partie interne. En cas de contamination

de la graisse par de la saleté, des débris, des

particules ou de l’eau, la partie supérieure

doit être entièrement remplacée.

Les clapets anti-retour ne doivent en aucun

cas être montés dans des systèmes où la

sortie de la vanne est exposée à l’air. Le côté

sortie de la vanne doit toujours être raccordé

au système ou correctement couvert, par

exemple à l’aide d’un embout soudé.

Montage

Retirez les résidus de soudure et les impuretés

des conduites et du corps de vanne avant de

procéder au montage. Vérifiez que le cône a

été entièrement revissé à l’arrière du

manuellement sans recourir à des

ou d’autres matériels. Ces vannes sont

éviter les pièges à liquide et

capuchon avant de le replacer dans le corps

de la vanne (SCA DN 50-125)

Informations importantes concernant les

vannes SCA-X :

La pleine capacité est obtenue uniquement

lorsque la tige est vissée vers l’extérieur

le capuchon », c'est-à-dire dans le sens

des aiguilles d'une montre (fig. 3).

Serrage

Serrez le capuchon à l’aide d’une clé

dynamométrique, conformément aux valeurs

indiquées dans le tableau (fig. 3).

Veuillez noter que la valeur de couple

maximale contenue dans le tableau (fig. 3)

doit être respectée et ne doit en aucun cas

être dépassée.

Informations importantes concernant les

vannes SCA-X/CHV-X 50 - 125 :

Pour un débit optimal, l’insert doit être installé

comme indiqué sur la fig. 10. Dans le cas

contraire, la valeur kv sera indiquée plus bas

dans la brochure technique.

Couleurs et identification

Les vannes SCA-X et CHV-X sont recouvertes en

usine

d’une couche de couleur primaire

rouge. La vanne peut être précisément

identifiée à l’aide de la bague d’identification

de couleur verte, située au sommet du

capuchon, ainsi que par un estampillage sur

le corps de la vanne.

La surface extérieure du corps de la vanne

doit être protégée de la corrosion à l’aide

revêtement adéquat appliqué après

l’installation et le montage.

Il est recommandé de protéger la plaque

signalétique lors de l’application de la

peinture sur la vanne.

(fig. 3).

« dans

inverse

d’un

Maintenance

Presse-étoupe (uniquement pour les

types SCA-X)

Lors des opérations de service et de

maintenance, remplacez uniquement le

presse-

étoupe complet, disponible en pièce

détachée.

ne doit pas être retiré lorsque la vanne est

sous pression. Toutefois, si les

précaution suivantes sont prises, il est possible

de remplacer le presse-étoupe pendant que la

vanne

Contre-siège (fig. 4)

Pour ouvrir la vanne, effectuez une rotation

de la tige dans le sens inverse des aiguilles

d'une montre jusqu'à ouverture complète de

la vanne.

Égalisation de la pression (fig. 5)

Dans certains cas, une pression se forme

derrière le presse-étoupe. C’est pourquoi un

volant de manœuvre ou un dispositif similaire

(pos. A) doit être fixé au sommet de la tige

pendant l’égalisation

pression peut être

progressivement le presse-étoupe.

Dépose du presse-étoupe (fig. 6)

Le presse-étoupe peut maintenant être retiré.

Démontage de la vanne (fig. 8)

Ne jamais retirer le capuchon si la vanne est

encore

En règle générale, le presse-étoupe

mesures de

est sous pression :

de la pression. La

égalisée en

sous pression.

dévissant

DN 15-40 (fig. 8a) :

- Vérifiez que le joint d'étanchéité (pos. A+B)

n'a pas été endommagé.

- Si le joint d’étanchéité (pos. A) est resté

à l’air libre ou s’il a été exposé à d’autres

fluides frigorigènes que ceux mentionnés

dans ce guide d’installation pendant plus

de 6 mois, il doit être remplacé.

- Vérifiez que la tige est exempte de rayures

de traces d’impacts.

- Si la bague du cône en téflon a été

endommagée, remplacez le cône entier.

DN 50-125 (fig. 8b) :

- Vérifiez que le ressort (pos. A) est intact.

- Vérifiez que le joint d'étanchéité (pos. B+E)

n'a pas été endommagé.

- Si le joint d’étanchéité (pos. A) est resté

à l’air libre ou s’il a été exposé à d’autres

fluides frigorigènes que ceux mentionnés

dans ce guide d’installation pendant plus

de 6 mois, il doit être remplacé.

- Vérifiez que la tige (pos. C) est exempte de

rayures et de marques d'impacts.

- Si la bague du cône en téflon (pos. D) a

endommagée, le cône entier doit être

remplacé.

Remplacement du cône (fig. 9)

DN 15-40

Le joint torique (pos. C) évite au cône de

tomber. Dégagez le cône du capuchon. Veillez

à

ne pas perdre le ressort au cours du processus.

Éliminez les impuretés si besoin. Montez le

joint torique (pos. C) sur le cône. Montez le

ressort et le cône dans le capot.

Ne PAS enlever ou nettoyer l’excédent de

graisse foncée entre le filetage de la tige et

la partie interne. En cas de contamination

de la graisse par de la saleté, des débris, des

particules ou de l’eau, la partie supérieure

doit être entièrement remplacée.

Montage

Avant le montage, retirez si besoin les

impuretés des tuyauteries et du corps.

Information importante concernant les

vannes SCA-X : la pleine capacité est

uniquement obtenue lorsque la tige est

vissée vers l’extérieur « dans le capuchon »,

c'est-à-dire dans le sens inverse des aiguilles

d’une montre (fig. 3).

Remarque :

dans le cas des vannes SCA-X et CHV-X,

tailles DN 15-40, il est important de vous

assurer que les parties inférieure et

supérieure de l’insert sont correctement

vissées ensemble (fig. 11) et que leur

raccord est fermement maintenu lors du

repositionnement du cône dans le corps.

Utilisez une clé dynamométrique pour serrer

le capuchon (fig. 3).

Serrage

Serrez le capuchon à l’aide d’une clé

dynamométrique, conformément aux valeurs

indiquées dans le tableau (fig. 3). Serrez le

presse-étoupe à l’aide d’une clé

dynamométrique, conformément aux valeurs

indiquées dans le tableau (fig. 7).

N’utilisez que des composants Danfoss

d’origine, en particulier pour tout

remplacement du presse-étoupe ou des joints

d’étanchéité. Les matériaux des nouveaux

composants sont homologués

frigorigène utilisé.

En cas de doute, veuillez prendre contact avec

Danfoss.

pour le fluide

et

été

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 6

Page 7

ESPAÑOL

Instalación

Refrigerantes

Aptas para HCFC, HFC, R-717 (amoníaco),

R-744 (CO2), propano, butano, isobutano y etano.

Se recomienda limitar el uso de estas válvulas a

circuitos cerrados. Si desea obten er más

información, póngase en contacto con Danfoss

Rango de temperatura

De –60 a +150 °C (de –76 a +302 °F).

Rango de presión

52 bar (754 psi).

La válvula debe instalarse de forma que el eje

quede en posición vertical y orientado hacia

arriba o en posición horizontal (consulte la fig. 1)

Las válvulas SCA-X deben abrirse manualmente,

sin hacer uso de herramientas u otros

dispositivos. Son válvulas diseñadas para

soportar

Sin embargo, el sistema de tuberías debe

diseñarse de tal forma que se eviten las

acumulaciones de líquido y se reduzca el riesgo

asociado a la presión

expansión térmica. Debe garantizarse que

la válvula se encuentre protegida frente a los

fenómenos transitorios

puedan producirse en el sistema (por ejemplo, el

fenómeno conocido como “golpe de ariete”).

Dirección del caudal

El caudal debe dirigirse hacia el cono, de acuerdo

con lo indicado por la flecha de

válvula (consulte la fig. 1).

Soldadura

La parte superior de la válvula debe

desmontarse antes de realizar la soldadura (fig.

2) con el fin de evitar que se produzcan daños en

las juntas tóricas del prensaestopas y en la junta

situada entre el cuerpo y la parte superior de la

válvula, así como en la junta de teflón del asiento

de la válvula. Tenga cuidado de no dañar el anillo

cónico de teflón y asegúrese de proteger toda

la parte superior de la válvula de la suciedad y el

agua al extraerla.

Los materiales y métodos de soldadura aplicados

al cuerpo de la válvula deberán ser compatibles

con el material de este. El cuerpo de la válvula

no debe someterse a tensiones (cargas externas)

tras su instalación.

Al finalizar la soldadura y antes de volver a

montar la válvula, deberá limpiarse el interior

de esta para eliminar los restos de soldadura. No

deben quedar restos de materiales de soldadura

ni suciedad en las roscas del cuerpo y la parte

superior de la válvula.

NO elimine ni sustituya la grasa de color oscuro

que se encuentra entre el eje roscado y la parte

superior de la válvula. Si la grasa se contamina

con suciedad, residuos, partículas o agua, deberá

sustituirse toda la parte superior.

No deberán montarse válvulas de cierre y

retención en sistemas en los que el lado de

salida de la válvula quede abierto a la atmósfera.

El lado de salida de la válvula siempre debe

conectarse al sistema o cerrarse debidamente

(por ejemplo, soldando una placa).

Montaje

Elimine los restos de materiales de soldadura

y la suciedad de las tuberías y el cuerpo de

la válvula antes de proceder a su montaje.

Compruebe que el cono se encuentre

completamente enroscado en el casquillo antes

de volver a acoplarlo al cuerpo de la válvula (SCA

DN 50-125) (consulte la fig. 3).

una presión

interna elevada.

hidráulica generada por la

asociados a la presión

la carcasa de la

.

.

que

Nota importante en relación con las válvulas

SCA-X:

Únicamente puede alcanzarse la capacidad

máxima si el eje se enrosca hacia fuera (esto es,

hacia el casquillo), es decir, en sentido

antihorario (consulte la fig. 3).

Apriete

Apriete el casquillo empleando una llave

dinamométrica y aplicando los valores de

par de apriete especificados en la tabla (consulte

la fig. 3).

Tenga en cuenta que deben respetarse los

valores de par de apriete máximos indicados en la

tabla (consulte la fig. 3), sin superarlos en

ningún caso.

Nota importante en relación con las válvulas

SCA-X y CHV-X de tamaños DN 50-125:

Para conseguir un caudal óptimo, la pieza debe

instalarse según se indica en la fig. 10. De lo

contrario, el valor kv será inferior al indicado en

el folleto técnico.

Colores e identificación

Las válvulas SCA-X y CHV-X reciben una

imprimación de color rojo durante su

fabricación. La identificación precisa de dichas

válvulas se lleva a cabo por medio de un anillo

característico de color verde situado en la parte

superior del casquillo, así como de la

estampación del cuerpo de

La superficie externa de la carcasa de las válvulas

debe protegerse frente a la corrosión aplicando

recubrimiento protector adecuado tras su

instalación y montaje.

Se recomienda proteger la placa de

características antes de pintar la válvula.

las válvulas.

un

Mantenimiento

Prensaestopas (sólo para válvulas SCA-X)

Sólo es preciso sustituir el conjunto del

prensaestopas como parte de las operaciones

servicio y mantenimiento; este elemento se

encuentra disponible como pieza de repuesto.

Como norma general, el prensaestopas no debe

desmontarse si el interior de la válvula se

encuentra

las

puede desmontarse aunque

la válvula se encuentre presurizada:

Sellado interno (consulte la fig. 4)

Para sellar internamente la válvula, gire el eje en

sentido antihorario hasta que la válvula quede

completamente abierta.

Igualación de presión (consulte la fig. 5)

En algunos casos, puede producirse una

acumulación de presión tras el prensaestopas

Debido a ello, debe acoplarse un volante o una

arandela grande a la parte superior del eje (pos.

A) mientras la presión se iguala.

La presión puede igualarse desenroscando

lentamente el prensaestopas.

Desmontaje del prensaestopas (consulte la

fig. 6)

Una vez llevados a cabo los pasos anteriores,

puede desmontarse el prensaestopas.

Desensamblaje de la válvula (consulte la

fig. 8)

No desmonte el casquillo mientras la válvula se

encuentre presurizada.

DN 15-40 (consulte la fig. 8a):

- Compruebe que la junta (pos. A+B) no

- Si la junta (pos. A) ha estado expuesta

presurizado. No obstante, si se adoptan

precauciones

presente daños.

al aire o a refrigerantes no indicados

en esta guía de instalación durante más de

seis meses, deberá sustituirla.

siguientes, el

prensaestopas

de

.

- Compruebe que el eje no presente arañazos

marcas de golpes por impacto.

- Si el anillo de teflón del cono ha sufrido daños,

deberá sustituir el conjunto del cono.

DN 50-125 (consulte la fig. 8b):

- Compruebe que el muelle (pos. A) esté

intacto.

- Compruebe que la junta (pos. B+E) no

presente daños.

- Si la junta (pos. A) ha estado expuesta

al aire o a refrigerantes no indicados

en esta guía de instalación durante más de

seis meses, deberá sustituirla.

- Compruebe que el eje (pos. C) no presente

arañazos ni marcas de golpes por impacto.

- Si el anillo de teflón del cono (pos. D) ha

sufrido daños, deberá sustituir el conjunto

cono.

Sustitución del cono (consulte la fig. 9)

DN 15-40:

La junta tórica (pos. C) impide que el cono pueda

desprenderse. Tire del cono hasta separarlo del

casquillo. Compruebe que el

separado durante el proceso. Limpie la suciedad

que pueda existir. Monte la junta tórica (pos. C) en

el cono. Monte el muelle y el cono en el

casquillo.

NO elimine ni sustituya la grasa de color oscuro

que se encuentra entre el eje roscado y la parte

superior de la válvula. Si la grasa se contamina

con suciedad, residuos, partículas o agua, deberá

sustituirse toda la parte superior.

Montaje

Antes de proceder a realizar el montaje, limpie la

suciedad que pueda existir en las tuberías

y la carcasa. Nota importante en relación con

válvulas SCA-X: Únicamente puede alcanzarse

capacidad máxima si el eje se enrosca hacia

fuera (esto es, hacia el casquillo), es decir,

en sentido antihorario (consulte la fig. 3).

Nota:

Para válvulas SCA-X y CHV-X de tamaños DN

15-40, es importante garantizar que las

partes inferior y superior del módulo queden

bien sujetas al enroscarlas (consulte la fig. 11)

y que la conexión roscada se mantenga

apretada al volver a instalar el cono en la

carcasa.

Emplee una llave dinamométrica para apretar el

casquillo (consulte la fig. 3).

Apriete

Apriete el casquillo empleando una llave

dinamométrica y aplicando los valores de par de

apriete especificados en la tabla (consulte la fig.

3). Apriete el prensaestopas empleando una

llave dinamométrica y aplicando los valores de

par de apriete especificados en la tabla (consulte

la fig. 7).

Use únicamente piezas de repuesto originales

fabricadas por Danfoss (incluidos los

prensaestopas y las juntas). Los materiales con

los que se fabrican las piezas de repuesto

poseen las homologaciones pertinentes para el

refrigerante correspondiente.

En caso de duda, póngase en contacto con su

distribuidor local de Danfoss.

muelle no se ha

ni

del

las

la

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 7

Page 8

ITALIANO

Installazione

Refrigeranti

Applicabile a HCFC, HFC, R717 (ammoniaca),

R744 (CO2), propano, butano, isobutano ed

etano.

La valvola è raccomandata solo per l'utilizzo in

circuiti chiusi. Per ulteriori informazioni,

contattare Danfoss.

Campo temperatura

–60/+150°C (–76/+302°F)

Campo di pressione

52 bar (754 psi)

La valvola deve essere installata con lo stelo

sulla parte superiore, rivolto verticalmente

verso l'alto o in posizione orizzontale (fig. 1). Le

valvole SCA-X devono essere aperte

manualmente senza l'ausilio di attrezzi o altri

dispositivi. La valvola è progettata per

tollerare pressioni interne estremamente

elevate. Tuttavia, il sistema di tubazioni deve

essere progettato per prevenire trappole di

liquido e ridurre il rischio di una pressione

idraulica causata dall'espansione termica.

È necessario assicurarsi che la valvola sia

protetta da transitori di pressione come

i "colpi d'ariete".

Direzione del flusso

Dirigere il flusso verso il cono, come indicato

dalla freccia sull'involucro della valvola (fig. 1).

Saldatura

Il coperchio deve essere rimosso prima della

saldatura (fig. 2) per prevenire danni agli

o-ring nel premistoppa, alla guarnizione

fra il corpo valvola e il coperchio e alla

guarnizione in teflon nella sede della valvola.

Fare attenzione a non danneggiare l’anello in

teflon del cono e assicurarsi che il coperchio

sia protetto per intero da sporcizia e acqua in

fase di rimozione.

Solo materiali e metodi di saldatura

compatibili con il materiale dell’involucro

della valvola devono essere applicati

all’involucro della valvola. L’involucro della

valvola deve essere esente da sollecitazioni

(carichi esterni) dopo l’installazione.

La valvola deve essere pulita internamente

per rimuovere i detriti della saldatura al

completamento dell’operazione e prima che

la valvola sia rimontata. Evitare che detriti

di saldatura e sporcizia si depositino nelle

filettature dell’involucro e del coperchio.

NON rimuovere né intervenire sul grasso

scuro tra la filettatura dell’asta e il coperchio.

Nel caso in cui il grasso sia stato contaminato

da sporco, detriti, particelle o acqua, è

necessario sostituire interamente la parte

superiore.

Valvole di intercettazione/ritegno non

devono essere montate in impianti in

cui il lato uscita della valvola sia esposto

all’atmosfera. Il lato uscita della valvola

deve sempre essere collegato all’impianto o

correttamente bloccato, ad esempio saldando

una piastra terminale.

Montaggio

Rimuovere i residui di saldatura e lo sporco dai

tubi e dal corpo valvola prima del montaggio.

Verificare che il cono sia stato completamente

avvitato in direzione del coperchio prima che

venga riposizionato nel corpo valvola

50-125) (fig. 3).

Importante per le valvole SCA-X:

È possibile ottenere una capacità piena solo

quando lo stelo è avvitato verso l'esterno,

coperchio", vale a dire in senso antiorario

3).

Serraggio

Serrare il coperchio con una chiave

dinamometrica, ai valori indicati nella tabella

(fig. 3).

Notare che è sempre necessario rispettare le

coppie massime riportate nella tabella (fig. 3);

le coppie massime non devono essere mai

superate.

Importante per le valvole SCA-X/CHV-X 50 125:

Per una portata ottimale, l'inserto deve essere

installato come indicato nella (fig. 10). In caso

contrario, il valore kv sarà inferiore a quello

indicato nella brochure tecnica.

Colori e identificazione

Le valvole SCA-X e CHV-X sono pitturate

con un primer rosso in fabbrica.

Un'identificazione precisa della valvola è

possibile tramite l'anello di identificazione

verde sulla parte superiore del coperchio e

tramite la stampigliatura sul corpo valvola. La

superficie esterna dell'involucro della valvola

deve essere protetta contro la corrosione con

un rivestimento protettivo idoneo dopo

l'installazione e il montaggio.

Si raccomanda di proteggere la targhetta

quando la valvola viene riverniciata.

(SCA DN

"nel

(fig.

Manutenzione

Guarnizione premistoppa (solo tipi SCA-X)

Quando si effettua un intervento di

riparazione o manutenzione, sostituire

solo il premistoppa completo, disponibile

come ricambio. Come regola generale, il

premistoppa non deve essere rimosso se

pressione interna è presente nella valvola.

Tuttavia, se ci si attiene alle seguenti misure

cautelative, il premistoppa può essere rimosso

con la valvola ancora sotto pressione:

Controtenuta (fig. 4)

Per posizionare la valvola in controtenuta,

ruotare lo stelo in senso antiorario fino a

quando la valvola non è completamente

aperta.

Equalizzazione della pressione (fig. 5)

In alcuni casi, la pressione si accumula dietro al

premistoppa. Un volantino o una rondella

grande (pos. A ) devono essere quindi fissati

sulla parte superiore dello stelo mentre la

pressione è equalizzata. La pressione può

essere equalizzata avvitando lentamente il

premistoppa.

Rimozione del premistoppa (fig. 6)

Il premistoppa può essere ora rimosso.

Smontaggio della valvola (fig. 8)

Non rimuovere il coperchio mentre la valvola

ancora sotto pressione.

DN 15-40 (fig. 8a):

- Controllare che la guarnizione (pos. A+B)

non abbia subito danni.

- Se la guarnizione (pos. A) è stata

esposta all’aria o ad altri refrigeranti

non menzionati nella presente guida

all’installazione per più di sei mesi,

dovrà essere sostituita.

- Verificare che lo stelo sia privo di graffi e

segni di impatto.

- Se l'anello in teflon del cono è danneggiato,

l'intero gruppo cono deve essere sostituito.

DN 50-125 (fig. 8b):

- Controllare che la molla (pos. A) sia intatta.

- Controllare che la guarnizione (pos. B+E)

non abbia subito danni.

- Se la guarnizione (pos. A) è stata

esposta all’aria o ad altri refrigeranti

non menzionati nella presente guida

all’installazione per più di sei mesi,

dovrà essere sostituita.

- Verificare che lo stelo (pos. C) sia privo di

graffi e segni di impatto.

- Se l'anello in teflon del cono (pos. D) è

danneggiato, l'intero gruppo cono deve

essere sostituito.

Sostituzione del cono (fig. 9)

DN 15-40:

L'o-ring (pos. C) previene la fuoriuscita del

cono. Rimuovere il cono dal coperchio.

Assicurarsi di non perdere la molla nel

processo. Rimuovere eventuale sporco.

Montare l'o-ring (pos. C) sul cono. Montare la

molla e il cono nel coperchio.

NON rimuovere né intervenire sul grasso

scuro tra la filettatura dell’asta e il coperchio.

Nel caso in cui il grasso sia stato contaminato

da sporco, detriti, particelle o acqua, è

necessario sostituire interamente la parte

superiore.

Montaggio

Rimuovere eventuale sporco dai tubi e

l'involucro prima dell'assemblaggio.

Importante per le valvole SCA-X: è possibile

ottenere una capacità piena solo quando lo

stelo è avvitato verso l'esterno, "nel coperchio",

vale a dire in senso antiorario (fig. 3).

Nota:

Per le SCA-X e CHV-X DN 15-40, è

importante assicurarsi che la parte inferiore

e la parte superiore dell’inserto siano ben

avvitate insieme (fig. 11) e che questa

connessione a vite sia mantenuta ben

serrata durante il riposizionamento del

cono nell’alloggiamento.

Utilizzare una chiave dinamometrica per

serrare il coperchio (fig. 3).

Serraggio

Serrare il coperchio con una chiave

dinamometrica, ai valori indicati nella tabella

(fig. 3). Serrare il premistoppa con una chiave

dinamometrica, ai valori indicati nella tabella

(fig. 7).

Utilizzare solo parti originali Danfoss

(compresi i premistoppa e le guarnizioni) per

la sostituzione. I materiali dei nuovi

componenti sono certificati per il refrigerante

pertinente.

In caso di dubbio, contattare l'ufficio vendite

Danfoss di zona.

è

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 8

Page 9

中文

安装

制冷剂

适用于 HCFC、HFC、R717(氨),

R 744 (CO 2)、丙烷、丁烷、异丁烷和乙

烷。

阀门应使用在密封的制冷系统内部。如需

了解更多详细信息请联系丹佛斯 。

温度范围

–60/+150°C (–76/+302°F)

压力范围

52 bar (754 psi)

安装该阀门时,需保证阀杆垂直向上。(图

1)。SCA-X 截止止回阀应手动打开,不能使

用工具或其他装置。该阀门的设计可以承

受很高的内部压力。尽管如此,管路系统

的设计也必须避免有存液弯

现因热膨胀导致的过高压力而损坏管路。管

路的设计应考虑对系统中出现瞬时“液击

现象的有效防护。

流向

流向应按照阀体上箭头所示的阀芯指向

(图1)。

焊接

在焊接之前应取下阀盖(图2),防止对填

料中的O型环、阀体和阀盖之间的垫圈、阀

座内的特氟龙垫圈造成损坏。 请小心,不

要损坏特氟龙阀芯,并确保阀盖在取下时不

会沾到土和水。

只有与阀体材料相兼容的材料和焊接方法才

能用于阀体。 安装完毕后,阀体不得再承

受任何压力(外部负载)。

焊接结束后且在重新装配阀门之前,应当清

洗阀门内部,以清除焊接碎屑。 避免外壳

和阀盖的螺纹上沉积焊接碎屑和灰尘。

切勿清除或维护主轴螺纹和阀盖之间的深色

油脂。 因为油脂已被土、杂质、颗粒物或

水污染,必须更换整个顶部零件。

截止止回阀不得安装在阀门出口侧与大气联

通。 阀门出口侧必须始终与系统连接或密

封,例如与焊接端板。

装配

装配前请清理管道和阀体内的焊渣及污

垢。检查阀锥在阀体内被重新放置之前,

已经完全向阀帽方向拧回 (SCA DN 50-

125) (图3)。

SCA-X

截止止回阀注意事项

只有当轴向外拧“入阀帽”,即逆时针方

向时才能获得完全容量(图3)。

紧固

使用扭矩扳手拧紧螺帽,并达到表中规定

的数值(图3)。

请务必遵守包含最大扭矩的该表(图3),

切勿超过。

,防止系统出

”

SCA-X/CHV-X 50 - 125 阀门注意事项:

如需获得最佳流量,插入物必须按照图10

中的指示安装。否则,kv值将低于技术手

册中的规定。

彩色和标识

SCA-X 和 CHV-X 值在工厂中使用红色底漆粉

刷。通过阀帽顶部的绿色 ID 环和阀体上的

冲压可以准确识别阀门。安装和组装后,

阀套外表面必须使用适当的保护层防止

腐蚀。

重新粉刷阀门时建议对铭牌进行保护。

维护

填 料( 仅 用 于 S C A - X 型 )

在进行维修和维护时,仅更换作为备件的

整套填料。一般来说,如果阀门内有内部

压力,不得移除填料。但是,如果采取以

下预防措施,可以在阀门处于压力下时移

除填料。

后 座( 图 4 )

如需将阀门置于后座,应逆时针转动轴,

直至阀门完全打开。

压 力 均 衡( 图 5 )

在某些情况下,压力在填料后形成。因此

应在压力处于平衡时拧紧轴顶部的手轮或

大垫圈(位置A)。可以通过慢慢拧出填料

使压力均衡。

移 除 填 料( 图 6 )

现在可以清除填料。

拆 卸 阀 门( 图 8 )

请勿在阀门处于压力下时移除阀帽。

DN 15-40(图8a):

- 检查垫圈(位置A+B)是否受到损坏。

- 如果垫片(位置 A)暴露在空气或安装

指导列表之外的制冷剂中超过 6 个月,

则必须更换。

- 检查轴是否有刮伤或撞击痕迹。

-

如果特氟龙阀板受损,必须更换整个阀

芯。

DN 50-125(图8b):

- 检查弹簧(位置 A)是否完好无损。

- 检查垫圈(位置 B+E)是否受到损坏。

- 如果垫片(位置 A)暴露在空气或安装

指导列表之外的制冷剂中超过 6 个月,

则必须更换。

- 检查轴(位置 C)是否有刮伤或撞击痕

迹。

- 如果特氟龙阀板(位置 D

)受损,必须更

换整个阀芯。

更 换 芯( 图 9 )

DN 15-40:

O 形圈(位置 C)可以防止阀锥脱落。将阀

锥拉离阀帽。确保弹簧在此过程中没有丢

失。清除所有灰尘。在阀芯上安装 O 形圈(

位置 C

)。在阀帽内安装弹簧和阀芯。

切勿清除或维护主轴螺纹和阀盖之间的深色

油脂。 因为油脂已被土、杂质、颗粒物或水

污染,必须更换整个顶部零件。

,

装配

在组装之前应清除管道和阀套上的所有异

物。SCA-X 阀门注意事项:只有当轴向外

拧“入阀帽”,即逆时针方向时才能获得

完全容量(图3)。

注意:

对于 SCA-X 和 CHV-X 尺寸的 DN 15-40,

必须确保插入体上下部分已紧紧旋在了一起

(图 11),且在壳体内重新放置阀锥的过程

中,螺丝接口必须一直保持紧密。

使用扭矩扳手拧紧阀帽 (图3)。

紧固

使用矩扳手拧紧螺帽,并达到表中规定的

数值(图3)。使用扭矩扳手拧紧填料,并达

到表中规定的数值(图7)。

请使用丹佛斯原厂的配件,(包括填料和垫

圈)进行更换。更换备件请提前确认新备件

的材质是 否适用于相关制冷剂。

如有任何疑问,请联系当地丹佛斯当地办事

处。

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 9

Page 10

POLSKI

Montaż

Czynniki chłodnicze

Dotyczy czynników chłodniczych: HCFC, HFC,

R717 (amoniak), R744 (CO2), propan, butan,

izobutan i etan.

Zawory te zaleca się stosować wyłącznie

w obiegach

informacji, skontaktuj się z firmą Danfoss.

Zakres temperatur

-60/+150°C (-76/+302°F)

Zakres ciśnień

Maksymalne ciśnienie robocze zaworów

wynosi 52 bary (754 psi)

Zawór należy zamontować z wrzecionem

skierowanym pionowo do góry lub w pozycji

poziomej (rys. 1). Zawory należy otwierać

ręcznie.

wytrzymał

rurociągów

aby uniknąć zamkniętych przestrzeni

cieczowych i zmniejszyć ryzyko wzrostu

ciśnienia spowodowanego

cieplną. Należy zapewnić ochronę zaworu

przed impulsami wysokiego

wynikającymi z uderzeń hydraulicznych.

Kierunek przepływu

Przepływ powinien być skierowany

grzybek, zgodnie ze strzałką

korpusie zaworu (rys. 1).

Spawanie

Przed spawaniem należy zdjąć pokrywę

zaworu (rys. 2), aby zapobiec uszkodzeniu

pierścieni O-ring w dławnicy oraz uszczelki

pomiędzy korpusem a pokrywą zaworu,

a także teflonowej uszczelki w gnieździe

zaworu. Należy zachować ostrożność, aby

nie uszkodzić teflonowego pierścienia

stożkowego, oraz upewnić się, czy podczas

demontażu pokrywa jest chroniona przed

kurzem i wodą.

Do spawania obudowy zaworu można

stosować tylko materiały i metody spawania

zgodne z materiałem obudowy. Po

montażu korpus zaworu nie może podlegać

zewnętrznym naprężeniom mechanicznym.

Po zakończeniu spawania, przed złożeniem

zaworu należy oczyścić wnętrze zaworu z

zanieczyszczeń mechanicznych po spawaniu.

Nie pozostawiać okruchów spawalniczych

ani zanieczyszczeń w gwintach korpusu i

pokrywy.

NIE należy usuwać ani poprawiać warstwy

ciemnego smaru między gwintem wrzeciona

a pokrywą. Jeśli smar został zanieczyszczony

kurzem, okruchami spawalniczymi, innymi

cząstkami lub wodą, należy wymienić całą

górną część.

Zawory zwrotne nie mogą być montowane

w instalacjach, w których wylotowa część

zaworu jest otwarta do atmosfery. Wylot

zaworu musi być zawsze podłączony do

instalacji lub należycie zaślepiony np.

przyspawaną dennicą.

Montaż elementów zaworu

Przed złożeniem zaworu należy usunąć z rur

oraz z korpusu zaworu okruchy spawalnicze

i wszelkie zanieczyszczenia. Przed zmianą

pozycji grzybka w korpusie zaworu upewnić

zamkniętych. Aby uzyskać więcej

Zawór został tak zaprojektowany, aby

wysokie ciśnienie. Jednak układ

powinien być zaprojektowany tak,

rozszerzalnością

ciśnienia

umieszczoną na

pod

się, że grzybek jest całkowicie wykręcony w

stronę pokrywy

Ważne dla zaworów SCA-X:

Pełną wydajność zaworu można uzyskać

wyłącznie wtedy, gdy wrzeciono jest

wykręcony do oporu w lewo (rys. 3).

Dokręcenie

Dokręcić pokrywę kluczem dynamometrycznym

momentem podanym w tabeli (rys. 3).

Należy pamiętać, aby zawsze przestrzegać

i nigdy nie przekraczać maksymalnego

momentu podanego w tabeli (rys. 3).

Ważne dla zaworów SCA-X/CHV-X 50 - 125:

Dla zapewnienia optymalnego przepływu

wkładka musi zostać zamontowana tak, jak

pokazano na rysunku (rys. 10). W przeciwnym

razie wartość kv będzie poniżej wartości

podanej w dokumentacji technicznej.

Kolory i identyfikacja

Zawory SCA-X i CHV-X malowane są w fabryce

czerwonym podkładem gruntującym. Zawór

można

precyzyjnie zidentyfikować za pomocą

zielonego

znajdującego się na górze pokrywy oraz

cechy numeratora na korpusie zaworu. Po

złożeniu i zamontowaniu zaworu, należy go

zabezpieczyć przed korozją pokrywając

odpowiednią powłoką ochronną.

Przed przystąpieniem do malowania

zaworu

identyfikacyjnego.

(SCA DN 50-125)

pierścienia identyfikacyjnego

zaleca się zabezpieczenie pierścienia

(rys. 3).

Serwis

Dławnica (wyłącznie typ SCA-X)

Podczas wykonywania prac serwisowych

należy wymieniać wyłącznie kompletną

dławnicę, która jest dostępna jako

część

zapasowa. Generalnie nie wolno

wymontowywać

zaworu panuje ciśnienie. Jeśli jednak zostaną

podjęte poniższe środki zapobiegawcze,

będzie można wymontować dławnicę

z zaworu, wewnątrz którego panuje ciśnienie.

Pełne wykręcenie wrzeciona (rys. 4)

Aby całkowicie wykręcic wrzeciono należy

obracać go w lewo, do oporu.

Wyrównywanie ciśnień (rys. 5)

W niektórych przypadkach pod dławnicą

tworzy się ciśnienie. W związku z tym przed

wyrównywaniem ciśnień należy przymocować

pokrętło lub dużą podkładkę (poz. A) na górnym

końcu wrzeciona. Ciśnienia można wyrównać

poprzez powolne wykręcanie dławnicy.

Demontaż dławnicy (rys. 6)

Można teraz zdemontować dławnicę.

Demontaż elementów zaworu (rys. 8)

Nie demontowywać pokrywy, gdy wewnątrz

zaworu nadal panuje ciśnienie.

DN 15-40 (rys. 8a):

- Sprawdzić, czy uszczelka (poz. A+B) nie

jest uszkodzona.

- Jeżeli uszczelka (poz. A) została

wystawiona na działania powietrza lub

czynników chłodniczych innych niż

wymienione w tej instrukcji instalacji

przez czas dłuższy niż 6 miesięcy,

wówczas należy ją wymienić.

- Sprawdzić, czy na wrzecionie nie ma

zarysowań i/lub śladów uderzeń.

dławnicy, gdy wewnątrz

- Jeśli uszkodzony jest teflonowy pierścień

grzybka, należy wymienić cały zespół

grzybka.

DN 50-125 (rys. 8b):

- Sprawdzić, czy sprężyna (poz. A) jest

nienaruszona.

- Sprawdzić, czy uszczelka (poz. B+E) nie jest

uszkodzona.

- Jeżeli uszczelka (poz. A) została

wystawiona na działania powietrza lub

czynników chłodniczych innych niż

wymienione w tej instrukcji instalacji

przez czas dłuższy niż 6 miesięcy,

wówczas należy ją wymienić.

- Sprawdzić, czy na trzpieniu (poz. C) nie ma

zarysowań i/lub śladów uderzeń.

- Jeśli uszkodzony jest teflonowy pierścień

grzybka (poz. D), należy wymienić cały

zespół grzybka.

Wymiana grzybka (rys. 9)

DN 15-40:

Pierścień O-ring (poz. C) zapobiega wypadnięciu

grzybka. Wyjąć grzybek z pokrywy zaworu.

Należy upewnić się, że podczas tego procesu

nie zagubiono sprężyny. Usunąć zabrudzenia,

jeżeli występują. Zamontować pierścień

O-ring (poz. C) na grzybku. Zamontować

w pokrywie zaworu sprężynę i grzybek.

NIE należy usuwać ani poprawiać warstwy

ciemnego smaru między gwintem wrzeciona

a pokrywą. Jeśli smar został zanieczyszczony

kurzem, okruchami spawalniczymi, innymi

cząstkami lub wodą, należy wymienić całą

górną część.

Montaż elementów zaworu

Usunąć z rur i korpusu zabrudzenia, jeżeli

występują. Ważne dla zaworów SCA-X: Pełną

wydajność można uzyskać wyłącznie wtedy,

gdy wrzeciono jest wykręcone do oporu,

w lewo (rys. 3).

Uwaga:

W odniesieniu do zaworów SCA-X i CHV-X o

średnicach DN 15–40 upewnić się, że dolna

i górna część wkładki jest dokładnie

dokręcona (rys. 11) oraz że połączenie to

będzie stabilne również podczas zmiany

pozycji grzybka w obudowie.

Dokręcić kluczem dynamometrycznym

pokrywę zaworu (rys. 3).

Dokręcenie

Dokręcić pokrywę kluczem dynamometrycznym

momentem podanym w tabeli (rys. 3).

Dokręcić dławnicę kluczem dynamometrycznym

momentem podanym w tabelce (rys. 7).

Używać wyłącznie oryginalnych części

zamiennych Danfoss, łącznie z dławnicami

i uszczelkami. Materiały, z których wykonano

nowe części, mają atest dopuszczający je do

użytku z określonym czynnikiem chłodniczym.

W razie wątpliwości należy skontaktować się z

lokalnym biurem sprzedaży firmy Danfoss.

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 10

Page 11

РУССКИЙ

Монтаж

Хладагенты

Пригодны для систем на ГХФУ, ГФУ, R717

(аммиак), R744 (CO2), пропане, бутане,

изобутане и этане.

Рекомендуется использовать клапан только в

закрытых контурах. Для получения более

подробной информации обращайтесь в

компанию Danfoss.

Диапазон температуры

–60/+150°C (–76/+302°F)

Диапазон давления

52 бар (754 фунта/кв. дюйм)

При установке клапана шток должен быть

направлен вертикально вверх или

горизонтально (рис. 1). Клапаны SCA-X должны

открываться вручную без использования

инструментов или иных устройств. Клапаны

выдерживают высокое внутреннее давление.

Однако система трубопроводов должна быть

спроектирована так, чтобы избежать

появления участков, в которых может

задерживаться жидкий хладагент,

и таким образом понизить риск

возникновения гидроудара при его тепловом

расширении. Необходимо обеспечить защиту

клапана от изменений давления в системе,

таких как «гидравлический удар».

Направление потока

Направление потока указано стрелкой на

корпусе клапана (рис. 1).

Сварка

Перед проведением сварочных работ

необходимо разобрать клапан (рис. 2), чтобы

избежать повреждения уплотнительных

колец и тефлоновых уплотнений

функционального модуля. Осторожно,

не повредите тефлоновое уплотнение.

Необходимо обеспечить защиту снятого

функционального модуля от грязи и воды.

Использоваться должны только материалы и

методы сварки, совместимые с материалом

корпуса клапана. После монтажа корпус

клапана не должен подвергаться внешним

воздействиям или нагрузкам.

После завершения сварочных работ, перед

сборкой клапана необходимо очистить

внутреннюю поверхность клапана от грязи и

окалины. Не допускайте попадания окалины

и грязи в резьбовые соединения между

корпусом и функциональным модулем

(крышкой).

Не удаляйте и не наносите дополнительную

смазку на резьбовое соединение шпинделя.

Если смазка загрязнена мусором, частицами

или водой, необходимо заменить

функциональный модуль.

Запрещается устанавливать обратнозапорные клапаны в системах, где выходной

штуцер сообщен с атмосферой. Выходной

штуцер должен быть всегда соединен с

системой, либо должен быть заглушен

при помощи приваренной пластины или

специальной заглушки.

Сборка

Перед сборкой удалите с труб и корпуса

клапана окалину и грязь любого типа. Перед

переустановкой конуса в корпусе клапана

убедитесь в том, что он был полностью

вывинчен в сторону крышки (

(fig. 3).

.

SCA DN 50-125)

Важная информация по к лапанам SCA-X:

Полная пропускная способность достигается

только, когда шпиндель полностью выкручен

находится в положении обратной посадки (рис.

3).

Затяжка

Затяните болты штока при помощи

динамометрического ключа до значений,

указанных в таблице (рис. 3).

Примите к сведению, что необходимо

соблюдать значения максимального момента

затяжки, указанные в таблице

строжайше запрещено превышать данные

значения

Важная информация по клапанам SCA-X/

CHV-X 50 - 125:

Для оптимального потока вкладыш должен

устанавливаться, как показано на рисунке

(рис. 10). В противном случае значение KV

будет ниже указанного в техническом

описании.

Покраска и маркировка

На заводе клапаны SCA-X и CHV-X

окрашиваются грунтовкой красного

цвета. Точная идентификация клапана

производится благодаря опознавательному

кольцу зеленого цвета в верхней части штока,

а также благодаря оттиску на корпусе

клапана. Необходимо обеспечить защиту

наружной поверхности корпуса клапана от

коррозии при помощи соответствующего

защитного покрытия после монтажа и сборки.

При повторной окраске клапана

рекомендуется обеспечить защиту заводской

таблички.

.

(рис. 3), и

и

Техническое обслуживание

Сальник (только модели SCA-X)

При выполнении технического обслуживания

заменяйте только комплектный сальник.

Запасные сальники имеются в наличии.

Как правило, запрещается удалять сальник,

если в клапане имеется внутреннее давление.

Однако, если принимаются следующие меры

предосторожности, сальник можно удалять из

клапана, все еще находится под давлением:

Посадка на верхнее седло (рис. 4)

Для посадки клапана на верхнее седло

поверните шпиндель против часовой стрелки

до полного открытия клапана.

Выравнивание давления (рис. 5)

В некоторых случаях за сальником образуется

давление. Поэтому в процессе выравнивания

давления наверху шпинделя закрепляется

маховик или большая шайба (поз. A).

Давление можно выровнять, медленно

откручивая сальник.

Демонтаж сальника (рис. 6)

Теперь можно снять сальник.

Разборка клапана (рис. 8)

Запрещается демонтировать шток, пока

клапан находится под давлением.

DN 15-40 (рис. 8a):

- Убедитесь, что прокладка (поз. A+B) не

повреждена.

- Прокладку (поз. A), которая подвергается

воздействию воздуха или

хладоносителей, не рекомендованных в

этом руководстве по установке,

в течение более 6 месяцев,

необходимо заменить.

- Убедитесь, что на шпинделе отсутствуют

царапины или следы ударов.

- Если тефлоновое конусное кольцо было

повреждено, замене подлежит весь конус

сборе.

в

DN 50-125 (рис. 8b):

- Убедитесь, что пружина (поз. A) не

повреждена.

- Убедитесь, что прокладка (поз. B+E) не

повреждена.

- Прокладку (поз. A), которая подвергается

воздействию воздуха или

хладоносителей, не рекомендованных в

этом руководстве по установке,

в течение более 6 месяцев,

необходимо заменить.

- Убедитесь, что шпиндель (поз. C) не имеет

царапин и следов удара.

- Если тефлоновое конусное кольцо (поз. D)

было повреждено, замене подлежит весь

конус в сборе.

Замена конуса (рис. 9)

DN 15-40:

Уплотнительное кольцо (поз. C)

предотвращает выпадение конуса. Вытащите

конус из штока. Убедитесь, что не потеряли

пружину в процессе. Удалите грязь, если

таковая имеется. Установите

на конус уплотнительное кольцо (поз. C).

Установите в шток пружину и конус.

Не удаляйте и не наносите дополнительную

смазку на резьбовое соединение шпинделя.

Если смазка загрязнена мусором, частицами

или водой, необходимо заменить

функциональный модуль.

Сборка

Перед сборкой с труб и корпуса удалите

грязь, если таковая имеется. Важная

информация по клапанам SCA-X: полная

пропускная способность достигается только

тогда, когда шпиндель выкручен, и находится

в положении обратной посадки т. е. против

часовой стрелки (рис. 3).

Примечание:

Для клапанов SCA-X и CHV-X с размерами

DN 15-40 важно сделать так, чтобы нижняя

и верхняя части вставки были плотно

свинчены (рис. 11) и чтобы данное

винтовое соседние оставалось плотным в

ходе переустановки конуса в корпусе.

Используйте динамометрический ключ для

затяжки болтов (рис. 3).

Затяжка

Затяните болты при помощи

динамометрического ключа до значений,

указанных в таблице (рис. 3). Затяните сальник

при помощи динамометрического

ключа до значений, указанных в таблице

7).

Для замены используйте только подлинные

детали производства компании Danfoss

(включая сальники и прокладки).

новых деталей сертифицированы

соответствующего хладагента.

Материалы

для

(рис.

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 11

Page 12

PORTUGUÊS

Instalação

Refrigerantes

Aplicável a HCFC, HFC, R717 (Amônia),

R744 (CO2), Propano, Butano, Isobutano e

Etano.

A válvula é recomendada apenas para uso em

circuitos fechados. Para mais informações,

entre em contato com a Danfoss.

Faixa de temperatura

–60/+150°C (–76/+302°F)

Faixa de temperatura

52 bar (754 psi)

A válvula deve ser instalada com o eixo na

parte superior para cima verticalmente ou em

posição horizontal (fig. 1). As válvulas SCA-X

devem ser abertas manualmente sem o uso de

ferramentas ou outros dispositivos. A válvula é

projetada para suportar uma alta pressão

interna. Entretanto, o sistema de tubulação

deve ser desenhado para evitar

líquido e reduzir o risco de pressã

causada pela expansão térmica. Deve-se

assegurar que a válvula fique protegida

contra transientes de pressão, como os

“golpes de aríete” no sistema.

Direção do fluxo

Direcione o fluxo em direção ao cone

conforme indicado por uma seta no corpo da

válvula (fig. 1).

Soldagem

A tampa deve ser removida antes da

soldagem (fig. 2) para evitar danos nos

o-rings e vedações nas gaxetas e entre o

corpo da válvula e a tampa, bem como o

anel de teflon no assento de válvula. Tenha

cuidado para não danificar o anel do cone

de teflon e certifique-se de que a tampa

toda esteja protegida contra sujeira e água

enquanto estiver removida.

Somente materiais e métodos de soldagem

compatíveis com o material do corpo da

válvula podem ser aplicados a ela. O corpo

da válvula deve estar livre de tensão (cargas

externas) após a instalação.

A válvula deve ser limpa internamente para

remover resíduos da soldagem no final do

processo e antes que a válvula seja montada

novamente. Evite resíduos de solda e sujeira

nas roscas do corpo e da tampa.

NÃO remova ou realize a manutenção do

lubrificante/graxa de cor escura entre a rosca

do eixo e a tampa. Caso o lubrificante/graxa

tenha sido contaminado por sujeira, resíduos

ou água, toda a tampa superior deve ser

substituída.

As válvulas de retenção e bloqueio não

podem ser montadas em sistemas em que

o lado de saída da válvula está aberto à

atmosfera. O lado de saída da válvula deve

estar sempre conectado ao sistema ou

tampado adequadamente, por exemplo,

com um cap ou uma tampa soldados na

extremidade.

Montagem

Remova os detritos da soldagem e qualquer

sujeira dos canos e do corpo da válvula antes

da montagem. Verifique se o cone foi

golpes de

o hidráulica

totalmente parafusado para trás em direção à

tampa antes que ele seja recolocado no corpo

da válvula (fig. 3).

Importante para as válvulas SCA-X:

A capacidade total somente é obtida quando

o eixo é parafusado para fora, “para dentro da

tampa”, isto é, no sentido anti-horário (fig. 3).

Torque

Aperte a tampa com uma chave de torque

nos valores indicados na tabela (fig. 3).

Observe que a tabela (fig. 3) contendo o

toque máximo deve ser respeitada e nunca

excedida.

Importante para as válvulas SCA-X/CHV-X 50

- 125:

Para um fluxo ideal, o inserto deve ser

instalado conforme o indicado em (fig. 10). De

outra maneira, o valor kv ficará abaixo do

indicado na brochura técnica.

Cores e identificação

As válvulas SCA-X e CHV-X são pintadas com

uma base de tinta vermelha na fábrica. A

identificação precisa da válvula

é feita pelo anel de identificação verde na

parte superior da tampa, assim como através

da estampagem no corpo da válvula. A

superfície externa do corpo da válvula deve

ser protegida contra corrosão com uma

camada protetora adequada após a instalação

e a montagem.

Recomenda-se proteger a placa do nome

quando a válvula é pintada novamente.

Manutenção

Prensa cabo (somente tipos SCA-X)

Ao executar serviços e manutenção, substitua

somente a prensa cabo completa, que está

disponível como peça de reposição. Como

regra geral, a prensa cabo não deve ser

removida se houver pressão interna na

válvula. Entretanto, se

as seguintes medidas de precaução forem

tomadas, a prensa cabo pode ser removida

a válvula ainda sob pressão:

Contravedação (fig. 4)

Para executar a contravedação na válvula, gire

o eixo no sentido anti-horário até que a

válvula fique completamente aberta.

Equalização da pressão (fig. 5)

Em alguns casos, forma-se pressão atrás da

prensa cabo. Neste caso, um volante ou uma

arruela maior (pos. A) deve ser fixado na parte

superior enquanto a pressão é atualizada.

Pode-se equalizar a pressão

lentamente a prensa para fora.

Remoção da prensa cabo (fig. 6)

Agora a prensa cabo pode ser removido.

Desmontando a válvula (fig. 8).

Não remova a tampa enquanto a válvula

ainda estiver sob pressão.

DN 15-40 (fig. 8a):

- Verifique se a junta (pos. A+B) não foi

danificada.

-

Se a junta de vedação (posição A) tiver

sido exposta ao ar ou a mais refrigerantes

do que os listados neste guia de

instalação por mais de ela deverá

ser substituída em 6 meses.

- Verifique se o eixo está isento de

arranhões e marcas de impacto.

aparafusando

com

- Se o anel de teflon do cone foi danificado,

todo o conjunto do cone deve ser

substituído.

DN 50-125 (fig. 8b):

- Verifique se a mola (pos. A) está intacta.

- Verifique se a junta (pos. B+E) não foi

danificada.

-

Se a junta de vedação (posição A) tiver

sido exposta ao ar ou a mais refrigerantes

do que os listados neste guia de

instalação por mais de ela deverá

ser substituída em 6 meses.

- Verifique se o eixo (pos. C) está isento de

arranhões e marcas de impacto.

- Se o anel de teflon do cone (pos. D) foi

danificado, todo o conjunto do cone deve

ser substituído.

Substituição do cone (fig. 9)

DN 15-40:

O anel de vedação (pos. C) impede que o

cone caia. Puxe o cone para liberá-lo do

castelo. Assegure-se de que a mola não se

perdeu no processo. Remova a sujeira se

houver. Monte o anel de vedação (pos. C) no

cone. Monte a mola e o cone na tampa.

NÃO remova ou realize a manutenção do

lubrificante/graxa de cor escura entre a rosca

do eixo e a tampa. Caso o lubrificante/graxa

tenha sido contaminado por sujeira, resíduos

ou água, toda a tampa superior deve ser

substituída.

Montagem

Remova a sujeira, se houver, dos canos e do

alojamento antes da montagem. Importante

para as válvulas SCA-X: A capacidade total

somente é obtida quando o eixo é parafusado

para fora, “dentro da tampa”, isto é, no sentido

anti-horário (fig. 3).

Observação:

Para os tamanhos DN 15-40 das válvulas

SCA-X e CHV-X é importante garantir que a

parte superior e inferior do inserto esteja

firmemente aparafusada (fig. 11) e que

esta conexão do parafuso seja mantida

durante o reposicionamento do cone no

corpo.

Use uma ferramenta de torque para apertar a

tampa (fig. 3).

Aperto

Aperte a tampa com uma chave de torque

nos valores indicados na tabela (fig. 3). Aperte

prensa cabo com uma chave de torque nos

valores indicados na tabela (fig. 7).

Utilize somente peças originais Danfoss

(incluindo prensa cabo e juntas) para as

substituições. Os materiais das peças novas

são certificados para o refrigerante relevante.

Em caso de dúvidas, entre em contato com a

Danfoss.

a

© Danfoss | DCS (MWA) | 2018.05

DKRCI.PI.FL1.T2.ML | 520H6172 | 12

Loading...

Loading...