Page 1

User Guide

Chiller and reversable chiller

Reciprocating, scroll and

screw compressors

Software Version 4.40.00

Page 2

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

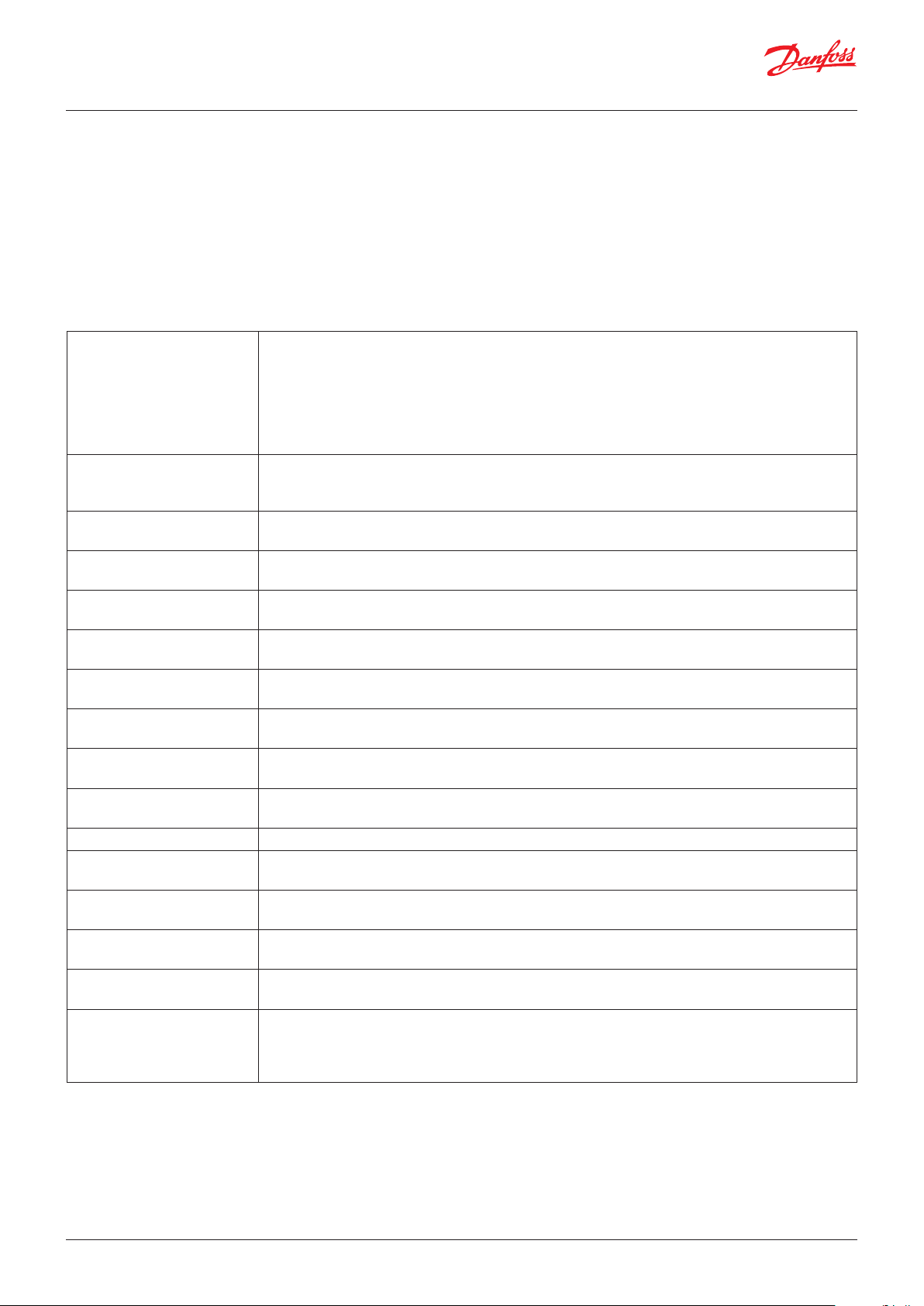

Contents

User Interface ...............................................................................4

LED Display, LCD Display, Keyboard, Unit status, Login, Start,

Parameter, Input/Output, I/O Display, I/O Config, I/O Prb

Calibration, I/O Commissioning, Alarm, EEV, VSH Monitor, VSH

Control, Clock, Language, Service, Hours Counters, Variable

speed pump

Parameters .................................................................................12

Display ........................................................................................12

Parameter: dSA, dSb, dsc, Log, Par

Password ....................................................................................13

Parameter: L01, L02, L03

SetUp ..........................................................................................13

Parameter: y01, y02, y03, y04, y05, y06, y08, y09

Serial setting ..............................................................................14

Parameter: Cid, Ser, bAU, COM

Evaporator .................................................................................15

Parameter: H1, H2, H3, H4, H5, H12

Compressor ................................................................................16

Parameter: H6, H7

Condenser ..................................................................................17

Parameter: H9, H10, H11

Heat Pump ..................................................................................18

Parameter: H40, H41, H42

Maintenance ..............................................................................19

Parameter: H43

Network settings .......................................................................20

Parameter: n01,…n17

Configuration .............................................................................22

Parameter: rEG, rET, rT1, rT2, o30, Er1

Main Setpoint ............................................................................24

Parameter: SC1, SCL, SCH, SH1, SHL, SHH, SRE

Economic Setpoint ....................................................................25

Parameter: SdS, SdM, SdC, SdH, SdO

Setpoint compensation in based on the outside temperature .. 26

Parameter: CC1, CC2, CC3, CC4, CH2, CH3, CH4

PI regulation ..............................................................................27

Parameter: CrC1, rH1, Rin, rC2, rC3

Dead zone regulation ................................................................28

Parameter: ddC, ddH, dd1, dd2, dd3, dd4, dd5, dd6, dd7, dd8 ...28

Digital output lock.....................................................................29

Parameter: DOn, Ain, Dos, DOd

Buzzer and relay ........................................................................29

Parameter: BUZ, Adl, AOF

Flow alarm ..................................................................................30

Parameter: AFr, AF1, AF2, AF3

ICE alarm ....................................................................................31

Parameter: AIS, AID, Air, AI1, AI2, AI3, AIT, AIo

Compressor oil delta pressure alarm .......................................32

Parameter: OPR, OdP, GdP

Circuit high temperature alarm ................................................32

Parameter: HTs, HTd

Pressure alarms from analogue input......................................33

Parameter: AHE, AHS, AHd, Alr, AL1, AL2, ALE, ALS, ALd, LPt,

AVO, VCt, SHS, SHb

High water temperature alarm in cooling mode.....................34

Parameter: Ats, Atd

Boiler water temperature alarm ...............................................34

Parameter: AbS, Abd

Fault of the regulation probe of the external coil ...................35

Parameter: ACM, ACS, ACd

Preventions ................................................................................35

Parameter: TMx, THo, TLo, HPE, HPo, HPh, LPE, LPo, LPh, PPt,

PPp, HFo

Superheat alarms ......................................................................37

Parameter: SHh, AHI, Ahi, AHd

Oil temperature alarms .............................................................37

Parameter: OTm, OTi, OTd

Screw compressors ....................................................................38

Parameter: C01, C02, CSO, CSb, T1, T2,T3, T4, C07, C08, T5, T6,

T21, T22, T24, T24, T25, T26, T27, T28, T29

Starting type of the compressor ..............................................42

Parameter: Sty, Sti, SSt, Stm, Sdd

Economizer ................................................................................43

Parameter: E01, EO2, EO3, EO4

Liquid injection ..........................................................................44

Parameter: T41, T42, T43, T44, T45

Compressor with unloaders ......................................................44

Parameter: C04, C05, C06, C08

Maximum number of compressor starts per hour ..................45

Parameter: CT0, CT1, CT2, CT3, CT4, CT5, CT6, CT7

Valve in the liquid line ...............................................................46

Parameter: Pd1, Pd2, Pd3, Pd4

Maximum compressor running hours .....................................47

Parameter: C50

Inverter compressor ..................................................................48

Parameter: IV0, IV1, IV2, IV3, IV4, IV5

Compressor enabling ................................................................50

Parameter: CT1, CT2, CT3, CT4, CT5, CT6, CT7, CT8

Heaters .......................................................................................50

Parameter: HE1, HE2, HE3, HE4, HE5, HE6, HE7

Pump of the internal coil ...........................................................51

Parameter: P01, P02, P03, P04

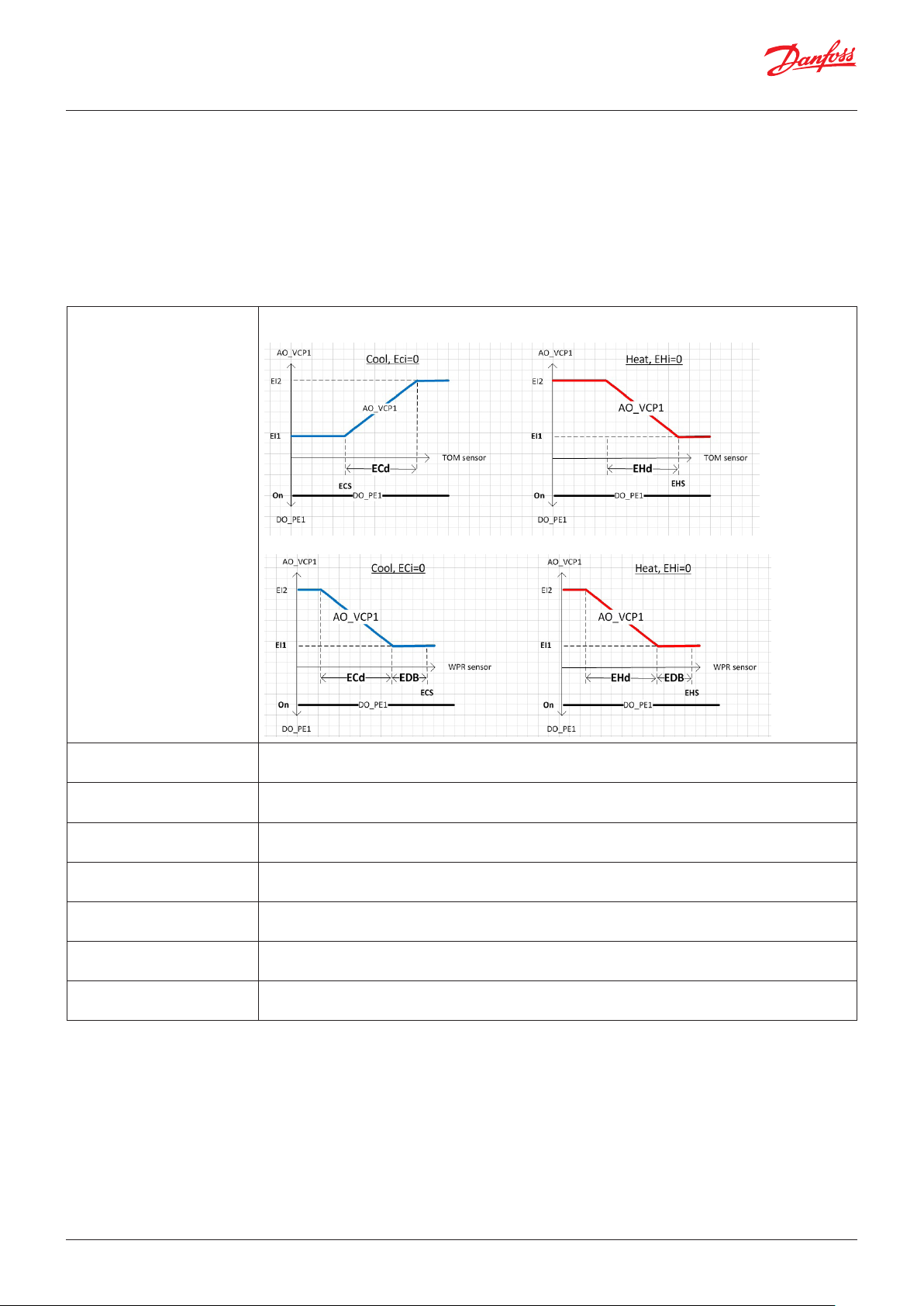

Modulating Pump ......................................................................52

Parameter: ERT, ECS, ECd, ECi, EHS, EHd, EHi, EDB, EI1, EI2, EI3

Fan for the internal coil .............................................................53

Parameter: P21, P22, P50

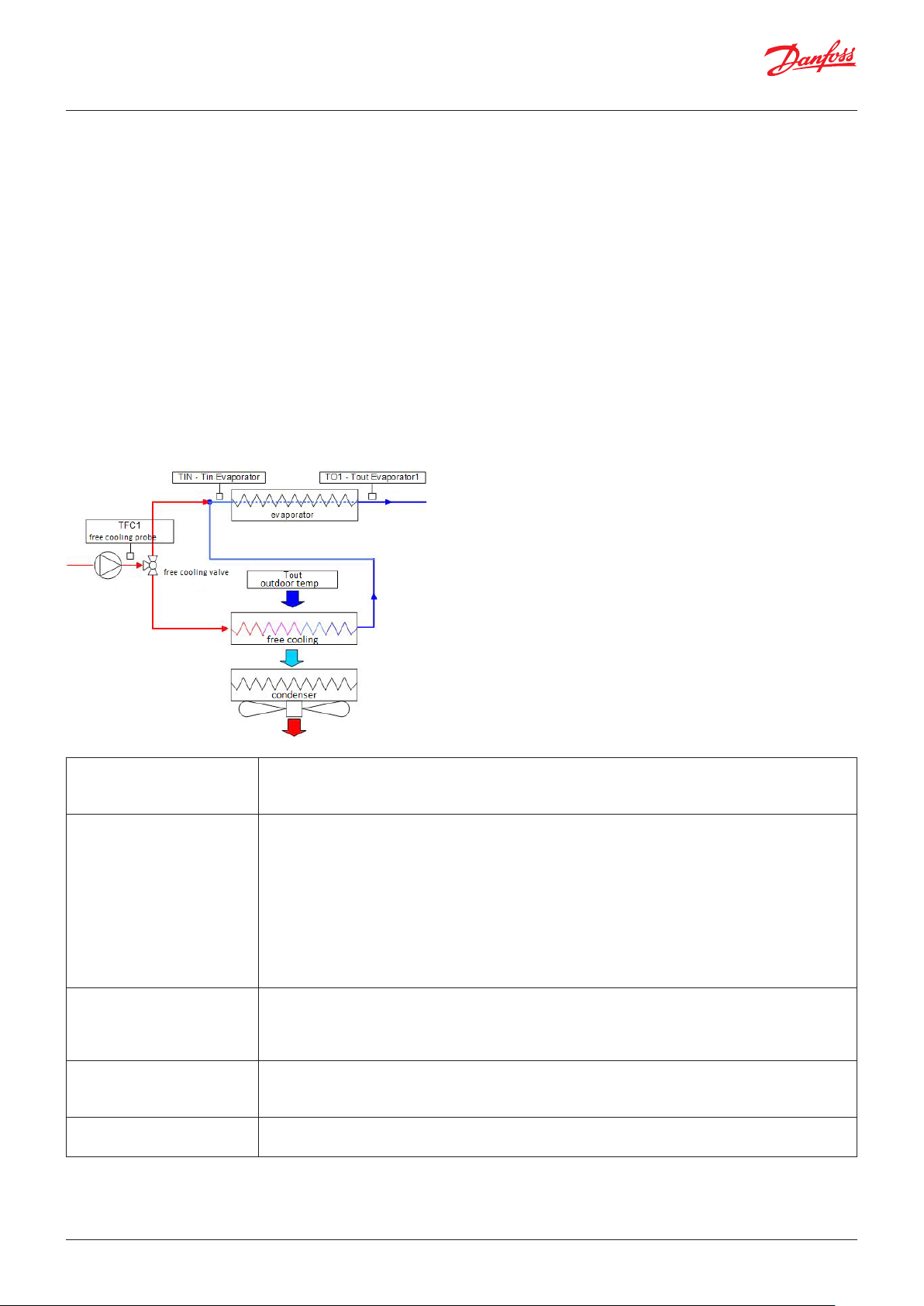

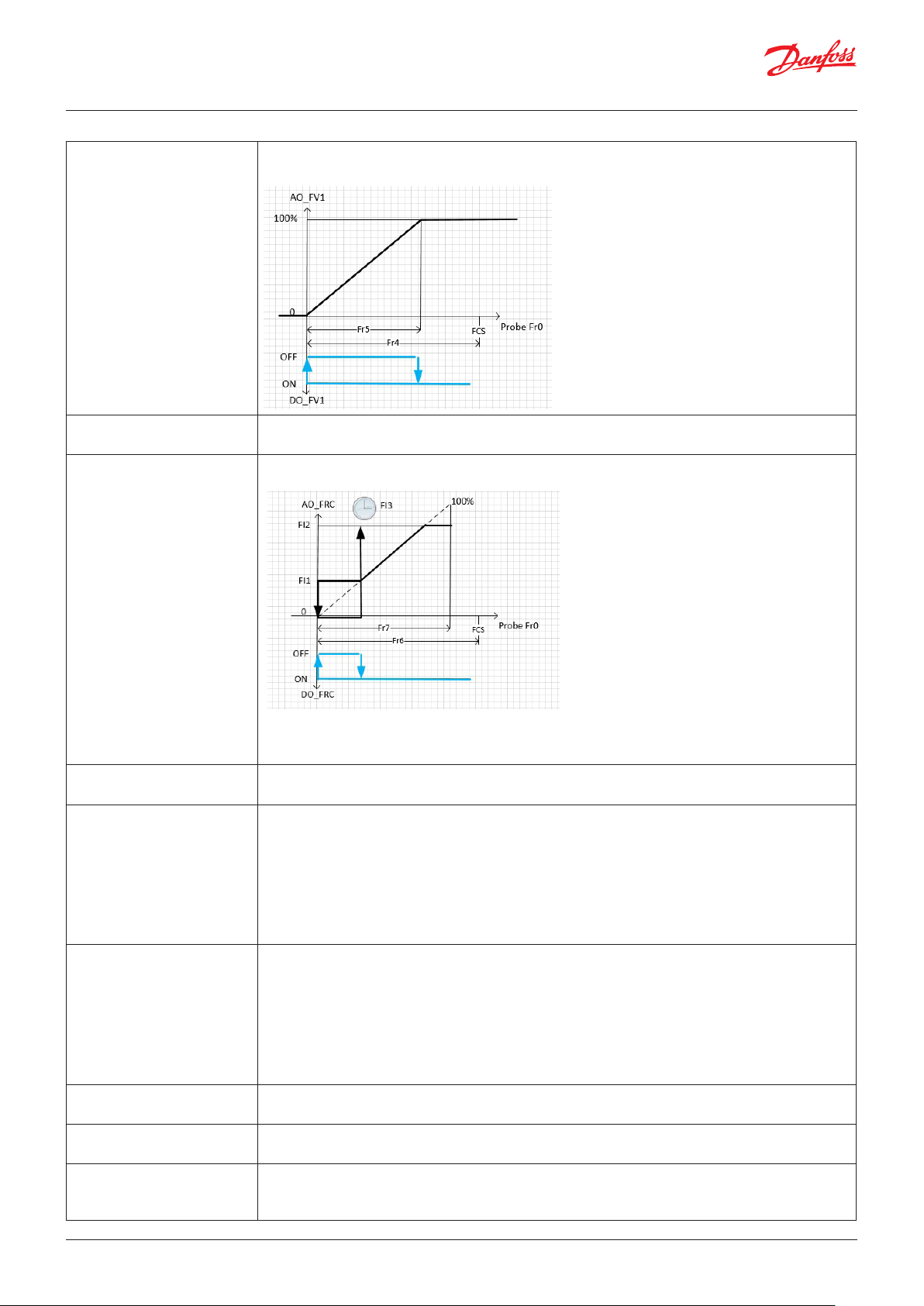

Free cooling ................................................................................54

Parameter: FrA, Fr1, Fr2, Fr3, Fr4, Fr5, Fr6, Fr7, Fr8, Fr9, FI1,

FI2, FI3

Valve in the water line ...............................................................56

Parameter: EF1, EF2

External coil ...............................................................................56

Parameter: F01

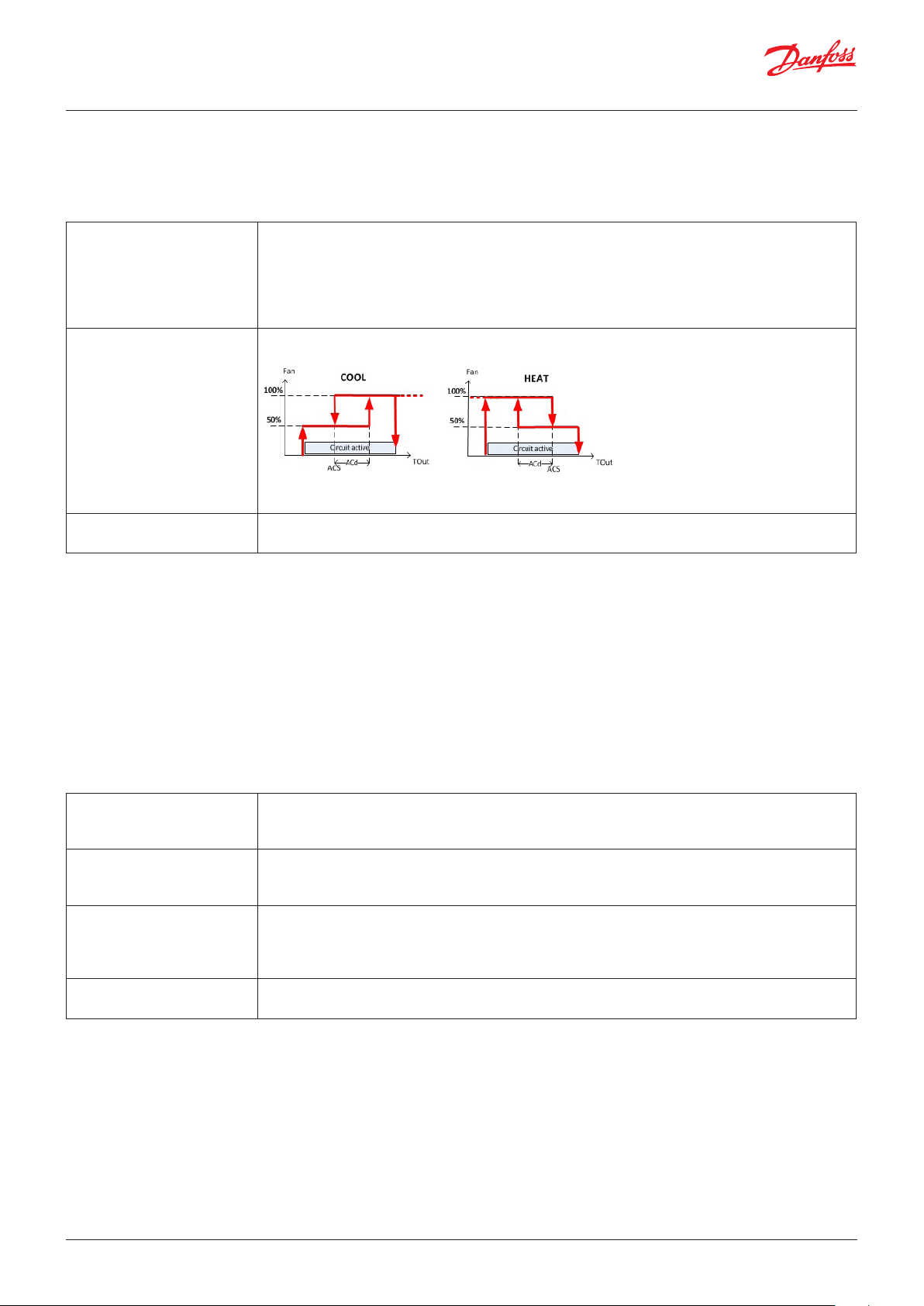

Fan requests ...............................................................................57

Parameter: F02, F03, FC, FCD, FCI, FCd, FHS, FHD, FHI, FHd

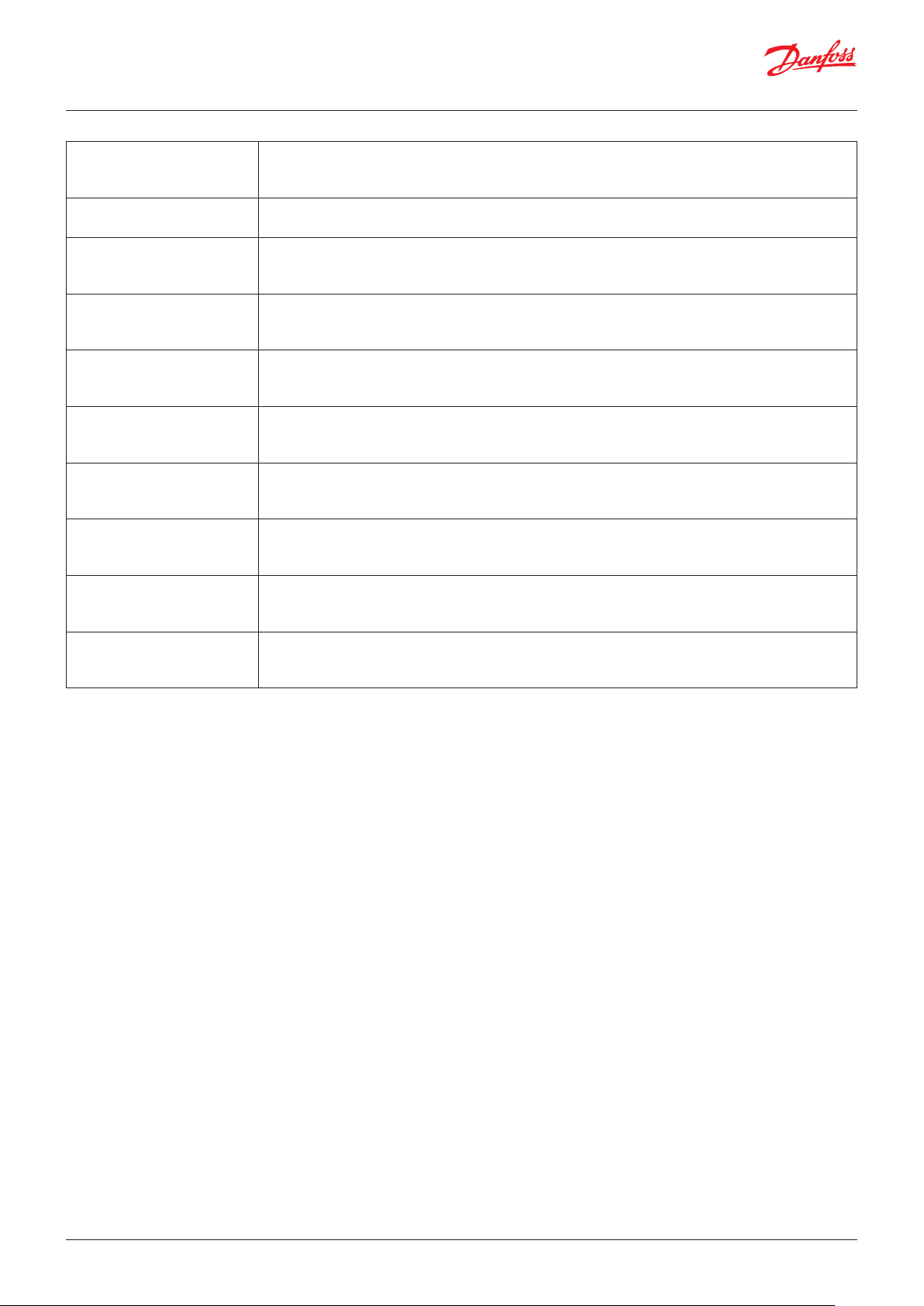

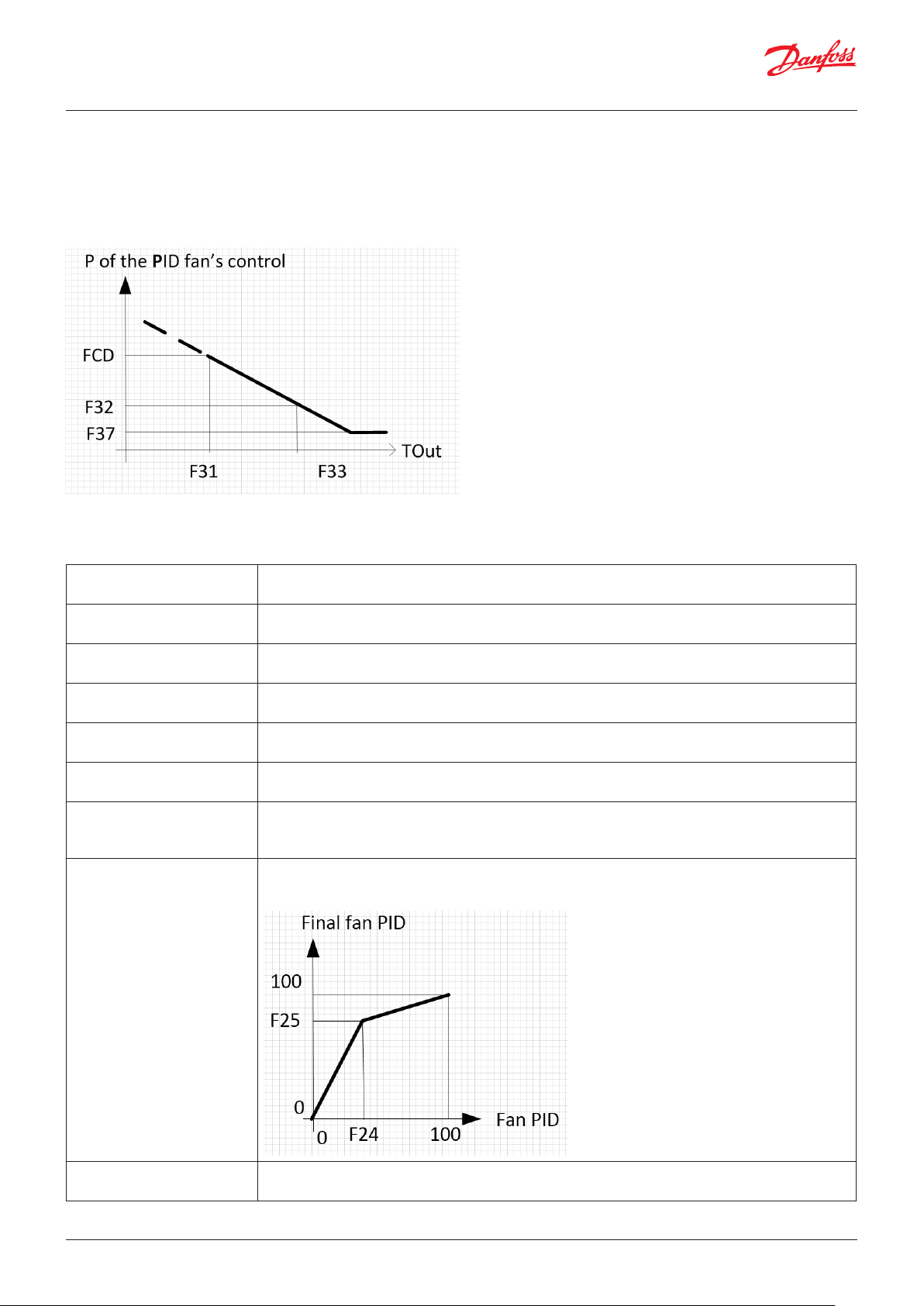

Fan regulation with a variable proportional part ...................59

Parameter: F31, F32, F33, F34, F35, F36, F37, F24, F25

2 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 3

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Economic setpoint for fan regulation ......................................60

Parameter: SS1, SS2, SS3, SS4

Stepless regulation of the fan ..................................................60

Parameter: F10, F11, F12, F13, F14, F20, F21, F22, F23

Hot gas bypass valve .................................................................61

Parameter: Bp0, Bp1

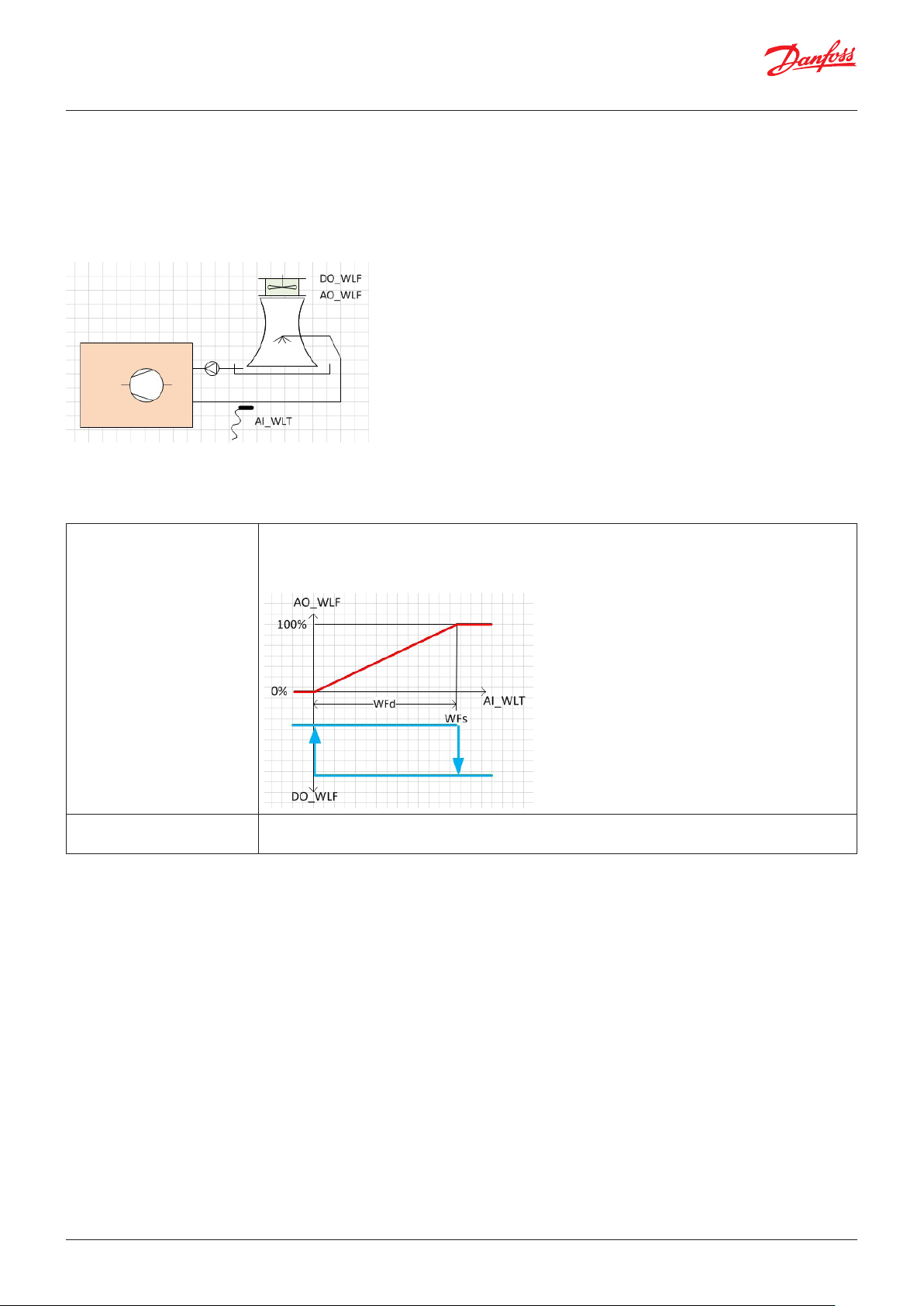

Cooling towers ...........................................................................62

Parameter: WFs, WFd

Reversing cycle valve (4 ways valve) ........................................63

Parameter: rE2, rE1, rE3, rE4

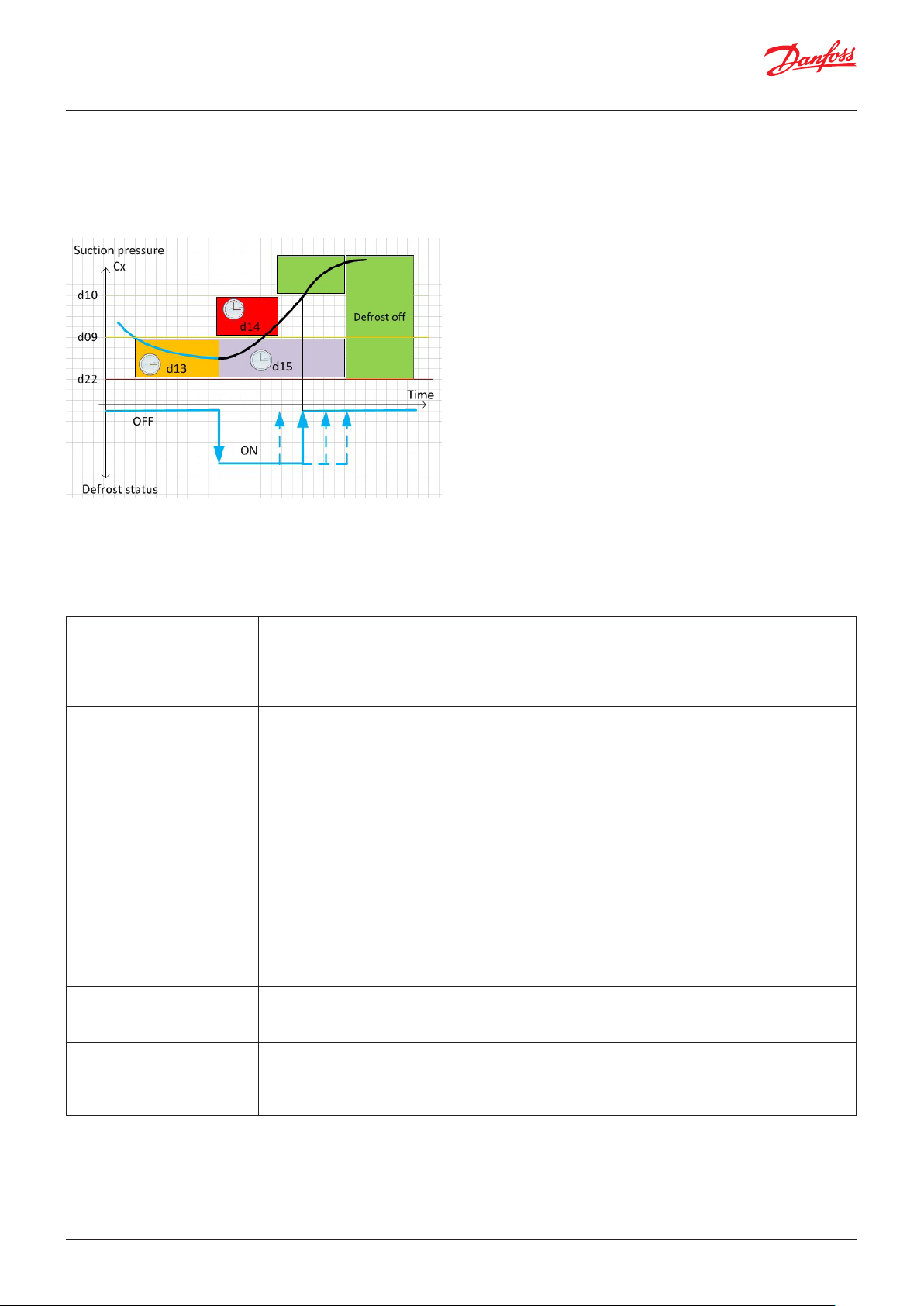

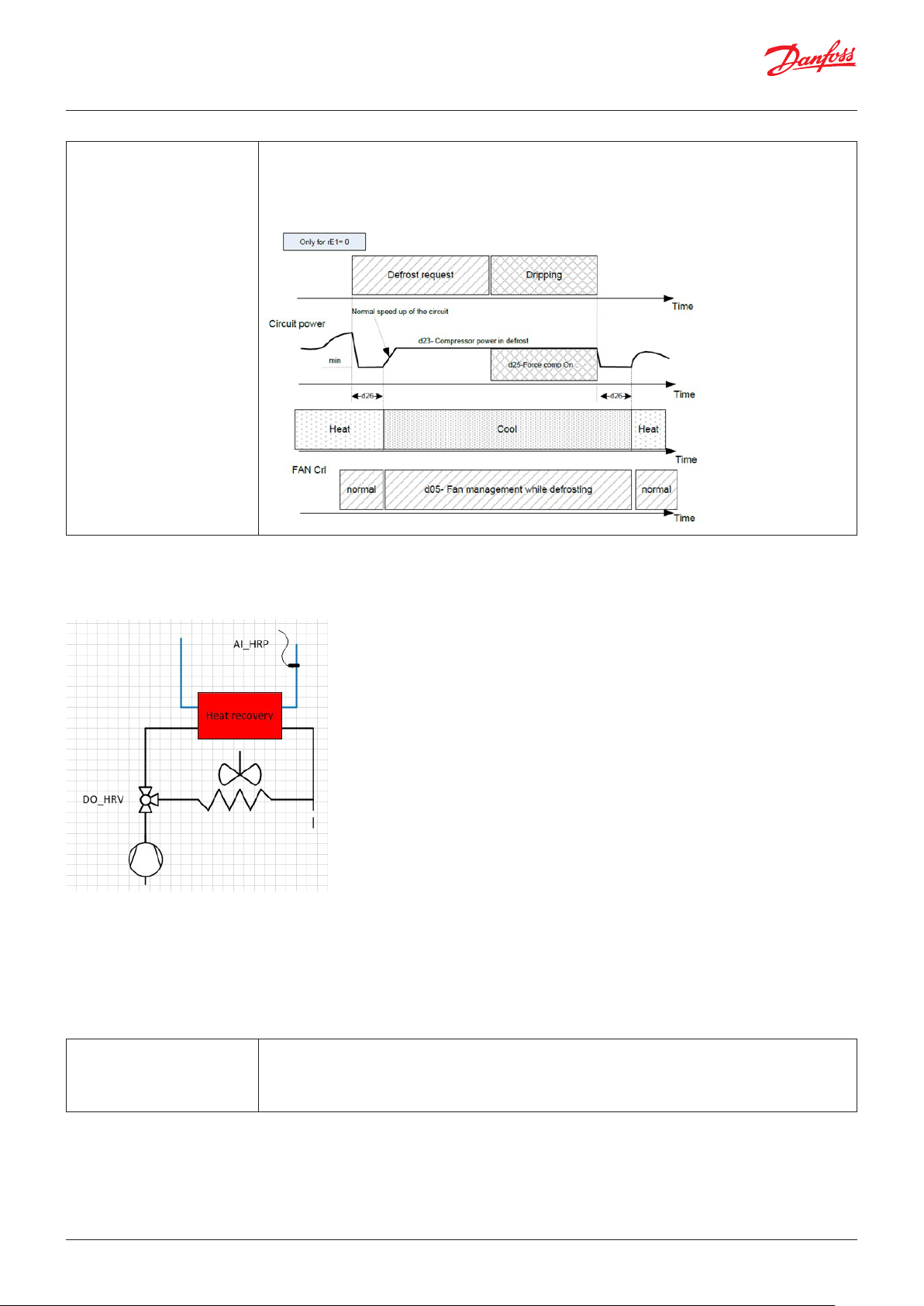

Defrost ........................................................................................64

Parameter: d01, d02, d03, d04, d05, d06, d07, d09, d10, d11,

d12, d13, d14, d15, d16, d20, d22, d23, d25, d26

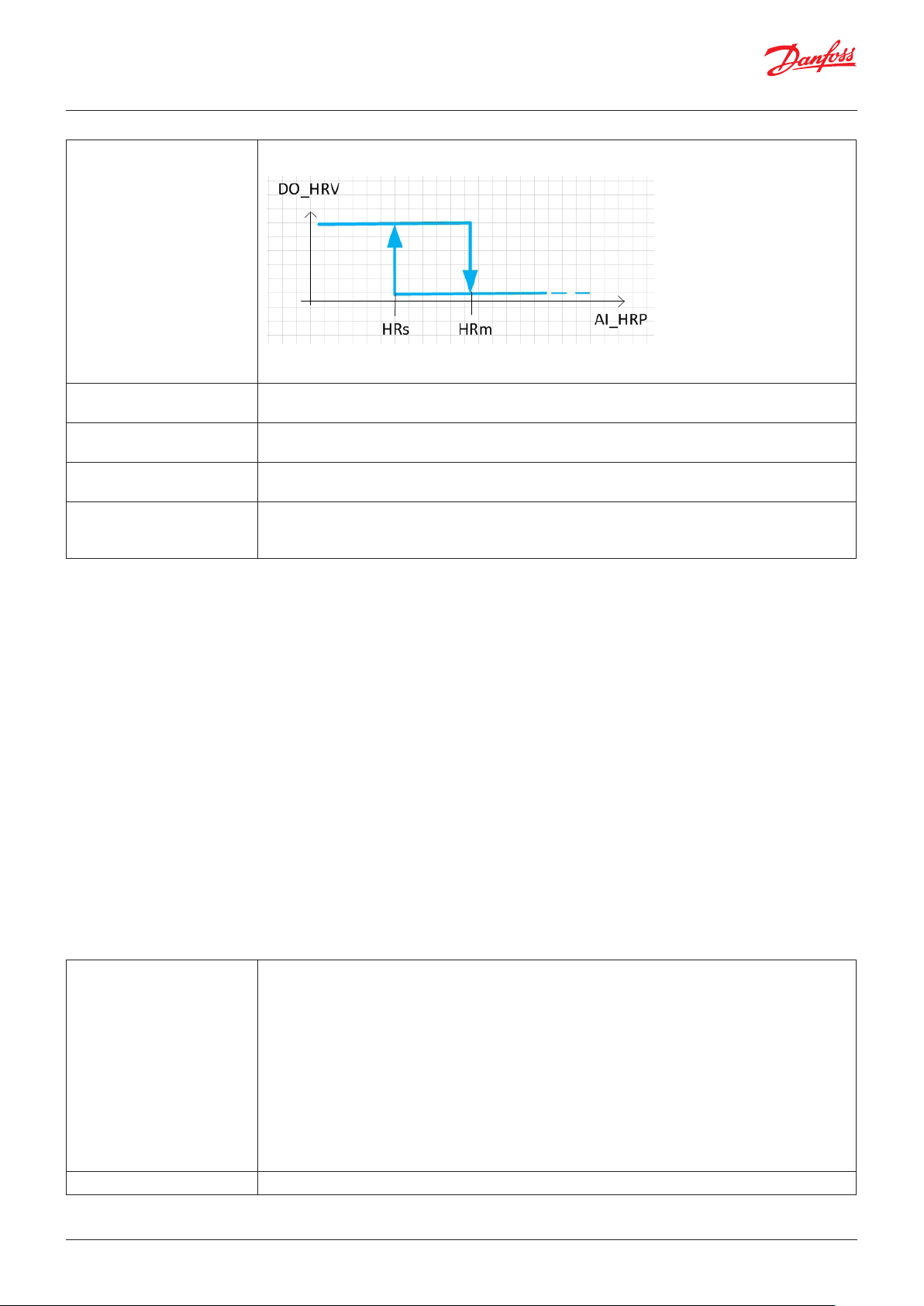

Heat recovery .............................................................................66

Parameter: HRs, HRm, HRc, HRn, HRt, HRo

Superheat ...................................................................................67

Parameter: V10, V20, bAt, ex1, ex2, ex3, N19, N04, N05, N20,

N22, N10, N09, N11, N32, N18, N17, N15, N21, SHO

Input output expansion module ..............................................69

Parameter: XCn

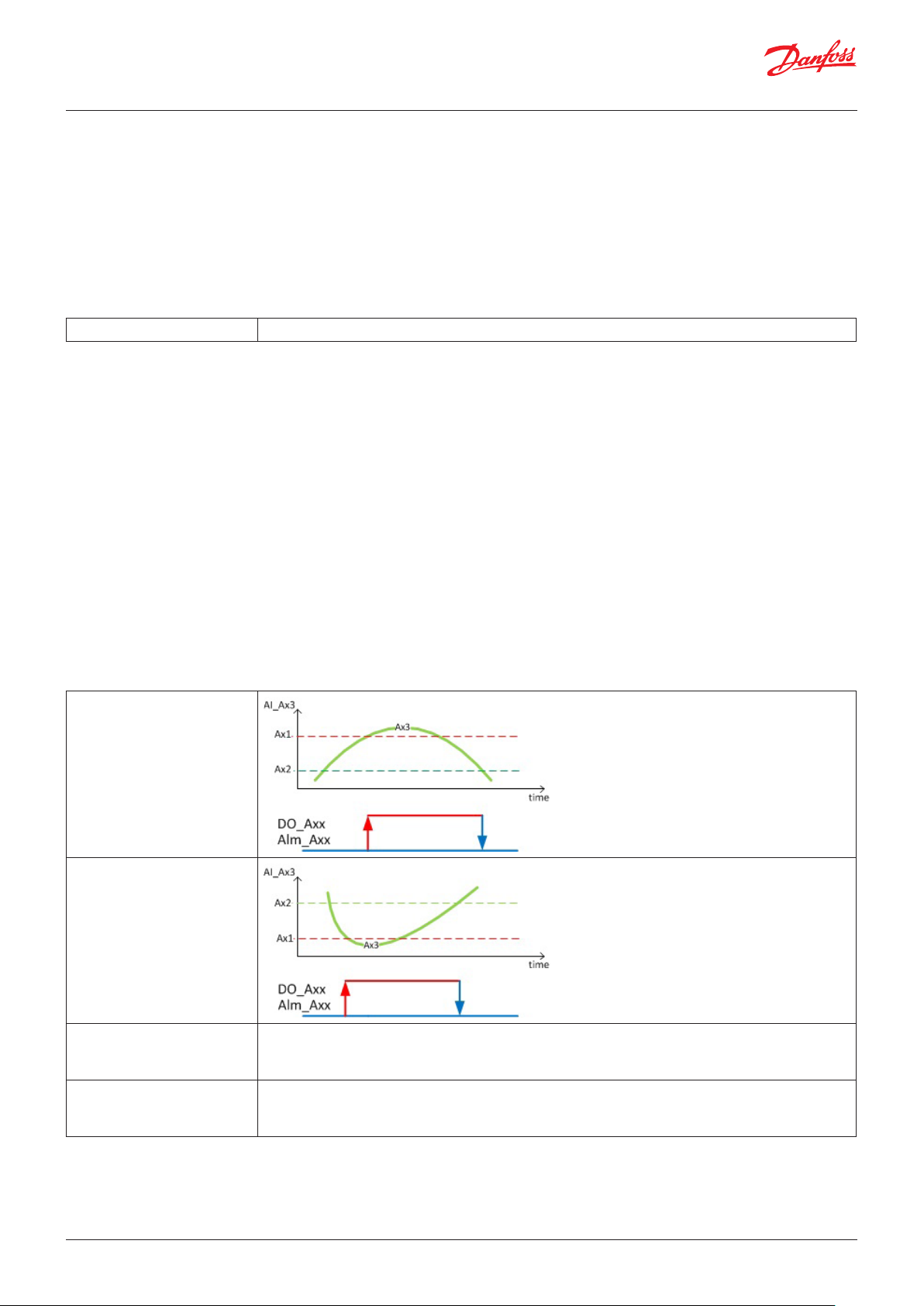

Auxiliary alarms .........................................................................69

Parameter: a11, a21, a31, a41, a12, a22, a32, a42, a13, a23,

a33, a43, a 14, a24, a34, a44

Oil Alarm Tandem .....................................................................70

Parameter: BME, BST, TD1, TD2, TD3, TD4, ADO, BOF, BFR

Compressor Oil Pump................................................................72

Parameter: OPE, OPO, OT1, OT2

Temperature delta of the oil .....................................................73

Parameter: OTD, OD1, OD2

How to set the power request remotely ..................................73

Parameter: RPE, RPS

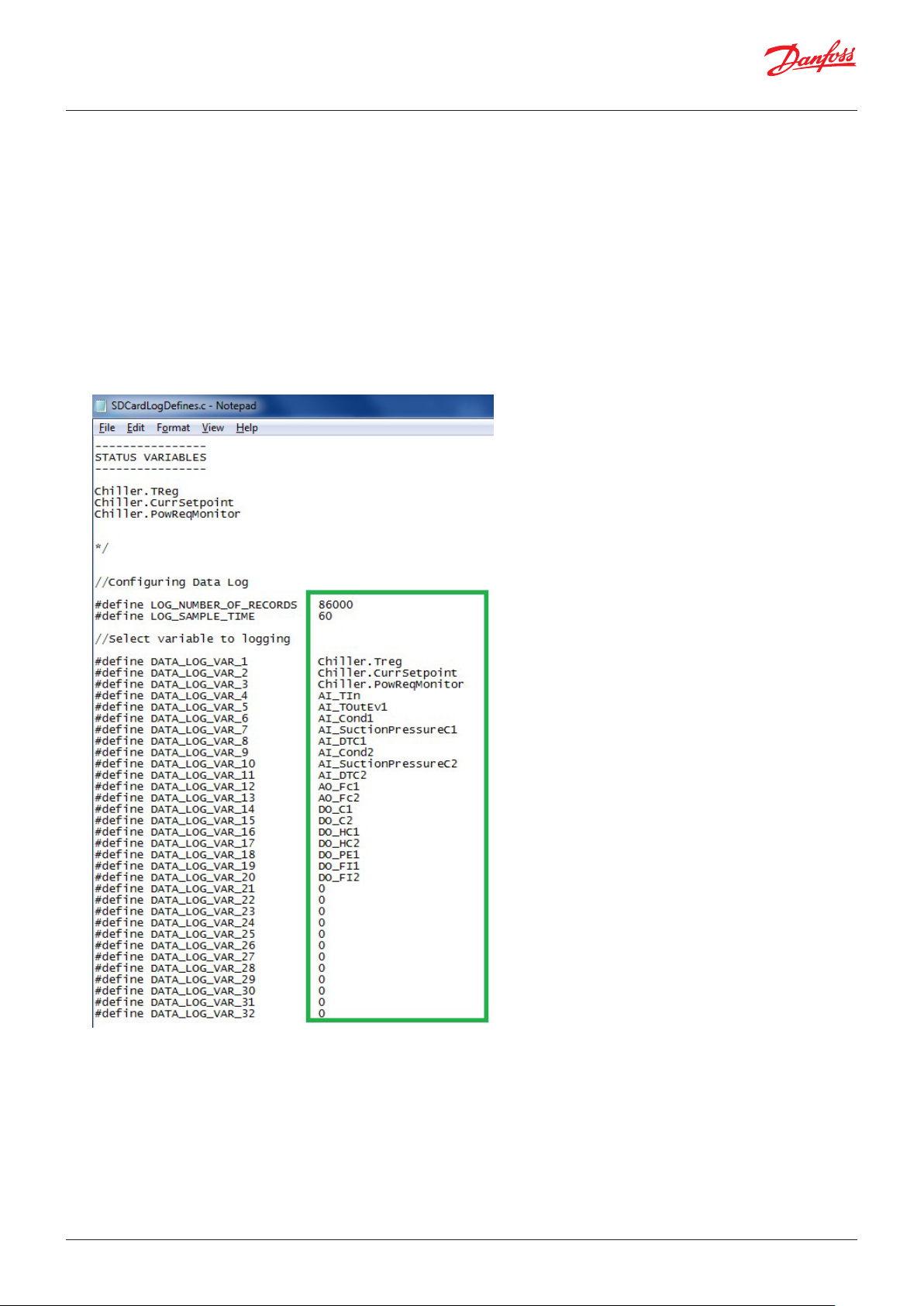

How to log data on an SD card .................................................74

Parameter: ENL

Commissioning ..........................................................................77

Parameter: Ort

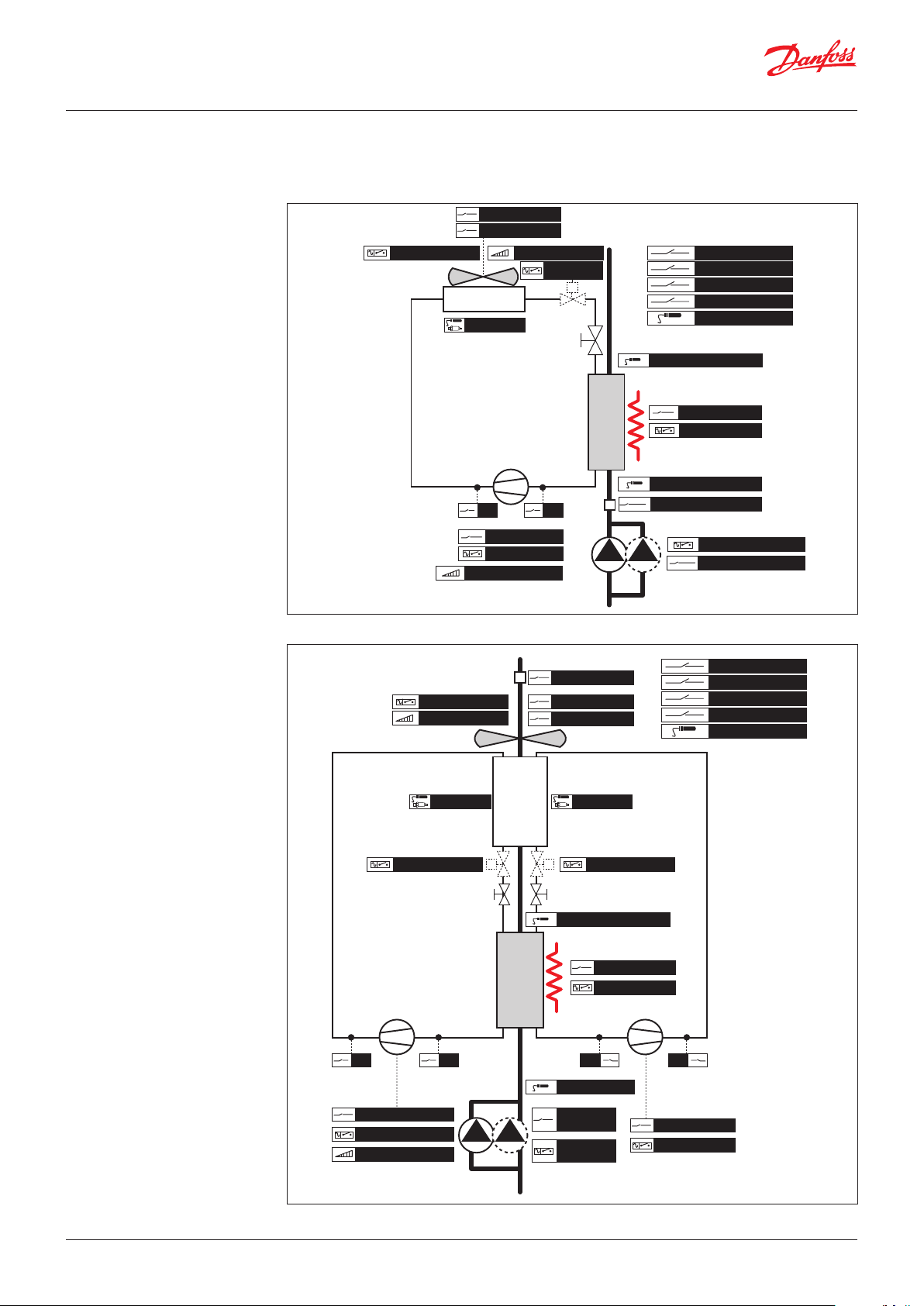

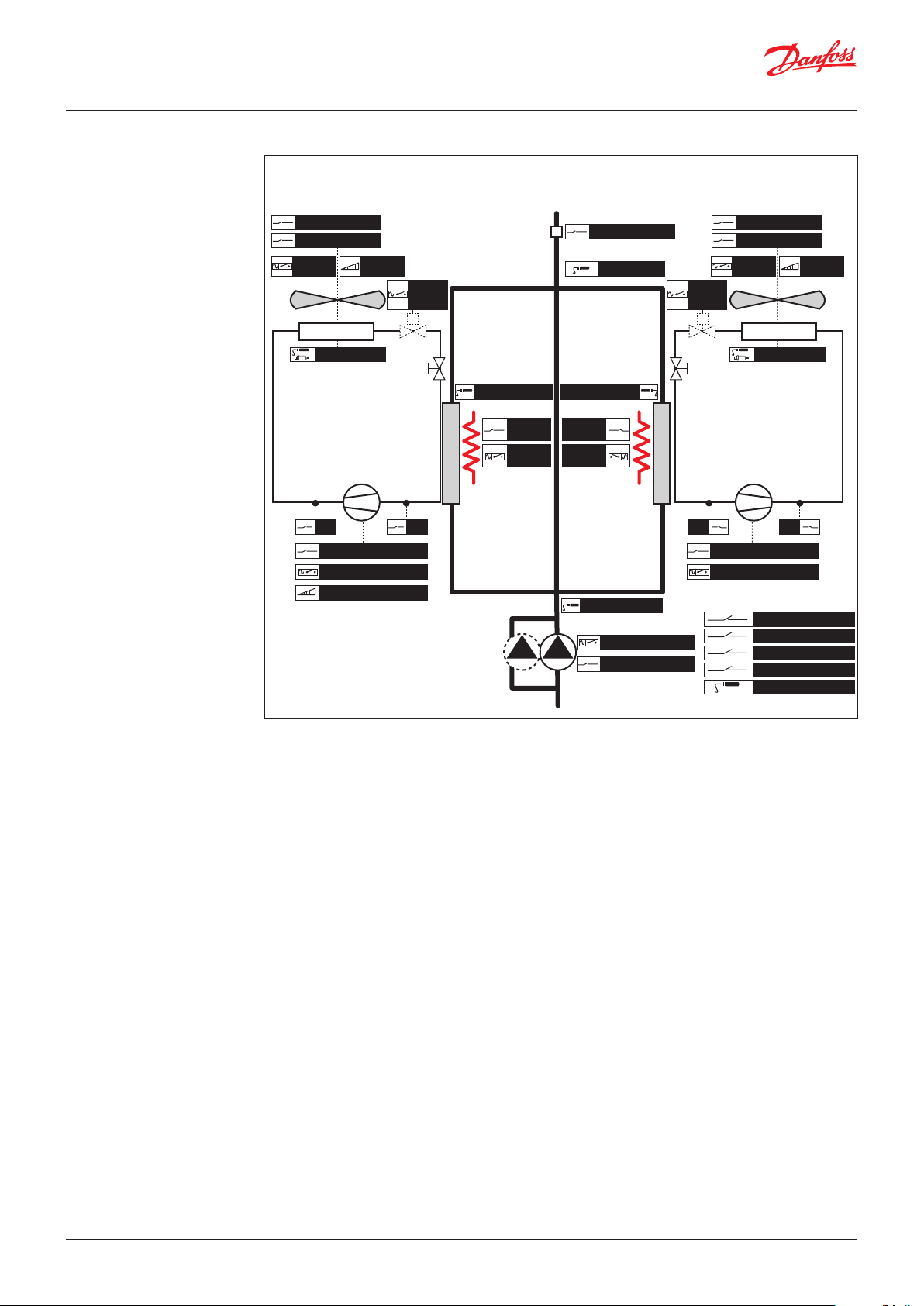

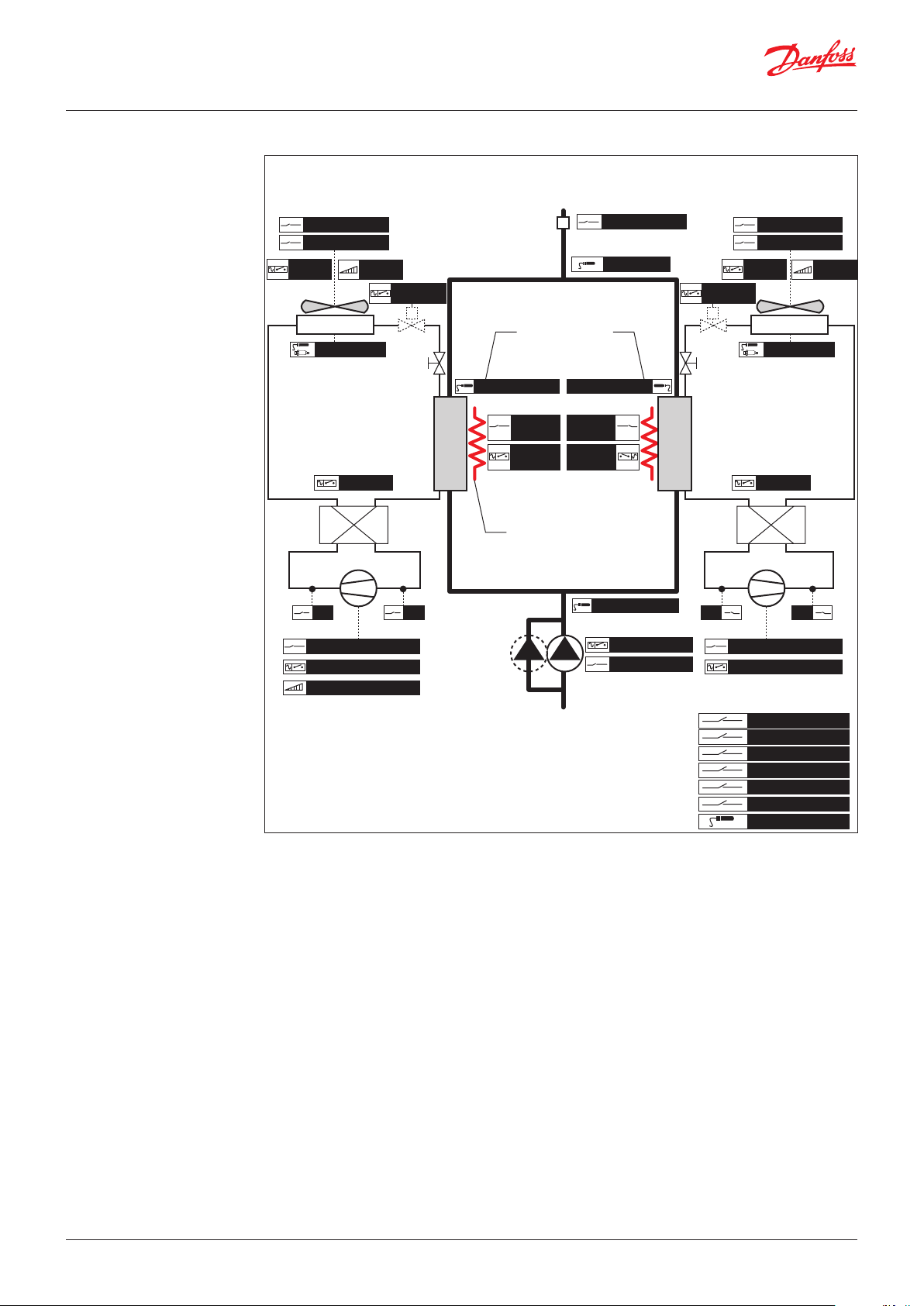

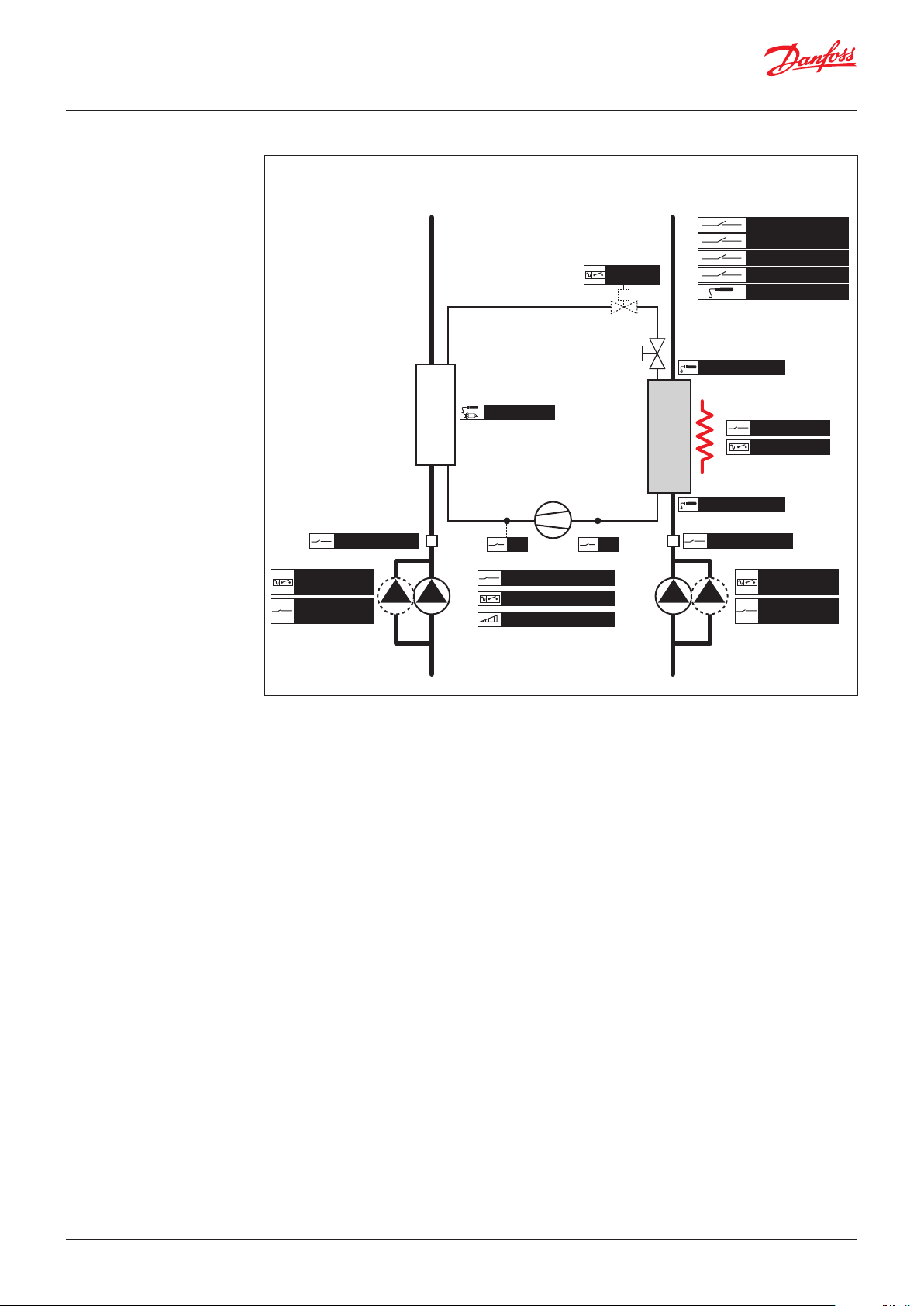

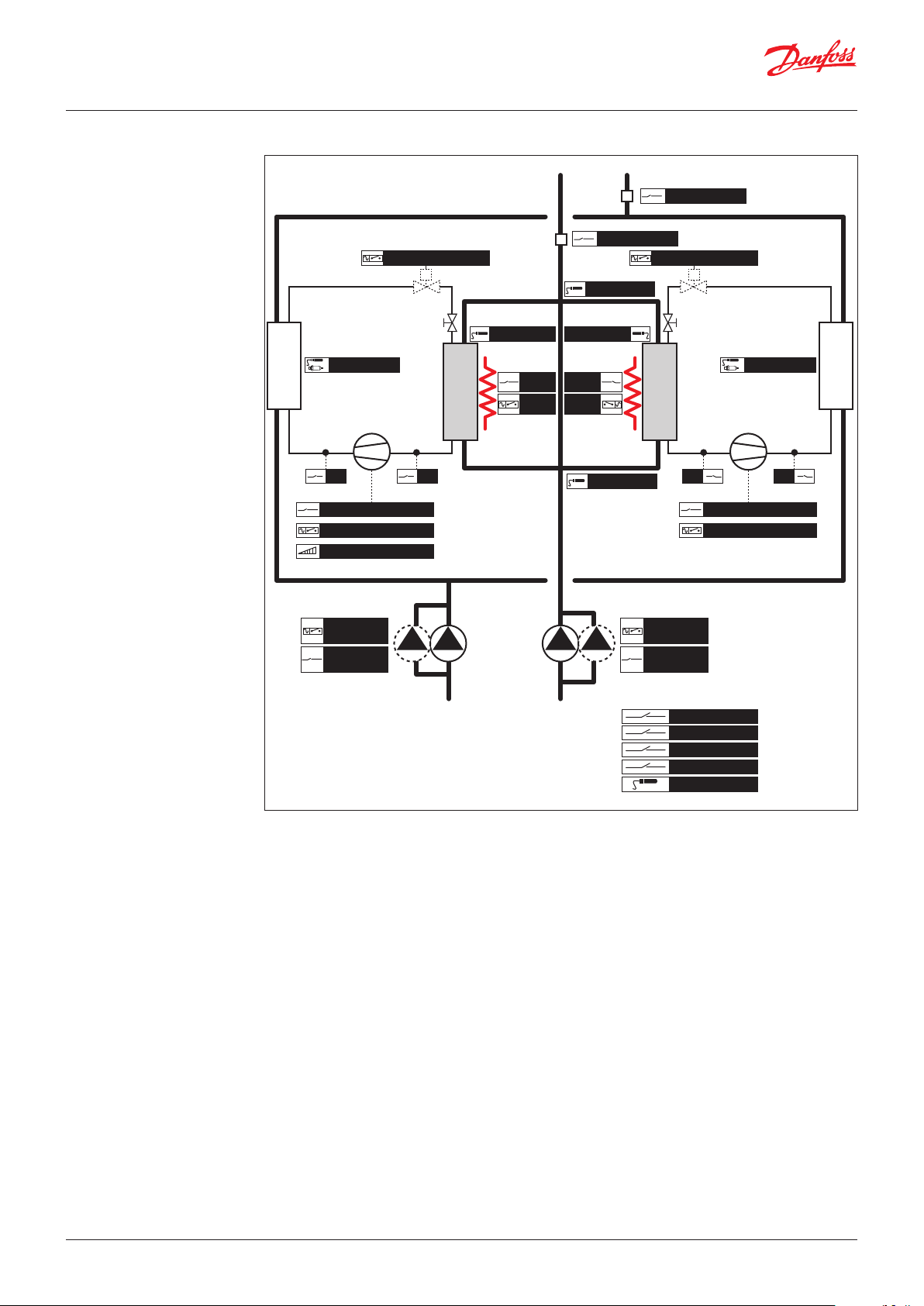

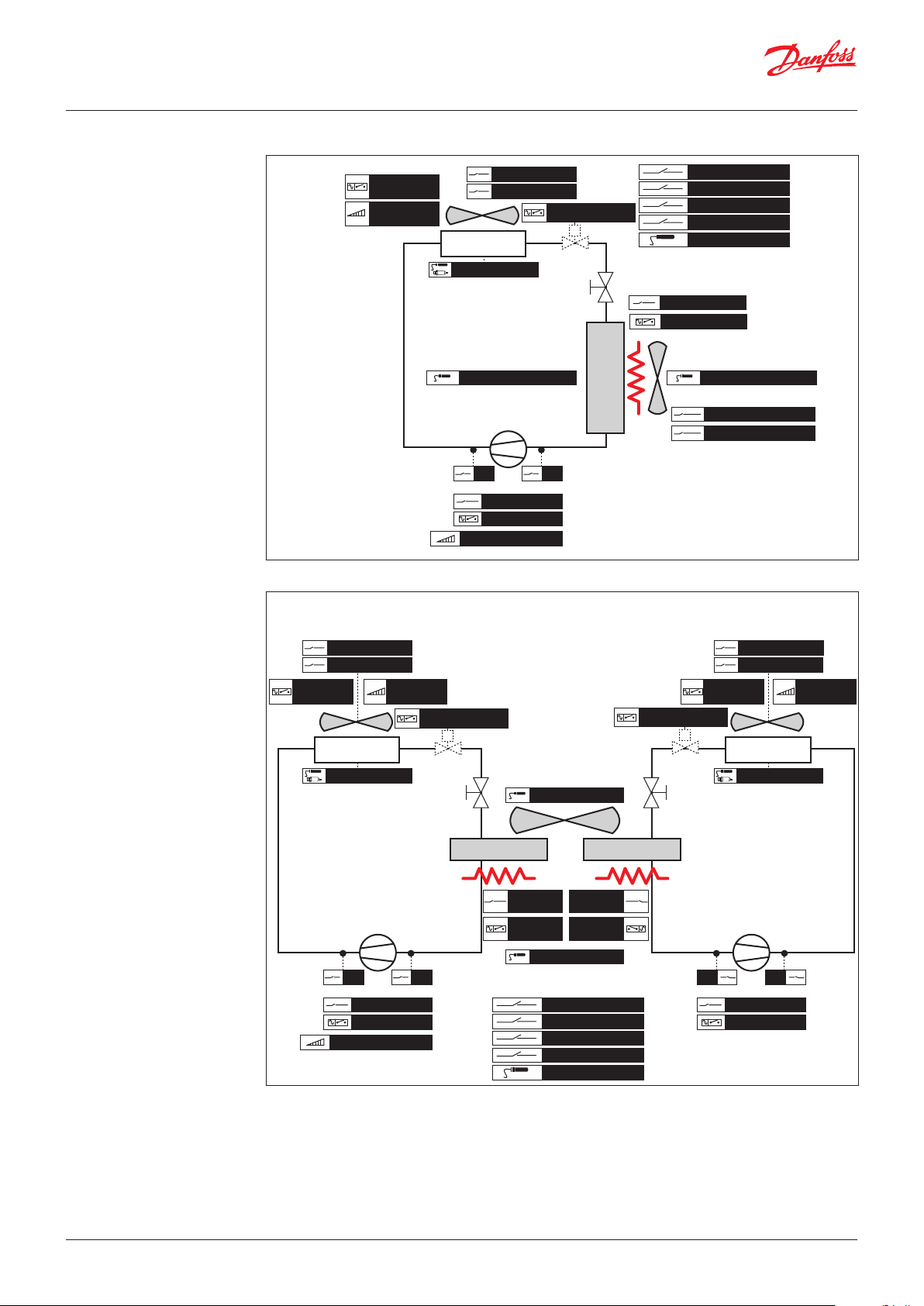

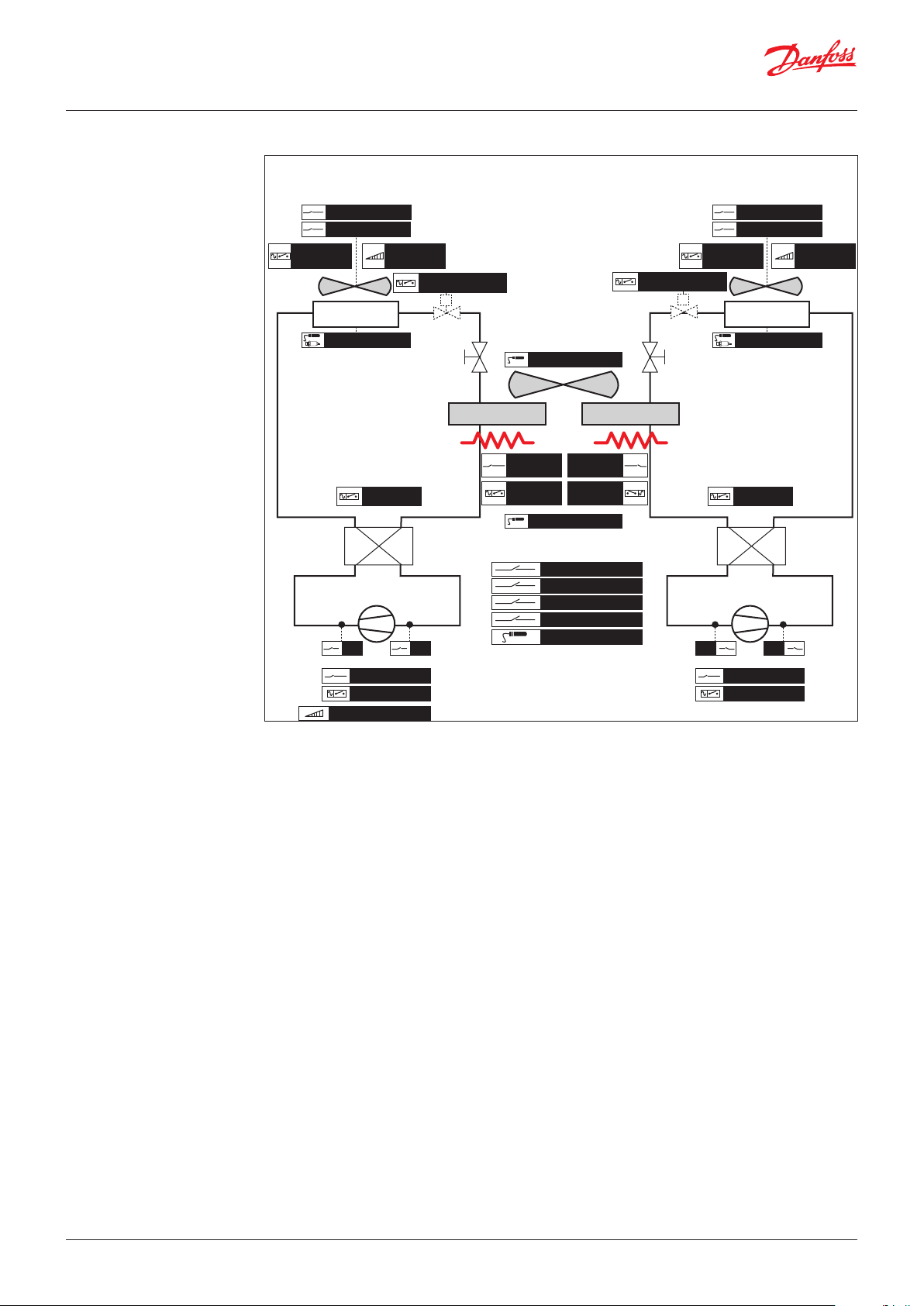

Graphic diagrams of some of the managed unit types ..........80

Status variables .........................................................................91

Software status ..........................................................................91

Parameter: A01, …, A19, C01, …, C04, E01, …, E08

Software info .............................................................................92

Parameter: F01, …, F07

Superheat info ...........................................................................93

Parameter: H01, …, H13

Preparatory: link to MCXShape manual

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 3

Page 4

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

User Interface

LED Display, LCD Display, Keyboard, Unit status, Login, Start,

Parameter, Input/Output, I/O Display, I/O Config, I/O Prb

Calibration, I/O Commissioning, Alarm, EEV, VSH Monitor, VSH

Control, Clock, Language, Service, Hours Counters, Variable

speed pump

Functionalities: Enable screen saver for LCD

Functionalities: Enable LED display

Enable support for MMILDS

Functionalities: Enable schema view

Functionalities: Enable I/O probe calibration

Functionalities: Enable override of input and output

Functionalities: Enable commissioning form

Functionalities: Enable EEV using EKE 1C

Enable MMI navigation

Functionalities: Enable EEV using EXD 316

Functionalities: Enable EEV using MCX driver

Functionalities: Enable VSH Modbus control

Functionalities: Enable Scheduler

Functionalities: Enable Evaporator variable capacity pump

Note: playing with MCXShape, it is very easy to customize the

structure and the visibility of the menu: so the following indication

cannot match with all the compiled software

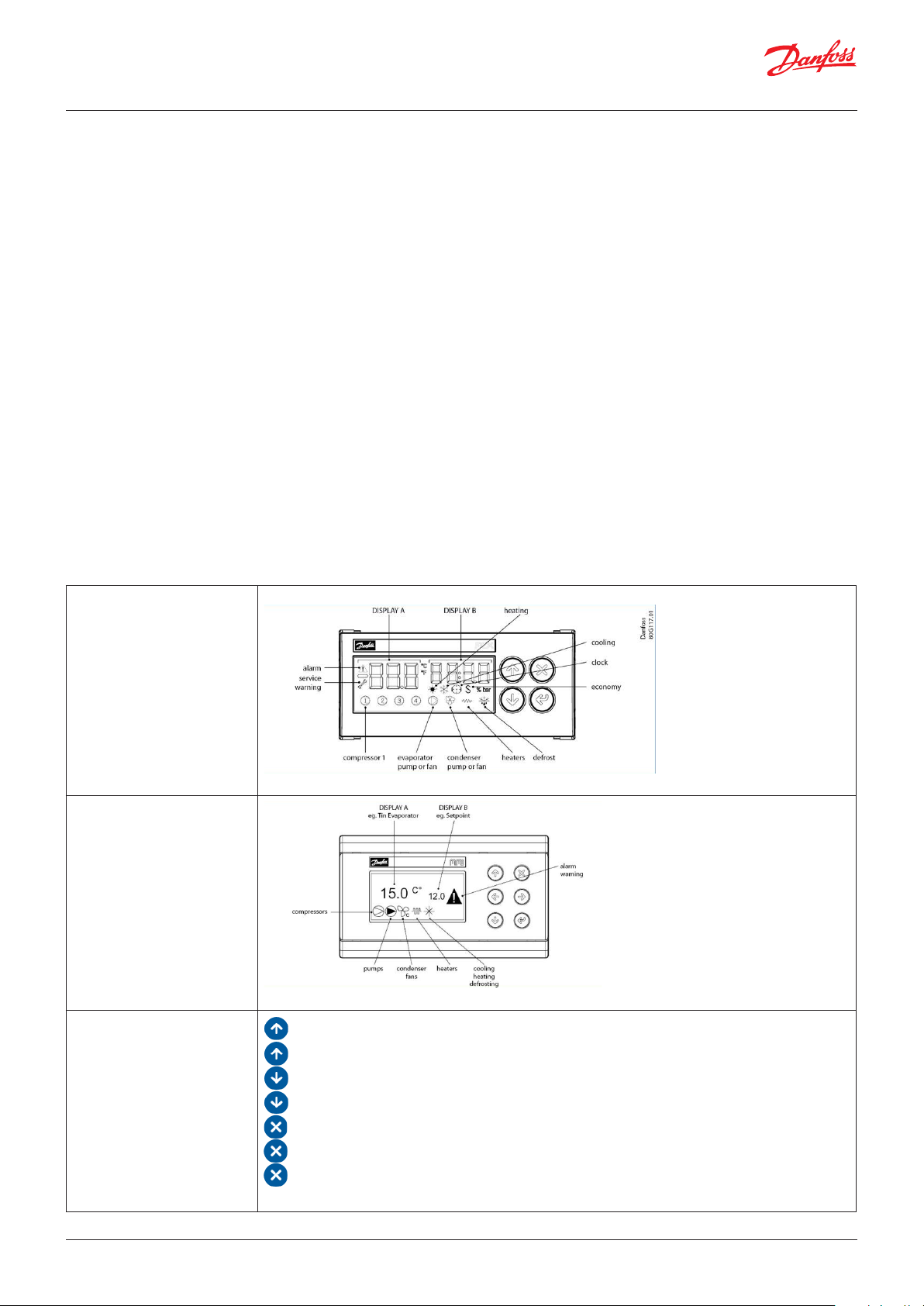

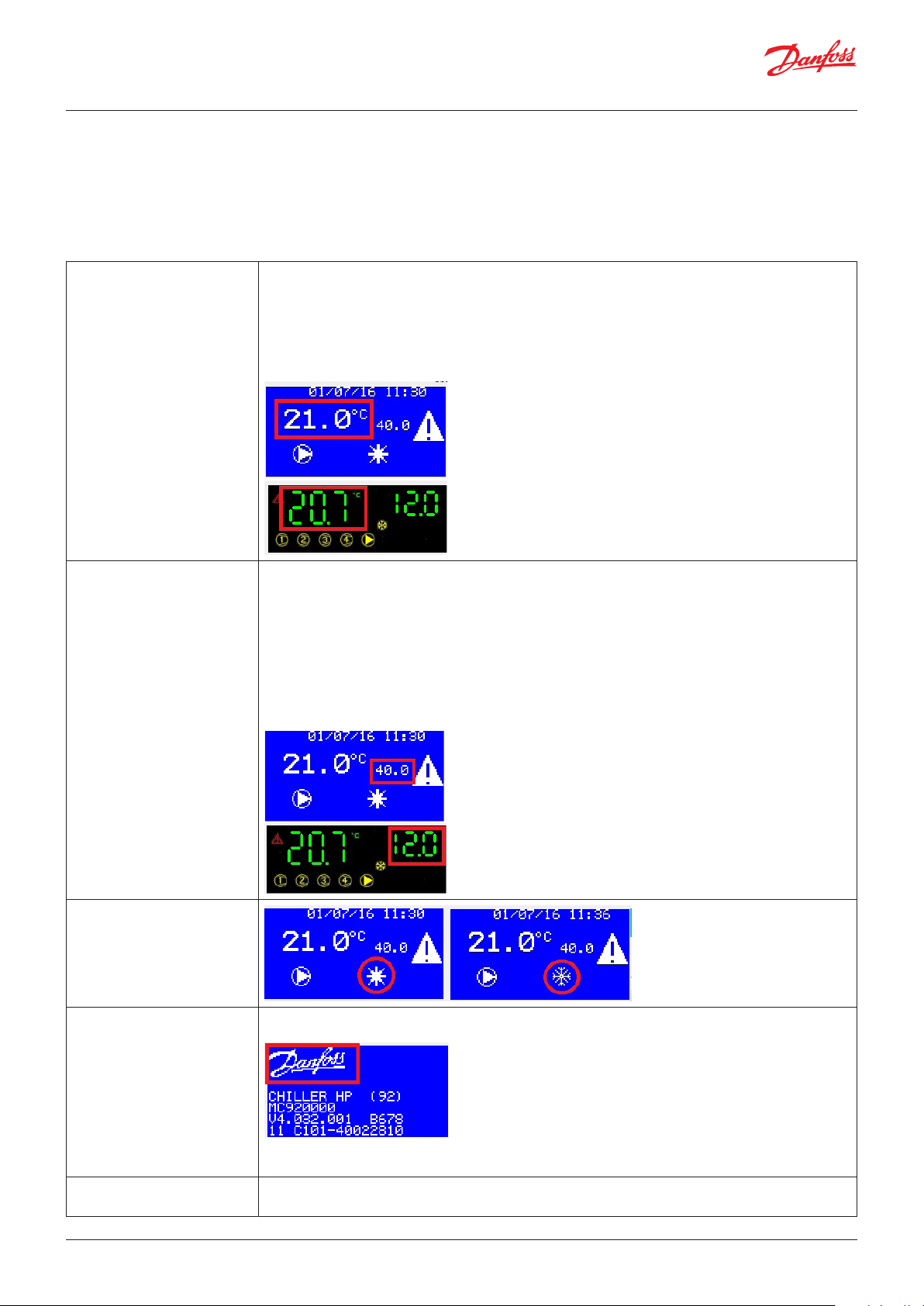

Main screen: LED Display Functionalities: Enable LED display

Note: check parameters dsA, dSb and dSC.

Main screen: LCD Display

Note: check parameters dsA, dSb and dSC.

Keyboard

: Scroll UP, increment a value

: 3s when in main screen: toggle ON/OFF

: Scroll down, decrement a value

: 3s when in main screen: toggle Heat/Cool mode

: exit and save,

: when in main screen: access the active alarm list

: 3s when in Alarm screen: manual reset

The LEFT and RIGHT keys, if present, allow you to move the cursor to the desired option

4 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 5

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

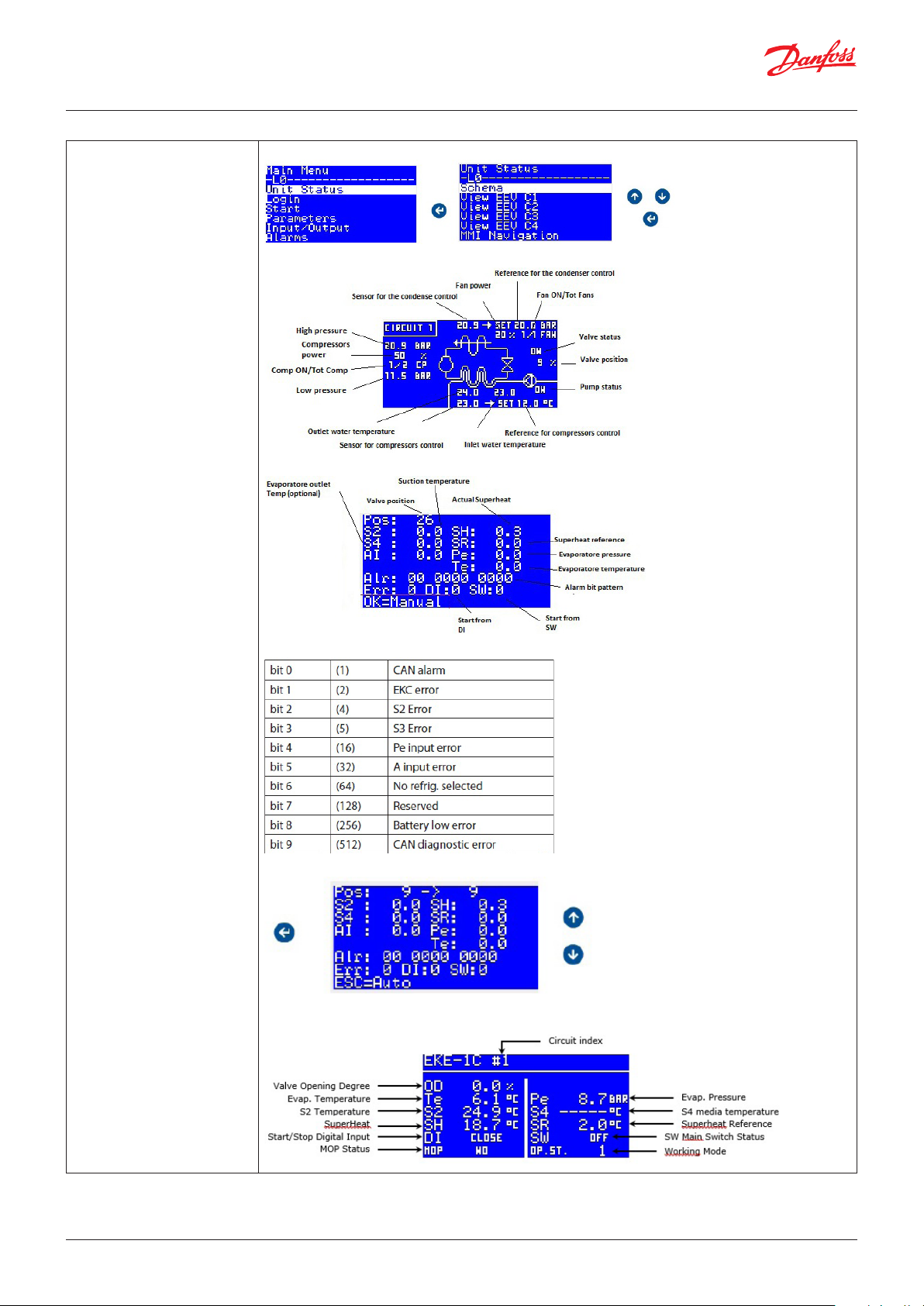

Menu: Unit Status Functionalities: Enable schema view

Schema:

View EEV Cx (for valve which is driven by EXD or MCX):

The alarms bit pattern is:

Note: by pressing “OK” key you manually tune the position of the valve

View EEV Cx (for valve which is driven by EKE):

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 5

Page 6

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

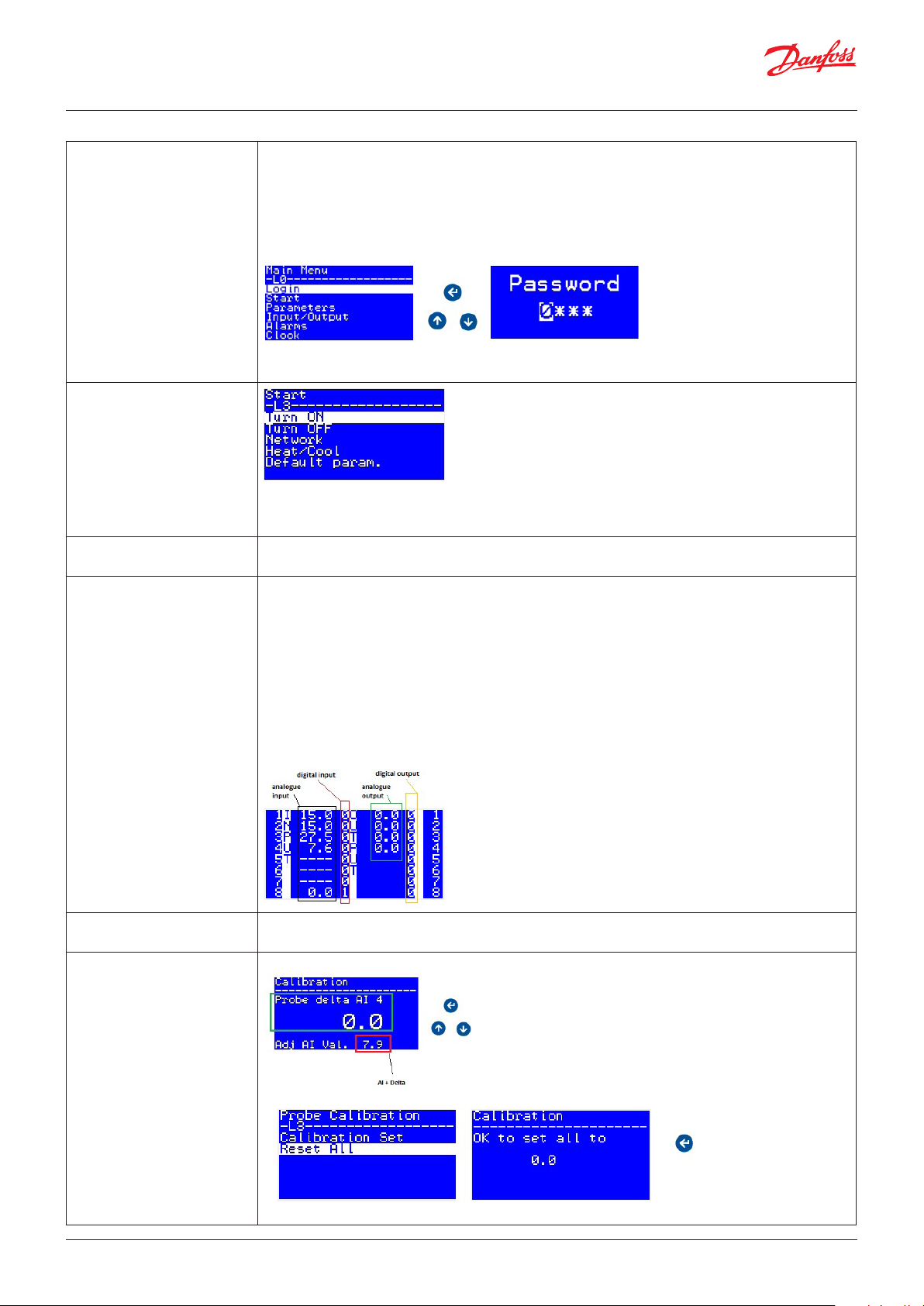

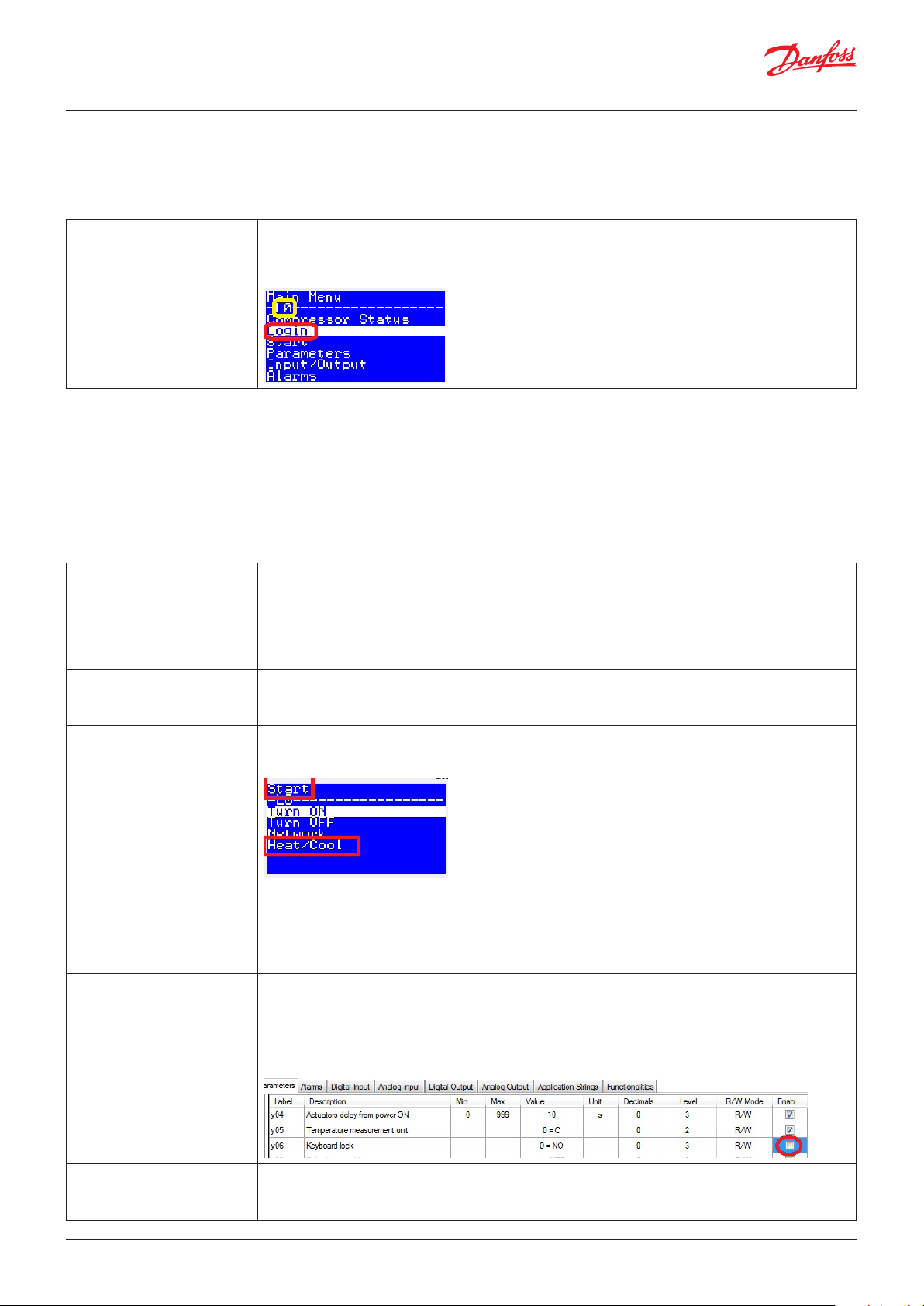

Menu: Login Parameters and Menu are organized into 4 access levels. Levels from 1 to 3 are linked to a password.

Elements cannot be accessed when they are on a higher level than the entering level. The level of

each parameter and menu is defined with MCXShape

• Level 0 is accessible without password

• Levels 1-3 are linked to a password (Check parameters L01, L02 and L03)

• Level 4 is not linked to a password, it can be used to make menu or parameters never reachable.

You can log in from the menu:

if the password provided is not correct you remain on the login screen. Otherwise you get back to

the main menu.

Menu: Start

Network menu: used to switch all the machines on or off in the Master and Slave network

Default param. menu: used to load the default value of the parameters which have been defined in

the .mcxs file

Menu: Parameter This menu contains all the parameters.

The meanings of the parameters are explained in the last part of this manual

Menu: I/O Display Display input and output values

LED display

Shows you (using the UP and DOWN keys) all the input and output values in sequence, showing the

I/O code on display A (“AI” for analogue input; “AO” for analogue output; “dI” for digital input and “dO”

for digital output) and its value on display B (analogue inputs that are not present or in alarm are

shown with “----”).

LCD display

You have access to three screens showing all the input and output values; each screen shows a group

of 8 I/O. Use UP and DOWN keys to scroll. The second and third screens are used with MCX15 and

MCX20 only.

The example below shows the first screen.

Menu: I/O Config This menu is prepared for future use

Note: it is under the 4th level of password

Menu: I/O Prb Calibration Functionalities: Enable I/O probe calibration

inside the “Reset All” menu, you can reset all the offsets to zero

Note: the screens calibration are not translated

6 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 7

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Menu: I/O Commissioning Functionalities: Enable override of input and output

Functionalities: Enable commissioning form

Note: the logic will not affect the override. The override is stopped for power off, "Reset all" command

and timeout that is defined into the menu "Setup"

Menu: Alarm Each alarm is described through an alarm description (for LCD display only), an alarm code and the

time since its activated in the format hours:minutes:seconds (seconds for LCD display only).

Note: You can also access alarm visualization by pressing the ESC key from the main screen.

The alarm is only reset if the alarm has ended and it will send you back to the main screen.

Note: Alarms can also be reset by holding ESC for 3 seconds on the alarm screens

Menu: EEV Functionalities: Enable EEV using EKE 1C

Functionalities: Enable EEV using EXD 316

The parameters inside the external drivers can be checked and changed in the Config EEVx menu.

The available parameters for the EXD are: r05, r09, r10, r12, A34, n04, n05, n06, n09, n10, n11, n15,

n17, n18, n19, n20, n21, n22, n32, n37, n38, n39, n40, n42, n43, n44, n45, n50, o10, o18, o20, o21,

o30, o45, o56, o61, n03

The available parameters for the EKE are: R012, R009, r105, r107, O030, N102, N015, N104, N017,

N021, N107, N009, N010, N116, N005, N019, N004, N020, N117, N119, N130, N011, N140, N141,

A034, A103, A104, A110, A102, I020, I022, I040, I042, I043, O020, O021, I067, R005, B101, O002,

O022, G003, N108, N109

The Load Factory menu overwrite the EXD parameters with the default ones

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 7

Page 8

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Menu: VSH Monitor Functionalities: Enable VSH Modbus control

VSH Status:

VSH Alarms:

The STW bit-map is:

VSH inverter details:

8 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 9

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

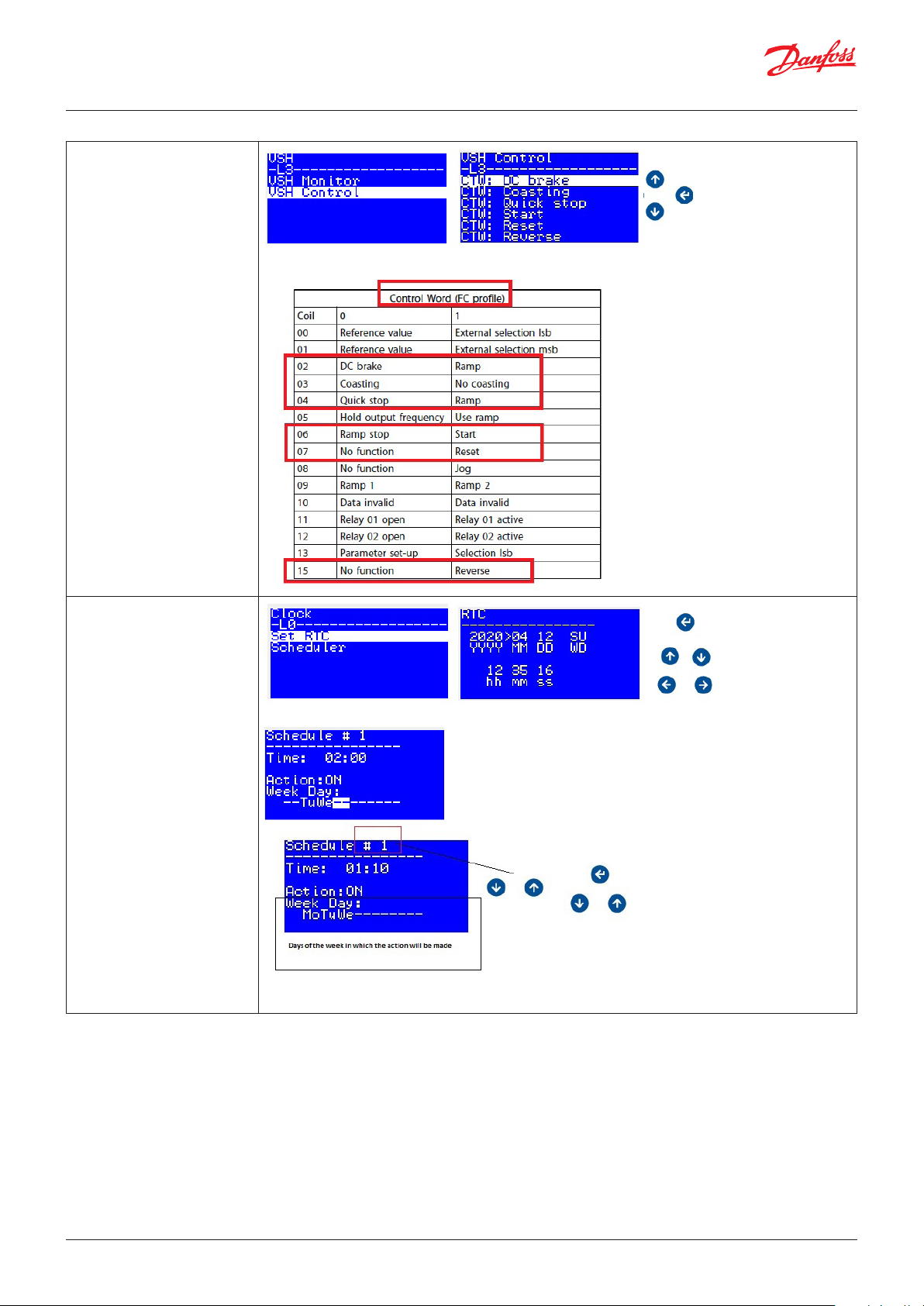

Menu: VSH Control

These commands are linked with the control word of the inverter

Menu: Clock

Functionalities: Enable Scheduler

Note: with the number beside to the function "Enable scheduler" you set the maximum amount of

records, before to change it consider that it also affects the EEPROM.

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 9

Page 10

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

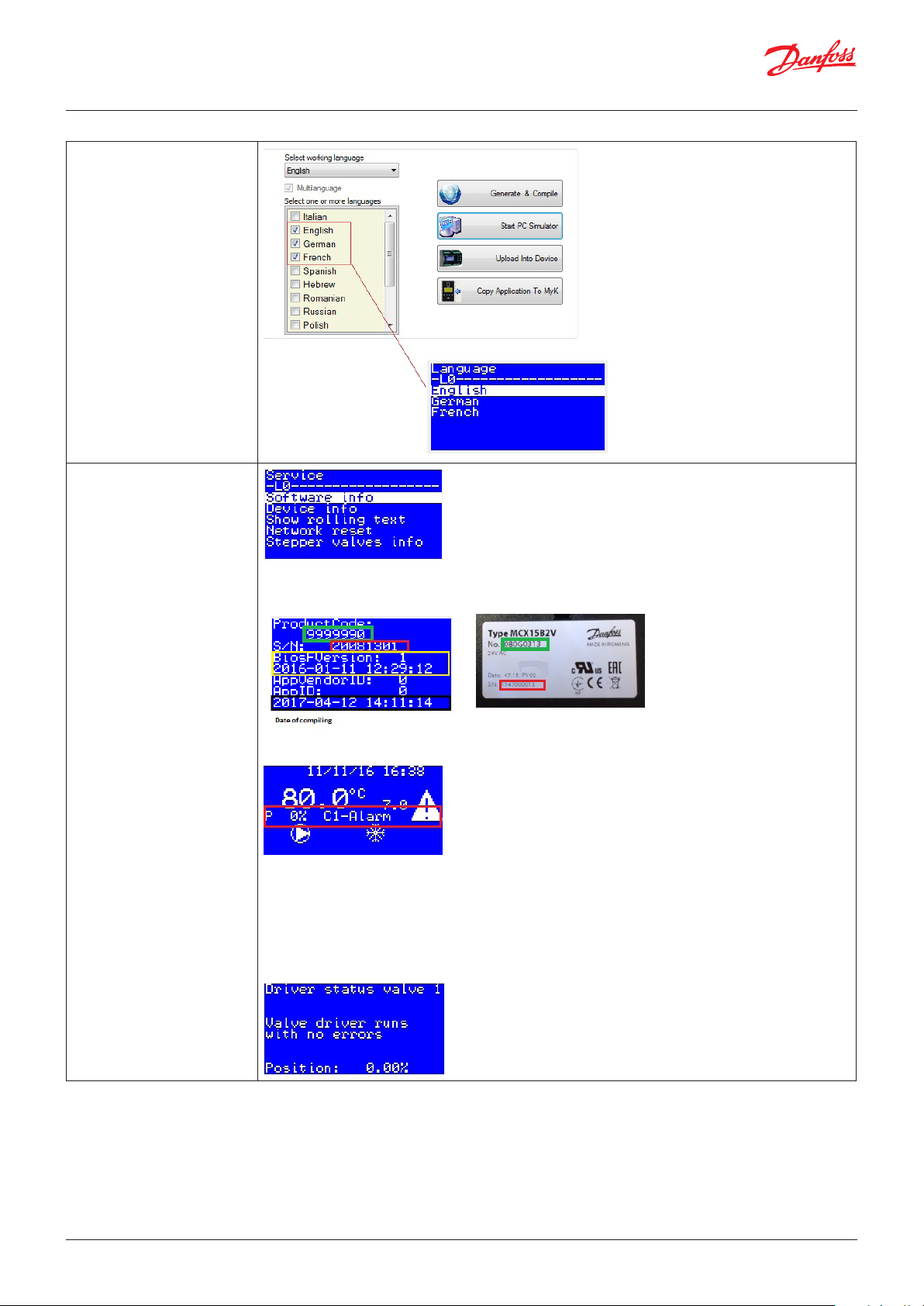

Menu: Language

Menu: Service

Software info: Check variables status F01-F07

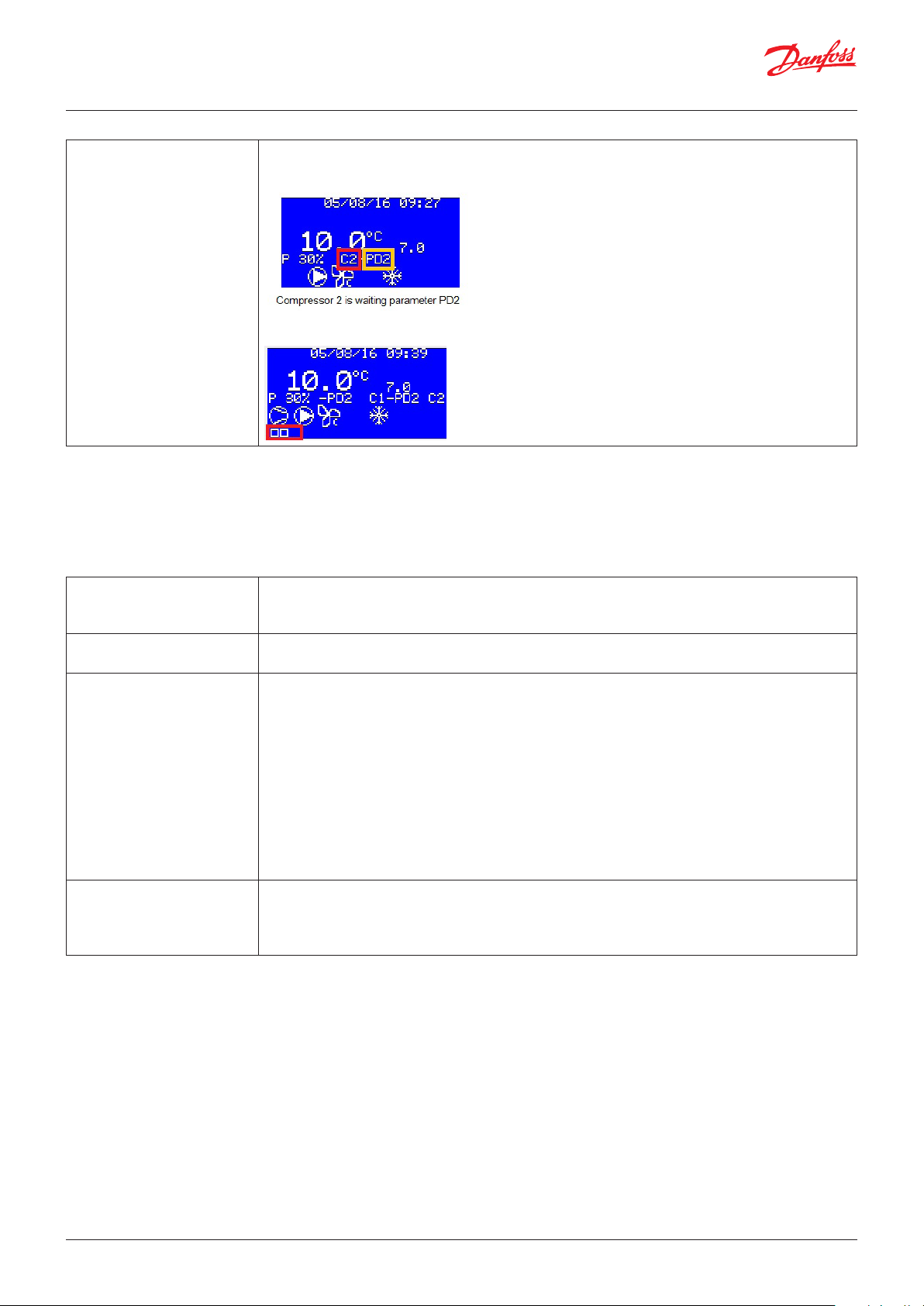

Device info:

Show rolling text:

Enabling rolling text will add additional information in the main screen

- P: Power demand

- Cx- Alarm: Compressor X is in alarm

- Cx- CTy: Compressor X is waiting for the parameter with the label CTy

- P-Down: Compressor is waiting for pump down to be switched off

- Cx- Prev: Circuit X is being reducing by prevention

Network reset: it restarts from zero the managing of the master slave network

Stepper valves info:

10 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 11

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Menu: Hours Counters Note: The Reset Counters menu resets to zero all the counters, compressors and both pumps.

For resetting the single compressor or pump push "Enter" button into the screen where are reported

the hours of the device.

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 11

Page 12

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Parameters

Display

Parameter: dSA, dSb, dsc, Log, Par

How to customize the main screen.

dSA-Display A value 0= OFF : Display A is not used

1= IdOF : Display A shows the state of the digital input ON/OFF

2 =SEt : Display A shows the set point of the compressors regulation

3 =rEg : Display A shows the probe used for regulation

4=AI1 : Display A shows the value of the analogue input 1

……

19 =AI16 : Display A shows the value of the analogue input 16

dSb-Display B value 0 =OFF : Display B is not used

1=IdOF : Display B shows the state of the digital input ON/OFF

2=SEt : Display B shows the set point of the compressors regulation

3 =rEg : Display B shows the probe used for regulation

4 =AI1 : Display B shows the value of the analogue input 1

…

19 =AI16 : Display B shows the value of the analogue input 16

20 =TcP1 : Display B shows the temperature calculated from the dP1 sensor

…

23 =TcP4 : Display B shows the temperature calculated from the dP4 sensor

dsc-Icone for cooling mode

Log- Logo Log=0 is combined with the image StartLogoDX in Chiller/BIN/Graph folder

Log=1 is combined with the image StartLogoDX_1 in Chiller/BIN/Graph folder

Note: the logo is shown just after the power on, pay attention to the size of the image because it is fit

in this screen

Par- Parameters version It is not used in the software, can be used to recognize different set of parameters

Note: this number is reported into the software information

12 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 13

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Password

Parameter: L01, L02, L03

How to change the passwords.

L01, L02, L03-

Level x password

Typing the parameter L0X, in the login screen, you will be able to see all the parameters and menu

with level <= of X;

The level of access is highlighted in the yellow square;

after 10 minutes of inactivity the display is set to an access level of zero

SetUp

Parameter: y01, y02, y03, y04, y05, y06, y08, y09

How to switch ON-OFF and change the application mode from parameters.

Functionalities: Enable scheduler

Functionalities: Enable show compressor status

Digital input: ONO

Digital output: UNT

y01- System ON/OFF 0=Machine OFF

1=Machine status depends on the DI _ONO

Defines whether the chiller is in the ON or OFF state, it can be changed from the menu, remotely by

Modbus or CANBUS and from start screen by holding the up arrow key.

Note1: The software is in ON status only if y02=ON and DI_ONO=ON

Note2: The chiller status is also reported in the digital output UNT_Unit Status

y02- Restart mode after

power OFF

y03- System heat/cool It works only with H40> 0 and rE2=UI;

0=OFF means that after power on, the chiller gets up in OFF state

1=ON means that after power on, the chiller gets up in ON state

2=EQUA means that after power on, the chiller keeps the same state as before power off

This defines whether the machine should be in chiller mode or heat pump mode.

This parameter can also be changed from the “Start” menu

y04- Actuators delay from

power ON

y05- Temperature

measurement unit

y06- Keyboard lock 0=No

y08- Scheduler enable 0=No means that the scheduler is disabled

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 13

It is in seconds and sets the delay when powered ON (not when the unit status changes to ON) before

activating any outputs. Its purpose is to distribute the drawn current and protect the elements and

particularly the compressor against repeated starts in the event of frequent power failures. When the

timer has elapsed, the controller starts to manage the outputs based on the other times and the other

normal functions.

0=C means that the user interface will show values in Celsius and bar

1=F means that the user interface will show values in Fahrenheit and PSI

1=Yes means that the user interface is locked

Note: This parameter can be adjusted in order to be set remotely because it is not enabled for the menu

1=Yes means that the scheduler is enabled

Note: the “Enable scheduler” functionality is required

Page 14

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

y09- Show rolling test 0=No

1=Yes

Provides information about what is going on in relation to the cutting in/out of the compressors

Note: If the functionalities “Enable show compressor status” is enabled in the UI, a small icon is

added for each compressor

Serial setting

Parameter: Cid, Ser, bAU, COM

How to configure the communication port.

Functionalities: Enable Modbus address different from CANBUS address

Cid – Serial address (CAN) Defines the ID in the CANBUS communication

Note: the baud rate and the settings of the CANBUS communication is tuned through the bios menu

or though the MYK

SEr – Serial address (MODBUS) Defines the ID in the Modbus communication

Note: the functionalities “Enable Modbus address different from CANBUS address” is required

bAU – Serial baud rate (Modbus)

COM – Serial settings

(Modbus)

Defines the baud rate in the Modbus communication

0 means Reserved: do not use

1 means 1200 bits/sec

2 means 4200 bits/sec

3 means 4800 bits/sec

4 means 9600 bits/sec

5 means 14400 bits/sec

6 means 19200 bits/sec

5 means 28800 bits/sec

8 means 38400 bits/sec

9 means 57600 bits/sec

8 means 115200 bits/sec

Defines the serial settings of the Modbus communication

0 means 8N1

1 means 8E2

2 means 8N2

14 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 15

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Evaporator

Parameter: H1, H2, H3, H4, H5, H12

How to configure the internal coils.

Digital input: OPE, OPE1, OPE2

Digital output: PE1, PE2, …, PE8, H1, …, H4

Analogue input: TIN, TOM, TO1, …, TO4

Analogue output: E1, …, E4

Alarms: AE1, AO7, AP0, AP1, …, AP9

H1 – Number of evaporators Defines the number of internal coils;

The supply temperature (TIN) is the same for all the coils.

Each coil has a “leaving temperature” (T01-T04) ; there is also a common “leaving temperature” sensor

for all the coils ( TOM)

H2 – Number of circuits per

evaporator

H3 – Air or water cooling Defines whether the evaporation process is managed by a pump (H3=H2O) or a fan (H3=Air):

H4 – Number of pump/fan per

evaporator

H5 – Number of heaters per

evaporator

H12 –Fan in common for each

evaporator

Defines the number of circuits for each internal coil;

Configuration accepted:

• 1 circuit per internal coil -> 0<H1<5

• 2 circuits per internal coil ->0<H1<3

• 3 circuits per internal coil H1=1

• 4 circuits per internal coil H1=1

• WATER evaporators (H3=H2O). For each evaporator, the H1,...,H4 digital outputs which are

necessary to manage the antifreeze heaters on the basis of the leaving water temperature TO1,...,TO4

are controlled. The number of heaters per evaporator is defined by H5.

• AIR evaporators (H3=Air). Only the “TO1_Tout Evaporator 1” input is used to measure the supply air

temperature even when more than one evaporator is present. The ice alarm AE1 is replaced with the

Low air temperature warning A07 which is set to the same parameters as the ice alarm.

Defines the pumps (or fan) per evaporator:

• WATER evaporators (H3=H2O): The PE1 and PE2 digital outputs are managed to control one pump

or two twin pumps.

• AIR evaporators (H3=Air): “PE1 and PE2” outputs are used to manage fans on the evaporator.

Note: check "Fun for internal coil"

Defines the number of heaters for each internal coil;

Configuration accepted:

• 1 heater per internal coil -> 0<H1<5

• 2 heaters per internal coil ->0<H1<3

• 3 heaters per internal coil ->H1=1

• 4 heaters per internal coil ->H1=1

0=NO means that each fan (AO ECx) works in relation to the evaporator pressure

1=Yes means that only the fan EC1 will work in relation to worst pressure in the evaporators

Note: the fan speed is managed with PI logic (check parameters ECS,….,Hi)

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 15

Page 16

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Compressor

Parameter: H6, H7

How to configure the compressors number.

H6 – Number of compressor

per circuit

H7 – Number of unloader per

compressor

Defines the number of compressor per circuit;

It’s not possible have circuits with different number of compressors

Configuration accepted:

• 1 compressor per circuit -> 0<H1*H2<5

• 2 compressors per circuit ->0<H1*H2<5

• 3 compressors per circuit ->0<H1*H2<3

• 4 compressors per circuit ->0<H1*H2<3

• >4 compressors per circuit ->0<H1*H2<2

Defines the number of compressor partialisation;

The number of regulation steps is equal to H6*H2*H1*(H7+1)

Activation and deactivation of the compressor’s unloader is defined by the parameters

“C04-Unloaders activation mode” and “ C05-Unloaders deactivation mode”

16 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 17

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Condenser

Parameter: H9, H10, H11

How to configure the external coil.

Digital input: OFC, FCL1, …, FCL4, OFC1, …, OFC12

Digital output: FC1, …, FC12

Analogue output: Fc1, …, Fc4

Alarm: AF1, …, AF12

H9 – Air or water cooler

condenser

H10 – Number of pump/fans

per condenser

H11 –Fan in common to all

condenser

Defines whether the fans or the pump regulate condensing.

0=AIR : Controls defrosting in heating mode.

1=HO : The configuration managed is H10=1 and H11=Yes

Note: the pump or fan behaviour is defined by parameters F01, F02 and F03

Defines the necessary digital output to control the pumps or fans on the condenser.

• Water-cooled units (H9=H2O).The single “Cond Fan1/Pump1” digital output is controlled to drive

a pump.

• Air-cooled units (H9=AIR). Contributes to defining the total number of managed ventilation steps and

thus of the corresponding ”Condenser Fan1”, ..., ”Condenser Fan8” digital outputs used to drive them.

On multi-circuits units, fans can be in common to all condensers.

If fans are not in common to all condensers (H11=0=NO), the following output are controlled:

• as many analogue inputs as the condensers (H1*H2)

• as many digital outputs as the condensers (H1*H2), multiplied by the number of fans per condenser

(H10); digital outputs for fans are assigned to condensers in a sequential and balanced way,

assuming that all condensers have the same number of fans; e.g. in a system made of 2 condensers

and 6 fans, “Cond Fan1/Pump1”, “Condenser Fan2” and “Condenser Fan3” outputs are assigned to

control fans belonging to the first condenser; “Condenser Fan4”, “Condenser Fan5” and “Condenser

Fan6” to the second condenser.

• as many analogue output s “InverterFanCond1”,...,”InverterFanCond4” for condensing control as for

the condensers (H1*H2).

If fans are common to all condensers (H11=1=YES) the following outputs are used:

• as before, as many analogue inputs for condensing controls as there are circuits per condenser

(H1*H2), but the one requiring the higher response from the control is used for regulation. Each

analogue input is then used for defrost control in heating mode;

• as many digital outputs as fans per condenser (H10);

• one analogue output “InverterFanCond1” for fan speed regulation.

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 17

Page 18

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Heat Pump

Parameter: H40, H41, H42

How to configure the heat pump mode

Functionalities: Enable Heat Pump Control

Digital output: HC1, …, HC4, BO1, …, BO4

Analogue input: SP1, …, SP4, dP1, …, dP4

H40 –Heat pump type 0=No means that the software does not perform heating mode

1=GAS means that the software performs the heating mode, the internal coil is the evaporator in

cooling mode and the condenser in heating mode

1=H2O means that the software performs the heating mode, the coils keep the same meaning in

both heating and cooling mode both

Note: one digital output “Reverse Valve C1”, ..., “Reverse Valve C4” per each circuit is reserved for

controlling the reverse flow valve

H41- Boiler number of heaters Boiler heaters “Boiler1”, ..., “Boiler4” are turned ON when the temperature measured by the regulation

probe enters in the area defined by the active regulation setpoint in heating (SH1) and differential rH1.

They are an alternative to the heat pump, not in addition.

Boiler heaters can be activated only if the temperature measured by the “BoilerSafety” probe is

under a specific safety limit AbS. If it is over the limit, alarm A14 is generated.

To reset the alarm there is a constant differential Abd to be considered.

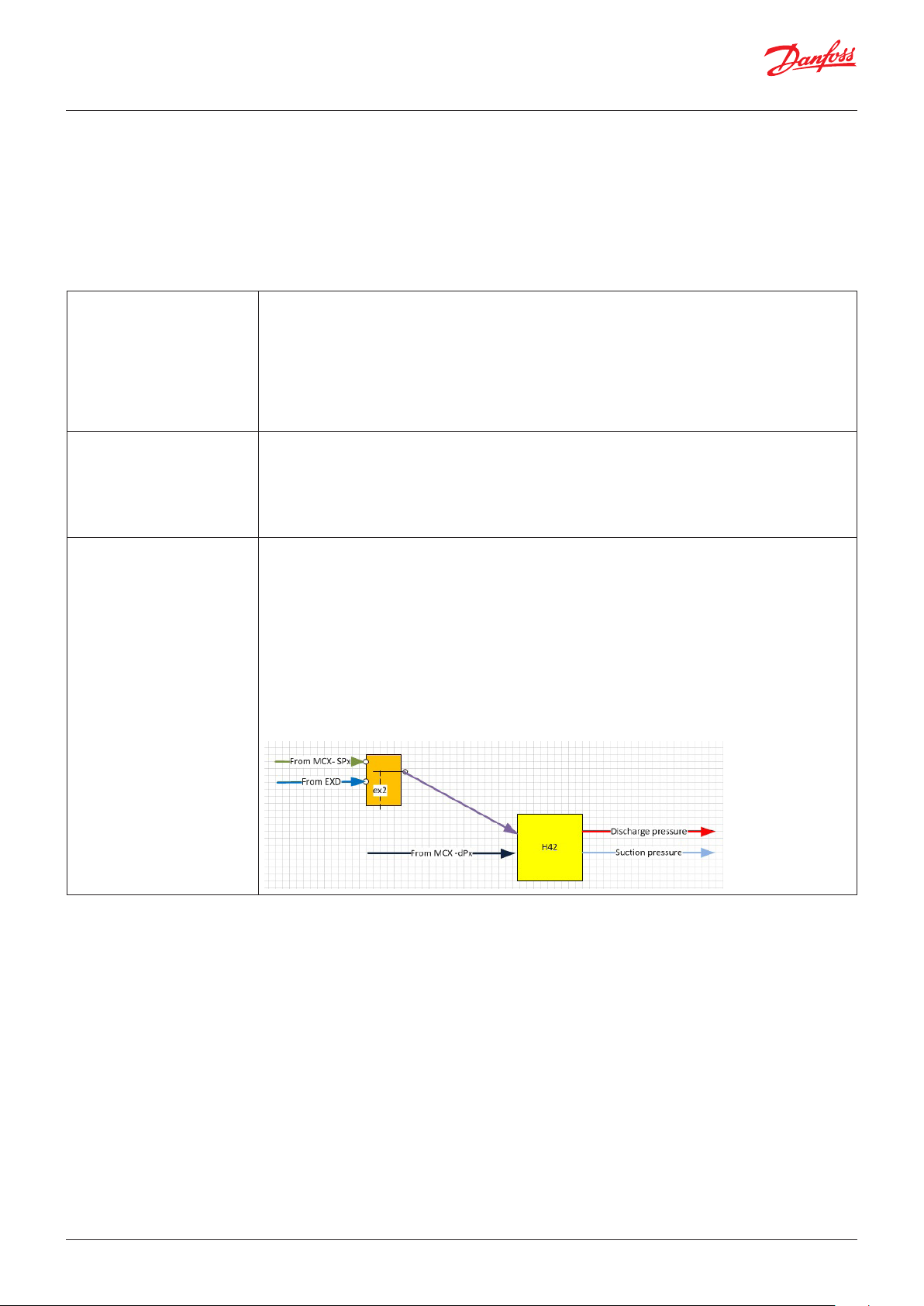

H42- Probe change in HP 0=No means that the probe is before the 4-way valve (close to the compressor):

• the sensor SPx – Suction pressure Cx measures low pressure

• the sensor dPx – Discharge pressure Cx measures high pressure

1=Yes means that the probe is after the 4-way valve (close to the coils):

• the sensor SPx – Suction pressure Cx measures low pressure in cooling mode and high pressure in

heating mode

• the sensor dPx – Discharge pressure Cx measures high pressure in cooling mode and low pressure

in heating mode

Note: if ex2=yes the variable used from H42 (pink line below) is always about low pressure, in

this case pay attention to set H42=No because in heating mode the discharge pressure will not

be available

18 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 19

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Maintenance

Parameter: H43

How to manually set the compressor power request.

Functionalities: Enable commissioning for power request

Digital output: MPR

H43- Manual chiller power The power request provided to the compressors is about H43 %

H43< zero means that the function is disabled

Note: if H43 >=0 the digital output MPR is closed

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 19

Page 20

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Network settings

Parameter: n01,…n17

The Master and Slave is a functionality that allow a group of machines to be

managed like one machine (Master) decides which and how many units (Slaves)

should run.

The max number of units is 8 (7 slaves + 1 master), the network is CANBUS.

The Master and Slave function optimizes:

- ageing of machines

- distribution of the load in order to improve the performance of the plant

- The backup units

Functionalities: Enable Master/Slave

Alarms: N01, N02, N03, N04, N05,N06, N07, N08

n01 –MCX network disable 0=NO means that the Master slave function is enabled

1=Yes means that the Master slave function is disabled

n02 –Number of slave nodes It has to be set equal to (“number of chillers in the network” -1)

n03- Auto master select 0=NO means that the master in the master slave network can be only the chiller with the CANBUS ID

equal to n15: if the master is not more available in the network, the other chillers will start to work in

standalone mode

1=Yes means that the master in the master slave network is the chiller with lowest CANBUS ID

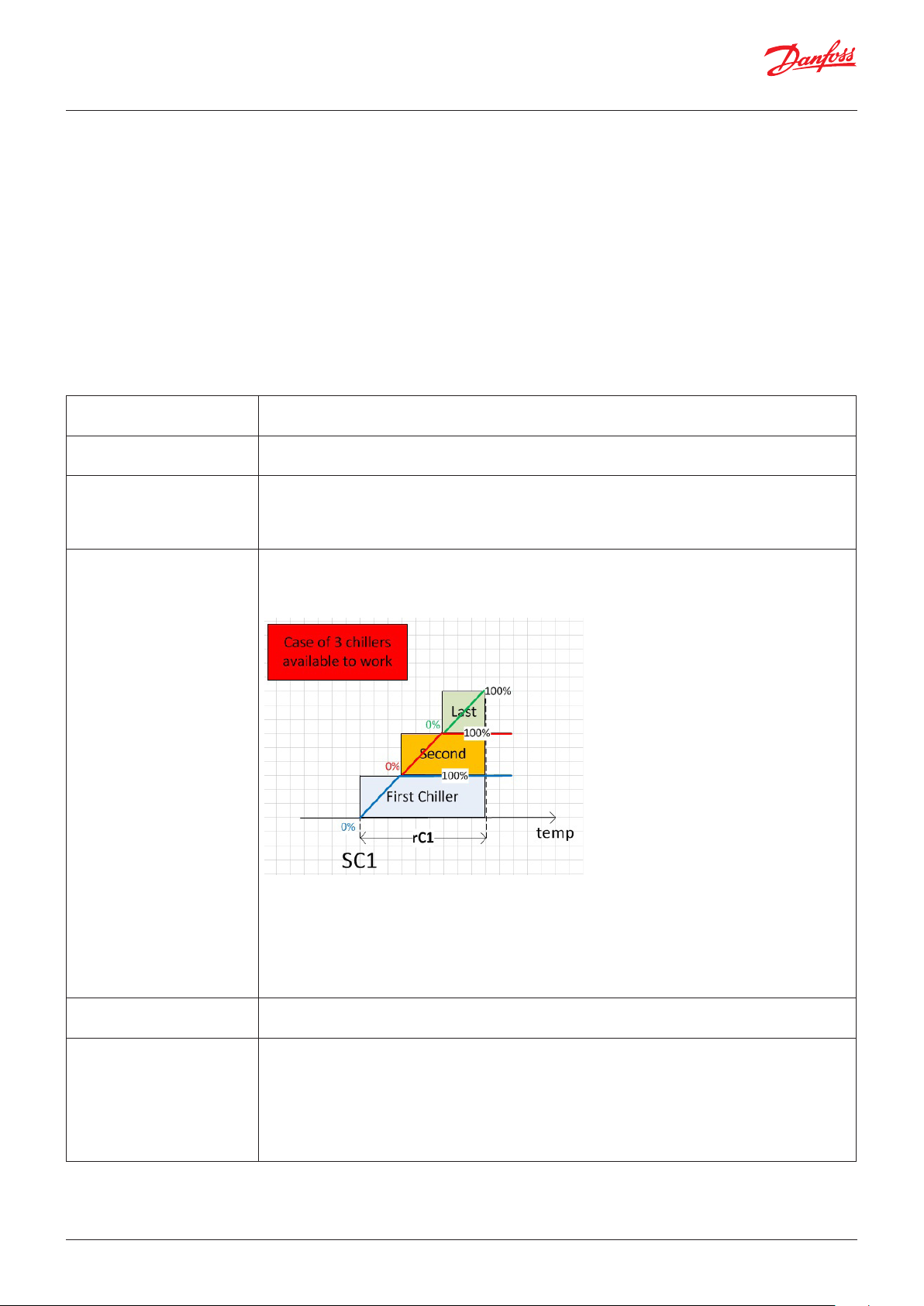

n04- Distribution algo 0= PWR The master, using its own sensors, decides how many chillers are working and the chillers’

power supply;

The maximum number of units that can work is related to the gap between setpoint and

temperature: practically the regulation band is divided for the number of machines (n02+1-n09):

1= CAP the master manages only the start order (following the ageing of the machines), chillers

manage their power as standalone machines.

If all the units which are running have capacity above n12 %, the master will switch on another chiller (the

youngest one).

If all the units which are running have capacity below n13 %, the master will switch off the oldest chiller

running

The minimum time between two actions of the master is n14 seconds

n05- Power Smart power

distribution enable

n06- Node rotation enable 0=No means that the start sequence of the machines is fixed; the order depends on the addressing,

20 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

1=Yes means that the master is allowed to cut-in the first chiller available without considering the

start order related to the ageing of the machines

the first to start is the machine with the smallest CANBUS ID, the first to stop is the chiller with the

highest CANBUS ID

1=Yes means that the start/stop sequence of the machines depends on the ageing of the chillers,

always starting with the youngest of the set and the oldest one is always the first to stop. In the case

that one machine works n17 hours more than another chiller that is switched off, the master will

exchange the unit in order to align the ageing.

Page 21

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

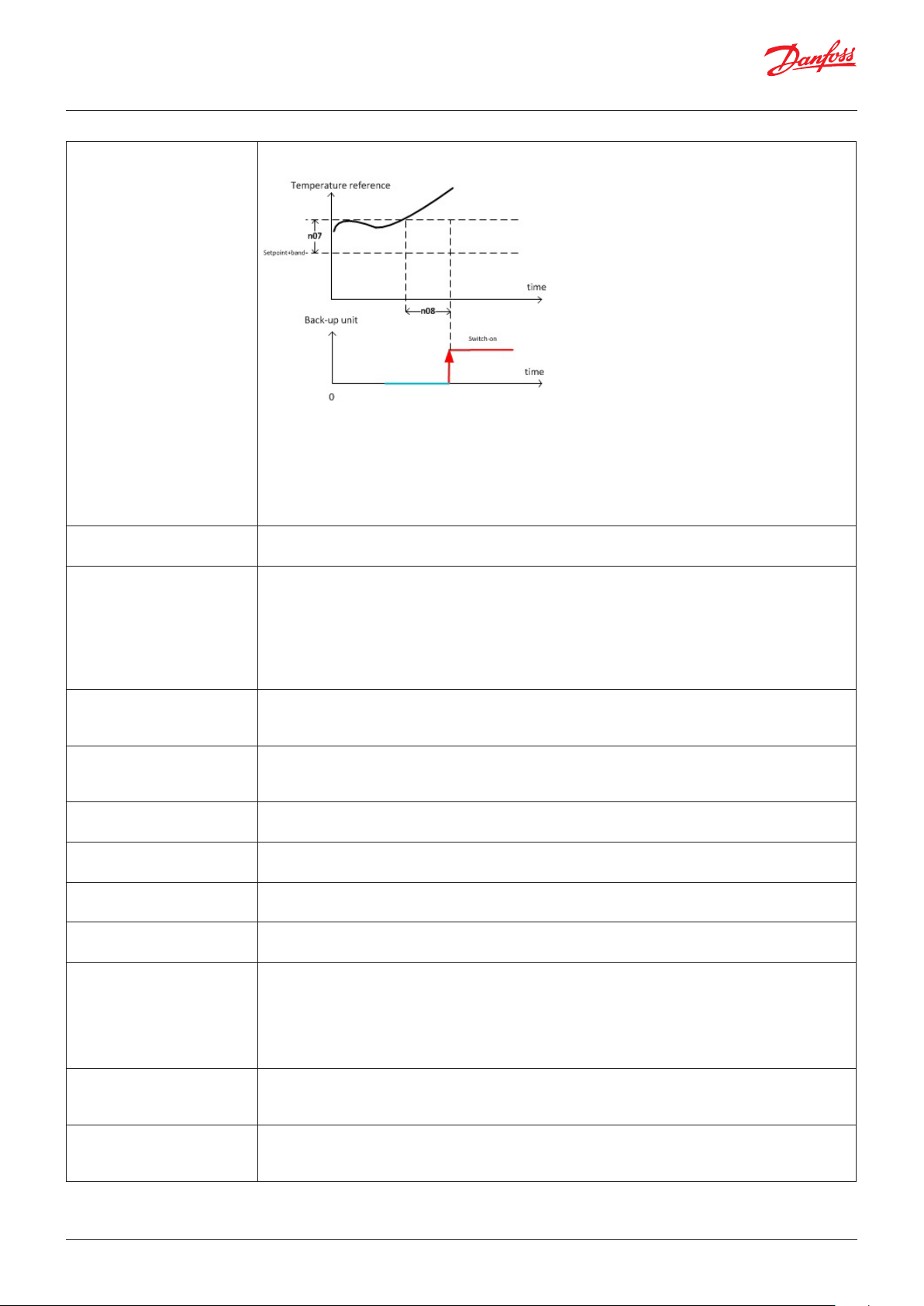

n07- Backup node offset When the gap between setpoint and temperature is above (n07+regulation band), the first backup

unit is allowed to work as a support, also considering parameter n08 .

Note: the offset to enable the other backup units is (n07*m+ regulation band):

• m = 2 for the second backup unit

• m = 3 for the third backup unit

• …

Note: the backup units will work running normally after the set point. It will be switched off when the

gap between setpoint and temperature is below the regulation band

Note: the pump behaviour is defined through the parameter P01

n08- Time to enable n07 It’s the time to stay far away from the setpoint in order to cut in the backup unit

Note: check parameter n07

n09-Number of back-up unit n09 defines the number of backup units inside the master slave network

A backup unit is never enabled (so does not provide cooling capacity) unless one of the following

situations occurs:

• one of the other units becomes unavailable

• Support (see parameter n07 and n08)

Note: The master chooses the backup unit (among all nodes present in the network) by looking at

the working time of every unit: the one which has worked the longest will be the backup unit.

n10 – Evaporator in common 0=No each chiller consider its own evaporator flow alarm

1=yes the master will read its “FPE” digital input (Flow Evaporator) and will send the information to

other slaves

n11 – Pump alarm in common 0=No each chiller considers its own pump alarm

1=yes the master will read its “AP1” digital input (Evap pump/fan overload alarm) and will send the

information to other slaves

n12 – Capacity upper

threshold

n13 – Capacity lower

threshold

n14 – Capacity step min time See parameter n04

See parameter n04

See parameter n04

n15 – Master node CAN ID It has to be set equal to the lowest ID in the CANBUS network

n16 – Slaves node CAN ID offset The slaves have to take the CAN ID in relation to the n15 just adding n16.

E.G. for n02 =3

• Master ID= n15

• Slave1 ID= n15+n16

• Slave2 ID= n15+n16+n16

• Slave3 ID= n15+n16+n16+n16

n17 – Maximum gap time for

unit rotation

n18 – Backup unit pump

status

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 21

It is in hours

If a running unit becomes older than a switched-off unit by more than n17 hours, the logic will

switch off the oldest unit running it will cause the other unit to be switched on.

0=OFF: the backup chillers in standby have the pump switched-off

1=ON: the backup chillers in standby have the pump switched-on

Note:during support or backup, the pump of the chiller follow P01 setting

Page 22

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Configuration

Parameter: rEG, rET, rT1, rT2, o30, Er1

rEG – Analogue input for

temperature regulation

rET – Regulation Type Defines the relation between the temperature gap and the power request to the circuits.

0= Tin : reference sensor is Tin_Tin Evaporator

1= ToM: reference sensor is TOM_Tout Evap Mix

2 =AI1: reference sensor is the analogue input 1

……

17 =AI16 : reference sensor is the analogue input 16

18 =SPT1: reference is the temperature calculated from the sensor SP1_Suction Press C1, the gas

type is set using parameter o31

0=P : Power request to the circuits increases in proportional way with the regulation error, i.e., it is

100% when the regulation error (the gap between setpoint and the reference sensor ) is equal to rC1

( rH1)

1=PI: the power request is the sum of P regulation (rET=0) plus a component (Integral part)

that increases in relation to the regulation error; the speed of the integral part depends on the

parameter rin_Ti.

For PI regulation, the balance is reached only when the regulation sensor gets the setpoint.

2=dZ : The delay between compressors activations varies between a maximum value dd5 and

minimum value dd6 proportional to the temperature position inside the regulation band defined by

the activation differential dd1.

Above setpoint + dead zone + activation differential, the delay among activations is equal to the minimum.

rT1- Minimum limit for

TReg TX

rT2- Maximum limit for

TReg TX

Similarly the action for the delay among compressors deactivations, which can vary between a

maximum value dd7 and a minimum value dd8, is proportional to the temperature position inside

the regulation band defined by the deactivation differential dd2.

Below a setpoint differential, the delay among activations is equal to the minimum value, dd8, up

to a limit threshold, dd3. Below that, all the compressors are immediately switched OFF to avoid the

unit ice alarm.

The analogue output rtr linearly replays the regulation probe (check parameter rET)

It gets to 0% when the regulation probe reaches a value of rT1

Note: if the regulation probe is in error the AO_rtr gets to 100%

The analogue output rtr linearly replays the regulation probe (check parameter rET)

It gets to 100% when the regulation probe reachs rT2 value

Note: if regulation probe is in error the the AO_rtr gets to 100%

22 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 23

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

o30 – Gas type 0=---

1=R12

2=R22

3=R134a

4=R502

5=R717

6=R13

7=R131b1

8=R23

9=R500

10=R503

11=R114

12=R142b

13=-14=R32

15=R227

16=R401a

17=R507

18=R402a

19=R404a

20= R407c

21= R407a

22= R407b

23= R410a

24= R170

25= R290

26=R600

27= R600a

28= R744

29= R1270

30=R417a

31=R422a

32=R413A

33=R422D

34=R427A

35=R438A

36=R513A

37=R407F

38=R1234ze

39=R1234yf

40=R448A

41=R449A

42=R452A

43=R450A

44=R452B

45=R454B

46=R1233zdE

47=R1234zeZ

48=R449B

49=R407H

Note: the gas definition is used when the translation of the pressure in temperature is required;

ReG=SPT1 and for the “internal” super heat control

o31 – Dew/Bubble Conversion

mode

Er1 – Emergency mode

max power

0=Dew

1=Bubble used for the gas that require the "Glide" approximation

Er1 = -1 the function is disabled

Er1 >= 0 when the digital input EEr is closed the power request is limited to Er1 instead of 100%

Note: the functionality “Enable emergency mode from DI” is required

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 23

Page 24

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Main Setpoint

Parameter: SC1, SCL, SCH, SH1, SHL, SHH, SRE

Analogue input: TRM

SC1 – Cooling temperature set

point

SCL – Minimum limit Defines the minimum limit of the setpoint in cooling mode

SCH – Maximum limit Defines the maximum limit of the setpoint in cooling mode

SH1 – heating temperature set

point

SHL – Minimum limit Defines the minimum limit of the setpoint in heating mode

SHH – Maximum limit Defines the maximum limit of the setpoint in heating mode

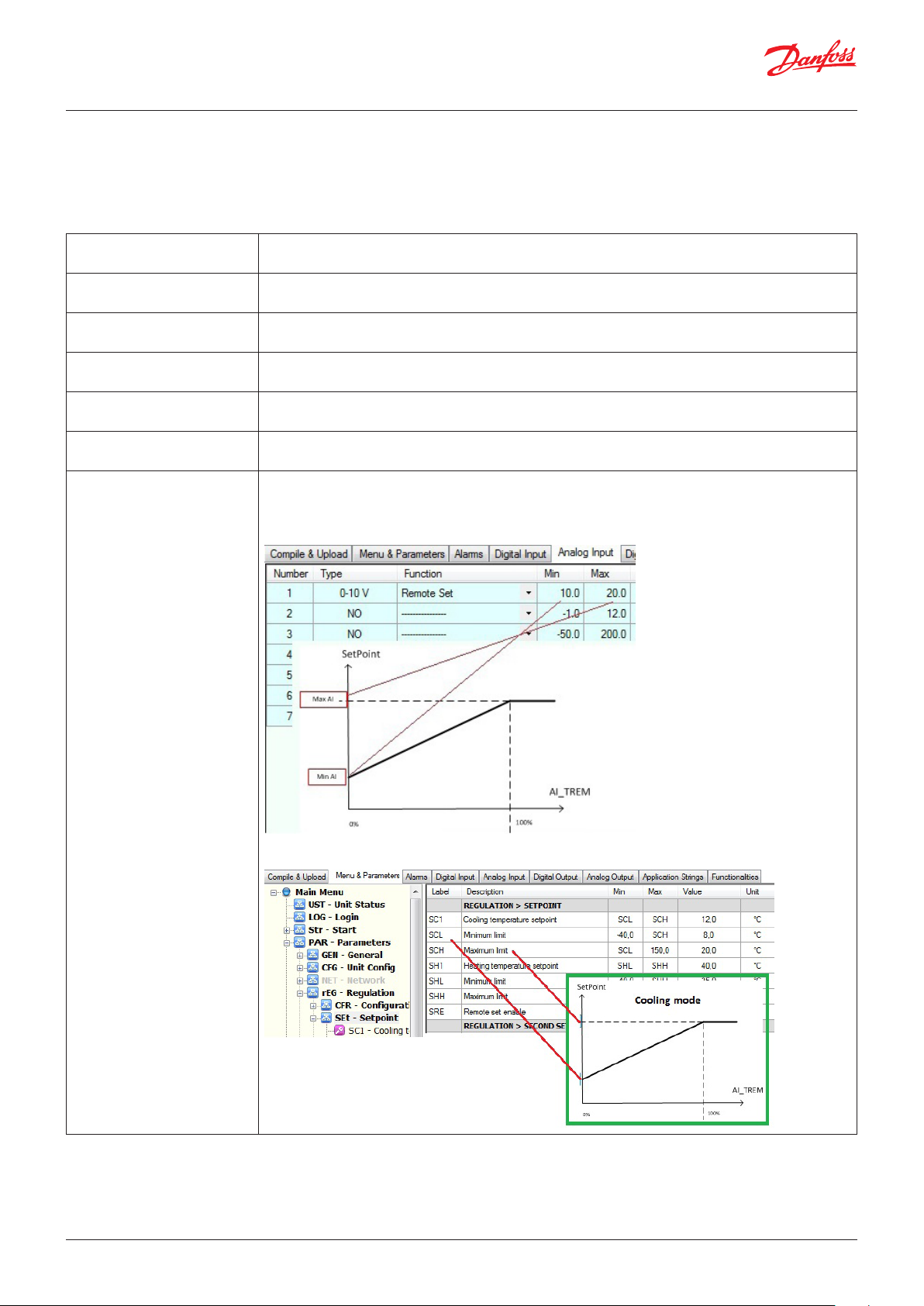

SRE- Remote set enable The regulation setpoint is defined through the analogue input TRM_Remote Set

Defines the setpoint in cooling mode

Note: This limit is not respected when adjusted through Modbus

Note: This limit is not respected when adjusted through Modbus

Defines the setpoint in heating mode

Note: This limit is not respected when adjusted through Modbus

Note: This limit is not respected when adjusted through Modbus

0=NO means that the function is not enabled

1=rEL means that

set point = main setpoint + offset from analogue input (TRM_Remote set)

2=Abs means that set point is linearly defined through AI_TREM, between SCL - SCH in cooling and

SHL - SHH in heating

24 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 25

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Economic Setpoint

Parameter: SdS, SdM, SdC, SdH, SdO

SdS- Setpoint selection 0=DI means that the digital input SET2_Reg offset from DI defines if use comfort setpoint (SC1 or

SH1) or the economic setpoint (SC1+SdC or SH1-SdH); in economic mode the proportional band in

the PI control is increased by SdO

1=PAR meaning that the parameter SdM_Setpoint mode defines whether comfort setpoint

(SC1 or SH1) or the economic setpoint (SC1+SdC or SH1-SdH) is to be used; in economic mode the

proportional band in the PI control is increased by SdO

SdM- Setpoint mode It works only for SdS=PAR

0=COMF meaning that chiller uses comfort setpoint ( SC1 or SH1)

1=ECO meaning that the chiller uses economic setpoint (SC1+SdC or SH1-SdH)

In economic mode the proportional band in the PI control is increased of SdO.

SdC-Offset for setpoint in cool-

ing

In economic status and cooling mode the regulation setpoint is shifted to SdC.

Note: see parameter SdS

SdH-Offset for setpoint

in heating

SdO-Offset for differential In economic mode the proportional band of regulation becomes rC1+SdO or rH1+SdO.

In economic status and heating mode the regulation setpoint is shifted to SdH.

Note: Take a look to parameter SdS

Note: look at parameter SdS

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 25

Page 26

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

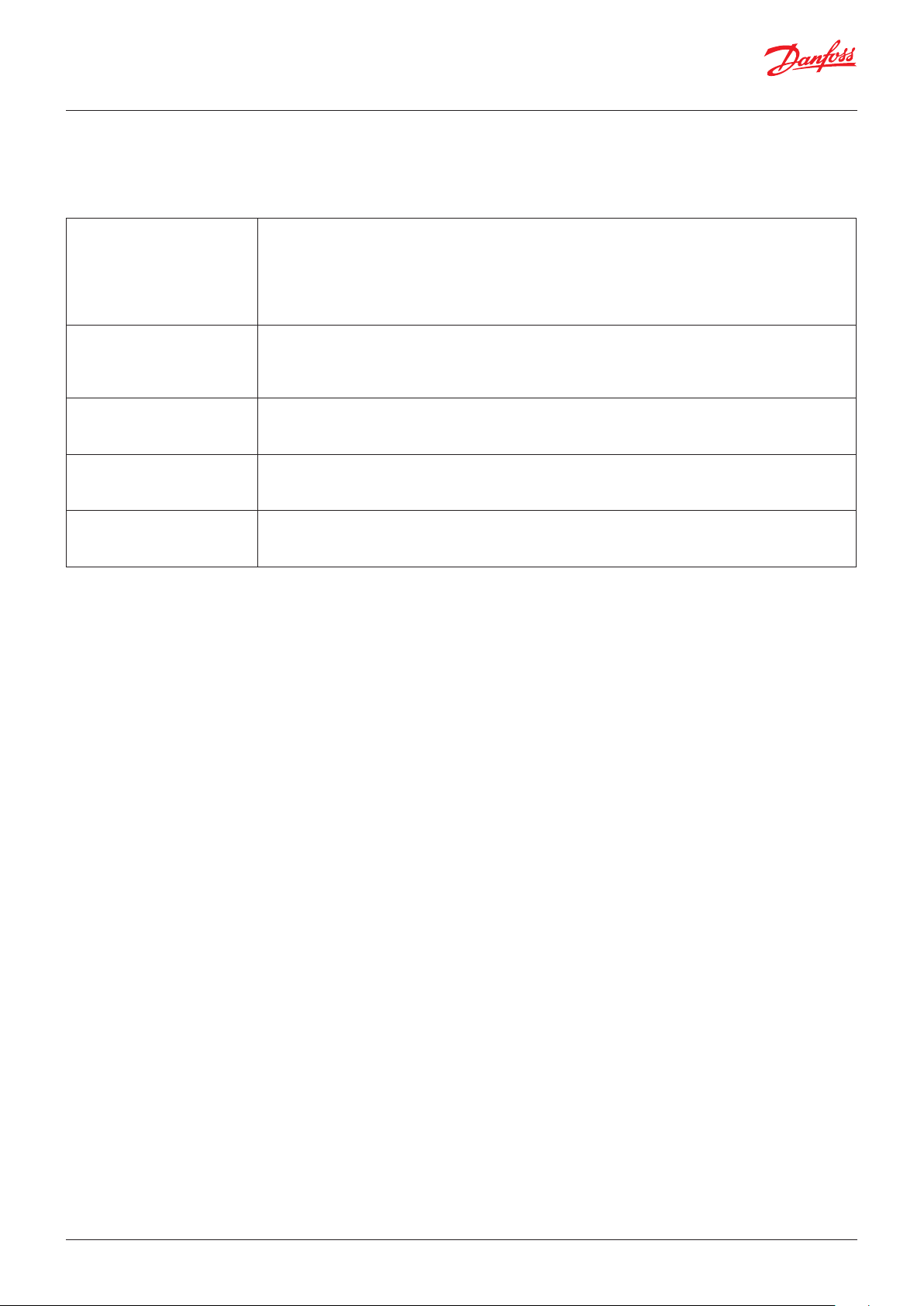

Setpoint compensation in based on the outside temperature

Parameter: CC1, CC2, CC3, CC4, CH2, CH3, CH4

Analogue input: OUt

CC1-Compensation enable 0=NO means compensation disable

1=YES means compensation enable

Note: this function adapts the setpoint to the outside temperature “Tout”

CC2-Outside temperature to

start cool comp.

It’s in °C

CC3-Outside temperature to

stop cool comp.

CC4-Maximum cooling

compensation

It’s in °C

It’s in °C

CH2-Outside temperature to

start heat comp.

CH3-Outside temperature to

stop heat comp.

CH4-Maximum heating

compensation.

26 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

It’s in °C

Like CC2 but used in heating mode

It’s in °C

Like CC3 but used in heating mode

It’s in °C

Like CC4 but used in heating mode

Page 27

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

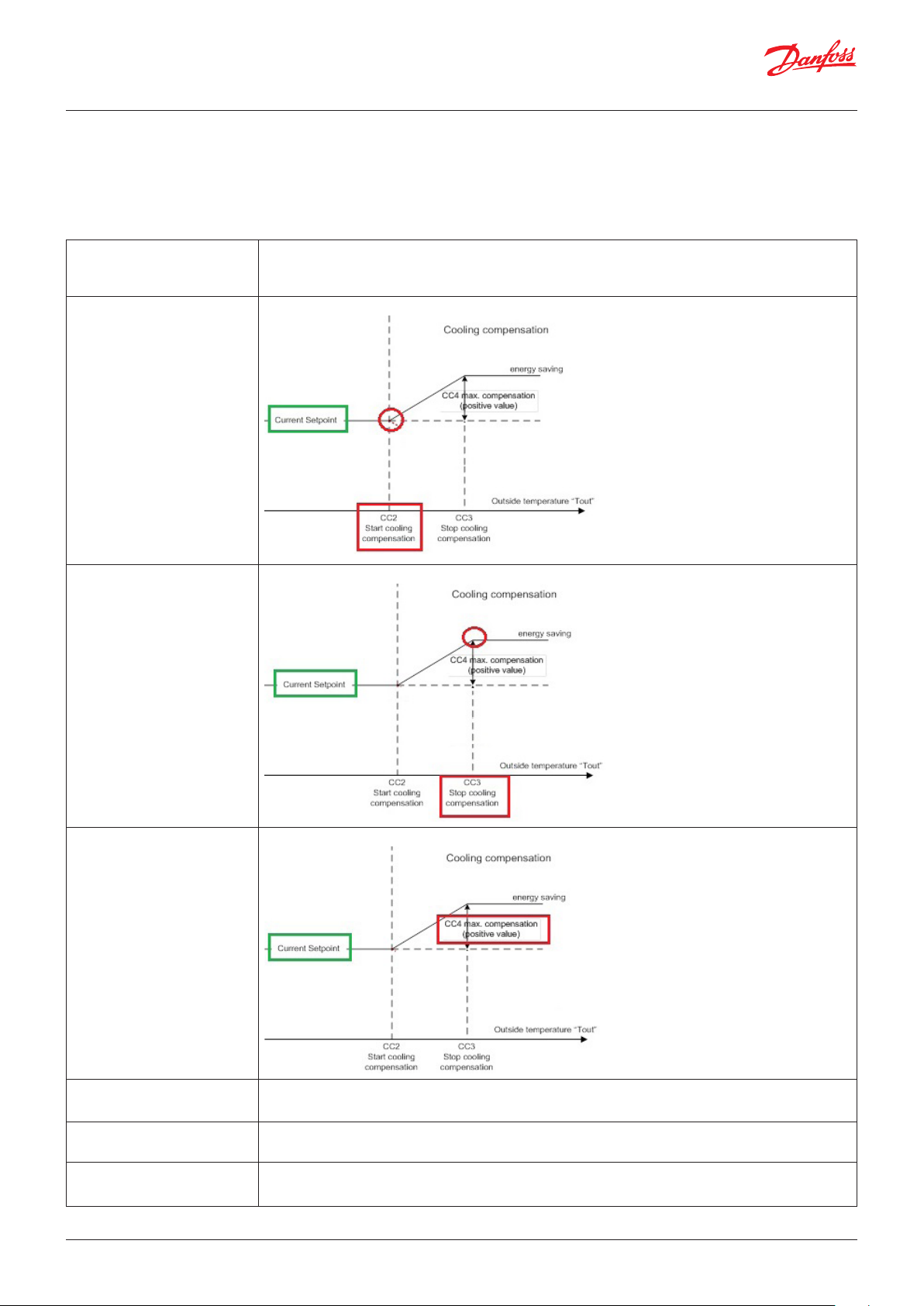

PI regulation

Parameter: CrC1, rH1, Rin, rC2, rC3

Note: the PI regulation is enabled when the parameter rET is equal to P or PI

rC1-Cooling temperature

differential.

rH1-Heating temperature

differential.

Rin- Ti It is the integral time of the PI regulation, the bigger the value of Rin the slower the action of the

rC2-Cut Off enable It enables the gradual reduction of the integral error once reached and exceeded the setpoint. The

rC3- Cut off offset

See parameter rET

See parameter rET

Integral part.

See parameter rET

error integral in fact tends to keep the compressors turned on even if the proportional part of the

error would require a shutdown. The amount of reduction is proportional to the distance from the

setpoint considering the rC3 band. For example, in cooling, the reduction is zero when the control

temperature is equal to the setpoint; the reduction is greatest when it is equal to setpoint-rC3.

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 27

Page 28

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

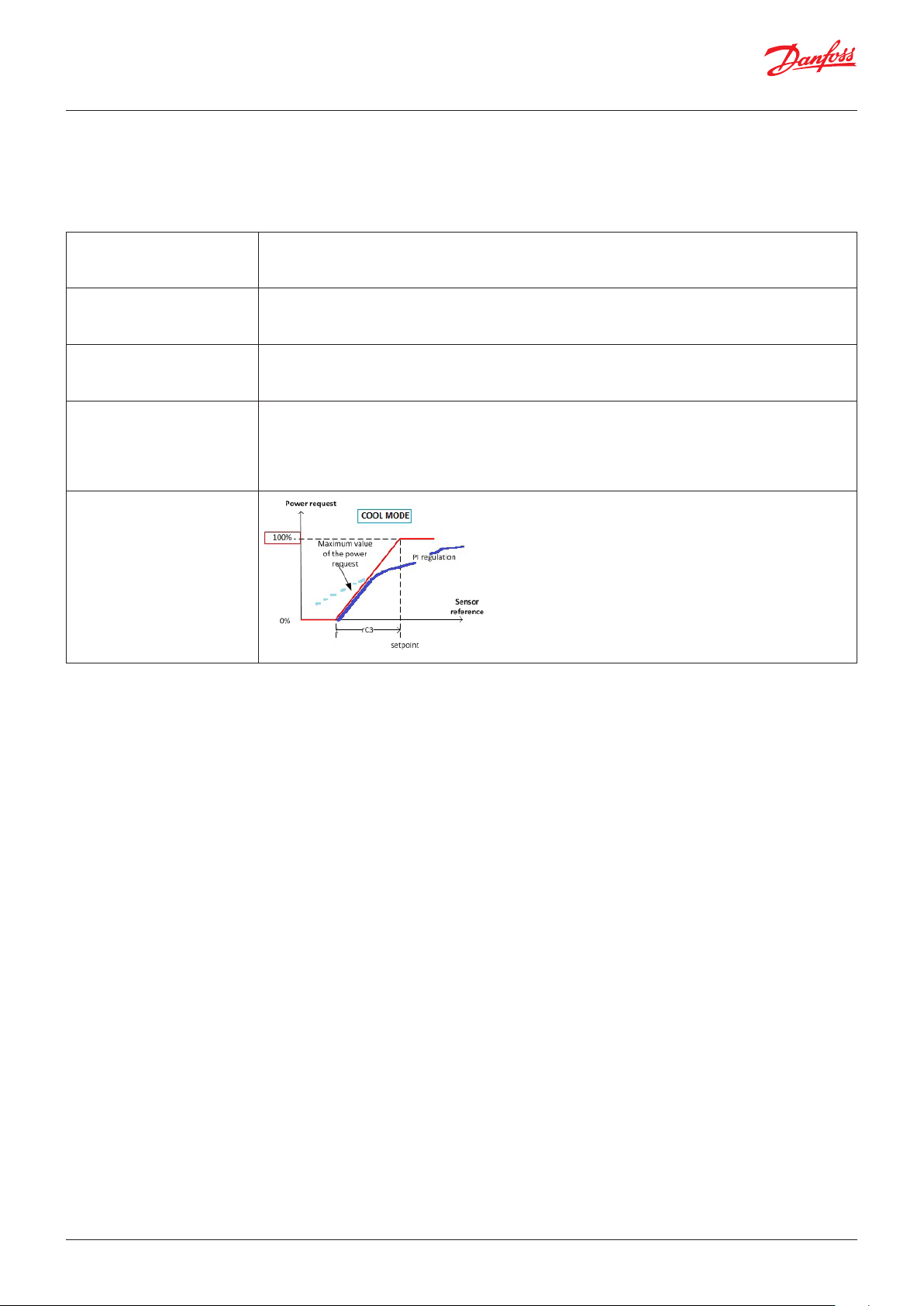

Dead zone regulation

Parameter: ddC, ddH, dd1, dd2, dd3, dd4, dd5, dd6, dd7, dd8

Functionalities: Enable Dead Zone Regulation

The dead zone regulation is enable when the parameter rET is equal to DZ

It is a variable time regulation mainly used when the regulated value is the

temperature of the fluid leaving the evaporator.

In the dead zone ddC no regulating action is taken.

Close to the dead zone the decision to cut the compressor in or out will

take a maximum time of (dd5 or dd7), a time that will decrease linearly

outside the dead zone. This variable time logic is described below.

ddC-Cooling dead zone In dead zone ddC no regulation action is taken.

This is above the setpoint and used in cooling mode

ddH-Heating dead zone In dead zone ddH no regulation action is taken.

This is below the setpoint used in heating mode

dd1-Comp activation

differential

dd2-Comp deactivation

differential

dd3-Min temp for OFF comp

in cooling

dd4-Max temp for OFF comp

in heating

dd5-Max delay of comp activation

dd6-Min delay of comp

activation

dd7-Max delay of comp

deactivation

dd8-Min delay of comp

deactivation

Defines the maximum temperature gap to have a minimum delay (dd6) in the compressor’s activation

Note: see picture in the parameter ddC and ddH

Defines the maximum temperature gap to have a minimum delay (dd6) in the compressor’s

deactivation

Note: see picture in the parameter ddC and ddH

Defines the minimum temperature below which the compressors are switched off

Note: see picture in the parameter ddC

Defines the maximum temperature above which the compressors are switched off

Note: see picture in the parameter ddH

Defines the maximum delay before a compressor cuts in

Note: see picture in the parameter ddC and ddH

Defines the minimum delay before a compressor cuts in

Note: see picture in the parameter ddC and ddH

Defines the maximum delay before a compressor cuts off

Note: see picture in the parameter ddC and ddH

Defines the minimum delay before a compressor cuts off

Note: see picture in the parameter ddC and ddH

28 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 29

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

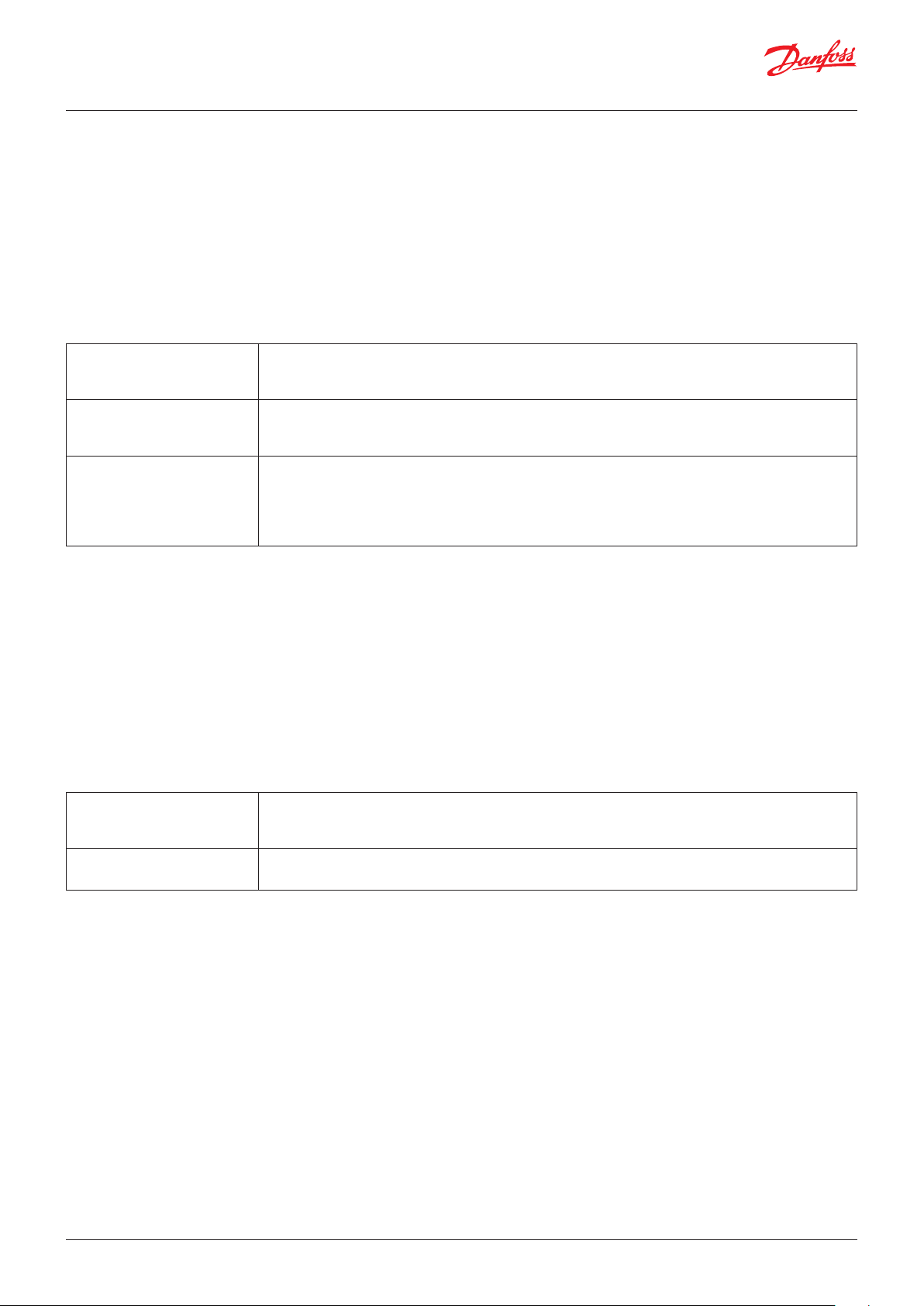

Digital output lock

Parameter: DOn, Ain, Dos, DOd

It is possible to lock a digital output in open position in relation to

an analogue input.

The lock condition is reported in the rolling text

Functionalities: Enable DO Locking from AI

DOn-Digital output number This is the number of the digital output to lock in open position;

The conditions to lock it are defined by AIn, DOs and DOd

AIn-Analogue input number This is the number of the analogue input to refer to lock the digital output DOn

DOs-Set point for locking This is the setpoint to compare with the value of the analogue input AIn for locking the digital output

DOn;

Note: set parameter DOd to lock the digital output DOn above or below the setpoint DOs

DOd-Differential to unlock

Buzzer and relay

Parameter: BUZ, Adl, AOF

BUZ-Buzzer activation time

number

Adl-Alarm relay activation

delay

AOF-Alarm relay active if unit

in off

It's in minutes.

Defines the maximum time that the buzzer can work;

BUZ=15 means that there is no limit in the active time of buzzer

It's in seconds.

Defines the delay of the alarm relay when there is an alarm

Defines whether the alarm relay works in the OFF state of the chiller

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 29

Page 30

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Flow alarm

Parameter: AFr, AF1, AF2, AF3

It is generated by the “Flow Evaporator” digital input.

In the event of an alarm:

• if there is the second pump “Evap Pump2”, the second pump

operating warning A08 will be activated before the flow switch

alarm A03;

• otherwise, all the compressors and all the other elements will be

immediately switched OFF, ignoring their protection times.

The alarm is delayed by AF1 seconds after the pump starts to

wait for the water flow to reach its steady value.

It is also delayed in normal functioning by AF2 seconds to filter

out temporary flow changes or air bubbles in the water circuit.

AFr-Reset Type Used in the alarm tab to set the reset type from the UI

The reset type is configurable through AFr to:

• manual: all the outputs are OFF, including the pump. After reset,

if the alarm is still active, the alarm is ignored (but still shown on

display) until the delay time from startup is elapsed to give the

unit the chance to start normally.

• automatic: all the outputs are OFF, excluding the pump which

tries to start every AF3 seconds; the alarm is ignored until the

delay time from startup is elapsed.

• semi-automatic: the pump tries to start every AF3 seconds for

AFr number of times, ignoring the alarm during its delay at

startup; exceeded the attempts of starting the pump, the alarm

can only be reset manually.

Digital input: FPE

Alarms: A03, A08

AF1-Delay from pump starting Used in the alarm tab to set the Startup delay from the UI

Note: Period starts when the pump starts and not from the power being turned on

AF2-Delay in steady operation Used in the alarm tab to set the Steady delay from the UI

AF3-Time to restart Defines the time to wait before restart the pump;

It works resetting both the automatic and semiautomatic alarms

30 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 31

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

ICE alarm

Parameter: AIS, AID, Air, AI1, AI2, AI3, AIT, AIo

Analogue input: TO1, TO2, TO3, TO4, TOUt

Alarms: AE1, AE2, AE3, AE4, AIT

Functionalities: Enable enhanced low temperature management

AIS-Ice alarm setpoint If TOx temperature goes below AIS °C the alarm AEx (x=1,2,3,4) is detected

ICE Alarm cuts in the heaters

Note: see parameter AI3 to set up the alarm’s behaviour in the OFF state

AID-Differential Above AIS +AID the ICE alarm is resettable

AIr-Reset Type Used in the alarm tab to set the reset type from the UI

AI1-Delay from pump starting

in cool

AI2-Delay from pump starting

in heat

AI3-Out status if unit

OFF - alarm

AIT-Ice tout alarm It’s in °C

AIo-Ice alarm offset It’s in °C

It’s in seconds

Used in the alarm tab to set the “Startup delay” from the UI

Used for the cooling mode

It’s in seconds

Defines the delay of the ice alarm from the pump starting in heating mode

Defines the chiller’s behaviour in relation to the ICE alarm when the chiller is in OFF state

0=HOFF means that the heaters will not be used

1=HON means that only the heaters will switch ON

2=HPON means that pump and heaters both will switch ON

Note: in the ON state the ICE Alarm switches on the heaters

If external temperature Tout goes below AIT °C, alarm AIT is generated

Note: the action of the alarm has to be defined in the alarm tab

The setpoint of the ice alarm becomes AIS+Alo, the sensor used to check the alarm is the minimum

in between Tin, TOx, TFC and Tout

Note: The functionality “Enable enhanced low temperature management” is required

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 31

Page 32

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Compressor oil delta pressure alarm

Parameter: OPR, OdP, GdP

The alarm is detected when the compressor runs.

The alarm A4x is triggered when the difference in between

the sensor defined by parameter OPR and the sensor OPx_Oil

pressure Compx is lower than OdP.

Alarm behavior has to be set in the Alarm tab

Analogue input: OP1, …, OP8, SP1, …, SP4, dP1, …, dP4

Alarms: A31, …, A35, A41, …, A48, dP0, dP1, …, dP4

OPR- Oil delta pressure

reference

OdP- Min oil delta pressure Measurements are in bar

GdP- Min gas delta pressure Measurements are in bar

0=SUC means that the alarm depends on suction pressure

1=DIS means that the alarm depends on discharge pressure

Note: check parameter H42

Defines the minimum delta pressure to generate the alarm

Alarm hysteresis is fixed and equal to 0.3 bar

When the gap between discharge and suction pressure is less than GdP bar the alarm dPx

is generated

Alarm hysteresis is fixed and equal to 0.3 bar

Note: The alarms have to be set in the alarm tab

Circuit high temperature alarm

Parameter: HTs, HTd

When the discharge temperature of the circuit is above HTs

parameter the “High discharge temp” alarm is generated.

When the discharge temperature goes below HTs-HTd the alarm

can be reset

Analogue input: dt1, dt2, dt3, dt4

Alarms: dt0, dt1, dt2, dt3, dt4

HTs- High discharge

temperature set

Defines the temperature setpoint above which the dtx alarm is generated

HTd- Differential Below HTs-HTd the alarm can be reset

32 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 33

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

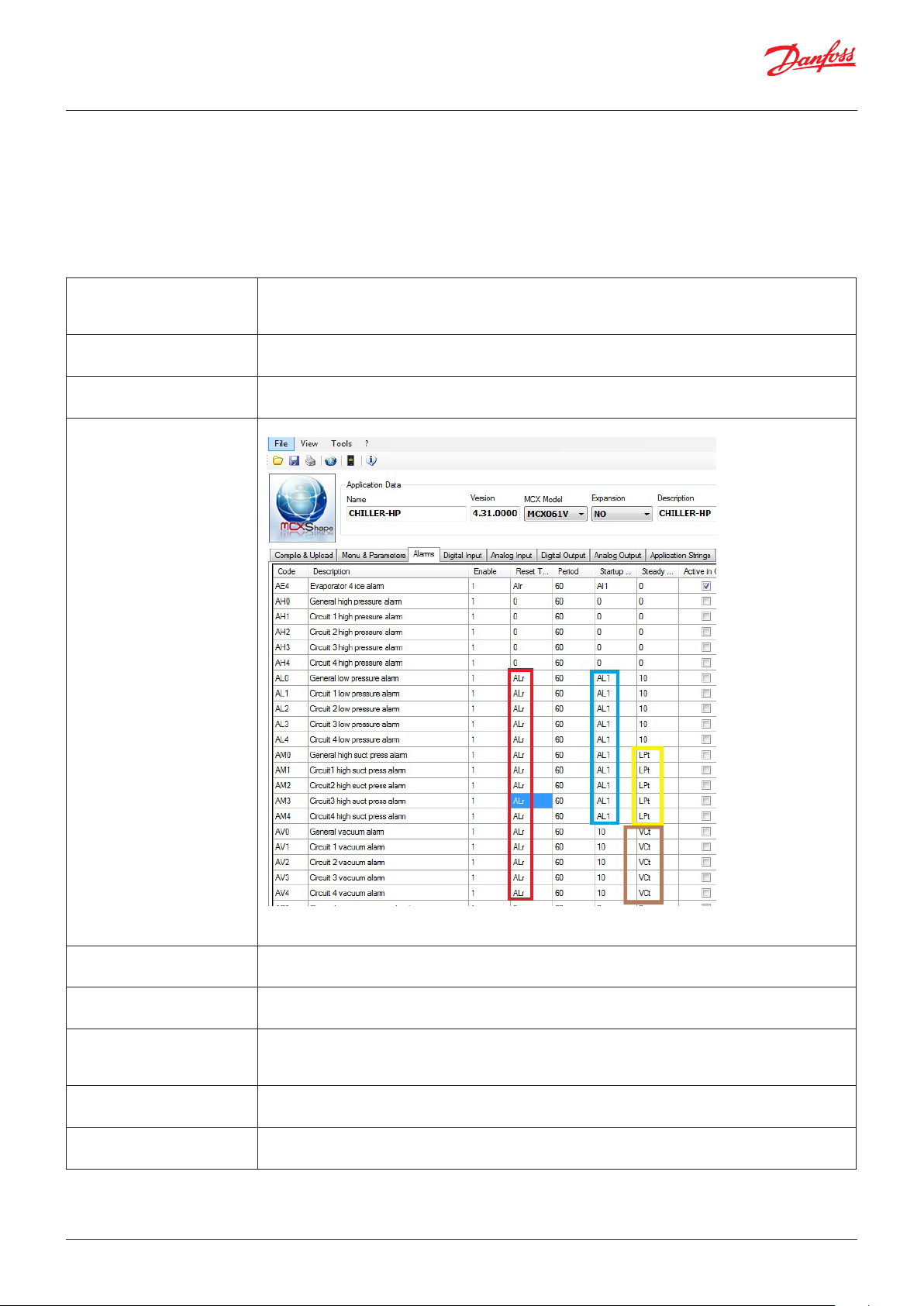

Pressure alarms from analogue input

Parameter: AHE, AHS, AHd, Alr, AL1, AL2, ALE, ALS, ALd, LPt, AVO, VCt, SHS, SHb

Analogue input: dP1, dP2, dP3, dP3, SP1, SP2, SP3, SP4

Alarms: AH0, AH1, AH2, AH3, AH4, AL0, AL1, AL2, AL3, AL4, AV0,

AV1, AV2, AV3, AV4, AM0, AM1, AM2. AM3, AM4

AHE- Enable HP alarm from AI 0=NO means disable

1=YES means enable

AHS- High pressure alarm

setpoint

AHd- High pressure alarm

hysteresis

Alr- Reset type Used in the alarm tab to set the reset type from the UI

When the discharge pressure (sensor dPx) goes above AHS, alarm AHx is triggered

Below AHS-AHd the alarm AHx can be reset

AL1- Delay from compressor

starting

AL2- Enable when compressor

OFF

ALE- Enable LP alarm from AI 0=NO means disable

ALS- Low pressure alarm

setpoint

ALd Low pressure alarm

hysteresis

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 33

Used in the alarm tab to set the startup delay from the UI

0=NO means that the low pressure alarm is not triggered when the circuit is switched off

1=YES means that the low pressure alarm is triggered also when the circuit is switched off

1=YES means enable

Note: it enables also the vacuum alarm

When the suction pressure (sensor SPx) goes below ALS alarm ALx is triggered

Above ALS+ALd the alarm ALx can be reset

Page 34

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

LPt- Low pressure bypass time Used in the alarm tab to set the Steady delay from the UI

AVO- Vacuum alarm offset When the suction pressure (sensor SPx) goes below ALS-AVO alarm AVx is triggered

Note: The alarm is enabled by ALE (the same used for Low pressure alarm)

AVd- Vacuum alarm hysteresis Above ALS- AVO + AVd the alarm AVx can be reset

VCt-Vacuum alarm bypass

time

SHS- High suction pressure

setpoint

SHb- High suction pressure

hysteresis

Used in the alarm tab to set the Steady delay from the UI

When the suction pressure (sensor SPx) goes above ASH, alarm AMx is triggered

Below SHS-SHb the alarm AMx can be reset

High water temperature alarm in cooling mode

Parameter: Ats, Atd

Analogue input: TOx

Alarms: A09

Ats- Setpoint in cooling In Cooling mode, when the water temperature (max in between TOx) goes above Ats, the alarm A09

is triggered

Note: The alarm’s action has to be set in the alarm tab

Atd- Differential Below Ats-Atd the alarm A09 can be reset

Boiler water temperature alarm

Parameter: AbS, Abd

It works only for heat pump configuration H40> 0 (heat pump)

and H41> 0 (Boiler with heaters)

The alarm A14 deactivates the heaters

Analogue input: BOI

Digital output: BOx

Alarms: A14

AbS- Setpoint When the water inside the boiler (BOI) goes above AbS, the alarm A14 is triggered

Alarm A14 deactivates the heaters

Abd - Differential Below Abs-Abd the alarm A14 can be reset

34 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 35

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Fault of the regulation probe of the external coil

Parameter: ACM, ACS, ACd

How set it up

ACM- Condenser fan/pump

status

ACS- Outside temp set for

fan/ pump

ACd- Outside temp diff. for

fan/pump

0=OFF means that if there is a condenser regulation probe fault, the Fan/Pump will be kept switched

OFF

1=ON_C means that if there is a condenser regulation probe fault, the Fan/pump will be switched ON

if at least one compressor is active in the circuit

2=FTou means that if there is a condenser regulation probe fault, the Fan/Pump will cut in in relation

to the TOut_ T out sensor, see parameter ACS and ACd

If ACM=FTou, in case of fault of condenser regulation probe, the fan will regulate in relation to the

outside temperature, following the picture below

Note. In case of outside temperature sensor fault the fan will works as ACM=ON_C

See parameter ACM

Preventions

Parameter: TMx, THo, TLo, HPE, HPo, HPh, LPE, LPo, LPh, PPt, PPp, HFo

The alarm's action has to be set in the alarm tab.

Info on prevention status through rolling text

Functionalities: Enable compressor high temperature prevention

Analogue input: CTx, dPx, SPx

Alarms: CTx, A8E, A8F

TMx- Max compressor

temperature

THo- Comp Max Temp Prev

Offset

TLo- Comp Max Temp Prev Diff It’s in °C

HPE- HP prevention enable 0=NO means disable

It’s in °C

When the temperature CTx goes above TMx the alarm CTx is triggered.

Note: the action of the alarm has to be defined in the alarm tab

It’s in °C

When the temperature CTx goes above TMx-THo, the screw compressor is set to minimum power

Note: it works only for screw compressors

When the temperature CTx goes below TMx-THo-TLo, the screw compressor restart to work with-

out limitation

Note: it works only for screw compressors

1=YES means enable

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 35

Page 36

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

HPo- HP prevention offset When the high pressure sensor goes above AHS-HPo, every PPt seconds the prevention decreases

the circuit power request by PPp

HPh- HP prevention hysteresis When the high pressure sensor goes below AHS-HPo -HPh, every PPt seconds the prevention in-

creases the circuit power request by PPp

Note: See HPo parameter

LPE- LP prevention enable 0=NO means disable

1=YES means enable

LPo- LP prevention offset When the low pressure sensor goes below ALS+LPo, every PPt seconds the prevention decreases

the circuit power request by PPp

LPh- HP prevention hysteresis When the low pressure sensor goes below ALS+LPo +LPh, every PPt seconds the prevention

increases the circuit power request by PPp

Note: See LPo parameter

PPt-Pressure decreasing

power period

PPp-Pressure decreasing

power %

HFo-HP fan offset Defines the offset to add /subtract to the setpoint FHS /FCS during the prevention

It is the period in between 2 corrections of the power request during the prevention

It is the correction (%) of the power request during the prevention

Note: if HFo=0 is like disable this function

36 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 37

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Superheat alarms

Parameter: SHh, AHI, Ahi, AHd

It gives the possibility to set a range outside which the superheating

triggers an alarm;

The alarm’s behaviour has to be set in the alarm’s tab

Functionalities: Enable superheating alarm on low and high values

Alarms: SL1, SL2, SL3, SL4, SH1, SH2, SH3, SH3

SHh-Max superheat temp If the superheat goes above SHh alarm is triggered

SHl-Min superheat temp If the superheat goes below SHl alarm is triggered

SHi-Alarm hysteresis The alarms can be reset only in between SHl+SHi and SHh-SHi

SHd-Superheat alarm delay Used in the alarm tab to set the “Steady delay” from the UI

Oil temperature alarms

Parameter: OTm, OTi, OTd

Allows the temperature to be set above the level where an oil’s

alarm is triggered;

The alarm’s behaviour has to be set in the alarm’s tab

Functionalities: Enable compressors oil temperature alarm

Analogue input: OT1, OT2, OT3, OT4, OT5, OT6, OT7, OT8

Alarms: OT1, OT2, OT3, OT4, OT5, OT6, OT7, OT8

OTm-Max oil temperature If the oil’s temperature goes above OTm alarm is triggered

OTi-Oil temp hysteresis The alarms can be reset only below OTm-OTi

OTd -Oil temp alarm delay Used in the alarm tab to set the “Steady delay” from the UI

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 37

Page 38

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Screw compressors

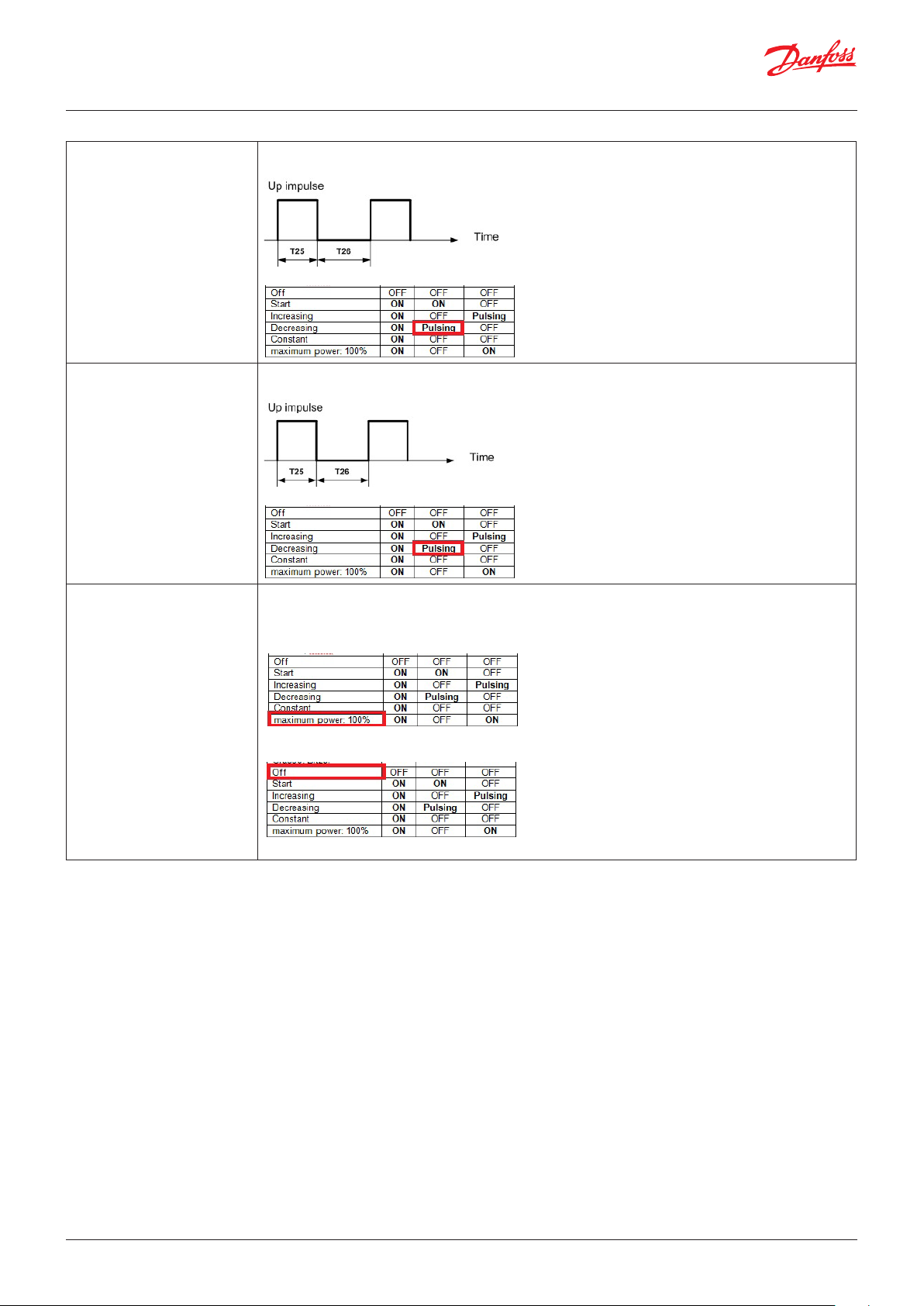

Parameter: C01, C02, CSO, CSb, T1, T2,T3, T4, C07, C08, T5, T6, T21, T22, T24, T24, T25, T26, T27, T28, T29

Only 1 screw compressor per circuit can be managed bot in step

and stepless mode.

Functionalities: Enable screw compressors

Analogue output: CxV, PVx

Digital output: C1, C1U1, C1U2, C1U3, C1U4, C2, C2U1, C2U2,

C2U3, C2U4, C3, C3U1, C3U2, C3U3, C3U4, C4, C4U1, C4U2,

C4U3, C4U4

C01- Rotation type Defines the start order of the compressors

0=LIFO means that there is no rotation and the last compressor to be cut in is the first compressor to

be cut out, the cut-in order is C1,C2…Cn, and the cut-out order is Cn…C2, C1

1=FIFO means that there is no rotation and the first compressor to be cut in is the first compressor to

be cut out, the cut-in order is C1,C2…Cn, and the cut-out order is C1,C2…Cn

2=tIME means running hours control; the compressor to be started is the one with the lowest

number of run hours; the compressor to be stopped is the one with the highest number of run hours.

3=BIN means binary logic, it works only for 2 compressors:

• Below 33% of power request, works only C1

• Between 33% and 66% of power request, works C2

• Above 66% both compressors are allowed to work

2=SRM: Reserved

C02- Compressor type Defines the type of compressors

0=SCW means that the compressors are screw type, check parameters CS0 and CSb

1=StD means that the compressors are standard type (not screw type)

CS0- Capacity control mode Defines whether the screw compressor works in step or stepless mode

0=STeP means that the screw compressor provides predefined steps of power, parameter H7 must

be equal 3.

Note: the digital outputs CxU4 (the ones which pulse) are replicated on analogue outputs PVx

The period of pulsing is 2*C07, the contact stays closed per CO7 seconds

1=LESS means that the screw compressors provides modulating power, parameters H7 and IV0

must be equal 0

Note: the analogue output CxV is the compressor x power request

38 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 39

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

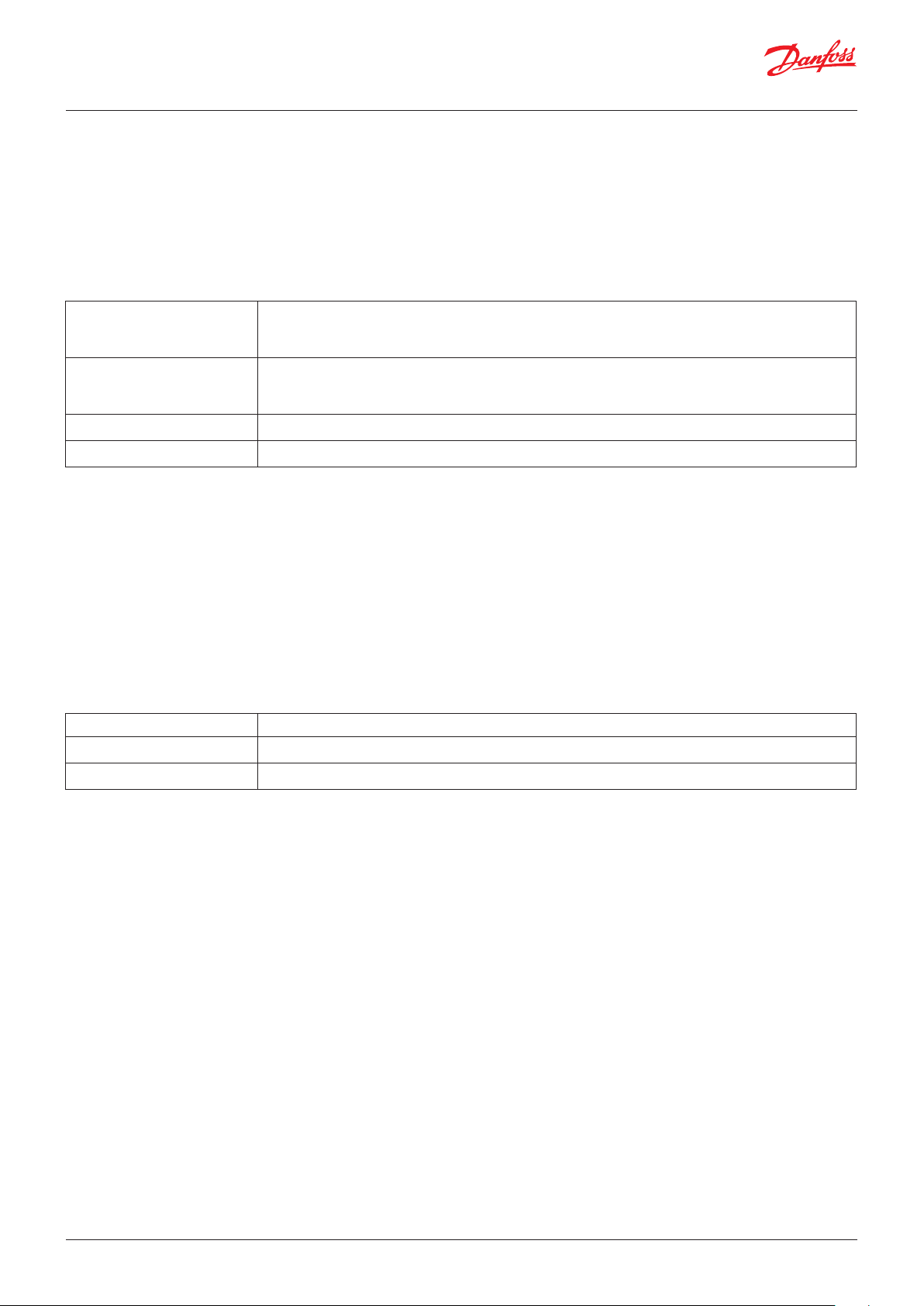

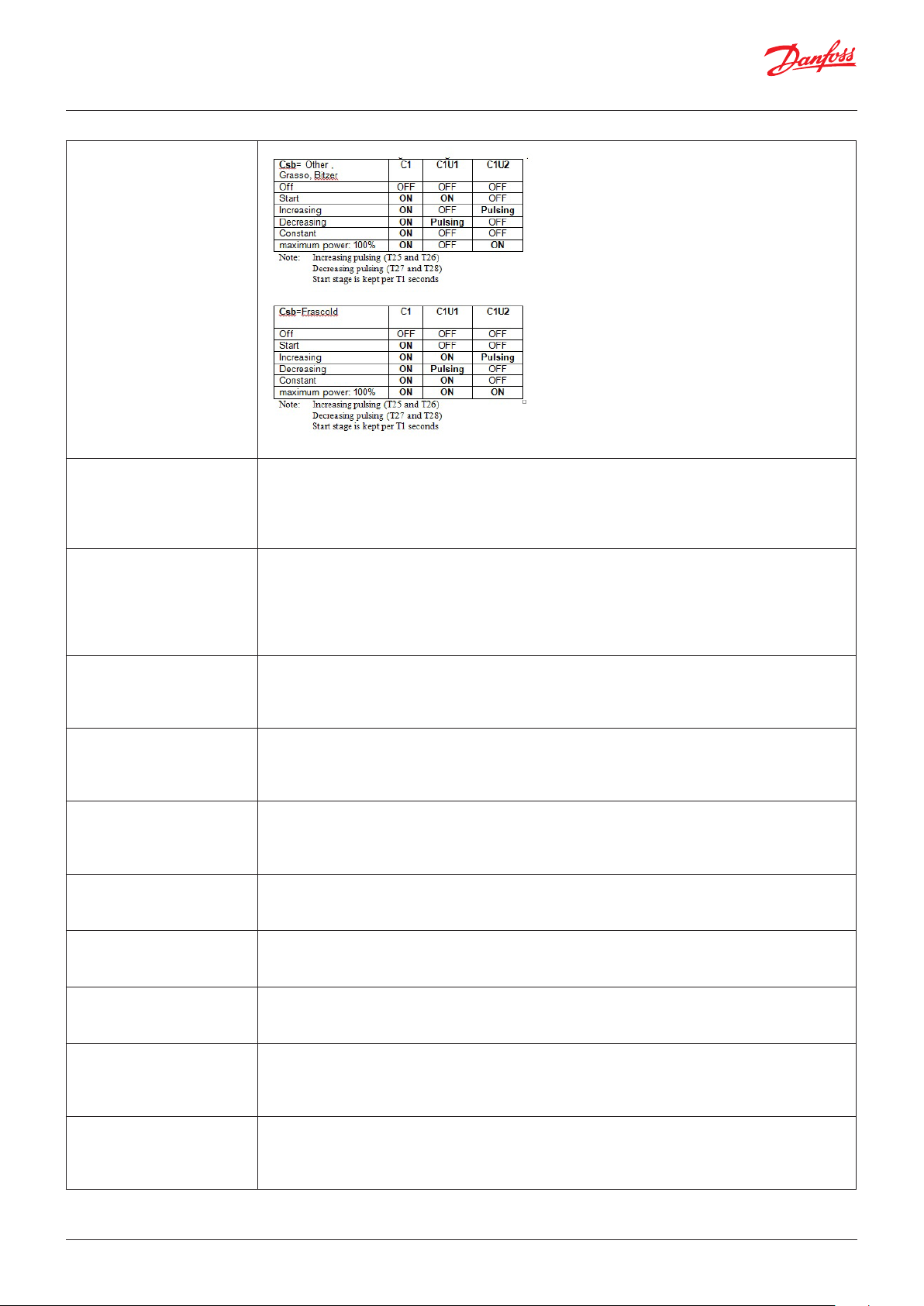

Note: this parameter works only for C02=0

CSb- Compressor brand Defines if the compressor’s brand and so the behavior of digital outputs. See also parameter CS0

0=Other

1=Fras

2=Bitz

3=Gras

T1-Min time step1/ stepless

startup

T2-Min time step2 It's in seconds

T3-Min time step3 It's in seconds

T4-Min time step4 It's in seconds

C07- Unloaders for pulsing

time

C08- Unloaders Stop delay It’s in seconds

T5-Special management step1 It enables the functionalities of the parameter T6

T6-Max time step1 It's in seconds,

T21-Balance power

distribution

It's in seconds:

• For step compressor (CS0=0): the minimum time that the 1st step has to be kept before increase/cut

off the compressor’s power

• For stepless compressor (CS0=1): The minimum time that the start stage has to be kept before

increase/decrease the compressor’s power

Note: check parameter CS0, T5, T6

• For step compressor (CS0=0): the minimum time that the 2nd step has to be kept before

increase/ decrease the compressor’s power

Note: check parameter CS0

• For step compressor (CS0=0): the minimum time that the 3rd step has to be kept before

increase/ decrease the compressor’s power

Note: check parameter CS0

• For step compressor (CS0=0): the minimum time that the 4th step has to be kept before

increase/ decrease the compressor’s power

Note: check parameter CS0

It’s in seconds

The CxU4 output pulses C07 seconds opened and C07 seconds closed

Note: it only works for screw step compressors (CS0=0)

Defines the minimum time that the power step of the compressor has to be kept before

increase/ decrease power

0=No

1=Yes

For step compressor (CS0=0), defines the maximum time that the compressor can keep step1,

after that the compressor’s power will be increased

Note: check parameter CS0 and T5

Used for stepless screw compressor.

0=No means that before cutting in a new compressor, the compressors which are working have to be

at maximum power; before decreasing the compressor power, a compressor has to be switched off

1=Yes means that before increasing a compressor’s power, all the compressors have to be switched on

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 39

Page 40

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

T22-Minimum power Used for stepless screw compressor.

It’s in %

Defines the minimum power request (in the circuit) above which the compressor is switched on.

After this Start stage of the compressor the compressor will be allowed to work

Note: check parameter T1

T23-Valve opening time Used for stepless screw compressor.

It’s in seconds

Defines the minimum time that the compressor spends to reach maximum power starting from the

start position

Note: depends on the Pulsing period - check parameters T25 and T26

T24-Valve closing time Used for stepless screw compressor.

It’s in seconds

Defines the minimum time that the compressor spends to reach the minimum power starting from

maximum power

Note: depends on the Pulsing period - check parameters T27 and T28

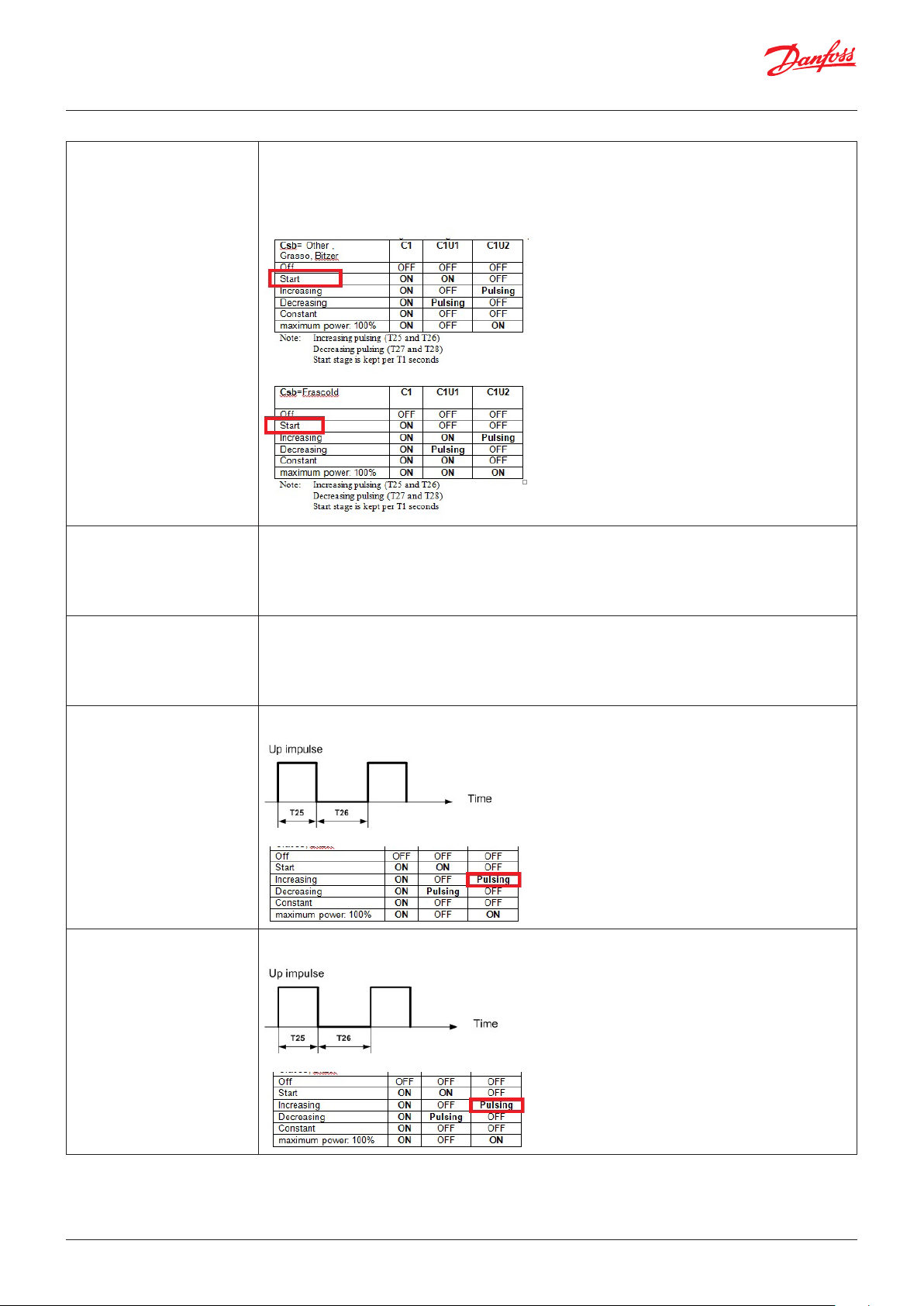

T25-Minimum time UP

impulse

Used for stepless screw compressor.

It's in milliseconds

T26-OFF time in between

UP impulses

40 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Used for stepless screw compressor.

It's in seconds

Page 41

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

T27-Minimum time

DOWN impulse

T28-OFF time in between

DOWN impulses

T29-% limit for max Open/

Close

Used for stepless screw compressor.

It's in milliseconds

Used for stepless screw compressor.

It’s in seconds

Used for stepless screw compressors.

It’s in %

When the circuit’s power request goes above (100-T29)% the compressor reaches the “Maximum

power 100%” stage

When the circuit’s power request goes below T29% the compressor is switched off

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 41

Page 42

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Starting type of the compressor

Parameter: Sty, Sti, SSt, Stm, Sdd

For the start of big compressors is possible to select a

PARTWINDING logic or STAR-DELTA logic

Functionalities: Enable motor starting type selection

Digital output: C1, C1P,C1S, C1D, C2, C2P, C2S, C2D, C3, C3P, C3S,

C3D, C4, C4P, C4S, C4D, C5, C5P, C5S, C5D, C6, C6P, C6S, C6D, C7,

C7P, C7S, C7D, C8, C8P C8S, C8D

Sty-Starting type Defines how to start a compressor in order to limit the start current

0=Dir : Direct start of the compressor (only Cx digital output)

1=PWin : Part winding start of the compressor (Cx and CxP digital outputs)

2=StDe : Star-Delta start of the compressor (Cx , CxS and CxD digital outputs)

Sti-Part winding delay It’s used for part winding starting type (Sty=1).

It's in milliseconds

Just Sti milliseconds after the start of the xth compressor (Cx= Closed) the digital output CxP is closed

SSt-Compressor start delay It’s used for “star-delta” starting type (Sty=2).

It's in milliseconds

Just SSt milliseconds before the start of the xth compressor (Cx= Closed) the digital output CxS is closed

Stm-Star time It’s used for “star-delta” starting type (Sty=2).

It's in milliseconds

It’s defines how long the star stage will be kept, the digital output Cxs will be opened after Stm

milliseconds from the compressor start (Cx=Closed)

Sdd-Star-Delta delay It’s used for “star-delta” starting type (Sty=2).

It’s in milliseconds

It’s defines the delay between the closing of the “Delta” connection (CxD=Closed)

from the opening of the “Star” connection (CxS=Closed)

42 | BC295150867120en-000201 © Danfoss | DCS (vt) | 2019.08

Page 43

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

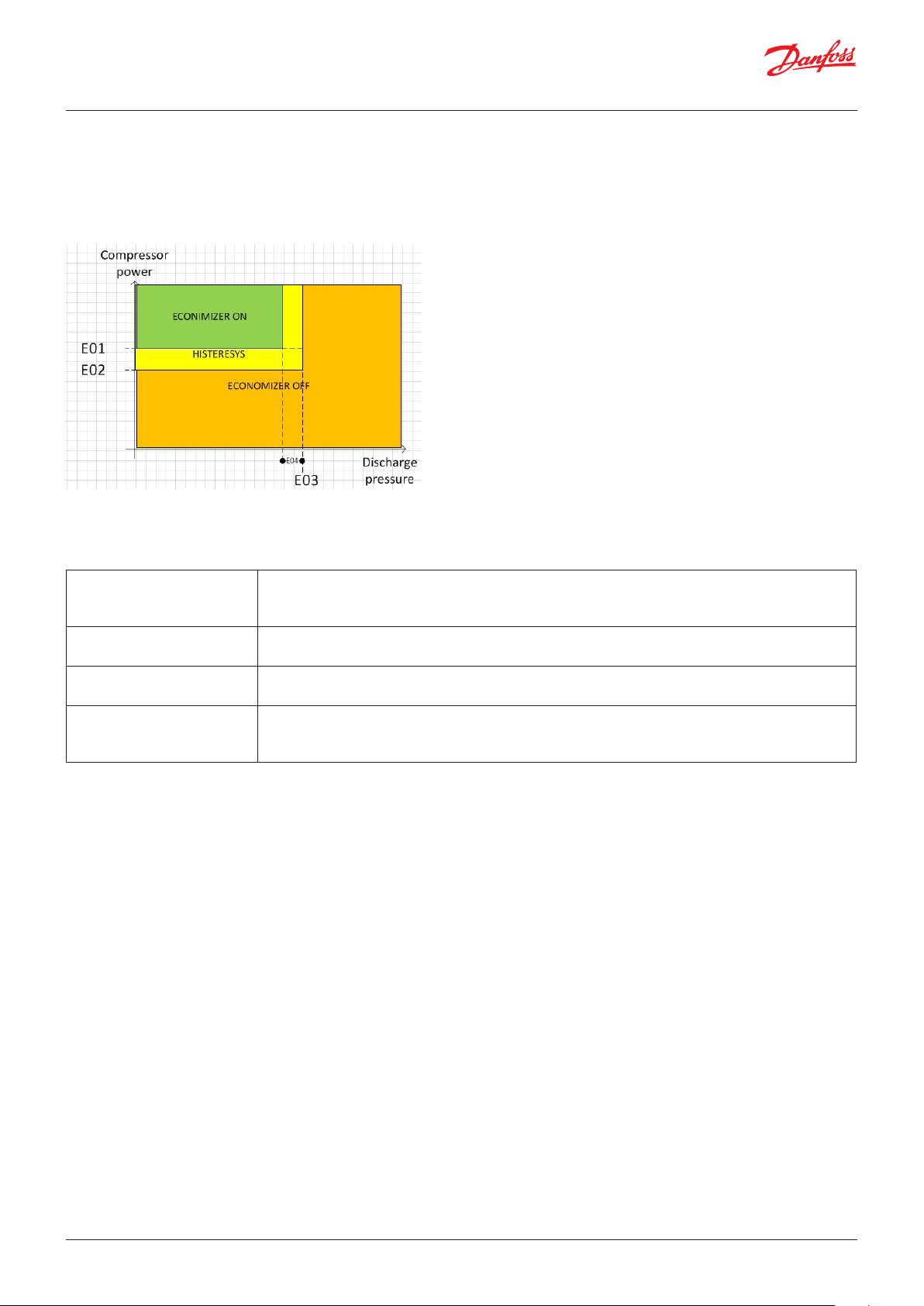

Economizer

Parameter: E01, EO2, EO3, EO4

The logic to manage the economizer considers one compressor

per circuit, like in the case of screw compressors

Digital output: EC1,EC2, EC3, EC4

Analogue input: dp1. dp2, dp3,dp4

E01-ON Setpoint It’s in %

When the compressor’s power is >= E01% and the discharge pressure is below E03-E04, the

economizer (digital output ECx) is opened

E02-OFF Setpoint It’s in %

When the compressor’s power is <= E02% the economizer (digital output ECx) is closed

E03-Pressure limit It’s in bar G

When the compressor’s power is >= E03 bar, the economizer (digital output ECx) is closed

E04-Pressure differential It’s in bar G

When the compressor’s power is >= E01% and the discharge pressure is below E03-E04 the

economizer (digital output ECx) is opened

© Danfoss | DCS (vt) | 2019.08 BC295150867120en-000201 | 43

Page 44

User Guide | Chiller and reversable chiller, reciprocating, scroll and screw compressors

Liquid injection

Parameter: T41, T42, T43, T44, T45

Liquid injection is managed in relation to the discharge

temperature and/or the value of the super heat

It’s designed for only one compressor per circuit.

Functionalities: Enable compressor’s liquid injection

Functionalities: Enable EEV

Digital output: LI1, LI2, LI3, LI4

Analogue input: dT1, dT2, dT3, dT4, and the value of

the superheat

T41-Discharge temperature set It’s in °C

When the discharge temperature " dTx" goes above T41 and compressor x is switched ON, liquid

injection valve "LIx" is opened

T42-Differential It’s in °C

When the discharge temperature "dTx" goes below T41 – T42, liquid injection valve "LIx" is closed.

Note: if the compressor is switched off, the valve is closed

T43-EEV SH Offset It’s in °C

When liquid injection x is working, the maximum SH of circuit x becomes T44-T43 and the minimum

SH becomes T45-T43

Note: Overread is on EXD or EKE drivers or in the internal SH drivers

T44- EEV SH Max It’s in °C

It has to be equal to the maximum SH used in the SH control logic (parameter N09)

T45- EEV SH Min It’s in °C

It has to be equal to the minimum SH used in the SH control logic (parameter N10)

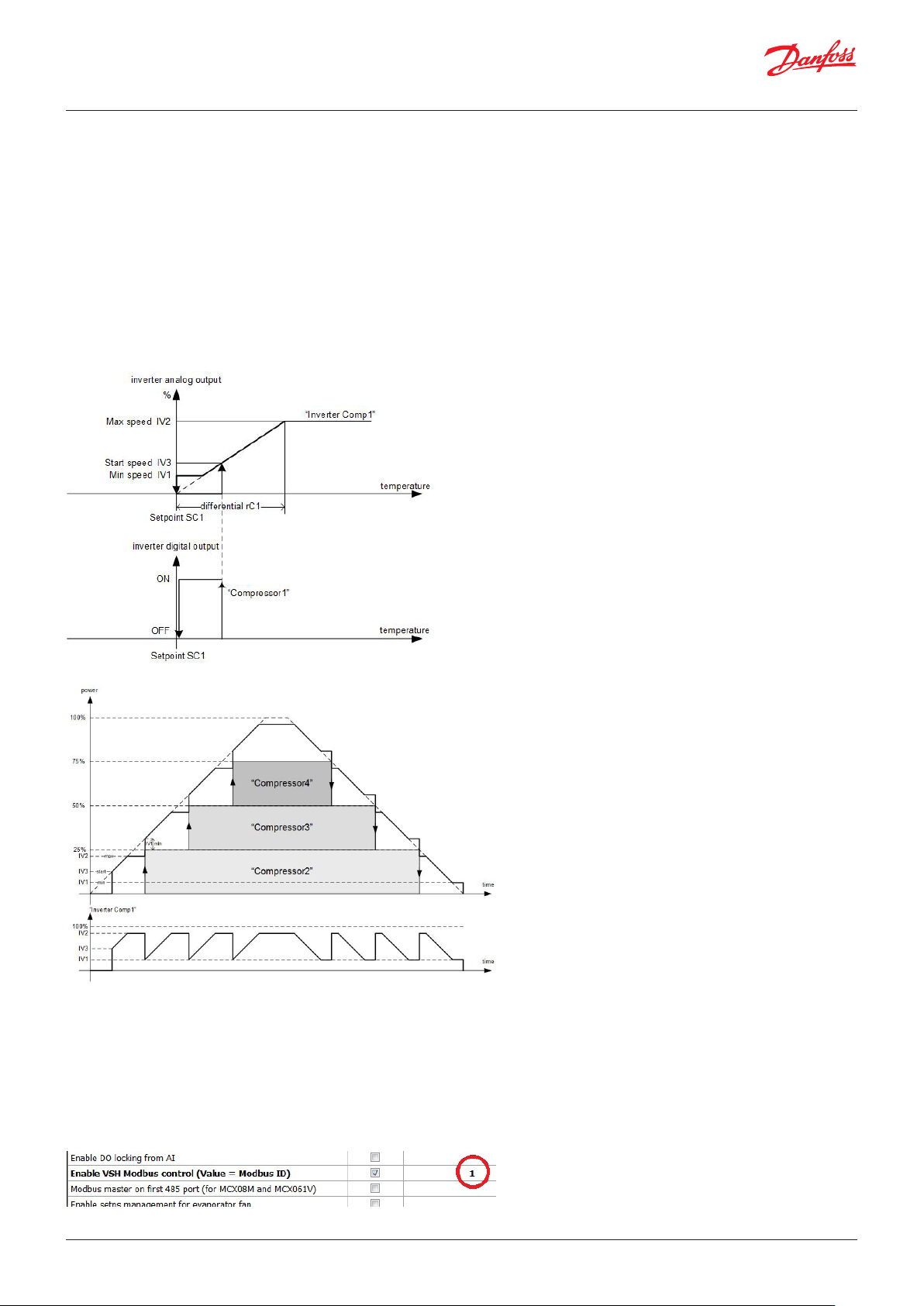

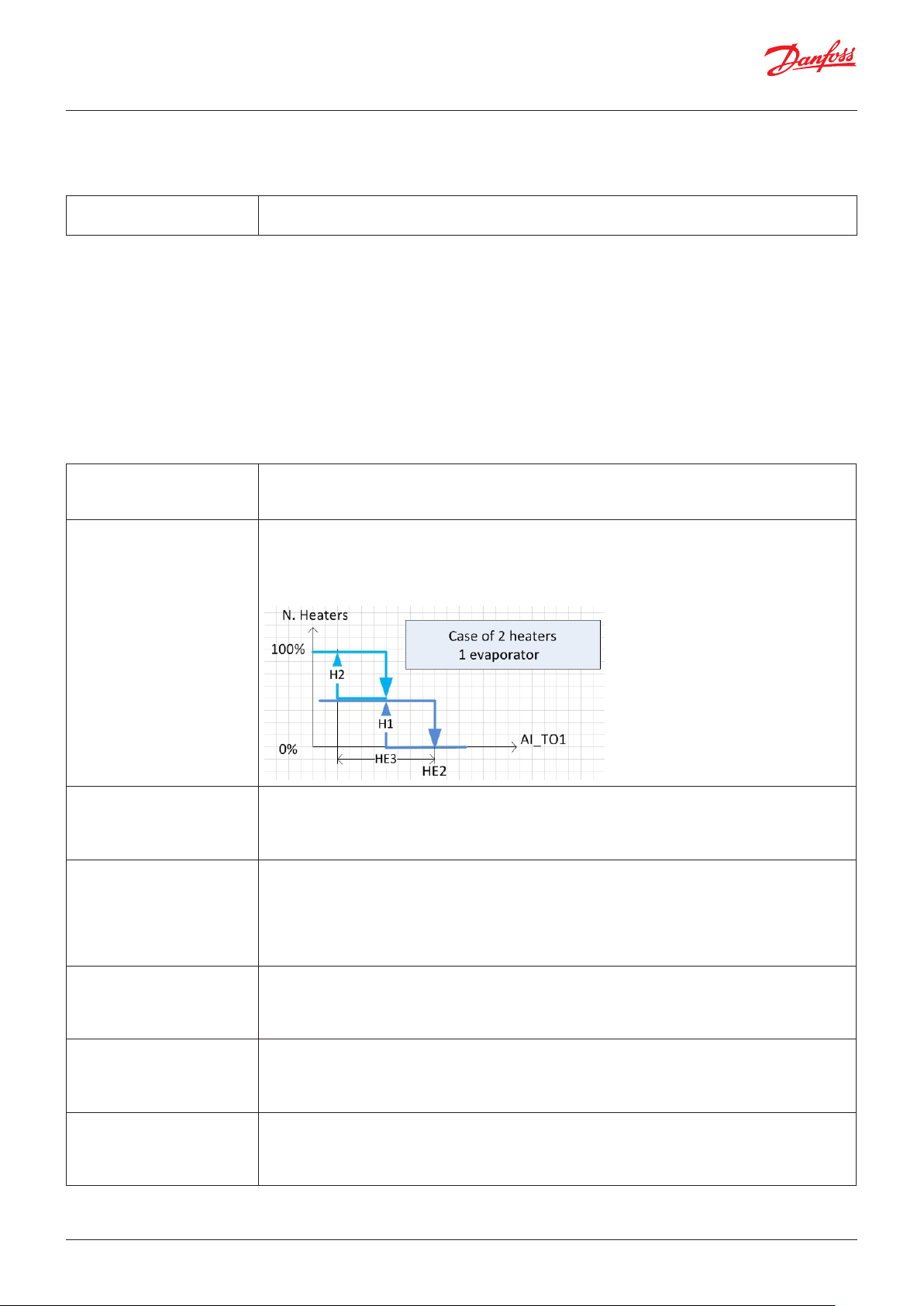

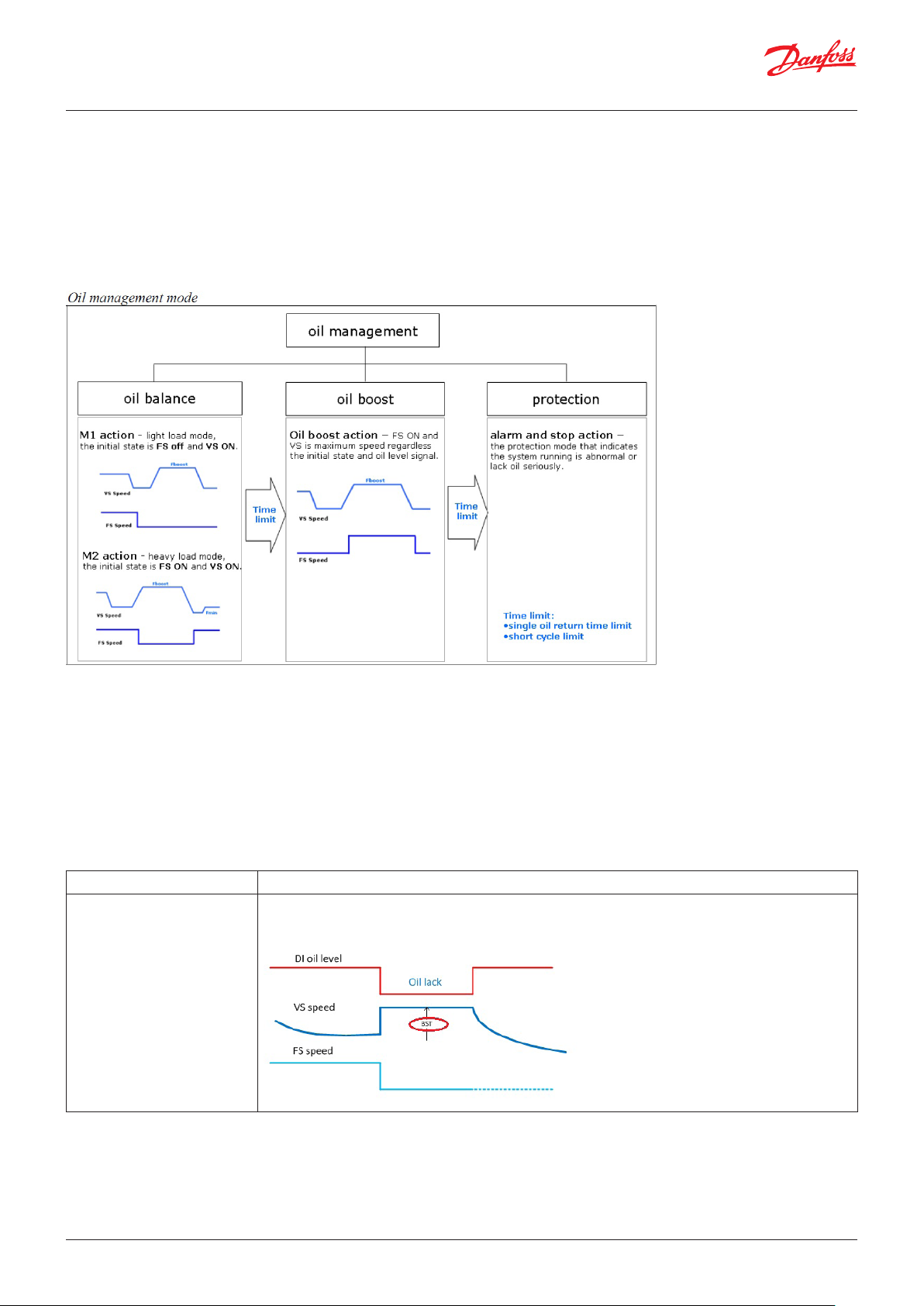

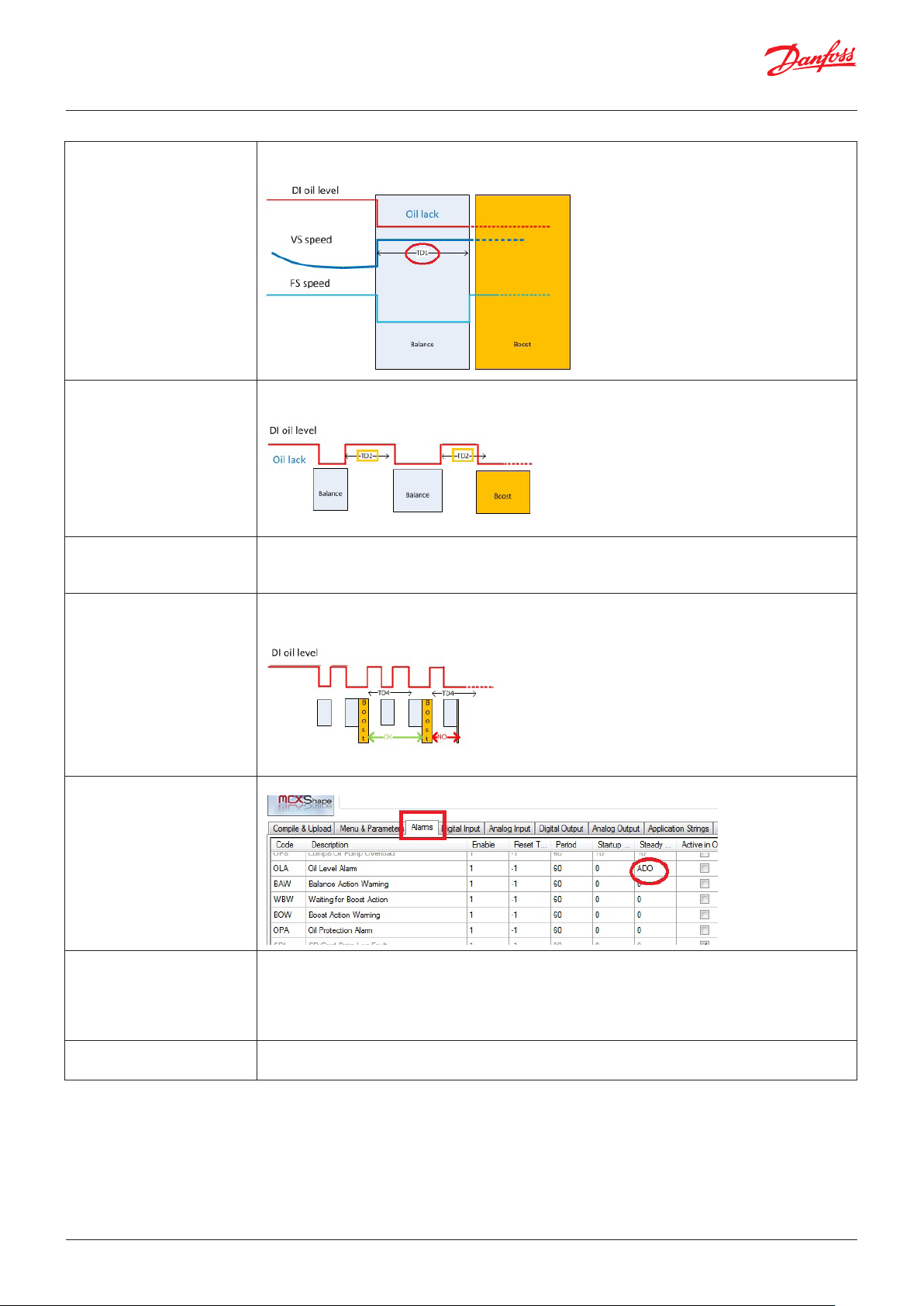

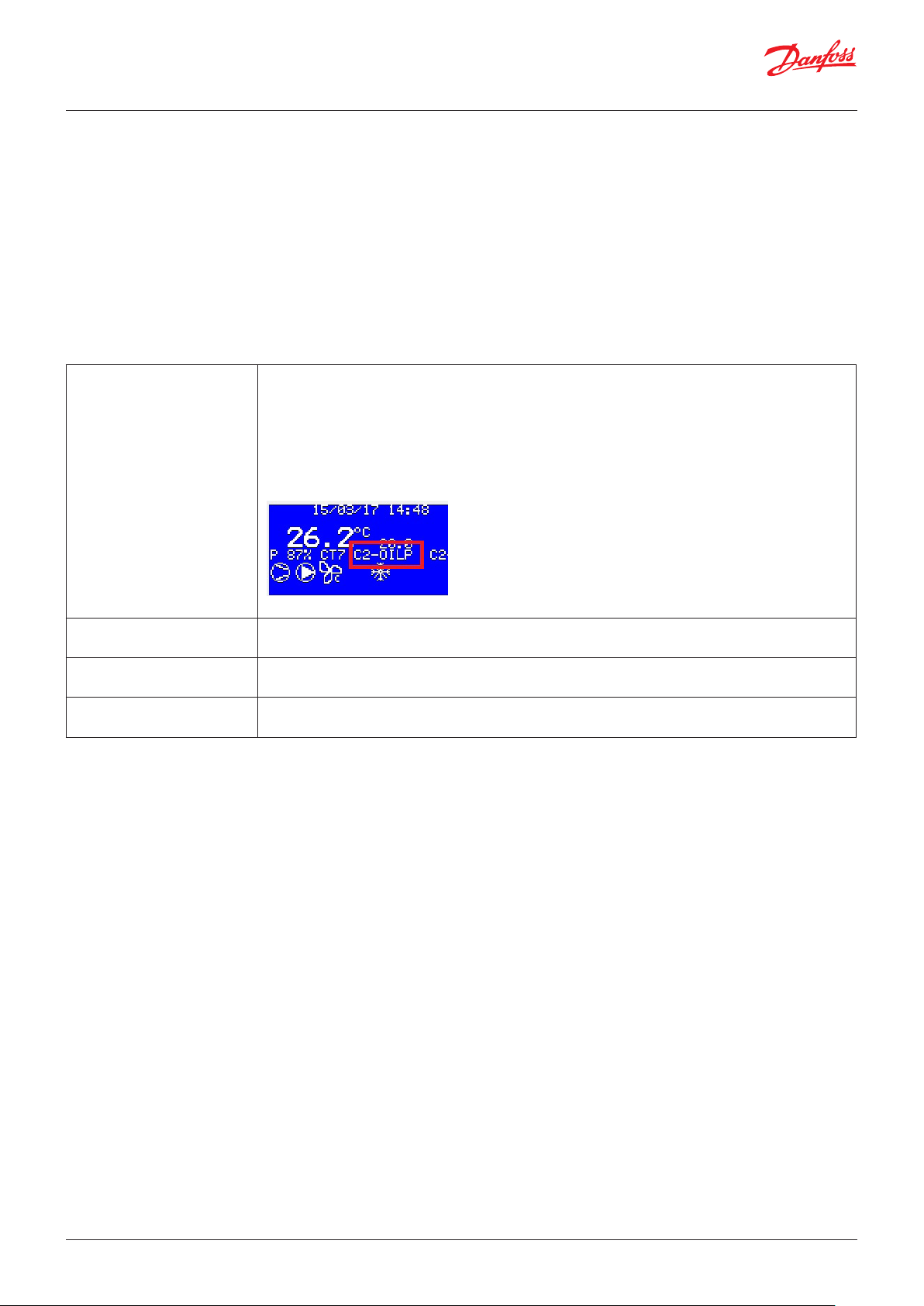

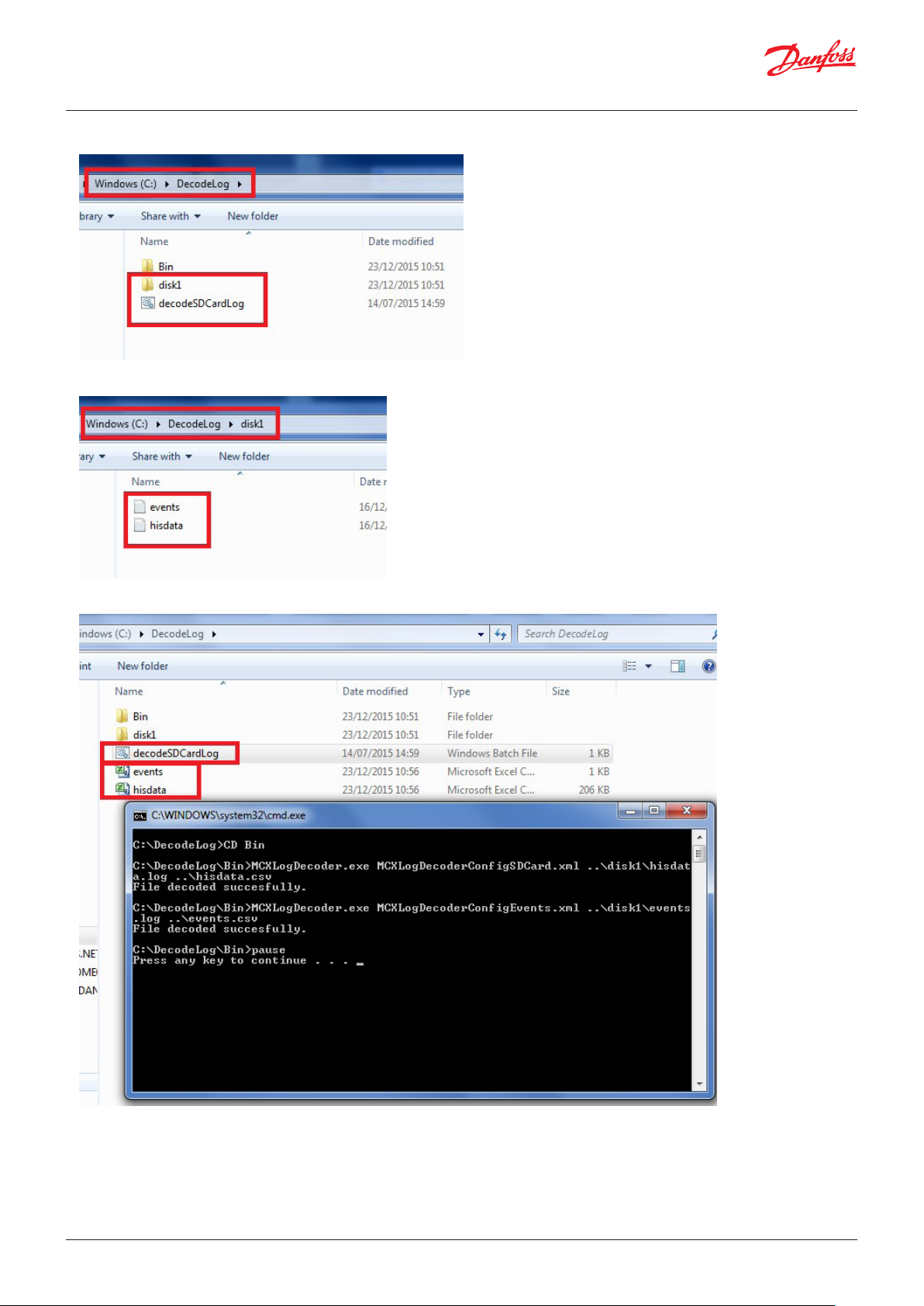

Compressor with unloaders