Page 1

Data Sheet

Electric regulating valve

Type CCMT 2, 8, 16 and 42

One valve, 4 applications: HPV, GBV, EV and EPR

The CCMT is an electrically operated valve

designed specically for operation in CO

systems.

The CCMT valve concept is designed to full

global refrigeration requirements.

The valve is capable of functioning either as an

expansion valve, as a pressure regulator for the

gascooler or as a gas bypass valve with backpressure regulation in transcritical or subcritical

applications.

2

Features:

• Designed for CO2 systems with maximum

working pressure of 140 bar / 2030 psig.

• Applicable to R744 (CO2) and other common

refrigerants. The CCMT is compatible with the

oil types PAG, POE and PVE.

• Regulating cone ensures optimum regulating

accuracy, particularly at part load.

• Patented cone and balance design.

• The PEEK seat provides excellent valve

tightness and robustness.

• Combined butt weld and solder connections.

• Top part with built-in strainer / lter.

• MOPD up to 90 bar / 1305 psi

• CCMT 16 – CCMT 42 is available with or

without integrated pressure transmitter.

• Standard M12 connector for simple and

exible connection to the motor driver.

• Low weight and compact design.

• Easy to service. Insert easily taken out by

removing top part.

• For manual operation and service of the

CCMT an AST-g service driver is available.

AI230186439989en-000901

Page 2

Type

Description

Single pack

Code no.

AK-XM 208C

Stepper output module

1

080Z0023

EKE 1 Series

Superheat controller / driver

1

080G5300

080G5350

080G5400

AST-G

Manual service driver1034G0013

Superheat controller / driver, type

EKE 1 series

Electronic controller type EKC 326

and EKC 313

Electronic driver type AK-XM 208C

Temperature sensors type AKS and

pressure transmitters type MBS

Electric regulating valve, type CCMT 2, 8, 16 and 42

Portfolio overview

Related products

Table 1: Related products

Table 2: Portfolio overview

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 2

Page 3

Danfoss

R64-3020.11

1

2

3 4

5

6

7

8

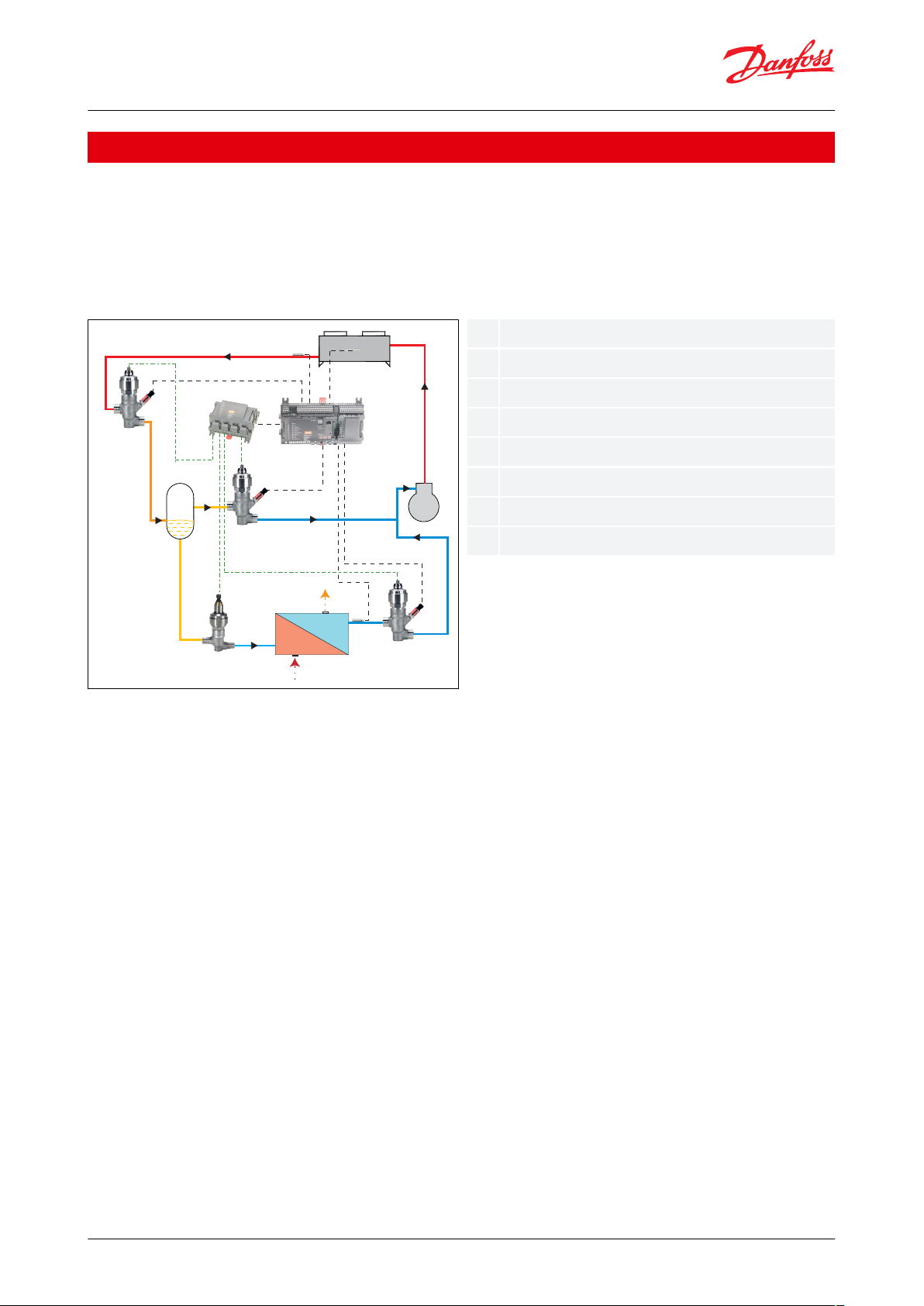

12345678Gas cooler

High pressure valve

Stepper motor driver

Master controller

Gas by-pass valve

Electric expansion valve

Evaporator

Electric pressure regulator

Electric regulating valve, type CCMT 2, 8, 16 and 42

Applications

The CCMT valve is developed for transcritical CO2 applications. The CCMT valve can be used in systems with ash gas

bypass, parallel compression as well as in stand-alone applications.

The CCMT valve can be used in transcritical and subcritical conditions.

CCMT valves are typically used as ash gas bypass and high pressure regulation.

Figure 1: Application

Application 1 - High Pressure Valve (HPV)

The function of the high pressure valve is to control the high pressure in the system according to the reference from

the controller. The reference can be set to obtain the optimum COP, optimum capacity or any other factors. Pressure

optimization is performed by the CCMT valve, which is installed at the outlet of the gas cooler (see the gure above)

and a matching Danfoss controller. This design provides the possibility to optimize gas cooler pressure in all

situations and intermediate receiver pressure independently. Please refer to the www.danfoss.com/CO2 for more

information on CO2 systems.

Application 2 - Gas bypass Valve (GBV)

A gas bypass valve is typically used to regulate the intermediate pressure in a transcritical CO2 refrigeration system,

in order to keep the intermediate pressure low. By venting ash gas generated through a gas bypass valve to the

suction side of the compressor after the transcritcal expansion, the pressure can be kept at a safe level for all

components situated in the liquid lines of a transcritical CO2 system . The two phase mixture from the CCMT valve

has to be separated before gas enters the gas bypass. For use in the gas bypass applicaton the EKC 326A controller is

recommended for CCMT 2 to CCMT 8

Application 3- Expansion Valve (EV)

A liquid expansion valve is typically used for injection in plate heat exchangers of CO2/CO2 cascades, or as an

expansion valve for CO2 evaporators. For the liquid injection applications CCMT 2 to CCMT 8 is used with EKC 313

controller.

Application 4 – Electric pressure regulator (EPR)

With CCMT valves, it is possible to obtain an accurate temperature or pressure control by modulating the pressure in

the evaporator.

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 3

Page 4

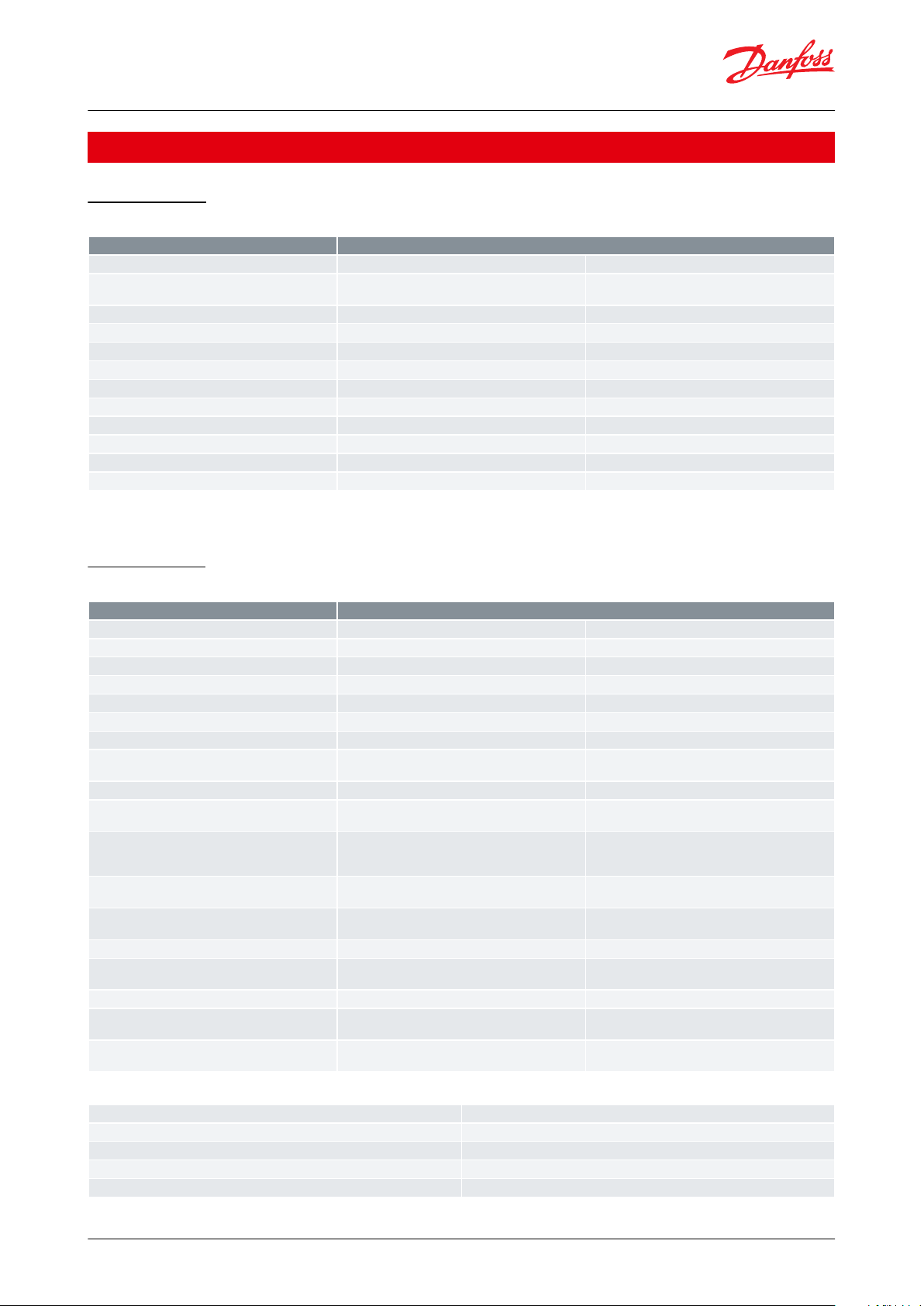

Features

Description

Parameter

CCMT 2 – CCMT 8

CCMT 16 - CCMT 42

Compatibility refrigerants

R744 and other refrigerants. Not applicable for am-

mable refrigerants and Ammonia.

R744 and other refrigerants. Not applicable for am-

mable refrigerants and Ammonia.

Refrigerant oils

PAG, POE and PVE

PAG, POE and PVE

MOPD

90 bar / 1305 psi

90 bar / 1305 psi

Max. working pressure (PS/MWP)

140 bar / 2030 psig

140 bar / 2030 psig

Refrigerant temperature range

(1)

–40 – 60 °C / -40 – 140 °F

–40 – 60 °C / -40 – 140 °F

Ambient temperature

–40 – 60 °C / -40 – 140 °F

–40 – 60 °C / -40 – 140 °F

Material specication

Stainless steel

Stainless steel

Expected lifetime

Min. 15 years

Min. 10 years

Build in strainer / lter

Yes, 6 slots, 1.1 mm height x 10 mm wide

Yes, 250 micron

Comply with P.E.D.

Fluid group I / Article 3, paragraph 3

Fluid group I / Article 3, paragraph 3

Approval

CE and UL approved

CE, UL, EAC, cUL, CRN

Features

Description

Parameter

CCMT 2 – CCMT 8

CCMT 16 - CCMT 42

Stepper motor type

Bi-polar - permanent magnet

Bi-polar - permanent magnet

Motor enclosure

IP 67

IP 67

Step mode

2 phase full step, microstepping (recomended)

2 phase full step, microstepping (recomended)

Phase resistance

52 Ω ±10%

29 Ω ±10%

Phase inductance

85 mH

36.7 mH

Phase current

Using chopper drive: 100 mA RMS -4 % +15 %

Using chopper drive: 300 mA RMS -4 % +15 %

Holding current

Voltage driver: Depends on application. Current controller: Full current allowed

Not needed.

Duty cycle

100% duty cycle is allowed / 20% recommended

100% duty cycle is allowed / 20% recommended

Max. total power

Voltage drive: 5.5 W Current drive: 1.3 W (UL: NEC

class 2)

Voltage drive: 10W Current drive: 2.8 W

Step rate

Chopper current drive: Max. 300 steps/sec.

(Recomended step rate: 200 steps/ sec.) Constant voltage drive: Max. 150 steps/sec.

Chopper current drive: Max. 300 steps/sec.

(Recomended step rate: 200 steps/ sec.) Constant voltage drive: Max. 150 steps/sec.

Total full steps

CCMT 2 , 4 and 8: 1100 steps

CCMT 16 : 800, CCMT 24 : 1400, CCMT 30 : 2300 and

CCMT 42 : 2200

Full travel time

CCMT 2, 4 and 8: 5 sec. ( at 220 steps/sec.)

CCMT 16 : 4 sec., CCMT 24 : 7 sec. CCMT 30 : 11.5 sec.

and CCMT 42 : 11 sec.( at 200 steps/sec.)

Reference position

Overdriving against full close position

Overdriving against full close position

Overdrive in close position

Max. 10% of total full steps

Max. 10% of total full steps and maximum one overdrive performed per hour.

Overdrive in open position

Not Allowed

Not Allowed

Electrical connection

M12 male connector with 0.3 m / 1 ft long cable

(4

wire: 0.5 mm2 / 20 AWG)

Integrated M12 male connector

Compatible controllers

EKE 1A, EKE 1B, EKE 1C, EKC 313, EKC 326A , AK-XM

208C

EKE 1A, EKE 1B, EKE 1C, AK-XM 208C

Pressure range

- 1 to 159 bar / 14.5 – 2306 psi sealed gauge

Electrical connection

Round Packard Metripack

Output signal

10 - 90 % of V supply

Supply voltage

5V DC ± 0.5V

Process connection

7/16-20 UNF-2A ISO 11926-2; Viton o-ring

Electric regulating valve, type CCMT 2, 8, 16 and 42

Product specication

Technical data

Table 3: Technical data

(1)

(1)

Measured at inlet of the valve

Measured at inlet of the valve

Electrical data

Table 4: Electrical data

Table 5: Pressure transmitter MBS 8250 (CCMT 16 - CCMT 42 with integrated pressure transmitter)

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 4

Page 5

X

Y

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

Y

X

Danfoss

27H313.10

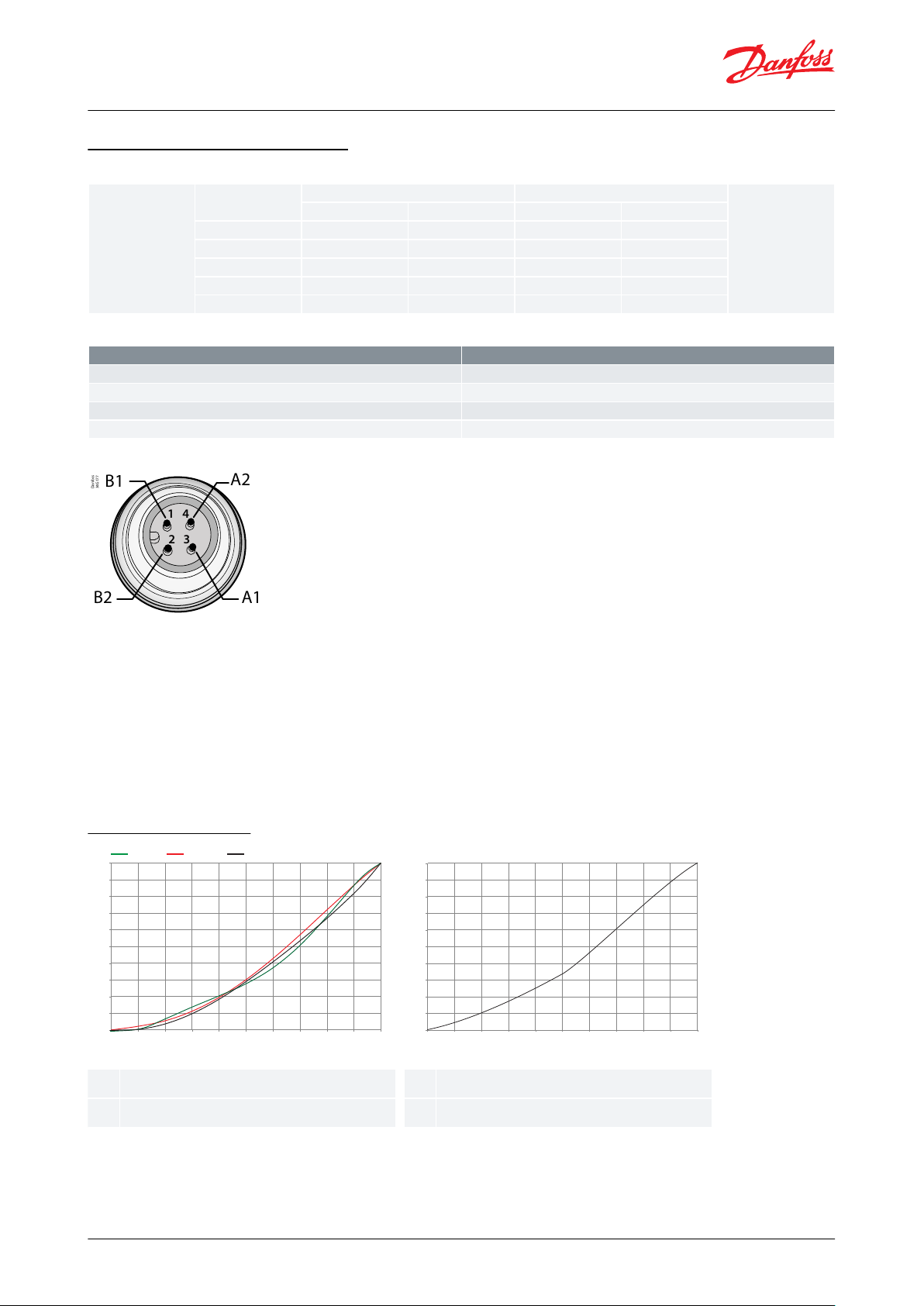

CCMT 3L

CCMT 5L

CCMT 8L

Opening %

% of capacity full open

X

Y

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

Y

X

Danfoss

27H314.10

CCMT 16 – CCMT 42

Opening %

% of capacity full open

CLOSING

STEP

Coil I (B)

Coil II (A)

OPENING

Red

Green

White

Black

1+-+-2+--+3-+-+4-++-1+-+-

Pin

Wire color

A1

WhiteA2BlackB1RedB2Green

B1

B2

A1

A2

1

3

2

4

Danfoss

34G177

Electric regulating valve, type CCMT 2, 8, 16 and 42

Stepper motor switch sequence

Table 6: Stepper motor switch sequence

Table 7: Danfoss cable connections

Figure 2: CCMT valve

If the controller driving the CCMT Light valve is from another manufacturer than Danfoss or a custom design, the

following points must be considered in order to overcome potential step loss.

To ensure total closing of the valve, and to compensate the lost steps after a dened number of changes in opening

degree. the controller should have a function to overdrive the valve in the closing direction. It is recommended to

overdrive ten percent of the full steps range at appropriate intervals.

WARNING:

At power failure the CCMT Light valve will remain in the actual opening position it has at the moment of power

failure, unless a safety device in the form of a battery backup is installed.

Flow characteristics

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 5

Page 6

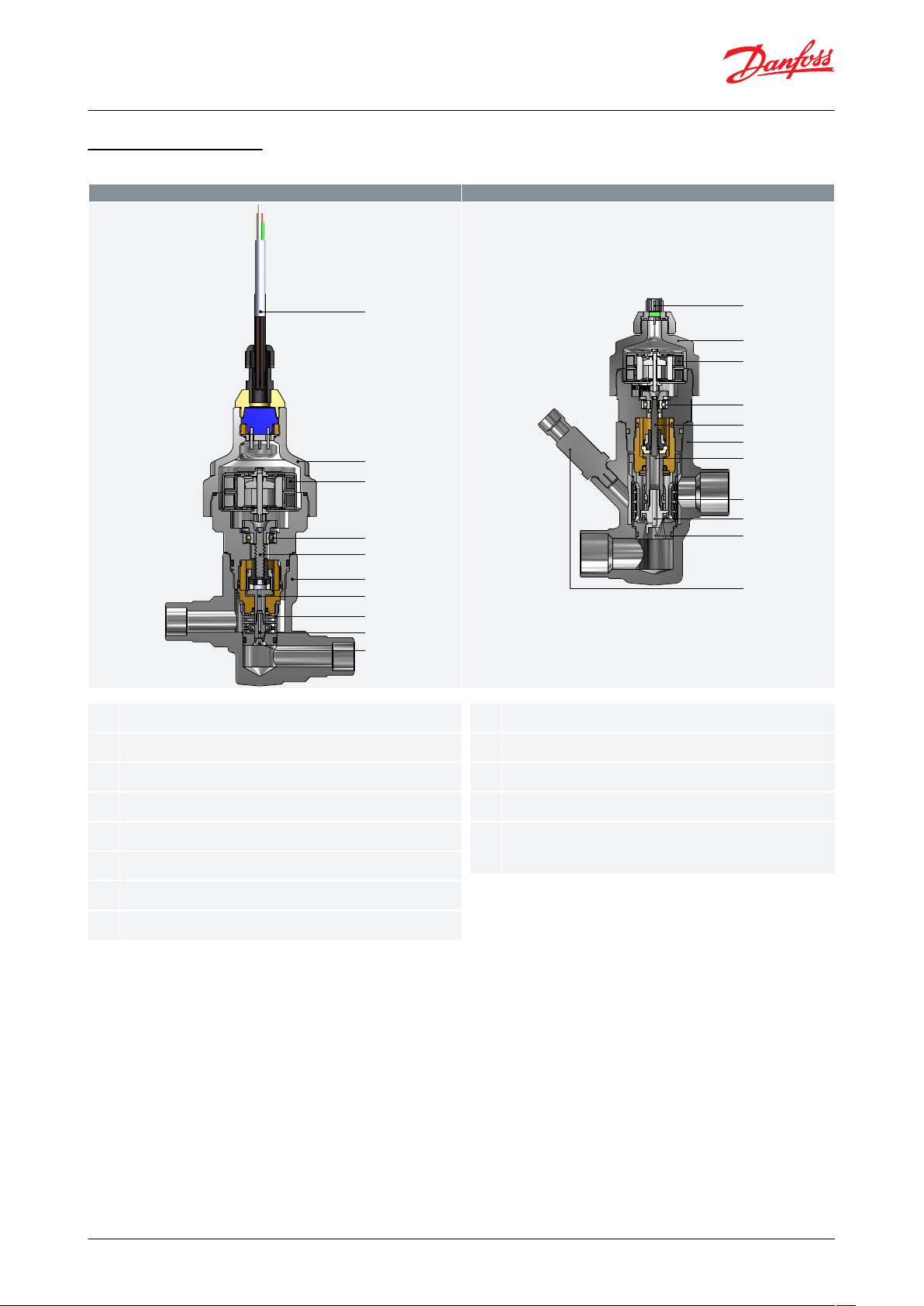

1a1b2345678a8b9

10

11

CCMT 2 - CCMT 8

CCMT 16 - CCMT 42

Danfoss

27H319.10

1a

9

7

6

5

4

3

2

8a

10

Danfoss

27H320.10

1b

2

3

4

6

7

5

8b

9

10

11

Cable with M12 male connector

M12 connector

Actuator housing

Stepper motor

Ball bearing

Spindle

Valve housing

Balance piston

Strainer

Filter

Valve cone

Nozzle

Pressure transmitter (not included in CCMT 16 -

CCMT 42 without integrated pressure transmitter)

Electric regulating valve, type CCMT 2, 8, 16 and 42

Design and materials

Table 8: Design and materials

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 6

Page 7

A

B

C

D

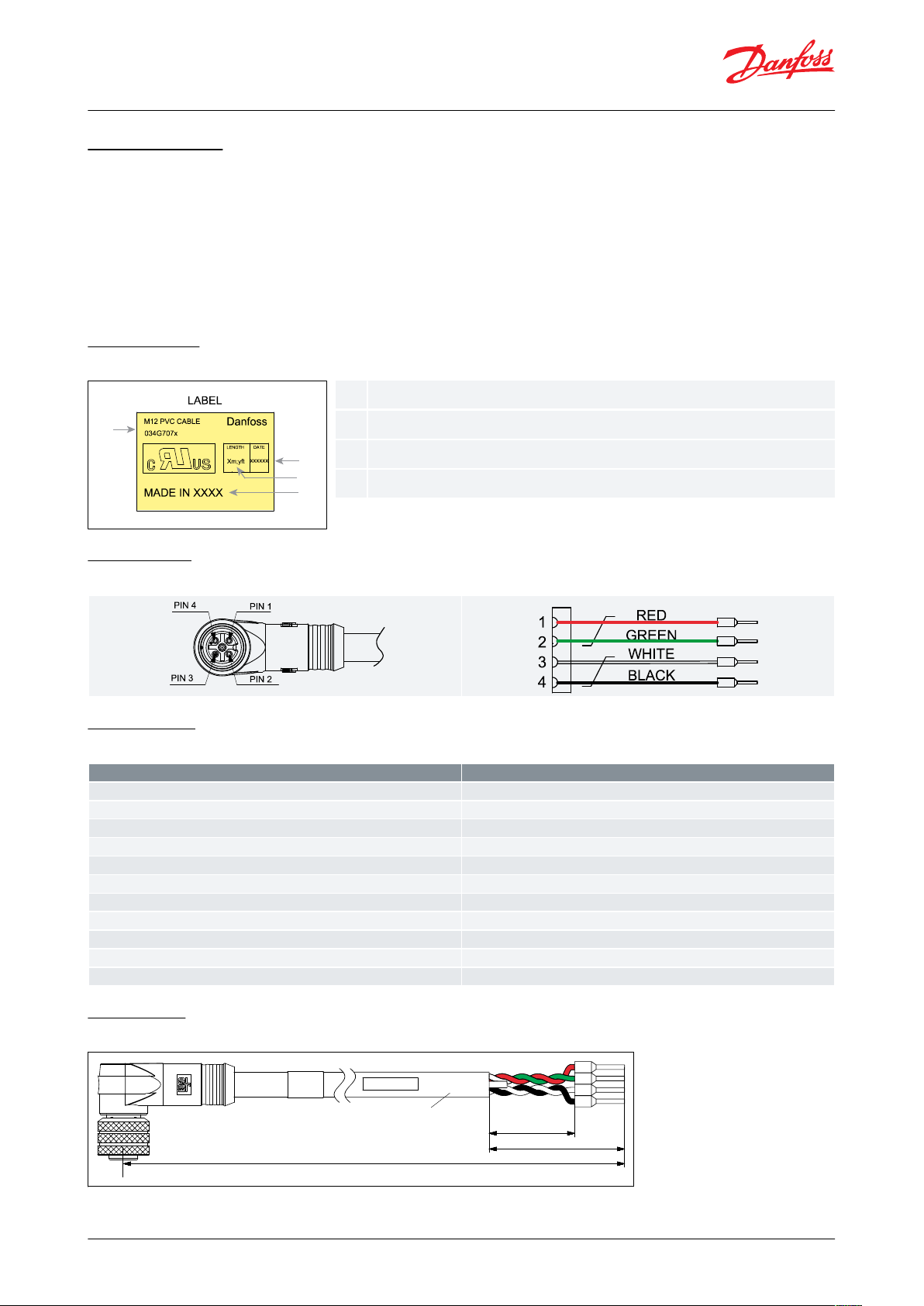

ABCDProduct type Code no.

Manufacturing date

Meters/Feets

Country

34G210.10

A2 black

A1 white

B1 red

B2 green

34G211.10

Features

Description

Jacket

PVC - black

Cable outer sheath

Oil - resistant

Water proof rating

IP 67

Operating temperature range

-40 – +80 °C

Wire type

Twisted pair, cross section 20 AWG / 0.5 mm2

Cable outer diameter

7.0 mm

Minimum bending radius

10 x cable diameter

Cable combustibility / test

Flame retardant / VW-1 / CSA FT - 1

M12 standard

EN 61076-2-101

Reference standard

UL style 2464 and DIN VDE 0812

LVD directive

73/23/EEC and 93/68/EEC

34G209.10

49 mm / 1.9 inch

Ø 6.3 mm / 1/4 inch

35 mm / 1.4 inch

2 + 0.089 meters / 6.6 + 0.3 feet

8 +0.3 meters / 26.2 +1 feet

Electric regulating valve, type CCMT 2, 8, 16 and 42

M12 angle cable

M12 angle cable

M12 angle female connector is intended for use with the standard M12 male connector on CCMT Light valves.

The Danfoss cable is designed to oer high exibility and proper tensile strength.

The Danfoss M12 cable also consists of paired, twisted wires, which decreases mutual inuence between signals

transmitted

along the cable and reduces inuence of external sources of interference. The cable thus provides a higher degree

of protection

against lost steps compared to other cables.

Identication

Figure 3: Identication

Connections

Table 9: Connections

Specication

Table 10: Specication

Dimensions

Figure 4: Dimensions

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 7

Page 8

CCMT 2 – CCMT 8(Weight:1.5 kg / 3.3 lb)

CCMT 16 – CCMT 42(Weight: 2.6 kg / 5.7 lb)

Danfoss

27N322.10

193 mm / 7.6 in

Ø 64 mm / 2.5 in

36.5 mm / 1.4 in

75 mm / 3 in

53.5 mm / 2.1 in

53.5 mm / 2.1 in

Ø 64 mm / 2.5 in

206 mm / 8.1 in

117 mm / 4.6 in

66.7 mm / 2.6 in

22.7 mm / 0.9 in

53.5 mm / 2.1 in

136.99 mm / 5.4 in

53.5 mm / 2.1 in

Danfoss

27N321.10

64 mm

[2.5 in]

2

0

6

m

m

[

8

.

1

i

n

]

1

1

7

m

m

[

4

.

6

i

n

]

6

7

m

m

[

2

.

6

i

n

]

53,5

mm

[2.1 in]

53,5 mm

[2.1 in]

2

2

,

7

m

m

[

0

.

9

i

n

]

101,8 mm

[4.0 in]

Electric regulating valve, type CCMT 2, 8, 16 and 42

CCMT 2 – CCMT 8

Table 11: CCMT 2 – CCMT 8

CCMT 16 – CCMT 42 (without integrated pressure transmitter)

Figure 5: CCMT 16 – CCMT 42

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 8

Page 9

Type

Connections

Flow rate

Single pack

Code no.

Weld

(1)

[in]

Solder ODF x ODF

[in]

kv [m3/h]

Cv [gpm]

CCMT 2

1/2 × 1/2

5/8 × 5/8

0.17

0.19

1

027H7200

CCMT 4

1/2 × 1/2

5/8 × 5/8

0.45

0.52

1

027H7201

CCMT 8

1/2 × 1/2

5/8 × 5/8

0.8

0.92

1

027H7202

CCMT 16

1 x 1

1

1

⁄8 x 11⁄8

1.6

1.85

1

027H7231

CCMT 24

1 x 1

1

1

⁄8 x 11⁄8

2.4

2.77

1

027H7232

CCMT 30

1 x 1

1

1

⁄8 x 11⁄8

3

3.47

1

027H7233

CCMT 42

1 x 1

1

1

⁄8 x 11⁄8

4.2

4.86

1

027H7234

CCMT 16

(2)

1 x 1

1

1

⁄8 x 11⁄8

1.6

1.85

1

027H8231

CCMT 24

(2)

1 x 1

1

1

⁄8 x 11⁄8

2.4

2.77

1

027H8232

CCMT 30

(2)

1 x 1

1

1

⁄8 x 11⁄8

3

3.47

1

027H8233

CCMT 42

(2)

1 x 1

1

1

⁄8 x 11⁄8

4.2

4.86

1

027H8234

Type

Description

Single pack

Code no.

Gasket

O-ring spare part kit for CCM / CCMT 2 - CCMT 42

1

027H7230

Type

Description

Industrial pack

Code no.

Packard cable

10 m / 32.8 ft cable for MBS 8250 pressure transmitter

14

064G0910

1

064G0950

Cable

Cable length (L)

Insulation

Packing format

Code no.

PVC - black

2 + 0.089 m / 6.6 + 0.3 ft

SR-PVC

Single pack

034G7073

8 + 0.3 m / 26.2 +1 ft

SR-PVC

Single pack

034G7074

Electric regulating valve, type CCMT 2, 8, 16 and 42

Ordering

Valve including actuator

(1)

(1)

OD according to EN 10220

OD according to EN 10220

(2)

(2)

Without integrated pressure transmitter

Without integrated pressure transmitter

Accessories

Spareparts

Table 12: Spareparts

Packard cable for MBS 8250 pressure transmitter

Table 13: Packard cable for MBS 8250 pressure transmitter

Ordering

Table 14: Ordering

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 9

Page 10

Electric regulating valve, type CCMT 2, 8, 16 and 42

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 10

Page 11

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI230186439989en-000901 | 11

Loading...

Loading...