Page 1

OperatingGuide

TermixBVX-FIROSEK

1.0TableofContents

1.0TableofContents.............................................1

........................................................................2

2.0Functionaldescription......................................3

3.0Safetynotes.....................................................4

3.1SafetyNotes–general............................................4

4.0Mounting........................................................5

4.1Mounting...........................................................5

4.2Dismantletheinsulation.........................................7

4.3Mountingthedisplayoftheenergymeter....................10

4.4Start-up..............................................................11

4.5Electricalconnections.............................................13

5.0Design.............................................................14

5.1Design...............................................................14

5.2Schematicdiagram................................................15

6.0Controls..........................................................16

6.1Heatingcircuit......................................................16

6.2DHWtemperaturecontrol........................................19

6.3Other.................................................................20

6.4Maintenance........................................................22

7.0Troubleshooting..............................................23

7.1Troubleshootingingeneral......................................23

7.2TroubleshootingDHW............................................24

7.3TroubleshootingHE...............................................25

7.4Disposal.............................................................27

8.0Declaration......................................................31

8.1Declarationofconformity........................................31

©Danfoss|2018.11VI.MP .D1.02/LUK40767|1

Page 2

OperatingGuideTermixBVX-FIROSEK

2|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 3

OperatingGuideTermixBVX-FIROSEK

2.0Functionaldescription

Districtheatingsubstationforindirectheatingwithtankfor

domestichotwaterpreparationandwiththermostaticor

electroniccontrol.Connectionsatthetopofthestation.

Application

TheT ermixBVX-FIROSEKsubstationisacompletesolutionfor

hotwaterandspaceheatingwithoptimalsafety,efficientenergy

transfer,service-friendlyonstructionandacompactdesign.The

substationisusedifaheatexchangerisrequiredoronaconversion

todistrictheatingwheretheexistingequipmentisunsuitablefor

directconnection.

Districtheating(DH)

Thesubstationisprefabricatedwithadifferentialpressure

controller,fittingpieceandsensorpocketsforinsertionofaheat

meteraswellasstrainersandballvalves.

Heating(HE)

Theheatingcircuitconsistsofaplateheatexchanger,safetyvalves,

manometer,thermometers,ballvalves,drainvalve,airvalves,

expansionvesselandcirculationpump.Thetemperatureofthe

heatingiselectronicallycontrolledwithanoutdoortemperature

sensor.Dependingontheapplication,differentheatexchangers

dimensionedforcentralorfloorheatingwillbeused.

Domestichotwater(DHW)

Thedomestichotwatercircuitconsistsofahotwatertankwithcoil

andapumpforcontrollingthetemperaturewithpossibilityfor

DHWpriority.TheDHWtankandcoilareenamelledandthetank

containsamagnesiumanode.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|3

Page 4

OperatingGuideTermixBVX-FIROSEK

3.0Safetynotes

3.1SafetyNotes–general

Thefollowinginstructionsrefertothestandarddesignof

substation.Specialversionsofsubstationsareavailableon

request.

Thisoperatingmanualshouldbereadcarefullybeforeinstallation

andstart-upofthesubstation.Themanufactureracceptsno

liabilityfordamageorfaultsthatresultfromnon-compliancewith

theoperatingmanual.Pleasereadandfollowalltheinstructions

carefullytopreventaccidents,injuryanddamagetoproperty.

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleasecomplywiththeinstructionsissuedbythesystem

manufacturerorsystemoperator.

Corrosionprotection

Allpipesandcomponentsaremadeofstainlesssteelandbrass.

Themaximumchloridecompoundsoftheflowmediumshouldnot

behigherthan150mg/l.

Theriskofequipmentcorrosionincreasesconsiderablyifthe

recommendedlevelofpermissiblechloridecompoundsis

exceeded.

Energysource

Thesubstationisdesignedfordistrictheatingastheprimary

sourceofenergy.However,alsootherenergysourcescanbeused

wheretheoperatingconditionsallowitandalwaysarecomparable

todistrictheating.

Application

Thesubstationisdesignedtobeconnectedtothehouse

installationinafrost-freeroom,wherethetemperaturedoesnot

exceed50°Candthehumiditydoesnotexceed60%.Donotcover

orwallupthesubstationorinanyotherwayblocktheentrance

tothestation.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Pleaseobserveinstructionscarefully

Toavoidinjurytopersonsanddamagetothedevice,itisabsolutely

necessarytoreadandobservetheseinstructionscarefully.

Warningofhighpressureandtemperature

Beawareoftheinstallation’spermissiblesystempressureand

temperature.

Themaximumtemperatureoftheflowmediuminthesubstationis

120°C.

Themaximumoperatingpressureofthesubstationis10bar.PN16

versionsareavailableonenquiry.

Theriskofpersonsbeinginjuredandequipmentdamagedincreases

considerablyiftherecommendedpermissibleoperatingparameters

areexceeded.

Thesubstationinstallationmustbeequippedwithsafetyvalves,

however,alwaysinaccordancewithlocalregulations.

Choiceofmaterial

Choiceofmaterialsalwaysincompliancewithlocallegislation.

Safetyvalve(s)

Werecommendmountingofsafetyvalve(s),however,alwaysin

compliancewithlocalregulations.

Connection

Thesubstationmustbeequippedwithfeaturesthatensurethat

thesubstationcanbeseparatedfromallenergysources(also

powersupply).

Emergency

Incaseofdangeroraccidents-fire,leaksorotherdangerous

circumstances-interruptallenergysourcestothestationif

possible,andseekexperthelp.

Incaseofdiscolouredorbad-smellingdomestichotwater,closeall

shut-offvalvesonthesubstation,informtheoperatingpersonnel

andcallforexperthelpimmediately.

REACH

AllDanfossA/SproductsfulfilltherequirementsinREACH.

OneoftheobligationsinREACHistoinformcustomersabout

presenceofCandidatelistsubstancesifany,weherebyinform

youaboutonesubstanceonthecandidatelist:Theproduct

containsbrasspartswhichcontainslead(CASno:7439-92-1)ina

concentrationabove0.1%w/w.

Storage

Anystorageofthesubstationwhichmaybenecessarypriorto

installationshouldbeinconditionswhicharedryandheated.

Warningofhotsurface

Thesubstationhasgothotsurfaces,whichcancauseskinburns.

Pleasebeextremelycautiousincloseproximitytothesubstation.

Powerfailurecanresultinthemotorvalvesbeingstuckinopen

position.Thesurfacesofthesubstationcangethot,whichcancause

skinburns.Theballvalvesondistrictheatingsupplyandreturnshould

beclosed.

Warningoftransportdamage

Beforesubstationinstallation,pleasemakesurethatthesubstation

hasnotbeendamagedduringtransport.

IMPORTANT-Tighteningofconnections

Duetovibrationsduringtransportallflangeconnections,screwjoints

andelectricalclampandscrewconnectionsmustbecheckedand

tightenedbeforewaterisaddedtothesystem.Afterwaterhasbeen

addedtothesystemandthesystemhasbeenputintooperation,

re-tightenALLconnections.

4|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 5

OperatingGuideTermixBVX-FIROSEK

4.0Mounting

4.1Mounting

Installationmustbeincompliancewithlocalstandardsand

regulations.

Districtheating(DH)-Inthefollowingsections,DHreferstothe

heatsourcewhichsuppliesthesubstations.Avarietyofenergy

sources,suchasoil,gasorsolarpower,couldbeusedasthe

primarysupplytoDanfosssubstations.Forthesakeofsimplicity,

DHcanbetakentomeantheprimarysupply.

Connections:

1.Hotwatercirculation(HWC)

2.Domesticcoldwater(DCW)

3.Domestichotwater(DHW)

4.Heating(HE)return

5.Heating(HE)supply

6.Districtheating(DH)return

7.Districtheating(DH)supply

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Connectionsizes:

Allconnections:

Dimensions(mm):

Withcover:

H1910xW600xD600(typeBVX1–x)

H1910xW600xD600(typeBVX2–x)

Weight(approx.):120-150kg

G¾”(int.thread)

Theconnectionsareatthetopofthestation.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|5

Page 6

OperatingGuideTermixBVX-FIROSEK

4.1.1Installation

Mounting:

Adequatespace

Pleaseallowadequatespacearoundthesubstationformounting

andmaintenancepurposes.

Orientation

Thestationmustbemountedsothatcomponents,keyholes

andlabelsareplacedcorrectly.Ifyouwishtomountthestation

differentlypleasecontactyoursupplier.

Drillings

Wheresubstationsaretobewall-mounted,drillingsareprovided

inthebackmountingplate.Floormountedunitshavesupport.

Labelling

Eachconnectiononthesubstationislabelled.

Beforeinstallation:

Cleanandrinse

Priortoinstallation,allsubstationpipesandconnectionsshouldbe

cleanedandrinsed.

Tightening

Duetovibrationduringtransport,allsubstationconnectionsmust

becheckedandtightenedbeforeinstallation.

Unusedconnections

Unusedconnectionsandshut-offvalvesmustbesealedwitha

plug.Shouldtheplugsrequireremoval,thismustonlybedoneby

anauthorizedservicetechnician.

Installation:

Strainer

Ifastrainerissuppliedwiththestationitmustbefittedaccording

toschematicdiagram.Pleasenotethatthestrainermaybe

suppliedloose.

Connections

Internalinstallationanddistrictheatingpipesconnectionsmustbe

madeusingthreaded,flangedorweldedconnections.

6|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 7

OperatingGuideTermixBVX-FIROSEK

4.2Dismantletheinsulation

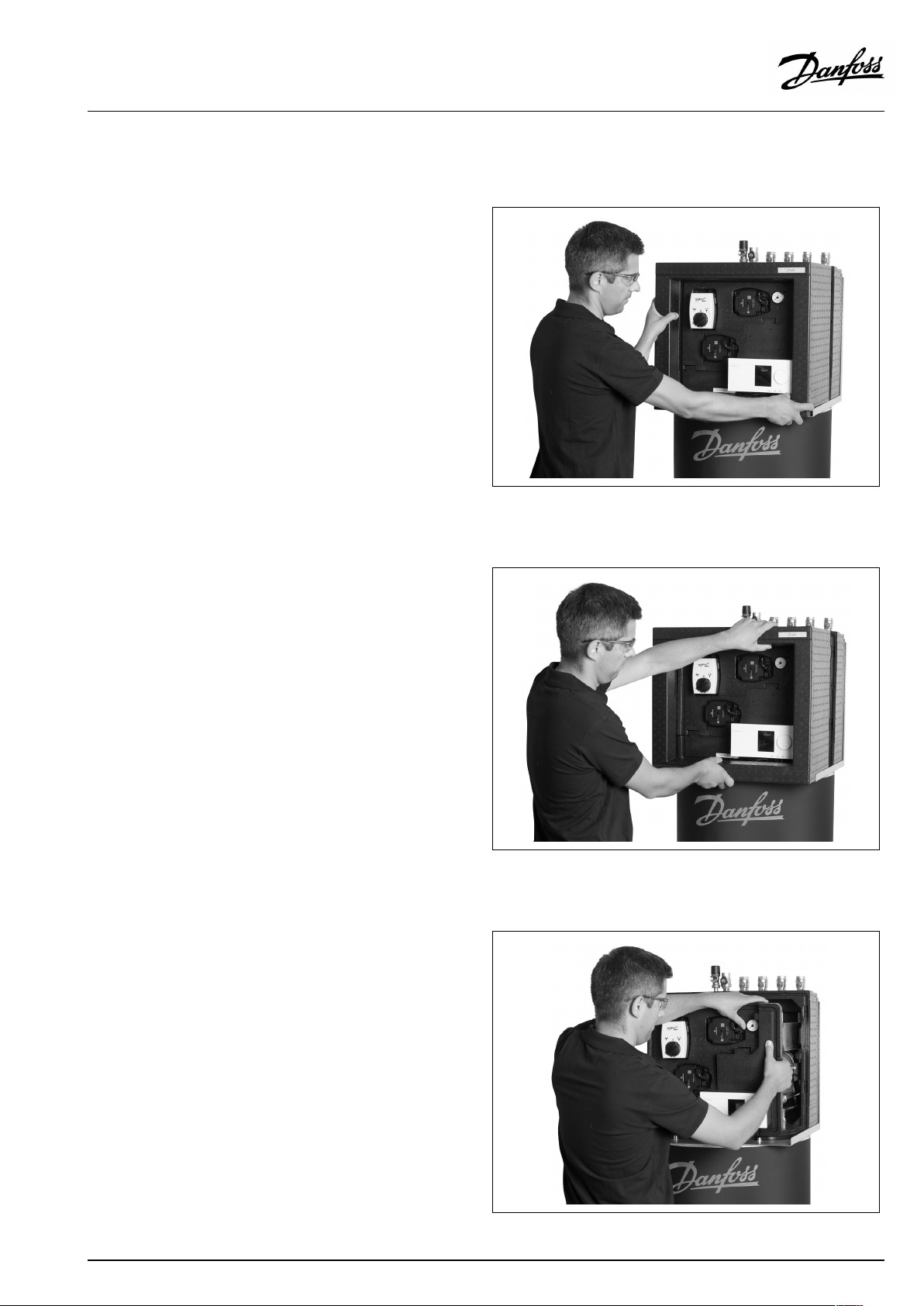

4.2.1Dismantletheinsulationcover

Pulloutslightlythebottomofthecover.

4.2.2Pulloutthecover

Pulloutthecover.

4.2.3RemovetheECLplate

RemovetheECLplate.BecarefulwiththecablesfromtheECLand

otherelectronics.

Attention:Duringreassemble,pleaseensurethatallcablesare

placedinthewiregrovesintheplate.Thiswillensureatightseal.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|7

Page 8

OperatingGuideTermixBVX-FIROSEK

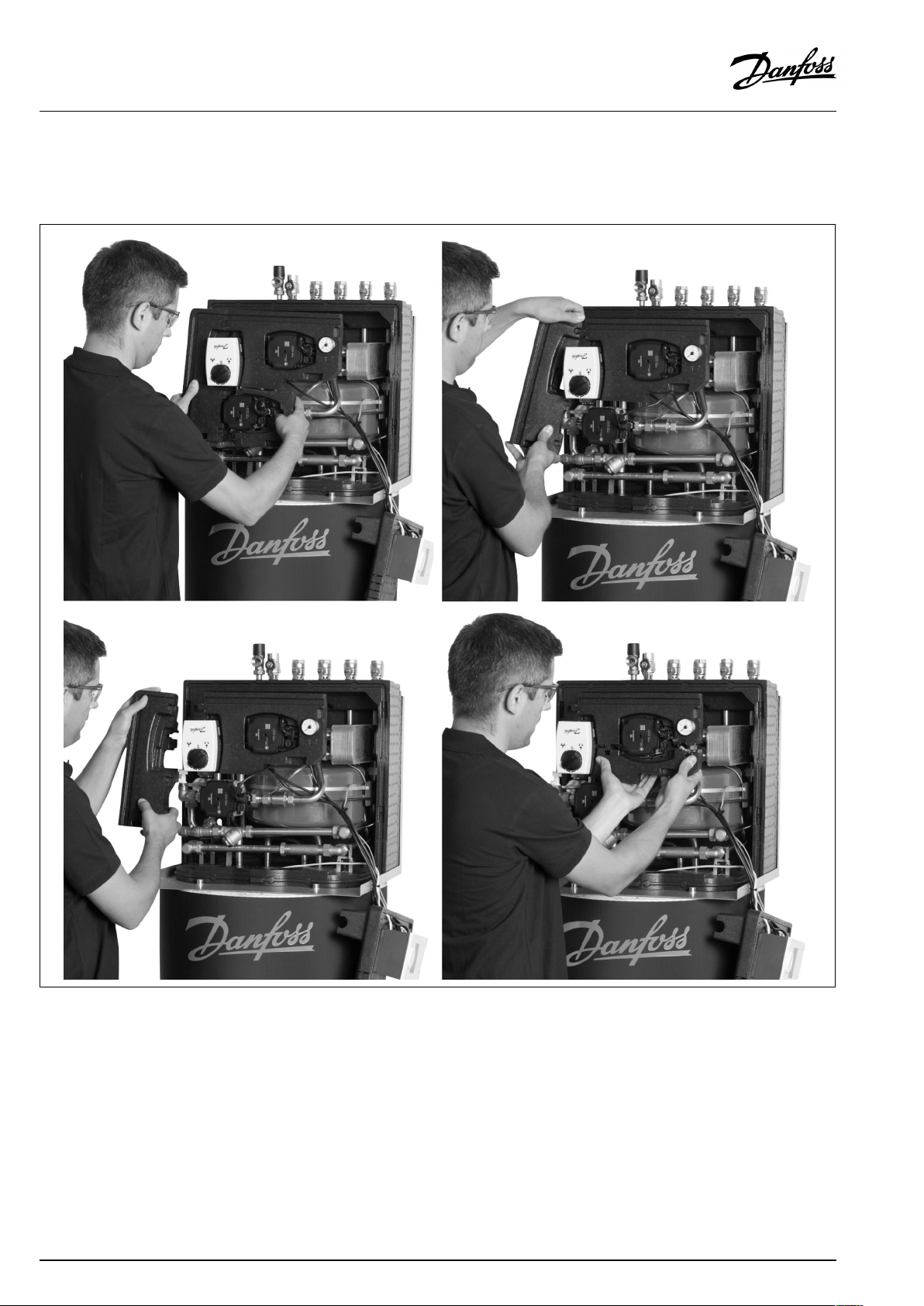

4.2.4Removeplate

Removeplate,bypullingsidewaysawayfromtheunit.

Attention:Duringreassemble,pleaseensurethatthecableisplacedinthewiregrove.Thiswillensureatightseal.

8|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 9

OperatingGuideTermixBVX-FIROSEK

4.2.5Removetheframe

Toremovetheframe,pullitslightlyforwardandthenup.

4.2.6Removethepumpplate

Pullbackthepumpplateandplaceitonthepipes.

Attention:Becarefulwiththewireforthepressuregauge.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|9

Page 10

OperatingGuideTermixBVX-FIROSEK

4.3Mountingthedisplayoftheenergymeter

Markthepositionofthefixationpointsofthebracketfortheenergy

displayandscrewthetwoplugssuppliedintotheinsulationfront.

Mountthebracketforthedisplayoftheenergymeter.

Mountthedisplay/calculatoroftheenergymeterontothebracket.

Pullthewiresfromthesensorsinsidetheunitthroughthe

duct/cut-outintheinsulationplate.

10|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 11

OperatingGuideTermixBVX-FIROSEK

4.4Start-up

Start-up,Indirectheating

Filling:

1:Firstfill

Whencarryingoutfirstfill,theheatexchangermustbeslowlyfilled

withwateruntilitreachesworkingpressure.

2:Pressuregauge

TheHEpressuregaugeindicatesthepressureoftheHEsystem.This

instructionmustbefollowedstrictly,toavoiddangeroussituations.

3:Supplyhose

AballvalvewithplugisinstalledintheHEreturnline.Tofillthe

system,theballvalvemustfirstbeclosed,theplugremovedand

asupplyhoseconnected.Onre-openingtheballvalve,system

fillcancommence.

4:Pre-pressure

Whenfillingthesystemwithwater,thepressuregaugeshouldbe

observedclosely.Theexpansionvesselissuppliedpre-pressurised

to0.5bar.Thepre-pressurerequiredateachsubstationwill

dependonsystemhead(thedistancebetweenthelowestand

highestpointinthesystem),forexample:

5:Fillingstop

Fillingmuststopwhenthepressuregaugeshowsapressure

approximately1-2barhigherthanthepre-pressuresetting.The

ballvalveisthenclosed,thehoseremovedandtheplugputback

in.

Re-tightenconnections

Afterwaterhasbeenaddedtothesystemandthesystemhasbeen

putintooperation,re-tightenALLconnections.

Pump

Thepumpmustbeswitchedoffduringsystemfill.

Height(m)Pressure(bar)

0–50,5

5–101,0

10–15

1,5

15–202,0

Start-up:

1:Pumpspeed

Setthepumptohighestspeedbeforestart-up.

2:Startpump

Startthepumpandheatthroughthesystem.

3:Openshut-offvalves

Theshut-offvalvesshouldthenbeopenedandtheunitobserved

asitentersservice.Visualcheckingshouldconfirmtemperatures,

pressures,acceptablethermalexpansionandabsenceofleakage.

Iftheheatexchangeroperatesinaccordancewithdesign,itcanbe

puttoregularuse.

4:Ventsystem

Switchoffthepumpandventtheinstallationaftertheradiators

havebeenwarmedup.

5:Adjustpumpspeed

Setthepumptothelowestspeedconsistentwithcomfortand

electricityconsumption.

Normallythechange-overswitchissetinthemidposition(default).

Howeverforsystemswithunderfloorheatingorsinglepipeloop

systems,itmaybenecessarytoturnthechange-overswitch

upwards.

Higherpumpspeedsareonlyusediftheheatingrequirement

increases.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|11

Page 12

OperatingGuideTermixBVX-FIROSEK

Underfloorheating:

Pumpstopfunction

Ifthesubstationisusedinconnectionwithunderfloorheating,the

circulationpumpmustbeconnectedtothepumpstopfunctionin

theunderfloorheatingcontroller.Thepumpmustbestoppedif

allunderfloorheatingcircuitsareclosed.

Warranty

Ifthisisnotpossible,thenflowmustbecontinuedthroughthe

by-pass.Failingthis,thepumpwillbeatriskofseizureandany

remainingwarrantywillbewithdrawn.

Summeroperation:

Switchoffpump

Insummerthecirculationpumpmustbeswitchedoffandthe

shut-offvalvetoHEsupplyclosed.

Runningpumpbi-weekly

Itisrecommendedtostartupthecirculationpump(for2minutes)

onceamonthduringsummer;theshut-offvalveoftheHEsupply

mustbeshut.

Electroniccontroller

Mostelectroniccontrollerswillstartupthepumpautomatically

(pleasenotemanufacturer´sinstructions).

12|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 13

OperatingGuideTermixBVX-FIROSEK

4.5Electricalconnections

Beforemakingelectricalconnections,pleasenotethe

following:

Safetynotes

Pleasereadtherelevantpartsofthesafetynotes.

230V

Thesubstationmustbeconnectedto230VACandearth.

Potentialbonding

Potentialbondingshouldbecarriedoutaccording

to60364-4-41:2007andIEC60364-5-54:2011.

Bondingpointonthemountingplatebelowrightcornermarked

withearthsymbol.

Disconnection

Thesubstationmustbeelectricallyconnectedsothatitcanbe

disconnectedforrepairs.

Outdoortemperaturesensor

Outdoorsensorsshouldbemountedsoastoavoidexposureto

directsunlight.Theyshouldnotbeplacedclosetodoors,windows

orventilationoutlets.

Theoutdoorsensormustbeconnectedtothestationonthe

terminalblockundertheelectroniccontrol.

Authorizedelectrician

Electricalconnectionsmustbemadebyanauthorizedelectricianonly.

Localstandards

Electricalconnectionsmustbemadeinaccordancewithcurrent

regulationsandlocalstandards.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|13

Page 14

OperatingGuideTermixBVX-FIROSEK

5.0Design

5.1Design

Yoursubstationmightlookdifferentthanthesubstationshown.

Designdescription

A

Heatexchanger,HE

E

Hotwatertankwithcoil

2

Singlecheckvalve

4

Safetyvalve

9

Strainer

14|©Danfoss|2018.11

10

Circulationpump

13

Chargingpump

14

Sensorpocket,energymeter

22

Testconnection

27

Actuator,HE

38

Expansiontank

41

Fittingpiece,energymeter

48

Airwent,manual

50

Diff.pressurecontrollerwithflowlimiter

VI.MP .D1.02/LUK40767

Page 15

OperatingGuideTermixBVX-FIROSEK

5.2Schematicdiagram

DHW

DCW

HWC

DH

Supply

DH

Return

Yoursubstationmightlookdifferentthantheschematicdiagramshown.

Schematicdescription

A

Heatexchanger,HE

E

Hotwatertankwithcoil

F

Electroniccontroller

1

Ballvalve

1A

Ballvalve,DVGW

2

Singlecheckvalve

4

Safetyvalve

9

Strainer

10

Circulationpump

DHW:DomesticHotWater

DCW:

HWC:

DHSupply:DistrictHeatingSupply

DHReturn:

HESupply:HeatingSupply

HEReturn:HeatingReturn

DomesticColdWater

HotWaterCirculation

DistrictHeatingReturn

13

Chargingpump

14

Sensorpocket,energymeter

16

Outdoorsensor

19

Surfacesensor

20

Filling/drainvalve

22

Testconnection

24

Deliveredloosewithstation

26

Pressuregauge

27

Actuator

29

2-waymotorizedvalve

35

Ballvalve/non-returnvalve

38

Expansiontank

41

Fittingpiece,energymeter

44

Immersionsensor

48

Airvent,manual

50

Diff.pressurecontrollerwithflowlimiter

HE

Supply

HE

Return

5.2.1Technicalparameters

Technicalparameters

Nominalpressure:PN10(PN16versionsareavailableonenquiry)

Max.DHsupplytemperature:

Brazingmaterial(HEX):

VI.MP .D1.02/LUK40767

T–max=120°C

Copper

©Danfoss|2018.11|15

Page 16

OperatingGuideTermixBVX-FIROSEK

6.0Controls

6.1Heatingcircuit

6.1.1Differentialpressurecontroller

Thedifferentialpressurecontrollersmoothsoutthefluctuationsin

pressurearrivingfromthedistrictheatingnetwork.Theoperating

pressureinthesubstationisthusheldsteady.

6.1.2HEtemperaturecontrol

TheHEflowtemperatureintheheatingcircuitiscontrolledbythe

HEtemperaturecontroller.

6.1.3Electroniccontrol

Substationswithelectroniccontrolmustbesetinaccordancewith

manufacturer´sinstructions.

Wheretheroomtemperatureiscontrolledbyradiatorthermostats,

itisrecommendedthatthermostatsbesetforminimum

temperatureineachroom.

16|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 17

OperatingGuideTermixBVX-FIROSEK

6.1.4Outdoortemperaturesensor(ESMT)

Outdoorsensorsshouldbemountedsoastoavoidexposureto

directsunlight.Theyshouldnotbeplacedclosetodoors,windows

orventilationoutlets.

6.1.5CirculatorpumpUPM3

UPM3Pumpscanbecontrolledinconstantpressure,proportional

pressureorconstantspeedmodedefinedbythemeansofasmart

userinterface.

Thevariablespeedmodulatingmodesallowthepumptomatchits

performancetothesystemrequirements,helpingtoreducenoise

whenthermostaticvalvesareclosingdown.

EnergylabellingclassA

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|17

Page 18

OperatingGuideTermixBVX-FIROSEK

6.1.6GrundfosUPM3AUTOLinstructions

Controlmode

Youcanswitchfromtheperformanceviewtothesettingsviewbypressingthepushbutton.Thesettingsviewshowswhichmode

controlsthecirculator.After2seconds,thedisplayswitchesbacktoperformanceview.

Ifyoupressthebuttonfor2to10seconds,theuserinterfaceswitchesto"settingselection"iftheuserinterfaceisunlocked.Youcan

changethesettingsastheyappear.Theselectionofthecontrolmodedependsonthesystemtypeandtheallocationofpressurelosses.

Ifyoupressthekeylockformorethan10seconds,youcantogglebetweenenabling/disablingthekeylockfunction.

Function

Proportionalpressure1

Proportionalpressure2

Proportionalpressure3

Constantpressure1

Constantpressure2

Constantpressure3

ConstantCurve1

ConstantCurve2

ConstantCurve3

ConstantCurveMax.

Operationstatus

Function

Standby**OnlyPWMcontrolled

0%≤P1≤25%

25%≤P1≤50%

50%≤P1≤75%

75%≤P1≤100%

Recommendedfor

2-pipesystems

1-pipesystems

Underfloorheating

Green

✪✪

✪✪✪

✪✪✪✪

✪✪

✪✪✪

✪✪✪✪

✪✪✪

✪✪✪✪

✪✪✪✪✪

✪✪✪✪

Green

✪

✪✪

✪✪✪

✪✪✪✪

✪✪✪✪✪

YellowYellowYellowYellow

YellowYellowYellowYellow

Alarmstatus

Function

Blocked

Supplyvoltagelow

Electricalerror

6.1.7HEpressuregauge

TheHEpressuregaugeindicatesthepressureoftheHEsystem.

RedYellowYellowYellowYellow

✪✪

✪✪

✪✪

18|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 19

OperatingGuideTermixBVX-FIROSEK

6.2DHWtemperaturecontrol

DHWtemperaturecontrol

TherearevarioustypesofDHWtemperaturecontrolusedin

Danfosssubstations.

DHWtemperatureshouldbeadjustedto45-50°C,asthisprovides

optimalutilisationofDHwater.AtDHWtemperaturesabove55°C,

thepossibilityoflimescaledepositsincreasessignificantly.

6.2.1Electric2–waymotorizedvalve

Actuatorswithorwithoutsafetyfunctionareavailablefor3-point

controls.Spring-returnactuatorscanbeusedtoprovidesafety

shut-offintheeventofpowerfailure.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|19

Page 20

OperatingGuideTermixBVX-FIROSEK

6.3Other

6.3.1Safetyvalve

Thepurposeofthesafetyvalveistoprotectthesubstationfrom

excessivepressure.

Theblow-offpipefromthesafetyvalvemustnotbeclosed.The

blow-offpipeoutletshouldbeplacedsothatitdischargesfreely

anditispossibletoobserveanydrippingfromthesafetyvalve.

Itisrecommendedtochecktheoperationofsafetyvalvesat

intervalsof6months.Thisisdonebyturningthevalveheadin

directionindicated.

6.3.2Strainer

Strainersshouldbecleanedregularlybyauthorizedpersonnel.The

frequencyofcleaningwoulddependonoperatingconditionsand

themanufacturer’sinstructions.

20|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 21

OperatingGuideTermixBVX-FIROSEK

6.3.3Fittingpiece

Thesubstationisequippedwithafittingpieceforenergymeter.

Assemblyofenergymeters:

1:Closeballvalves

ClosetheballvalvesonDHSupplyandDHReturn,ifthereiswater

onthesystem.

2:Loosennuts

Loosenthenutsonthefittingpiece.

3:Removefittingpiece

Removethefittingpieceandreplaceitwiththeenergymeter.Do

notforgetthegaskets.

4:Tightenconnections

Aftermountingoftheenergymeterremembertocheckand

tightenallthreadedconnections.

Sensorpocket,energymeter

Thesensorsoftheenergymeterismountedinthesensorpockets.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|21

Page 22

OperatingGuideTermixBVX-FIROSEK

6.4Maintenance

Thesubstationrequireslittlemonitoring,apartfromroutine

checks.Itisrecommendedtoreadtheenergymeteratregular

intervals,andtowritedownthemeterreadings.

RegularinspectionsofthesubstationaccordingtothisInstruction

arerecommended,whichshouldinclude:

Strainers

Cleaningofstrainers.

Meters

Checkingofalloperatingparameterssuchasmeterreadings.

Temperatures

Checkingofalltemperatures,suchasDHsupplytemperatureand

DHWtemperature.

Connections

Checkingallconnectionsforleakages.

Safetyvalves

Theoperationofthesafetyvalvesshouldbecheckedbyturning

thevalveheadintheindicateddirection.

Venting

Checkingthatthesystemisthoroughlyvented.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

Inspectionsshouldbecarriedoutminimumeverytwoyears.

SparepartscanbeorderedfromDanfoss.Pleaseensurethatany

enquiryincludesthesubstationserialnumber.

22|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 23

OperatingGuideTermixBVX-FIROSEK

7.0Troubleshooting

7.1Troubleshootingingeneral

Intheeventofoperatingdisturbances,thefollowingbasicfeatures

shouldbecheckedbeforecarryingoutactualtroubleshooting:

•thesubstationisconnectedtoelectricity,

•thestrainerontheDHsupplypipeisclean,

•thesupplytemperatureoftheDHisatthenormallevel

(summer,atleast60°C-winter,atleast70°C),

•thedifferentialpressureisequaltoorhigherthanthenormal

(local)differentialpressureintheDHnetwork–ifindoubt,ask

theDHplantsupervisor,

•pressureonthesystem-checktheHEpressuregauge.

Authorizedpersonnelonly

Assembly,start-upandmaintenanceworkmustbeperformedby

qualifiedandauthorizedpersonnelonly.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|23

Page 24

OperatingGuideTermixBVX-FIROSEK

7.2TroubleshootingDHW

ProblemPossiblecauseSolution

ToolittleornoDHW.

Taptemperaturetoohigh;DHWtapload

toohigh.

Temperaturedropduringtapping.

Thermostaticcontrolvalvedoesnotclose

Strainerinsupplyorreturnlineclogged.Cleanstrainer(s).

DHWcirculationpumpoutoforderorwith

toolowsetting.

Defectiveorcloggednon-returnvalve.

Noelectricity.Check.

Wrongsettingofautomaticcontrols,ifany.Toadjustanelectroniccontrollerfor

Scalingoftheplateheatexchanger.

Defectivemotorizedvalve.Check(usemanualfunction)–replace.

Defectivetemperaturesensors.

Defectivecontroller.

DCWisbeingmixedwiththeDHW,e.g.ina

defectivethermostaticmixingvalve.

Defectiveorcloggednon-returnvalveon

circulationvalve.

Thermostaticvalveadjustedtoatoohigh

level.

Scalingoftheplateheatexchanger.

LargerDHWflowthanthesubstationhas

beendesignedfor.

TemperaturedifferencebetweenDH

supplyandDHWsetpointtoolow.

Checkcirculationpump.

Replace–clean.

DHW,pls.noteenclosedinstructionsfor

electroniccontroller.

Replace–rinseout.

Check–replace.

Check–replace.

Check–replace. Hotwaterinsometapsbutnotinall.

Replace–clean.

Check–set.

Replace–rinseout.

ReduceDHWflow.

Lowerthesetpointtemperatureorincrease

theDHsupplytemperature.

24|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 25

OperatingGuideTermixBVX-FIROSEK

7.3TroubleshootingHE

ProblemPossiblecauseSolution

Toolittleornoheat.StrainercloggedinDHorHEcircuit

Unevenheatdistribution.Airpocketsinthesystem.Venttheinstallationthoroughly.

DHsupplytemperaturetoohigh.

DHsupplytemperaturetoolow.

(radiatorcircuit).

ThefilterintheenergymeteronDHcircuit

clogged.

Defectiveorwronglyadjusteddifferential

pressurecontroller.

Sensordefective–orpossiblydirtinthe

valvehousing.

Automaticcontrols,ifany,wronglysetor

defective-possiblypowerfailure.

Pumpoutofoperation.Checkifthepumpisreceivingpowerand

Thepumpissetattoolowspeedof

rotation.

Pressuredrop–thepressuredropon

theradiatorcircuitshowslowerthan

recommendedoperatingpressure.

Airpocketsinthesystem.Venttheinstallationthoroughly.

Limitingofthereturntemperatureadjusted

toolow.

Defectiveradiatorvalves.

Unevenheatdistributioninbuilding

becauseofincorrectlysetbalancingvalves,

orbecausetherearenobalancingvalves.

Diameterofpipetosubstationtoosmallor

branchpipetoolong.

Wrongsettingofthermostatorof

automaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongsettingofautomaticcontrols,ifany.

Defectivecontroller.Thecontrollerdoes

notreactasitshouldaccordingtothe

instructions.

Defectivesensoronself-actingthermostat.

Wrongplacement/fittingofoutdoor

temperaturesensor.

Strainerclogged.Cleangate/strainer.

Cleangate/strainer(s).

Cleanthefilter(afterconsultingtheDH

plantoperator).

Checktheoperationofthedifferential

pressurecontroller–cleanthevalveseatif

required.

Checktheoperationofthethermostat–

cleanthevalveseatifrequired.

Checkifthesettingofthecontroller

iscorrect–seeseparateinstructions.

Checkthepowersupply.Temporary

settingofmotorto“manual”control–see

instructionsonautomaticcontrols.

thatitturns.Checkifthereisairtrappedin

thepumphousing–seepumpmanual.

Setthepumpathigherspeedofrotation.

Fillwateronthesystemandcheckthe

functioningofthepressureexpansion

vesselifrequired.

Adjustaccordingtoinstructions.

Check–replace.

Adjust/installbalancingvalves.

Checkpipedimensions.

Adjustautomaticcontrols,–see

instructionsforautomaticcontrols.

Callautomaticcontrolsmanufactureror

replacetheregulator.

Replacethermostat–orsensoronly.

Adjustautomaticcontrols–seeinstructions

forautomaticcontrols.

Callinautomaticcontrolsmanufactureror

replacecontroller.

Replacethermostat–orsensoronly.

Adjustlocationofoutdoortemperature

sensor.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|25

Page 26

OperatingGuideTermixBVX-FIROSEK

ToohighDHreturntemperature.

Noiseinsystem.

Heatloadtoohigh.

Toosmallheatingsurface/toosmall

radiatorscomparedtothetotalheating

requirementofthebuilding.

Poorutilizationofexistingheatingsurface.

Defectivesensoronself-actingthermostat.

Thesystemissinglepipeloop.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Airinsystem.

Defectiveorincorrectlysetradiatorvalve(s).

Singlepipeloopsystemsrequirespecial

one-piperadiatorvalves.

Dirtinthemotorizedvalveorinthe

differentialpressurecontroller.

Defectivemotorizedvalve,sensoror

automaticcontroller.

Electroniccontrollernotadjustedcorrectly.Adjustaccordingtoinstructions.

Pumppressuretoohigh.Adjustpumptoalowerlevel.

Defectivemotorizedvalve,sensoror

electroniccontroller.

Increasetotalheatingsurface.

Makesuretheheatisdistributedevenly

acrossthefullheatingsurface–openall

radiatorsandkeeptheradiatorsinthe

systemfromheatingupatthebottom.It

isextremelyimportanttokeepthesupply

temperaturetotheradiatorsaslowas

possible,whilemaintainingareasonable

levelofcomfort.

Thesystemshouldfeatureelectronic

controlsaswellasreturnsensors.

Ventthesystem.

Check–set/replace.

Check–cleanout.

Check–replace.

Check–replace.

26|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 27

OperatingGuideTermixBVX-FIROSEK

7.4Disposal

Disposal

Thisproductshouldbedismantledanditscomponents

sorted,ifpossible,invariousgroupsbeforerecycling

ordisposal.

Alwaysfollowthelocaldisposalregulations.

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|27

Page 28

OperatingGuideTermixBVX-FIROSEK

28|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 29

OperatingGuideTermixBVX-FIROSEK

29|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 30

OperatingGuideTermixBVX-FIROSEK

30|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Page 31

OperatingGuideTermixBVX-FIROSEK

8.0Declaration

8.1Declarationofconformity

Category0withelectricalequipment

VI.MP .D1.02/LUK40767

©Danfoss|2018.11|31

Page 32

OperatingGuideTermixBVX-FIROSEK

32|©Danfoss|2018.11

VI.MP .D1.02/LUK40767

Loading...

Loading...