Page 1

Fact sheet

Termix BVX-E RO SEK( ECL310/A337)SW Schwerin Friedrichsthal

Indirect substation for single-family houses or apartments

Application

The Termix BVX-E RO SEK substation is

a complete solution for hot water and

space heating with optimal safety, efficient energy transfer, service-friendly

construction and a compact design.

The substation is used if a heat exchanger is required or on a conversion

to district heating where the existing

equipment is unsuitable for direct connection.

District heating (DH)

The substation is prefabricated with

a differential pressure controller, fitting

piece and sensor pockets for insertion

of a heat meter as well as strainers and

ball valves.

Heating (HE)

The heating circuit consists of a plate

heat exchanger, safety valves, manometer, thermometers, ball valves, drain

valve, air valves and circulation pump.

The temperature of the heating is electronically controlled with an outdoor

temperature sensor.

Domestic hot water (DHW)

The domestic hot water circuit consists of a hot water tank with coil and

a pump for controlling the temperature with possibility for DHW priority.

The DHW tank and coil are enamelled

and the tank contains a magnesium

anode.

Construction

All pipes are made of stainless steel.

The connections are made with nuts

and gaskets. The Termix BVX-E RO SEK

is completed by a white steel cover in

a modern design with door and including external thermometers.

FEATURES AND BENEFITS

• Substation for single-family

houses or apartments

• DHW regulation with pump control

• Indirect heating with electronic control

• Suitable in cases of low

district heating capacity

• Operates independently of differential

pressure and flow temperature

• Pipes and plate heat exchanger

• Made of stainless steel

www.danfoss.com

Page 2

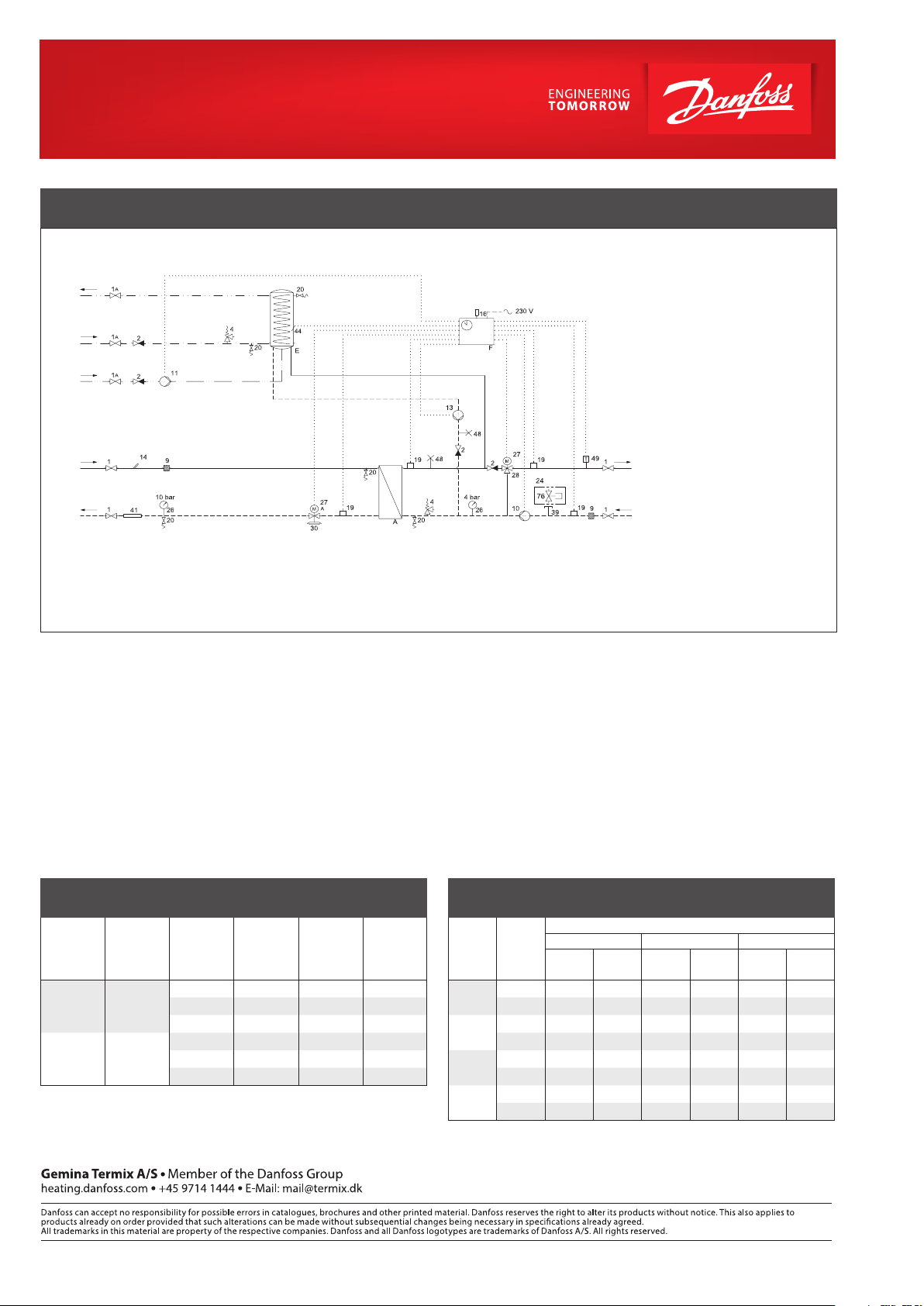

CIRCUIT DIAGRAM EXAMPLE

DHW

DCW

Circ.

DH

Supply

DH

Return

A Plate heat exchanger, HE

E DHW tank with coil

F Electronic controller

1 Ball valve

1A Ball valve, DVGW

2 Non-return valve

4 Safet y valve

9 Strainer

10 Circulation pump, HE

11 Domestic hot water pump

13 Charging pump

14 Sensor pocket, heat meter

13

HE

Supply

HE

Return

16 Outdoor sensor

19 Sur face sensor

20 Filling / drain valve

24 Delivered loose with unit

26 Manometer

27 Actuator

27A Actuator with spring return

28 3-way motorized valve

30 Flow control w. control

valve

39 Connection closed

41 Fitting piece, heat meter

44 Immersion sensor

48 Air escape, manual

49 Safety thermostat

76 Capvalve for expansion

Technical parameters:

Nominal pressure: PN 10

Max. supply temperature: T

Brazing material (HEX): Copper

= 120 °C

max

Weight incl. cover: 120 – 150 k g

Cover: White-lacquered

steel sheet

Dimensions (mm):

With cover:

H 1890 × W 540 × D 640

CAPACITY, WEIGHT AND DIMENSIONS

DHW: CAPACITY EXAMPLES, 10°C / 50°C

Substation

type

Tan k

volume

[l]

Coil

supply/return temp.

[°C]

80 / 40 486 546 22,6

BVX 1-x 100

70 / 30 245 305 11,4

60 / 30 172 232 8,0

80 / 40 486 576 22,6

BVX 2-x 150

70 / 30 245 335 11,4

60 / 30 172 262 8,0

* Output first hour = constant output + 60% of tank volume

DHW

constant

capacity

[l/h]

DHW

capacity

first hour*

[l/h]

DHW

constant

capacity

[kW]

Connections sizes:

DH + HE + DCW + DHW + Circ.: ¾“ G (int. thread)

HEATING: CAPACITY EXAMPLES

Sub-

station

type

[kPa]*

BVX x-1

BVX x-2

BVX x-3

BVX x-4

* Heat meter not included

70 / 40 – 35 / 60 °C 80 / 45 – 4 0 / 70°C 90 / 45 – 4 0 / 70°C

∆ p

Capacity

[kW]

Flow

[l/h]

30 15 518 17 476 23 673

35 16 555 18 510 25 724

30 19 671 21 619 30 865

35 21 718 23 662 32 929

30 22 773 25 715 34 990

35 24 828 27 765 37 1073

30 30 1018 33 941 45 1306

35 32 1089 35 1006 49 1404

Temperature

Capacity

[kW]

Flow

[l/h]

Capacity

[kW]

Flow

[l/h]

© Danfoss | DHS-SRMT/ PL | 2018. 11

VL.MG.W1.02

Loading...

Loading...