Operating Guide

(Bar)

-15 020406080 100 120 °C

510203045607590 °C

(Bar)

45

40

35

30

25

20

15

10

(Bar)

45

40

35

30

25

20

15

10

-15 020406080 100 110 °C

A

B

A

L

B

G

A

ØC

A

D

C

B

L

øH

D

MISURA

øA

G

F

CB

10

050100 110130 150

)

P

(bar)

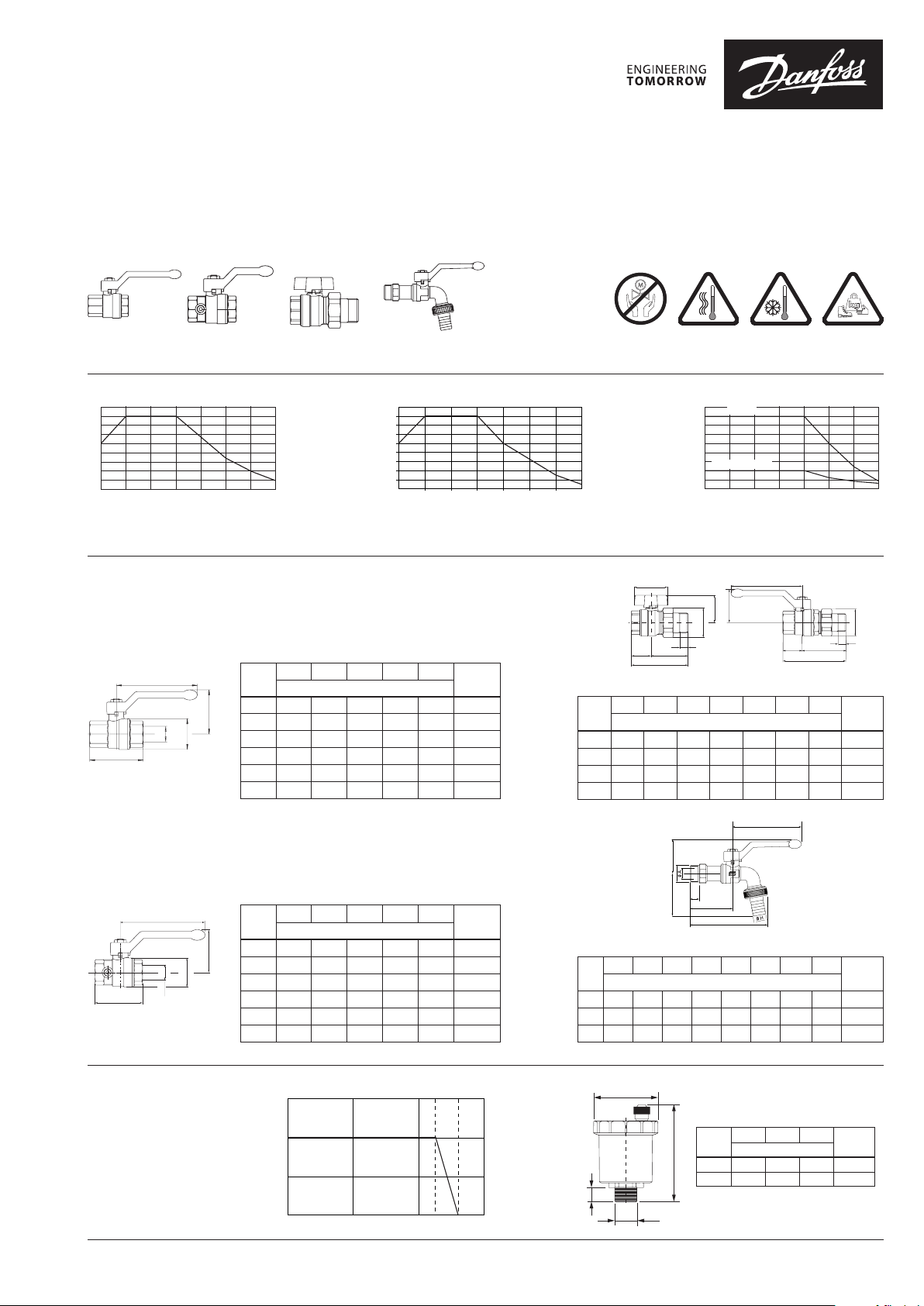

Ball valves

BVR, BVR-D, BVR-F, BVR-C

BVR BVR-D BVR-F BVR-C

45

40

35

30

25

20

15

10

5

0

BVR DN 15-50

A B ØC ØD L

ØD

L

BVR (DN 15-50)

DN

15 85 49 32 15 61 200

20 105 57 40 20 70 335

ØC

25 105 61 48 25 84 480

32 130 70 5 7.5 32 96 762

40 130 76 70 40 10 6.5 1116

50 165 92 85.5 50 12 7.5 1880

(mm)

MAINTENANCE

FREE

DN25

DN 15-DN 20

5

0

BVR-D DN 15-50

5

0

BVR-C DN 15-25

BVR-F DN 15-32

B

B

Weight

(g)

ØC

DE

F

DE

BVR-F (DN 15-25) BVR- F (DN 32)

A B ØC D E F G

DN

15 47 35 33 25 50 10 75 220

20 56 42 40.5 29 5 7.5 12 86.5 354

25 56 46 49 34.5 67. 5 14 102 572

32 130 70 41 55 74 15 12 9 1070

(mm)

F

G

Weight

(g)

ØC

ØD

BVR-D (DN 15-50)

Air vent

© Danfoss | 2018.01

A B ØC ØD L

DN

(mm)

15 85 46 30 15 58 250

20 105 53 38 20 65 360

25 105 57 46 25 75 490

32 130 70 5 7.5 32 86.5 787

40 130 76 70 40 98 115 5

50 165 92 85.5 50 116 18 60

max

5

Weight

(g)

misura

F

G

L

BVR-C

ØA B C D F G L ØH

DN

(mm)

15 10 52.1 41.8 85 11. 7 52.5 95.5 14. 8 200

20 15 58.9 45.7 85 12 .3 58.6

110 .4

25 20 78 49 85 12.5 80 15 4 46 630

ØD

ØD H a

DN

H

10 46 70 10.5 150

(mm)

15 46 70 10. 5 154

a

t(°C

DN

Weight

(g)

20 310

Weight

(g)

VI.BO.L1.00 | 1

Danf

already on order pro

All trademarks in this material are property of the respec

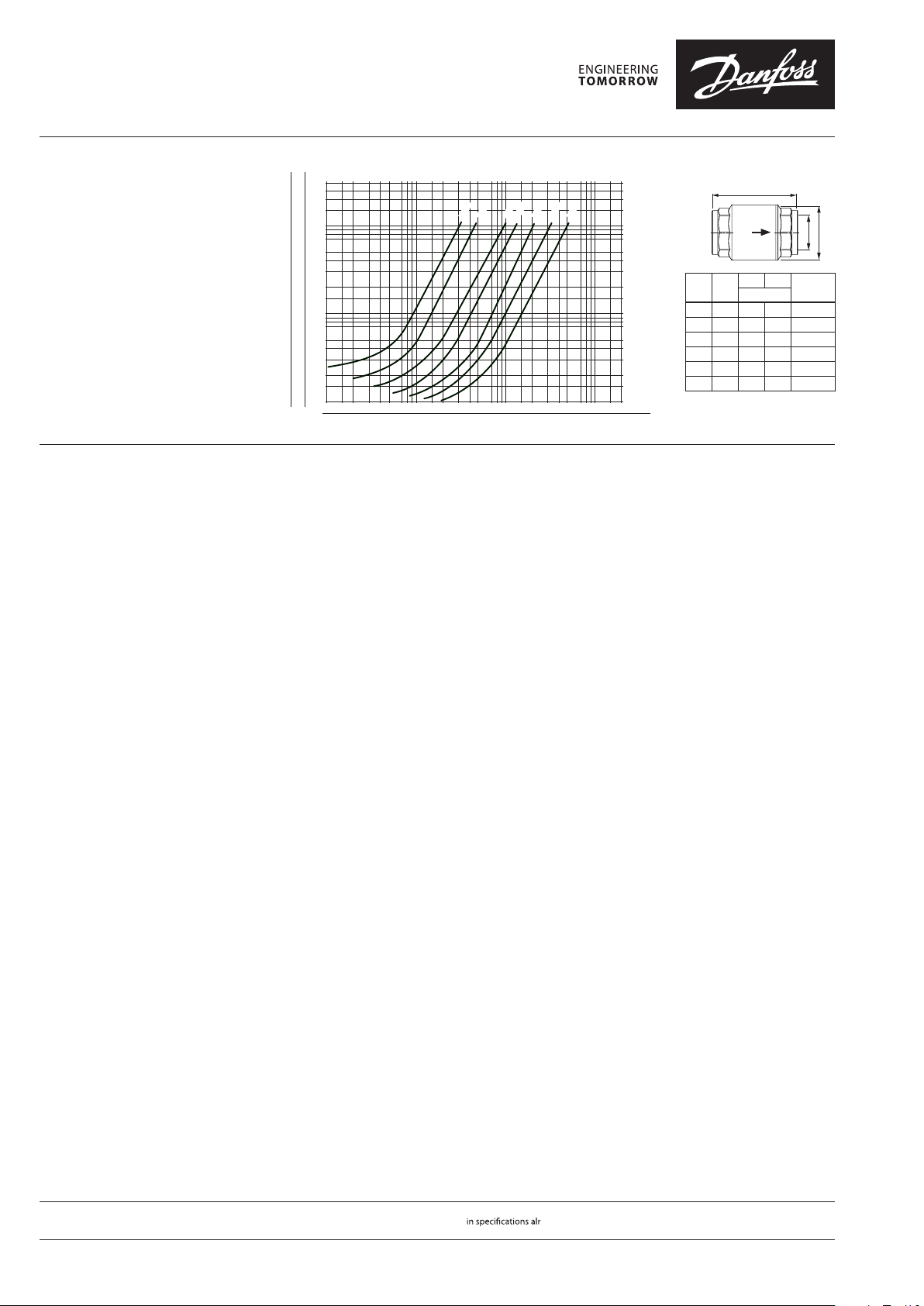

Ball valves

0.05

0.02

0.01

daPa

0.10.2 0.51 2510 20 50 100 200 mc/h

bar

kPa

Non return valve

Maximum temperature limit (°C)

For appropriate installation, check pertinent pressure/temperature diagram,

as shown on our main technical data sheets.

Security notes

• If overpressure or overheating are possible, the piping system must be

provided with adequate protection systems

• Befo re assembling, check on the valve th e marked pressure limit (it refers

to a temperature of 20°C)

• Immediately prior to valve installation, the pipework to which the valve

is to be fastened should be checked for cleanliness and freedom from

debris.

• Do not operate any maintenance with piping system under pressure

• Do not overstress the assembled valve with additional weight

• Do not hit or strike the valve

• Open/close slowly to avoid hammer shock

• Do not overheat the valve

• The operator should use suitable hand protection at extreme temperature

conditions.

• The valve should only be used in the open or closed position. Regulating

or throttling service should be avoided.

• After installation, the valve may be opened and closed fully to confirm

satisfactory operation.

mm H2O

2

200

20000

1

100

10000

0.5

50

5000

0.2

20

2000

0.1

10

1000

5

500

200

2

100

1

100 200 500 1000 2000 5000 10000 20000 50000 100000 200000 l/h

L

DN 20

DN 15

DN 10

DN 25

DN 50

DN 40

DN 32

G

D

D L

DN

G

(“)

(mm)

Weight

(g)

15 ½ 32 58 150

20 ¾ 39 65 225

25 1 47 75 330

32 1 ¼ 60 80 545

40 1 ½ 67 86 685

50 2 83 94 102 5

Installation

• Confirm that the pipe threading length is correct to avoid excessive

penetration of the pipe into the valve, which would otherwise cause

damage.

• Ensure the threads are properly engaged and proceed to tighten the

valve onto the pipe. The wrench must only be located on the valve end

into which the pipe is being threaded to avoid distortion of the valve.

• After installation, the valve may be opened and closed fully to confirm

satisfactory operation.

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

2 | © Danfoss | DHS-SRMT/SI | 2018.01

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VI.BO.L1.00

Loading...

Loading...