Page 1

Installation Guide

BV 1 and BV 2

Block valves

HCFC, HFC, R717 (Ammonia), R744 (CO2)

006R9501

006R9501

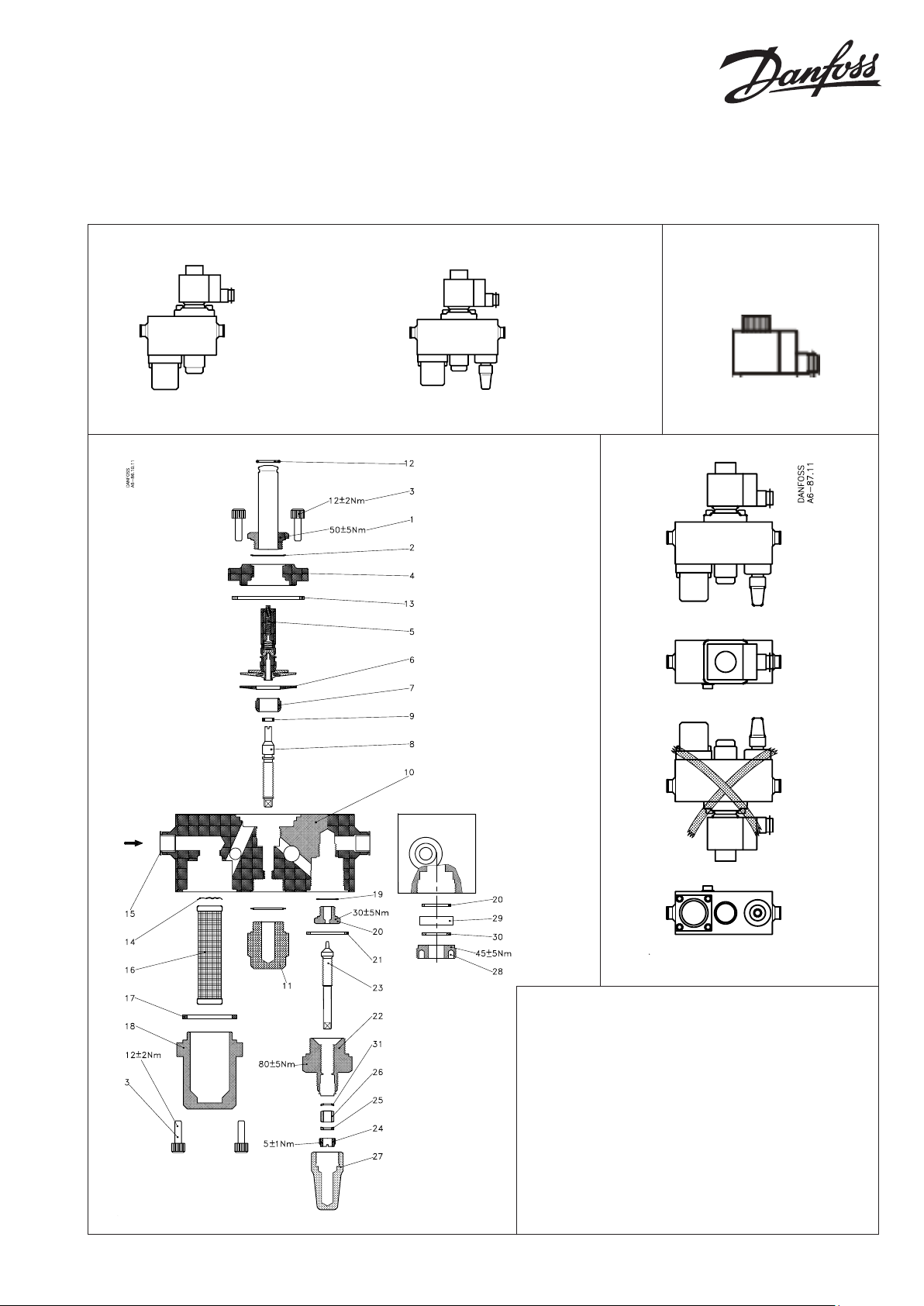

BV 1 BV 2 Coil

BV 1 & BV 2

Connections DN 10/DN15

Max. working pressure, PB = 28 bar (Pe)

Test pressure p' = 42 bar (Pe)

Medium temperature = −40°C → 105°C

EVRST:

Min. opening di. pressure = 0

Max. opening di. pressure

with 12 W coil: 21 bar

with 10 W coil: 14 bar

© Danfoss A/S (AC-MCI/MWA), 2012-11 DKRCI.PI.FP0.A1.02 / 520H7038 1

Page 2

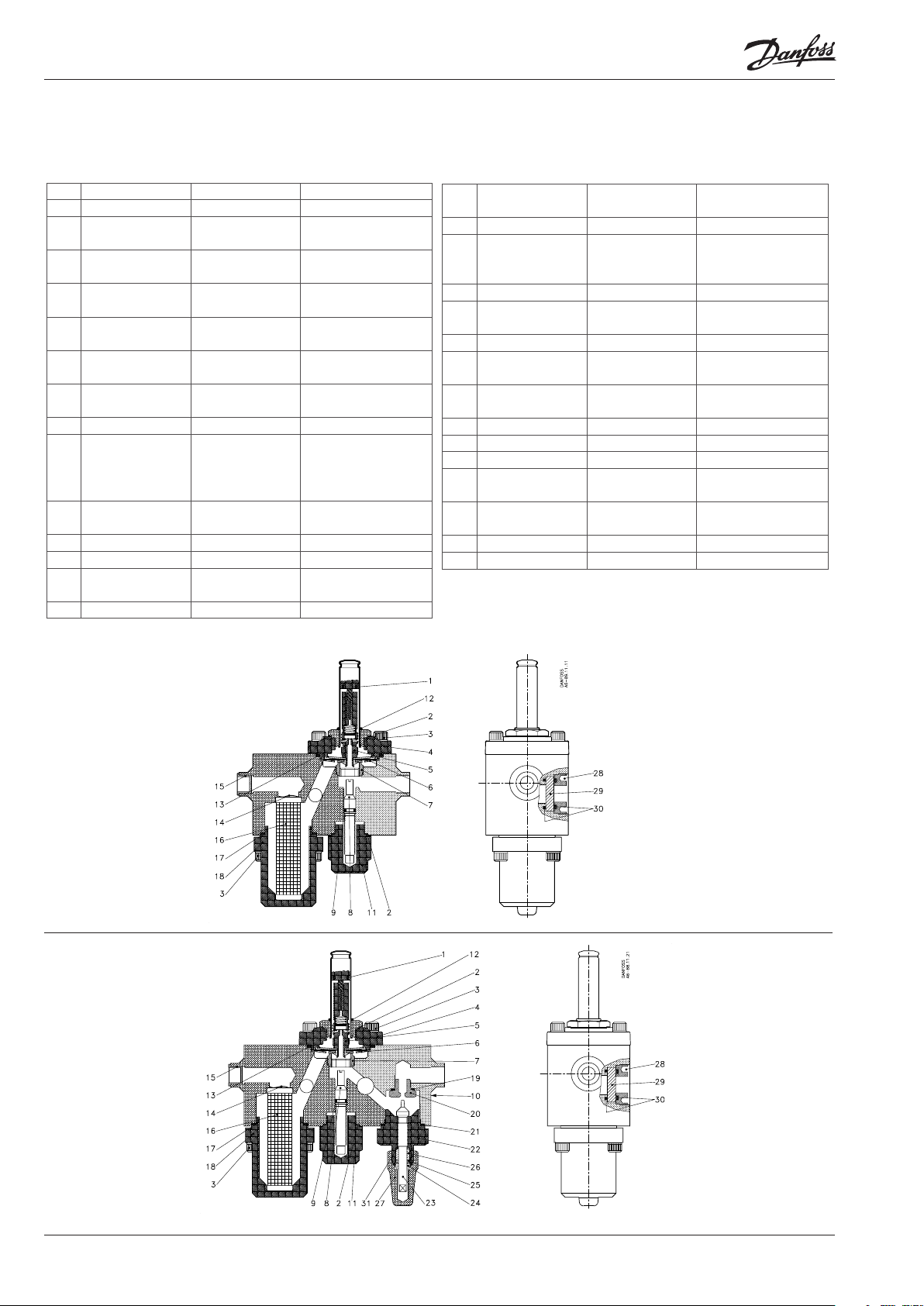

Part list is referring to drawings both at the previous and this page

No. Part Material DIN

1 Ass. Armature Stainless steel X 2 Cr N i 19 -11

2 Gasket Aluminium

3 Screw M6x20 Stainless steel RS A2-70 912

W 1- 4301

4 Cover Stainless steel EN 10204

W 1-430 8

5 Ass. Diagphram/

armature

6 Washer Stainless steel X5C rNi18-10

7 Valve seat Stainless steel 18/8 Free cutting st.

8 Spindle manual Stainless steel 18/8 Free cutting st.

9 O-ring Chloropren Chloropren

10 Valve Block Stainless steel SANMAC

11 Cap Stainless steel 18/8 Free cutting st.

12 O-ring Chloropren Chloropren

13 Rubber gasket Chloropren Chloropren

14 Crinkled spring

washer

15 Cap Plastics Plastics

Stainless steel/

teflon tissure

W 1- 4301

W 1-4305

W 1-4305

304/304L

EN10088 -3

W 1-4307

W 1-4305

Spring steel Spring steel

No. Part Material DIN

16 Strainer insert

FA 15

17 Refrig. Gasket Klingersil C4430 C4430

18 Strainer housing Stainless steel 18/8 Free cutting st.

19 Gasket Aluminium 30,255

20 Orifice Stainless steel X10CrNiS 18-9

21 Refrig. Gasket Klingersil C4430 C4430

22 Shaft sealing Stainless steel EN 10088

23 Spindle Stainless steel X10CiN iS 18 -9

24 Sealing nut Stainless steel W 1- 4305

25 Sealing nut Stainless steel

26 Teflon gasket Tefl on Tefl on

27 Cap 6F Stainless steel 18/8 Free cutting st.

28 Sealing ring Stainless steel 18/8 Free cutting st.

29 Glass Glass Glass

30 O-ring Chloropren Chloropren

Stainless steel

tissue

Stainless steel tissue

W 1-4305

EN 10088

W 1-4305

W 1-4305

W 1-4305

W 1-4305

W 1-4305

BV 1

BV 2

2 DKRCI.PI.FP0.A1.02 / 520H7038 © Danfoss A/S (AC-MCI/MWA), 2012-11

Page 3

Refrigerants:

Applicable to HCFC, HFC, R717 (Ammonia) and R744 (CO2).

Installation:

The valve must be installed in ow direction (arrow).

It is recommended to disassemble the valve before welding and/

or to use a wet cloth wrapped around the valve body to prevent

heat generation from welding to damage the internal parts of the

valve.

Capacity

Service:

At servicing and maintenance of the complete valve, it is recommended to change the orice, manual spindle, diaphragm

and armature in the solenoid valve part as well as the orice and

spindle assembly in the regulating unit.

Spare part set containing these components can be found in the

spare parts manual.

Typ e kv value

m3/h

Connections

BV 1 1,52*) DN 10

DN15

BV 2 0,36*)

0,77*)

*) Fully open valves

DN 10

DN 15

Capacity

kv-curves for BV 2

Number of spindle

rotations from

closed valve

The curves are based on subcooled liquid ahead of valve (no ashgas)

© Danfoss A/S (AC-MCI/MWA), 2012-11 DKRCI.PI.FP0.A1.02 / 520H7038 3

Page 4

www.danfoss.com/ir

4 DKRCI.PI.FP0.A1.02 / 520H7038 © Danfoss A/S (AC-MCI/MWA), 2012-11

Loading...

Loading...