Page 1

Installation guide

1

5

°

M

A

X

1

5

M

A

X

1

5

°

A

X

1

5

M

A

X

!

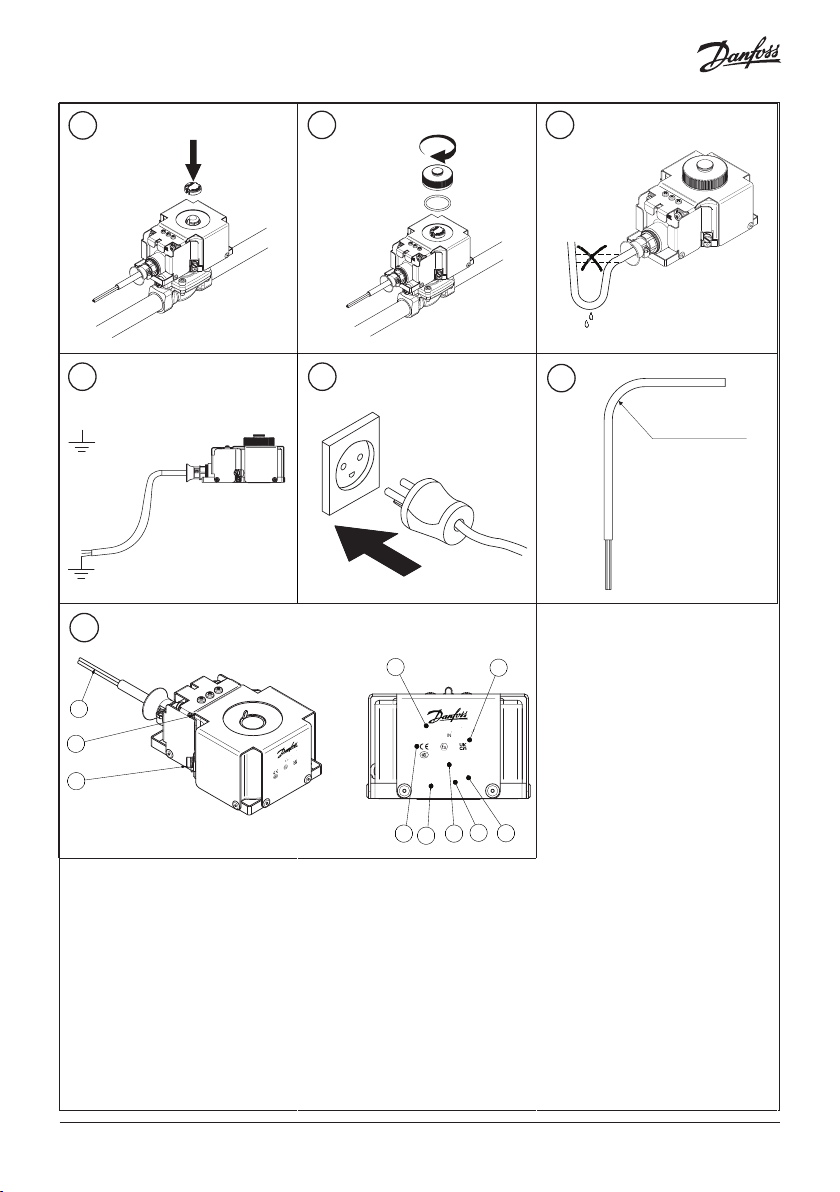

Solenoid coil for control in potentially explosive areas

Type BI

A B

018R9600

018R9600Info for UK customers only: 22 Wycombe End, HP9 1NB, GB

1

4

90°

© Danfoss | Climate Solutions | 2022.03

EV

AKV

2

°

5

3

°

M

6

AN381048038901en-000101 | 1

Page 2

7

Nordborg

,

ycomb

,

,

643

0

N

g

,

22W

y

e

End

,

9

1

,

GB

EIN

C

A

CO

8 9

1.5 Nm ± 0.15 Nm

10 11

II

1

2

3

0539

Exmb IICT4 Gb

IECExULD 21.0024X

UL21ATEX 2606X

UL21UKEX2374X

-40°C≤Ta ≤40°C

240V50/60Hz0,047A

0843

II2G

Z8525

I

r > 35mm

9

comb

MAD

0539

Exmb IICT4Gb

IECExULD 21.0024X

UL21 ATEX 2606X

UL21UKEX2374X

-40°C≤Ta≤40°C

240V50/60Hz0,047A

5

ordbor

IL018Z8585

II2G

4

DK

HP

NB

HIN

0843

Z8525

7

8

610

© Danfoss | Climate Solutions | 2022.03

AN381048038901en-000101 | 2

Page 3

II

Identification

1

Green/Yellow cord for earthing

2

Week and date of manufacturing

3

External earth terminal

4

Code number

5

Voltage

6

Approval/Certificate number

7

Frequency

8

Ambient temperature range

9

Country of manufacturing

10

Approval logos

Description and approval

Solenoid valve for control in potentially

explosive area.

EU Directives

ATEX 2014/34/EU

EMC 2014/30/EU

RoHS Directive 2011/65/EU

- including amendment 2015/863

EX Certifications

Ex mb IIC T4 Gb

IECEx ULD 21.0024X

UL 21 ATEX 2606X

UL21UKEX2374X

The coil may only be installed with following valve combinations

Valves works with A: Valves works with B: Valves works with both:

• EVM-EVRF-EVRP-EVRB

• AKV

• EVR 2, 3, 6

• EVRS(T) 3

• EV210BW

• EV210B

• ICLX

• VDH

• VDHT EAM

• VDHT

• VPH

• EVRA 3

• E V220B 6, 10, 12, 14, 18, 22

• EV221BW

• EV251B

• EVRS(T) 10-20

• ICF

• EV227B

• EVRA 10, 15, 20 (Before 1996)

• EVRA(T) 10, 15, 20 (Before 1996)

• E VR 10, 15, 20, 22, 25, 32, 40

• E V220B 15, 20, 25, 32, 40, 50

• EV220BW

• EV220B 65, 80, 100

• EV250BW

• EV250B

• VDH 30 EC

• EV222B

• EV224B

• EVRA 10, 15, 20, 25, 32, 40

(After 1996)

• EVRA(T) 10, 15, 20 (After 1996)

• AK VA

• EVRA(T) 3

Application and specification:

Ambient temp. -40 °C ≤ T

Media -40 °C < T

≤ +40 °C Protection degree IP67(Evaluated by Danfoss)

ambient

< +90 °C Polution degree 3 (EN60730-1)

media

Humidity 0 - 97 % Over voltage category II (2.5 kV)

Voltage +6 / -10 % Mode of operation Type 1 action (EN60730-1)

Connection 3-Wire cable 3 x 0.75mm² External earth wire Minimum wire gauge

> 4mm²

Weight 1.0 kg Purpose of control Independently mounted/

incorporated class I control

© Danfoss | Climate Solutions | 2022.03

AN381048038901en-000101 | 3

Page 4

Safety instruction

All national safety regulations must be

complied with in connection with

installation, start-up and operation of

Danfoss solenoid valve. Furthermore, the

requirements of the declaration of

conformity and national regulations for

installation in explosion area. Disregarding

such regulations involves a risk of serious

personal injury or extensive material

damage. Work in connection with the

solenoid valve mentioned must be

performed only by suitable qualified persons.

Safety requirements for use in explosive

atmospheres are fullfilled through

compliance certificates:

• Ex mb IIC T4 Gb

• IECEx ULD 21.0024X

• UL 21 ATEX 2606X

• UL21UKEX2374X

Specific Condition of Safe Use

• Protect the coil against external impact

• Protect the coil against direct sunlight and

other ultraviolet sources

• Disconnect the power before dismounting

the coil

• Install the coil and cable according to

IEC/EN/ EN BS 60079-14

• The cable supplied with the solenoids

must not be handled or flexed, and shall

be protected against impact if the ambient

temperature is below 0 °C

• Installation and handling of the cable shall

be done at temperature above 0 °C

• The cable is only for fixed installation and

the minimum bending diameter for fixed

installation: r ≥ 35 mm ( 2 )

I

• The cable jacket material is PVC

• The cable operating temperature range is

-40 – 90 °C

• The product is provided with a yellow/green

PE Conductor as well as an external earth

terminal. These shall not be used simultaneously.

If the external earth connection is connected

to earth or bonding system, the PE Conductor must be cut off, isolated and not con nected. If the PE Conductor is connected to

earth, the external earth terminal must be

left without any connection. For the external

earth terminal the size of the earth core shall

be minimum 4 mm² and the installer shall

use a suitable method e.g. crimp terminal

to ensure secureness of the external earth

connection. The screw for external PE shall

be mounted with 1.2 Nm ± 0.2. The external

earth conductors shall be physically secured

close to the coil connection to ensure that

the conductors cannot be readily loosened

or twisted

• The end user must ensure the earthing of

the coil is maintained

• Non-detachable cords method Z repairing not

allowed. If the coil failed, it must be replaced

by a new coil

UK-CA contact address:

Danfoss Ltd.

22 Wycombe End,

HP9 1NB, GB

CE contact address:

Danfoss A/S

DK-6430 Nordborg

Denmark

© Danfoss | Climate Solutions | 2022.03

AN381048038901en-000101 | 4

Loading...

Loading...