Page 1

Dan

70-1122.11

.13

Data sheet

Oil Motor Pump type BFPM 21

Application

Function

The BFPM range is a series of Danfoss oil pumps in

combination with a highly efficient permanent

magnet motor.

The BFPM Electronic Controller must be used for

controlling BFPM motor pumps (see separate data

sheet for BFPM Electronic Controller).

BFPM 21 is designed for small domestic oil

burners up to 24 l/h.

BFPM 21 features:

• Light oil and kerosene

• 1- or 2-pipe operation

• 1-stage

• Built-in pressure regulator

• Solenoid valve cut-off

• Cartridge filter

O

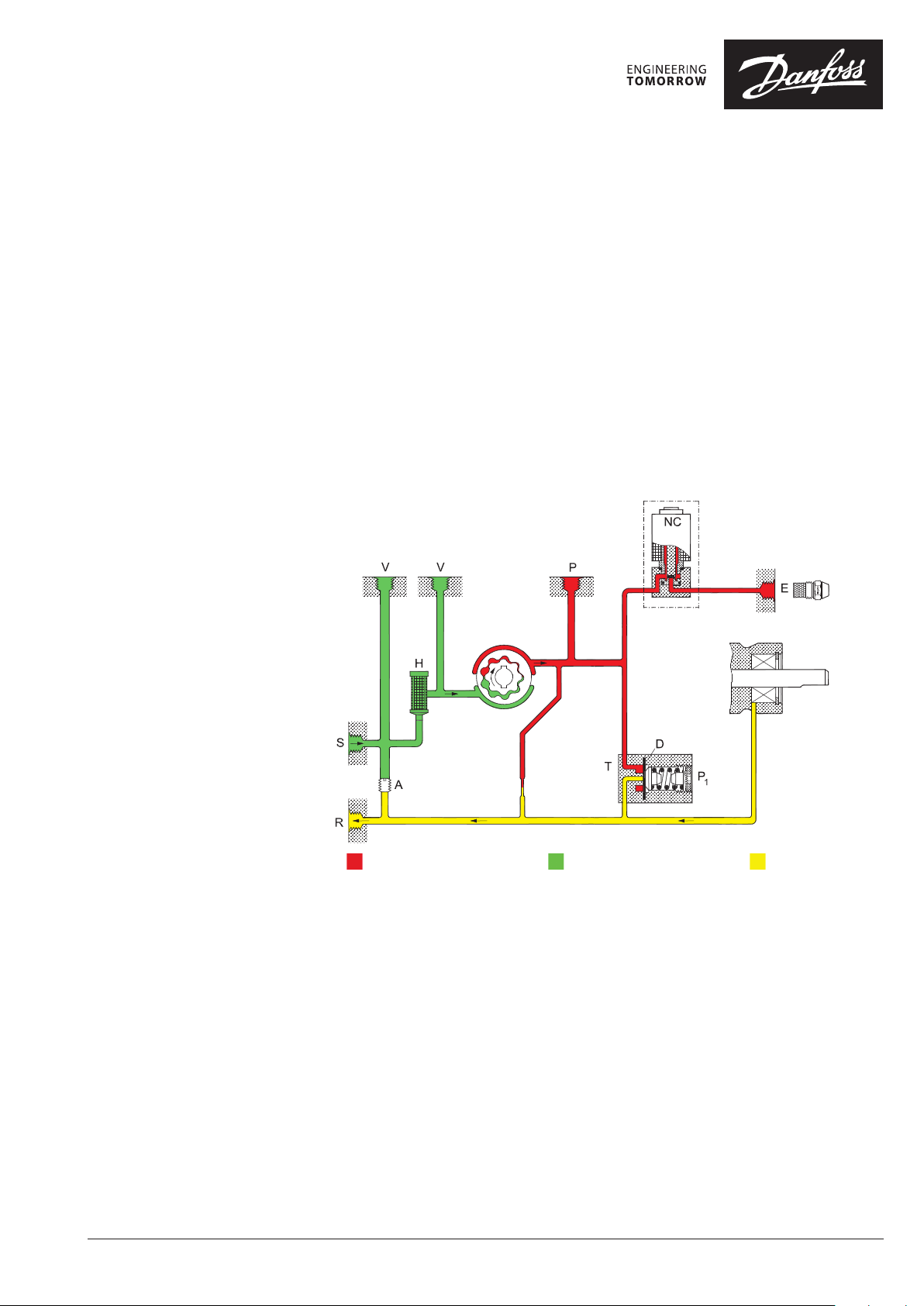

Pressure Suction Return

From the suction inlet (S) oil is drawn through the

filter (H) to the gear set, where the pressure is

increased. When voltage is applied to the

NC-valve, it opens and releases oil to the nozzle

outlet.

By means of the diaphragm (D) in the pressure

regulator (T), the pressure is kept constant at the

value set on adjustment screw (P1).

In 2-pipe systems the excess oil is led back to the

return outlet (R) and the tank.

In 1-pipe systems with plugged return outlet (R)

and screw (A) removed, the oil is returned

internally to the gear set (see figure).

Cut-off function, solenoid valve

When the burner stops, the voltage to the

NC-valve is cut off and the oil flow to the nozzle

outlet is cut off immediately.

foss

Bleeding

In 2-pipe systems the pump is self-priming, i.e.

bleeding is performed via the constriction (O) to

the return outlet (R).

In 1-pipe systems with plugged return outlet (R),

bleeding must be performed through the nozzle

outlet (E) or the pressure gauge port (P).

Warranty

For pumps used outside the stated technical data

and used with oil containing abrasive particles

Danfoss cannot give any warranty.

Note! The solenoid valve must be replaced after

250.000 operations or 10 years (approved life

expectancy).

© Danfoss | 2019.05

VD.DK.L3.02| 1

Page 2

Data sheet Oil Motor Pump type BFPM 21

Identification

Technical Data

BFPM 2 1 L 3 L

L: left hand nozzle outlet

3: capacity 24 l/h

L: left hand rotation

1: with one solenoid valve

2: cartridge filter, pressure adjustment on front

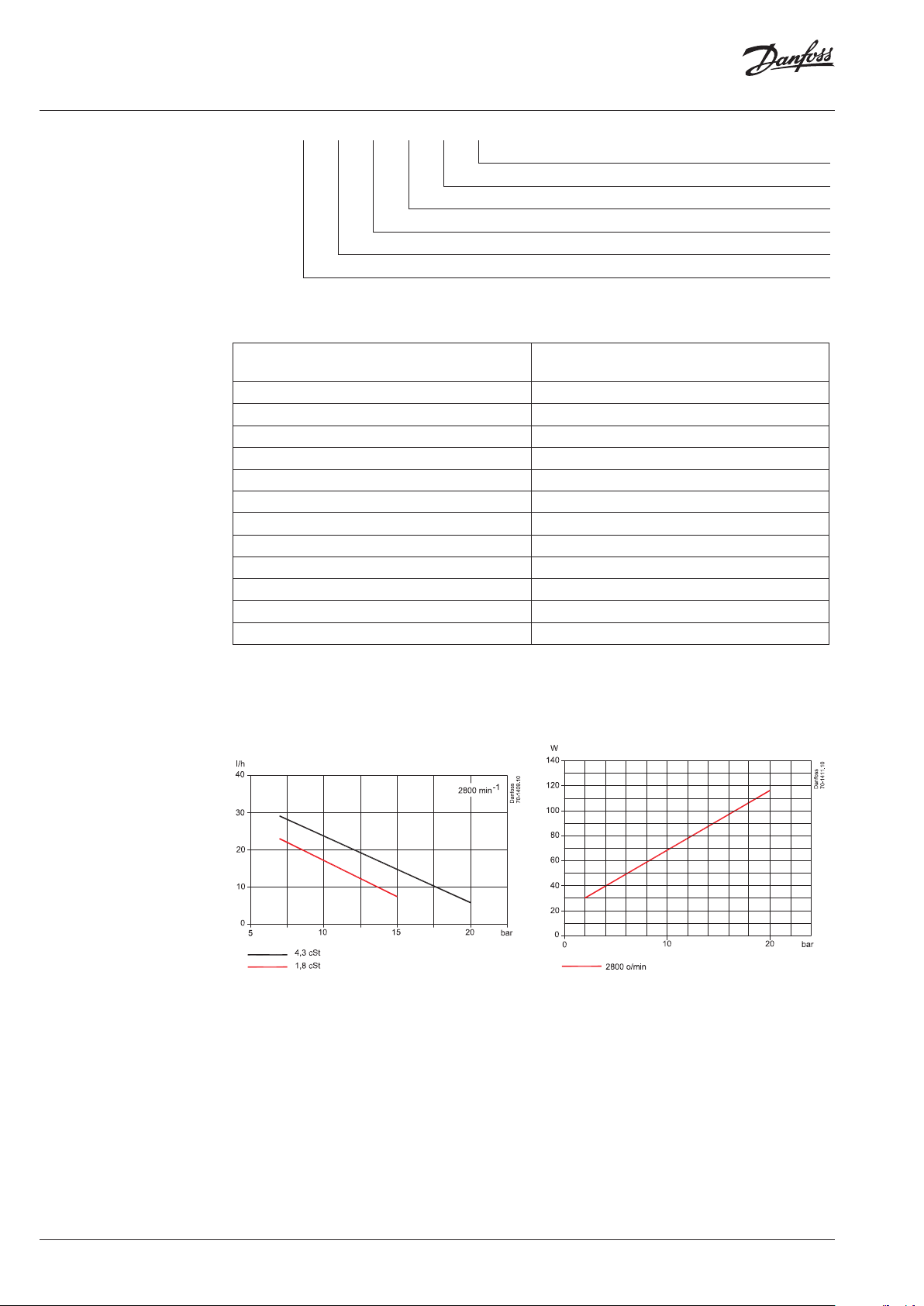

Nozzle capacity at 4.3 cSt., 10 bar, 2800 min

Oil types

-1

Standard fuel gas oil and fuel gas oil acc. to DIN V

51603-6 EL A Bio-10 (Max. 10% FAME)

Viscosity range (measured in suction inlet) (1.3) 1.8 to 12.0 cSt. (mm2/s)

Filter area/mesh 11 cm²/200 µm

Pressure range

1)

7 to 20 bar

Default setting 10 ±1 bar

Max. pressure in suction inlet/return outlet 2 bar

Speed 400 to 3400 min

-1

Ambient/transport temperature -20 to +70° C

Temperature of medium 0 to +70° C

Power supply/drive BFPM motor

2)

230 V switched from controller

Coil power consumption 9 W

Coil rated voltage (other voltages on request) 220/240V, 50/60 Hz

Coil enclosure IP 40

1)

Max. 12 bar at 1.3 cSt., max. 15 bar at 1.8 cSt.

2)

Warning: Do not connect BFPM motor directly to 230 V/50 Hz power supply!

Nozzle capacity Power consumption

2 | © Danfoss | 2019.05

VD.DK.L3.02

Page 3

Data sheet Oil Motor Pump type BFPM 21

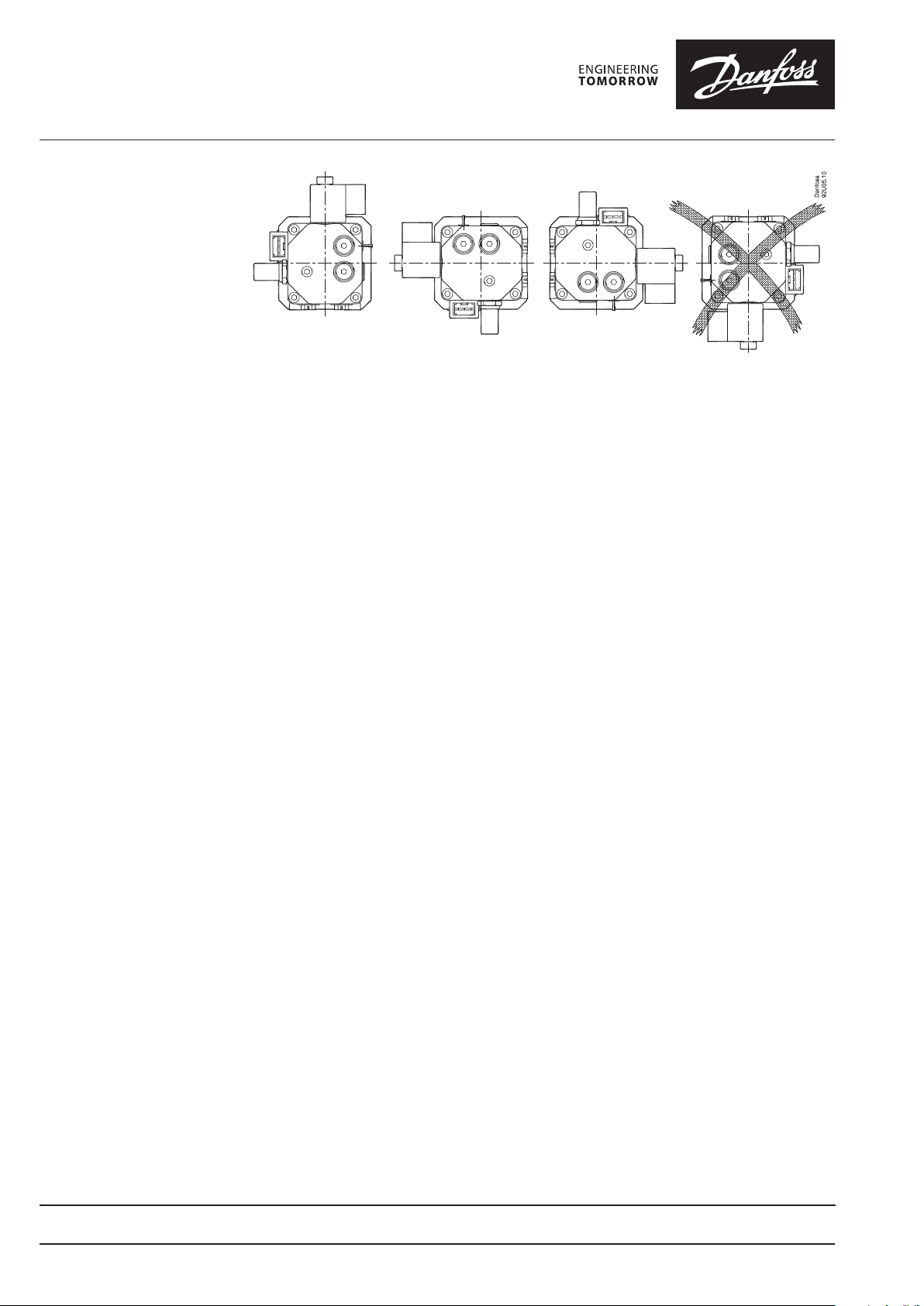

Connections

Change-over and

Filter Replacement

P1: Pressure adjustment

S: Suction inlet G1/4

R: Return outlet G1/4

E: Nozzle outlet G1/8

P: Pressure gauge port G1/8

V: Vacuum gauge port G1/8

H: Filter

H: Filter

A: 2-pipe operation, with screw

B: 1-pipe operation, without screw

Dimensions

VD.DK.L3.02

© Danfoss | 2019.05 | 3

Page 4

Danfos

produc

Al

Danfoss A/S

Heating Segment • heating

Data sheet Oil Motor Pump type BFPM 21

Mounting

Additional documentation on burner components is available on http://heating.danfoss.com/

.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its products w ithout notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are p roperty of the respective companies. Danfoss and al l Danfoss logotypes are trademarks of Danfoss A/S. All rights reser ved.

4 | © Danfoss | DHS-SDBT/DK | 2019.05

VD.DK.L3.02

Loading...

Loading...