Page 1

Data Sheet

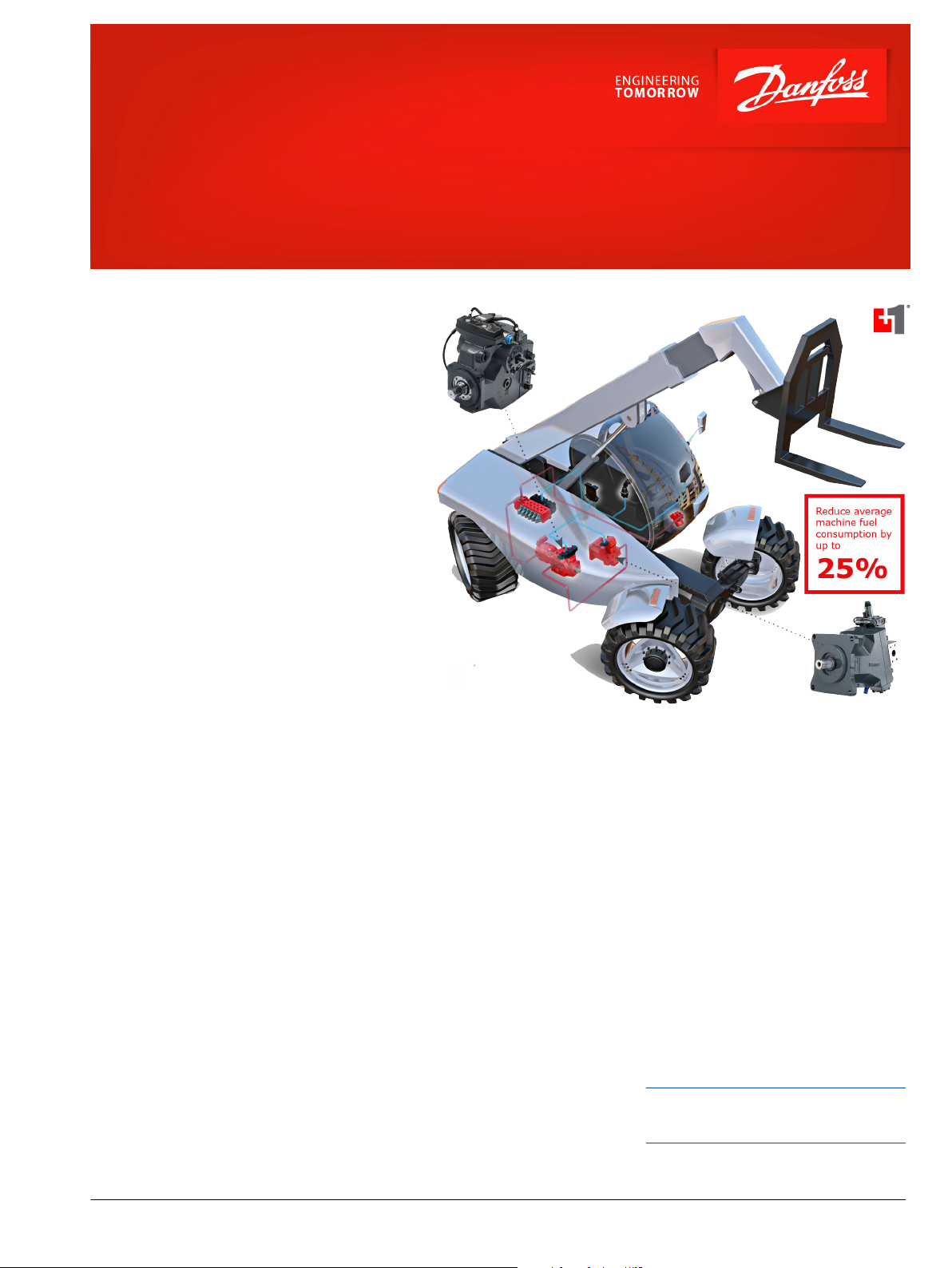

Propel Application Software

Best Point Control (BPC)

Danfoss Best Point Control (BPC) BPC is an innovative

propel application software that can dramatically

increase the efficiency of a machine.

By detecting the power required for the operating

conditions and automatically adjusting the engine

speed to meet optimum efficiency points, BPC adds

instant value to virtually any application.

As a PLUS+1® compliant software block, BPC offers

plug-and-perform integration into existing work

flows.

Regardless of the application, BPC helps to reduce

development time and almost instantly increases

machine control.

Target applications:

•

Telehandler, wheel-loader, dumper, sweeper,

forklift trucks, forestry machines etc.

•

Mobile machines demanding better fuel efficiency

and require a high level of controllability.

Features

Basic functions

•

One drive mode for all operating points

and use cases

•

Machine and engine overspeed

protection

•

Hydrostatic ratio control: intelligent

adjustment of hydraulic pump and

hydraulic motor depending on the load

•

Drive pedal scaling: operator can adjust

the pedal resolution to achieve better

machine controllability and

performance

•

Minimum engine speed adjustment: to

ensure high machine performance and

to provide the oil flow, required for

other sub-systems like work functions

•

Calibration routines to simplify machine

start-up

•

No Engine PPU: accepts J1939 standard

message, no need for additional PPU.

•

Vehicle speed limitation

Flexibility

•

Transmission control: flexible integration

of multiple different final drive solutions

(e.g. 2MT)

•

Modular software design: fit to a variety

of application types

•

Work hydraulic pressure sensor: works in

conjunction with other sub-systems like

Work Function Control

•

Functional safety: designed according to

safety standards for shorter time to

market

Performance and Fuel Economy

•

Best Point Control: depending on the

machine’s load situation, the diesel

engine and the hydrostatic drivetrain

are controlled at their best efficiency

points

•

Vehicle speed control: driver is

controlling the machine movement and

software controls the diesel engine and

hydrostatic ratio

•

Power management functions: electronic

pressure limiter and antistall for more

machine performance

•

Temperature compensation for

predictable performance

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | May 2016 AI00000272en-US0102 | 1

Page 2

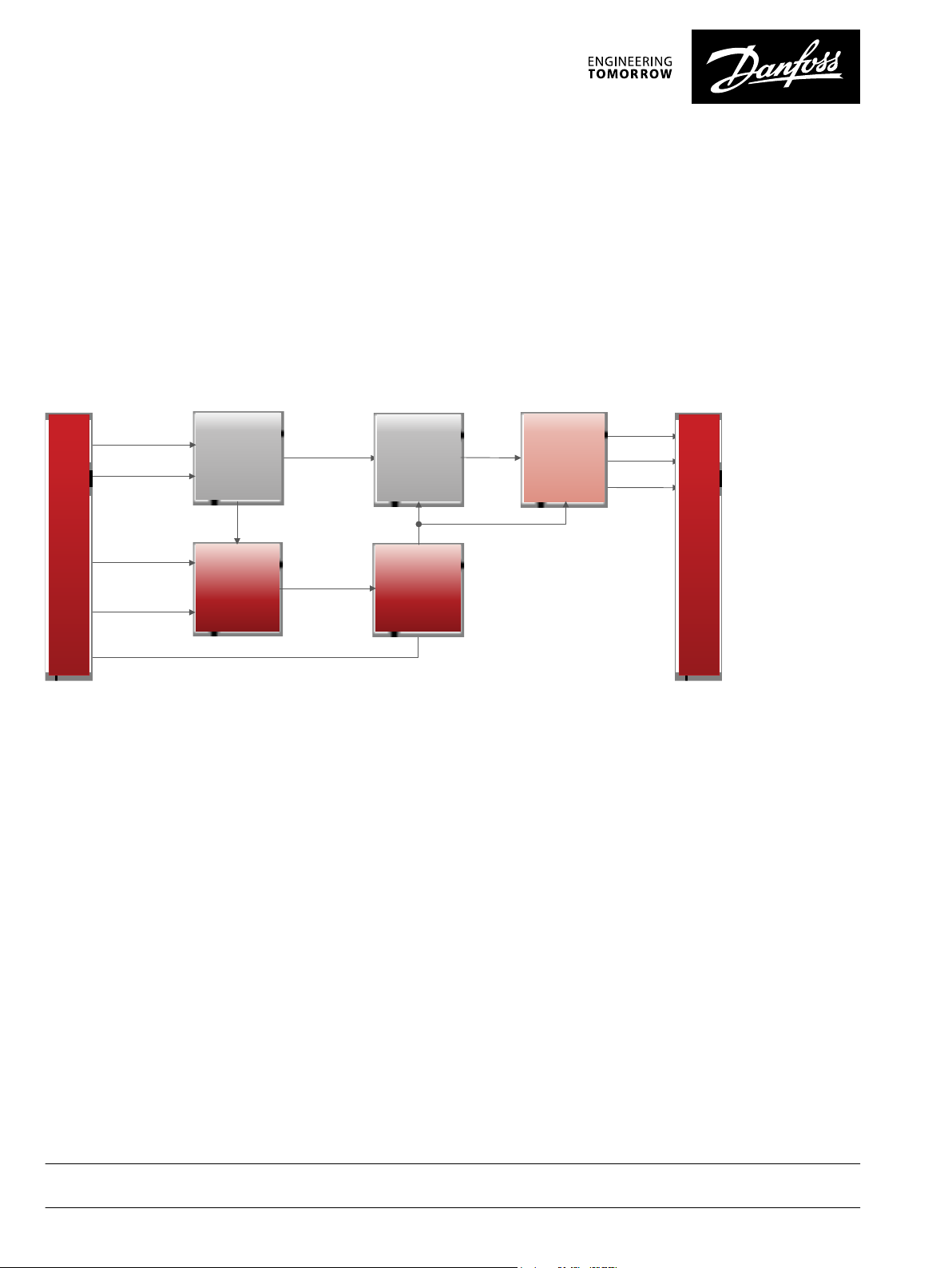

System Requirements

Current Engine

Power on CAN

Delta Vehicle

Speed

Ratio

Request

Vehicle Speed

Request

Engine

Power

Control

Engine Power

Request

Pedal Signal

Hydraulic

Ratio

Control

Vehicle

Speed

Control

External Engine

Speed Request

Ground Speed

External Engine

Power Request

Pump SP

Motor SP

Engine SP

Trans-

mission

Control

Output Conditioning

Drive Control

Transmission

Control

Engine Control

Engine

Speed

Control

Engine

Set Point

Input Conditioning

•

CAN controlled Diesel engine

•

H1 pump with embedded controller incl. swashplate angle

sensor

•

H1 bent axis motor with electric proportional control

•

Final drive configuration e.g. dropbox or dual motor gearbox

BPC Block Diagram

Modular software structure for flexible adaption to customer specific

requirements

Other available Danfoss literature

•

H1 Axial Piston Pumps – Product Line Overview, L1012919

•

H1 Axial Piston Motors – Product Line Overview, L1019304

System Inputs and Outputs

The following inputs and outputs to be considered for a typical

BPC baseline configuration

•

Drive direction switch (FNR) optional via CAN

•

Drive pedal (redundant)

•

Drive enable optional via CAN

•

Manual engine speed setpoint

•

Drive pedal scaling

•

Inch pedal (redundant)

•

Park brake switch

•

Seat switch

•

CAN connection to the engine controller, CAN messages

according J1939

•

Engine speed signal, optional via CAN

•

Hydro motor speed signal

•

Pump control (pre-configured on embedded controller)

•

Hydro motor proportional control

•

Park Brake control

•

Feedback signal Park Brake released

•

Work hydraulic pressure sensor

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | May 2016 AI00000272en-US0102

Loading...

Loading...