Operating Guide

TR(TW)700

AVT

ENGLISH

DANSK

DEUTSCH

ESPAÑOL

NEDERLANDS

SLOVENŠČINA

ČESKY

POLSKI

LIETUVIŲ K.

РУССКИЙ

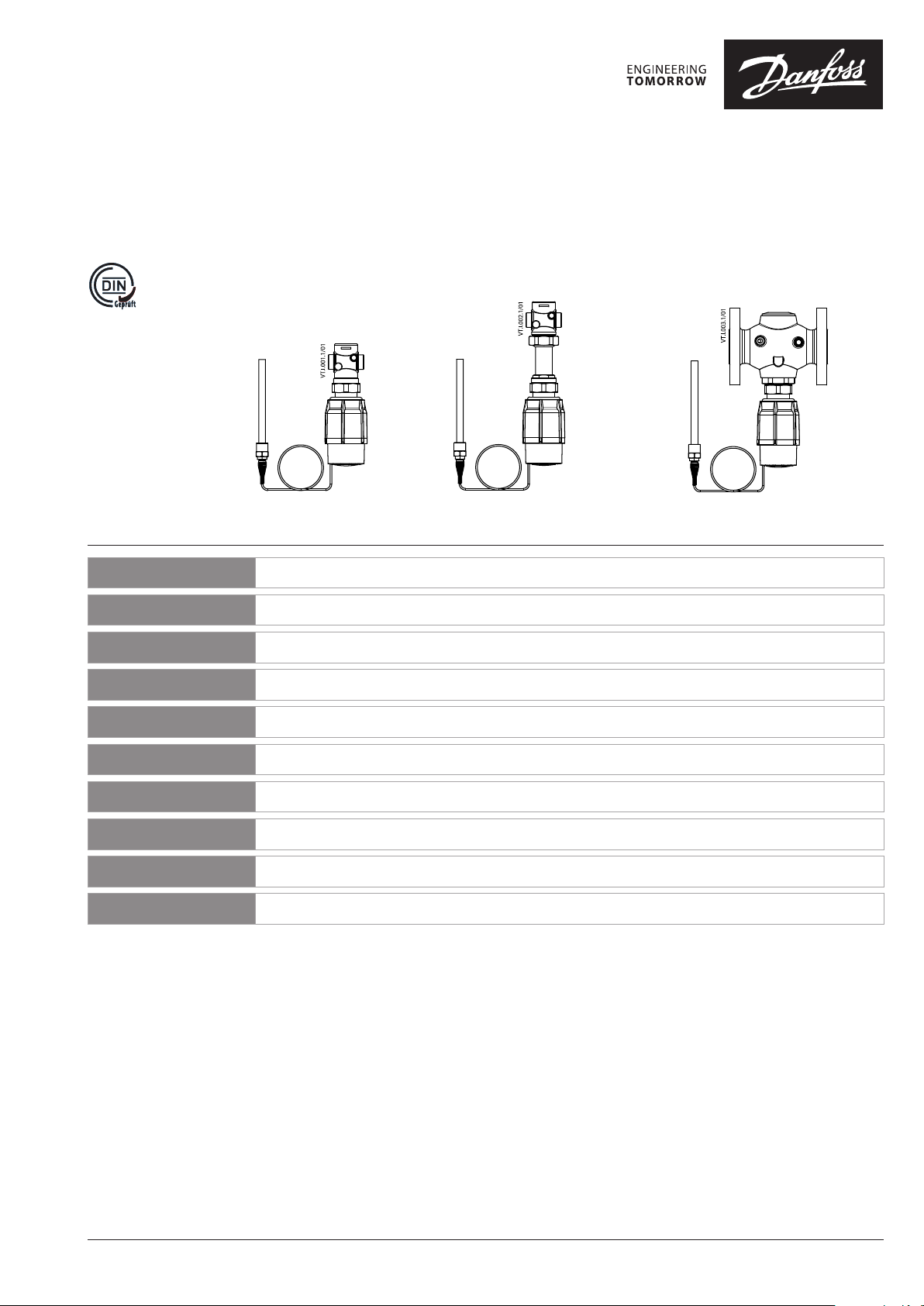

AVT/VG

AVT/VGU

Temperature actuator AVT www.danfoss.com Page 5

Teperaturaktuator AVT www.danfoss.dk Side 6

Thermostat AVT www.danfoss.de Seite 7

Actuador de temperatura AVT www.danfoss.es Page 8

Temperatuurregelaar AVT www.danfoss.nl Blz. 9

Pogon regulatorja temperature AVT www.danfoss.si Str an 10

Pohon přímočinného regulátoru teploty AVT www.danfoss.pl Strana 11

Siłownik termiczny AVT www.danfoss.pl Strona 12

Temperatūros pavara AVT www.danfoss.com Page 13

Термостатический элемент AVT www.danfoss.com Стр. 14

AVT/VGS AVT/VGF

AVT/VGUF

© Danfoss | 2017.08

VI.GC.W3.8N | 1

AVT

➊

①

②

③

④

⑤

❷

②

①

③

⑥

④

2 | © Danfoss | 2017.08

⑤

VI.GC.W3.8N

AVT

❸

❹

①

①

③

⑧

②

③

④

⑤

②

④

DN L (mm)

15 69

20 74

25 79

32 104

40 114

50 134

❺

❽

⑦

①

②

①

◯ ◯

②

❾

⑥

❻ ❼

②

③

①

④

① ③

②

④

⑤

VI.GC.W3.8N

© Danfoss | 2017.08 | 3

AVT

❿

⓫

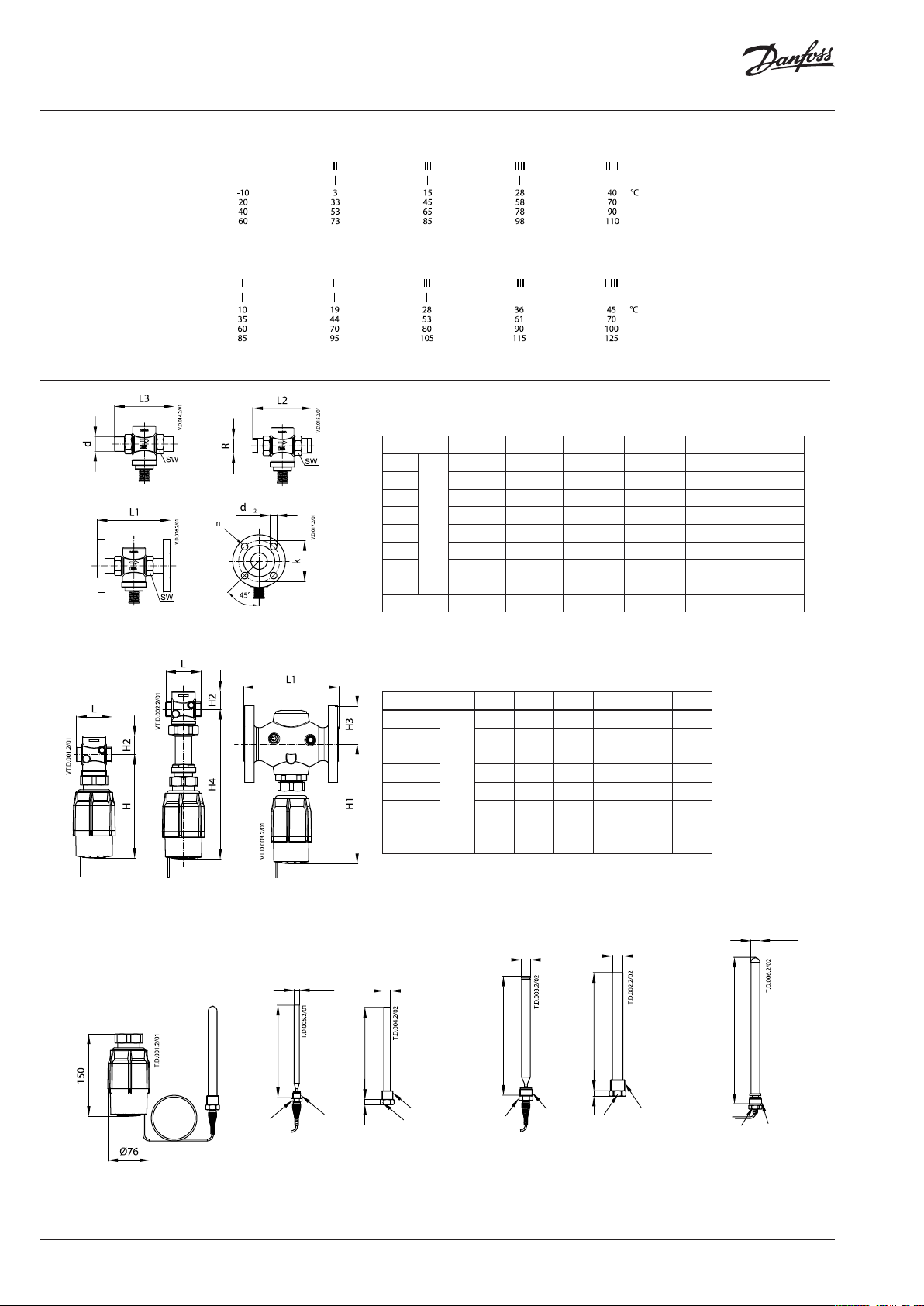

AVT ... 170 mm, 210 mm

AVT ... 255 mm

SW

d

R

L1

L2

L3

k

d

DN

15 20 25 32 40 50

32 (G ¾A) 41 (G 1A) 50 (G 1¼A) 63 (G 1¾A) 70 (G 2A) 82 (G 2½A)

21 26 33 42 47 60

⁄ ⁄ 1 1⁄ - -

130 150 160 - - -

mm

131 144 160 177 - 139 154 159 18 4 204 234

65 75 85 100 110 125

14 14 14 18 18 18

n

4 4 4 4 4 4

AVT/VG/VGU AVT/VGS AVT/VGF/VGUF

174

SW 17

Ø 9,5

M14×1

DN 15 20 25 32 40 50

L

L1 130 150 160 180 200 230

H (VG) 180 180 180 222 222 222

H (VGU) 183 183 183 225 225 225

H (VGS) 257 257 257 - - H1 130 230 230 222 222 222

H2 34 34 37 62 62 62

H3 47 52 57 70 75 82

Ø 12

170

6

R ½

SW 22

65 70 75 100 110 130

mm

Ø 16

223

SW 22

M22×1

215

10

SW 27

Ø 19

R ¾

SW 22

Ø 16

266

R ¾

AVT

4 | © Danfoss | 2017.08

AV T 170

AV T 170

Immersion pocket

AVT 210

AVT 210

Immersion pocket

AVT 255

VI.GC.W3.8N

AVT

ENGLISH

Safety Notes

Prior to assembly and commissioning to

avoid injury of persons and damages of

the devices, it is absolutely necessary to

carefully read and observe these instructions.

Necessary assembly, start-up, and maintenance

work must be performed only by qualified,

trained and authorized personnel.

Prior to assembly and maintenance work on the

controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Disposal instruction

This product shou ld be dismantled and its

components sor ted, if possible, in various

groups before rec ycling or disposal.

Always follow the local d isposal regulations.

Definition of Application

The temperature actuator AVT is, in

combination with Danfoss valves and Danfoss

controller combinations, used for temperature

control of water and water glycol mixtures for

heating, district heating and cooling systems.

The temperature controllers (temperature

actuators with valves) with the temperature

actuator AVT are type-tested acc. to EN 14597

and comply with the safety requirements for

temperature control and temperature limiting

units in heat systems.

The technical parameters on the product labels

determine the use.

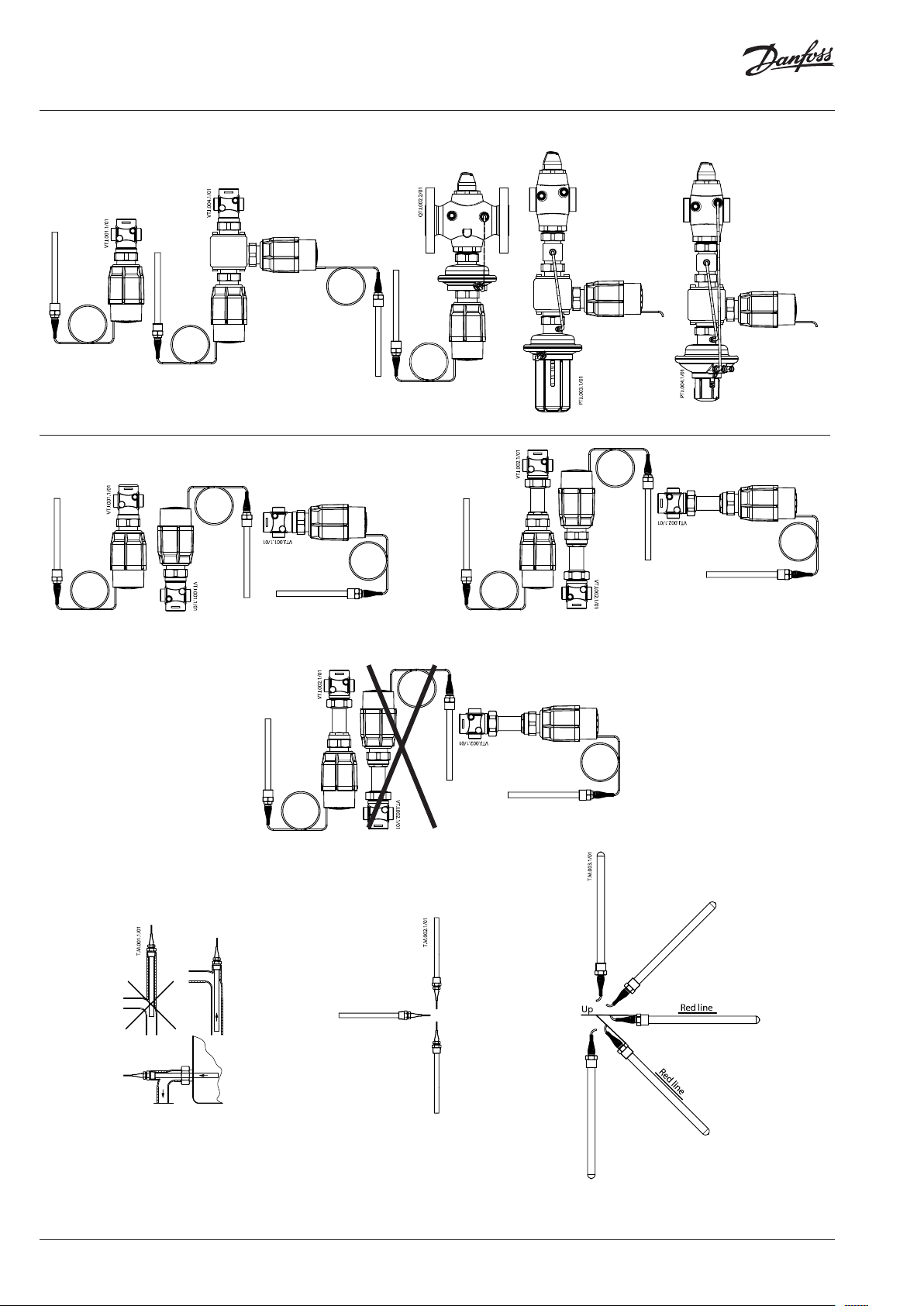

Application examples ➊

Temperature actuator AVT can be combined

with:

① VG(F), VGU(F) and VGS valves.

② Combination pieces K2, K3 and valves

mentioned above.

③ Flow and temperature controller AVQT

and Flow and temperature controller with

integrated control valve AVQMT.

④ Differential pressure and temperature

controller with flow limitation (and fixed

setting) AVPBT(-F).

⑤ Differential pressure, flow and temperature

controller AVPQT.

Assembly

Admissible Installation Positions

Temperature actuator with valves

- In combination with VG(F) or VGU(F) valves:

• Can be installed in any position ①.

- In combination with VGS valves:

• Medium temperatures up to 160 °C:

Can be installed in any position ②.

• Medium temperatures > 160 °C:

Can be installed horizontal and in

horizontal pipelines with the actuator

oriented downwards ③.

Admissible installation positio ns in

combination with AVQT, AVQMT,

AVPBT(-F) and AVPQT - see relevant instructions.

❷

Temperature sensor

- The capillary tube may not be twisted or

buckled. The minimum bending radius is

50 mm ④.

- The place of installation must be chosen in

a way that the temperature of the medium

is directly taken without any delay. Avoid

overheating of temperature sensor

- The temperature sensor must be immersed

into the medium in its full length.

Temperature sensors 170 mm R½” and

210 mm R¾”:

- The temperature sensor may be installed in

any position ⑤.

Temperature sensor 255 mm R¾”:

- The temperature sensor must be installed as

shown on the picture ⑥.

Installation Location and Installation

Scheme

• AVT/valve ①, AVT/AV T/valve ② return

• AVT/valve ③, AVT/AV T/valve ④ flow

➌

mounting

mounting

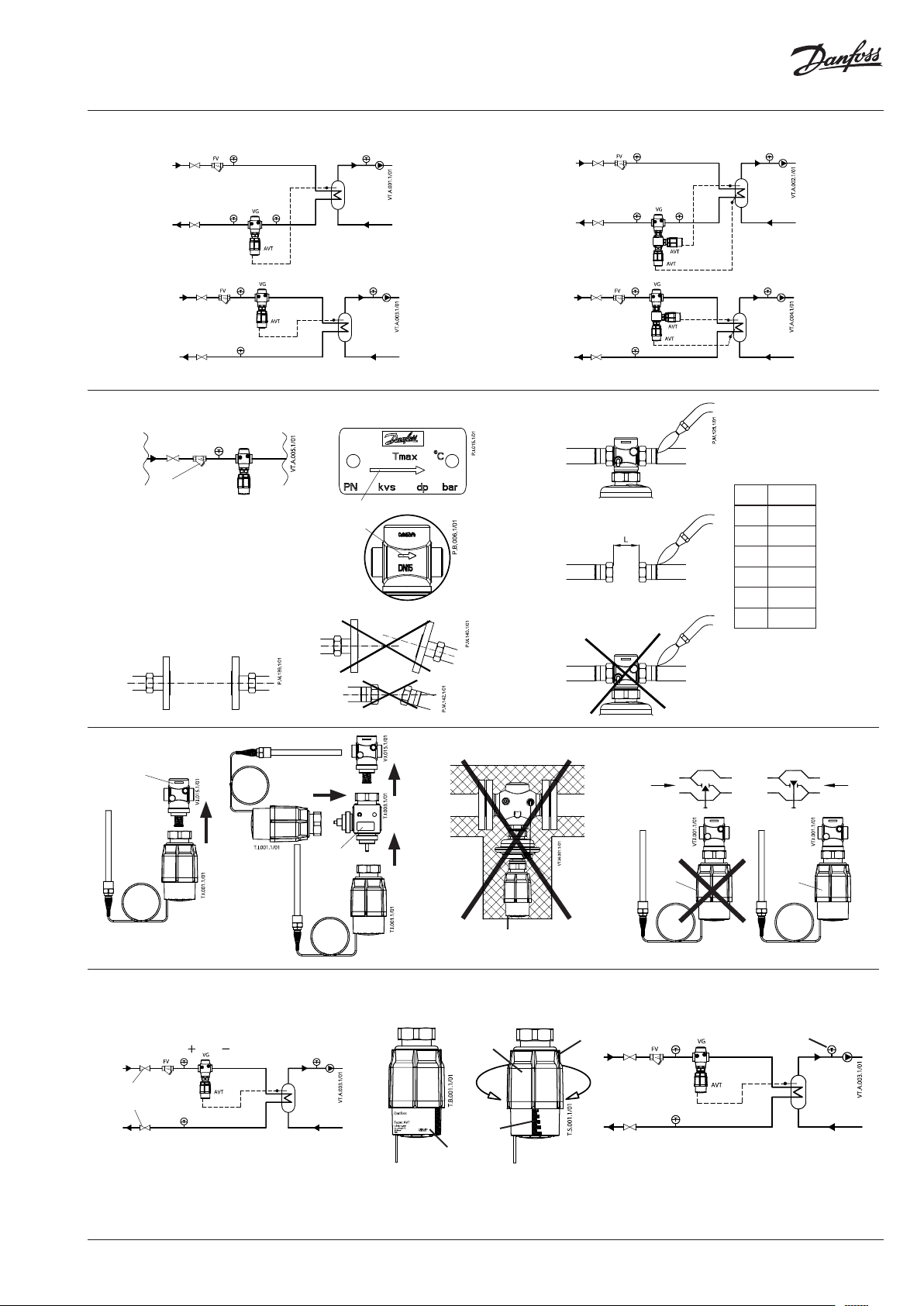

Valve Installation ➍

1. Clean pipeline system prior to assembly.

2. The installation of a strainer in front of the

controller is strongly recommended ①.

3. Install temperature indicators in the system

part to be controlled.

4. Install valve

• The flow direction indicated on the

product label ② or on the valve ③ must be

observed.

• The valve with mounted weld-on

tailpieces may only be spot welded to the

pipeline ④.

The weld-on tailpieces may be welded only

without the valve and seals! ⑤⑥

If these instructions are not observed, high

welding temperatures may destroy the

seals.

• Flanges ⑦ in the pipeline must be in

parallel position and sealing surfaces must

be clean and without any damage.

Tighten screws in flanges crosswise in 3

steps up to the maximum torque (50 Nm).

5. Caution:

Mechanical loads of the valve body by the

pipelines are not permitted ⑧.

Mounting of temperature actuator ❺

Before mounting the actuator, carry out Filling

the system, First start-up and Leak and pressure

tests, see ❽.

Place temperature actuator AVT at the valve ②

or combination piece ③ and tighten union nut

with wrench SW 50. Torque 35 Nm.

Insulation ❻

Do not insulate the temperature actuator and

the valve as well.

Start-up ❼

Valves VG, VGF and VGS ① are normally

opened (NO) valves.

Filling the system and Leak and pressure test

should be done without mounted temperature

actuator ② - valve has to be open.

Valves VGU and VGUF ③ are normally

closed (NC) valves.

Filling the system and Leak and pressure test

should be done with open valve. Temperature

actuator ④ could be mounted and set in a way

that the valve is open.

Filling the system, first start-up ❽

1. Slowly open shut-off devices in the flow

pipeline ①.

2. Slowly open shut-off devices ② in the return

pipeline.

Leak and Pressure Tests

Pressure must be gradually incre ased at

the +/- side of the valve . Do not test with

closed valve.

Non-compliance may cause damages at the

actuator or the valve.

A pressure test of the entire system must be

carried out in accordance with manufacturer’s

instructions.

The maximum test pressure for the valves is:

1.5 × PN

PN - see product label!

Putting out of operation

1. Slowly close shut-off devices ① in the flow

pipeline.

2. Slowly close shut-off devices ② in the return

pipeline.

Settings ❾

Temperature Setting

The temperature setting range is indicated on

product label ①.

Pre-conditions:

The system must be opened and the flow of the

medium guaranteed.

Procedure:

• Set desired setpoint by turning the setting

adjuster ②.

- Turning to the left (counter-clockwise)

increases the setpoint.

- Turning to the right (clockwise) reduces the

setpoint.

• The position of the setpoint adjuster on a

scale value ③ means:

1 minimum setpoint

5 maximum setpoint

• Observe temperature indicator ⑤.

• Wait for about 3 to 5 min. until the

temperature indicator shows the final value.

• If the device is used as a temperature

monitor, the setting adjuster ② must be

sealed by a sealing wire ④.

Adjustment diagram ❿

Temperature setting

Relation between scale numbers 1-5 and closing

temperature.

The values given are app roximate

Dimensions, Weights ⓫

1)

Conical ext. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

VI.GC.W3.8N

© Danfoss | 2017.08 | 5

AVT

DANSK

Sikkerhedsnoter

Disse instruktioner SKAL læses

omhyggeligt forud for montering og

indkøring samt respekteres for at undgå skader

på personer og udstyr.

Nødvendigt monterings-, opstart- og

vedligeholdelsesarbejde må kun udføres af

faglært og autoriseret personale.

Forud for monterings- og

vedligeholdelsesarbejde på regulatoren skal

systemet være:

- trykløst,

- nedkølet,

- tømt og

- rengjort.

Systemproducentens eller -operatørens

instruktioner skal overholdes.

Bortskaffelsesinstruktion

Dette produk t skal, om muligt, adskilles og

sorteres i dets fo rskellige materialegrupp er,

før det genbrug es eller bortskaf fes.

Lokal lovgivning for bor tskaffelse skal altid

overholdes.

Anvendelse

Temperaturaktuatoren anvendes sammen

med Danfoss-ventiler og Danfossregulatorkombinationer til temperaturstyring

af vand og vand-glycol-blandinger til varme-,

fjernvarme- og kølesystemer.

Temperaturregulatorerne (temperaturaktuatorer

med ventiler) med temperaturaktuatoren

AVT er typetestet iht. EN 14597 og overholder

sikkerhedskravene til temperaturstyringsog temperaturbegrænsningsenheder i

varmesystemer.

De tekniske parametre på produktetiketterne

fastlægger anvendelsen.

Anvendelseseksempler ➊

Temperaturaktuatoren AVT kan kombineres

med:

① VG(F), VGU(F) og VGS ventiler.

② Kombinationsstykkerne K2 og K3 samt

ovennævnte ventiler.

③ Flowregulatorer AVQT og flowregulator med

indbygget manøvreventil AVQMT.

④ Differenstrykregulator med

flowbegrænsning og fast indstilling

AVPBT(-F).

⑤ Differenstryks-, flow- og

temperaturregulator.

Montering

Tilladelige installationsstillinger ❷

Temperaturaktuator med ventiler

- I kombination med VG(F) eller VGU(F)

ventiler:

• Kan monteres i alle stillinger ①.

- I kombination med VGS ventiler:

• Medietemperaturer op til 160 °C:

Kan monteres i alle positioner ②.

• Medietemperaturer > 160 °C:

Må kun installeres i vandrette rørledninger

og med aktuatoren hængende nedad ③.

Tilladelig installation Stillinger i

kombination med AVQT, AVQMT og

AVPBT(-F) - se de relevante instruktioner.

Temperaturføler

- Kapillarrøret må ikke drejes eller bøjes. Min.

bukkeradius er 50 mm ④.

- Installationsstedet skal vælges, så

medietemperaturen kan tages direkte

uden forsinkelse. Undgå overhedning af

temperaturføleren.

- Temperaturføleren skal nedsænkes i mediet i

sin fulde længde.

Temperaturaktuatorer med sensorer 170 mm

R½” og 210 mm R¾”:

- Temperaturføleren kan installeres i alle

stillinger ⑤.

Temperaturaktuatorer med sensorer 255

mm R¾”

- Temperaturføleren skal installeres som vist

på billedet ⑥.

Installationsplacering og installationsplan ➌

• AVT/ventil ①, AVT/AVT/ventilmontering i

returledning ②.

• AVT/ventil ③, AVT/AVT/ventilmontering i

flowledning ④.

Ventilinstallation ➍

1. Rengør rørledningssystemet før montering.

2. Det anbefales stærkt at installere et filter

foran regulatoren ①.

3. Monter temperaturmålere før og efter den

systemdel, der skal reguleres.

4. Installer ventilen

• Den flowretning, der vises på

produktetiketten ② eller på ventilen ③

skal respekteres.

• Ventilen med monterede svejsestudser må

kun klemmes fast til rørledningen ④.

Svejsestudserne må kun svejses uden ventil

og pakninger! ⑤⑥

Høje svejsetemperaturer kan ødelægge

pakningerne, hvis disse instruktioner ikke

overholdes.

• Flanger ⑦ i rørledningen skal være

placeret parallelt, og pakfladerne skal være

rene og uden skader. Krydsspænd skruerne

i flangerne i 3 trin til maks. moment

(50 Nm).

5. Forsigtig:

Rørledningerne må ikke belaste ventilhuset

mekanisk ⑧.

Montering af temperaturaktuator ❺

Foretag fyldning af systemet, første opstart

og lækage- og trykprøvning, før aktuatoren

monteres. Se ❽.

Anbring temperaturaktuatoren AVT ved

membranen og spænd omløbermøtrikken med

nøgle SW 50. Moment 35 Nm.

Isolering ❻

Opstart ❼

Ventilerne VG, VGF og VGS ① er normalt

åbne ventiler (NO).

Påfyldning af systemet og lækage- og

trykprøvning bør gennemføres, uden at

temperaturaktuatoren ② er monteret.

Ventilerne VGU og VGUF ③ er normalt

lukkede ventiler (NC).

Påfyldning af systemet og lækage- og

trykprøvning bør gennemføres, uden at

temperaturaktuatoren ④ er monteret.

Påfyldning af systemet, første opstart ❽

1. Åbn langsomt for afspærringsanordningerne

① i flowledningen.

2. Åbn langsomt for afspærringsanordningerne

② i returledningen.

Lækage- og trykprøvning

Trykket skal øges gradvist på ventile ns +/side.

Respekteres dette ikke, kan der opstå skader på

aktuator eller ventil.

Der skal udføres en trykprøvning af

hele systemet i overensstemmelse med

producentens instruktioner.

Det maksimale prøvetryk for ventilen er:

1,5 × PN

PN fremgår af produktetiketten!

Standsning

1. Luk langsomt for afspærringsanordningerne

① i flowledningen.

2. Luk langsomt for afspærringsanordningerne

② i returledningen.

Indstilling af sætpunkter ❾

Indstilling af temperatur

Temperaturindstillingsområdet fremgår af

produktetiketten ①.

Forudsætninger:

Systemet skal være åbent og medieflowet sikret.

Fremgangsmåde:

• Indstil det ønskede sætpunkt ved at dreje

justerskruen ②.

- Drejes til venstre, forhøjes sætpunktet.

- Drejes til højre, sænkes sætpunktet.

• Stillingen for sætpunktjusterskruen ③ på en

skala betyder:

1 min. sætpunkt

5 maks. sætpunkt

• Hold øje med temperaturmåleren ⑤.

• Vent i ca. 3-5 min, til temperaturmålerne

viser den endelige værdi.

• Hvis anordningen anvendes som

temperaturovervågning, skal justerskruen ②

forsegles med en plombe ④.

Indjusteringsdiagram ❿

Temperaturindstilling

Forhold mellem skalatal 1-5 og lukketemperatur.

De angivne værdier er vejledende

Mål, vægt ⓫

1)

Konisk udv. gevind iht. EN 10226-1

2)

Flanger PN 25 iht. EN 1092-2

6 | © Danfoss | 2017.08

VI.GC.W3.8N

AVT

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung vor der Montage unbedingt zu

beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Vor Montage und Wartungsarbeiten am Regler

die Anlage:

- drucklos machen,

- abkühlen,

- entleeren und

- reinigen.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Anweisung zur Entsorgung

Dieses Produkt so llte ausgebaut und in

dessen Bestandteile zerle gt werden.

Sortieren Sie di e einzelnen Bestandteile

entsprechend der Entso rgungsgruppen zur

Wiederverwertung oder Entsorgung.

Beachten sie dabei immer die lokalen

Entsorgungsrichtlinien.

Bestimmungsgemäße Verwendung

Der Thermostat wird in Verbindung mit DanfossVentilen zur Regelung und Überwachung der

Temperatur von Wasser und Wasser-GlykolGemischen in Heizungs-, Fernheizungs- und

Kühlungsanlagen eingesetzt.

Die Regler (Thermostat mit Ventil) sind nach EN

14597 typgeprüft

Die technischen Daten auf den Typenschildern

sind für den Einsatz maßgebend.

Kombinationsbeispiele ➊

Der Thermostat AVT kann kombiniert werden

mit:

① den Ventilen VG(F), VGU(F) und VGS.

② den Kombinationsstücken K2, K3 und den

oben genannten Ventilen.

③ dem Volumenstromregler AVQT und dem

Volumenstromregler mit Motorstellventil

AVQMT.

④ den Differenzdruckregler mit

Volumenstrom-begrenzung AVPBT(-F).

⑤ Volumenstrom-, Differenzdruck- und

Temperaturregler.

Montage

Zulässige Einbaulagen ❷

Thermostat mit Ventil

- Mit Ventil VG(F) oder VGU(F):

• Einbaulage beliebig ①.

- Mit Ventil VGS:

• Mediumstemperaturen bis 160 °C:

Einbaulage beliebig ②.

• Mediumstemperaturen > 160 °C:

Einbau nur in waagerechte Rohrleitung

mit nach unten hängendem Antrieb

zulässig ③.

Zulässige Einbaulagen mit AVQT, AVQMT

und AVPBT(-F) - siehe entsprechende

Bedienungsanleitung.

Temperaturfühler

- Das Verbindungsrohr darf nicht verdreht

oder geknickt werden. Der min. Biegeradius

beträgt 50 mm ④.

- Der Einbauort ist so zu wählen, dass die

Temperatur des Mediums direkt und ohne

Verzögerung erfasst wird. Überhitzung des

Temperaturfühlers muss vermieden werden.

- Der Temperaturfühler muss mit seiner

ganzen Länge in das Medium eintauchen.

Thermostat mit Fühlern 170mm, R½” und

210mm, R¾”:

- Die Einbaulage des Temperaturfühlers ist

beliebig ⑤.

Thermostat mit Fühlern 255mm, R¾”:

- Der Temperaturfühler muss wie in der

Abbildung gezeigt eingebaut werden ⑥.

Einbauort, Einbauschema ➌

• AVT/Ventil ①, AVT/AV T/Ventil ② Einbau im

Rücklauf.

• AVT/Venitl ③, AVT/AV T/Ve ntil ④ Einbau im

Vorlauf.

Einbau Ventil ➍

1. Rohrleitung vor der Montage reinigen.

2. Es ist empfehlenswert einen

Schmutzfänger ① vor dem Regler

einzubauen.

3. Temperaturanzeiger vor und hinter den

entsprechenden Anlageteilen einbauen.

4. Ventil einbauen

• Durchflussrichtung ② auf dem Typenschild

oder Ventil ③ beachten.

• Ventil mit angeschraubten

Anschweißenden nur an die Rohrleitung

anheften ④.

Das Einschweißen der Anschweißenden

ist nur ohne Ventil und Dichtungen

zulässig! ⑤⑥

Bei Nichtbeachtung zerstören die hohen

Schweißtemperaturen die Dichtungen des

Ventils.

• Flansche ⑦ in der Rohrleitung müssen

parallel, Dichtflächen sauber und ohne

Beschädigungen sein.

Schrauben über Kreuz in 3 Stufen bis zum

max. Drehmoment anziehen (50 Nm).

5. Achtung:

Mechanische Belastungen des Ventilgehäuses

durch die Rohrleitungen sind nicht zulässig ⑧.

Montage Thermostat ❺

Vor der Montage des Thermostaten die Anlage

füllen, in Betrieb nehmen und Dichtheits- und

Druckprüfung durchführen, siehe ❽.

Thermostat AVT oder Kombinationsstück ③ am

Ventil einbauen ② und Überwurfmutter mit

Gabelschlüssel SW 50 anziehen.

Anzugsmoment 35Nm.

Isolierung ❻

Inbetriebnahme ❼

Ventile VG, VGF und VGS ① sind ohne

Thermostat geöffnet (NO).

Füllen der Anlage und Dichtheits- und

Druckprüfungen sollten ohne eingebauten

Thermostaten ② durchgeführt werden.

Ventile VGU und VGUF ③ sind ohne

Thermostat geschlossen (NC).

Füllen der Anlage und Dichtheits- und Druck-

prüfungen sollten ohne eingebauten Thermostaten ④ durchgeführt werden.

Füllung der Anlage, Inbetriebnahme ❽

1. Absperrarmaturen ① im Vorlauf langsam

öffnen.

2. Abperrarmaturen ② im Rücklauf langsam

öffnen.

Dichtheits- und Druckprüfung

Druckerhöhung muss am +/- Anschluss

gleichmäßig erfolgen.

Nichtbeachtung kann zu Schäden am Antrieb

und/oder Ventil führen.

Die Druckprüfung der Anlage muss nach den

Vorgaben des Anlagenherstellers durchgeführt

werden.

Max. Prüfdruck ist: 1,5 × PN

PN siehe Typenschild!

Außerbetriebnahme

1. Absperrarmaturen ① im Vorlauf langsam

schließen.

2. Absperrarmaturen ② im Rücklauf langsam

schließen.

Einstellung Sollwerte ❾

Temperatureinstellung

Temperaturanzeige beachtenl ①.

Voraussetzungen:

Die Anlage muss geöffnet und ein Durchfluss

des Mediums gewährleistet sein.

Vorgehensweise:

• Den geforderten Sollwert durch Drehen des

Sollwertstellers einstellen ②.

- Linksdrehung erhöht den Sollwert.

- Rechtsdrehung reduziert den Sollwert.

• Die Stellung des Sollwertstellers auf dem

Skalenwert ③ bedeutet:

1 niedrigster Sollwert

5 maximaler Sollwert

• Temperaturanzeige beachten ⑤.

• Nach einer Sollwertverstellung ca. 3 – 5 Min.

abwarten, bis die Temperaturanzeige den

Endwert anzeigt.

• Wird das Gerät als Temperaturwächter

eingesetzt, muss der Sollwertsteller ② durch

Plombierdraht gesichert werden ④.

Einstelldiagramm ❿

Temperatureinstellung

Verhältnis zwischen den Skalenmarkierungen

1–5 und der Temperatur.

Die angegebe nen Werte sind nur

Richtwerte.

Abmessungen, Gewichte ⓫

1)

Kegeliges Außengewinde nach EN 10226-1

2)

Flansche PN 25, nach EN 1092-2

VI.GC.W3.8N

© Danfoss | 2017.08 | 7

AVT

ESPAÑOL

Notas de seguridad

Antes del montaje y de la puesta en

marcha, para evitar daños personales y

perjuicios en los dispositivos, es absolutamente

necesario leer cuidadosamente estas

instrucciones.

El montaje, la puesta en marcha y el trabajo

de mantenimiento necesario deberán ser

realizados solo por personal cualificado y

autorizado.

Antes del montaje y el trabajo de

mantenimiento del controlador, el sistema debe

ser:

- despresurizado

- enfriado,

- vaciado y

- limpiado.

Por favor, cumpla con las instrucciones del

fabricante del sistema o del operador del

sistema.

Instucciones de eliminación

Este producto deb e ser desmontado y si es

posible, sus componentes d eben ser

separados en varios grup os antes de su reciclado o

destrucción.

Siga siempre la regulació n local sobre

eliminación.

Aplicaciones

El actuador de temperatura , en combinación

con las válvulas Danfoss y los reguladores

Danfoss, se utiliza para el control de la

temperatura del agua y mezcla agua/glicol

en sistemas de Calefacción, District Heating y

Refrigeración. Los reguladores de temperatura

(Actuador de temperatura con válvula) con

el actuador de temperatura AVT han sido

probados de acuerdo a EN 14597 y cumplen con

las exigencias de seguridad para el control de

temperatura y limitaciones de temperatura en

sistemas de calefacción.

Los parámetros técnicos en la etiquetas del

producto determinan su uso.

Ejemplos de aplicación ➊

Actuador de temperatura AVT se puede

combinar con:

① Válvulas VG(F), VGU(F) y VGS.

② Piezas de combinación K2, K3 y válvulas

mencionadas arriba.

③ Reguladores de caudal AVQT y Reguladores

de caudal con válvula de control integrada

AVQMT.

④ Regulador de presión diferencial con

limitación de caudal y ajuste fijo AVPBT(-F).

⑤ Regulador AVPQT de presión diferencial,

caudal y temperatura.

Montaje

Posiciones permitidas de instalación ❷

Actuador de temperatura con válvulas

- En combinación con válvulas VG(F) ó VGU(F):

• Se pueden instalar en cualquier

posición ①.

- En combinación con válvulas VGS:

• Temperatura del medio hasta 160 ºC:

Puede ser instalado en cualquier

posición ②.

• Temperatura del medio > 160 °C:

Instalación permitida sólo en horizontal

con el actuador hacia abajo ③.

Posiciones permitidas e n combinación

con AVQT, AVQMT and AVPBT(-F) - véase

instrucciones correspondientes.

Sensor de temperatura

- El tubo capilar no puede doblarse ni torcerse.

El radio de flexión mínimo es 50 mm ④.

- El lugar de la instalación debe ser escogido

de forma que la temperatura del medio

pueda ser medida directamente. Evite

sobrecalentamiento del sensor de

temperatura.

- El sensor de temperatura debe estar

completamente sumergido en el medio.

Sonda de temperaturade 170 mm R½” y 210

mm R¾”:

- La sonda de temperatura se puede instalar

en cualquier posición ⑤.

Sonda de temperatura con de 255 mm R¾”:

- La sonda de temperatura se debe instalar

como se muestra en la figura ⑥.

Posición de Instalación y Esquema de

Instalación

• AVT/válvula ①, AVT/AVT/ válvula ② Montaje

en retorno

• AVT/válvula ③, AV T/AVT/válvul a ④ Montaje

en impulsión

➌

Instalación de la válvula ➍

1. Limpie el sistema de tuberías antes del

montaje.

2. Se recomientda la instalación de un filtro

delante del controlador ①.

3. Instale indicadores de temperatura en la

parte del sistema a controlar.

4. Instale la válvula

• Observe la dirección del caudal indicada

en la etiqueta del producto o en la válvula

② ③.

• La válvula con conectores para soldar solo

pueden ser fijados a la tubería ④.

Los conectores para soldar solo pueden

soldarse sin la válvula y sin sellos! ⑤⑥

Si estas instrucciones no se tienen en

cuenta, las altas temperaturas al soldar

pueden destruir los sellos.

• Las bridas ⑦ en la tubería deben estar

en posición paralela y las superficies que

sellan deben estar limpias y sin ningún

daño.

Apriete los tornillos en las bridas en

diagonal en 3 pasos hasta el máximo

(50 Nm).

5. Precaución:

No se permiten cargas mecánicas del cuerpo de

la válvula por las tuberías ⑧.

Montaje del actuador de temperatura ❺

Antes del montaje del actuador, realice el

llenado del sistema, la primera puesta en

marcha y la prueba de presión y escapes,

véase ❽.

Coloque el actuador de temperatura AVT en el

diafragma y apriete la tuerca de unión con una

llave SW50. Torque 35 Nm.

Aislamiento ❻

No aísle el actuador de temperatura ni la

válvula.

Puesta en marcha ❼

Válvulas VG, VGF y VGS ① son

normalmente abiertas (NO).

El llenado del sistema y las pruebas de presión

y escapes se deben realizar sin tener el

actuador ② de temperatura montado.

VálvulasVGU y VGUF ③ son normalmente

cerradas (NC).

El llenado del sistema y las pruebas de presión y

escapes se deben realizar sin tener el actuador

④ de temperatura montado.

Llenado del sistema, primera puesta en

marcha

1. Abra lentamente los dispositivos de corte ①

2. Abra lentamente los dispositivos de corte ②

Escapes y pruebas de presión

El incumplimiento puede causar daños en el

actuador o la válvula.

Una prueba de presión del sistema completo

debe ser realizada de acuerdo con las

instrucciones del fabricante.

La presión máxima de prueba es: 1,5 × PN

PN ver etiqueta del producto!

Fuera de operación

1. Cierre lentamente los dispositivos de

2. Cierre lentamente los dispositivos de

❽

en la tubería de impulsión.

en la tubería de retorno.

La presión debe aum entar graduelmente

en los lados +/- de la válvula.

corte ① en la tubería de impulsión.

corte ② en la tubería de retorno.

Ajustes ❾

Ajuste de temperatura

Los rangos de ajuste de temperatura ①.

Condiciones previas:

EL sistema debe estar abierto y el caudal

garantizado.

Procedimiento:

• Fije el punto ajuste deseado girando el

mando de ajuste ②.

- Girando a la izquierda aumenta el punto de

ajuste.

- Girando a la derecha disminuye el punto de

ajuste.

• La posición del mando de ajuste en la

escala de valores ③ significa:

1 mínimo punto de ajuste

5 máximo punto de ajuste

• Observe el indicador de temperatura ⑤.

• Espere entre 3 y 5 min. para que el

indicador de temperatura muestre el valor

final.

• Si el dispositivo se utiliza como monitor de

la temperatura, el mando de ajuste ② se

debe sellar con un alambre lacrado ④.

Diagrama de ajuste ❿

Ajuste de la temperatura

Relación entre los valores 1 a 5 de la escala y la

temperatura de cierre.

Los valores indicados son aprox imados.

Dimensiones, Pesos ⓫

1)

Rosca externa cónica acc. to EN 10226-1

2)

Bridas PN 25, acc. to EN 1092-2

8 | © Danfoss | 2017.08

VI.GC.W3.8N

AVT

afgevoerd op een milieuverantwoorde

wijze. Apparatuur die elektrische onderdelen

Voor toegestane installatieposities in

combinatie met AVQT, AVQMT en

NEDERLANDS

Veiligheidsvoorschriften

Alvorens een begin wordt gemaakt met

de montage en inbedrijfstelling is het

absoluut noodzakelijk dat deze instructies

zorgvuldig worden gelezen en opgevolgd om

letsel en schade aan de apparatuur te

voorkomen.

Montage-, inbedrijfstellings- en

onderhoudswerkzaamheden moeten worden

uitgevoerd door voldoende gekwalificeerd

personeel.

Zorg ervoor dat voor de start van montageof onderhoudswerkzaamheden het systeem

voldoet aan de volgende voorwaarden:

- drukloos

- afgekoeld

- geleegd

- schoongemaakt.

Neem alle instructies betreffende

installatiecomponenten van andere fabrikaten

in acht.

Afvalverwerking

Dit product of d elen ervan dien en te worden

bevat, mag niet samen met huishoudelijk afval

worden afge voerd.

Deze apparatuur m oet apart worden ingezamel d

samen met ander elektrisch en elektronisch afval

conform de geldende we tgeving.

Toepassing

De temperatuurregelaar wordt, in combinatie

met Danfoss regelafsluiters en Danfoss

regelcombinaties, toegepast voor de

temperatuurregeling van water of water-glycol

mengsels van verwarmings-, stadsverwarmingsen koelinstallaties. De regelingen

(temperatuurregelaars met regelafsluiters)

met de AVT temperatuurregelingen zijn

getest volgens EN 14597 en voldoen aan

de veiligheidseisen die mogen worden

gesteld aan temperatuurregelaars

en temperatuurbegrenzers in

verwarmingssystemen.

De technische gegevens zoals vermeldt op het

product zijn bepalend voor de toepassing.

Installatie voorbeelden ➊

De temperatuurregelaar AVT kan worden

gecombineerd met:

① VG(F), VGU(F) en VGS regelafsluiters.

② Combinatie adapters K2, K3 en de

regelafsluiters zoals hierboven vermeld.

③ Volumestroomregelaar AVQT en

volumestroomregelaar met geïntegreerde

regelafsluiter AVQMT.

④ Drukverschilregelaar AVPBT(-F) met vaste

volumestroombegrenzing.

⑤ Verschildruk, flow en temperatuurregelaar

AVPQT.

Montage

Toegestane montage posities ❷

Temperatuurregelaar met regelafsluiters

- In combinatie met VG(F) of VGU(F)

regelafsluiters:

• Kan in elke gewenste positie worden

geïnstalleerdn ①.

- In combinatie met VGS regelafsluiters:

• Mediumtemperatuur tot 160 °C:

Can be installed in any position ②.

• Mediumtemperatuur > 160 °C:

Montage alleen toegestaan in horizontale

leidingen met het regelelement

omlaagn ③.

AVPBT(-F): Zie de instructies bij de regelafslu iters.

Temperatuurvoeler

- De capillaire leiding mag niet worden

gedraaid of geknikt. De minimale buigradius

is 50 mm ④.

- De temperatuurvoeler moet zodanig worden

geplaatst dat de mediumtemperatuur

direct en zonder vertraging kan worden

gemeten. Vermijdt oververhitting van de

temperatuurvoeler.

- De temperatuurvoeler moet volledig in het

medium ondergedompeld zijn.

Temperatuurregelaars met voelers 170 mm

R½” en 210 mm R¾”:

- De temperatuurvoeler mag in elke gewenste

positie worden gemonteerd ⑤.

Temperatuurregelaars met voelers 255 mm

R¾”:

- De temperatuurvoeler moet worden

geïnstalleerd zoals getoond op de

afbeelding ⑥.

Principeschema’s ➌

• AVT + regelafsluiter ①, AVT + AVT +

regelafsluiter ② Montage in de retour.

• AVT + regelafsluiter ③, AVT + AVT +

regelafsluiter ④ Montage in de aanvoer

Installatie van de regelafsluiter ➍

1. Zorg dat de installatie schoon is.

2. Het toepassen van een filter voor de

regelafsluiter wordt sterk aanbevolen ①.

3. Monteer thermometers in het geregelde

deel van de installatie.

4. Monteer de afsluiter

• Er dient rekening te worden gehouden met

de stromingsrichting zoals vermeld op de

regelafsluiter of het productlabel ② ③.

• Een regelafsluiter met voorgemonteerde

laskoppelingen enkel met een puntlas

vastzetten ④.

De laskoppelingen mogen alleen worden

vastgelast nadat de regelafsluiter en

pakkingen zijn verwijderd. ⑤⑥

Als deze instructie wordt genegeerd

kunnen de hoge lastemperaturen

de pakkingen en de regelafsluiter

beschadigen.

• Flenzen ⑦ in de leiding moeten parallel

aan elkaar zijn en de aansluitingen moeten

vlak en onbeschadigd zijn.

Draai de schroeven in de flenzen kruislings

en in drie stappen aan tot het maximale

draaimoment (50 Nm).

5. Waarschuwing:

Mechanische belasting van het afsluiterhuis

door de leidingen is niet toegestaan ⑧.

Montage van de temperatuurregelaar ❺

Zorg ervoor dat alvorens over te gaan tot het

monteren van de temperatuurregelaar de

installatie is gevuld en afgeperst op lekken.

(Zie ❽).

Plaats de temperatuurregelaar AVT en draai de

6-kant aan met steeksleutel 50.

Het gewenste moment is 35 Nm.

Verzegeling ❻

In bedrijfstellen ❼

De regelafsluiter s VG, VGF en VGS ① zijn

normaal geopende (NO) regelafsluiters.

Het vullen en afpersen van de installatie dient te

geschieden voordat de temperatuurregelaar is

gemonteerd.

De afsluiters VGU en VGUF ③ zijn normaal

gesloten (NC) regelafsluiters.

Het vullen en afpersen van de installatie dient te

geschieden met open regelafsluiter.

De temperatuurregelaar ④ kan gemonteerd zijn

en zo ingesteld dat de afsluiter open is.

Het vullen van het systeem,

inbedrijfstellen

1. Draai langzaam de afsluiter open ① in de

aanvoer.

2. Draai langzaam de afsluiter open ② in de

retour.

❽

Afpersen

De druk moet aan b eide zijden van de

regelafsluiter gelijkmatig worden

verhoogd om schade a an de regelafsluiter of de

temperatuurregelaar te voorkomen.

De volledige installatie dient volledig te worden

afgeperst volgens de plaatselijk geldende

normen.

De maximale afpersdruk voor de regelafsluiters

is: 1,5 × PN

Voor PN - Zie afsluiterhuis of bijbehorende

documentatie.

Buiten gebruik stellen

1. Sluit langzaam de afsluiters ① in de aanvoer.

2. S Sluit langzaam de afsluiters ② in de retour.

Instellingen ❾

Temperatatuurinstelling

Het instelbereik van de AVT staat vermeld op

een sticker op het product ①.

Voorwaarden:

Alle afsluiters in het systeem moeten geopend

zijn en de volumestroom moet voldoende zijn.

Procedure:

• Stel de gewenste instelling in met de

instelknop ②.

- Met de klok mee draaien verhoogt de

instelling.

- Tegen de klok in draaien verlaag de

instelling.

• De schaal op de temperatuurregelaar ③

geeft aan:

1 minimale instelling

5 maximale instelling

• Lees de temperatuur af op de

thermometer ⑤.

• Wacht ongeveer 3 tot 5 minuten tot de

thermometer de definitieve waarde

aangeeft.

• Als de regelaar wordt gebruikt als

temperatuurbegrenzing moet de

instelknop ② worden verzegeld ④ .

Insteldiagram ❿

Temperatuurinstelling

Relatie tussen schaalwaarden 1-5 en

sluittemperatuur

De waarden zijn bij be nadering

Afmetingen, Gewicht ⓫

1)

Uitwendige draad volgens EN 10226-1

2)

Flenzen PN 25, volgens EN 1092-2

VI.GC.W3.8N

© Danfoss | 2017.08 | 9

AVT

SLOVENŠČINA

Varnostna opozorila

Izjemno pomembno je, da pred montažo

in zagonom skrbno preberete navodila in

se jih držite. S tem se izognete poškodbam ljudi

in okvaram na opremi.

Nujna sestavna, zagonska in vzdrževalna dela

lahko izvajajo samo kvalificirani, šolani in

pooblaščeni delavci.

Pred sestavo in vzdrževalnimi deli na regulatorju

mora biti sistem:

- tlačno izravnan,

- ohlajen,

- izpraznjen in

- očiščen.

Prosimo, upoštevajte navodila proizvajalca

sistema ali sistemskega operaterja.

Navodila za rokovanje z odsluženim

izdelkom

Pred recikliranjem ali odlaganj em

odsluženega izdelka na odpad, ga j e

potrebno razstaviti in njegove sestavne dele, če

je le mogoče, sortirati po sku pinah.

Vedno upoštevajte lokalno zakonod ajo glede

rokovanja z odpadki.

Opis naprave

Pogon temperaturnega regulatorja –

termostatski pogon – se uporablja skupaj

z Danfossovimi ventili in Danfossovimi

kombiniranimi regulatorji za regulacijo

temperature v sistemih ogrevanja, daljinskega

ogrevanja in hlajenja napolnjenih z vodo

ali z mešanico vode in glikola. Regulatorji

temperature (termostatski pogon in ventil) s

temperaturnim regulatorjem AVT so tipsko

odobreni skladno z EN 14597 in ustrezajo

varnostnim pogojem za regulacijo temperature

in omejevanje temperature v ogrevalnih

sistemih.

Tehnični podatki na etiketi izdelka določajo

uporabo.

Primeri uporabe ➊

Termostatski pogon AVT lahko kombinirate z:

① ventili VG(F), VGU(F) in VGS.

② kombinacijskimi kosi K2, K3 in zgoraj

navedenimi ventili.

③ regulatorji pretoka AVQT in regulatorji

pretoka in temperature z regul.

④ regulatorji diferenčnega tlaka in

omejevalniki pretoka s fiksno nastavitvijo dif.

tlaka AVPBT(-F).

⑤ Regulator diferencnega tlaka, pretoka in

temperature.

Montaža

Dopustni položaji vgradnje ❷

Termostatski pogon z ventili

- Kombiniran z ventili VG(F) ali VGU(F):

• Lahko se vgradi v kateremkoli položaju ①.

- Kombiniran z ventili VGS:

• Temperatura medija do 160 °C:

Lahko se vgradi v kateremkoli položaju ②.

• Temperatura medija > 160 °C:

Vgradnja dovoljena samo v horizontalni

položaj tako, da je pogon obrnjen

navzdol ③.

Dopustni položaj i vgradnje v kombinaciji z

regulatorji AVQT, AVQMT in AVPBT(-F) -

glejte ustrezna navodila.

Tipalo temperature

- Kapilara ne sme biti zavozlana ali

prepognjena. Minimalni polmer ukrivljanja je

50 mm ④.

- Mesto vgradnje je potrebno tako izbrati, da

se temperatura medija meri brez zakasnitve.

Izogibajte se pregrevanju temperaturnega

tipala.

- Temperaturno tipalo mora biti potopljeno v

medij po celotni dolžini.

Termostatski pogoni s tipali dimenzij 170 mm

R1/2” in 210 mm R¾”:

- Tipalo temperature sme biti vgrajeno v

katerikoli smeri ⑤.

Termostatski pogoni s tipalom dimenzije 255

mm R¾”:

- Tipalo temperature mora biti vgrajeno tako,

kot je prikazano na sliki ⑥.

Mesto vgradnje in shema vgradnje ➌

• AVT/ventil ①, AV T/AVT/ventil ② vgradnja v

povratek

• AVT/ventil ③, AV T/AVT/ventil ④ ventil

vgradnja v dovod

Vgradnja ventila ➍

1. Pred montažo očistite cevovod.

2. Močno priporočamo vgradnjo filtra pred

regulator ①.

3. V regulirani del sistema vgradite termometer.

4. Vgradite ventil

• Upoštevajte puščico na etiketi proizvoda

oz. na proizvodu samem, ki kaže smer

pretoka ② ③.

• Ventil z vgrajenimi varilnimi priključki se

lahko samo pritrdi na cevovod ④.

Varilni priključki so nato lahko polno

varjeni samo brez ventila in tesnil! ⑤⑥

Ob neupoštevanju teh navodil lahko visoke

temperature pri varjenju uničijo tesnila.

• Protiprirobnice ⑦ morajo biti vzporedne,

tesnilne površine morajo biti čiste.in brez

poškodb.

Pritegnite vijake na prirobnicah križem v

treh korakih do maksimalnega momenta

(50 Nm).

5. Opozorilo:

Mehanske obremenitve cevovoda na telo

ventila niso dovoljene ⑧.

Vgradnja termostatskega pogona ❺

Pred vgradnjo termostatskega pogona izvedite

Polnjenje sistema, prvi zagon in test Tesnosti in

tlaka, glejte ❽.

Termostatski pogon AVT prislonite na ventil

② ali kombinacijski kos ③ in privijte matico z

viličastim ključem SW 50. Moment 35Nm.

Izolacija ❻

Ne izolirajte termostata kakor tudi ne ventila.

Zagon ❼

Ventili VG, VGF in VGS ① so normalno

odprti ventili (NO).

Polnjenje sistema in test tesnosti in tlačni

preizkus se opravljajo brez termostatskega

pogona ②.

Ventili VGU in VGUF ③ so normalno zaprti

ventili (NC).

Polnenje sistema in Test tesnosti in tlačni

preizkus morajo biti opravljeni pri odprtem

ventilu. Montirajte termostat AVT ④ in ga

nastavite na najvišjo možno vrednost, tako da

bo ventil odprt.

Polnjenje sistema, prvi zagon ❽

1. Počasi odprite zaporne organe ① v dovodu.

2. Počasi odprite zaporne organe ② v

povratku.

Test tesnosti in tlaka

Na priključkih mo ra tlak naraščati

postopoma +/- .

Neskladnost z navodili lahko povzroči poškodbe

na pogonu ali na ventilu.

Tlačni preizkus celotnega sistema se mora

izvajati po navodilih proizvajalca..

Maksimalni preizkusni tlak je: 1.5 × PN

PN glejte napisno ploščico!

Jemanje iz obratovanja

1. Počasi zaprite zaporne organe ① v dovodu.

2. Počasi zaprite zaporne organe ② v povratku.

Nastavitev regulatorja ❾

Nastavitev temperature

Območje nastavljanja temperature je označeno

na napisni ploščici ①.

Predpogoji

Sistem mora biti odprt in pretok mora biti

garantiran.

Postopek:

• Nastavite želeno temperaturo z vrtenjem

nastavnega gumba ②.

- Vrtenje v levo povišuje nastavljeno točko.

- Vrtenje v desno znižuje nastavljeno točko.

• Položaj nastavnega gumba na skali ③

pomeni:

1 minimalna nastavitev

5 maksimalna nastavitev

• Opazujte termometer ⑤.

• Počakajte približno 3 do 5 minut dokler

termometer ne pokaže končne vrednosti

• Če uporabljate napravo za nadzor

temperature, plombirajte naastavni gumb ②

s pomočjo plombirne žice ④.

Nastavitveni diagram ❿

Nastavitev temperature

Povezava med števili skale 1–5 in zaporno

temperaturo.

Navedene vrednosti so p ribližne

Dimenzije, masa ⓫

1)

Konični zunanji navoj po EN 10226-1

2)

Prirobnice PN 25, glede na EN 1092-2

10 | © Danfoss | 2017.08

VI.GC.W3.8N

AVT

Přípustné instalační polohy v kombinaci s

AVQT, AVQMT a AVPBT(-F): viz odpovídající

ČESKY

Bezpečnostní informace

Z důvodu maximálního snížení možnosti

poranění osob nebo vzniku škod na

majetku je bezpodmínečně nutné se před

vlastní montáží a uvedením regulátoru do

provozu pečlivě seznámit se všemi zde

uvedenými bezpečnostními informaci.

Nezbytné montážní práce, kroky při uvádění

do provozu a opravy mohou provádět pouze

kvalifikovaní, proškolení pracovníci, kteří pro

tuto činnost byly určeni.

Před montáží nebo před případnou opravou

nebo servisem regulátoru je nutné, aby

regulovaný systém splňoval následující

podmínky:

- nebyl pod tlakem

- byl dostatečně ochlazen

- vyprázdněn a

- vyčištěn.

Postupujte podle návodu výrobce systému

nebo jeho provozovatele.

Pokyny pro likvidaci

Tento výrobek by měl být před re cyklací

nebo likvi dací rozebrán na součástky a ty

umístěny do různých skupin odpa du.

Vždy dbejte aktuálních pokynů místní legislativy.

Aplikační oblast

Pohon přímočinného regulátoru teploty,

v kombinaci s ventily Danfoss a různými

kombinacemi regulátorů Danfoss, je využíván

k regulaci teploty vody a směsi vody s

glykolem v systémech vytápění, v systémech

centralizovaného zásobování teplem a v

chladících systémech.

Přímočinné regulátory teploty (pohony a

ventily) spolu s pohonem přímočinného

regulátoru teploty AVT jsou typově testovány

podle normy EN 14597 a splňují bezpečnostní

požadavky kladené na regulaci teploty a

jednotky omezovačů teploty v topných

systémech.

Technické parametry uvedené na typovém

štítku výrobku určuji jeho použití.

Příklady použití ➊

Pohon přímočinného regulátoru teploty AVT je

možné kombinovat spolu s:

① Ventily VG(F), VGU(F) a VGS.

② Připojovacími díly K2, K3 a typy ventilů

uvedených výše.

③ Regulátory průtoku AVQT a regulátory

průtoku s integrovaným regulačním

ventilem AVQMT.

④ Regulátor diferenčního tlaku s omezováním

průtoku a pevným nastavením AVPBT(-F).

⑤ Regulátory diferenčního tlaku, průtoku a

teploty AVPQT.

Montáž

Přípustná instalační poloha ❷

Pohon přímočinného regulátoru teploty s

ventily

- V kombinaci s ventily VG(F) nebo VGU(F):

• Je možné je instalovat do jakékoliv

polohy ①.

- V kombinaci s ventily VGS:

• Teplota média do 160 °C:

Regulátor lze instalovat v jakékoliv

poloze ②.

• Teplota média vyšší než 160 °C:

Regulátor je možné instalovat pouze

na vodorovné části potrubí, kdy pohon

regulátoru směřuje dolů ③.

návody k použití.

Teplotní senzor

- Kapilární trubice nesmí být nikde

překroucená nebo zlomená. Poloměr stočení

kapiláry musí být minimálně 50 mm ④.

- Umístění musí být zvolené tak, aby teplota

měřeného média byla odečítaná okamžitě

bez prodlevy. Zabraňte přehřívání teplotního

senzoru.

- Teplotní senzor musí být do měřeného

média ponořen v celé své délce.

Pohon přímočinného regulátoru teploty se

senzorem 170 mm R½ ´´ a 210 mm R¾ ´´:

- Teplotní senzor je možné instalovat v

jakékoliv poloze ⑤.

Pohon přímočinného regulátoru teploty se

senzorem 255 mm R ¾ ”:

- Teplotní senzor je možné instalovat pouze v

polohách vyznačených na obrázku ⑥.

Umístění a schéma instalace ➌

• AVT/ventil ①, AV T/AVT/ventil ② Montáž na

přívodní větev

• AVT/ventil ③, AVT/AVT/ventil ④ Montáž na

přívodní větev

Instalace ventilu ➍

1. Před montáží vyčistěte potrubní systém.

2. Před regulátor doporučujeme nainstalovat

filtr ①.

3. Do části systému, která má být regulována,

nainstalujte indikátory teploty.

4. Nainstalujte ventil.

• Při montáži dejte pozor na to, aby na štítku

vyznačený směr proudění média odpovídal

skutečnosti ② ③.

• Ventil s s namontovanými navařovacími

koncovkami může být napojen pouze

přímo na potrubí ④.

Koncovky musí být navařovány bez těsnění

a připojeného ventilu! ⑤⑥

Jestliže nebude postupováno podle tohoto

návodu, tak může vysoká svařovací teplota

zničit těsnění.

• Příruby ⑦ na potrubí musí být k sobě

orientovány kolmo, kdy styčné těsnící

plochy musí být čisté a bez poškození.

Šrouby na přírubě dotahujte napříč a ve

třech krocích až do dosažení maximálního

kroutícího momentu (50 Nm).

5. Upozornění:

Ventil namontovaný na potrubí se nesmí

žádným způsobem mechanicky zatěžovat ⑧.

Montáž pohonu přímočinného

regulátoru teploty

Před montáží pohonu přímočinného regulátoru

teploty proveďte operace plnění systému,

první spuštění, zkoušku těsnosti a tlakovou

zkoušku ❽.

Pohon AVT ② umístěte na membránu a pomocí

klíče SW 50 utáhněte převlečnou matku.

Utahovací moment je 35Nm.

❺

Izolace ❻

Zahájení provozu ❼

Ventily VG, VGF a VGS ① jsou ve výchozím

stavu otevřené (NO).

Filling the system and Leak and pressure test

should be done without mounted temperature

actuator ② - valve has to be open.

Ventily VGU a VGUF ③ jsou ve výchozím

stavu zavřené (NC).

Plnění systému, tlakovou zkoušku a zkoušku

těsnosti je nutné provádět bez namontovaného

pohonu přímočinného regulátoru teploty..

Plnění systému, první spuštění ❽

1. Pomalu otevřete uzavírací armatury ①

přívodní větve.

2. Pomalu otevřete uzavírací armatury ②

vratné větve.

Tlaková zkouška a zkouška těsnosti

Tlak v +/- spojích musí být zv yšován

postupně.

Nedodržení tohoto postupu může způsobit

poškození pohonu nebo ventilu.

Tlaková zkouška celého systému se může

provádět pouze podle návodu výrobce systému.

Maximální povolený zkušební tlak je: 1,5 × PN

Hodnota PN je uvedená na typovém štítku

výrobku!

Odstavování

1. Pomalu uzavřete uzavírací armatury ①

přívodní větve.

2. Pomalu uzavřete uzavírací armatury ②

vratné větve.

Nastavení ❾

Nastavení teploty

Rozsah nastavení teplot je vyznačen na

typovém štítku výrobku ①.

Počáteční podmínky

Systém musí být otevřen a musí v něm být

zaručen průtok média.

Postup:

• Požadovanou hodnotu nastavení zvolte

otočením ovladače ②.

- Otáčením doleva hodnotu nastavení

zvyšujete.

- Otáčením doprava hodnotu nastavení

snižujete.

• Nastavení ovladače na hodnotu vyznačenou

na stupnici ③ znamená:

1 minimální hodnota nastavení

5 maximální hodnota nastavení

• Zkontrolujte hodnotu na indikátoru

teploty ⑤.

• Počkejte asi 3 až 5 minut, než se teplota

ustálí na konečné hodnotě.

• Jestliže je zařízení používáno pro sledování

teploty, tak je nutné ovladač ② zaplombovat

pomocí plombovacího drátku ④.

Diagram nastavení ❿

Nastavování teploty

Vztah mezi čísly 1–5 na stupnici a uzavírací

teplotou.

Uvedené hodnot y jsou pouze orientační.

Rozměry, Hmotnost ⓫

1)

Kónický vnější závit dle normy EN 10226-1

2)

Příruba PN 25 dle normy EN 1092-2

VI.GC.W3.8N

© Danfoss | 2017.08 | 11

AVT

Ten produkt powinien być rozebrany a jeg o

komponenty posegregowane, jeśli to

możliwe, na różne grupy przed poddaniem

są zaworami

POLSKI

Warunki bezpieczeństwa

W celu uniknięcia zranienia osób i

uszkodzenia urządzeń należy

bezwzględnie przed montażem i

uruchomieniem zaworu zapoznać się dokładnie

z niniejszą instrukcją.

Czynności związane z montażem,

uruchomieniem i obsługą mogą być

dokonywane wyłącznie przez osoby

uprawnione i odpowiednio wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ostudzić urządzenie,

- opróżnić układ,

- oczyścić.

Prosimy stosować się do instrukcji producenta

lub operatora układu.

Instructiuni de dispensare

recyklingowi lub utylizacji.

Zawsze stosuj się do miejscowych pr zepisów w

zakresie usuwania odpadów.

Zastosowanie

Siłownik termiczny, w połączeniu z zaworami

i regulatorami Danfoss, służy do regulowania

temperatury wody lub mieszaniny wody z

glikolem w instalacjach grzewczych, sieciach

cieplnych i układach chłodzenia.

Regulatory temperatury (zawory z siłownikami

termicznymi) z siłownikiem termicznym

AVT poddawane są badaniom typu wg

EN 14597 i spełniają wymogi bezpieczeństwa,

dotyczące urządzeń do regulacji i ograniczania

temperatury w instalacjach grzewczych.

Dane techniczne na tabliczce znamionowej

określają zakres zastosowań

Przykłady zastosowań ➊

Siłownik termiczny AVT można połączyć z:

① Zaworami VG(F), VGU(F) i VGS.

② Łącznikami kombinacyjnymi K2, K3 i

wymienionymi wyżej zaworami.

③ Regulatorem przepływu AVQT oraz z

regulatorem przepływu ze zintegrowanym

zaworem regulacyjnym AVQMT.

④ Regulatorem różnicy ciśnień z

ograniczeniem przepływu o stałej astawie

AVPBT(-F).

⑤ Regulatorem różnicy ciśnień, przepływu

dodając funkcję regulacji temperatury

AVPQT.

Montaż

Dopuszczalne pozycje montażu ❷

Siłownik termiczny z zaworami

- W połączeniu z zaworami VG(F) lub VGU(F):

• Montaż w dowolnej pozycji ①.

- W połączeniu z zaworami VGS:

• Temperatury czynnika do 160 °C:

montaż w dowolnej pozycji ②.

• Temperatury czynnika > 160 °C:

montaż dozwolony tylko na rurociągu

poziomym, z siłownikiem skierowanym w

dół ③.

Dopuszczal ne pozycje montażu w

połączeni u z AVQT, AVQMT i AVPBT-F -

patrz. odpowiednie instrukcje.

12 | © Danfoss | 2017.08

Czujnik temperatury

- Rurka kapilarna nie może być skręcona ani

wybrzuszona. Minimalny promień gięcia

wynosi 50 mm ④.

- Miejsce montażu musi być tak dobrane,

aby temperatura czynnika była odbierana

natychmiastowo, bez żadnej zwłoki. Unikać

przegrzewania czujnika temperatury.

- Czujnik temperatury musi być zanurzony w

czynniku na całej swojej długości.

Siłowniki termiczne z czujnikami 170 mm R ½”

i 210 mm R ¾”:

- Czujnik temperatury można montować w

dowolnej pozycji ⑤.

Siłowniki termiczne z czujnikami 255 mm

R ¾ ”:

- Czujnik temperatury należy zamontować w

sposób przedstawiony na rysunku ⑥.

Miejsce i schemat montażu ➌

• AVT/zawór ①, AVT/AV T/zawór ② montaż na

rurociągu powrotnym

• AV T/za wór ③, AV T/AVT/ zawór ④ montaż na

rurociągu zasilającym

Montaż zaworu ➍

1. Przed zamontowaniem zaworu przepłukać

instalację.

2. Przed regulatorem zamontować filtr ①.

3. Zamontować wskaźniki temperatury

(termometry) w tej części układu, która

będzie regulowana.

4. Zamontować zawór

• Należy zachować kierunek przepływu

zaznaczony na tabliczce znamionowej lub

na korpusie zaworu ② ③.

• Zawór z zamocowanymi końcówkami do

przyspawania może być tylko punktowo

przyspawany do rurociągu ④.

Końcówki mogą być przyspawane tylko

bez zaworu i uszczelnienia! ⑤⑥

Niezastosowanie się do tego zalecenia

może spowodować uszkodzenie

uszczelnień wskutek wysokiej temperatury.

• Kołnierze ⑦ na rurociągu muszą być

równoległe a powierzchnie pod uszczelki

czyste i bez uszkodzeń.

Dokręcać śruby przy kołnierzach po

przekątnej, w trzech krokach, aż do

uzyskania maksymalnego momentu (50 Nm).

5. Uwaga:

Nie można dopuścić do powstania

mechanicznych obciążeń korpusu zaworu od

rurociągów ⑧.

Montaż siłownika termicznego ❺

Przed zamontowaniem siłownika należy

przeprowadzić napełnienie i rozruch układu

oraz próby szczelności i ciśnieniowe, patrz. ❽.

Zamontuj siłownik termiczny AVT na zaworze

② lub regulatorze i dokręcić nakrętkę łączącą

kluczem SW 50. Moment 35Nm.

Izolacja ❻

Siłownik ani zawór nie może być izolowany.

Uruchomienie ❼

Zawory VG, VGF oraz VGS ① są zaworami

normalnie otwartymi (NO) .

Napełnienie oraz próby szczelności i

ciśnienia układu należy przeprowadzić bez

zamontowanego siłownika termicznego.

Zawory VGU oraz VGUF ③

normalnie zamkniętymi (NC).

Napełnianie i próby szczelności i cisnienia

układu należy przeprowadzić przy otwartym

zaworze. Siłownik termiczny może być

zamontowany ale nastawa musi utrzymać zawór

w pozycji otwartej.

Napełnienie układu, pierwsze

uruchomienie

1. Powoli otworzyć zawory odcinające ① na

rurociągu zasilającym.

2. Powoli otworzyć zawory odcinające ② na

rurociągu powrotnym.

❽

Próby szczelności i ciśnienia

Ciśnienie po stronie +/- zaworu nale ży

zwiększać stopniowo.

Nie zastosowanie się do powyższego może

spowodować uszkodzenie siłownika lub zaworu.

Próba ciśnienia dla całego układu musi

być przeprowadzona zgodnie z instrukcją

producenta lub projektanta.

Maksymalne ciśnienie próbne dla zaworów

wynosi: 1,5 × PN

Ciśnienie nominalne PN podano na tabliczce

znamionowej urządzenia.

Odłączenie zaworu

1. Powoli zamknąć armaturę odcinającą ① na

rurociągu zasilającym.

2. Powoli zamknąć armaturę odcinającą ② na

rurociągu powrotnym.

Nastawy ❾

Nastawa temperatury

Wartość nastawionej temperatury można

pośrednio odczytać z położenia skali

nastawnika ①.

Warunki wstępne

Układ musi pracować w trakcie zadawania

nastawy.

Tok postępowania:

• Dokonać ustawienia obracając pokrętłem

nastawczym ②.

- Obracanie w lewo zwiększa wartość

nastawy.

- Obracanie w prawo zmniejsza wartość

nastawy.

• Pozycja położenia pokrętła nastawczego na

skali ③ oznacza:

1 nastawa minimalna

5 nastawa maksymalna

• Obserwować wskaźnik temperatury

(termometr) ⑤.

• Odczekać około 3 do 5 min. aż wskaźnik

temperatury pokaże ostateczną wartość.

• Jeżeli urządzenie ma służyć do

kontrolowania temperatury, wówczas

pokrętło nastawcze ② należy zaplombować

④.

Schemat nastaw ❿

Nastawianie temperatury

Zależność między skalą 1–5 i temperaturą

zamknięcia.

Podane wartości są prz ybliżone.

Wymiary, Ciężar ⓫

1)

Stożkowy gwint zewnętrzny wg EN 10226-1

2)

Kołnierze PN 25 wg EN 1092-2

VI.GC.W3.8N

AVT

surūšiuotos, jei įmanoma, pagal atskiras

LIETUVIŲ KALBA

Saugumo reikalavimai

Iki montavimo ir paleidimo būkite

atsargūs, kad nesusižeistumėte ir

nesugadintumėte prietaisų, būtina nuodugniai

perskaityti ir laikytis šių instrukcijų.

Prietaisų montavimą, paleidimą bei priežiūrą

privalo vykdyti tiktai kvalifikuoti, apmokyti ir

įgalioti tokius darbus atlikti specialistai.

Prieš pradedant montavimo ir priežiūros darbus

sistema turi būti paruošta:

- kad joje nebūtų slėgio,

- ataušinta,

- ištuštinta ir

- išvalyta.

Rekomenduojame laikytis sistemos gamintojų

arba sistemos operatoriaus instrukcijų.

Utilizācijas instrukcija

Šis gaminys turi būti išmontuotas ir jo dal ys

medžiagų grupes, prieš sunaikinant.

Vadovaukitės vietinėmis sunaikinimo

nuostatomis.

Pritaikymas

Temperatūros pavara kartu su Danfoss

vožtuvais ir Danfoss reguliatoriais naudojama

temperatūrai reguliuoti šildymo, centralizuoto

šildymo bei aušinimo sistemose, kur terpė yra

vanduo ar gliukolio tirpalas. Temperatūros

reguliatoriai (temperatūros pavaros su

vožtuvais) su temperatūros pavara AVT turi

tipo sertifikatą pagal EN 14597 ir atititinka

saugumo reikalavimus, keliamus temperatūros

reguliavimo ir temperatūros apribojimo

prietaisams šildymo sistemose.

Techniniai parametrai yra nurodyti ant produkto

žymėje.

Pritaikymo pavyzdžiai ➊

Temperatūros pavara gali būti naudojama

derinyje su:

① VG(F), VGU(F) ir VGS vožtuvais.

② Derinių komplektai K2, K3 ir vožtuvai

paminėti aukščiau.

③ Srauto reguliatoriai AVQT ir srauto

reguliatoriai su integruotu vožtuvu AVQMT.

④ Slėgio perkryčio reguliatoriai su srauto

apribojimu ir fiksuotu nustatymu AVPBT(-F).

⑤ Slėgio perkryčio, srauto ir temperatūros

reguliatorius AVPQT.

Montavimas

Leistinos montavimo padėtys ❷

Temperatūros pavara su vožtuvais

- Derinyje su VG(F) arba VGU(F) vožtuvais.

• Gali būti montuojami bet kurioje

padėtyje ①.

- Derinyje su VGS vožtuvais:

• Terpės temperatūra iki 160 °C:

Galima montuoti bet kurioje padėtyje ②.

• Terpės temperatūra > 160 °C:

Montavimas leistinas tiktai horizontaliame

vamzdyne, kai pavara pritvirtinta padėtyje

- žemyn ③.

Leistinos montavimo padė tys derinyje su

AVQT, AVQMT ir AVPBT(-F) - žiūrėkite

atitinkamas instrukcijas.

Temperatūros daviklis

- Kapiliarinio vamzdelio negalima persukti

arba sulenkti. Minimalus sulenkimo

spindulys yra 50 mm ④.

- Vieta montavimui turi būti parenkama taip,

kad terpės temperatūra būtų tiesiogiai

matuojama be jokio uždelsimo.

- Temperatūros daviklis turi būti panardintas į

terpę visu savo ilgiu.

Temperatūros pavaros su davikliais 170 mm R

½” ir 210 mm R ¾”:

- Temperatūros daviklį galima montuoti bet

kurioje padėtyje ⑤.

Temperatūros pavaros su davikliais 255 mm

R ¾ ”:

- Temperatūros daviklį būtina montuoti taip,

kaip parodyta paveikslėlyje ⑥.

Montavimo vieta ir montavimo schema ➌

• AVT/vožtuvas ①, AV T/AVT/vož tuvas ②

montuojami grąžinimo vamzdyne

• AVT/vožtuvas ③, AVT/AV T/vo žtuv as ④

montuojami tiekimo vamzdyne

Vožtuvo montavimas ➍

1. Išvalykite vamzdyną prieš pradėdami

montavimą.

2. Labai rekomenduojame sumontuoti filtrą

priešais reguliatorių ①.

3. Sumontuokite temperatūros indikatorius

toje sistemos dalyje, kuri bus reguliuojama.

4. Sumontuokite vožtuvą.

• Būtina laikytis srauto krypties, kuri

nurodyta ant etiketės ar ant vožtuvo ②③.

• Privirinimui skirti atvamzdžiai tik

pritvirtinami ④.

Privirinami fitingai gali būti virinami tiktai

be vožtuvo ir tarpinių ⑤⑥

Jeigu nesilaikysite šių reikalavimų, aukšta

temperatūra gali pažeisti įrenginį.

• Flanšai ⑦ vamzdyne turi būti lygiagretūs,

sandarinimo vietos turi būti švarios ir be

pažeidimų.

Užveržkite varžtus flanšuose kryžmai

per 3 žingsnius iki maksimalaus sukimo

momento (50 Nm).

5. Dėmesio:

Mechaninės vožtuvo korpuso apkrovos

neleistinos ⑧.

Temperatūros pavaros montavimas ❺

Prieš montuojant pavarą, pirmiausia įvykdykite

Sistemos pripildymo, Pirmo paleidimo

reikalavimus ir atlikite pralaidumo ir slėgio

testus ❽.

Uždėkite temparatūros pavarą AVT ant

diafragmos ir užveržkite jungiamą ją veržlę su

veržliarakčiu SW 50. Sukimo momentas 35Nm.

Insulation ❻

Nereikia izoliuoti temperatūros vožtuvo ir

pavaros.

Paleidimas ❼

Vožtuvai VG, VGF ir VGS ① yra normaliai

atidaryti (NO) vožtuvai.

Sistemos pripildymas, slëgioir pralaidumo

bandymai turi bûti atliekami be termostatinio

elemento.

Vožtuvai VGU ir VGUF ③ yra normaliai

uždaryti (NC) vož tuvai.

Pripildant sistemą, pralaidumo ir slėgio

bandymai turėtų būti atliekami, vožtuvui

esant atidarytam. Temperatūros pavarą

galima sumontuoti ir nustatyti , vožtuvui esant

atidarytam.

Sistemos pripildymas, pirmasis

paleidimas

1. Iš lėto atidarykite uždarymo įrenginius ①

tiekimo vamzdyne.

2. Iš lėto atidarykite uždarymo įrenginius ②

grąžinimo vamzdyne.

❽

Pralaidumo ir slėgio bandymai

Slėgis turi būti palaipsniui didinamas prie

+/- sujungimo.

Neatitikimas gali sukelti pavaros arba vožtuvo

gedimus.

Visos sistemos slėgio bandymas turi būti

vykdomas, remiantis gamintojo instrukcijomis

Maksimalus bandymo slėgis yra: 1,5 × PN

PN - žiūrėkite žymę ant gaminio!

Darbo nutraukimas

1. Iš lėto uždarykite uždarymo įrenginius ①

tiekimo vamzdyne.

2. Iš lėto uždarykite uždarymo įrenginius ②

grąžinimo vamzdyne.

Palaikomos vertės nustatymas ❾

Temperatūros nustatymas

Temperatūros nustatymo ribos nurodytos ant

gaminio žymės ①.

Išankstinės sąlygos

Sistema turi būti atidaryta ir užtikrintas terpės

srautas.

Procedūra:

• Nustatykite norimą vertę, pasukdami

nustatymo rankenėlę ②.

- Pasukus į kairę, vertė didėja.

- Pasukus į dešinę, vertė mažėja.

• Nustatymo rankenėlės padėtis vertės

skalėje ③ reiškia:

1 minimalus dydis

5 maksimalus dydis

• Stebėkite temperatūros indikatorių ⑤.

• Palaukite nuo 3 iki 5 minučių, kol

temperatūros indikatorius parodys galutinę

vertę.

• Jeigu įrenginys naudojamas kaip

temperatūros kontrolės prietaisas,

nustatymo rankenėlė ② turi būti

užplombuota plombavimo viela ④.

Reguliavimo diagrama ❿

Temperatūros nustatymas

Ryšys tarp skalės padalų 1–5 ir uždarymo

temperatūros.

Nurodytos reik šmės yra apytikslės

Matmenys, svoris ⓫

1)

Kūginis išorinis sriegis pagal EN 10226-1

2)

Flanšai PN 25, pagal EN 1092-2

VI.GC.W3.8N

© Danfoss | 2017.08 | 13

AVT

РУССКИЙ

Правила техники безопасности

Для предупреждения травматизма и

повреждения оборудования перед

началом производства работ по его

монтажу и вводу в эксплуатацию следует

изучить и соблюдать настоящую

инструкцию.

Монтаж, наладку и техническое

обслуживание оборудования может

выполнять только квалифицированный

персонал, имеющий допуск к таким

работам.

В целях соблюдения правил техники

безопасности перед началом работ по

монтажу или обслуживанию регулятора

необходимо произвести следующие

действия с трубопроводной системой:

- сбросить давление;

- охладить;

- опорожнить;

- прочистить.

При этом также должна соблюдаться

инструкция по эксплуатации системы.

Инструкция по утилизации

Перед переработкой или ути лизацией

следует разобрать эт о устройство и

рассортировать его элементы по группам

материалов.

Всегда соблюдайте местные инструкция по

утилизации.

Область применения

Термостатический элемент в комбинации

с клапанами Danfoss используется для

регулирования температуры воды или

водного раствора гликоля в системах

централизованного теплоснабжения или

охлаждения.

Регуляторы температуры (термостатические

элементы AVT с клапанами) соответствуют

EN 14597 и отвечают всем требованиям

безопасности для регуляторов и

ограничителей температуры.

Условия применения регулятора

определяются техническими

характеристиками, указанными на этикетке

изделия.

Пример применения ➊

Термостатический элемент AVT может быть

использован в сочетании с:

① клапанами VG(F), VGU(F) и VGS;

② соединительными деталями К2, К3 и

упомянутыми выше клапанами;

③ регуляторами расхода AVQT и

комбинированными регулирующими

клапанами AVQMT;

④ регулятором перепада давлений с

ограничением расхода AVPBT(-F);

⑤ Комбинированный регулятор

температуры и перепада давлений с

функцией автоматического ограничения

расхода AVPQT.

Монтаж

Монтажные положения регулятора ❷

Регулятор температуры

- в комбинации с кланами VG(F) или

VGU В (F):

• может устанавливаться в любой

позиции ①.

- В комбинации с кланами VGS:

• при температуре регулируемой среды

до 160 °C:

может устанавливаться в любом

положении ②;

• при температуре регулируемой среды

выше 160 °C:

допускается устанавливать только

на горизонтальном трубопроводе

регулирующим элементом вниз ③.

Допустимые монтажные положения в

комбинации с AVQT, AVQMT и AVPBT(-F)

приведены в соответствующих

инструкциях.

Термочувствительный датчик

- Капиллярная трубка не должна быть

перекручена или согнута. Минимальный

радиус изгиба – 50 мм ④.

- Место установки датчика должно быть

выбрано таким образом, чтобы он

отражал среднюю температуру среды.

Необходимо исключить перегрев

термочувствительного датчика.

- Термочувствительный датчик должен

быть погружен в среду на полную длину.

Термостатический элемент с датчиком

170 мм R ½” и 210 мм R ¾”:

- может быть установлен в любой позиции

⑤.

Термостатический элемент с датчиками

255 мм R ¾”:

- следует устанавливать как показано на

рисунке ⑥.

Место и схема установки ➌

• AVT/клапан ①, AVT/AVT/клапан ② на

обратном трубопроводе.

• AVT/клапан ③, AVT/AVT/клапан ④ на

подающем трубопроводе

Монтаж клапана ➍

1. Перед монтажом клапана промойте

трубопроводную систему.

2. До регулятора (по ходу движения среды)

рекомендуется установка сетчатого

фильтра ①.

3. Установите в системе термометры для

контроля температуры.

4. Установка клапана

• Клапан устанавливается так, чтобы

направление стрелки на этикетке ②

или на его корпусе ③ совпадало с

направлением движения регулируемой

среды.

• Резьбовой клапан монтируется с

помощью приварных фитингов, которые

при установленном между ними клапане

должны предварительно фиксироваться

на трубопроводе прихваткой ④.

Окончательная приварка фитингов к

трубопроводу может производиться

только при отсутствии клапана и

уплотнительных прокладок! ⑤⑥

При несоблюдении этих инструкций

высокая температура сварки может

повредить уплотнения фитингов и сам

клапан.

• При применении фланцевого клапана

ответные фланцы ⑦ на трубопроводе

должны быть установлены параллельно

и их уплотняемые поверхности должны

быть чистыми и без повреждений.

Болты на фланцах следует затягивать

крестообразно в три этапа до

достижения максимального крутящего

момента (50 Nm).

5. Внимание!

Механические нагрузки на корпус клапана

от трубопроводов недопустимы ⑧.

Установка термостатического

элемента

Перед монтажом выполните заполнение

системы и первый пуск, проведите испытание

на прочность и герметичность ❽.

Установите термостатический элемент AVT на

клапан ② и затяните его гайку ключом SW 50.

Крутящий момент 35 Нм.

❺

Теплоизоляция ❻

Не допускается теплоизолировать клапан и

термостатический элемент.

Запуск ❼

Клапаны являютс я нормально

открытыми VG, VGF и VGS ①.

Заполнение системы, испытание на

прочность и герметичность должны

выполняться без термостатического

элемента.

Клапаны VGU and VGUF ③ являются

нормально закрытыми.

Заполнение системы, испытание на

прочность и герметичность следует

производить при полностью открытом

клапане регулятора температуры. Для этого

термостатический элемент должен быть

установлен на клапане и настроен так, чтобы

клапан оказался открытым.

Заполнение системы, первый пуск ❽

1. Медленно откройте запорное

устройство ① на подающем

трубопроводе.

2. Медленно откройте запорное устройство

② на обратном рубопроводе.

Испытания на прочность и

герметичность

Показания манометров,

установленных в точках +/-, должны

увеличиваться.

Если этого не происходит, то вероятно

поврежден клапан или регулирующий

элемент.

Испытания на герметичность всей системы

должны проводиться в соответствии

с инструкциями производителей

оборудования. Максимальное испытательное

давление определяется как: 1,5 Pу

Pу (PN) указывается на этикетках

оборудования.

Вывод из эксплуатации

1. Медленно закройте запорные

устройства ① на подающем

трубопроводе.

2. Медленно закройте запорные

устройства ② на обратном трубопроводе.

14 | © Danfoss | 2017.08

VI.GC.W3.8N

AVT

Установка значений регулируемых

величин

Установка температуры

Диапазон температур указан на этикетке ①.

Предварительное условие

Система должна быть открыта и обеспечено

поступление носителя.

Последовательность:

• Установите требуемое значение

• Цифры на шкале ③ настроечной рукоятки

1 – минимальное значение;

5 – максимальное значение.

• Следите за показаниями термометра ⑤.

• Подождите 3-5 мин. пока термометр

• После настройки рукоятка ② может

Шкала настройки ❿

Температурная настройка

Соотношение между делениями шкалы (1-5) и

температурой закрытия.

* мм (mm)

❾

температуры поворотом настроечной

рукоятки ②.

- Вращение рукоятки против часовой

стрелки увеличивает установленное

значение температуры.

- Вращение по часовой стрелки – снижает

установленное значение.

означают:

не покажет стабильное значение

температуры.

быть опломбирована пломбировочной

проволокой ④.

Указанные значения являются

приблизительными.

Габаритные и присоединительные

размеры

1)

Коническая наружная резьба

2)

Фланцы Pу 25 соответствуют EN 1092-2

⓫

соответствует EN 10226-1

VI.GC.W3.8N

© Danfoss | 2017.08 | 15

Danf

already on order pro

All trademarks in this material are property of the respec

AVT

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

16 | © Danfoss | DHS-SRMT/SI | 2017.08

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

73695160 / VI.GC.W3.8N

Loading...

Loading...