Danfoss AVQM Series, AVQMT Series Instructions Manual

Instructions

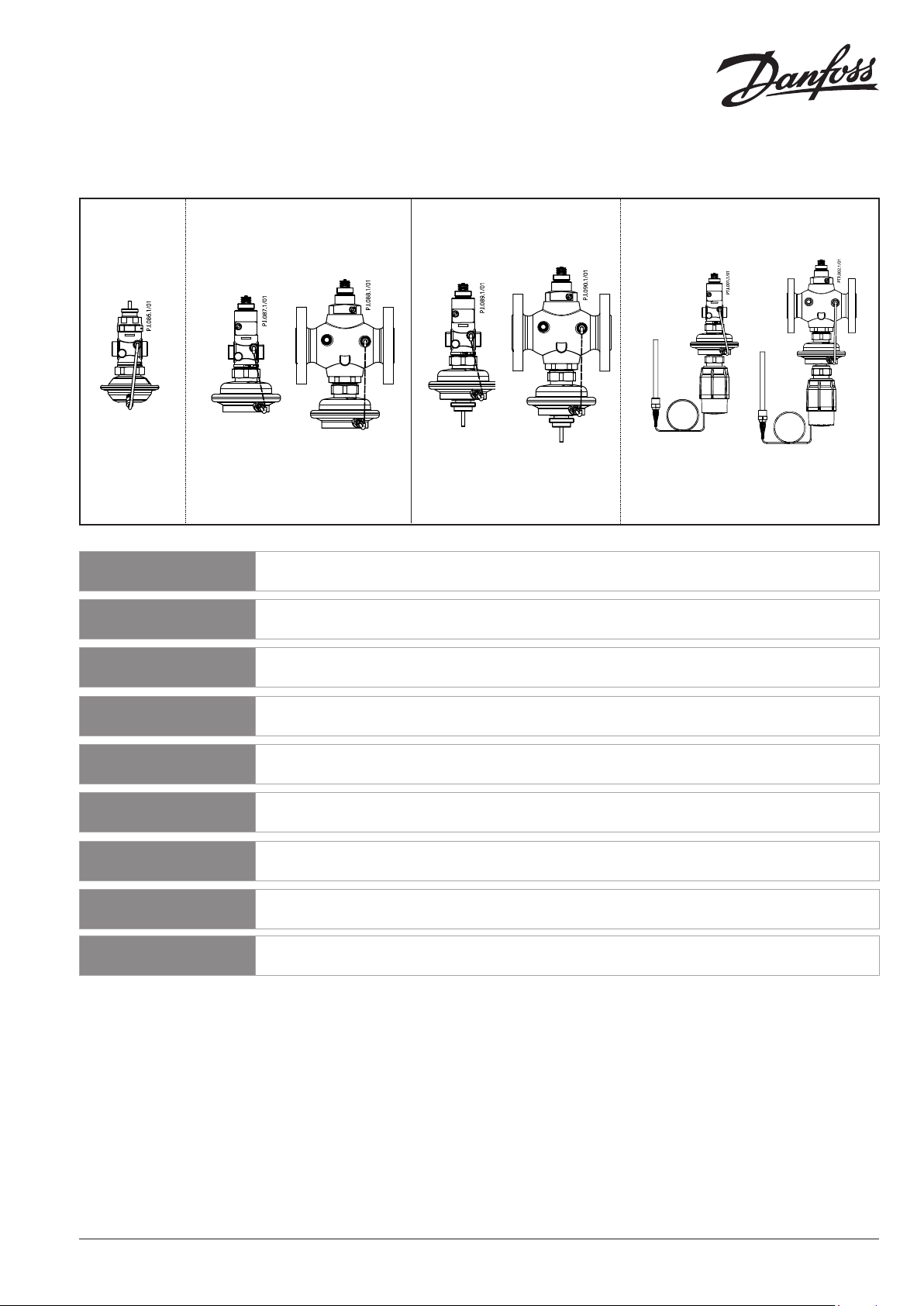

AVQM, AVQMT – PN 16, 25 / DN 15-50

AVQM (PN 16) AVQM (PN 25) AVQMT (PN 25) AVQMT/AVT (PN 25)

DN 15-32 DN 15-50 DN 32-50 DN 15-50 DN 32-50 DN 15-50 DN 32-50

∆p = 0.2 ∆p = 0.2 ∆p = 0.2 ∆p = 0.2 ∆p = 0.2 ∆p = 0.2 ∆p = 0.2

ENGLISH

DANSK

DEUTSCH

ESPAÑOL

SLOVENŠČINA

POLSKI

MAGYAR

SRPSKI

ITALIANO

Flow (and temperature) controller with integrated control

valve AVQM, AVQMT

Flow- (og temperatur-)regulator med indbygget motorventil

AVQM, AVQMT

Volumenstrom (und Temperatur-) Regler mit Motorstellventil

AVQM, AVQMT

Regulador de caudal (y temperatura) con válvula de control

integrada AVQM, AVQMT

Regulator pretoka (in temperature) z regulacijskim ventilom

AVQM, AVQMT

Regulator przepływu (i temperatury) z zaworem

regulacyjnym AVQM, AVQMT

Térfogatáram(és hőmérséklet) szabályozó, motoros

szabályozó-szeleppel egybeépítve AVQM, AVQMT

Uputstvo AVQM, AVQMT-PN 16, 25/DN 15-50 grejanje.danfoss.com Strana 21

Flow (and temperature) controller with integrated control

valve AVQM, AVQMT

www.danfoss.com Page 7

www.danfoss.dk Side 9

www.danfoss.de Seite 11

www.danfoss.es Página 13

www.danfoss.si Stran 15

www.danfoss.pl Strona 17

www.danfoss.hu Oldal 19

www.danfoss.it Pagina 23

73695050 DH -SMT/SI VI.DB .T3.3F © Dan foss 02/2011 1

❾

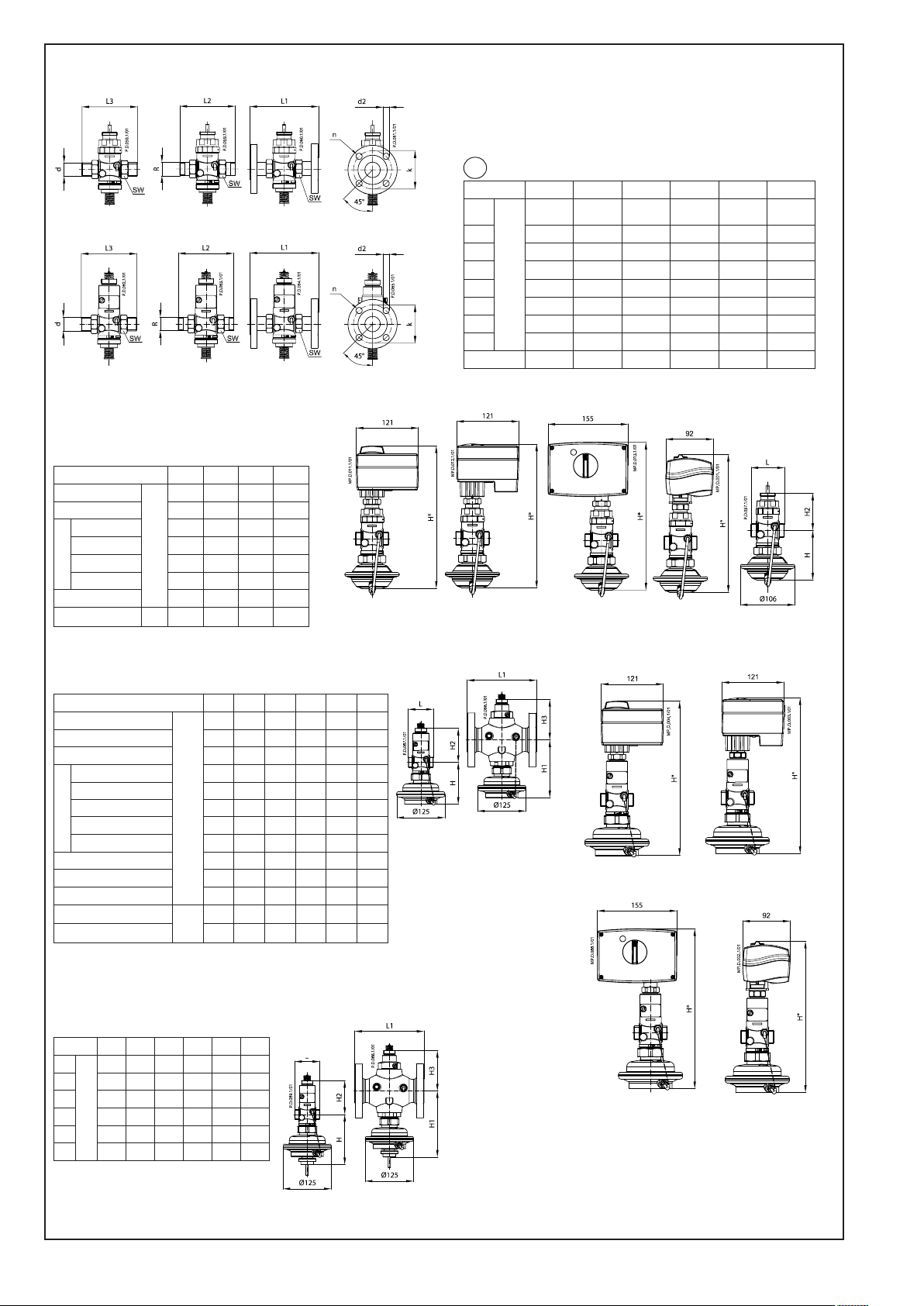

AVQM PN 16

AVQM PN 25

AVQM PN 16

DN 15 20 25 32

L

H 97 97 97 97

AMV(E) 10 277 – – –

AMV(E) 13 280 – – –

H*

AMV(E) 2./3. 290 290 293 294

AMV 150 278 – – –

H2 73 73 76 77

Valve weight kg 1,9 1,9 2,0

65 70 75 100

mm

AMV(E) 10 +

AVQM (DN 15)

T1

DN

SW

d

1)

R

2)

L1

mm

L2

L3

k

d

2

n

AMV(E) 13 +

AVQM (DN 15)

15 20 25 32 40 50

32

(G ¾A)

41

(G 1A)

50

(G 1¼A)

63

(G 1¾A)

70

(G 2A)

21 26 33 42 47 60

½ ¾ 1 1 ¼ - 130 150 160 - - 131 144 160 177 - 139 154 159 184 204 234

65 75 85 100 110 125

14 14 14 18 18 18

4 4 4 4 4 4

AMV(E) 2./ 3. +

AVQM (DN 15-32)

AMV 150 +

AVQM (DN 15)

AVQM PN 16

82 (G

2½A)

AVQM PN 25

DN 15 20 25 32 40 50

L

L1 - - - 180 200 230

H 109 109 109 150 150 150

AMV(E) 10 307 - - - - AMV(E) 13 304 - - - - -

H*

AMV(E) 2./3. (thread) 317 317 320 375 375 375

AMV(E) 2./3. (flange) - - - 390 390 390

AMV 150 305 - - - - H1 - - - 150 150 150

H2 88 88 91 105 105 105

H3 - - - 105 105 105

Valve weight (thread)

Valve weight (flange) - - - 10,3 11,8 13,9

3)

65 70 75 100 110 130

mm

3.0 3.0 3.2 5.8 5.9 6.6

kg

AVQMT PN 25

DN 15 20 25 32 40 50

L

65 70 75 100 110 130

L1 - - - 180 200 230

H 131 131 131 172 172 172

mm

H1 - - - 172 172 172

H2 88 88 91 105 105 105

H3 - - - 105 105 105

3)

AVQM PN 25

DN 15-50

AVQM PN 25

DN 32-50

AMV(E) 10 +

AVQM (DN 15)

AMV(E) 2./3. +

AVQM

AMV(E) 13 +

AVQM (DN 15)

AMV 150 +

AVQM (DN 15)

AVQMT PN 25

DN 15-50

2 VI.DB .T3.3F © Dan foss 02/2011 73695050 DH -SMT/SI

AVQMT PN 25

DN 32-50

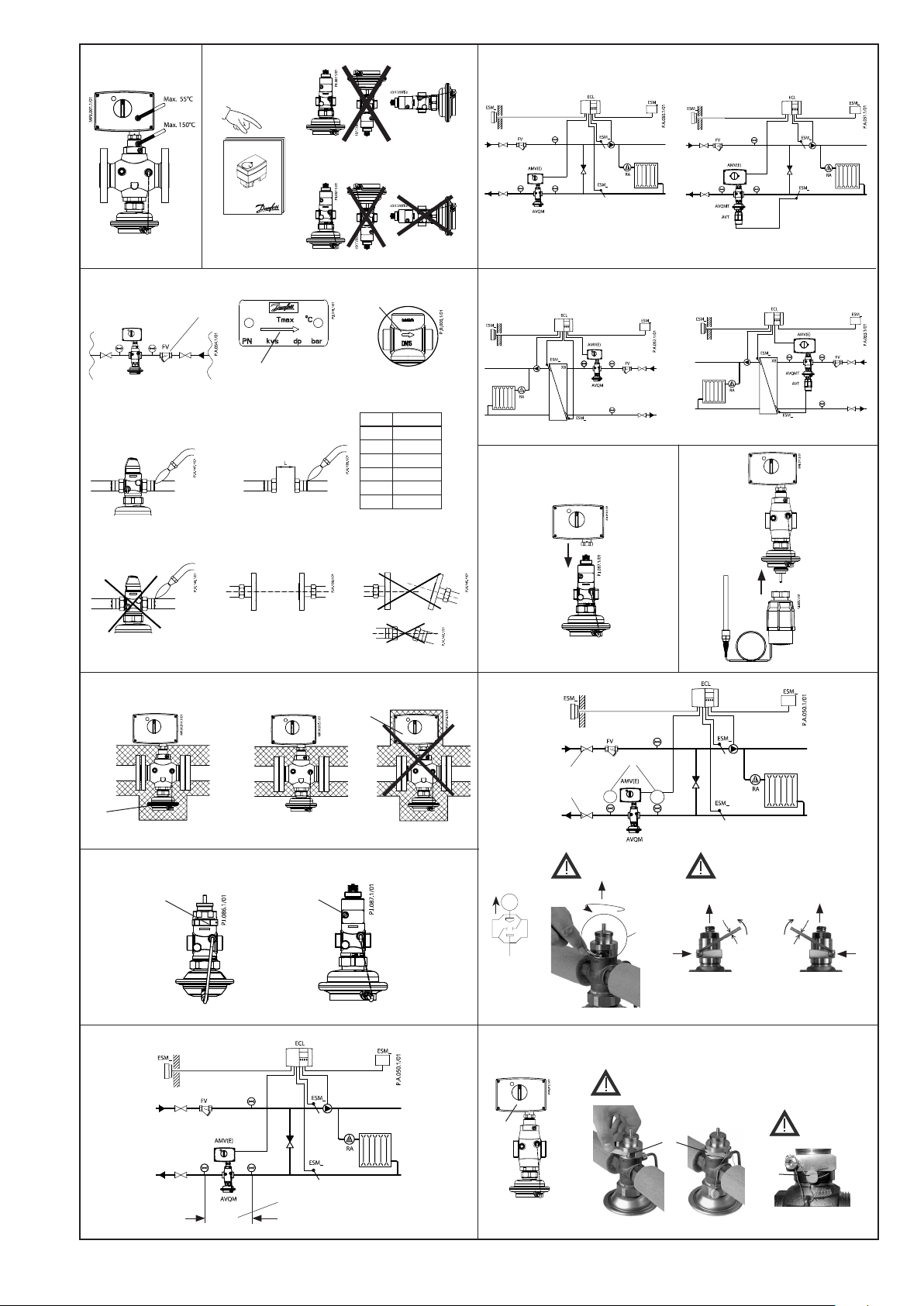

❶ ❷

AMV(E)

< 100 °C

> 100 °C

❸

❺

④

⑥

❽

①

②

⑤

⑦ ⑧

③

DN L (mm)

15 69

20 74

25 79

32 104

40 114

50 134

②

❹

❻

❿

❼

< 100 °C

> 100 oC

①

②

–

+

①

③

⓫

⓬

①

PN 16

②

PN 25

M

⓮

PN 16

⑥

④

PN 16

⑤

①

②

①

Δp

v

73695050 DH -SMT/SI VI.DB .T3.3F © Dan foss 02/2011 3

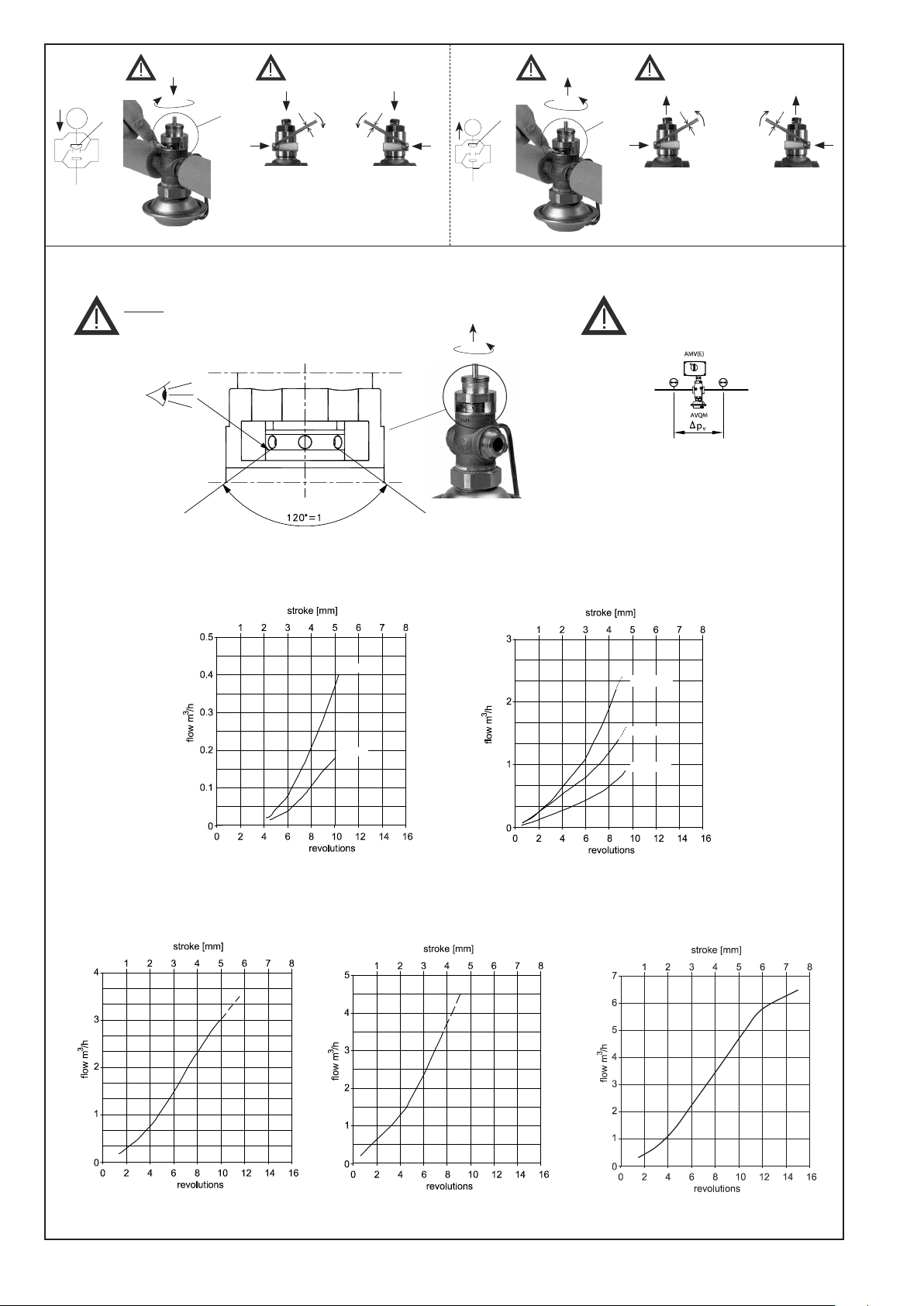

PN 25

4 mm

⑦

③

⑧

4 mm

⑤

PN 25

⓭

PN 16 PN 16

PN 25

PN 25

⓯

⑤

⑥

4 mm

⑦

4 mm

④

M

①

M

③

④

②

⑩

⑧

⑨

4 mm

⑪

⑫

4 mm

⑨

PN 16

1 = 120°

Δpv:

—

0.5 … 12 bar

_ _ _ 1.0 … 12 bar

kvs 1.0

kvs 0.4

DN 15

kvs 4.0

kvs 2.5

kvs 1.6

DN 32 kvs 10DN 25 kvs 8.0DN 20 kvs 6.3

4 VI.DB .T3.3F © Dan foss 02/2011 73695050 DH -SMT/SI

⓰

PN 25

1 = 360°

1 = 360°

kvs 1.0

kvs 0.4

DN 15

1 = 360°

Δpv:

—

0.5 … 12 bar

_ _ _ 1.0 … 12 bar

kvs 4.0

kvs 2.5

kvs 1.6

DN 20 kvs 6.3

DN 25 kvs 8.0

DN 32 kvs 12.5

73695050 DH -SMT/SI VI.DB .T3.3F © Dan foss 02/2011 5

⓰

PN 25

1 = 360°

1 = 360°

DN 40 kvs 16, 20

1 = 360°

Δpv:

—

0.5 … 12 bar

_ _ _ 1.0 … 12 bar

DN 50 kvs 20, 25

6 VI.DB .T3.3F © Dan foss 02/2011 73695050 DH -SMT/SI

ENGLISH

Safety Notes

Prior to assembly and commissioning to

avoid injury of persons and damages of

the devices, it is absolutely necessary

carefully read and observe these instructions.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorized

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

to

Definition of Application

The controller is in combination with

electrical actuators (AMV(E) used for flow

and temperature control of water and

water glycol mixtures for heating, district

heating and cooling systems.

AVQM PN 16 could be combined with

electrical actuators AMV(E) 10/13 (DN15

only), AMV(E) 20/23, AMV 20/23 SL,

AMV(E) 30/33, AMV 30, AMV 150.

AVQM(T) PN 25 could be combined

with electrical actuators AMV(E) 10/13

(DN15 only), AMV(E) 20/23, AMV 20/23 SL,

AMV(E) 30/33, AMV 30, AMV 150.

AVQMT PN 25 could be combined with

temperature actuator AVT or safety

temperature monitor (actuator) STM.

The technical parameters on the product

labels determine the use.

Assembly

Admissible Temperatures ❶

Admissible Installation Positions ❷

Medium temperatures up to 100 °C:

- Can be installed in any position,

except

with electrical actuator oriented

downwards.

Medium temperatures > 100 °C:

- Installation permitted only in horizontal

pipelines with the electrical actuator

oriented upwards.

Other details:

See instructions for electrical actuator

AMV(E). In case of AVQMT controller see

instructions for temperature actuator AVT

or safety temperature monitor (actuator)

STM as well.

Installation Location and

Installation Scheme

AVQM(T) return mounting ❸

AVQM(T) flow mounting ❹

Valve Installation ❺

1. Clean pipeline system prior to assembly.

2. The installation of a strainer ① in

front of the controller is strongly

recommended.

3. Install valve

• The flow direction indicated on the

product label ② or on the valve ③

must be observed.

• The valve with mounted weld-on

tailpieces may only be spot welded to

the pipeline ④.

The weld-on tailpieces may be welded

only without the valve and seals! ⑤⑥

If these instructions are not observed,

high welding temperatures may

destroy the seals.

• Flanges ⑦ in the pipeline must be in

parallel position and sealing surfaces

must be clean and without any

damage.

Tighten screws in flanges crosswise

in 3 steps up to the maximum torque

(50 Nm).

4. Caution:

Mechanical loads of the valve body by the

pipelines are not permitted ⑧.

Mounting of electrical actuator ❻

Place electrical actuator AMV(E) on the

valve and tighten union nut with wrench

SW 32.

Torque 25 Nm.

Other details:

See instructions for electrical

actuator AMV(E).

Mounting of temperature

actuator ❼

(relevant only at AVQMT controllers)

Place temperature actuator AVT or STM at

the diaphragm and tighten union nut with

wrench SW 50.

Torque 35 Nm.

Other details:

See instructions for temperature

actuator AVT or STM.

Insulation ❽

For medium temperatures up to 100 °C the

pressure actuator ① may also be insulated.

Insulation of electrical actuator ②

AMV(E) is not allowed.

Dimensions, Weights ❾

1)

Conical ext. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

3)

Other flange dimensions – see table

for tailpieces.

T1

Start-up ❿

Filling the system, first start-up

1. Open valves in the system.

2. Slowly open shut-off devices ① in the

flow pipeline.

3. Slowly open shut-off devices ② in the

return pipeline.

Leak and Pressure Tests

Do not test closed control valve with

pressures of more than 16 bar. Otherwise,

the valve may be damaged.

Pressure tests should be carried out prior

to the installation of the electrical actuator.

This guarantees that the valve is opened.

Before pressure test, open the adjustable

flow restrictor ④⑤ by turning it:

- at PN 16 controller to the left (counter

clockwise) ⑥

- at PN 25 controller to the left

(counter clockwise) ⑦ or to the right

(clockwise) ⑧

Pressure must be gradually

increased at the (+/-)

connection ③.

Non-compliance may cause damages at

the actuator or the valve.

A pressure test of the entire system

must be carried out in accordance with

manufacturer’s instructions.

The maximum test pressure is: 1.5 × PN

PN – see product label!

Putting out of operation

1. Slowly close shut-off devices ① in the

flow pipeline.

2. Slowly close shut-off devices ② in the

return pipeline.

73695050 DH -SMT/SI VI.DB .T3.3F © Dan foss 02/2011 7

Settings

No

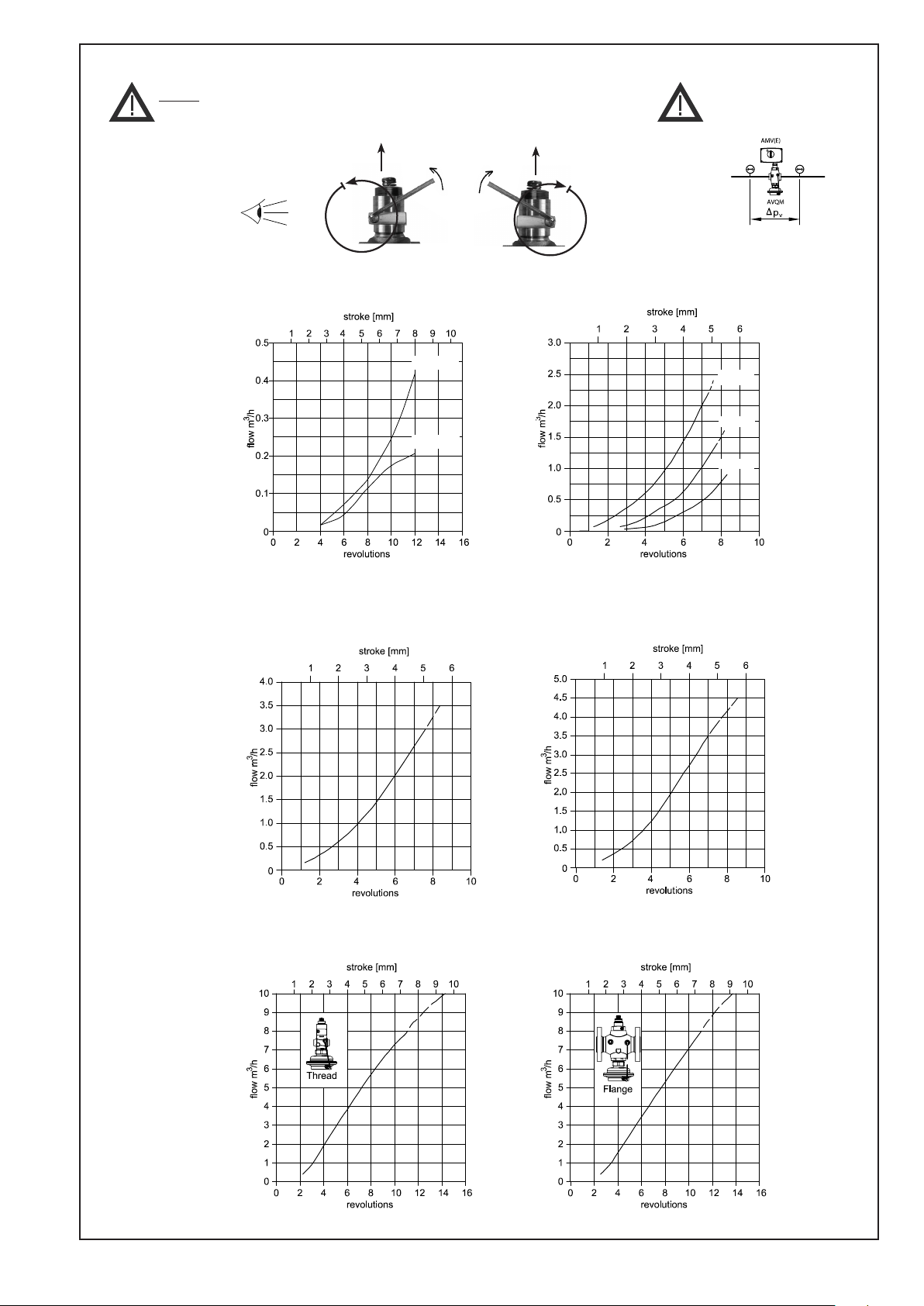

Flow Adjusting Curves PN 16 ⓯

Flow Rate Setting ⓫

The flow rate is adjusted by means of

limitation of control valve stroke ①②.

There are two possibilities:

1. Adjustment with the flow adjusting

curves,

2. Adjustment with heat meter.

Pre-condition ⓬

(min. diff. pressure over the valve)

To achieve maximum flow rate the pressure

difference Δpv ① across the control valve

must be at least: Δp

= 0.5 bar

min

Adjustment with flow adjusting

curves ⓭

The system don’t need to be active for

being adjusted.

1. Close control valve ① by turning the

adjustable flow restrictor ③④ to its

stop:

- at PN 16 controller to the right

(clockwise) ⑤

- at PN 25 controller to the right

(clockwise) ⑥ or to the left (counter

clockwise) ⑦

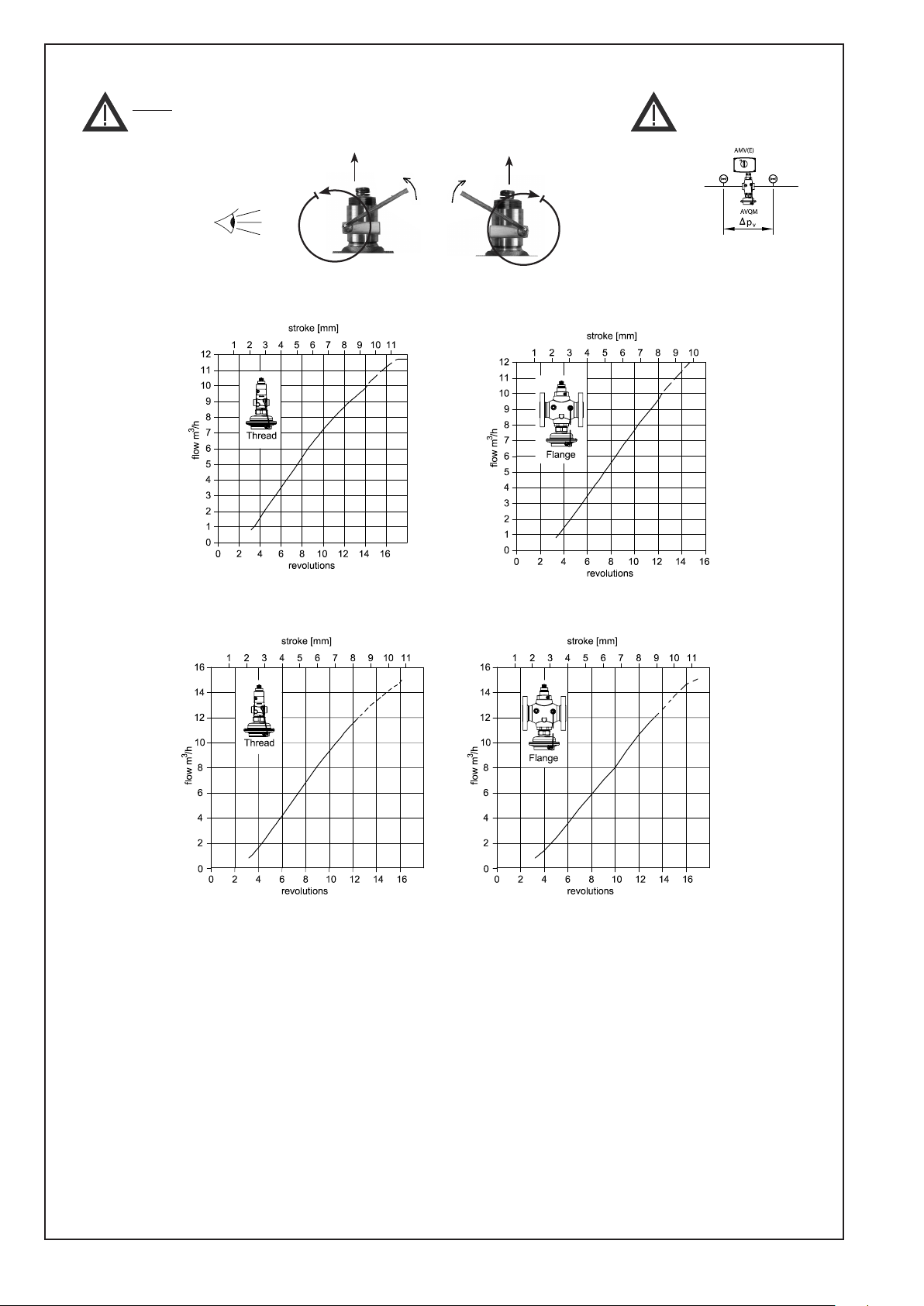

2. Select flow adjusting curve in the

diagram (see ⓯⓰).

Necessary

flow rate

Revolutions of

adjusting throttle

For PN 16 controller: 1 = 120°

For PN 25 controller: 1 = 360°

3. Open control valve ② with the

adjustable flow restrictor ⑧⑨ by

determined number of revolutions:

• at PN 16 controller to the left (counter

clockwise) ⑩

• at PN 25 controller to the left (counter

clockwise) ⑪ or to the right

(clockwise) ⑫

4. The setting of the valve stroke is

completed, continue with step 2,

Adjustment with Heat Meter.

Flow Adjusting Curves PN 25 ⓰

Adjustment with Heat Meter

Pre-condition:

The setting should be carried out when the

electrical actuator AMV(E) is dismounted. If

the electrical actuator is mounted, the stem

of the actuator must be retracted.

The system must be in operation. All units

in the system ❿ or a bypass must be

completely open.

1. Observe heat meter indicator. ⓭

At PN 16 controller:

- turning to the left (counter clockwise)

② increases the flow rate

- turning to the right (clockwise) ⑤

decreases the flow rate

At PN 25 controller:

- turning to the left (counter

clockwise) ⑪ or to the right

(clockwise) ⑫ increases the flow rate

- turning to the right (clockwise) ⑥

or to the left (counter clockwise) ⑦

decreases the flow rate.

After the adjustment has been completed ⓮

:

2. If not yet done, install the actuator ①,

see section Mounting of electrical

actuator.

3. Shortly throttle the system and then

reopen it (e.g. by means of the electrical

actuator).

4. Verify flow rate.

The control valve setting is completed.

5. The adjustable flow restrictor ②③ may

be sealed.

Temperature setting

(relevant only at AVQMT controllers)

See instructions for temperature actuator

AVT or safety temperature monitor

(actuator) STM.

The setting may be verified with help of a

heat meter if the system is in operation,

see next section.

8 VI.DB .T3.3F © Dan foss 02/2011 73695050 DH -SMT/SI

DANSK

Sikkerhedsnoter

Disse instruktioner SKAL læses omhyggeligt

forud for montering og indkøring samt

respekteres for at undgå skader på personer

og udstyr. Nødvendigt monterings-, opstartog vedligeholdelsesarbejde må kun

udføres af faglært og autoriseret personale.

Forud for monterings- og

vedligeholdelsesarbejde på regulatoren

skal systemet være:

- trykløst,

- nedkølet,

- tømt og

- rengjort.

Systemproducentens eller -operatørens

instruktioner skal overholdes.

Anvendelse

Regulatoren anvendes sammen med

elektriske aktuatorer AMV(E) til flow- (og

temperatur)styring af vand og vandglycolblandinger til varme-, ernvarme- og

kølesystemer.

AVQM PN 16 kan evt. kombineres med de

elektriske aktuatorer AMV(E) 10/13 (kun DN

15), AMV(E) 20/23, AMV 20/23 SL, AMV(E)

30/33, AMV 30 og AMV 150.

AVQM(T) PN 25 kan evt. kombineres med

de elektriske aktuatorer AMV(E) 10/13 (kun

DN 15), AMV(E) 20/23, AMV 20/23 SL,

AMV(E) 30/33, AMV 30 og AMV 150.

AVQMT PN 25 kan evt. kombineres med

temperaturaktuator AVT eller

sikkerhedstemperaturovervågning

(aktuator) STM.

De tekniske parametre på

produktetiketterne fastlægger

anvendelsen.

Montering

Tilladelige temperaturer ❶

Tilladelige positioner ❷

Medietemperaturer op til 100 °C:

- Kan installeres i alle positioner bortset

fra elektriske aktuatorer, der hænger

nedad

.

Medietemperaturer > 100 °C:

- Må kun installeres i vandrette

rørledninger med den elektriske

aktuator vendende opad.

Indbygning

AVQM(T) montering i returledning ❸

AVQM(T) montering i flowledning ❹

Ventilinstallation ❺

1. Rengør rørledningssystemet før

montering.

2. Det anbefales stærkt at installere et filter

foran regulatoren ①.

3. Installer ventilen

• Den flowretning, der vises på

produktetiketten eller på ventilen, skal

respekteres ② ③.

• Ventilen med monterede svejsestudser

må kun klemmes fast til

rørledningen ④.

TSvejsestudserne må kun svejses uden

ventil og pakninger! ⑤⑥

Høje svejsetemperaturer kan

ødelægge pakningerne, hvis disse

instruktioner ikke overholdes.

• Flanger ⑦ i rørledningen skal være

placeret parallelt, og pakfladerne skal

være rene og uden skader.

Krydsspænd skruerne i flangerne i 3

trin til maks. moment (50 Nm).

4. Forsigtig:

Rørledningerne må ikke belaste

ventilhuset mekanisk ⑧.

Montering af elektrisk aktuator ❻

Anbring den elektriske aktuator AMV(E) på

ventilen og spænd omløbermøtrikken med

nøgle SW 32.

Moment 25 Nm.

Andre detaljer:

Se instruktioner for elektrisk

aktuator AMV(E).

Montering af temperaturaktuator ❼

(kun relevant ved AVQMT-regulatorer)

Anbring temperaturaktuatoren AVT eller

STM ved membranen, og spænd

omløbermøtrikken med nøgle SW 50.

Moment 35 Nm.

Andre detaljer:

Se instruktioner for temperaturaktuator

AVT eller STM.

Mål, vægt ❾

1)

Konisk udv. gevind iht. EN 10226-1

2)

langer PN 25 iht. EN 1092-2

3)

Øvrige flangedimensioner – se tabel T1

for nipler.

* Ventilvægt (Valve weight)

** gevind (thread)

Opstart ❿

Påfyldning af systemet, første

opstart

1. Åbn ventilerne i systemet.

2. Åbn langsomt for afspærringsventilerne ① i flowledningen.

3. Åbn langsomt for afspærringsventilerne ② i returledningen.

Lækage- og trykprøvning

Afprøv ikke lukkede manøvreventiler med

tryk over 16 bar. Det kan beskadige

ventilen.

Trykprøvninger bør udføres før

monteringen af den elektriske aktuator.

Dette sikrer, at ventilen åbnes.

Før trykprøvning åbnes den justerbare

flowbegrænser ④ ⑤ ved at dreje den:

- i PN 16-regulatoren til venstre (mod

uret) ⑥

- i PN 25-regulatoren til venstre (mod

uret) ⑦ eller til højre (med uret) 8

Trykket skal øges gradvist ved (+/-)

tilslutningen ③.

Respekteres dette ikke, kan der opstå

skader på aktuator eller ventil. Der skal

udføres en trykprøvning af hele systemet i

overensstemmelse med producentens

instruktioner. Det maksimale prøvetryk er:

1,5 × PN

PN fremgår af produktetiketten!

Stop af anlæg

1. Luk langsomt for

afspærringsanordningerne ① i

flowledningen.

2. Luk langsomt for

afspærringsanordningerne ② i

returledningen.

Isolering ❽

Ved medietemperaturer op til 100 °C kan

Andre detaljer:

Se instruktioner til elektrisk aktuator

AMV(E). I tilfælde af AVQMT-regulator se

også instruktioner til temperaturaktuator

AVT eller sikkerhedstemperaturovervågning

(aktuator) STM.

73695050 DH -SMT/SI VI.DB .T3.3F © Dan foss 02/2011 9

trykaktuatoren ① også være isoleret.

Isolering af elektrisk aktuator ②

AMV(E) er ikke tilladt.

Loading...

Loading...