Page 1

Data sheet

Pressure independent control valve with integrated flow limiter

AVQM (PN 16) - return and flow mounting

Description

AVQM is a self-acting flow controller with

integrated control valve developed for the

use in district heating / cooling systems. The

controller prevents flow to exceed set max

flow. In a combination with electrical actuators

AMV(E) and ECL electronic controllers the flow

and temperature can be controlled to achieve

highest energy savings.

AVQM has a control valve with adjustable flow

limiter, connection neck for electrical actuator and

a pressure actuator with one control diaphragm.

Controllers are used together with Danfoss

electrical actuators:

• AMV 150 1)

• AMV(E) 10 1) / AMV(E) 20 / AMV(E) 30

• AMV(E) 13 1) / AMV(E) 23 / AMV(E) 33 with

spring return function

• AMV 20 SL / AMV 23 SL / AMV 30 SL with stroke

limitation

1)

AMV 150 / AMV(E) 10 / AMV(E) 13 can be combined w ith DN 15

controller only.

AVQM combined with AMV(E) 13, AMV(E) 23 (SL)

or AMV(E) 33 (SL) has been approved according

to DIN 32730.

Main data:

• DN 15-32

• kVS 0.4-10 m3/h

• Flow range 0.015-6.0 m3/h

• PN 16

• Differential pressure over control valve ∆p

0.2 bar

MCV

• Temperature:

Circulation water / glycolic water up to 30 %

2 … 150 °C

• Connections:

Ext. thread (weld-on, thread and flange

tailpieces)

Ordering

Example:

Flow controller with integrated

control valvefor flow rate 0.7

m3/h; PN 16; T

thread

150 °C; ext.

max

- 1× AVQM DN 15 controller

Code No: 003H 6735

Option:

- 1× Weld-on tailpieces

Code No: 003H690 8

AVQM Controller

Picture

DN Q

(mm) (m3/h) (m3/h)

15

20 3.5 6.3

25 4.5 8.0

32 6 10

max

0.18 0.4

0.4 1.0 003H 6734

0.9 1.6 003 H6735

1.6 2.5 003H6736

2.4 4.0 003H6737

k

VS

Connection Code No.

Cylindr. ext. thread acc. to ISO 228 / 1

G ¾ A

G 1 A

G 1¼ A

G 1¾ A

003H 6733

003H6738

003H 6739

00 3H674 0

The controller will be delivered

completely assembled, inclusive

impulse tube between valve and

actuator. Electrical actuator

AMV(E) must be ordered

separately.

© Danfoss | 2019.02 VD.DB.V9.02 | 1

Page 2

Data sheet AVQM (PN 16)

Ordering (continuous)

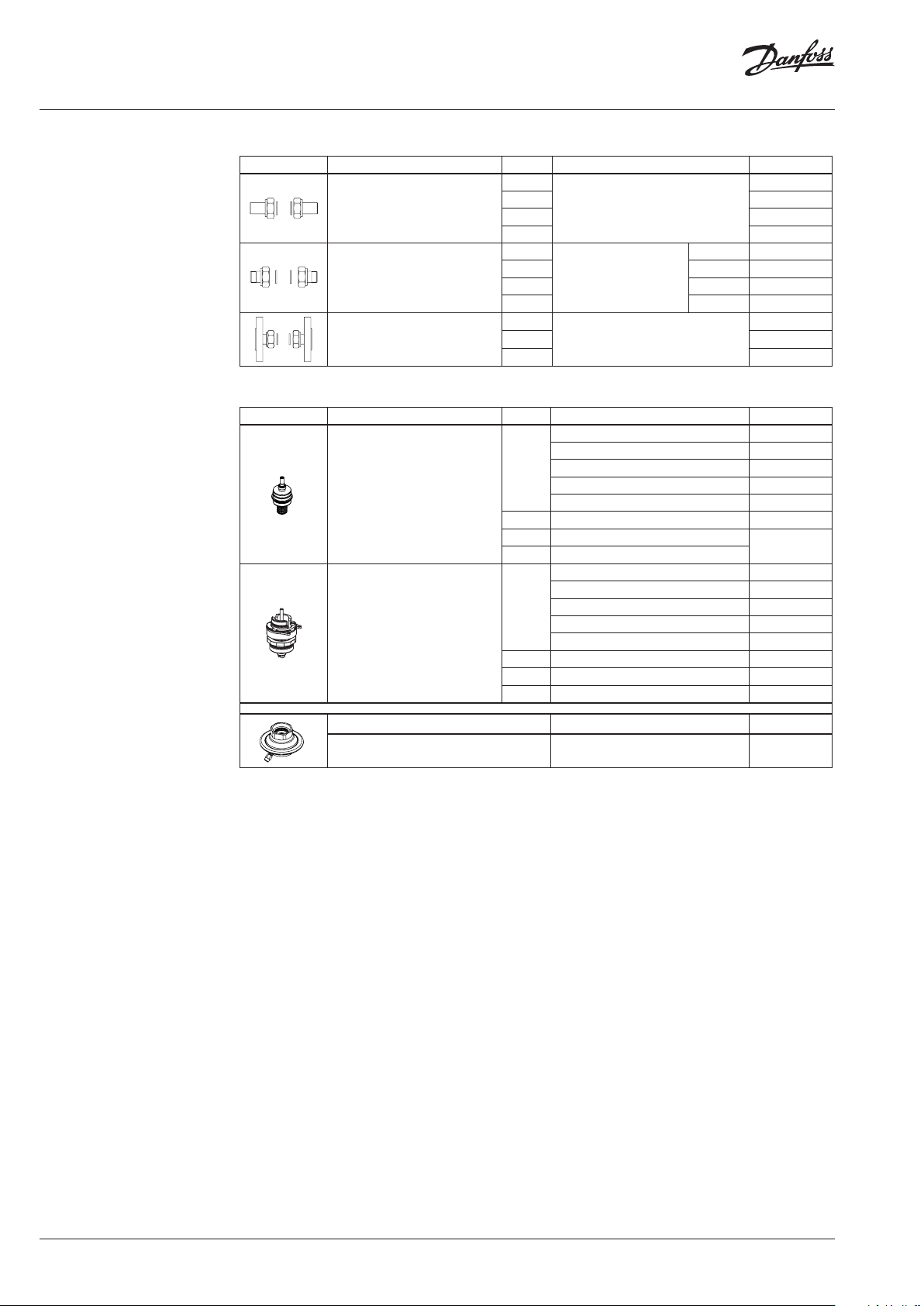

Accessories

Picture Type designation DN Connection Code No.

15

Weld-on tailpieces

External thread tailpieces

Flange tailpieces

20 003H6909

25 00 3H6910

32 0 03 H69 11

15

20 R ¾ 003H6903

Conical ex t. thread acc. to

25 R 1 003H6904

32 R 1¼ 003H6905

15

20 003H 6916

25 0 03H6 917

EN 10226 -1

Flanges PN 25, acc. to EN 1092-2

-

R ½ 003H6902

Service kits

Picture Type designation DN kVS (m3/h) Code No.

0.4 003H6861

1.0 003H6862

15

Valve insert

20 6.3 003H6996

25 8.0

32 10

15

Control valve insert

20 6.3 003H 6891

25 8.0 003H68 92

32 10 003H6795

1.6 003H6863

2.5 003H6864

4.0 003H6865

0.4 003H6886

1.0 0 03H6887

1.6 003H6888

2.5 003H6889

4.0 003H6890

003H6908

003H 6915

003H6867

Type designation Δp setting range (bar) Code No.

Actuator 0.2 003H6825

2 | VD.DB.V9.02 © Danfoss | 2019.02

Page 3

Data sheet AVQM (PN 16)

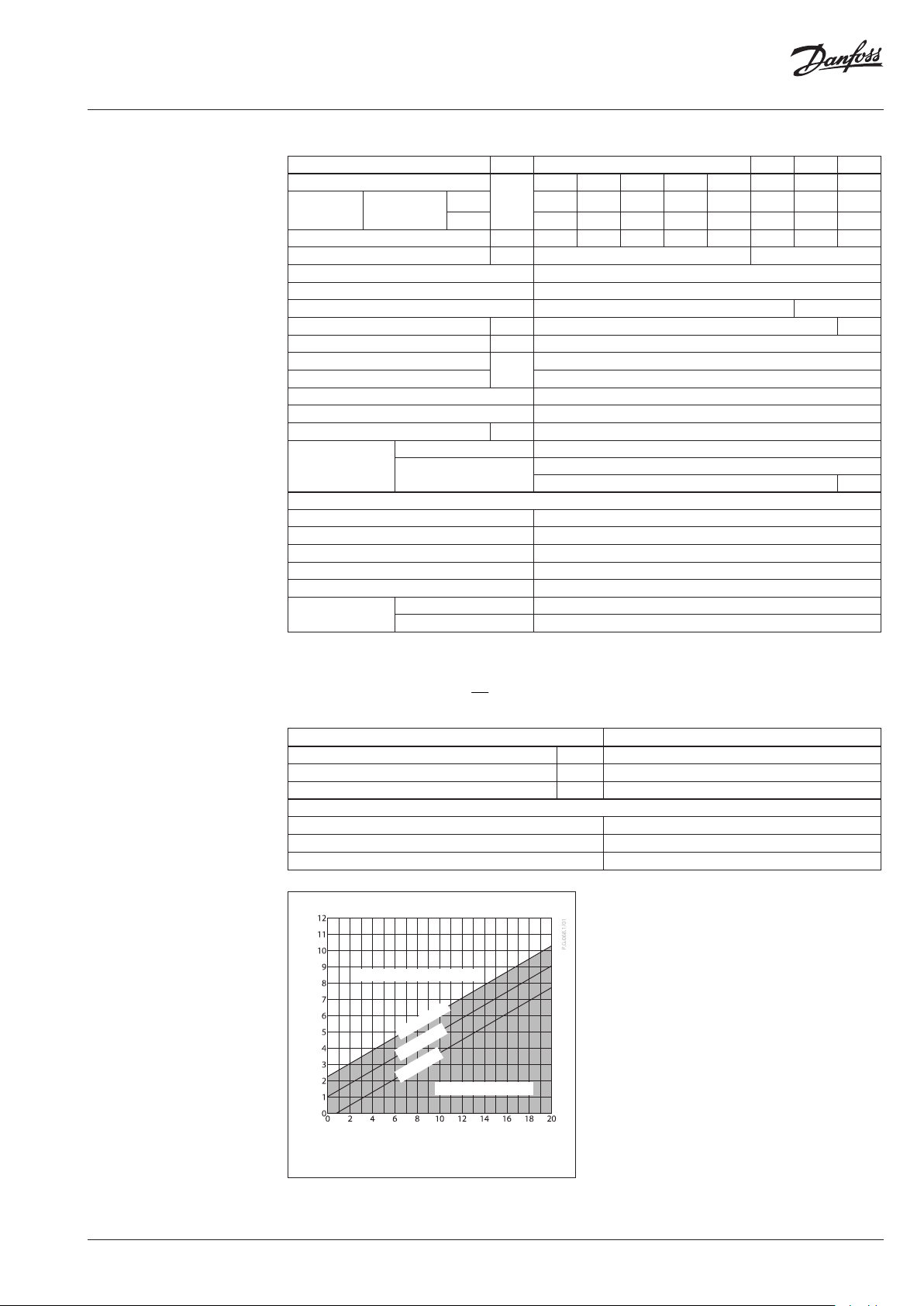

Technical data

Valve

Nominal diameter DN 15 20 25 32

k

value of dp controller

VS

Range of max.

flow setting

p

= 0.2 bar

MCV

Available ∆p required for Q

Q

Q

max

min

max

m3/h

2)

Stroke mm 5 7

Control valve authority 1 (100%) in the range of flow setting

Control characteristic Logarithmic

Cavitation factor z ≥ 0.6 ≥ 0.55

Leakage acc. to standard IEC 534 % of k

Nominal pressure PN 25

Min. differential pressure

Max. differential pressure 12

Medium Circulation water / glycolic water up to 30 %

Medium pH Min. 7, max. 10

Medium temperature ºC 2 … 150

valve External thread

Connections

tailpieces

Materials

Valve body Red bronze CuSn5ZnPb (Rg5)

Valve seat Stainless steel, mat. No. 1.4571

Valve cone Dezincing free brass CuZn36Pb2As

Sealing DP EPDM

Sealing MC V Metal

Pressure relieve

system

Control valve insert Valve insert Piston

0.4 1.0 1.6 2.5 4.0 6.3 8.0 10

0. 015 0.02 0.03 0.07 0.07 0.16 0.2 0.16

0.18 0.4 0.9 1.6 2.4 3. 5 4.5 6.0

bar 0.4 0.4 0.5 0.6 0.6 0.5 0.5 0.6

VS

bar

≤ 0.02 ≤ 0.05

see remark

1)

Weld-on and external thread

Flange -

Note:

DP - diff. pressu re controller, MCV - control valve

2)

For flows smal ler than Q

->

p

max

min

2

Q

p

MCV

k

VS

Actuator

Typ e AVQM

Actuator size cm

Nominal pressure PN 16

Differential pressure over MCV - motorized control valve bar 0.2

Materials

Housing

Diaphragm EPDM

Impulse tube Copper tube Ø 6 × 1 mm

No Cavitation noise

T=150 °C

T=130 °C

T=80 °C

Cavitation noise

2

39

Zinc plated, DIN 1624, No. 1.0338

Manometric Pressure downstrem [bar]

Manometric Pressure upstrem [bar]

Cavitation area for cavitation factor z=0.6

VD.DB.V9.02 | 3© Danfoss | 2019.02

Page 4

Data sheet AVQM (PN 16)

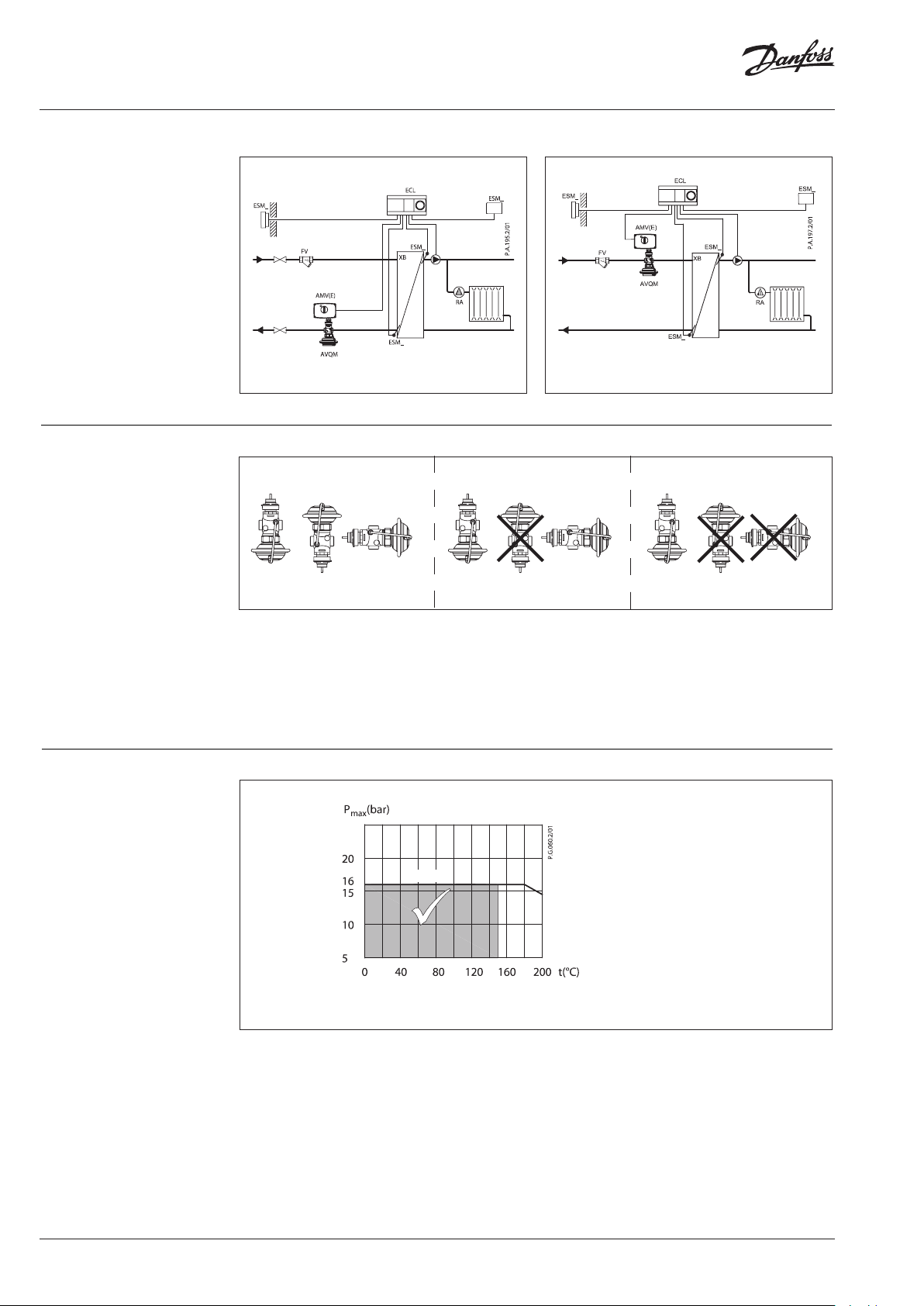

Application principles Flow mounting

Return mounting

Indirectly connec ted heating system

Indirectly connec ted heating system

Installation positions

Pressure temperature

diagram

Media temperature 100 °C Media temperature 130 °C Media temperature 150 °C

Electrical actuator

Note!

Installation positions for electrical actuators AMV(E)

have to be observed as well. Please see relevant

Data sheet.

PN 16

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-3).

CuSn5ZnPb (Rg5) PN 16

4 | VD.DB.V9.02 © Danfoss | 2019.02

Page 5

Data sheet AVQM (PN 16)

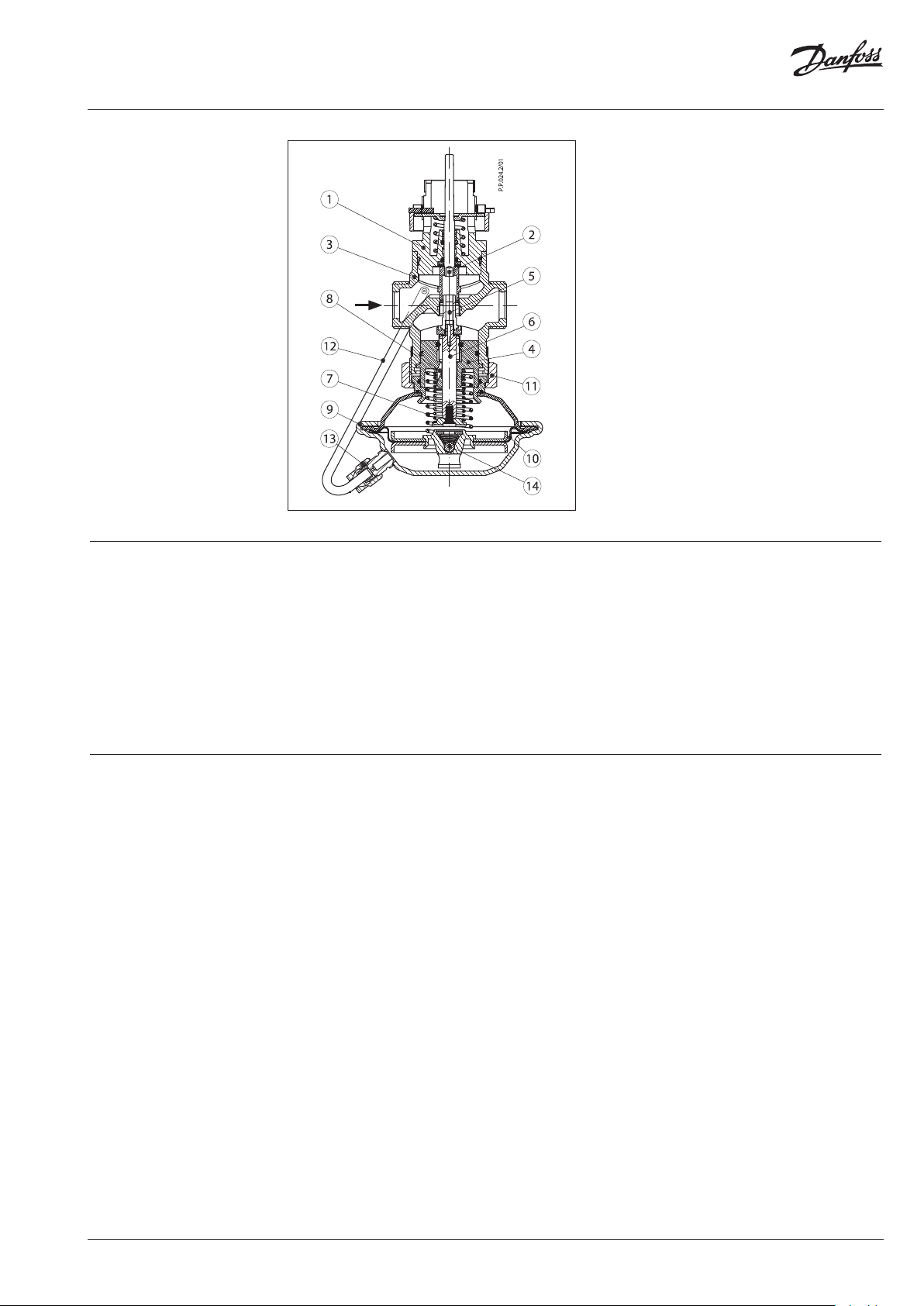

Design

1. Control valve insert

2. Adjustable flow restrictor

3. Valve body

4. Valve insert

5. Pressure relieved valve cone

6. Valve stem

7. Built-in spring for flow rate

control

8. Control drain

9. Actuator

10. Control diaphragm

11. Union nut

12. Impulse tube

13. Compression fitting for

impulse tube

14. Excess pressure safety valve

Function

Settings

Flow volume causes pressure drop across the

adjustable flow restrictor. Resulting pressures are

being transferred through the impulse tubes

and/or control drain in the actuator stem to the

actuator chambers and act on control diaphragm

for flow control. The flow restrictor diff. pressure

is controlled and limited by means of built-in

spring for flow control. Control valve closes

on rising differential pressure and opens on

falling differential pressure to control max flow.

Max flow limiting

Max flow limiting is being done by the

adjustment of the flow restrictor position. The

adjustment can be performed on the basis

of flow adjustment diagram (see relevant

instructions) and / or by the means of heat meter.

Additionally the electrical actuator will operate

from zero to set max. flow according to the load.

Controller is equipped with excess pressure

safety valve, which protects control diaphragm

for flow control from too high differential

pressure.

VD.DB.V9.02 | 5© Danfoss | 2019.02

Page 6

Data sheet AVQM (PN 16)

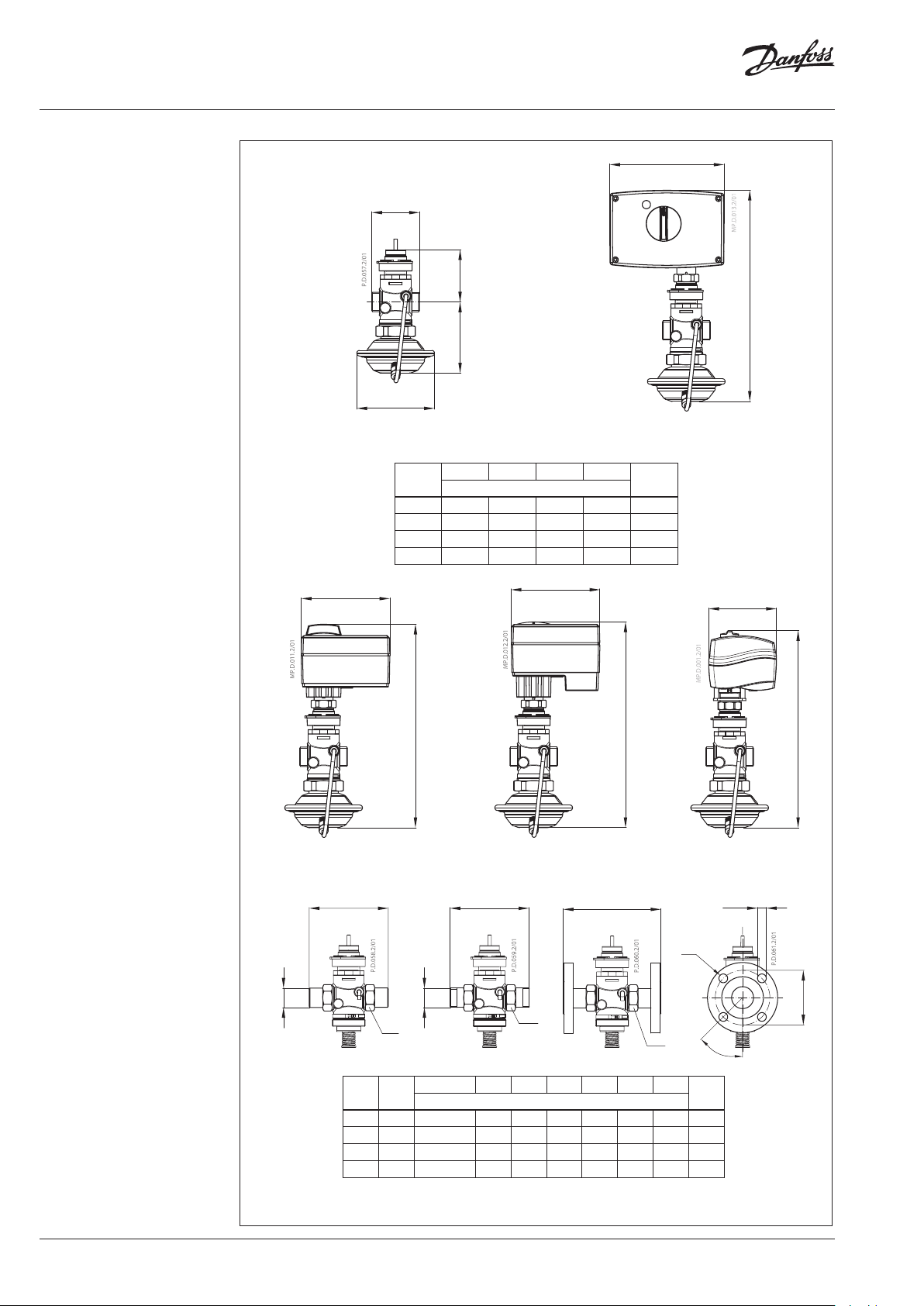

Dimensions

Ø 106

AVQM (DN 15-32)

121

L

1

H

H

DN

L H H

mm

H

1

15 65 97 72 289 1.9

20 70 97 72 289 1.9

25 75 97 75 292 2.0

32 100 97 76 293 2.5

121

Weight

2

155

AMV(E) 2./ 3. +

AVQM (DN 15-32)

(kg)

2

H

92

AMV(E) 10 +

AVQM (DN 15)

d

276

279

AMV(E) 13 +

AVQM (DN 15)

L

3

R

SW

SW d L1 2)L2L

1)

DN R

15 ⁄ 32 (G ⁄A) 21 13 0 120 139 65 14 4

20 ⁄ 41 (G 1A) 26 150 131 154 75 14 4

25 1 50 (G 1⁄A) 33 160 145 159 85 14 4

32 1⁄ 63 (G 1³⁄A) 42 - 177 18 4 10 0 18 4

1)

Conical ex t. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

L

2

L

1

SW

SW

k d

3

mm

AVQM (DN 15)

n

2

n

AMV 150 +

d

2

45°

277

k

6 | VD.DB.V9.02 © Danfoss | 2019.02

Page 7

Data sheet AVQM (PN 16)

VD.DB.V9.02 | 7© Danfoss | 2019.02

Page 8

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet AVQM (PN 16)

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2019.028 | VD.DB.V9.02

Loading...

Loading...