Page 1

Data sheet

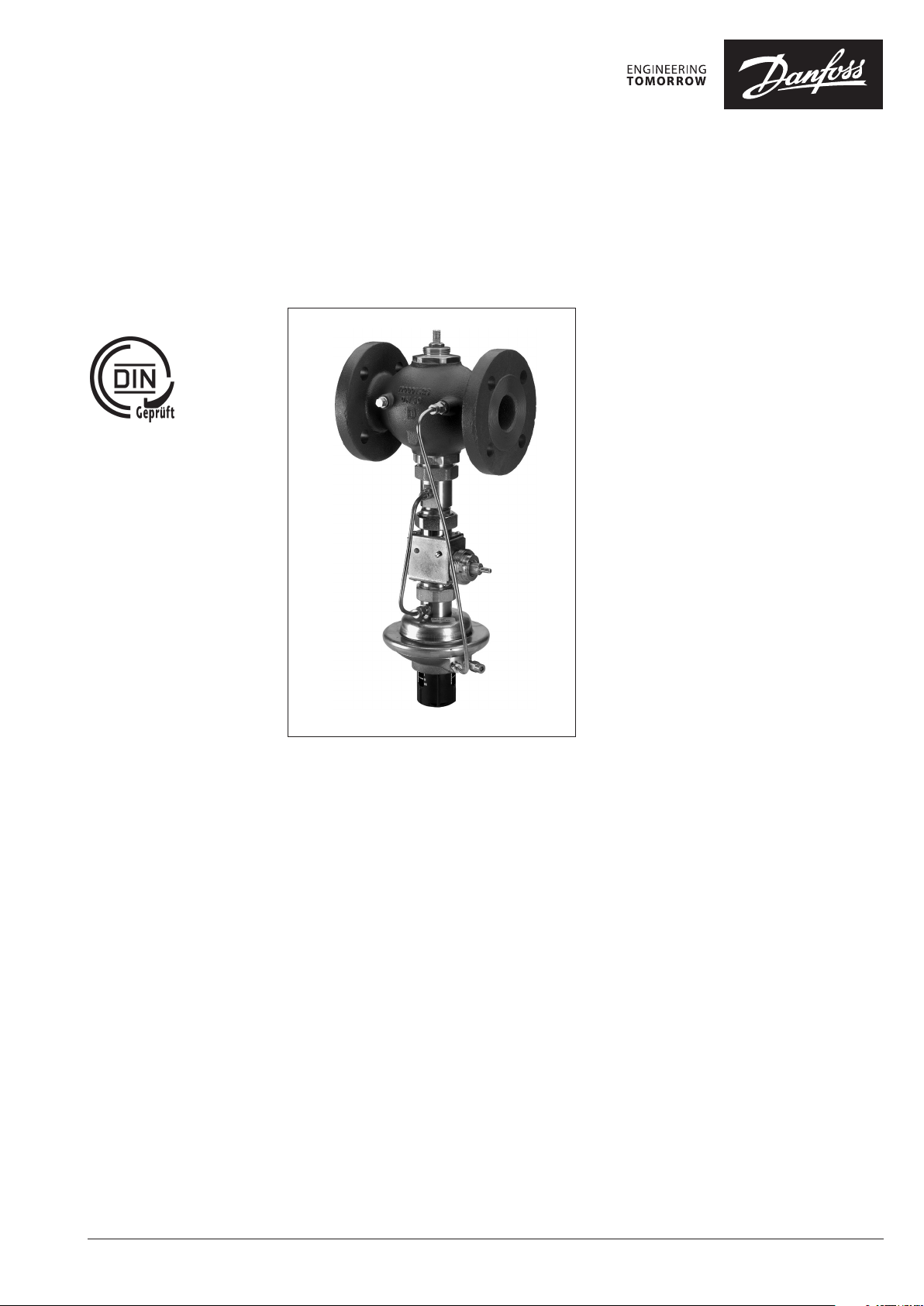

Differential pressure, flow and temperature controller (PN 25)

AVPQT - return mounting, adjustable setting

Description

The AVPQT is a self-acting differential pressure,

flow and temperature controller primarily for use

in district heating systems. The controller closes

on rising differential pressure or temperature, or

when set max. flow is exceeded.

AVPQT controller can be combined with AVT or

STM thermostatic actuators.

The AVPQT controller have a control valve with

adjustable flow restrictor, combination piece

with connection neck for thermostat, an actuator

with two control diaphragms and handle for

differential pressure setting.

The controllers combined with AVT and STM

thermostats are type-tested acc. to EN 14597.

Controllers combined with STM thermostats

protect systems against exceeding temperatures.

Applications:

- District heating systems acc. to DIN 4747

- Heating systems acc. to EN 12828 (DIN 4751)

and EN 12953-6 (DIN 4752)

- Water heating systems for drinking and

industrial waters acc. to DIN 4753.

Main data:

• DN 15-50

• kVS 4.0-25 m3/h

• Flow range: 0.07-15 m3/h

• PN 25

• Setting range: 0.2-1.0 bar

• Flow restrictor ∆pb: 0.2 bar

• Setting ranges:

- AVT:

−10 … 40 °C / 20 … 70 °C / 40 … 90 °C / 60 … 110 °C

and

10 … 45 °C / 35 … 70 °C / 60 …

- STM:

20

…

75 °C / 40

• Temperature:

- Circulation water / glycolic water up to 30 %:

2 … 150 °C

• Connections:

- Ext. thread (weld-on, thread and flange

tailpieces)

- Flange

…

95 °C / 30

100 °C / 85

…

110 °C

…

125 °C

© Danfoss | 2017.01

VD.DC.M5.02 | 1

Page 2

Data sheet AVPQT (PN 25)

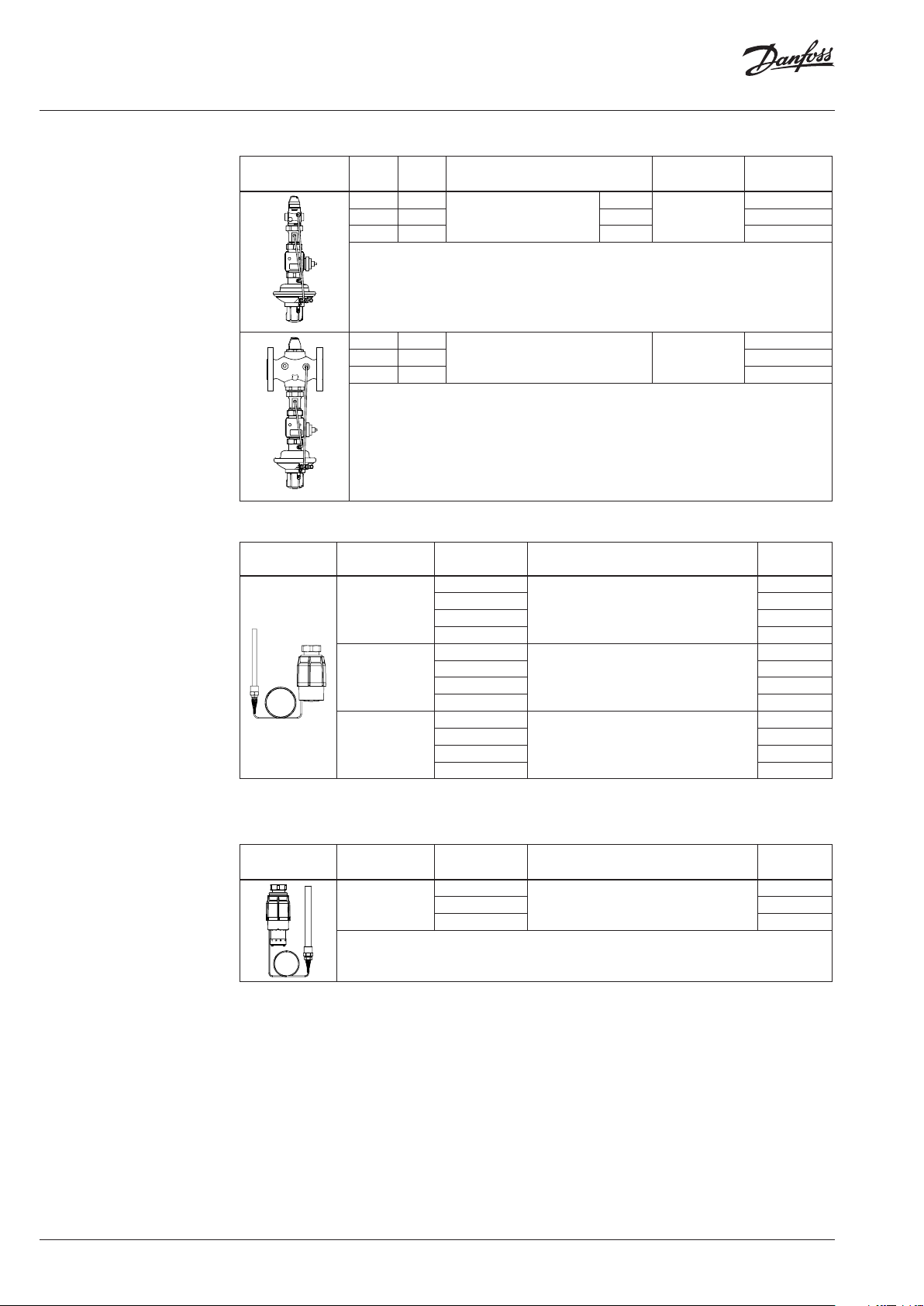

Ordering

Example:

AVT (or STM) / AVPQT controller:

Differential pressure; flow and

temperature controller; return

mounting; DN 15; kVS 4.0; PN 25;

setting range 0.2-1.0 bar;

T

150 °C; ext. thread;

max

- 1× AVPQT DN 15 controller

Code No: 003H6807

- 1× AVT thermostatic actuator,

40 … 90 °C

Code No: 065-0598

- 1× Impulse tube set AV R ⁄

Code No: 003H6852

Option:

- 1× Weld-on tailpieces

Code No: 003H6908

The controller AVPQT will be

delivered completely assembled,

inclusive combination piece and

impulse tubes between valve and

actuator. Thermostatic actuator

AVT will be delivered separately.

External impulse tube (AV) must be

ordered separately.

In case of safety temp. monitoring

STM should be ordered instead of

AV T.

AVPQT Controller (return mounting)

Picture

DN k

(mm) (m3/h)

15 4.0

20 6.3 G 1 A 003H6808

25 8.0 G 1¼ A 003H6809

32 12. 5

40 20 00 3H 6811

50 25 00 3H6812

VS

AVT Thermostatic actuator

Picture For valves

DN 15-2 5

DN 32-50

DN 15- 50

1)

conic male thre ad EN 10226-1

2)

without immersion pocket

Connection

Cylindr, ext, thread acc, to ISO

Setting range

–10 … +40

20 … 70 065-0597

40 … 90 065-0598

60 … 110 065-0599

−10 … +4 0

20 … 70 065-0601

40 … 90 065-0602

60 … 110 065-0603

10 … 45

35 … 70 065-0605

60 … 100 065-0606

85 … 12 5 065-0607

228/1

Flanges PN 25, acc, to EN 1092-2 0. 2-1.0

Temperature sensor with brass immersion

(°C)

pocket, length, connection

255 mm, R ¾

Δp setting range

G ¾ A

170 mm, R ½

210 mm, R ¾

1)

1)

1) 2)

(bar)

0. 2-1.0

Code No,

003H68 07

003 H6810

Code No.

065-0596

065-0600

065-0604

2 | VD.DC.M5.02

STM Safety temperature monitor (actuator)

Picture For valves

1)

conic male thre ad EN 10226-1

DN 15- 50

Limit range

(°C)

30 … 11 0

20 … 75 065-0609

40 … 95 065-0610

Temperature sensor with brass immersion

pocket, length, connection

210 mm, R ¾

1)

© Danfoss | 2017.01

Code No.

065-0608

Page 3

Data sheet AVPQT (PN 25)

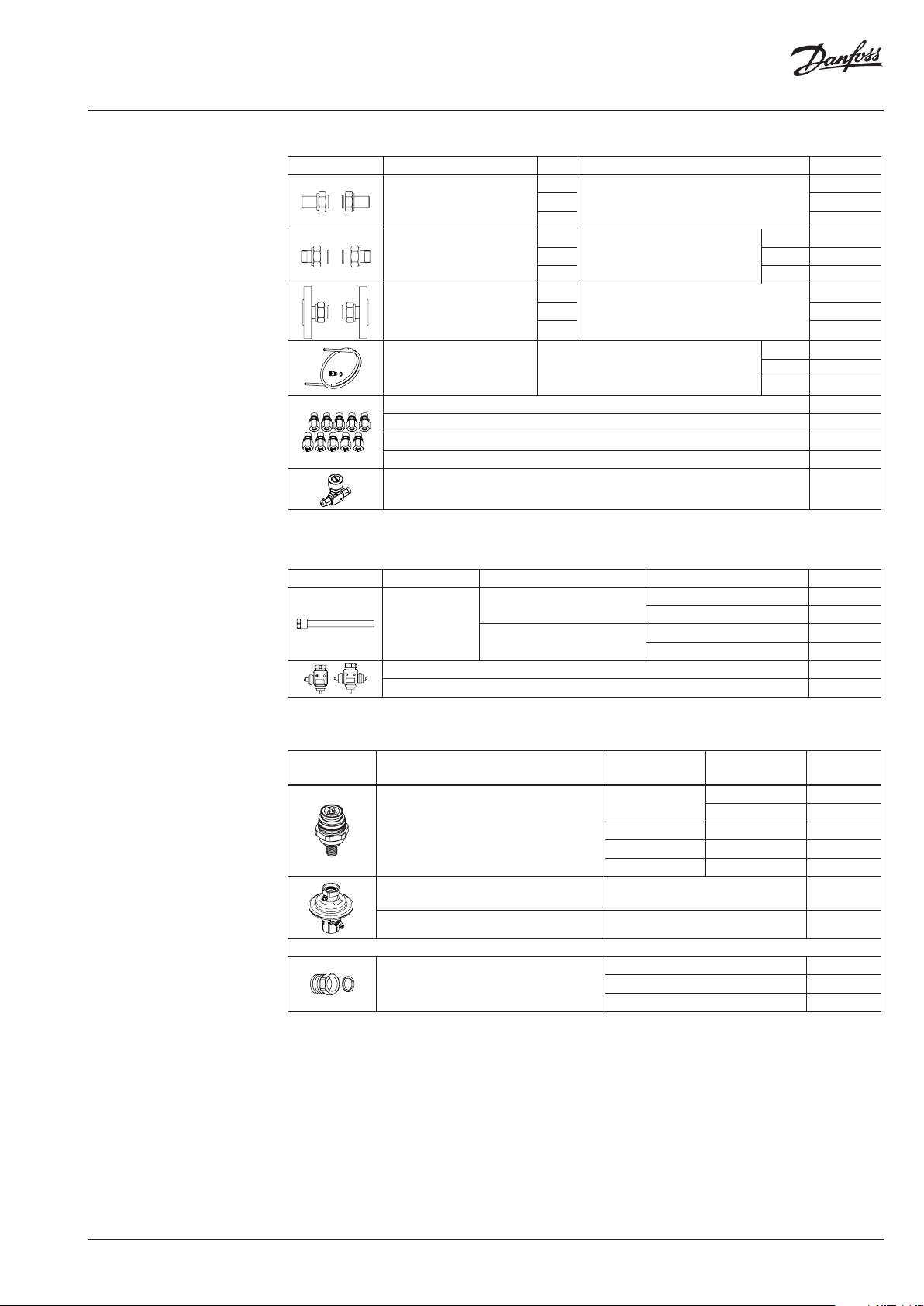

Ordering (continuous)

Accessories for AVPQT

Picture Type designation DN Connection Code No.

15

Weld-on tailpieces

20 003H6909

-

25 00 3H6910

External thread tailpieces

15

20 R ¾ 003H6903

25 R 1 003H6904

Conical ex t. thread acc. to

EN 10226-1

R ½ 003H6902

15

Flange tailpieces

20 003H6916

Flanges PN 25, acc. to EN 1092-2

25 0 03H6 917

Description:

Impulse tube set AV

- 1× copper tube Ø6 × 1 × 1500 mm

- 1× compression t ting 1) for imp. tube

connection to pipe Ø6 × 1 mm

1)

10 compression fittings for imp. tube connection to pipe, Ø6 × 1 mm R ⁄ 003H6857

1)

10 compression fittings for imp. tube connection to pipe, Ø6 × 1 mm R ⁄ 003H6858

1)

10 compression fittings for imp. tube connection to pipe, Ø6 × 1 mm R ½ 003H6859

1)

10 compression fittings for imp. tube connection to actuator, Ø6 × 1 mm G ⁄ 003 H6931

R ⁄ 003H6852

R ⁄ 003H 6853

R ½ 003H6854

Shut off valve Ø6 mm 003H0276

1)

Compression fitting consists of a nipple, compression ring and nut.

Accessories for thermostats

Picture Type designation For controllers Material Code No.

Brass 06 5-4 414

Brass 065 -4416

Immersion pocket

PN 25

AVT / AVPQT DN 15-25

AVT / AVPQT DN 32-50

STM / AVPQT DN 15-50

Stainless steel, mat. No. 1.4571

Stainless steel, mat. No. 1.4435

Combination piece K2 003H6855

Combination piece K3 003H6856

1)

Not for AVT the rmostatic actuator code nu mbers: 065-0604, 065-0605, 065-0606, 065-0607

003H6908

003H6 915

065- 4415

06 5-4 417

1)

1)

1)

1)

Service kits

Picture Type designation DN

Valve insert

Type designation

Actuator with adjustable handle 0. 2-1.0 003H6842

Housing of sensor stuffing box

k

VS

(m3/h)

15

2.5 003H6864

4.0 003H6865

Code No.

20 6.3 003H6866

25 8.0 003H6867

32 / 40 / 50 12.5 / 20 / 25 003H6868

∆p setting range

(bar)

Code No.

for sensors

AVT R ½ 065-4420

AVT R ¾ 065-4421

© Danfoss | 2017.01

VD.DC.M5.02 | 3

Page 4

Data sheet AVPQT (PN 25)

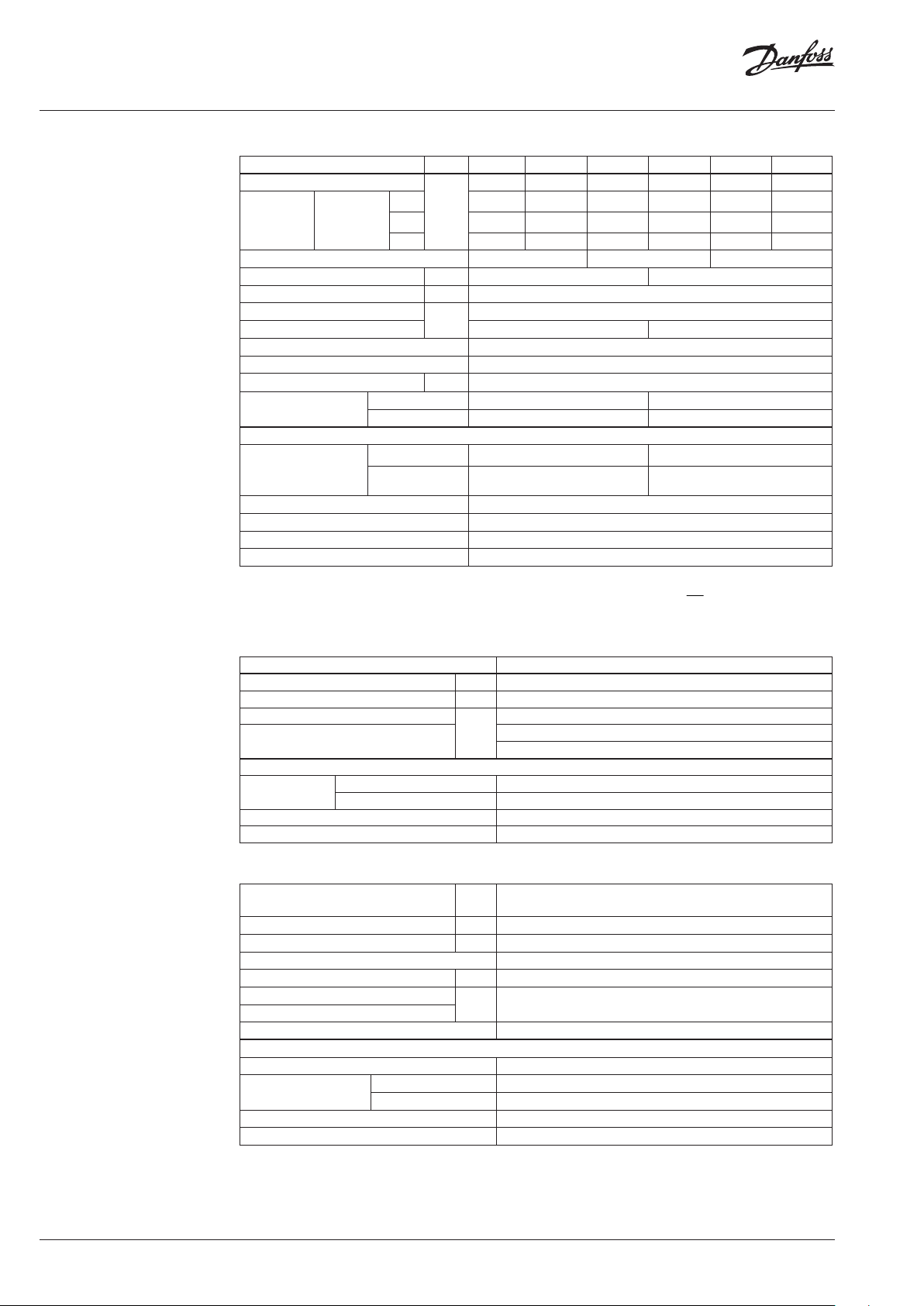

Technical data

Valve

Nominal diameter DN 15 20 25 32 40 50

kVS value

from

Range of max.

flow setting

∆pb 1) = 0.2 bar

m3/h

to

3)

to

Cavitation factor z ≥ 0.6 ≥ 0.55 ≥ 0.5

Leakage acc. to standard IEC 534 % of k

Nominal pressure PN 25

Min. differential pressure

Max. differential pressure 20 16

bar

Medium Circulation water / glycolic water up to 30 %

Medium pH Min. 7, max. 10

Medium temperature °C 2 … 150

Connections

valve External thread Flange

tailpieces Weld-on, external thread and flange -

Materials

thread Red bronze CuSn5ZnPb (Rg5) -

Valve body

flange -

Valve seat Stainless steel, mat. No. 1.4571

Valve cone Dezincing free brass CuZn36Pb2As

Sealing EPDM

Pressure relieve system

1)

∆pb - differe ntial pressure over flow rest rictor

2)

Depends o n the flow rate and valve kVS ; For Q

3)

Higher ma x flow are achieved at highe r differential pressu res over AVPQT controller. In general at p > 1-1 .5 ba r

4.0 6.3 8.0 12. 5 20 25

0.07 0.16 0.2 0.4 0.8 0.8

2.2 3.0 3.5 8.0 10 12

2.4 3.5 4.5 10 12 15

VS

≤ 0.02 ≤ 0.05

see remark

2)

Ductile iron

EN-GJS-400-18-LT (GGG 40.3)

Piston

= Q

-> ∆p

set

max

≥ 0.5 bar; For Q

min

< Q

->

set

p

max

min

2

Q

k

VS

p

b

Actuator

Typ e AVPQ T

Actuator size cm

Nominal pressure PN 25

Flow restrictor diff. pressure, ∆p

b

Di. pressure setting ranges and

spring colours

Materials

Actuator housing

Upper casing of diaphragm

Lower casing of diaphragm

Diaphragm EPDM

Impulse tube Copper tube Ø6 × 1 mm

bar

2

54

0.2

0. 2-1.0

yellow

Stainless steel, mat. No.1.4301

Dezincing free brass CuZn36Pb2As

AVT Thermostatic actuator

Setting range X

s

°C

Time constant T acc. to EN 14597 s max. 50 (170 mm, 210 mm), max. 30 (255 mm)

Gain K

s

mm/°K 0.2 (170 mm), 0.3 (210 mm), 0.7 (255 mm)

Max. adm. temperature at sensor 50 °C above maximum setpoint

Max. amb. temperature at thermostat °C 0 … 70

Nominal pressure sensor

Nominal pressure immerison pocket

PN 25

Capillary tube length 5 m (170 mm, 210 mm), 4 m (255 mm)

Materials

Temperature sensor Cooper

Ms design Brass, nickel-plated

Immersion pocket

1)

Stainless steel design Mat. No. 1.4571 (170 mm), mat. No. 1.4435 (210 mm)

Handle for temp. setting Polyamide, glass fiber-reinforced

Scale carrier Polyamide

1)

for sensor 170 and 210 mm

−10 … 40 / 20 … 70 / 40 … 90 / 60 … 110

10 … 45 / 35 … 70 / 60 … 100 / 85 … 125

4 | VD.DC.M5.02

© Danfoss | 2017.01

Page 5

Data sheet AVPQT (PN 25)

Technical data (continuous)

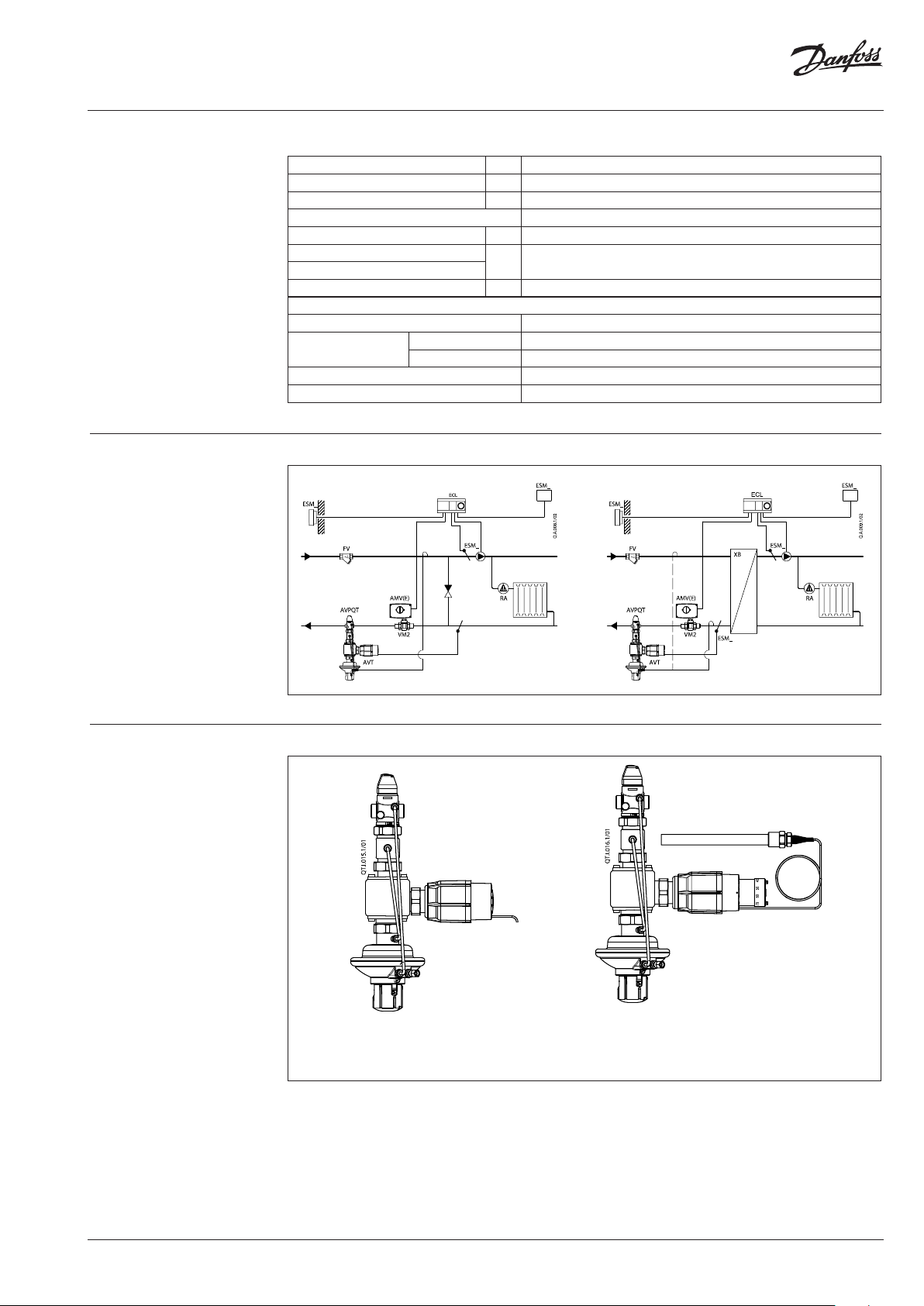

Application principles

The controller must be installed

in the return pipe only.

STM Safety temperature monitor (actuator)

Limit range X

Time constant T acc. to EN 14597 s ma x. 100

Gain K

Max. adm. temperature at sensor 80 °C above ma ximum setpoint

Max. amb. temperature at thermostat °C 0 … 70

Nominal pressure sensor

Nominal pressure immerison pocket

Capillary tube length m 5

Materials

Temperature sensor Cooper

Immersion pocket

Handle for temp. setting Polyamide, glass fiber-reinforced

Scale carrier Polyamide

s

s

Ms design Brass, nickel-plated

Stainless steel design mat. No. 1.4435

°C 20 … 75 / 40 … 95 / 30 … 110

mm/°K 0.3

PN 25

Combinations

AVT / AVPQT

- Differential pressure, flow and temperature controller

STM / AVPQT

- Differential pressure and flow controller with

safety temperature monitor

© Danfoss | 2017.01

VD.DC.M5.02 | 5

Page 6

Data sheet AVPQT (PN 25)

Installation positions

Differential pressure, flow and temperature

controller

Up to medium temperature of 100 °C the

controllers can be installed in any position.

Temperature sensor

The place of installation must be chosen in a way

that the temperature of the medium is directly

taken without any delay. Avoid overheating of

temperature sensor. The temperature sensor

must be immersed into the medium in its full length.

Temperature sensors 170 mm R½ and 210 mm R¾

- The temperature sensor may be installed in

any position.

For higher temperatures the controllers have

to be installed in horizontal pipes only, with a

pressure and temperature actuator oriented

downwards.

Temperature sensor 255 mm R¾

- The temperature sensor must be installed as

shown on the picture.

Pressure temperature

diagram

6 | VD.DC.M5.02

② EN-GJS- 400-18-LT (GGG 40.3) PN 25

① CuSn5ZnPb (Rg5) PN 25

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2 and EN 1092-3).

© Danfoss | 2017.01

Page 7

Data sheet AVPQT (PN 25)

Flow diagram

Sizing and setting diagram

Relation between actual flow and number of revolutions on flow restictor. Values given are approximate.

DN 50 k

25

VS

12. 5

VS

DN 25 k

DN 20 k

DN 15 k

DN 40 k

20

VS

8.0

VS

6.3

VS

4.0

VS

DN 32 k

1 = 360 º

Flow can be adjusted by turning flow restrictor screw

counter-clockwise as shown in this diagram.

Water flow shown at dif ferential pressure across flow

Remark:

Controllers D N 40 and DN 50 have the same cur ve up to 9 revolutions.

restrictor 0.2 bar (20 kPa) and across the controller

from 0.5 bar (50 kPa) to 16/20 bar (1600/2000 kPa).

© Danfoss | 2017.01

VD.DC.M5.02 | 7

Page 8

Data sheet AVPQT (PN 25)

Sizing

- inderectly connected heating

system

Example

Motorised control valve (MCV) for indirectly

connected heating system requires differential

pressure of 0.3 (30 kPa) bar and flow less than

1150 l/h. Return temperature is limited to 70 °C.

Given data (AVPQT):

Q

= 1.15 m3/h (1150 l/h)

max

∆p

= 1.0 bar (100 kPa)

min

∆p

∆p

∆pb 1) = 0.2 bar (20 kPa)

Remark:

1)

∆pb is differe ntial pressure over flow rest rictor

= 0.05 bar (5 kPa)

exchanger

= 0.3 bar (30 kPa) selected

MCV

The differential pressure set value is:

∆p

∆p

∆p

= ∆p

set value

set value

set value

exchanger

= 0.05 + 0.3

= 0.35 bar (35 kPa)

+ ∆p

MCV

The total pressure loss across the controller is:

∆p

= ∆p

AVPQT

∆p

= 1.0 − 0.05 − 0.3

AVPQT

∆p

= 0.65 bar (65 kPa)

AVPQT

min

− ∆p

exchanger

− ∆p

Q

max

MCV

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

pp

1.15

bAVPQT

0.20.65

kv = 1.7 m3/h

Solution:

The example selects:

- AVPQT DN 15, kVS value 4.0, with differential

pressure setting range 0.2-1.0 bar, flow setting

range 0.15-1.4 m3/h and

- AVT 170 mm, temperature setting range

40 … 90 °C.

p

p

min

AVPQ T

AVT

p

b

p

AVPQT

p

MCV

exchanger

8 | VD.DC.M5.02

© Danfoss | 2017.01

Page 9

Data sheet AVPQT (PN 25)

Design

1. Cover

2. Adjustable flow restrictor

3. Valve body

4. Valve insert

5. Pressure relieved valve cone

6. Valve stem

7. Control drain

8. Control diaphragm for flow

control

9. Control diaphragm for diff.

pressure control

10. Setting spring for diff.

pressure control

11. Handle for diff. pressure

setting, prepared for sealing

12. Union nut

13. Compression fitting for

impulse tube

14. Impulse tube

15. Upper casing of diaphragm

16. Lower casing of diaphragm

17. Thermostatic actuator AVT,

STM

18. Thermostat stem

19. Bellows

20. Setting spring for

temperature control

21. Handle for temperature

setting, prepared for sealing

22. Scale carrier

23. Capillary tube

24. Flexible protected pipe

(at 255mm only)

25. Temperature sensor

26. Immersion pocket

27. Combination piece K2

28. Connection piece V

29. Sensor stuffing box

30. Housing of sensor stuffing

box

31. Eccess pressure safety valve

32. Safety spring

AVT 255

AV T 170

AV T 210

STM

24

AVT

STM

© Danfoss | 2017.01

AVPQT

VD.DC.M5.02 | 9

Page 10

Data sheet AVPQT (PN 25)

Function

Differential pressure, flow and temperature

controller

Flow volume causes pressure drop across

the adjustable flow restrictor. Resulting

pressures are being transferred through the

impulse tubes and/or control drain in the

actuator stem to the actuator chambers and

act on control diaphragm for flow control.

The flow restrictor diff. pressure is controlled

and limited by means of built-in spring for

flow control. Control valve closes on rising

differential pressure and opens on falling

differential pressure to control max flow.

Pressure changes from flow and return pipes

are being transferred through the impulse

tubes to the actuator chambers and act on

control diaphragm for diff. pressure control.

The diff. pressure is controlled by means

of setting spring for diff. pressure control.

Control valve closes on rising differential

pressure and opens on falling differential

pressure to maintain constant differential

pressure.

Controller is equipped with excess pressure

safety valve, which protects control

diaphragm for diff. pressure control from too

high differential pressure.

Safety Temperature Monitor (STM)

- Function

The safety temperature monitor is

proportional temperature controller which

controls temperature and protects the system

against exceeding temperatures. The valve

cone is soft sealed and pressure relieved.

Handle for limit setting can be sealed.

- Extended safety function

If there is a leakage in the area of the

temperature sensor, the capillary tube, or the

thermostat, the valve closes by a safety spring

in the safety thermostat. In this case safety

temperature monitor (actuator) must be

replaced.

- Physical Function Principle

The safety temperature monitor operates

in accordance with the liquid expansion

principle. The temperature sensor, the

capillary tube and the bellows are filled with

liquid. As the temperature at the temperature

sensor rises, the liquid expands, the

thermostat stem moves out and closes the

valve.

Temperature Controller (AVT)

- Function

By increasing of medium temperature valve

cone moves towards the seat (valve closes),

by decreasing of medium temperature valve

cone moves away from the seat (valve opens).

Handle for temperature setting can be sealed.

- Physical Function Principle

Medium temperature changes cause pressure

changes in temperature sensor. Resulting

pressure is being transferred through the

capillary tube to the bellows. Bellows moves

thermostat stem and opens or closes the

valve.

In case the temperature at the temperature

sensor exceeds the adjusted set point, safety

temperature monitor interrupts energy

supply by closing the valve. As soon as the

temperature at the temperature sensor drops,

the valve opens automatically.

Settings Temperature setting (AVT)

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

Differential pressure setting

Differential pressure setting is being done by

the adjustment of the setting spring for diff.

pressure control. The adjustment can be done by

means of handle for diff. pressure setting and/or

pressure indicators.

Temperature setting is being done by the

adjustment of the setting spring for temperature

control. The adjustment can be done by means

of handle for temperature setting and/or

temperature indicators.

Limit setting (STM)

Limit setting is being done by the adjustment of

the setting spring for temperature control. The

adjustment can be done by means of handle for

limit setting and/or temperature indicators.

10 | VD.DC.M5.02

© Danfoss | 2017.01

Page 11

Data sheet AVPQT (PN 25)

Adjustment diagram Differential pressure setting

Relation between scale figures and differential

pressure.

Note: The values given are approximate

Temperature setting

Relation between scale numbers 1-5 and closing

temperature.

Note: The values given are approximate

AVT Thermostat ... 210 mm

AVT Thermostat ... 255 mm

Note:

STM Safety temperature monitor (actuator):

temperature scale is already written on the product

© Danfoss | 2017.01

VD.DC.M5.02 | 11

Page 12

Data sheet AVPQT (PN 25)

Dimensions

H

150

Ø 76

AVT / AVPQT

H

STM / AVPQT

AVT

DN 15 20 25 32 40 50

H (AV T AVPQT ) mm 402 402 405 474 474 474

Weight (AVPQT) kg 3.0 3.3 3.5 8.2 11 12

Weight (AVT ) 1.3 (sensor 170 mm), 1.5 (210 mm), 1.6 (255 mm)

194

Ø 82

STM

12 | VD.DC.M5.02

DN 15 20 25 32 40 50

H (STM AVPQT) mm 402 402 405 474 474 474

Weight (AVPQT) kg 3.0 3.3 3.5 8.2 11 12

Weight (STM) 2.6 (sensor 210 mm)

© Danfoss | 2017.01

Page 13

Data sheet AVPQT (PN 25)

Dimensions (continuous)

174

SW 17

AV T 170

SW 25 (R ½)

SW 27 (R ¾)

R ½; R ¾

Ø 9.5

170

6

M14×1

AV T 170

Immersion p ocket

M 20×1 (R ½)

M 22×1 (R ¾)

Housing of sensor

stuffing box

Ø 12

SW 22

26 (R ½)

30 (R ¾)

R ½

SW 22

Combination piece K2

223

AV T 210

STM

85

Ø 16

M22×1

Immersion p ocket

109

Ø 19

215

10

SW 27

AVT 210 / STM

R ¾

SW 22

108

Combination piece K3

Ø 16

266

R ¾

AVT 255

109

L

3

L

2

L

1

d

2

n

d

SW

R

SW

k

SW

DN R

1)

SW d L

2)

L2L

1

mm

k d

3

2

n

15 ⁄ 32 (G ⁄A) 21 130 120 139 65 14 4

20 ⁄ 41 (G 1A) 26 15 0 131 154 75 14 4

25 1 50 (G 1⁄A) 33 160 145 159 85 14 4

32 1⁄ - 42 - 17 7 184 100 18 4

40 - - 47 - - 204 11 0 18 4

50 - - 60 - - 234 125 18 4

1)

Conical ex t. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

© Danfoss | 2017.01

VD.DC.M5.02 | 13

Page 14

Data sheet AVPQT (PN 25)

14 | VD.DC.M5.02

© Danfoss | 2017.01

Page 15

Data sheet AVPQT (PN 25)

© Danfoss | 2017.01

VD.DC.M5.02 | 15

Page 16

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet AVPQT (PN 25)

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

16 | VD.DC.M5.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2017.01

Loading...

Loading...