Page 1

Data sheet

Differential pressure controller (PN 16)

AVPL - return mounting, adjustable setting

Description

Ordering

Example:

Differential pressure controller,

return mounting, DN 15, kvs 1.0,

PN 16, setting range 0.05 - 0.25 bar,

t

120 °C, ext. thread

max

- 1× AVPL DN 15 controller

Code No: 003L5030

Option:

- 1× Weld-on tailpieces

Code No: 003H6908

It can be used on primary side of house

substations for smaller systems such as one and

two-family houses.

The controller could be used to control the

differential pressure across radiator systems and

similar systems to keep a constant differential

pressure even with a variable system resistance

kva and/or supply pressure ∆p0.

Main data:

• DN 15

• kvs 1.0, 1.6 m3/h

• PN 16

• Setting range: 0.05-0.25 bar

(factory setting 0.1 bar)

AVPL is a self-acting differential pressure

controller primarily for use in district heating

systems. The controller closes on rising

differential pressure.

• Temperature:

- Circulation water / glycolic water up to 30%:

2 … 120 °C

• Connections:

- Ext thread (weld-on and thread tailpieces)

The controller has a control valve and an actuator

with one control diaphragm.

AVPL Controller

Picture

* Controller inc l. impulse tube set AH (1.5 m at kvs 1.0 and 2.5 m at kvs 1.6) and nipple G⁄ - R⁄ fo r impulse tube connecti on to pipe

DN

(mm)

15

kVS

(m3h)

1.0

1.6 003L5031

Ext. thread acc. to ISO 228/1 G ¾ A 0.05-0.25

Connection

∆p setting range

(bar)

Code No. *

003L5030

Accessories

Picture Type designation DN Connection Code No.

© Danfoss | 2020.03

Weld-on tailpieces

15

External thread tailpieces

Description:

Impulse tube set AH

Fitting for impulse tube connection to pipe

EPP insulation box

10 EPDM o-rings for impulse tube 003L8175

1)

The material fo r the insulation box is approve d according to the fire hazard classif ication B2, DIN 4102.

1)

- 1× copper tube Ø 3 × 1 mm

- 2× fitting for imp. tube connec tion

to actuator and pipe G /

Conical ex t. thread acc. to

EN 10226-1

- 003H6908

AI180286474027en-000902 | 1

R / 003H6902

1.5 m 003L3561

2.5 m 003L5043

5 m 003L3562

G / - R / 003L5042

G / - R ¼ 003L8151

00 3L817 0

Page 2

Data sheet Differential pressure controller AVPL (PN 16)

Technical data

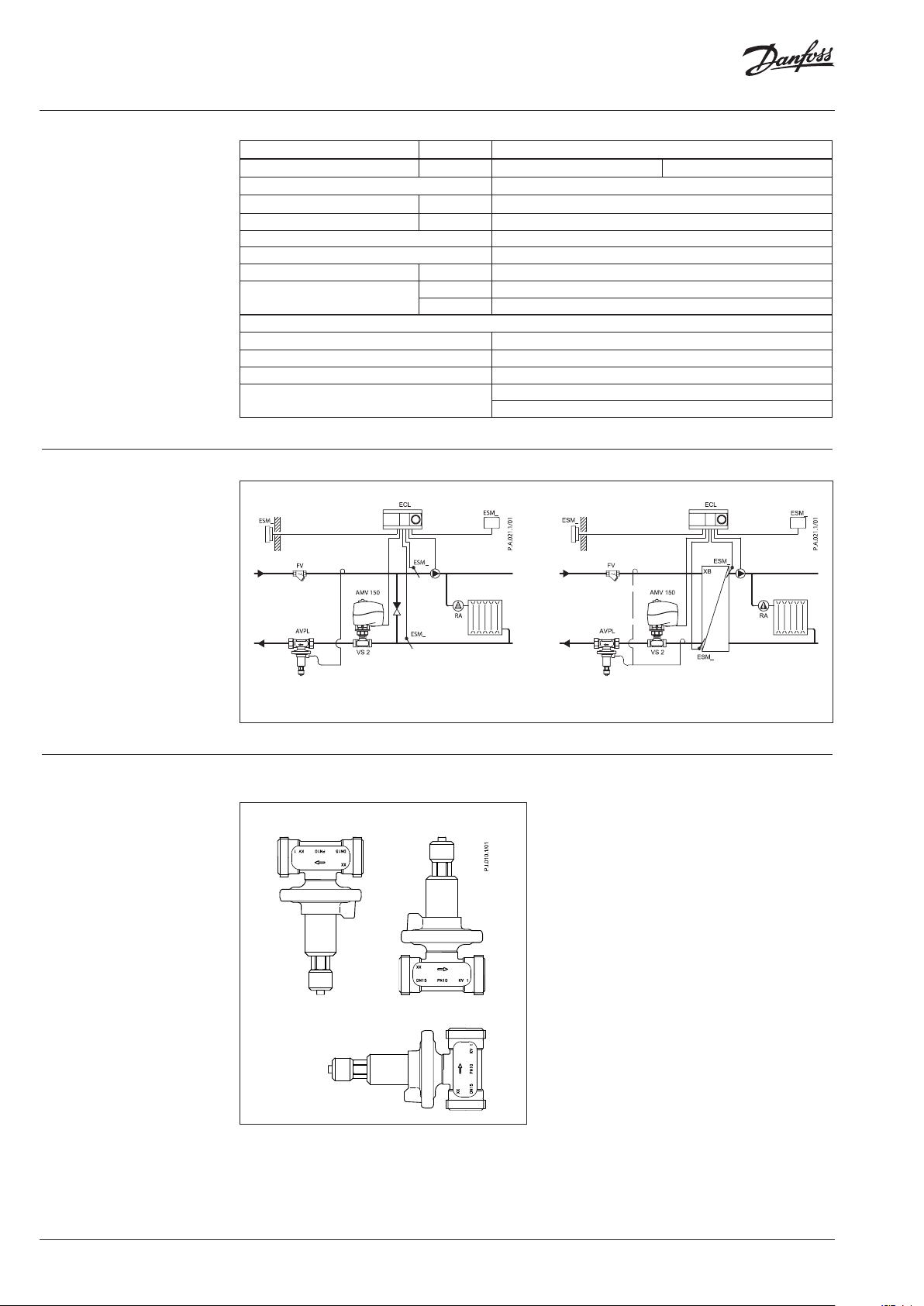

Application principles

The controller AVPL could be

installed in the return pipeline only.

Nominal diameter DN

k

value m3/h 1.0 1.6

vs

Cavitation factor z 0.5

Nominal pressure PN 16

Max. differential pressure bar 4.5

Medium Circulation water / glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature

Connections

Materials

Valve body, etc. Dezincing free brass CuZn36Pb2As

Cone, seat, spindle and spring Stainless steel

Diaphragm and O-ring EPDM

Impulse tube

o

C 2 … 120

valve External thread

tailpieces Weld-on and external thread

Copper tube Ø 3 × 1 mm

Stainless steel tube Ø 0.8 × 0.2 × 800 mm

15

Installation positions

Direct-connected heating system Indirectly connected heating system

The controllers can be installed in any position.

2 | © Danfoss | 2020.03

AI180286474027en-000902

Page 3

Data sheet Differential pressure controller AVPL (PN 16)

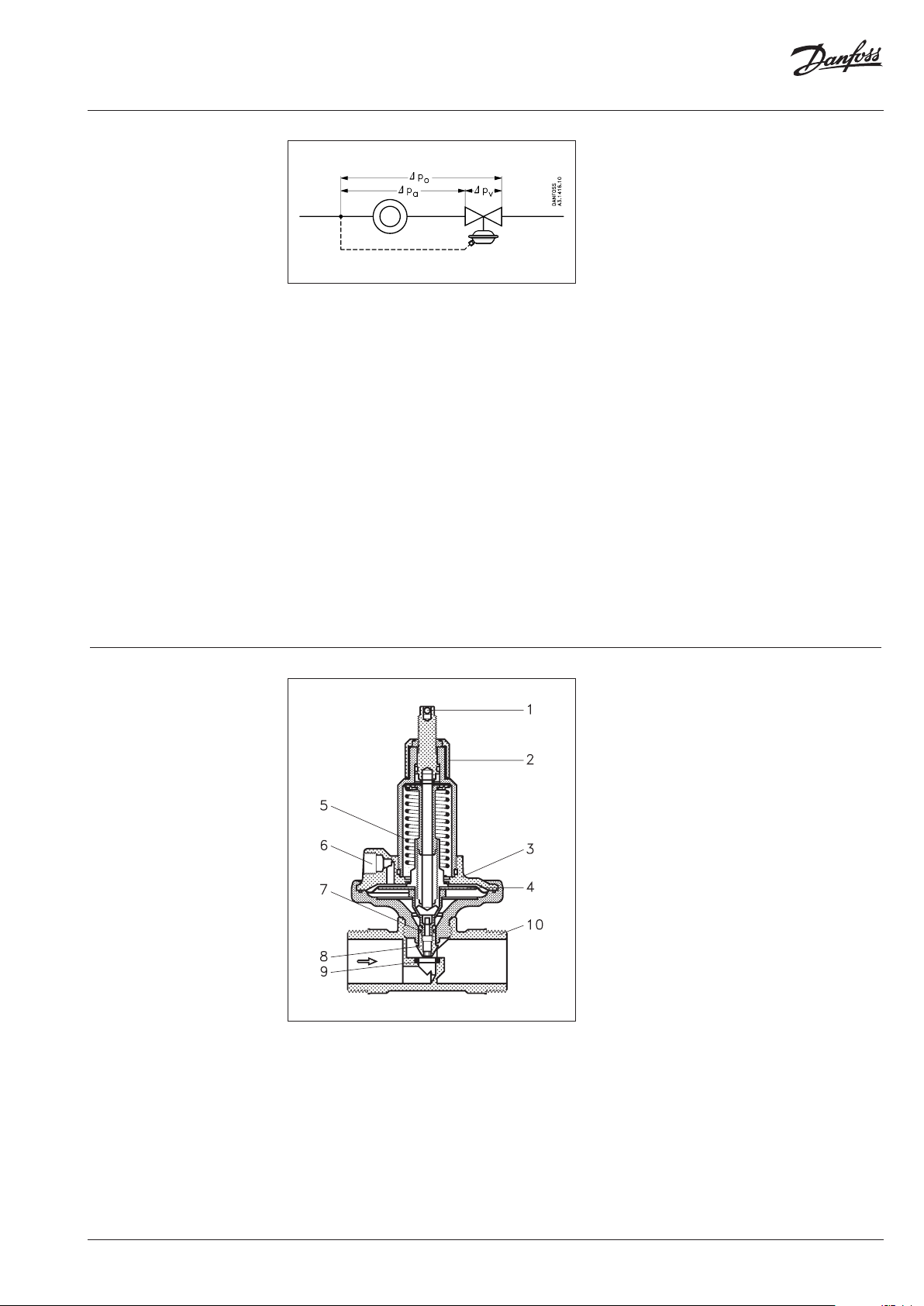

Sizing

Considering the correlation between the

capacity of the system kva, the system flow Q

and the differential pressure ∆pa, the controller

setting ∆pi is determined by:

∆pi = ∆pa = (Q/kva)

2

Based on the stated differential pressure of

the district heating ∆po and the calculated

differential pressure of the system ∆pa, the

differential pressure across the controller valve is

expressed as:

∆pv = ∆po - ∆p

a

Finally, a check is required to ensure that the

actual capacity of the controller k

than its max. capacity k

kvv = Q / √∆pv ≤ k

vs

vs

is smaller

vv

Example:

A heating system with a number of parallel hot

surfaces.

Required flow:

Q = 0.24 m3/h

Total capacity of the system determined to be kva

= 0.6 m3/h.

Calculation of the differential pressure across the

system:

∆pa = (Q/ kva )2 = (0.24 /0.6)2 = 0.16 bar (16 kPa)

The differential pressure from the district heating

is stated to be:

∆po = 0.5 bar (50 kPa) min

Calculation of the differential pressure across the

controller valve:

∆pv = ∆po - ∆pa = 0.5 bar - 0.16 bar = 0.34 bar (34 kPa)

In this example the capacity of the controller

valve is:

kvv = Q/√∆pv = 0.24/√0.34 = 0.412 m3/h

which is less that the max. capacity of the

controller = kvs = 1.0 m3/h.

Design

1. Spindle for differential

pressure setting

2. Bushing

3. Actuator

4. Control diaphragm

5. Setting spring for diff.

pressure control

6. Connection for impulse tube

7. O-ring

8. Pressure relieved valve cone

9. Seat

10. Valve body

AI180286474027en-000902

© Danfoss | 2020.03 | 3

Page 4

Data sheet Differential pressure controller AVPL (PN 16)

2

va

a

k

Q

p

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

=∆

2

vv

v

k

Q

p

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

=∆

()

( )

2

vv

2

va

o

k1k1

p+∆

=

()

()

2

vvs

2

va

o

max

k1k1

p

Q

max

min

+

∆

=

Function AVPL is a proportional controller which operates

according to the following principle:

The degree of opening of the control valve / kv

value is proportional to the deviation between

the controlled and set differential pressure,

∆pa – ∆ps. Thus the resistance/kv value is adjusted

to the actual differential pressure ∆pv and

accordingly, the flow Q is adjusted so that the

desired differential pressure ∆pa is obtained

across the actual resistance kva in the system.

Differential pressure across the system

Differential pressure across the controller

Differential pressure from the district heating

Settings

∆po = ∆pa + ∆p

AVPL can be set to any differential pressure

v

within the range 5 kPa to 25 kPa (0.05 bar to

0.25 bar). The factory pre-setting of the AVPL is

10 kPa (0.1 bar), 1 kPa for each turn.

Rewritten the flow can be expressed as

The max. flow is limited by the min. differential

pressure of the district heating ∆p

capacity of the system k

capacity of the controller k

, and of the max.

va

max

.

v

vs

, the max.

o

min

Max. system flow:

The chosen deviation is large enough to ensure

a stable control and small enough to keep the

controlled differential pressure within acceptable

limits.

As mentioned above, the proportional effect

depends on the correlation between the

controller valve’s degree of opening and the

deviation between the controlled and set

differential pressure. Furthermore, the deviation

depends on the actual differential pressure

across the control valve and the actual control

setting.

The controller is designed in such a way that the

controlled and the set differential pressures are

equal when the flow is about 250 l/h for AVPL 1.0

and 400 l/h for AVPL 1.6 at nominal differential

pressure 50 kPa (∆pv). At min. and max. flow the

controlled differential pressure deviates from the

set pressure with ±1…3 kPa, depending on the

actual differential pressure and setting.

4 | © Danfoss | 2020.03

AI180286474027en-000902

Page 5

Data sheet Differential pressure controller AVPL (PN 16)

Dimensions

DN

15 (kvs 1.0)

15 (kvs 1.6) 0.69

L1

(mm)L2(mm)L3(mm)H(mm)D(mm)aISO 228/1bIS O 7/1

65 120 139 10 4 63 G ¾ A R ½

Weight

(kg)

0.64

Fittings

AI180286474027en-000902

© Danfoss | 2020.03 | 5

Page 6

Data sheet Differential pressure controller AVPL (PN 16)

6 | © Danfoss | 2020.03

AI180286474027en-000902

Page 7

Data sheet Differential pressure controller AVPL (PN 16)

AI180286474027en-000902

© Danfoss | 2020.03 | 7

Page 8

Data sheet Differential pressure controller AVPL (PN 16)

8 | © Danfoss | DHS-SRMT/SI | 2020.03

AI180286474027en-000902

Loading...

Loading...