Page 1

Operating Guide

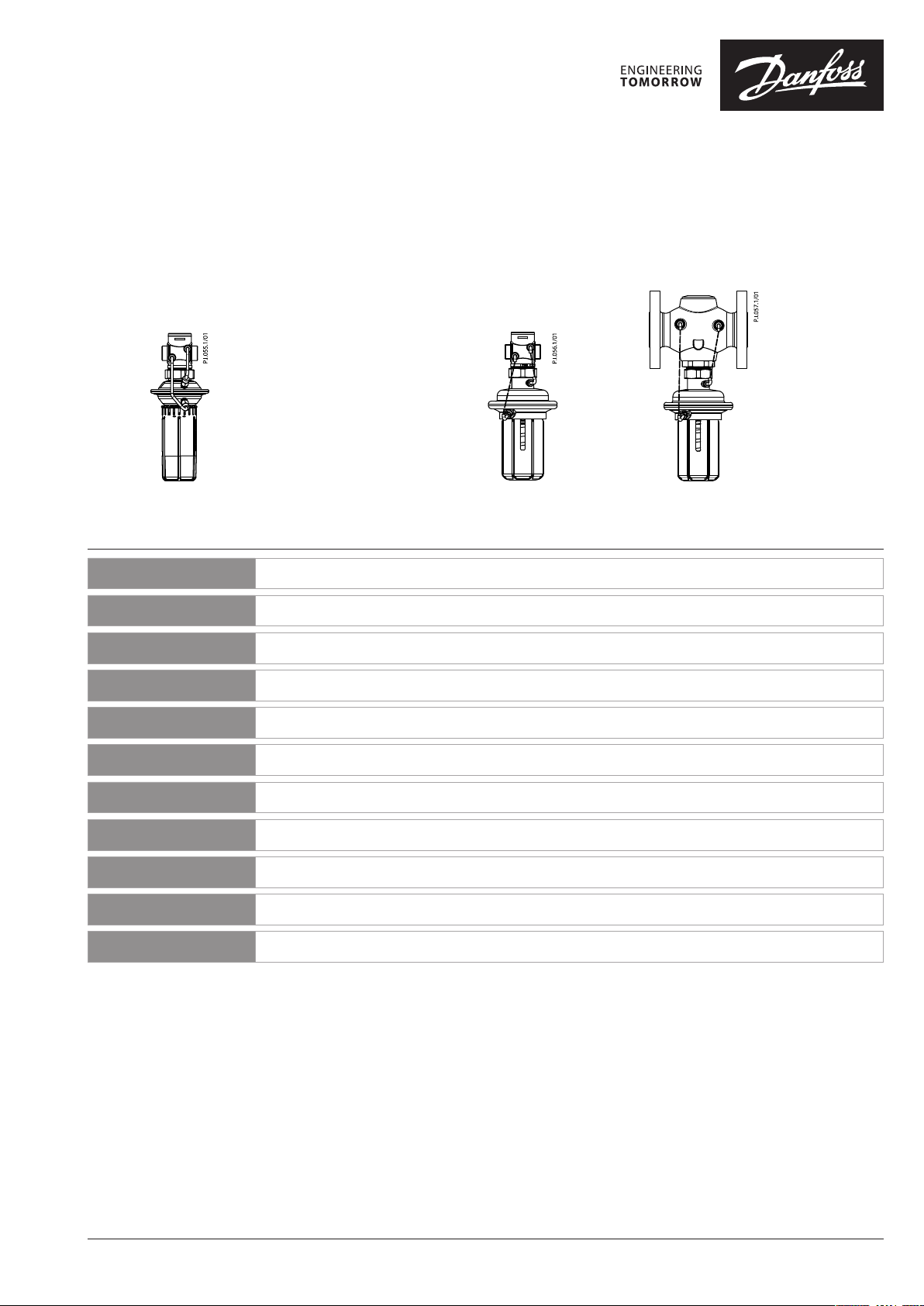

AVPA - PN 16, 25 / 73695060

Differential pressure relief controller

AVPA – PN 16, 25/DN 15 – 50

AVPA (PN16) AVPA (PN25)

DN 15 - 25

p = 0.05 - 0.5

p = 0.2 - 1.0

ENGLISH

DANSK

DEUTSCH

ESPAÑOL

ČESKY

POLSKI

РУССКИЙ

LIETUVIŲ K.

MAGYAR

NEDERLANDS

SLOVENŠČINA

DN 15 - 50

p = 0.2 - 1.0

p = 0.3 - 2.0

Differential pressure relief controller AVPA www.danfoss.com Page 4

Differenstrykaflastningsregulator AVPA www.danfoss.da Page 4

Differenzdrucküberströmregler AVPA

Reguladores de presión diferencial de alivio AVPA www.danfoss.es Page 6

Regulátor diferenčního tlaku přepouštěním AVPA www.danfoss.cz Page 6

Regulator upustowy różnicy ciśnień AVPA www.danfoss.pl Page 7

Регулятор перепуска AVPA www.danfoss.ru Page 8

Slėgio perkryčio reguliatorius apvadui AVPA www.danfoss.lt Page 9

Nyomáskülönbség-szabályozó túláramszelep AVPA

Drukverschil overstort regelaar AVPA

Prelivni regulator diferenčnega tlaka AVPA www.danfoss.si Page 11

DN 32 - 50

p = 0.2 - 1.0

p = 0.3 - 2.0

www.danfoss.de Page 5

www.danfoss.hu Page 9

www.danfoss.nl Page 10

© Danfoss | 2021.09 AQ00008644639901-000201 | 1

Page 2

AVPA - PN 16, 25

❶

❸

< 100 °C

①

❷

> 100 °C

③

②

⑥

❹

> 100 °C

④

< 100 °C

⑦

⑤

DN L (mm)

15 69

20 74

25 79

32 104

40 114

50 134

⑧

❺

①

①

③

②

⊕

①

AQ00008644639901-000201 2 | © Danfoss | 2021.09

Page 3

AVPA - PN 16, 25

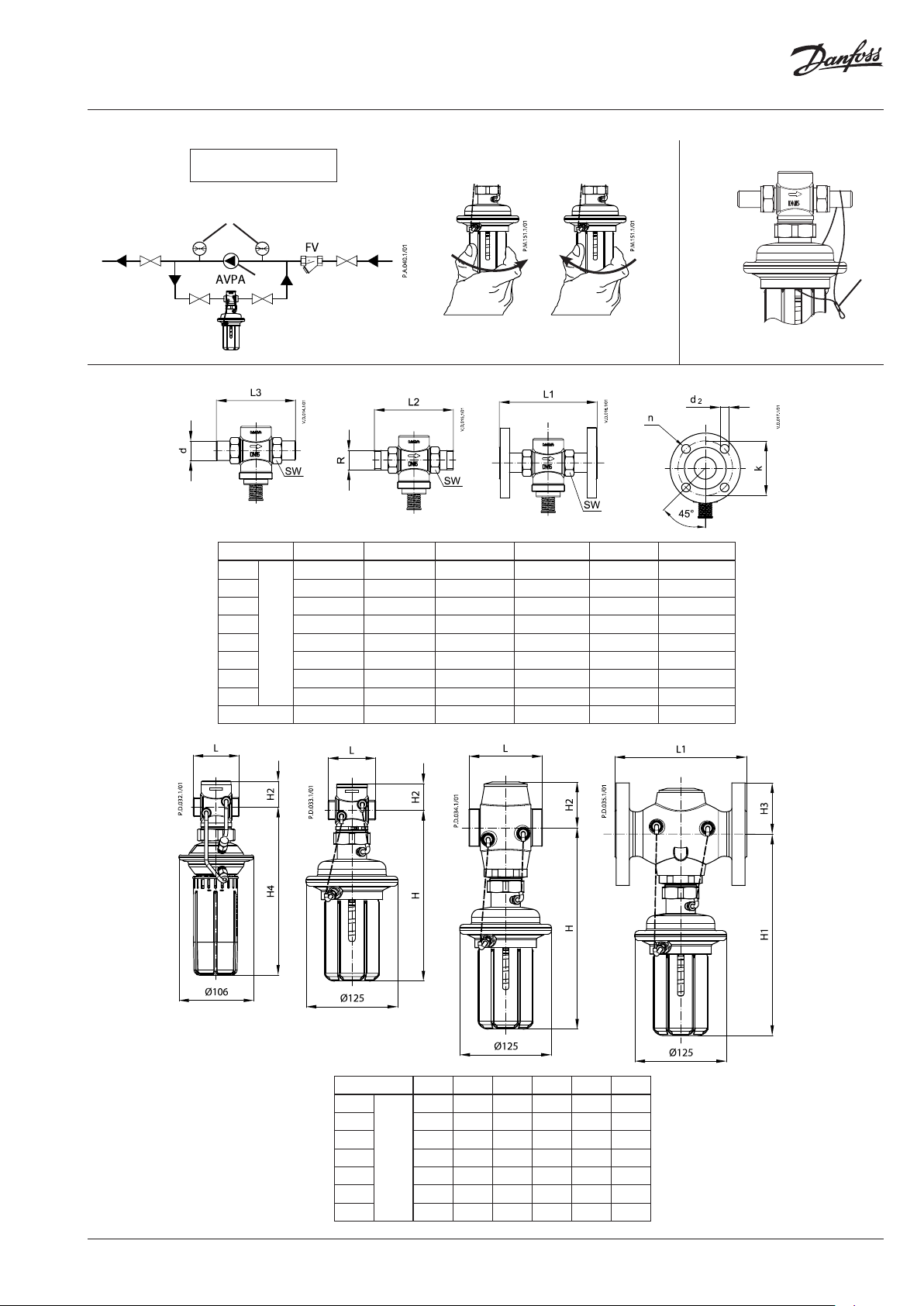

❻

❽

①

∆p = 1.0 - 4.5 bar

③

DN 15 20 25 32 40 50

SW

d 21 26 33 42 47 60

R 1) 1/ 3/ 1 11/ - L1 2) 130 150 160 - - L2 131 144 160 17 7 - L3 139 154 159 184 204 234

k 65 75 85 100 110 125

d2 14 14 14 18 18 18

n 4 4 4 4 4 4

②

④

32 (G ¾A) 41 (G 1A) 50 (G 1¼A) 63 (G 1¾A) 70 (G 2A) 82 (G 2½A)

mm

⑤

❼

①

DN 15 20 25 32 40 50

L

L1 - - - 180 200 230

H 232 232 232 275 275 275

H1 - - - 275 275 275

H2 34 34 37 62 62 62

H3 - - - 70 75 82

H4 232 232 232 - - -

65 70 75 100 110 130

mm

© Danfoss | 2021.09 | 3AQ00008644639901-000201

Page 4

AVPA - PN 16, 25

ENGLISH

Safety Notes

Prior to assembly and commissioning

to avoid injury of persons and

damages of the devices, it is

absolutely necessary to carefully read and

observe these instructions.

Necessary assembly, start-up, and maintenance

work must be performed only by qualified,

trained and authorized personnel.

Prior to assembly and maintenance work on the

controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Definition of Application

The controller is used for differential pressure

relief control of water and water glycol mixtures

for heating, district heating and cooling

systems.

The technical parameters on the product labels

determine the use.

Assembly

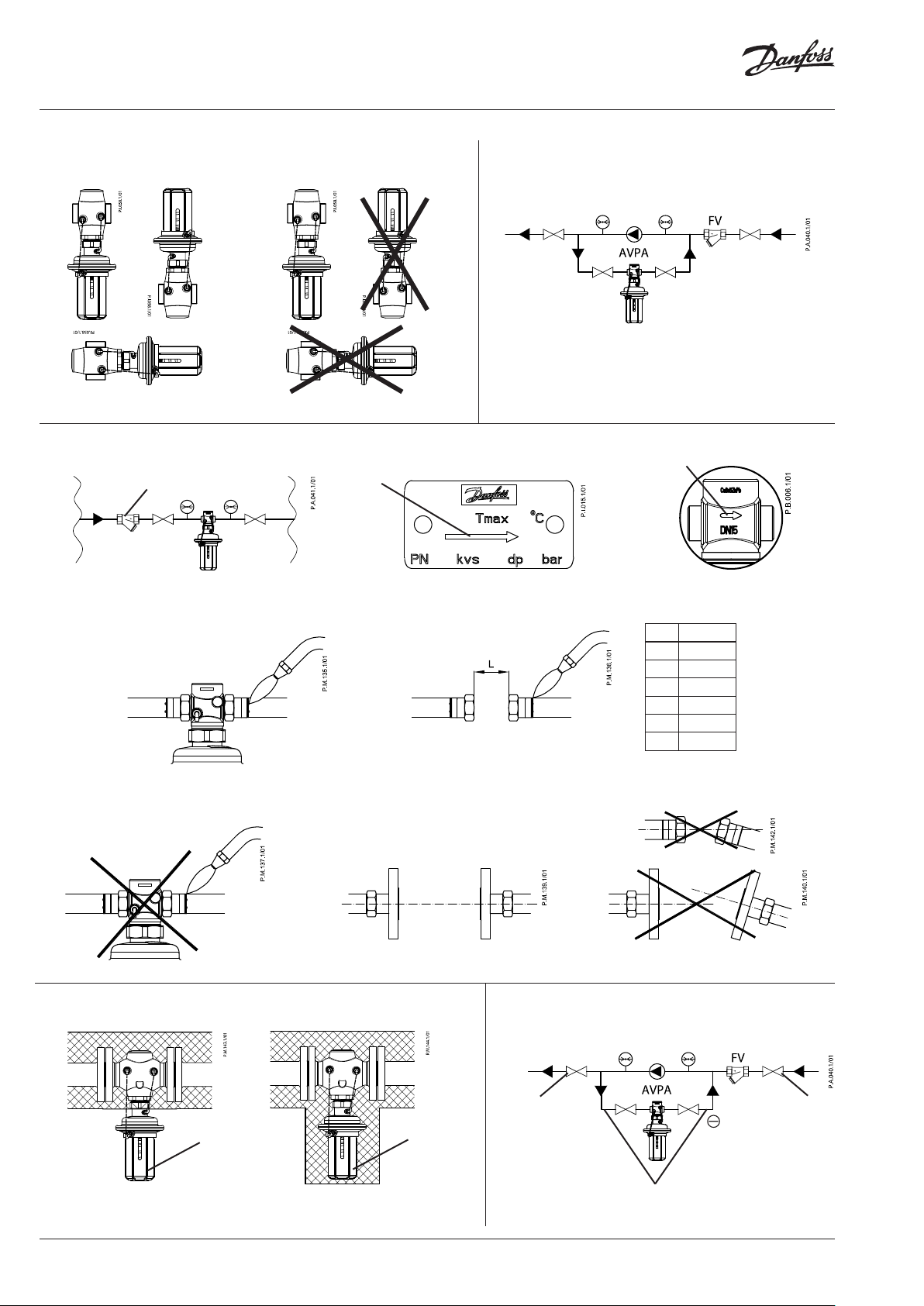

Admissible Installation Positions ❶

Medium temperatures up to 100 °C:

- Can by installed in any position.

Medium temperatures > 100 °C:

- Installation permitted only in horizontal

pipelines with the actuator oriented

downwards.

Installation Location and Installation

Scheme ❷

AVPA by-pass mounting

Valve Installation ❸

1. Clean pipeline system prior to assembly.

2. The installation of a strainer ① in front of the

controller is strongly recommended.

3. Install pressure indicators in front of and

behind the system part to be controlled.

4. Install valve

• The flow direction indicated on the product

label ② or on the valve must be observed ③.

• The valve with mounted weld-on tailpieces

may only be spot welded to the pipeline ④.

The weld-on tailpieces may be welded only

without the valve and seals! ⑤⑥

If these instructions are not observed, high

welding temperatures may destroy the seals.

• Flanges ⑦ in the pipeline must be in parallel

position and sealing surfaces must be clean

and without any damage.

Tighten screws in flanges crosswise in 3

steps up to the maximum torque (50 Nm).

5. Caution:

Mechanical loads of the valve body by the

pipelines are not permitted ⑧.

Insulation ❹

For medium temperatures up to 100 °C the

pressure actuator ① may also be insulated.

Start-up ❺

The valve is closed without pressure .

The valve opens when the d ifferential

pressure ① rises above the adjusted

set-point.

Filling the system, first start-up

1. Slowly open shut-off devices ② in the flow

pipeline.

2. Slowly open shut-off devices ③ in the return

pipeline.

Leak and Pressure Tests

Pressure must be gradually incre ased

at the +/- connection ①.

Non-compliance may cause damages at the

actuator or the valve.

A pressure test of the entire system must be

carried out in accordance with manufacturer’s

instructions.

The maximum test pressure is:

1.5 × PN

PN - see product label !

Putting out of operation

1. Slowly close shut-off devices ② in the flow

pipeline.

2. Slowly close shut-off devices ③ in the return

pipeline.

Settings ❻

Differential Pressure Setting

The diff. pressure setting range is indicated on

the product label ①.

Procedure:

1. Start system, see section “Filling the system,

first start-up“.

Completely open all

shut-off devices in the system.

2. Start pump operation ②

3. Adjustment

Observe pressure indicators ③ or/and

alternatively see handle scale indication.

Increase the setting ④ (stress the spring):

PN16 turn to the right (clockwise), PN25 turn

to the left (counter-clockwise).

Decrease the setting ⑤ (relieve the spring):

PN16 turn to the left (counter-clockwise),

PN25 turn to the right (clockwise).

Seal ❼

The set-point adjuster can be sealed by a seal

wire ①, if necessary.

Dimensions ❽

1)

Conical ext. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

DANSK

Sikkerhedsnoter

Disse instruktioner SKAL læses

omhyggeligt forud for montering og

indkøring samt respekteres for at

undgå skader på personer og udstyr.

Nødvendigt monterings-, opstart- og

vedligeholdelsesarbejde må kun udføres af

faglært og autoriseret personale.

Forud for monterings- og

vedligeholdelsesarbejde på regulatoren skal

systemet være:

- trykløst,

- nedkølet,

- tømt og

- rengjort.

Systemproducentens eller -operatørens

instruktioner skal overholdes.

Anvendelse

Regulatoren anvendes til styring af

differenstrykaflastningen af vand og vandglycolblandinger til varme-, fjernvarme- og

kølesystemer.

De tekniske parametre på produktetiketterne

fastlægger anvendelsen.

Montering

Tilladelige installationsstillinger ❶

Medietemperaturer op til 100 °C:

- Kan monteres i alle stillinger.

Medietemperaturer > 100 °C:

- Må kun installeres i vandrette rørledninger

og med aktuatoren hængende nedad.

Installationsplacering og

installationsplan ❷

AVPA by-pass-montering

Ventilinstallation ❸

1. Rengør rørledningssystemet før montering.

2. Det anbefales stærkt at installere et filter

foran regulatoren ①.

3. Installer trykvisere før og efter den

systemdel, der skal reguleres.

4. Installer ventilen

• Den flowretning, der vises på

produktetiketten eller på ventilen, skal

respekteres ②③.

• Ventilen med monterede svejsestudser

må kun klemmes fast til rørledningen ④.

Svejsestudserne må kun svejses uden ventil

og pakninger! ⑤⑥

Høje svejsetemperaturer kan ødelægge

pakningerne, hvis disse instruktioner ikke

overholdes.

• Flanger ⑦ i rørledningen skal være placeret

parallelt, og pakfladerne skal være rene

og uden skader. Krydsspænd skruerne i

flangerne i 3 trin til maks. moment (50 Nm).

5. Forsigtig:

Rørledningerne må ikke belaste ventilhuset

mekanisk. ⑧

Isolering ❹

Ved medietemperaturer op til 100 °C kan

trykaktuatoren ① også være isoleret.

AQ00008644639901-000201 4 | © Danfoss | 2021.09

Page 5

AVPA - PN 16, 25

Opstart ❺

Ventilen lukkes uden tr yk. Ventilen

åbnes, når dif ferenstrykket ① stige r

over det indstillede sæ tpunkt.

Påfyldning af systemet, første opstart

1. Åbn langsomt for afspæ

rringsanordningerne ② i flowledningen.

2. Åbn langsomt for afspæ

rringsanordningerne ③ i returledningen.

Lækage- og trykprøvning

Trykket skal øges gradvist ved +/tilslutningen ①.

Respekteres dette ikke, kan der opstå

skader på aktuator eller ventil. Der skal

udføres en trykprøvning af hele systemet

i overensstemmelse med producentens

instruktioner.

Det maksimale prøvetryk er

1.5 × PN

PN fremgår af produktetiketten!

Standsning

1. Luk langsomt for afspæ rringsanordningerne

② i flowledningen.

2. Luk langsomt for afspæ rringsanordningerne

③ i returledningen.

Indstilling af sætpunkter ❻

Differenstrykindstilling

Indstillingsområdet for differenstrykket fremgår

af produktetiketten ①.

Fremgangsmåde:

1. Se afsnittet “Påfyldning af systemet, første

opstart” ved start af systemet“. Åbn alle

afspærringsanordninger i systemet helt.

2. Start pumpedrift ②

3. Justering Hold øje med trykviserne ③

og/eller se alternativt på håndgrebets

skalavisning.

Øg indstillingen ④(spænd fjederen): PN16

drejer til højre (med uret), og PN25 drejer til

venstre (mod uret).

Sænk indstillingen ⑤(aflast fjederen): PN16

drejer til venstre (mod uret), og PN25 drejer

til højre (med uret).

Plombering ❼

Sætpunktsstilleskruen kan om nødvendigt

forsegles med en plombe ①.

Mål ❽

1)

Konisk udv. gevind iht. EN 10226-1

2)

Flanger PN 25 iht. EN 1092-2

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung vor der Montage

unbedingt zu beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Vor Montage und Wartungsarbeiten am Regler

die Anlage:

- drucklos machen,

- abkühlen,

- entleeren und

- reinigen.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Bestimmungsgemäße Verwendung

Der Regler regelt den Differenzdruck

überwiegend in Bypassleitungen von Wasser

und Wasser-Glykol-Gemischen in Heizungs-,

Fernheizungs- und Kühlungsanlagen.

Die technischen Daten auf den Typenschildern

sind für den Einsatz maßgebend.

Montage

Zulässige Einbaulagen ❶

Mediumstemperaturen bis 100 °C:

- Einbaulage beliebig.

Mediumstemperaturen > 100 °C:

- Einbau nur in waagerechte Rohrleitung mit

nach unten hängendem Antrieb zulässig.

Einbauort, Einbauschema ❷

AVPA Einbau im Bypass

Einbau Ventil ❸

1. Rohrleitung vor der Montage reinigen.

2. Es ist empfehlenswert einen Schmutzfänger

① vor dem Regler einzubauen.

3. Druckanzeiger vor und hinter dem Ventil

bzw. den entsprechenden Anlageteilen

einbauen.

4. Ventil einbauen

• Durchflussrichtung ② auf dem Typenschild

oder Ventil beachten ③.

• Ventil mit angeschraubten Anschweißenden

nur an die Rohrleitung anheften ④.

Das Einschweißen der Anschweißenden ist

nur ohne Ventil und Dichtungen zulässig!

⑤⑥

Bei Nichtbeachtung zerstören die hohen

Schweißtemperaturen die Dichtungen des

Ventils.

• Flansche ⑦ in der Rohrleitung müssen

parallel, Dichtflächen sauber und ohne

Beschädigungen sein.

Schrauben über Kreuz in 3 Stufen bis zum

max. Drehmoment anziehen (50 Nm).

5. Achtung:

Mechanische Belastungen des Ventilgehäuses

durch die Rohrleitungen sind nicht zulässig ⑧.

Isolierung ❹

Bei Mediumstemperaturen bis 100 °C kann auch

der Druckantrieb ① soliert werden.

Inbetriebnahme ❺

Ohne Druck blei bt das Ventil

geschlossen. Das Ventil öf fnet sich,

über den eingestellten Sollwert steigt.

wenn der Druck vor de m Ventil ①

Füllung der Anlage, Inbetriebnahme

1. Absperrarmaturen ② langsam öffnen.

2. Abperrarmaturen ③ langsam öffnen.

Dichtheits- und Druckprüfung

Druckerhöhung muss am +/Anschluss ① gleichmäßig erfolgen.

Nichtbeachtung kann zu Schäden am Antrieb

und/oder Ventil führen.

Die Druckprüfung der Anlage muss nach

den der Vorgaben des Anlagenherstellers

durchgeführt werden.

Max. Prüfdruck ist:

1.5 × PN

PN siehe Typenschild!

Außerbetriebnahme

1. Absperrarmaturen ② langsam schließen.

2. Absperrarmaturen ③ langsam schließen.

Einstellung Sollwerte ❻

Einstellung Differenzdruck

Sollwertbereich siehe Typenschild ①.

Vorgehensweise:

1. Anlage in Betrieb nehmen, siehe Abschnitt

“Füllung der Anlage, Inbetriebnahme”.

Alle Armaturen in der Anlage ganz öffnen.

2. Pumpe in Betrieb nehmen ②

3. Einstellung

Die Druckanzeigen ③ oder/und

Skalabezeichnungen (Richtwerte!) beachten.

Einstellung erhöhen ④(Feder spannen):

PN16-Rechtsdrehung (im Uhrzeigersinn),

PN25-Linksdrehung (gegen den

Uhrzeigersinn).

Einstellung verringern ⑤(Feder

entspannen): PN16-Linksdrehung (gegen

den Uhrzeigersinn), PN25-Rechtsdrehung

(im Uhrzeigersinn).

Plombierung ❼

Bei Bedarf kann der Sollwertsteller ① durch

Plombierdraht gesichert werden.

Abmessungen ❽

1)

Kegeliges Außengewinde nach EN 10226-1

2)

Flansche PN 25, nach EN 1092-2

© Danfoss | 2021.09 | 5AQ00008644639901-000201

Page 6

AVPA - PN 16, 25

ESPAÑOL

Notas de seguridad

Antes del montaje y de la puesta en

marcha, para evitar daños personales

y perjuicios en los dispositivos, es

absolutamente necesario leer cuidadosamente

estas instrucciones.

El montaje, la puesta en marcha y el trabajo

de mantenimiento necesario deberán ser

realizados solo por personal cualificado y

autorizado.

Antes del montaje y el trabajo de

mantenimiento del controlador, el sistema debe

ser:

- despresurizado

- enfriado,

- vaciado y

- limpiado.

Por favor, cumpla con las instrucciones del

fabricante del sistema o del operador del

sistema.

Aplicación

El controlador se utiliza para el control de la

presión diferencial de alivio de agua y mezcla

agua/glycol en sistemas de Calefacción, District

Heating y Refrigeración.

Los parámetros técnicos en la etiquetas del

producto determinan su uso.

Montaje

Posiciones permitidas

de instalación ❶

Temperatura del medio hasta 100 °C:

- Puede ser instalado en cualquier posición.

Temperatura del medio > 100 °C:

- Instalación permitida sólo en horizontal con

el actuador hacia abajo.

Posición de instalación y Esquema de

instalación ❷

AVPA Montaje en by-pass

Instalación de la válvula ❸

1. Limpie el sistema de tuberías antes del

montaje.

2. Se recomientda la instalación de un filtro

delante del controlador ①.

3. Instale indicadores de presión delante y

detrás de la parte del sistema a controlar.

4. Instale la válvula

• Observe la dirección del caudal indicada en

la etiqueta del producto o en la válvula ②

③.

• La válvula con conectores para soldar solo

pueden ser fijados a la tubería ④.

Los conectores para soldar solo pueden

soldarse sin la válvula y sin sellos ⑤⑥

Si estas instrucciones no se tienen en cuenta,

las altas temperaturas al soldar pueden

destruir los sellos.

• Las bridas ⑦ en la tubería deben estar en

posición paralela y las superficies que sellan

deben estar limpias y sin ningún daño.

Apriete los tornillos en las bridas en diagonal

en 3 pasos hasta el máximo (50 Nm).

5. Precaución:

No se permiten cargas mecánicas del cuerpo de

la válvula por las tuberías ⑧.

Aislamiento ❹

Para temperaturas del medio hasta 100 °C el

actuador de presión ① también puede ser

aislado.

Puesta en marcha ❺

La válvula está cerrada sin presión.

La válvula abre cuando la pre sión

diferencial ① sobrepasa el valor

ajustado.

Llenado del sistema, primera puesta en

marcha

1. Abra lentamente todos los dispositivos de

corte ② en la tubería de impulsión.

2. Abra lentamente todos los dispositivos de

corte ③ en la tubería de retorno.

Escapes y pruebas de presión

La presión debe ir aum entando

gradualmente en la cone xión +/- ①.

El incumplimiento puede causar daños en el

actuador o la válvula.

Una prueba de presión del sistema completo

debe ser realizada de acuerdo con las

instrucciones del fabricante.

La presión máxima de prueba es:

1.5 × PN

PN ver etiqueta del producto!

Fuera de operación

1. Cierre lentamente los dispositivos de corte

② en la tubería de impulsión.

2. Cierre lentamente los dispositivos de corte

③ en la tubería de retorno.

Ajustes ❻

Ajuste de la Presión Diferencial

El rango de ajuste de la presión diferencial se

indica en la etiqueta del producto ①.

Procedimiento:

1. Puesta en marcha del sistema, véase sección

“Llenado del sistema, primera puesta en

marcha“

Abra completamente todos los dispositivos

de corte del sistema.

2. Puesta en marcha de la bomba ②

3. Ajuste

Observe los indicadores de presión ③ y/o

bien mirar la indicación de la escala

Aumentar el ajuste ④(tensionar el muelle):

para PN16, girar a la derecha (sentido de

las agujas del reloj); para PN25, girar a la

izquierda (sentido contrario al de las agujas

del reloj).

Reducir el ajuste ⑤(liberar el muelle): para

PN16, girar a la izquierda (sentido contrario

al de las agujas del reloj); para PN25, girar a la

derecha (sentido de las agujas del reloj).

Sellado ❼

El punto de ajuste fijado puede sellarse con un

alambre sellado ①, si fuera necesario.

Dimensiones ❽

1)

Rosca externa cónica acc. to EN 10226-1

2)

Bridas PN 25, acc. to EN 1092-2

ČESKY

Bezpečnostní informace

Z důvodu maximálního snížení

možnosti poranění osob nebo vzniku

škod na majetku je bezpodmínečně

nutné se před vlastní montáží a uvedením

regulátoru do provozu pečlivě seznámit se

všemi zde uvedenými bezpečnostními

informaci.

Nezbytné montážní práce, kroky při uvádění

do provozu a opravy mohou provádět pouze

kvalifikovaní, proškolení pracovníci, kteří pro

tuto činnost byly určeni.

Před montáží nebo před případnou opravou

nebo servisem regulátoru je nutné, aby

regulovaný systém splňoval následující

podmínky:

- nebyl pod tlakem

- byl dostatečně ochlazen

- vyprázdněn a

- vyčištěn.

Postupujte podle návodu výrobce systému

nebo jeho provozovatele.

Aplikační oblast

Regulátor je určen pro regulaci diferenčního

tlaku přepouštěním vody a směsi vody s

glykolem v systémech vytápění, v systémech

centralizovaného zásobování teplem a v

chladících systémech.

Technické parametry uvedené na typovém

štítku výrobku určuji jeho použití.

Montáž

Přípustná instalační poloha ❶

Teplota média do 100 °C:

- Regulátor lze instalovat v jakékoliv poloze.

Teplota média vyšší než 100 °C:

- Regulátor je možné instalovat pouze

na vodorovné části potrubí, kdy pohon

regulátoru směřuje dolů.

Umístění a schéma instalace ❷

AVPA Montáž na obtokovou větev

Instalace ventilu ❸

1. Před montáží vyčistěte potrubní systém.

2. Před regulátor doporučujeme nainstalovat

filtr ①.

3. Před a za regulovanou součást systému

namontujte tlakoměr.

4. Nainstalujte ventil.

• Při montáži dejte pozor na to ② aby na štítku

vyznačený směr proudění média odpovídal

skutečnosti ③.

• Ventil s namontovanými navařovacími

koncovkami může být napojen pouze přímo

na potrubí ④.

Koncovky musí být navařovány bez těsnění a

připojeného ventilu! ⑤⑥

Jestliže nebude postupováno podle tohoto

návodu, tak může vysoká svařovací teplota

zničit těsnění.

• Příruby ⑦ na potrubí musí být k sobě

orientovány kolmo, kdy styčné těsnící plochy

musí být čisté a bez poškození. Šrouby na

přírubě dotahujte napříč a ve třech krocích

až do dosažení maximálního kroutícího

momentu (50 Nm).

5. Upozornění:

Ventil namontovaný na potrubí se nesmí

žádným způsobem mechanicky zatěžovat ⑧.

AQ00008644639901-000201 6 | © Danfoss | 2021.09

Page 7

AVPA - PN 16, 25

Izolace ❹

Při teplotě média do 100 °C je možné

přímočinný pohon regulátoru ① také

zaizolovat.

Zahájení provozu ❺

V případě, že je tlak rovn oměrný, tak

je ventil uzavřen. Ventil se otevře v

překročí nastavenou hodnotu.

okamžiku, kdy diferenční tl ak ①

Plnění systému, první spuštění

1. Pomalu otevřete uzavírací armatury ②

přívodní větve.

2. Pomalu otevřete uzavírací armatury ③

vratné větve.

Tlaková zkouška a zkouška těsnost

Tlak v +/- spojích ① musí být

zvyšován pos tupně, nikdy ne naráz.

Nedodržení tohoto postupu může způsobit

poškození ovládacího prvku nebo ventilu.

Tlaková zkouška celého systému se může

provádět pouze podle návodu výrobce systému.

Maximální povolený zkušební tlak je:

1.5 × PN

Hodnota PN je uvedená na typovém štítku

výrobku!

Odstavování

1. Pomalu uzavřete uzavírací armatury ②

přívodní větve.

2. Pomalu uzavřete uzavírací armatury ③

vratné větve.

Nastavení ❻

Nastavení diferenčního tlaku

Nastavovací rozsah diferenčního tlaku je

vyznačen na typovém štítku výrobku ①.

Postup:

1. Systém zprovozněte, viz kapitola „Plnění

systému, první spuštění“. Zcela otevřete

všechny uzavírací armatury systému.

2. Zapněte čerpadlo ②

3. Nastavení

Zkontrolujte tlakoměr ③ a/anebo

zkontrolujte měrku v držáku.

Zvýšení nastavení ④(stlačení pružiny): PN16

otočte doprava (ve směru chodu hodinových

ručiček), PN25 otočte doleva (proti směru

chodu hodinových ručiček).

Snížení nastavení ⑤(uvolnění pružiny):

PN16 otočte doleva (proti směru chodu

hodinových ručiček), PN25 otočte doprava

(ve směru chodu hodinových ručiček).

Těsnění ❼

Nastavenou polohu lze v případě nutnosti

zajistit drátovou plombou ①.

Rozměry ❽

1)

Kónický vnější závit dle normy EN 10226-1

2)

Příruba PN 25 dle normy EN 1092-2

POLSKI

Warunki bezpieczeństwa

W celu uniknięcia zranienia osób i

uszkodzenia urządzeń należy

bezwzględnie przed montażem i

uruchomieniem zaworu zapoznać się dokładnie

z niniejszą instrukcją.

Czynności związane z montażem,

uruchomieniem i obsługą mogą być

dokonywane wyłącznie przez osoby

uprawnione i odpowiednio wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ostudzić urządzenia,

- opróżnić układ,

- oczyścić.

Prosimy stosować się do instrukcji producenta

lub operatora układu.

Zastosowanie

Regulator jest stosowany do upustowej regulacji

różnicy ciśnień, dla wody i roztworów wody z

glikolem w instalacjach grzewczych, sieciach

cieplnych i instalacjach chłodzenia.

Dane techniczne na tabliczce znamionowej

określają zakres zastosowań.

Montaż

Dopuszczalne pozycje montażu. ❶

Temperatury czynnika do 100 °C:

- montaż w dowolnej pozycji.

Temperatury czynnika > 100 °C:

- montaż dozwolony tylko na rurociągu

poziomym, z siłownikiem skierowanym w

dół.

Miejsce i schemat montażu ❷

AVPA montaż na obejściu

Montaż zaworu ❸

1. Przed zamontowaniem zaworu przepłukać

instalację.

2. Przed regulatorem zamontować filtra ①.

3. Zamontować manometry przed i za tą

częścią układu, która będzie regulowana.

4. Zamontować zawór.

• Należy zachować kierunek przepływu

zaznaczony na tabliczce znamionowej lub na

korpusie zaworu ②③.

• Zawór z zamocowanymi końcówkami do

przyspawania może być tylko lpunktowo

przyspawany do rurociągu ④.

Końcówki mogą być przyspawane tylko bez

zaworu i uszczelnienia! ⑤⑥

Nie zastosowanie się do tego zalecenia

może spowodować uszkodzenie uszczelnień

wskutek wysokiej temperatury.

• Kołnierze ⑦ na rurociągu muszą być

równoległe a powierzchnie pod uszczelki

czyste i bez uszkodzeń.

Dokręcać śruby przy kołnierzach po

przekątnej, w trzech krokach, aż do

uzyskania maksymalnego momentu (50 Nm).

5. Uwaga:

Nie można dopuścić do powstania

mechanicznych obciążeń korpusu zaworu od

rurociągów ⑧.

Izolacja. ❹

Dla temperatur czynnika do 100 °C siłownik

ciśnieniowy ① może być zaizolowany.

Uruchomienie ❺

Bez oddział ywania ciśnienia zawór

pozostaje zamknięt y. Zawór otwiera

powyżej nastawionej wartości.

się, kiedy różnica ciśnień ① wzrasta

Napełnienie układu, pierwsze

uruchomienie.

1. Powoli otworzyć armaturę odcinającą na

rurociągu zasilającym ②.

2. Powoli otworzyć armaturę odcinającą na

rurociągu powrotnym ③.

Próby szczelności i ciśnienia.

Ciśnienie na podłączeniach +/- ①

należy zwięks zać stopniowo.

Nie przestrzeganie powyższych zasad może

spowodować uszkodzenie siłownika lub zaworu.

Próba ciśnienia dla całego układu musi

być przeprowadzona zgodnie z instrukcją

producenta lub projektanta.

Maksymalne ciśnienie próbne wynosi:

1.5 × PN

Ciśnienie nominalne PN podano na tabliczce

znamionowej urządzenia!

Odłączenie zaworu.

1. Powoli zamknąć armaturę odcinającą ② na

rurociągu zasilającym.

2. Powoli zamknąć armaturę odcinającą ③ na

rurociągu powrotnym.

Nastawy. ❻

Nastawa różnicy ciśnień.

Zakres nastawy różnicy ciśnień podano na

tabliczce znamionowej zaworu ①.

Tok postępowania:

1. Uruchomić układ zgodnie z „Napełnienie

układu, pierwsze uruchomienie”.

Otworzyć całkowicie wszelką armaturę

odcinającą w układzie regulowanym.

2. Uruchomić pompę ②

3. Dokonać nastawienia.

Obserwować wskazania manometrów ③ i/

lub alternatywnie nastawiać według skali

pokrętła nastawczego.

Zwiększyć nastawę ④(naprężyć sprężynę):

PN16 należy obrócić w prawo (zgodnie z

ruchem wskazówek zegara), PN25 — w lewo

(przeciwnie do ruchu wskazówek zegara).

Zmniejszyć nastawę ⑤(poluzować

sprężynę): PN16 należy obrócić w lewo

(przeciwnie do ruchu wskazówek zegara),

PN25 — w prawo (zgodnie z ruchem

wskazówek zegara).

Plomba. ❼

Nakrętka nastawcza może zostać w razie

potrzeby zaplombowana ①.

Wymiary ❽

1)

Stożkowy gwint zewnętrzny wg EN 10226-1

2)

Kołnierze PN 25 wg EN 1092-2

© Danfoss | 2021.09 | 7AQ00008644639901-000201

Page 8

AVPA - PN 16, 25

РУССКИЙ

Правила техники безопасности

Для предупреждения травматизма

и повреждения оборудования

перед началом производства работ

по его монтажу и вводу в эксплуатацию

следует изучить и соблюдать настоящую

инструкцию. Монтаж, наладку и техническое

обслуживание оборудования может

выполнять только квалифицированный

персонал, имеющий допуск к таким работам.

В целях соблюдения правил техники

безопасности перед началом работ по

монтажу или обслуживанию регулятора

необходимо произвести следующие действия

с трубопроводной системой:

- сбросить давление;

- охладить;

- опорожнить;

- прочистить.

При этом должна также соблюдаться

инструкция по эксплуатации системы.

Область применения

Регулятор используется на байпасных

трубопроводах для перепуска воды или

водного раствора гликоля в системах

централизованного теплоснабжения или

охлаждения.

Условия применения регулятора

определяются техническими

характеристиками, указанными на этикетке

изделия.

Монтаж

Монтажные положения регулятора ❶

Температура регулируемой среды до 100 °C:

- Регулятор может устанавливаться в любом

положении.

Температура регулируемой среды выше 100

°C:

- Установка регулятора разрешается

только на горизонтальном трубопроводе

регулирующим элементом вниз.

Размещение регулятора и схема

установки ❷

AVPA Размещение на байпасе

Монтаж клапана ❸

1. Перед монтажом клапана промойте

трубопроводную систему.

2. До регулятора (по ходу движения среды)

рекомендуется установка сетчатого

фильтра ①.

3. Для контроля давлений до и после

регулируемой системы необходимо

предусмотреть показывающие

манометры.

4. Установка клапана

• Установите клапан так, чтобы направление

стрелки на этикетке ② или на его корпусе

③ совпадало с направлением движения

регулируемой среды.

• Резьбовой клапан монтируется с

помощью приварных фитингов, которые

при установленном между ними клапане

должны предварительно фиксироваться

на трубопроводе прихваткой ④.

Окончательная приварка фитингов к

трубопроводу может производиться

только при отсутствии клапана и

уплотнительных прокладок! ⑤⑥

При несоблюдении этих инструкций

высокая температура сварки может

повредить уплотнения фитингов и самого

клапана.

• Flanges ⑦ in the pipeline must be in parallel

position and sealing surfaces must be clean

and without any damage.

Tighten screws in flanges crosswise in 3

steps up to the maximum torque (50 Nm).

5. Внимание!

Механические нагрузки на корпус клапана

от трубопроводов недопустимы ⑧.

Тепловая изоляция ❹

При температурах перемещаемой среды до

100 °C регулирующий элемент ① может быть

теплоизолирован.

Запуск ❺

Клапан закрыт при отсутствии

перепада давлений. К лапан

открывается когда разница

давлений ① между точками

отбора импульсов превышает величину

настройки.

Заполнение системы, первый пуск

1. Медленно откройте запорное устройство

② на подающем трубопроводе.

2. Медленно откройте запорное устройство

③ на обратном трубопроводе.

Испытания на прочность и

герметичность

Показания манометров,

установленных в точках +/- ①,

должны увеличиваться.

Если этого не происходит, то вероятно

поврежден клапан или регулирующий

элемент.

Испытания на герметичность всей системы

должны проводиться в соответствии

с инструкциями производителей

оборудования.

Максимальное испытательное давление

определяется как:

1.5 × PN

Pу (PN) указывается на этикетках

оборудования.

Вывод из эксплуатации

1. Медленно закройте запорное устройство

② на подающем трубопроводе.

2. Медленно закройте запорное устройство

③ на обратном трубопроводе.

Установка значений регулируемых

величин ❻

Установка перепада давлений

Диапазон установки перепада давлений

указан на этикетке регулирующего блока ①.

Последовательность настройки:

1. Запустите систему (см. раздел

“Заполнение системы, первый пуск

“). Полностью откройте все запорные

устройства в системе.

2. Включите насос ②

3. Настройка

Производите настройку, следя за

показаниями манометров ③.

Чтобы увеличить настройку ④(сжать

пружину): Ру16 — поверните вправо (по

часовой стрелке), Ру25 — поверните

влево (против часовой стрелки).

Чтобы уменьшить настройку ⑤(разжать

пружину): Ру16 — поверните налево

(против часовой стрелки), Ру25 —

поверните вправо (по часовой стрелке).

Пломбирование ❼

При необходимости устройство

регулировки перепада давлений может

быть опломбировано пломбировочной

проволокой ①.

Габаритные размеры ❽

1)

Коническая наружная резьба

соответствует EN y10226-1.

2)

Фланцы Pу 25 соответствуют EN 1092-2.

AQ00008644639901-000201 8 | © Danfoss | 2021.09

Page 9

AVPA - PN 16, 25

LIETUVIŲ K.

Saugumo reikalavimai

Iki montavimo ir paledimo būkite

atsargūs, kad nesusižeistumėte ir

nesugadintumėte prietaisų, būtina

nuodugniai perskaityti ir laikytis šių instrukcijų.

Prietaisų montavimą, paleidimą bei priežiūrą

privalo vykdyti tiktai kvalifikuoti, apmokyti ir

įgalioti tokius darbus atlikti specialistai.

Prieš pradedant reguliatoriaus surinkimo ir

priežiūros darbus sistema turi būti paruošta:

- kad joje nebūtų slėgio

- ataušinta

- ištuštinta ir

- išvalyta.

Rekomenduojame laikytis sistemos gamintojų

arba sistemos operatoriaus instrukcijų.

Pritaikymas

Reguliatorius naudojamas slėgio perkyčio

reguliavimui apvade, kur terpė yra vanduo

arba gliukolio tirpalas, centralizuoto šildymo ir

aušinimo sistemose.

Techniniai parametrai yra nurodyti ant produkto

žymėje.

Surinkimas

Leistinos montavimo padėtys ❶

Terpės temperatūra iki 100 °C:

- Galima montuoti bet kurioje padėtyje.

Terpės temperatūra > 100 °C:

- Montavimas leistinas tiktai horizontaliame

vamzdyne, kai pavara pritvirtinta padėtyje žemyn.

Montavimo vieta ir montavimo

schema ❷

AVPA montavimas apvade

Vožtuvo montavimas ❸

1. Išvalykite vamzdyną prieš pradėdami

montavimą.

2. Labai rekomenduojame sumontuoti filtrą

priešais reguliatorių ①.

3. Sumontuokite slėgio indikatorius priešais ir

už tos sistemos dalies, kuri bus reguliuojama.

4. Sumontuokite vožtuvą.

• Būtina laikytis srauto krypties, kuri nurodyta

ant etiketės ar ant vožtuvo ② ③.

• Privirinimui skirti atvamzdžiai tik

pritvirtinami ④.

Privirinami fitingai gali būti virinami tiktai be

vožtuvo ir užsklandų. ⑤⑥

Jeigu nesilaikysite šių reikalavimų, aukšta

temperatūra gali pažeisti įrenginį.

• Flanšai ⑦ vamzdyne turi būti lygiagretūs,

sandarinimo vietos turi būti švarios ir be

pažeidimų.

Užveržkite varžtus flanšuose kryžmai per 3

žingsnius iki maksimalaus sukimo momento

(50 Nm).

5. Dėmesio:

Mechaninės vožtuvo korpuso apkrovos

neleistinos ⑧.

Izoliavimas ❹

Kai terpės temperatūra siekia iki 100 °C, slėgio

pavara ① taip pat gali būti izoliuota.

Paleidimas ❺

Vožtuvas yra uždaromas be

slėgio. Vožtuvas atsidaro, kai

slėgio perkrytis ① pakyla

aukščiau nustatytos vertės.

Sistemos pripildymas, pirmasis

paleidimas

1. Iš lėto atidarykite uždarymo įrenginius ②

tiekiamame vamzdyne.

2. Iš lėto atidarykite uždarymo įrenginius ③

grąžinamame vamzdyne.

Pralaidumo ir slėgio bandymai

Slėgis turi būti palaipsniui d idinamas

prie +/- sujungimo ①.

Neatitikimas gali sukelti pavaros arba vožtuvo

gedimus.

Visos sistemos slėgio bandymas turi būti

vykdomas, reminatis gamintojo instrukcijomis.

Maksimalus bandymo slėgis yra:

1.5 × PN

PN - žiūrėkite etiketę ant gaminio!

Darbo nutraukimas

1. Iš lėto uždarykite įrenginius ② tiekiamame

vamzdyne.

2. Iš lėto uždarykite įrenginius ③ grąžinimo

vamzdyne.

Palaikomos vertės nustatymas ❻

Slėgio perkryčio nustatymas

Slėgio perkryčio nustatymo ribos yra nurodytos

gaminio etiketėje ①.

Procedūra:

1. Paleiskite sistemą. Žiūrėkite skyrių “Sistemos

pripildymas, pirmas paleidimas”.

Pilnai atidarykite uždarymo įrenginius.

2. Įjunkite siurblį ②

3. Adjustment

Reguliavimas

Stebėkite slėgio indikatorius ③ ir/arba galite

stebėti rankinį skalės indikatorių.

Padidinkite nuostatą ④(įtempkite

spyruoklę): PN16 sukite dešinėn (pagal

laikrodžio rodyklę), PN25 sukite kairėn (prieš

laikrodžio rodyklę).

Sumažinkite nuostatą ⑤(atleiskite

spyruoklę): PN16 sukite kairėn (prieš

laikrodžio rodyklę), PN25 sukite dešinėn

(pagal laikrodžio rodyklę).

Plombavimas ❼

Vertės nustatymo rankeną galima užplombuoti

specialiu laidu ① jeigu tai būtina.

Matmenys, svoris ❽

1)

Kūginis išor. sriegis pagal EN 10226-1

2)

Flanšai PN 25, pagal EN 1092-2

MAGYAR

Saugumo reikalavimai

Összeszerelés és üzembe helyezés

előtt feltétlenül olvassa el és tartsa be

ezen útmutató utasításait a személyi

sérülések és a készülék meghibásodásának

elkerülése érdekében!

Az összeszerelést, üzembe helyezést és

karbantartást csak szakképzett és arra

feljogosított személy végezheti.

A szerelési és karbantartási munkálatok előtt a

rendszert:

- nyomásmentesíteni kell,

- le kell hűteni,

- le kell üríteni,

- és meg kell tisztítani.

Kérjük, tartsa be a rendszer gyártójának és

üzemeltetőjének rendelkezéseit!

Az alkalmazás leírása

A szabályzó nyomáskülönbség szabályozásra

alkalmas túláram szelep üzemmódban fűtő,

távfűtő és hűtő rendszerekben. Az áramló közeg

víz, ill. víz-glikol keverék lehet.

A működést meghatározó paraméterek a

termék címkéjén olvashatók.

Szerelés

Lehetséges beépítési helyzetek ❶

Max. 100 °C közeghőmérsékletig:

- Bármely helyzetben beépíthető.

Ha a közeghőmérséklet > 100 °C:

- Csak vízszintes csőszakaszokba építhető be,

függőleges szelepmozgató helyzettel.

Beépítési hely és kapcsolási séma ❷

AVPA mindig túláramszelep funkcióban

Szelep beépítés ❸

1. A munka megkezdése előtt végezze el a

csővezeték hálózat tisztítását!

2. Erősen ajánlott egy szűrő beépítése a

szabályzó elé ①.

3. A szabályozandó szakasz előtt és után

építsen be nyomásmérőt.

4. A szelep beépítése:

• A beépítésnél vegye figyelembe a

termékcímkén ② ill. a szelepen feltüntetett

áramlási irányt ③!

• A hegesztett toldatokkal csatlakoztatható

szelepeket a csővezetékhez csak néhány

ponton szabad hegesztéssel rögzíteni ④!

A toldatok csak a szelep és a tömítőelemek

levétele után hegeszthetőek körül! ⑤⑥

Ha ezeket az útmutatásokat nem tartja

be, a magas hegesztési hőmérsékleten a

tömítőelemek tönkremennek.

Karimás szelepek

• A csővezetékek karimáinak ⑦

párhuzamosan kell állnia, és a tömítőfelületeknek szennyeződés-mentesnek és

épnek kell lenniük!

A karimákat összekötő csavarokat három

lépésben szorítsa meg a max. nyomaték

eléréséig (50 Nm)!

5. Figyelem!:

A szeleptestet a csővezetékekkel mechanikusan

terhelni tilos! ⑧.

© Danfoss | 2021.09 | 9AQ00008644639901-000201

Page 10

AVPA - PN 16, 25

Szigetelés ❹

100 °C közeghőmérséklet alatt a membránházat

① is be lehet szigetelni.

Üzembe helyezés ❺

A szelep nyomásmentes állapotban

zárva van. A szelep ak kor kezd nyitni,

meghaladja a beállított értéket.

ha a nyomáskülönbség ①

A rendszer feltöltése, első üzembe

helyezése

1. Lassan nyissa meg az elzárószelepet ②, az

előremenő ágban.

2. Lassan nyissa a szelepet ③ a visszatérő

ágban.

Tömítettség- és nyomáspróba

A nyomást fokozatosan emeljük a

+/- pontokon ①.

Az útmutatások be nem tartása a

szelepmozgató, ill. a szelep károsodását

eredményezheti!

A rendszer nyomáspróbáját a gyártó

rendelkezéseinek betartásával kell végezni.

A próbanyomás max. értéke:

1.5 × PN

A PN-értéket a termékcímkén találja!

Üzemen kívül helyezés

1. Lassan zárja az elzáró szerelvényeket ② az

előremenő ágban!

2. Lassan zárja az elzáró szerelvényeket ③ a

visszatérő ágban!

A kívánt érték beállítása ❻

A nyomáskülönbség beállítása

A beállítható nyomástartomány a termékcímkén

① van feltüntetve.

Útmutatás:

1. Helyezze üzembe a berendezést a „A

rendszer feltöltése, első üzembe helyezése”

fejezetben leírtak szerint.

2. Indítsa el a szivattyút! ②

3. Beállítás:

Figyelje a nyomásmérők különbségét ③,

vagy a beállítóskálát, illetve mindkettőt.

A beállítás ④ (a rugófeszesség) növelése:

forgassa a PN16-ost jobbra (az óramutató

járásával megegyező irányba), a PN25-öst

balra (az óramutató járásával ellentétes

irányba).

A beállítás ⑤ (a rugófeszesség) csökkentése:

forgassa a PN16-ost balra (az óramutató

járásával ellentétes irányba), a PN25-öst

jobbra (az óramutató járásával megegyező

irányba).

Plombálás ❼

Az alapérték-beállítót szükség esetén plombálni

lehet ①.

Méretek és súlyok ❽

1)

Kúpos külső menet az EN 10226-1 szerint

2)

PN 25 karimák a EN 1092-2 szerint

NEDERLANDS

Veiligheid

Om verwondingen aan personen en

schade aan de apparatuur te

voorkomen is het absoluut

noodzakelijk om deze instructies zorgvuldig te

lezen en te bestuderen.

Noodzakelijke (de)montage, inbedrijfstelling

en onderhoud dient alleen door deskundig,

getraind en bevoegd personeel te worden

uitgevoerd.

Voorafgaand aan montage- of

onderhoudswerkzaamheden moet het systeem

worden:

- afgesloten,

- afgekoeld,

- afgetapt en

- gereinigd.

Volg altijd de instructies van de

installatiebouwer- of beheerder op.

Toepassing

De regelaar wordt gebruikt voor het d.m.v.

overstorten constant houden van het

drukverschil in installaties voor verwarming,

stadsverwarming en koeling, gevuld met water

of water-glycol mengsels.

De technische gegevens op het type-plaatje

bepalen de toepassings mogelijkheden.

Montage

Toegestane montage posities ❶

Mediumtemperatuur tot 100 °C:

- Mag in alle standen gemonteerd worde.

Mediumtemperatuur > 100 °C:

- Montage alleen toegestaan in horizontale

leidingen met het regelelement omlaag.

Plaats in de installatie en

installatieschema ❷

AVPA overstort (by-pass) montage

Afsluiter installeren ❸

1. Reinig eerst het leidingsysteem.

2. Plaatsing van een vuilfilter voor de regelaar

wordt sterk aanbevolen ①.

3. Monteer drukmeters voor en na het

installatiedeel dat geregeld wordt.

4. Monteer de afsluiter

• Let op de stromingsrichting die op het type-

plaatje of op de afsluiter staat aangegeven

② ③.

• De afsluiter met gemonteerde

laskoppelingen mag alleen met laspunten

aan de leiding gehecht worden ④.

Daarna de afsluiter en pakkingen uitnemen

en de koppelingen definitief vast lassen!

⑤⑥

Als deze instructies niet worden opgevolgd

kunnen hoge lastemperaturen de pakkingen

beschadigen.

• De flenzen ⑦ in de leiding moeten

evenwijdig zijn en de sluitvlakken moeten

schoon zijn en onbeschadigd.

Zet de bouten in 3 stappen kruislings vast

met het maximum koppel (50 Nm).

5. Let op:

Mechanische belasting van het afsluiterhuis

door de leidingen is niet toegestaan ⑧.

Isolatie ❹

Bij mediumtemperaturen tot 100 °C mag het

membraanhuis ① ook geïsoleerd worden.

Ingebruikname ❺

Zonder drukver schil is de afsluiter

gesloten. De afsluite r opent wanneer

ingestelde waarde stijgt.

het drukvers chil ① boven de

Vullen van het systeem, eerste

inbedrijfstelling

1. Draai afsluiter ② in de aanvoer langzaam

open.

2. Draai afsluiter ③ in de retour langzaam

open.

Lek- en druktest

De druk op de +/- aansluiting ① mag

alleen geleidelijk opgevoerd worden.

Het niet opvolgen van deze instructie kan

schade veroorzaken aan regelaar of afsluiter.

Een druktest van het gehele systeem dient

uitgevoerd te worden overeenkomstig de

voorschriften van de fabrikant / installateur.

De maximum testdruk is:

1.5 × PN

PN zie het type-plaatje op het product.

Uit bedrijf nemen

1. Draai de afsluiter ② in de aanvoer langzaam

dicht.

2. Draai de afsluiter ③ in de retour langzaam

dicht.

Instellingen ❻

Instellen van het drukverschil

Het instelbereik is aangegeven op het typeplaatje ①.

Procedure:

1. Start het systeem, zie paragraaf “Vullen van

het systeem, eerste inbedrijfstelling”

Zet alle afsluiters in het systeem volledig

open

2. Zet de pomp aan ②

3. Instelling

Kijk naar de de drukmeters ③ en/of zie de

schaalaanduiding van de instelknop.

De instelling verhogen ④(de veer onder

spanning zetten): PN16 naar rechts draaien

(met de wijzers van de klok mee), PN25

naar links draaien (tegen de wijzers van de

klok in).

De instelling verlagen ⑤(de veer

ontspannen): PN16 naar links draaien (tegen

de wijzers van de klok in), PN25 naar rechts

draaien (met de wijzers van de klok mee).

Als het gewenste druk verschil niet

wordt gehaald dan wordt dit

lage weerstand in het a fnamecircuit (immers

alle afsluiters zij n open gezet).

mogelijk veroor zaakt door een te

Verzegeling ❼

Indien gewenst kan de instelling verzegeld

worden ①.

Afmetingen, gewicht ❽

1)

Uitwendige draad volgens EN 10226-1

2)

Flenzen PN 25, volgens EN 1092-2

AQ00008644639901-000201 10 | © Danfoss | 2021.09

Page 11

AVPA - PN 16, 25

SLOVENŠČINA

Varnostna opozorila

Izjemno pomembno je, da pred

montažo in zagonom skrbno

preberete navodila in se jih držite. S

tem se izognete poškodbam ljudi in okvaram na

opremi.

Nujna sestavna, zagonska in vzdrževalna dela

lahko izvajajo samo kvalificirani, šolani in

pooblaščeni delavci.

Pred sestavo in vzdrževalnimi deli na regulatorju

mora biti sistem:

- tlačno izravnan,

- ohlajen,

- izpraznjen in

- očiščen.

Prosimo, upoštevajte navodila proizvajalca

sistema ali sistemskega operaterja.

Opis naprave

Regulator se uporablja za prelivno regulacijo

diferenčnega tlaka v sistemih ogrevanja,

daljinskega ogrevanja in hlajenja napolnjenih z

vodo ali z mešanico vode in glikola.

Tehnični podatki na etiketi izdelka določajo

uporabo.

Montaža

Dopustni položaji vgradnje ❶

Temperatura medija do 100 °C:

- Lahko se vgradi v kateremkoli položaju.

Temperatura medija > 100 °C:

- Vgradnja dovoljena samo v horizontalni

položaj tako, da je pogon obrnjen navzdol.

Lokacija namestitve in shema

vgradnje ❷

AVPA vgradnja v by-pass

Vgradnja ventila ❸

1. Pred montažo očistite cevovod.

2. Močno priporočamo vgradnjo filtra pred

regulator ①.

3. Vgradite manometer pred in za sistem, ki ga

regulirate.

4. Vgradite ventil

• Upoštevajte puščico na etiketi proizvoda

② oz. na proizvodu samem ③, ki kaže smer

pretoka.

• Ventil z vgrajenimi varilnimi priključki se

lahko samo pritrdi na cevovod ④.

Varilni priključki so nato lahko polno varjeni

samo brez ventila in tesnil! ⑤⑥

Ob neupoštevanju teh navodil lahko visoke

temperature pri varjenju uničijo tesnila.

• Protiprirobnice ⑦ morajo biti vzporedne,

tesnilne površine morajo biti čiste.in brez

poškodb.

Pritegnite vijake na prirobnicah križem v treh

korakih do maksimalnega momenta (50 Nm).

5. Opozorilo:

Mehanske obremenit ve cevovoda na telo

ventila niso dovoljene ⑧.

Izolacija ❹

Pri temperaturi medija do 100 °C, je lahko tlačni

pogon ① tudi izoliran.

Zagon ❺

Ventil je brez tlaka zaprt. Ventil od pira

kadar diferenčni tlak ① naraste na d

nastavljeno vrednost.

Polnjenje sistema, prvi zagon

1. Počasi odprite zaporne organe ② iv dovodu.

2. Počasi odprite zaporne organe ③ v

povratku.

Test tesnosti in tlaka

Na priključkih mo ra tlak naraščati

postopoma +/- ①.

Neskladnost z navodili lahko povzroči poškodbe

na pogonu ali na ventilu.

Tlačni preizkus celotnega sistema se mora

izvajati po navodilih proizvajalca..

Maksimalni preizkusni tlak je:

1.5 × PN

PN glejte napisno ploščico!

Jemanje iz obratovanja

1. Počasi zaprite zaporne organe ② v dovodu.

2. Počasi zaprite zaporne organe ③ v povratku.

Nastavitev regulatorja ❻

Nastavitev diferenčnega tlaka

Področje nastavitev diferenčnega tlaka je

prikazano na etiketi na ohišju ①.

Postopek:

1. Zaženite sistem, poglejte poglavje “Polnjenje

sistema, prvi zagon“

Popolnoma odprite vse zaporne organe v

sistemu.

2. Zaženite obtočno črpalko ②

3. Nastavitev:

Opazujte indikator tlaka ③ ali/in alternativno

si pomagajte s kazalnikom na skali.

Povečanje nastavljene vrednosti ④

(obremenitev vzmeti): Obrnite PN16 v desno

(v smeri urinega kazalca) in PN25 v levo (proti

smeri urinega kazalca).

Zmanjšanje nastavljene vrednosti ⑤

(razbremenitev vzmeti): Obrnite PN16 v levo

(proti smeri urinega kazalca) in PN25 v desno

(v smeri urinega kazalca).

Plombiranje ❼

Element za nastavitev diferenčnega tlaka se

lahko plombira s plombirno žico ①, če je to

zahtevano.

Dimenzije, masa ❽

1)

Konični zunanji navoj po EN 10226-1

2)

Prirobnice PN 25, glede na EN 1092-2

© Danfoss | 2021.09 | 11AQ00008644639901-000201

Page 12

AVPA - PN 16, 25

73695060 / AQ00008644639901-00020112 | © Danfoss | DCS-S/SI | 2021.09

Loading...

Loading...